Method for conveying concrete by adopting track trolley with buffer unloading and empty bucket restoration

A track trolley and concrete technology, which is applied in the processing of building materials, construction, building construction, etc., can solve the problems of waste of human resources, small capacity of dumping bucket, troublesome tire maintenance, etc. The effect of promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1. Adopt the method for transporting concrete by rail trolley with buffer unloading and empty bucket reset

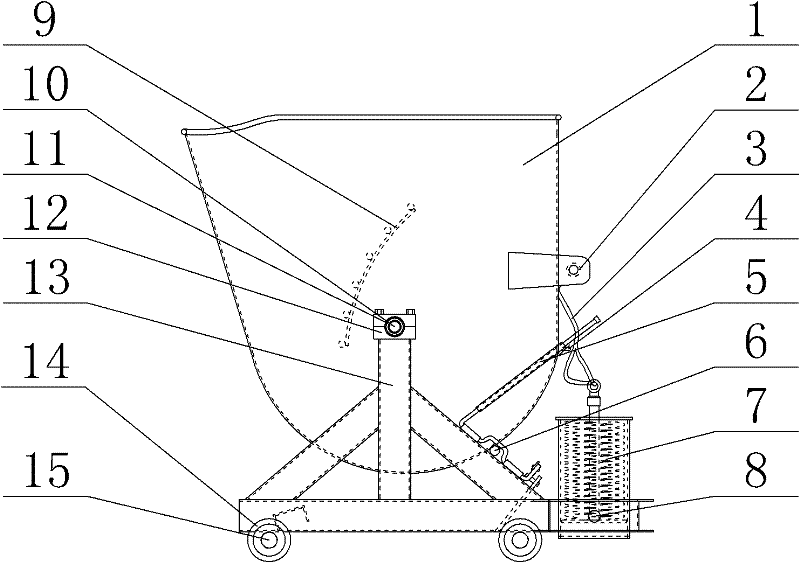

[0019] The method is: use the rail trolley combined with the material hopper 1 and the vehicle frame 13 with rail wheels to carry out loading and unloading to transport concrete; Loading, so that the material hopper 1 is evenly loaded; when unloading, use the positioning device 23 and the buffer 7 connected to the vehicle frame 13 to loosen the material hopper 1 and control the discharge speed of the material hopper 1 respectively; after the unloading is completed, Utilize the characteristic of the buffer spring 27 in the buffer to reset the material hopper 1.

[0020] The present invention specifically adopts the method comprising the following steps:

[0021] Loading: use manual or mechanical means to load the material hopper 1, and under the action of the diverter plate 9, the material hopper 1 can be loaded evenly;

[0022] Unloading: Transport t...

Embodiment 2

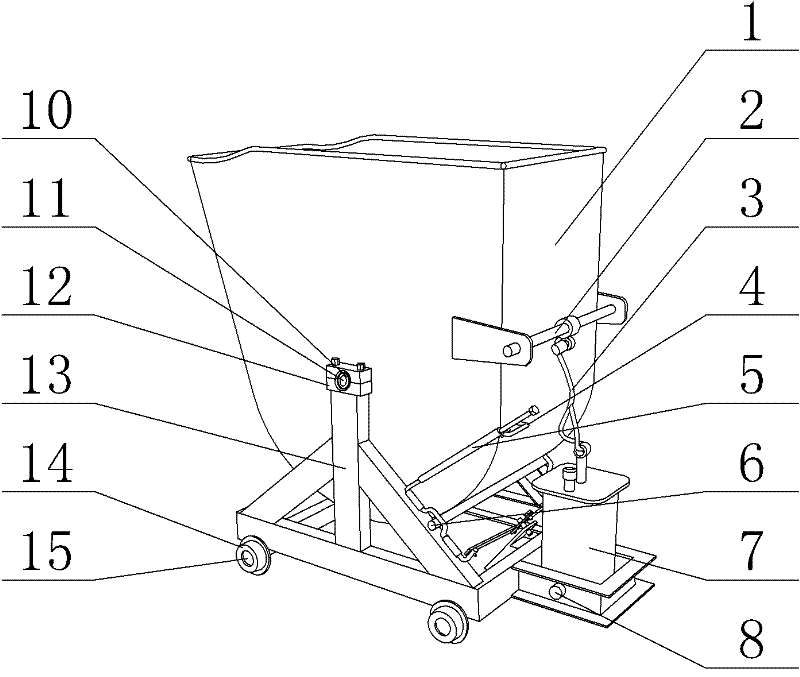

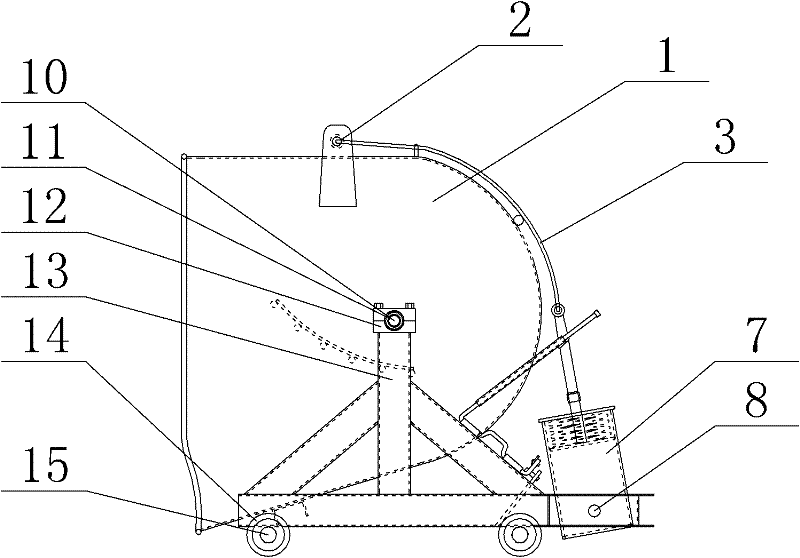

[0024] Embodiment 2. Rail trolley with buffer unloading and empty bucket reset

[0025] The structure of the track trolley is as follows Figure 1 to Figure 6 As shown, it is mainly composed of a material bucket 1, a buffer 7, a vehicle frame 13 with rail wheels and a positioning device 23, wherein: the two sides of the material bucket 1 are connected to the vehicle through the material bucket rotating shaft 10, bearing 11 and bearing seat 12. The tops of the two vertical bars of the frame 13 are movably connected, and the hopper push-pull handle 2 of the material hopper 1 is connected with the underframe of the vehicle frame 13 through the positioning device 23 . Buffer 7 is contained on the underframe of vehicle frame 13.

[0026] The lower part of the material hopper 1 is semicircular, and the upper part is in the form of an opening. The edge of the upper mouth is sealed with steel bars or steel pipes, and two lugs are welded on the outside. The splitter plate 9 is welded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com