Air ring breaking device

A balloon and detection device technology, which is applied in the directions of transportation and packaging, delivery of filamentous materials, and thin material processing, etc., can solve problems such as yarn breakage, bobbin unwinding, yarn drop-off, and balloon inability to fully expand, etc. Achieve the effects of improving product competitiveness, increasing unwinding speed, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

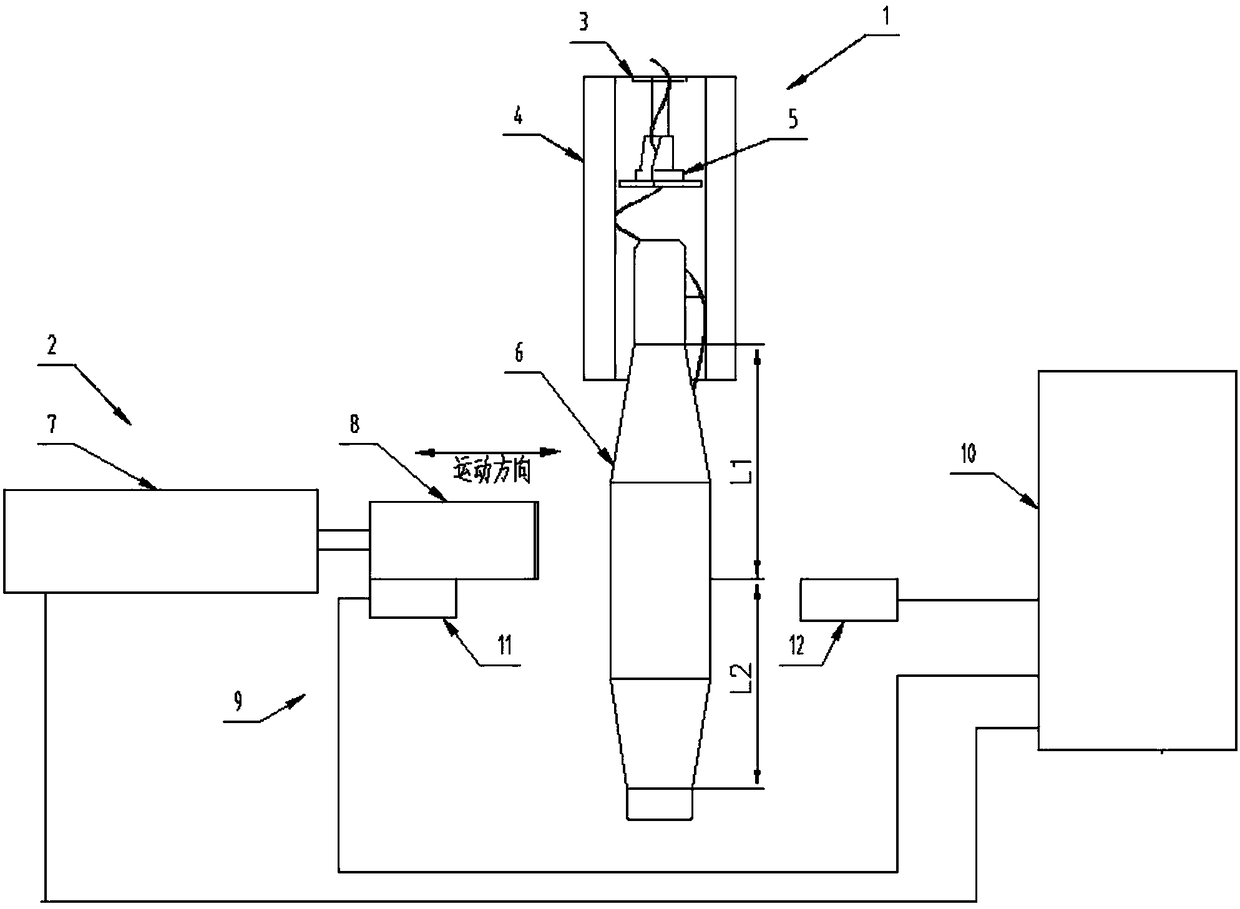

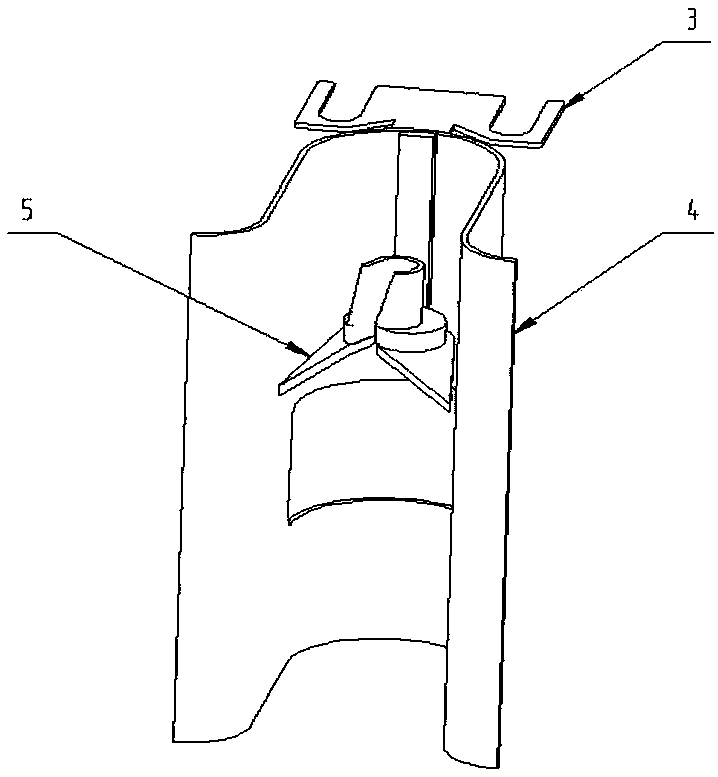

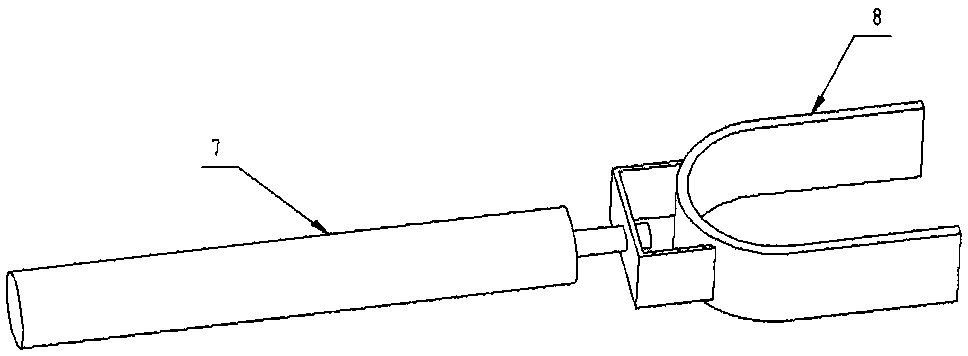

[0020] like Figure 1-3 As shown in the figure, a balloon rupture device includes a balloon rupture mechanism I1 that wraps a bobbin exposed at one end of the cop 6 and a part of the yarn, and a balloon rupture mechanism II2 arranged at 1 / 3 of the bobbin withdrawal line. The balloon rupture mechanism I2 includes a fixed bracket 3, a balloon rupture shield 4 installed on the fixed bracket 3, and a yarn guide 5 is provided in the balloon rupture shield 4; Part of the cop wrap. The balloon rupture device II2 includes a balloon generator 8, a cylinder 7 connected to the balloon generator 8 for driving its movement, a detection device 9 for detecting the yarn unwinding position, and a control device 10 for controlling the action of the cylinder. ; The detection device 10 is arranged at 1 / 3 of the cop yarn withdrawal line, and the cylinder is located above the detection device. The initial state of the cylinder is a contracted state. The cross section of the balloon rupture plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com