Columnar tube and rolling method thereof

A cylindrical and bobbin technology, applied in the field of cylindrical bobbin packages, can solve the problems of bobbin revolution fluctuation and uncontrollability, and achieve the effects of high yarn unwinding speed, entanglement prevention, and end face structure improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

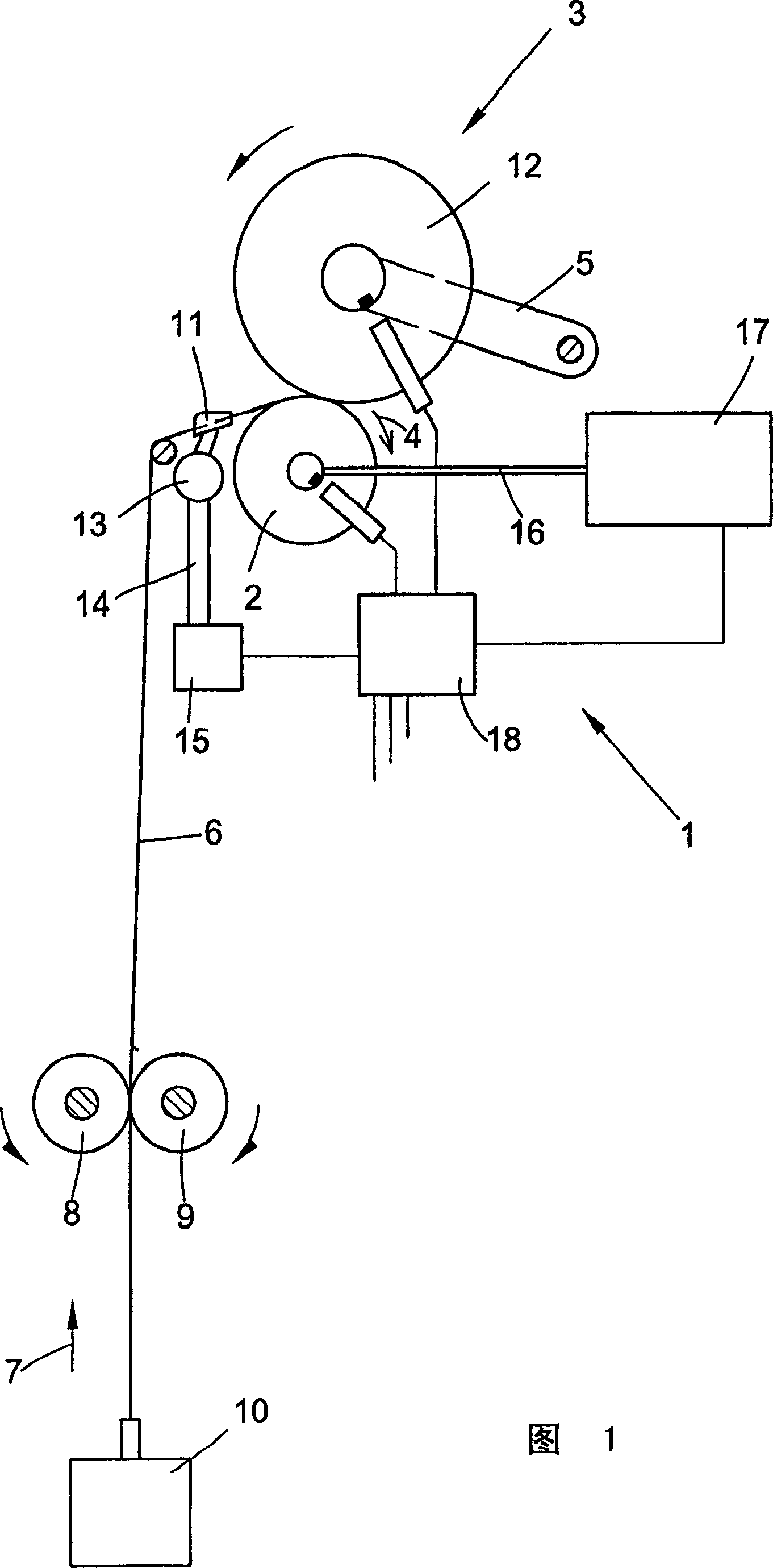

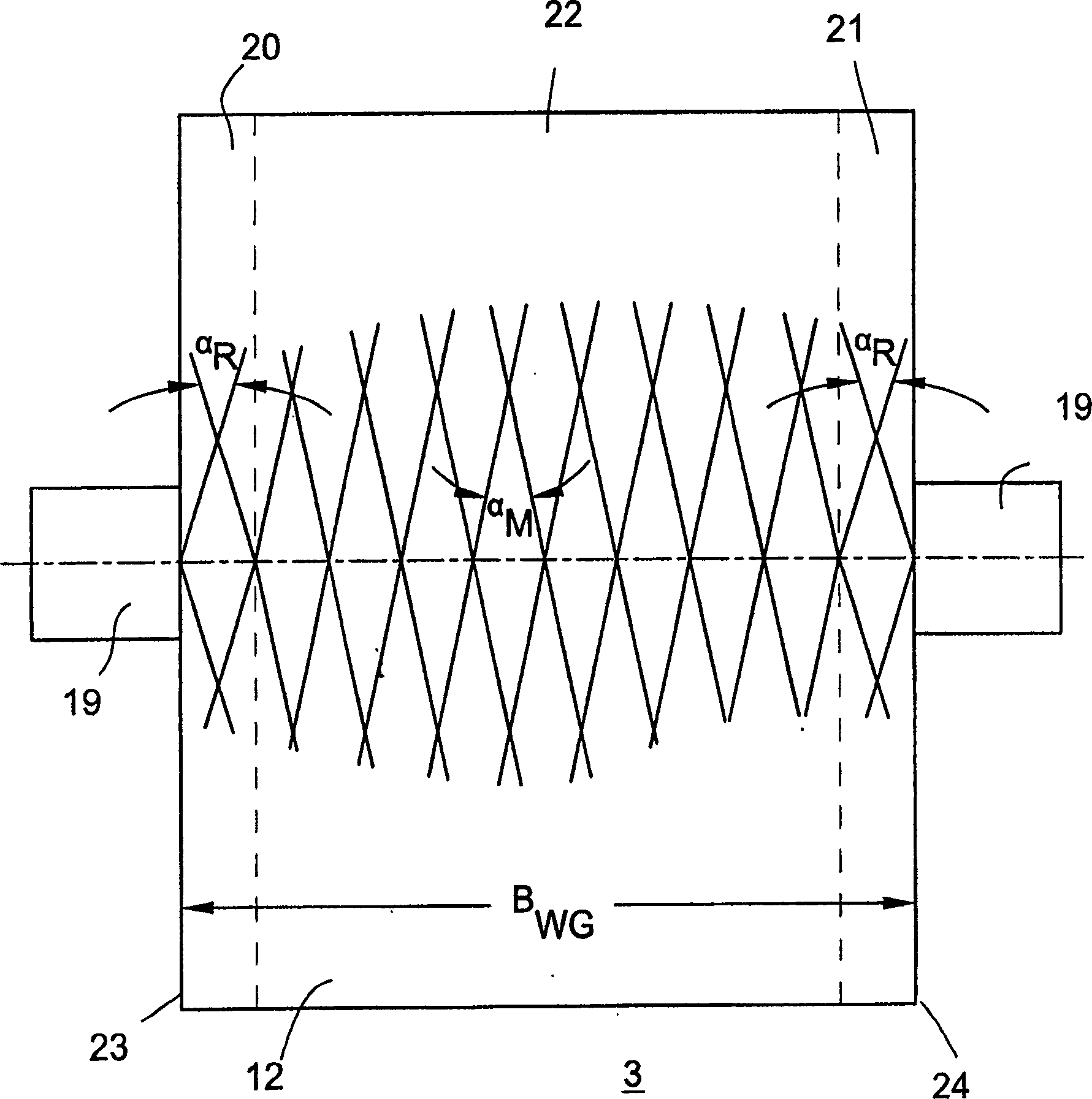

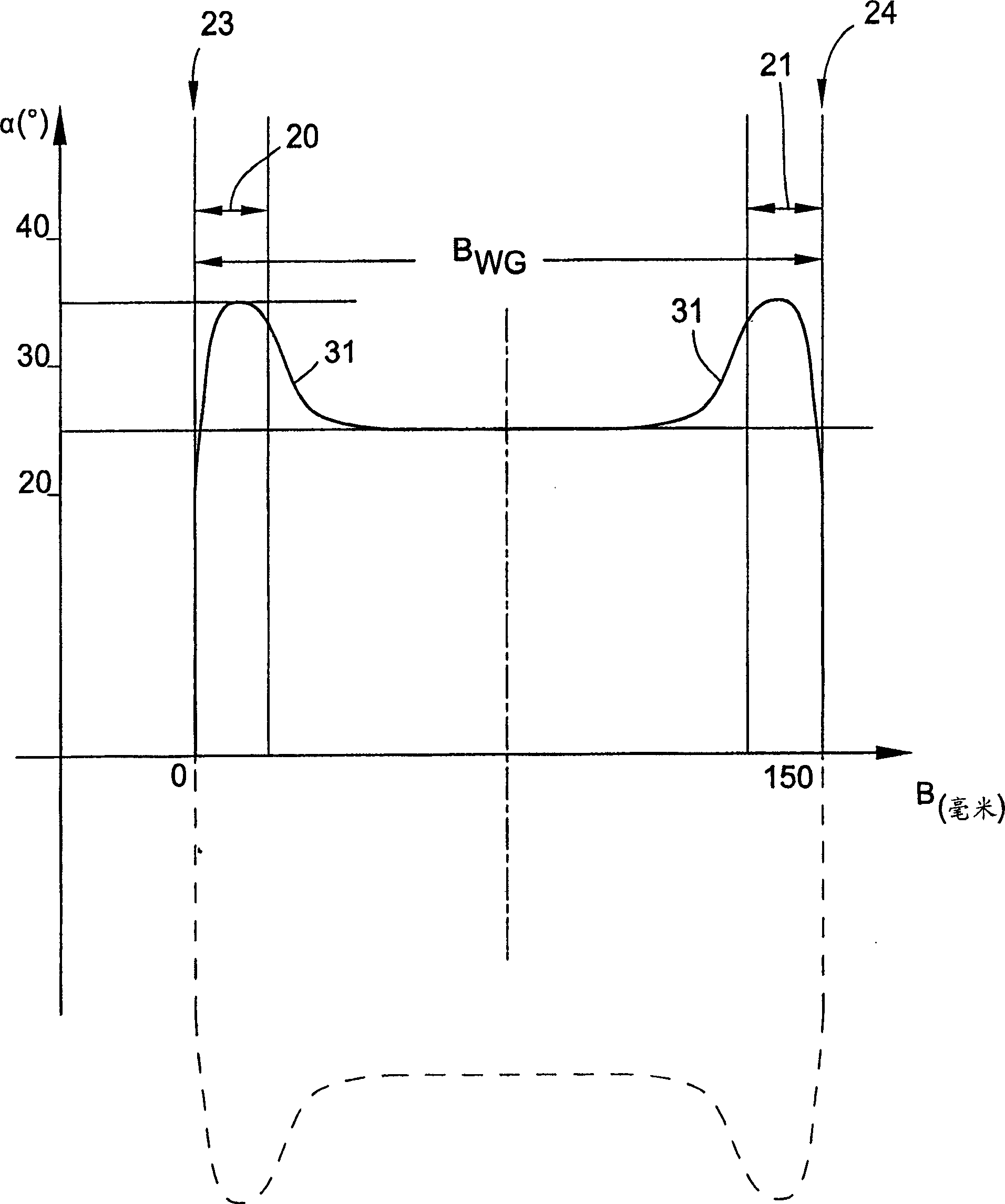

[0024] Figure 1 shows a winding device for the production of cylindrical packages on a rotor spinning machine. The winding device 1 has a drum 2 which drives a cylindrical bobbin 3 by means of friction. Drum 2 rotates in the direction of arrow 4. The bobbin 3 is supported by a rotatable bobbin holder 5 and rests against the drum 2 . Roller 2 is under pressure. The yarn 6 is drawn in the direction of the arrow 7 by means of cooperating yarn delivery roller pairs 8, 9 from the spinning box 10 of the spinning position at a constant yarn speed and is wound into a bobbin by means of a reciprocating yarn guide 11 3 of cylindrical windings 12 . The yarn guide 11 is a part of the reciprocating mechanism 13, which is connected to the motor 15 through an effective connector 14, and is driven by the motor. The drum 2 is driven by the shaft of the motor 17 . The motors 15 and 17 are all controlled by a microprocessor 18, where the intersection angle α of the cylindrical bobbin 3 is r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com