A sizing machine warp creel structure

A technology of beam creel and sizing machine, which is applied in the field of textile equipment, can solve the problems of shaking affecting sizing quality and reducing yarn breakage rate, and achieve the effects of reducing replacement, reducing yarn breakage rate and improving sizing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

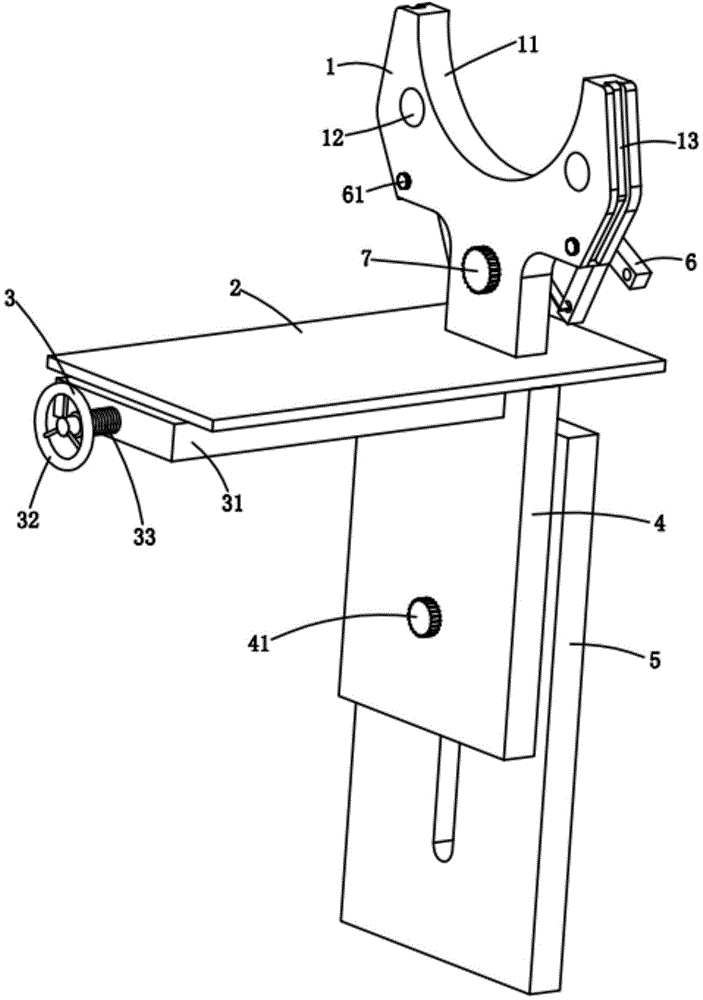

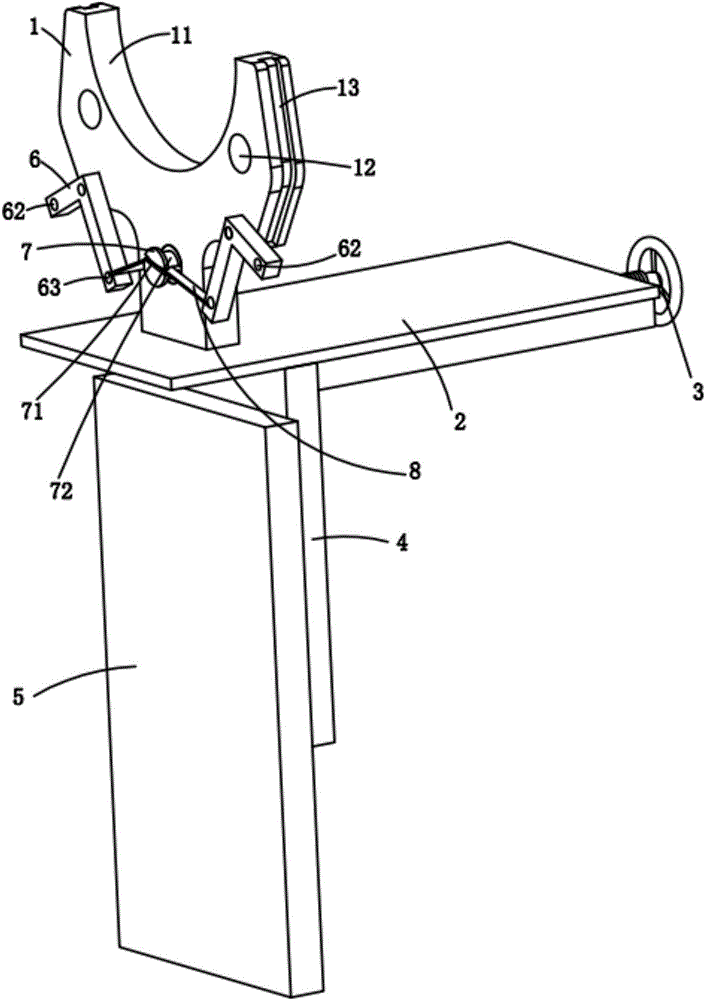

[0016] Embodiment: refer to attached figure 1 and attached figure 2 , a novel sizing machine warp beam frame structure, comprising a warp beam bracket 1 for placing a warp beam, a bracket base 2, an adjustment mechanism 3, a lifting mechanism 4 and a bracket 5, and the warp beam bracket 1 is fixed On the bracket base 2, the bracket base 2 is connected with the adjustment mechanism 3, the adjustment mechanism 3 is fixed on the lifting mechanism 4, and the lifting mechanism 4 is arranged on the support 5 through the adjustment screw 41; U-shaped groove 11, and an "L"-shaped connecting plate 6 is symmetrically arranged on both sides of U-shaped groove 11, the intersection of connecting plate 6 is hinged on the warp beam bracket 1 by rotating shaft 61, and one end of connecting plate 6 is opened There is a first connecting hole 62, and the other end is provided with a second connecting hole 63; both sides of the warp beam bracket 1 are provided with open slots 13, and the warp b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com