Patents

Literature

50results about How to "Improve sizing quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

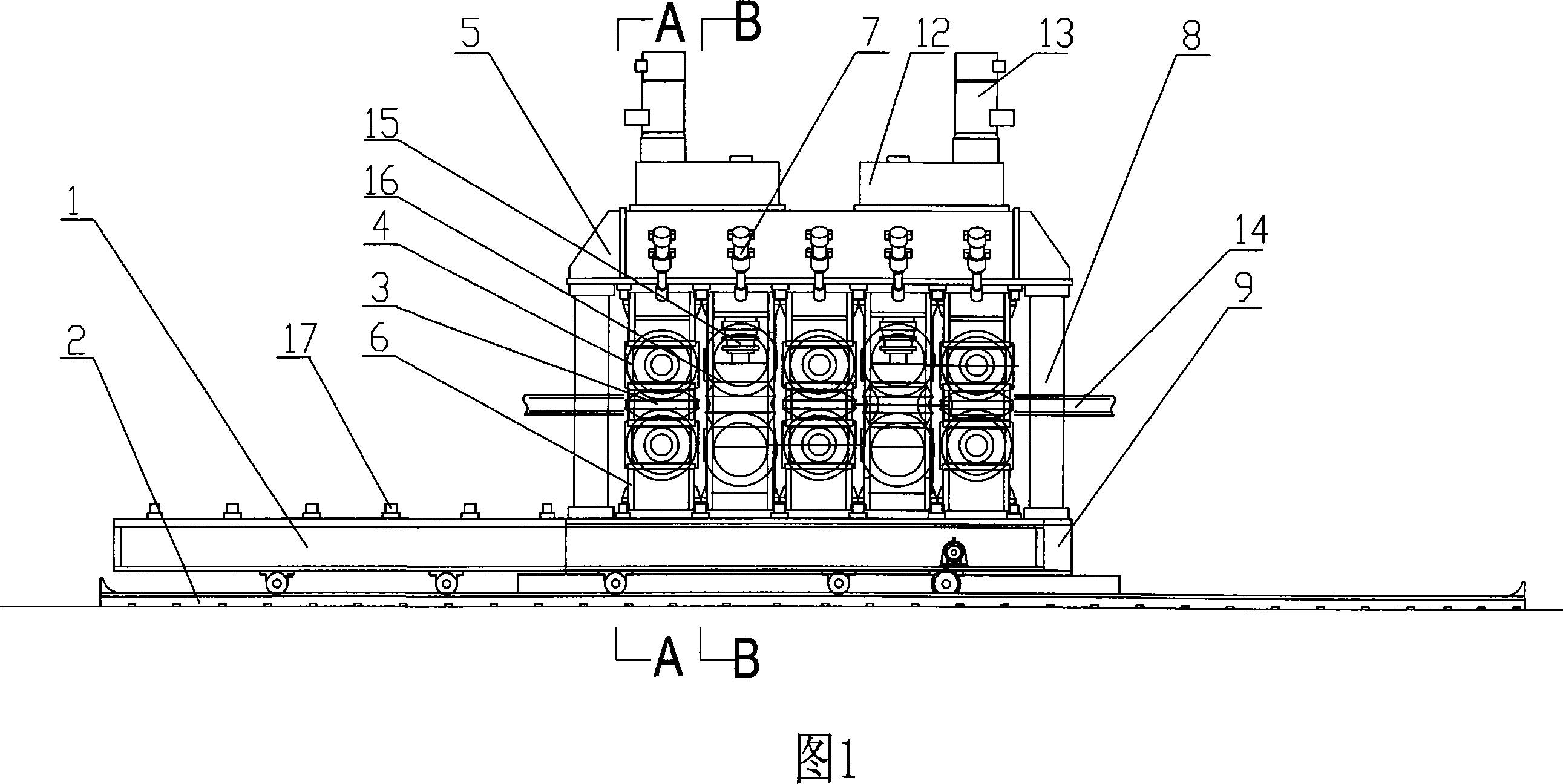

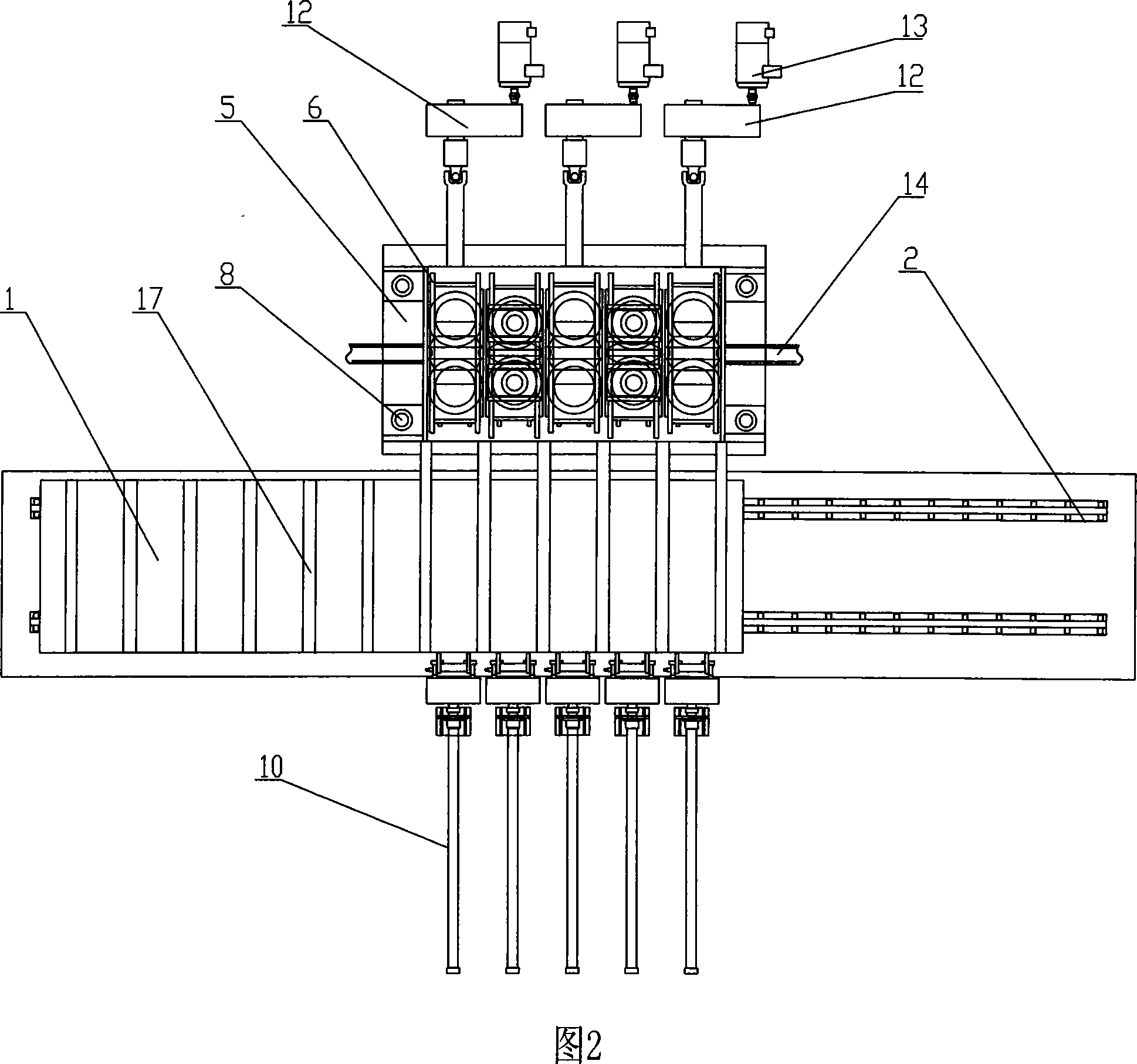

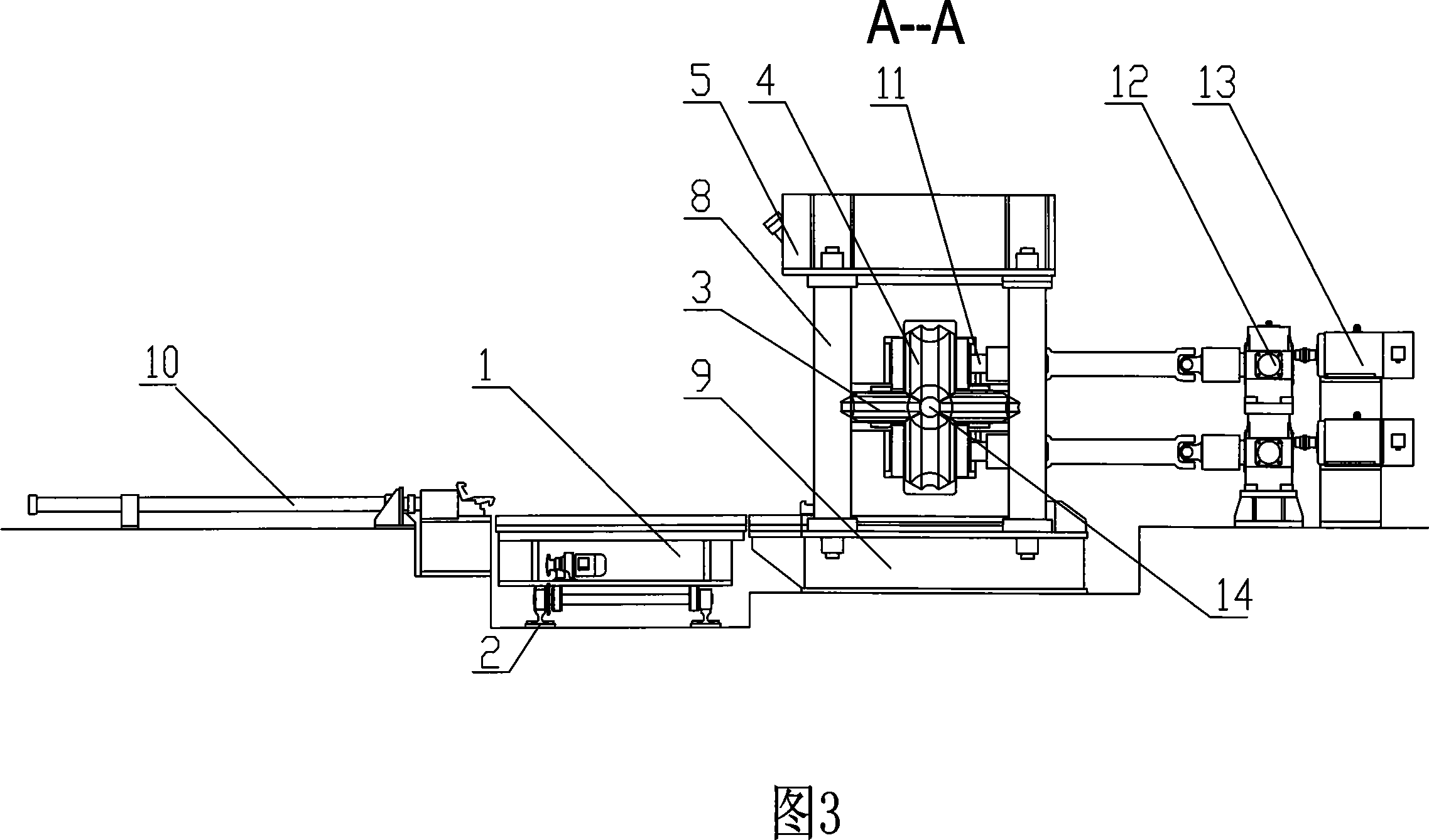

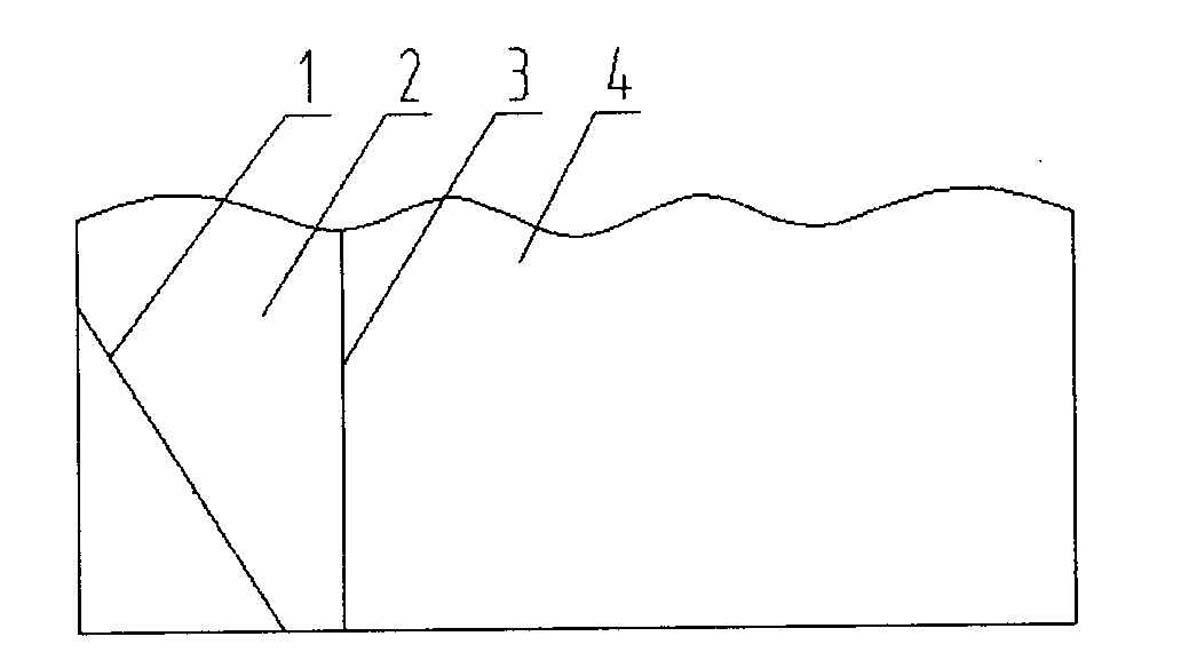

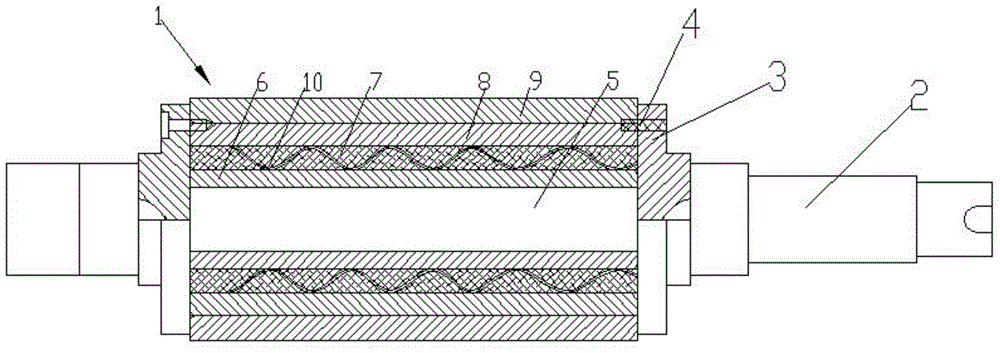

Seamless pipe four-roller type hot sizing stand

InactiveCN101032724AReasonable structural designCompact structureMetal rolling stand detailsRolling mill drivesHydraulic cylinderPulp and paper industry

The present invention relates to one kind of four roller type hot sizing machine for seamless steel pipe. The hot sizing machine includes one main sizing mechanism on one side of the rail and comprising one frame, one horizontal sizing roller set and one side vertical sizing roller set; one roller changing carriage with roller changing hydraulic cylinder for pushing the horizontal sizing roller set and the side vertical sizing roller set into the square frame or drawing out; and horizontal sizing roller set and side vertical sizing roller set locking hydraulic cylinder. The present invention has reasonable design, compact structure, closed pass structure resulting in increased sizing reduction and raised sizing quality, high production efficiency and other advantages.

Owner:DALIAN SAGE GROUP

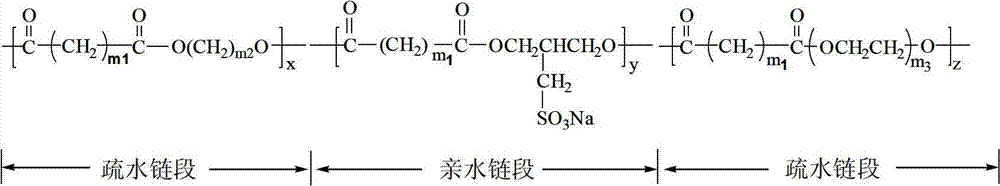

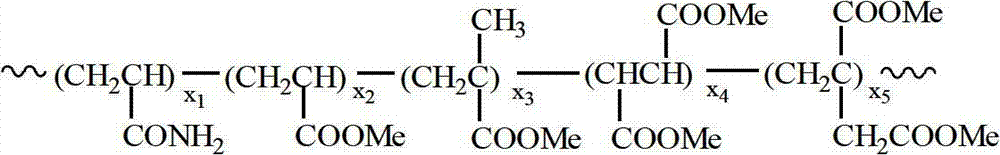

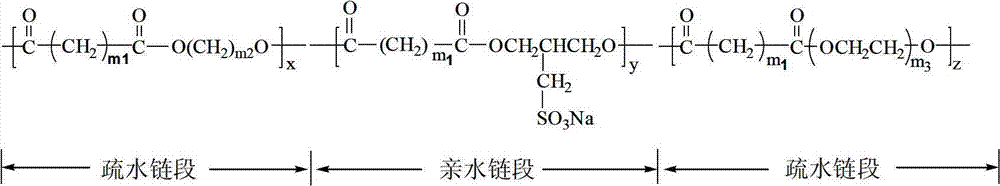

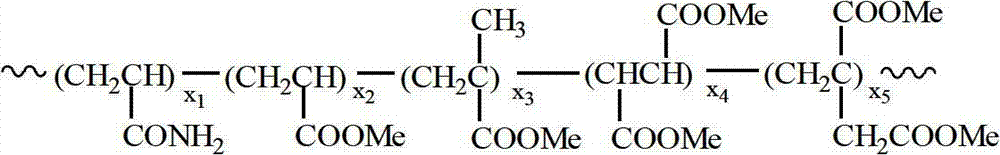

Aliphatic aqueous polyester graft copolymer, adhesion accelerant for improving adhesion strength on terylene fibers by starch slurry, and preparation method thereof

The present invention relates to the field of materials, especially to a slurry for textile warp sizing, and discloses an aliphatic aqueous polyester graft copolymer and a preparation method for an adhesion accelerant for improving adhesion strength on terylene fibers by a starch slurry, wherein the main chain of the graft copolymer is a random copolymer of hydrophobic polyester chain segment aliphatic dicarboxylic acid diol ester and hydrophilic polyester chain segment aliphatic dicarboxylic acid (1,2-dihydroxy-3-propylsulfonate)ester, the graft branch chain is a random copolymer of acrylamide and a vinyl carboxylate, and the adhesion accelerant comprises, by weight, 15-28% of an aliphatic aqueous polyester graft copolymer, 1-6% of a hydroxyl plasticizer, 1-8% of an amino plasticizer, and the balance of water . The preparation process comprises: firstly synthesizing an aliphatic aqueous polyester main chain, carrying out graft copolymerization of the aliphatic aqueous polyester main chain and a hydrophilic vinyl monomer, and finally dissolving plasticizers in the aqueous slurry of the graft copolymer to obtain the adhesion accelerant.

Owner:西达(无锡)生物科技有限公司 +1

Improved starch textile sizing agent

The invention provides an improved starch textile sizing agent. The improved starch textile sizing agent is prepared from the following raw materials in parts by weight: 8-17 parts of ethylhexyl-2-acrylate, 9-13 parts of dibutyl diacrylate, 10-15 parts of diallyl phthalate, 5-8 parts of hydroxypropyl methylcellulose, 4-7 parts of nano-silicon nitride, 6-8 parts of hydroxypropyl distarch phosphate, 4-9 parts of lauryl alcohol polyoxyethylene, 7-10 parts of polyacrylate, 15-26 parts of modified starch, 18-27 parts of polyvinyl alcohol, 20-26 parts of nano-silicon dioxide modified starch, 8-14 parts of protein size, 3-5 parts of kaolin, 6-15 parts of wheat starch and 2-3 parts of polyacrylate. The improved starch textile sizing agent has the beneficial effects that the sizing yarn quality is improved, the sizing agent high in strength and low in tension is easy to desize, the adhesiveness of the sizing agent is improved, and the sizing yarn quality is improved; besides, the improved starch textile sizing agent is quick to biodegrade and small in environmental pollution.

Owner:QINGDAO JINGSHITONG PRECISION MACHINERY MFG

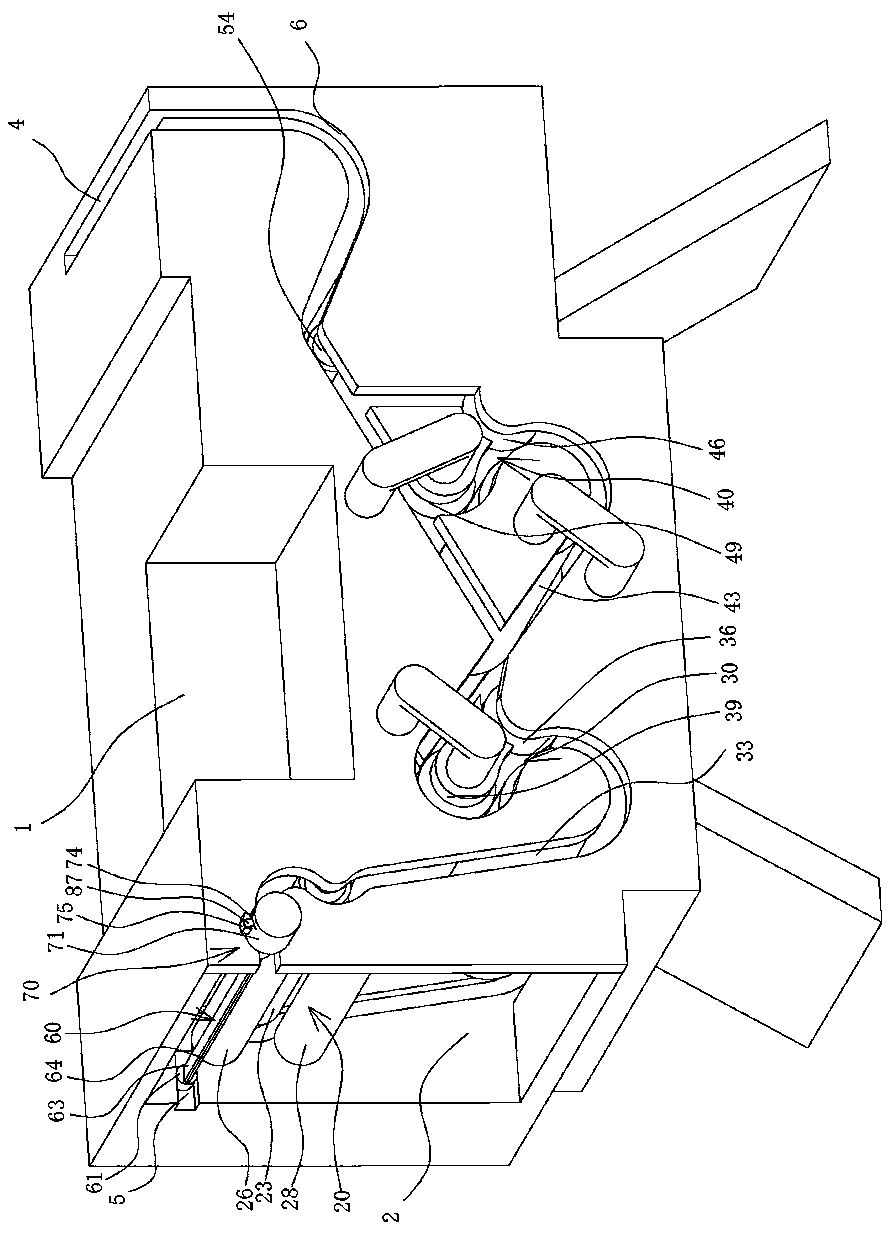

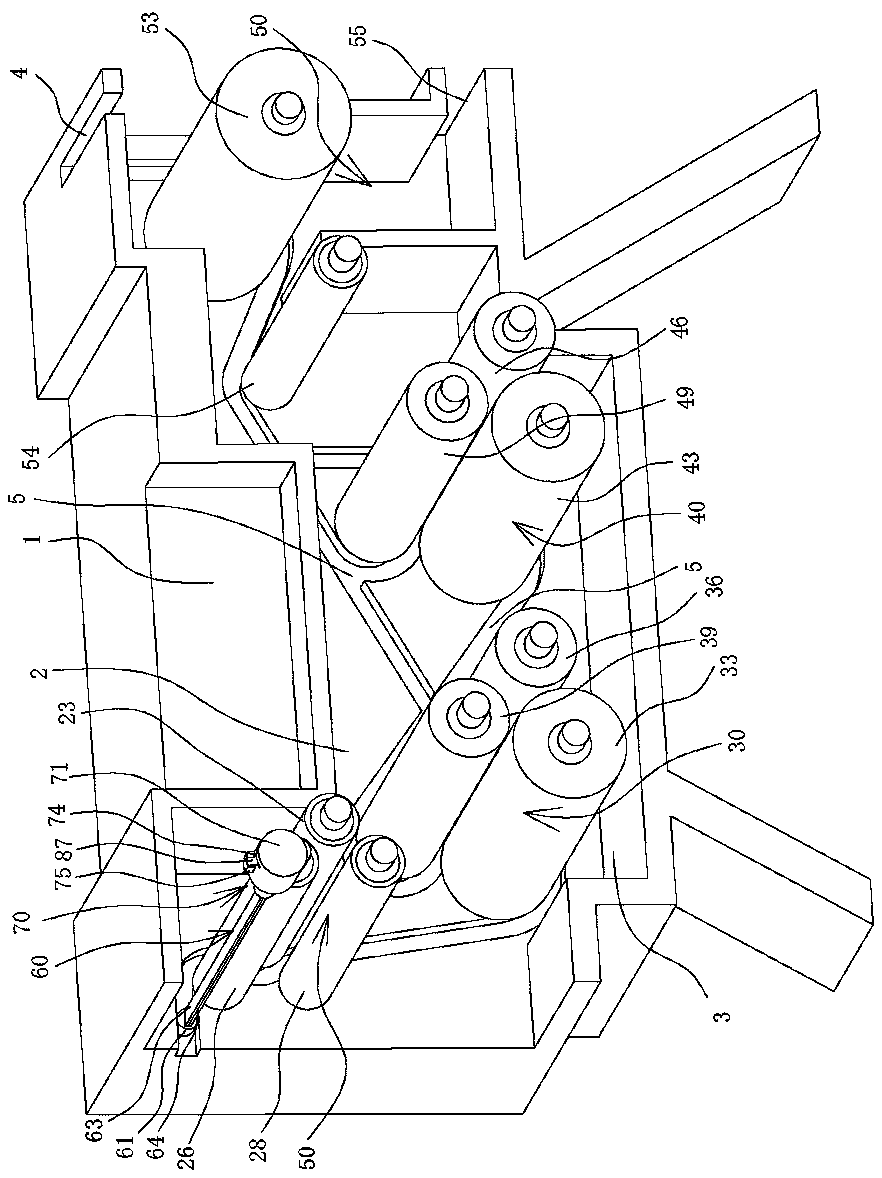

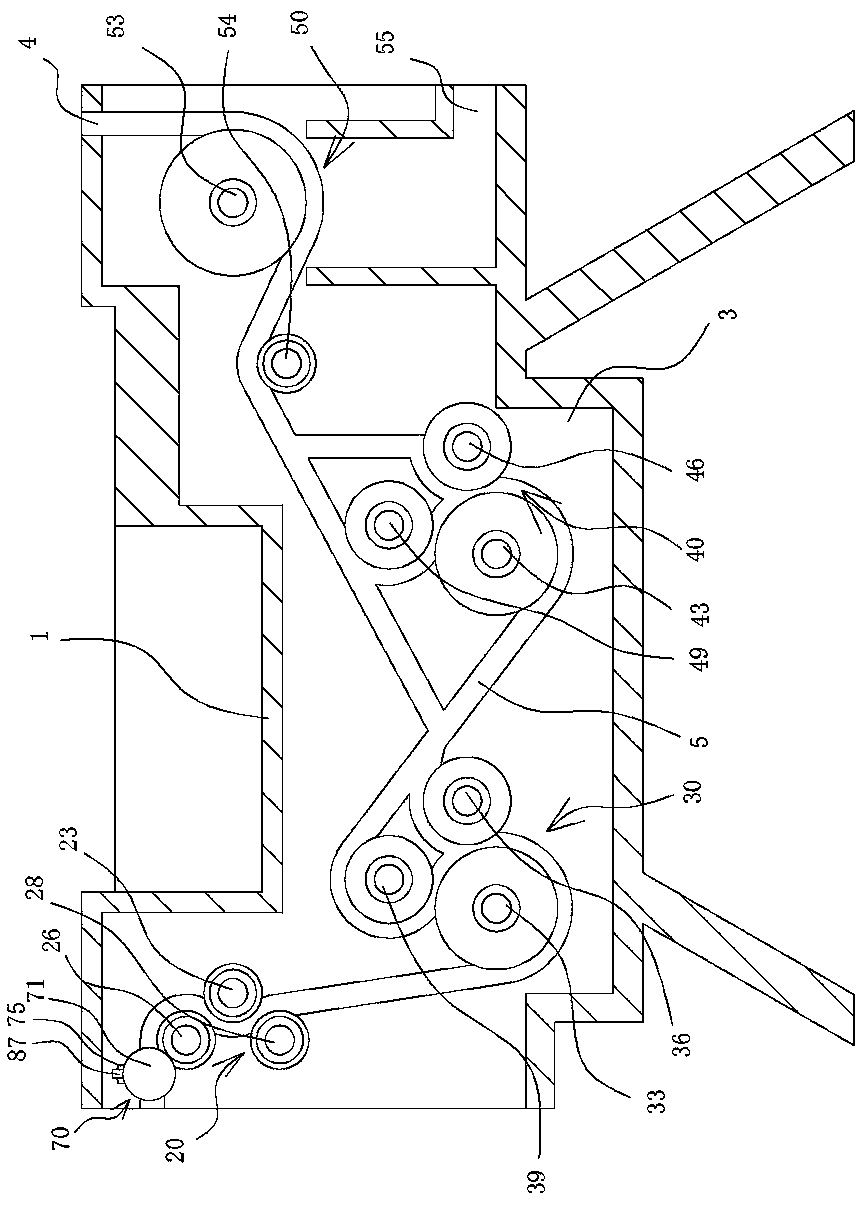

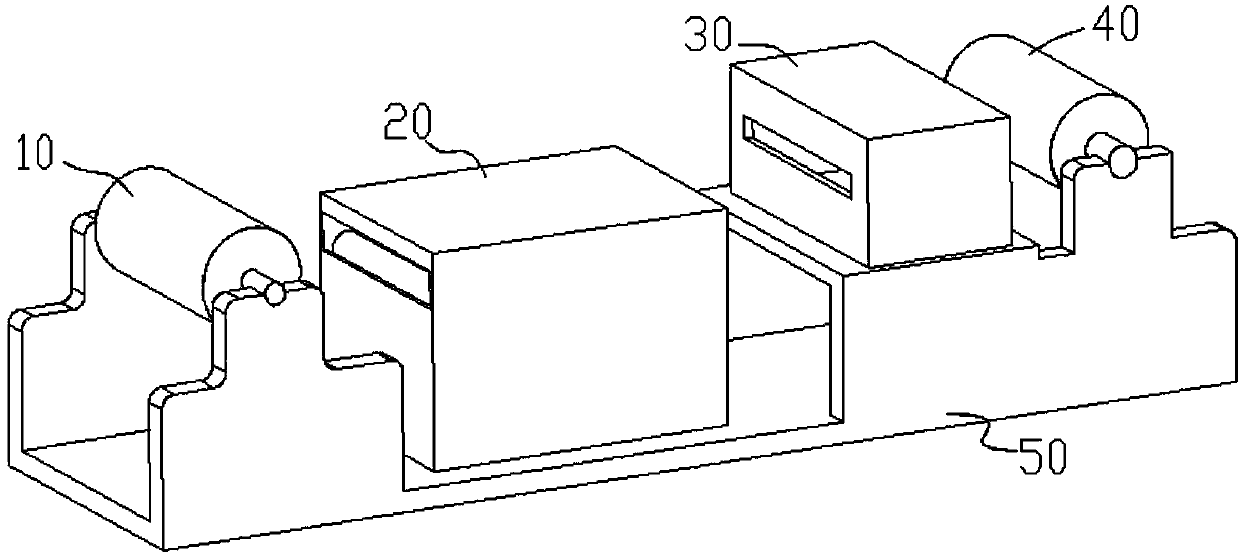

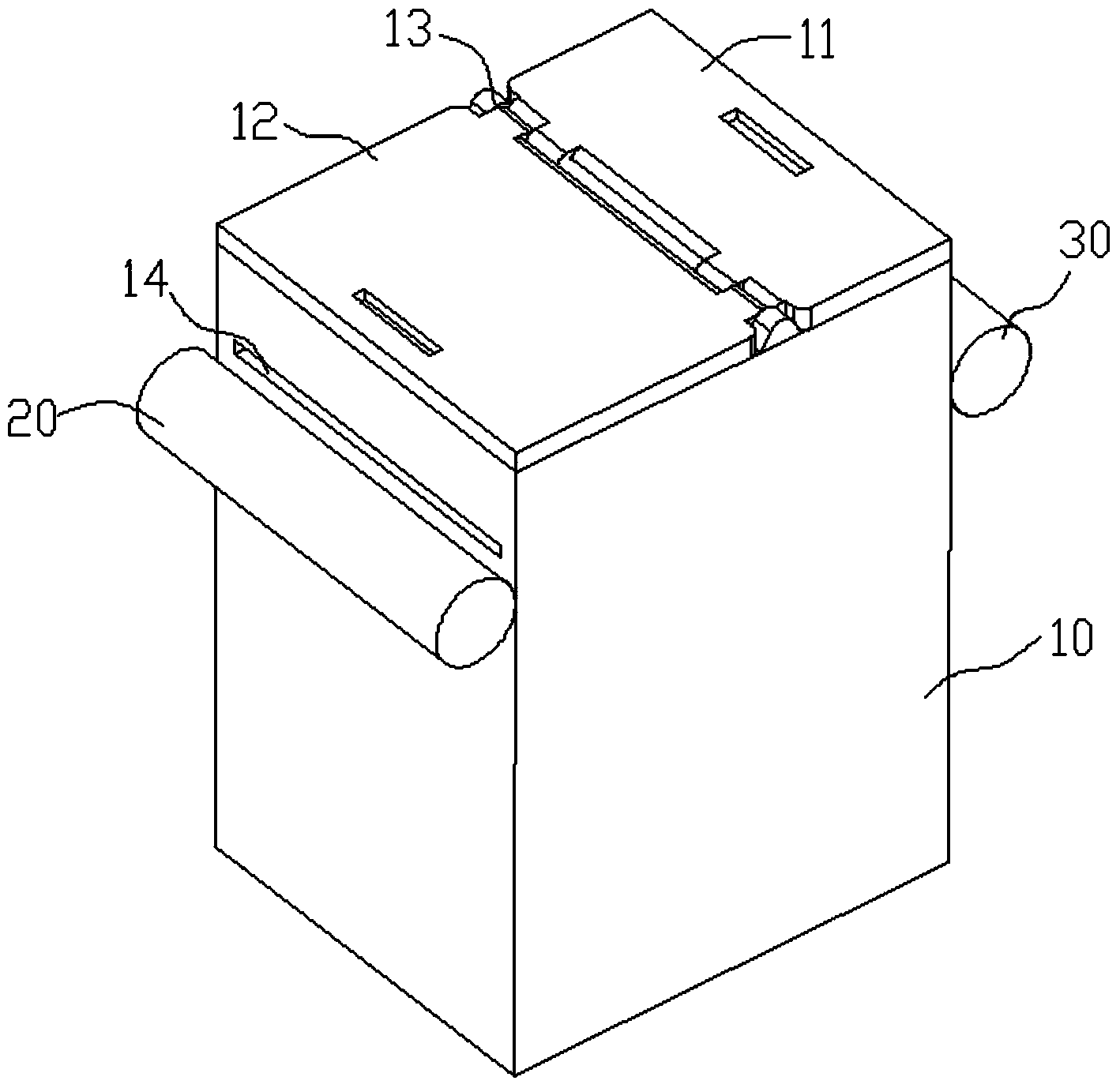

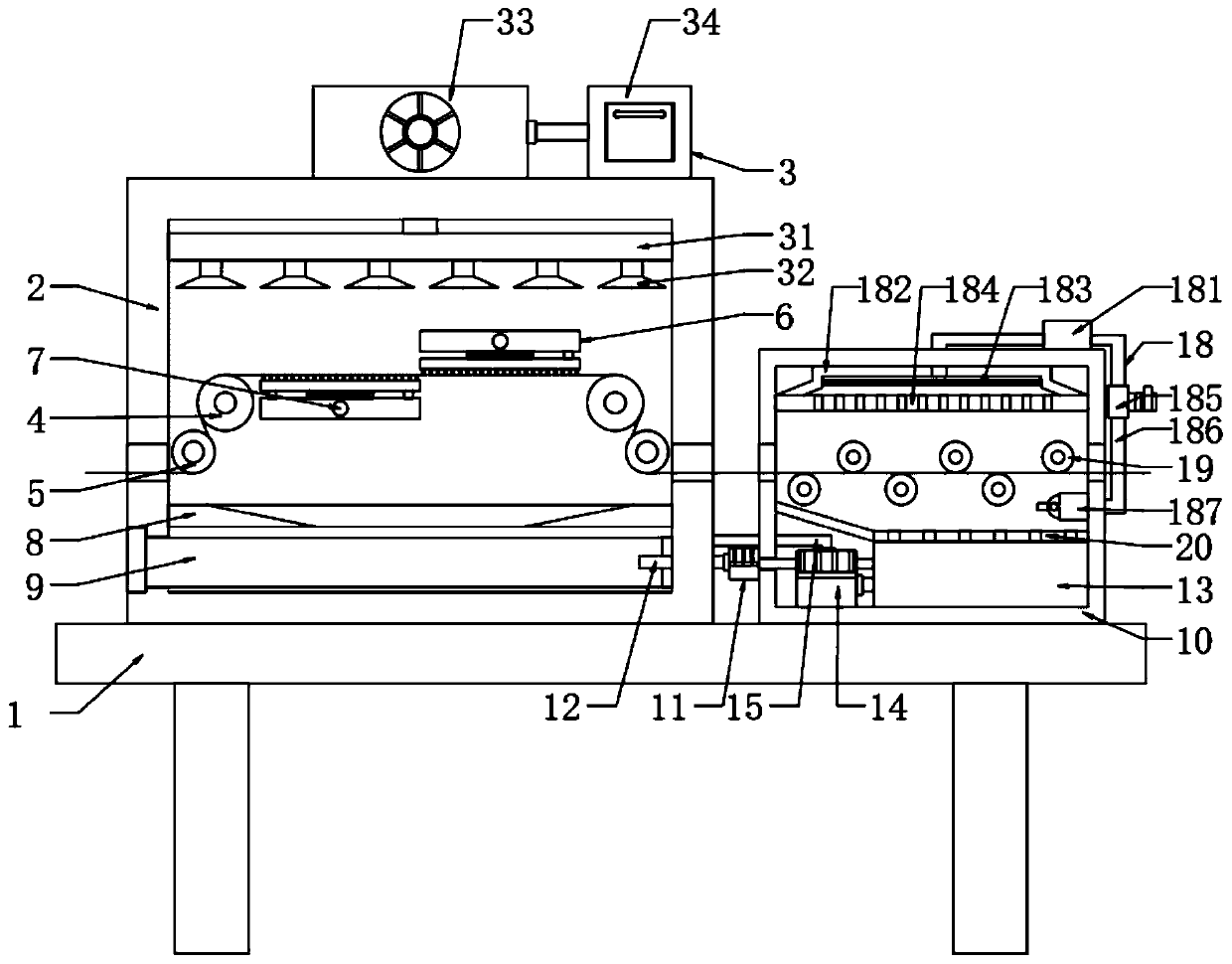

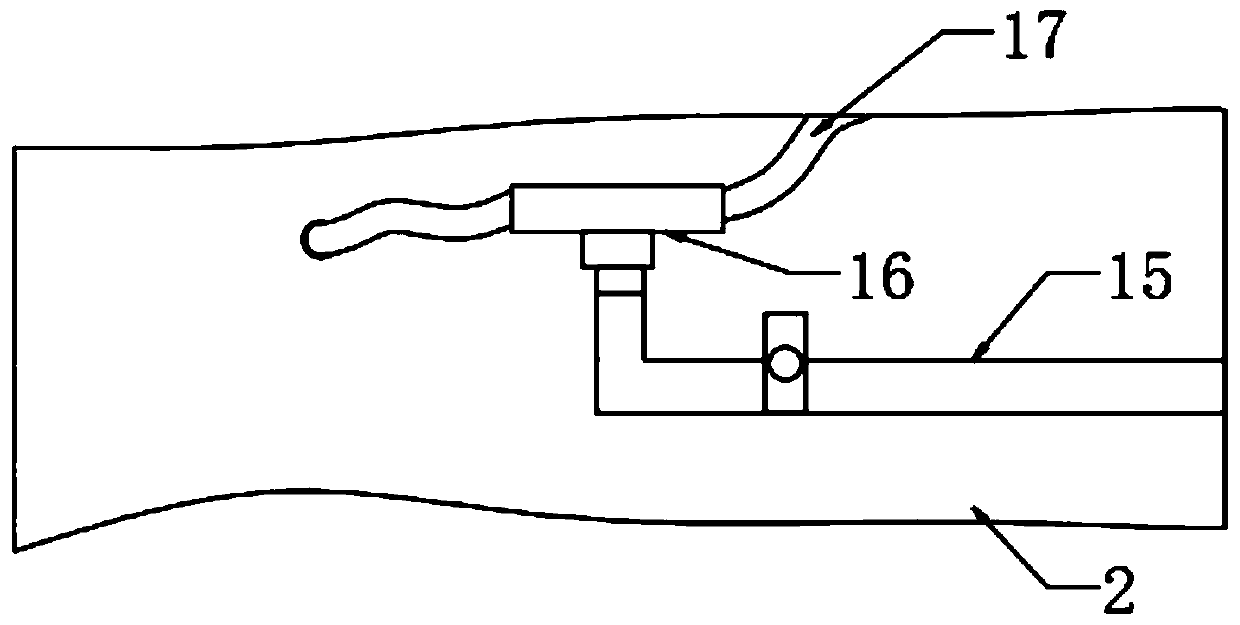

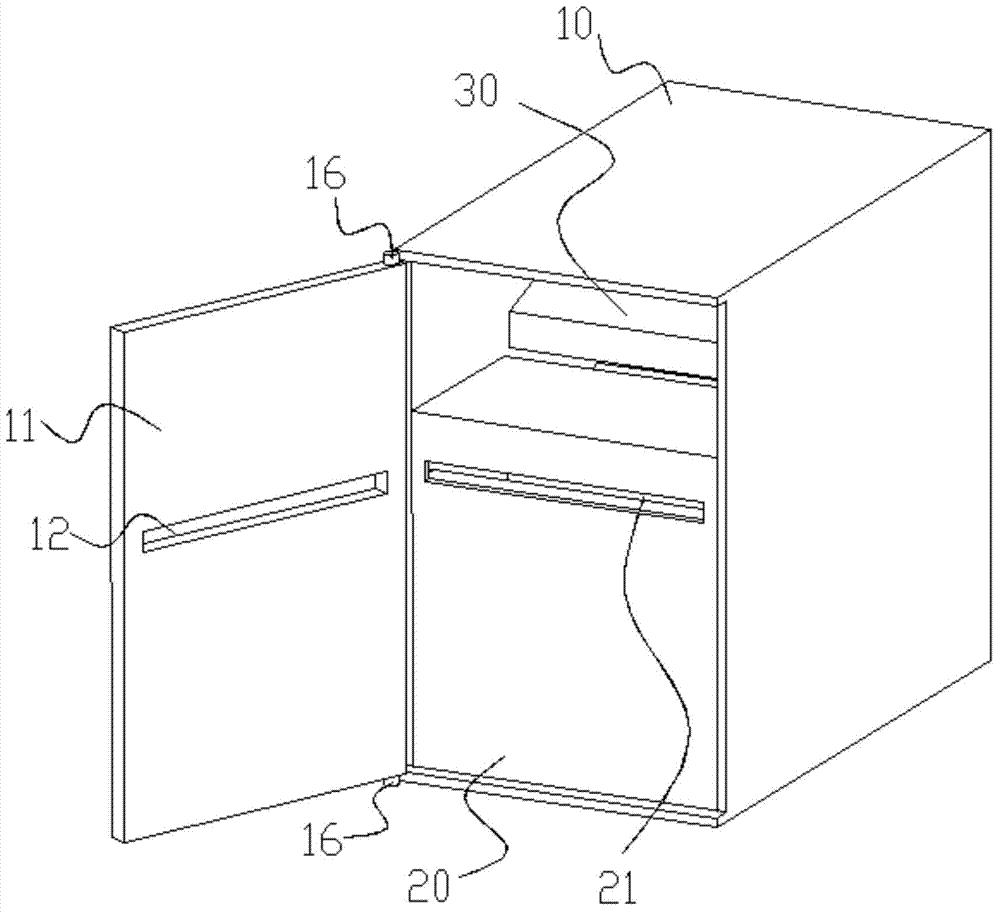

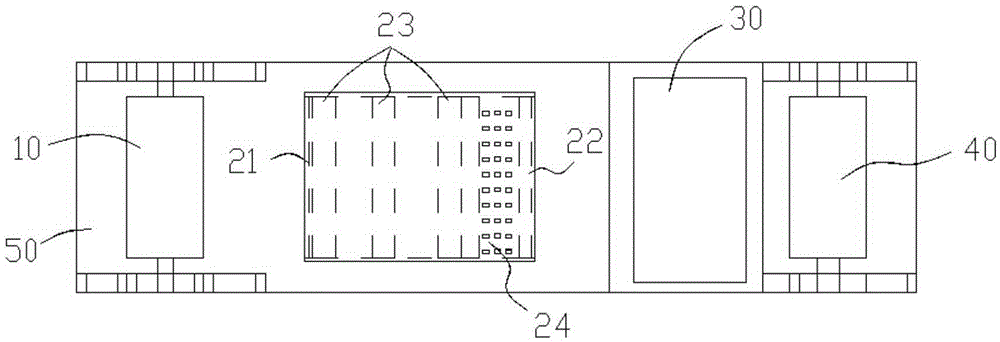

Automatic sizing machine

InactiveCN110894645AReduce labor intensityWork lessLiquid/gas/vapor treatment machines driving mechanismsLiquid/gas/vapor removalYarnControl engineering

The invention discloses an automatic sizing machine. The automatic sizing machine comprises a machine case, wherein a discharge hole is formed in one side of the machine case; a power mechanism is arranged in the machine case; a carding machine is connected to one side of the power mechanism; a first sizing mechanism is connected to one side of the carding mechanism; a second sizing mechanism is connected to one side of the power mechanism; size slots are arranged on one side of the first sizing mechanism and one side of the second sizing mechanism; a drying mechanism is connected to one sideof the power mechanism; a first sliding slot is arranged on one side of the inner wall of the machine case; a second sliding slot corresponding to the first sliding slot is arranged on one side of themachine case; a clamping mechanism that can clamp yarn and move in the machine case is arranged in the first sliding slot; and the other end of the clamping mechanism extends to the outside of the machine case after passing through the second sliding slot. The automatic sizing machine has the beneficial effects that a sizing mode can be changed according to sizing requirements of different kindsof yarn, so that the automatic sizing machine is wider in application range, meanwhile, more convenient for yarn traction movement when the yarn is loading, and reduced in labor intensity of operatingpersonnel.

Owner:台州达邦贸易有限公司

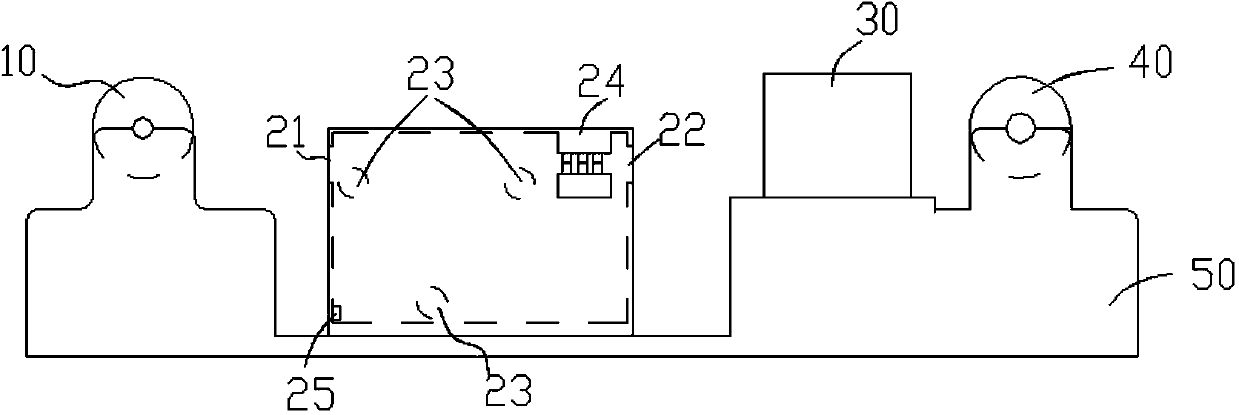

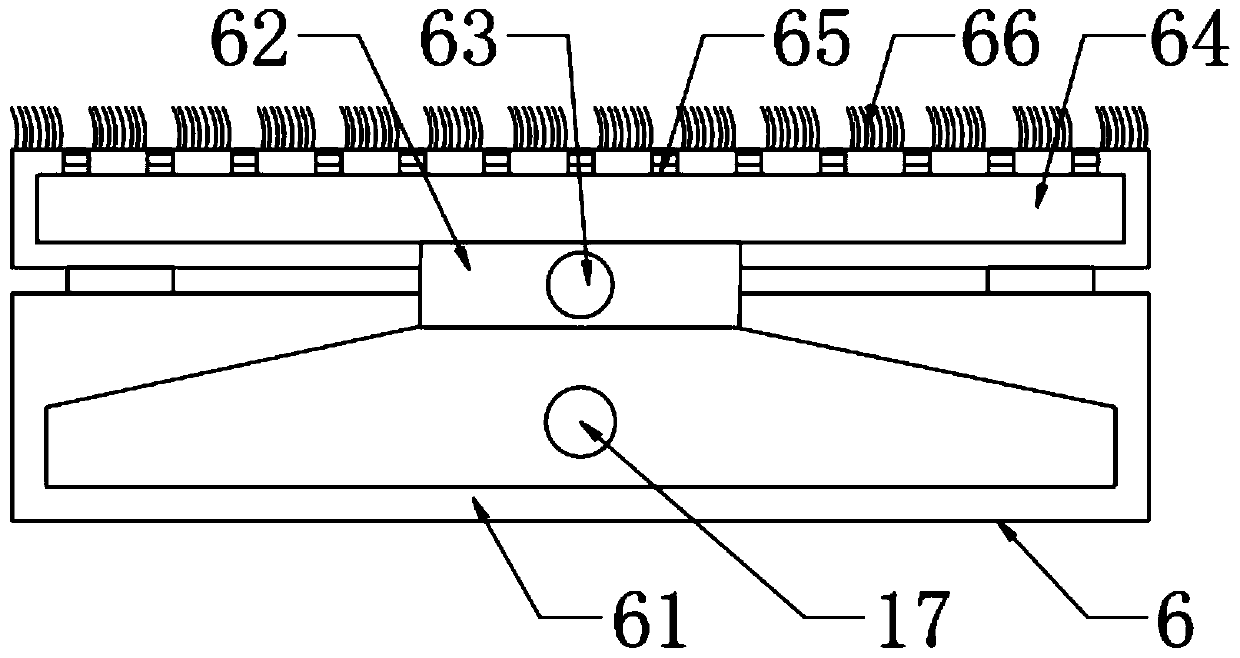

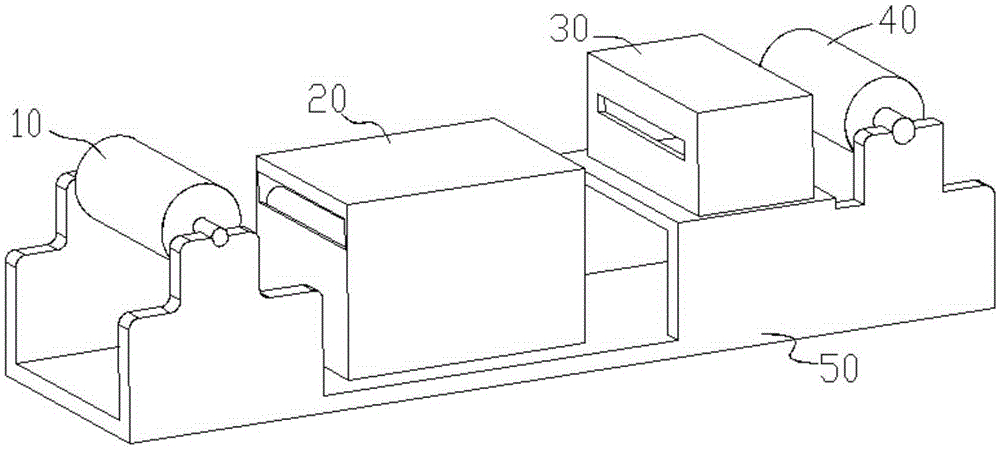

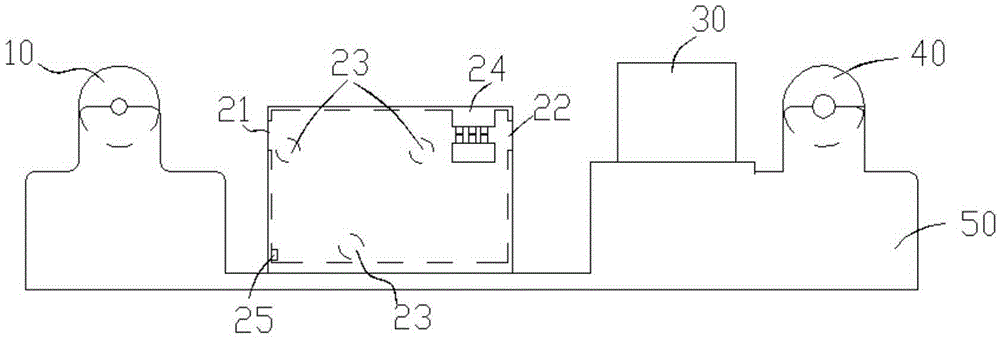

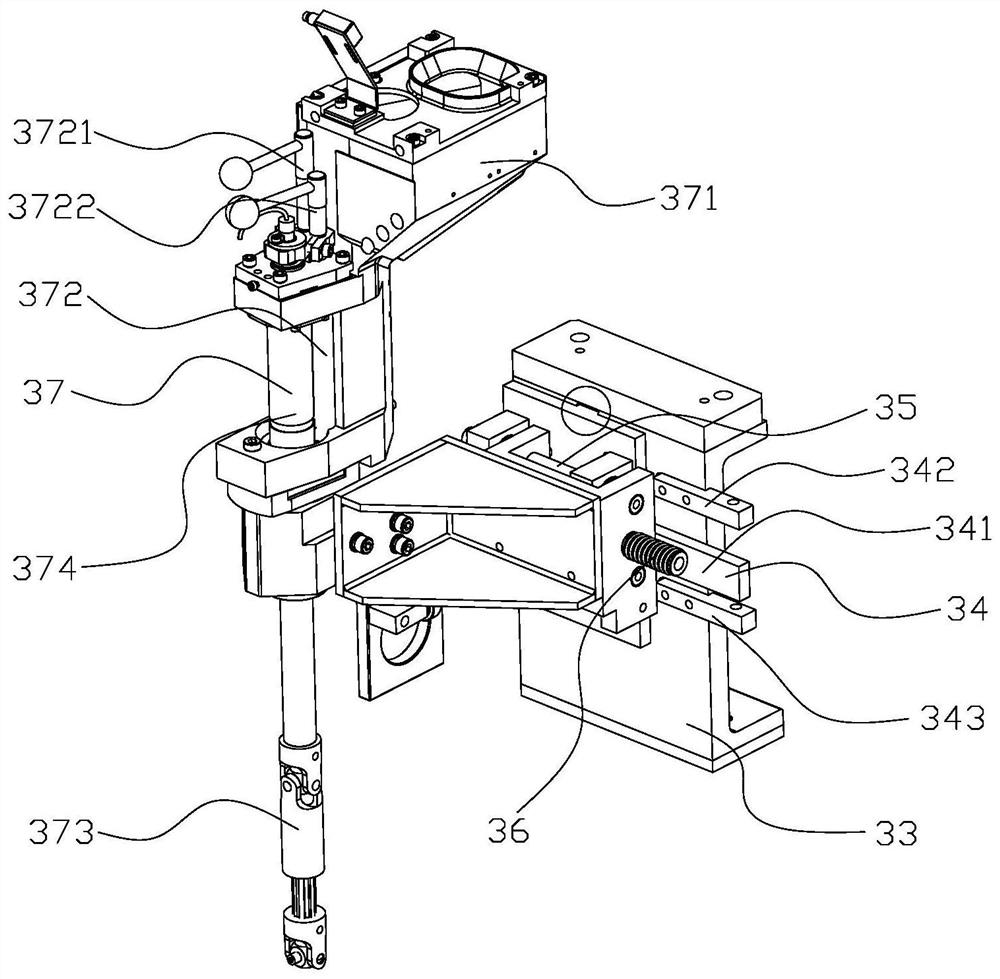

Sizing device for textiles

ActiveCN103993442AFully absorbedUniform sizeTextile treatment containersLiquid/gas/vapor textile treatmentBristleSlurry

The invention discloses a sizing device for textiles. The sizing device comprises a bottom plate. A pay-off roller and a take-up roller are fixed to the bottom plate. A size storage tank and a drying tank are sequentially arranged between the pay-off roller and the take-up roller. A sizing roller and a size brushing device are arranged in the size storage tank, and a feed port and a discharge port are further formed in two side faces of the size storage tank. The size brushing device is composed of a bristle fixing plate and bristles, wherein the bristles are fixed to the bristle fixing plate, and the bristle fixing plate is arranged in the size storage tank. By means of the sizing device, cloth is completely immersed into size through the sizing roller in the size storage tank, the cloth can fully absorb size, sizing is even, and sizing quality is high; the size brushing device is arranged at the position, close to the discharge port, of the size storage tank, residual size on the cloth can be brushed back into the size storage tank through the bristles, size can be effectively saved, and production cost can be reduced.

Owner:启东市丰武农副产品专业合作社

Additive capable of improving mechanical properties of ordinary starch and preparation method of additive

InactiveCN105780475AImprove mechanical propertiesExcellent sizing qualityFibre treatmentEmulsionStearic acid

The invention discloses an additive capable of improving the mechanical properties of ordinary starch. The additive comprises the following components in parts by mass: 15-30 parts of glycol, 20-30 parts of glycerin, 20-30 parts of fatty alcohol-polyoxyethylene ether, 10-20 parts of stearic acid polyoxyethylene ether and 5-10 parts of an organic silicon compound, wherein the melting point of the fatty alcohol-polyoxyethylene ether is 20 DEG C, and the melting point of the stearic acid polyoxyethylene ether is 40 DEG C. A preparation method of the additive comprises the following steps: adding the materials into containers in different steps, emulsifying by using a high-speed emulsifier in different steps, adding the emulsified components into one same container, and further emulsifying, thereby obtaining an emulsion, namely, a finished product. By adopting the additive, the mechanical properties (adhesion property and wearing resistance) of the ordinary starch can be improved.

Owner:ZHEJIANG YUBO TEXTILE CO LTD

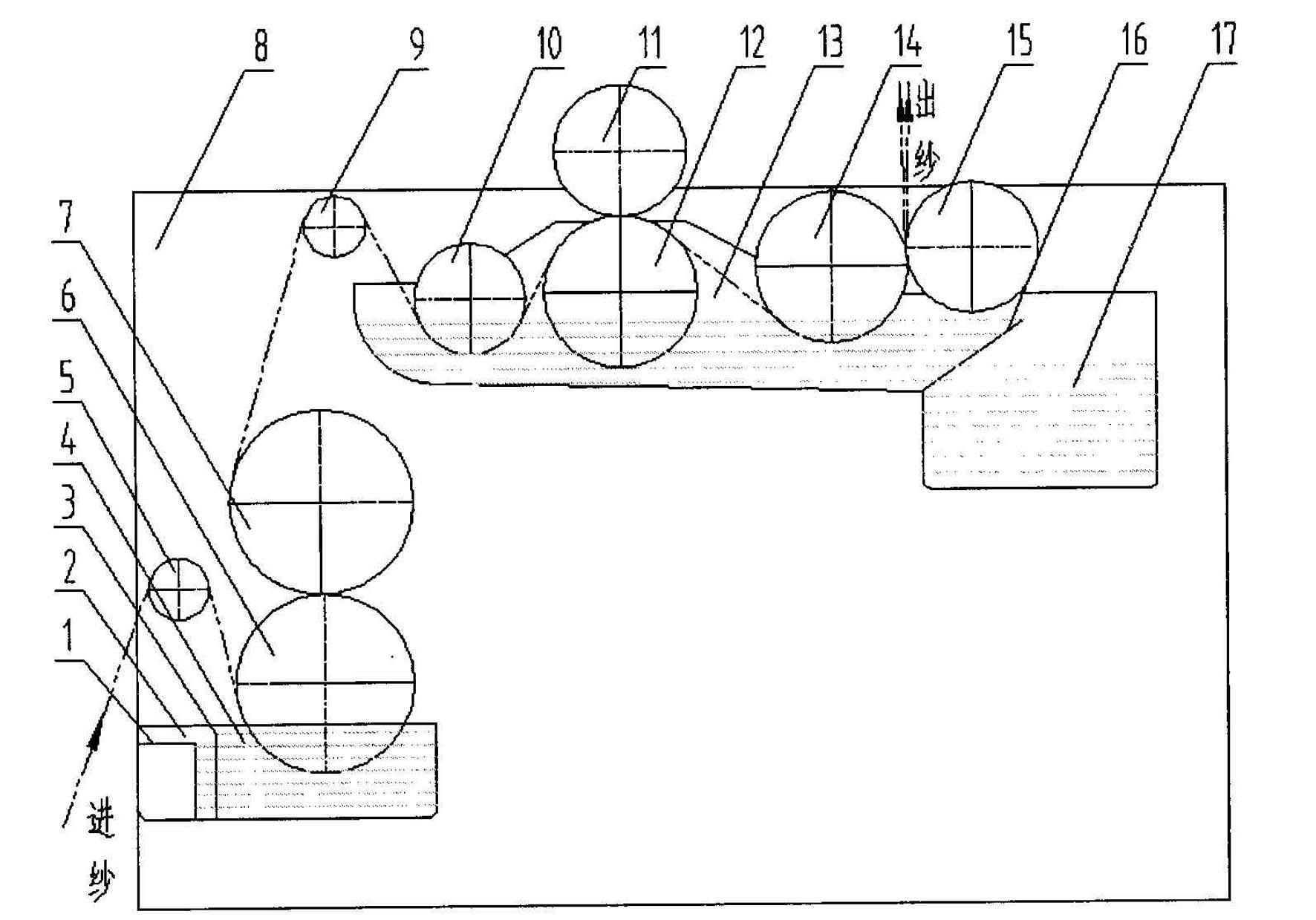

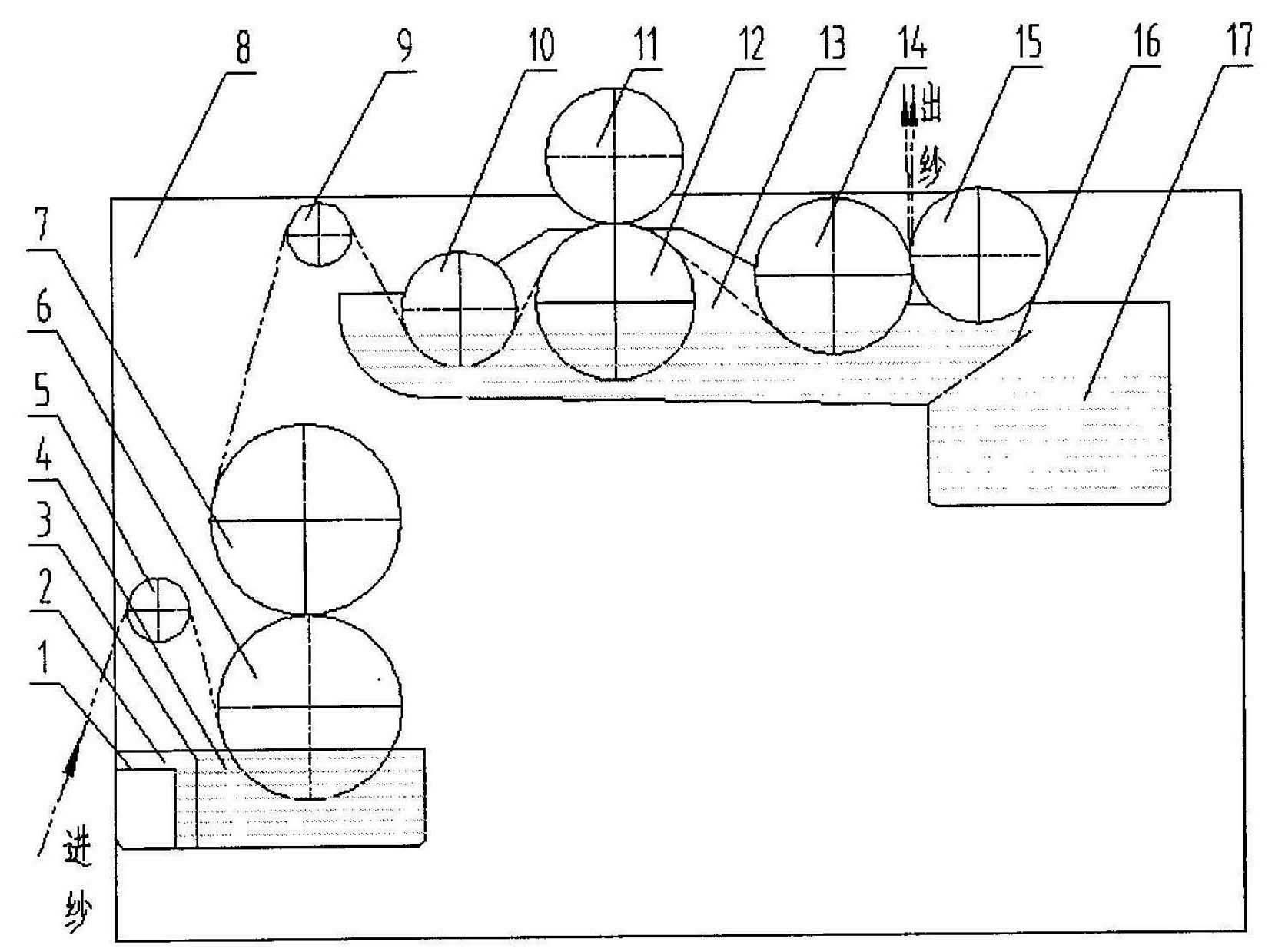

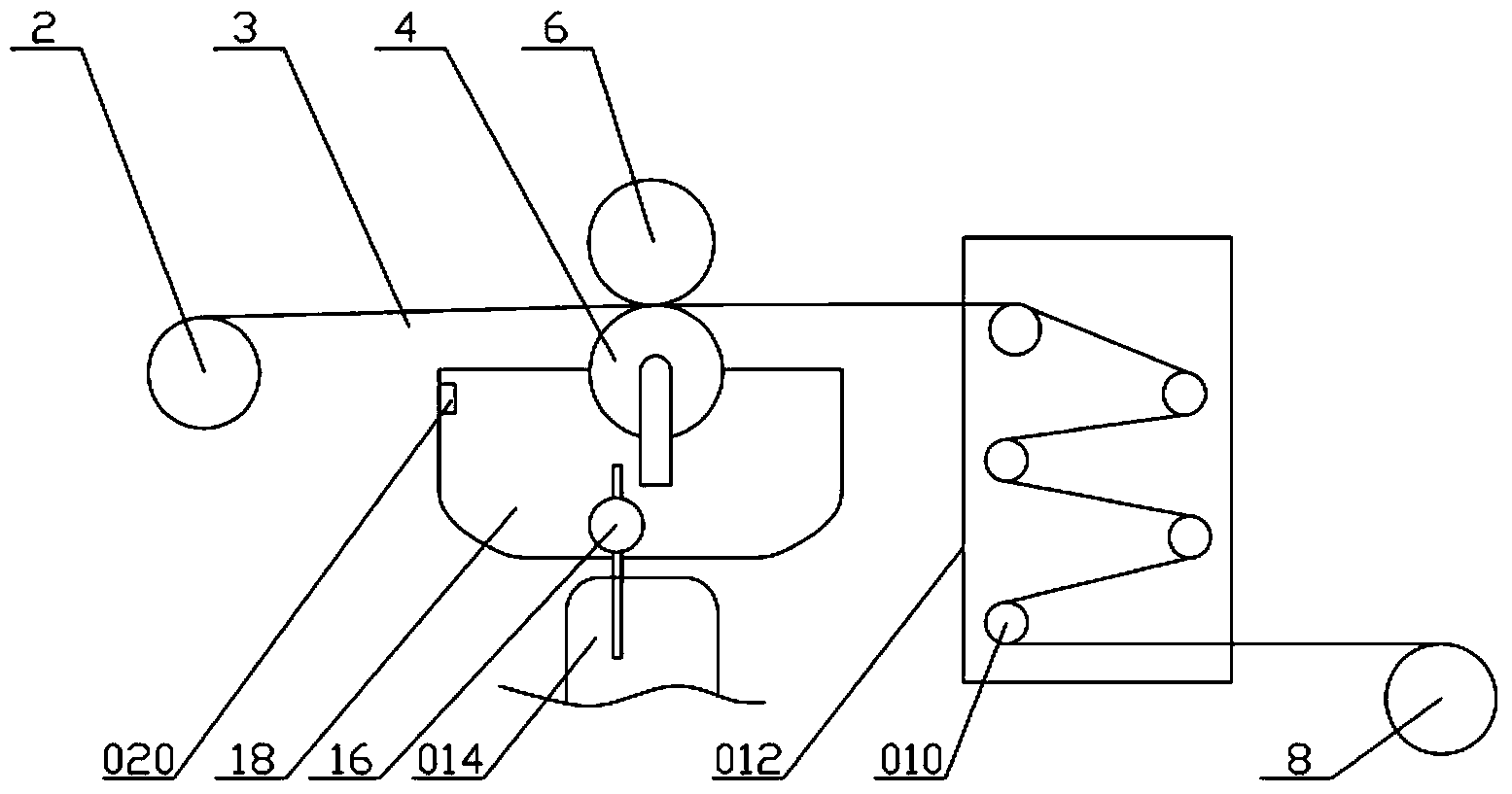

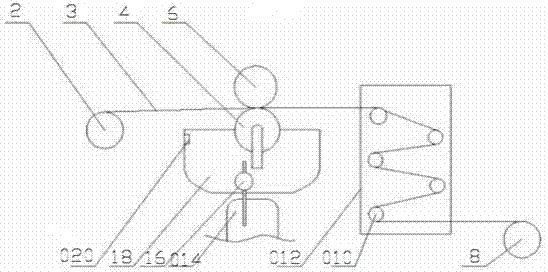

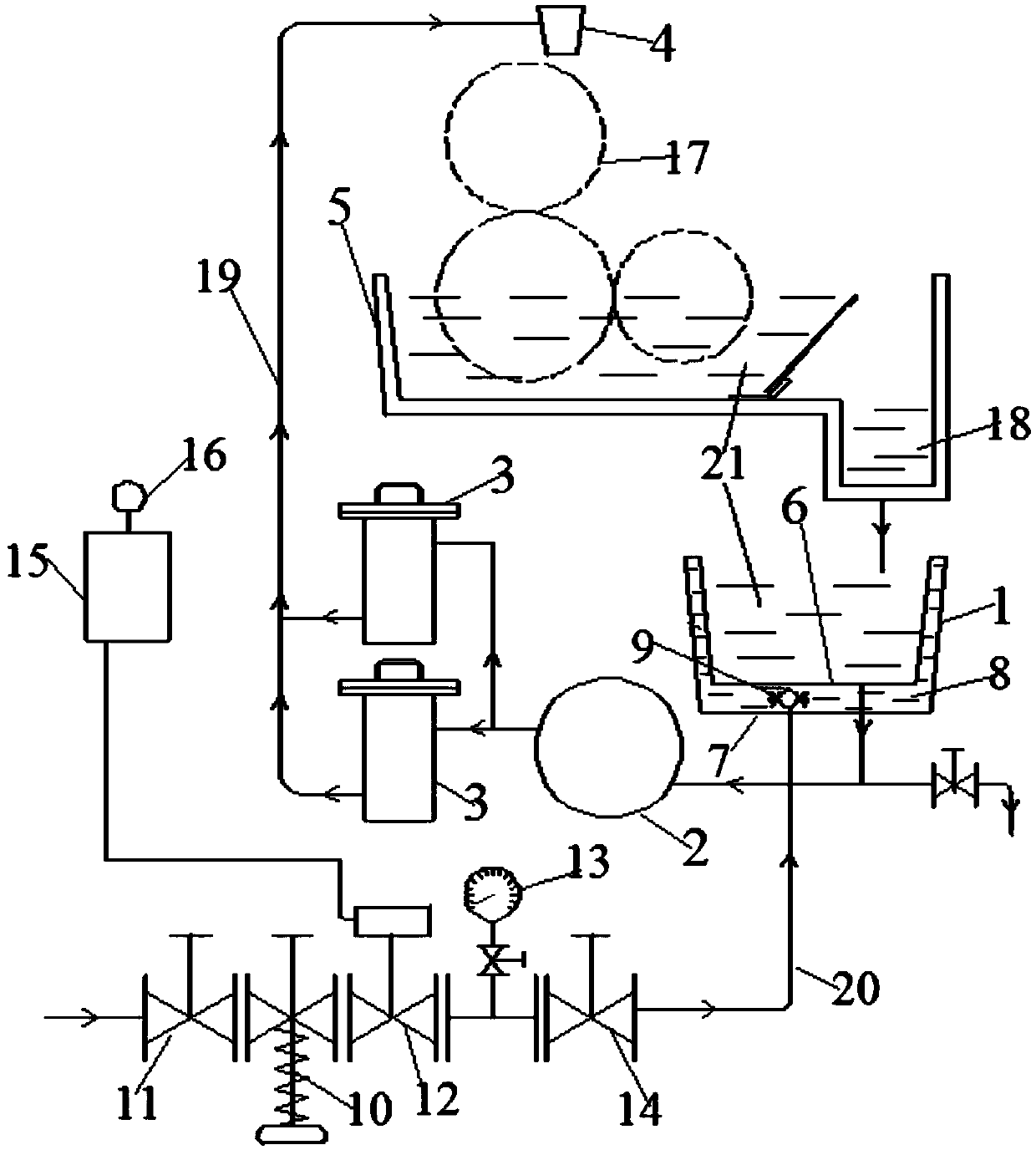

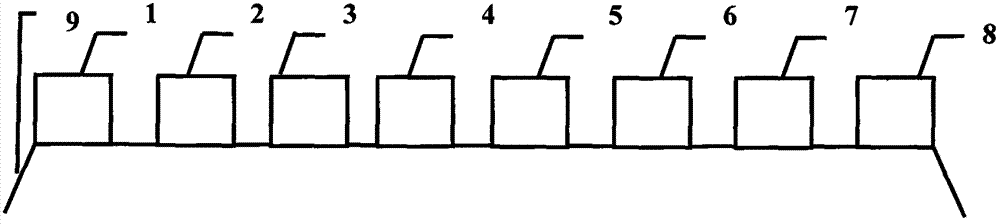

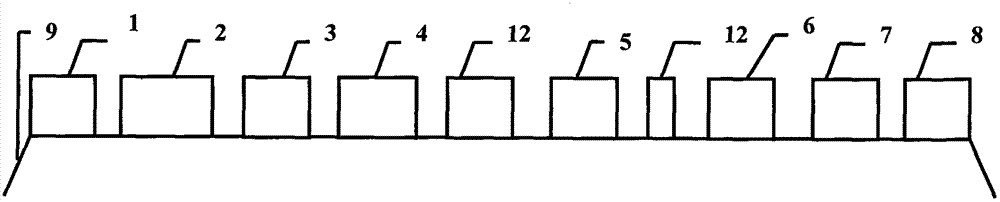

Pre-wetting size vat device of pre-wetting sizing machine

InactiveCN102587062AShorten the lengthImprove work efficiencySucessive textile treatmentsTextile treatment carriersYarnPulp and paper industry

The invention discloses a pre-wetting size vat device of a pre-wetting sizing machine. The pre-wetting size vat device comprises a machine frame, a main size vat, a main water tank, a yarn guide roller, a water charging roller, a water squeezing roller, a yarn guide roller, an immersing roller, a first sizing roller, a second sizing roller, a first size squeezing roller and a second size squeezing roller, wherein the main size vat is arranged at the upper part of the machine frame; the main water tank is arranged on the machine frame which is arranged at the bottom front side of the main size vat; the yarn guide roller, the water charging roller, the water squeezing roller, the yarn guide roller and the immersing roller are arranged along the yarn running direction in sequence; the first size squeezing roller is arranged above the first sizing roller; the second size squeezing roller is arranged at the rear side of the second sizing roller; the yarn guide roller is arranged on the machine frame which is arranged at the top front side of the main size vat; the yarn guide roller, the water charging roller and the water squeezing roller are arranged above the main water and below the yarn guide roller respectively; the lower part of the water charging roller is immersed in the main water tank; the yarn guide roller is arranged above the front side of the water charging roller; the lower parts of the immersing roller, the first sizing roller, the second sizing roller and the second size squeezing roller are all immersed in the horizontally arranged main size vat; a preparatory size vat is arranged at the rear part of the main size vat; and a size vat overflowing plate is arranged between the main size vat and the preparatory size vat.

Owner:CHTC HEAVY IND

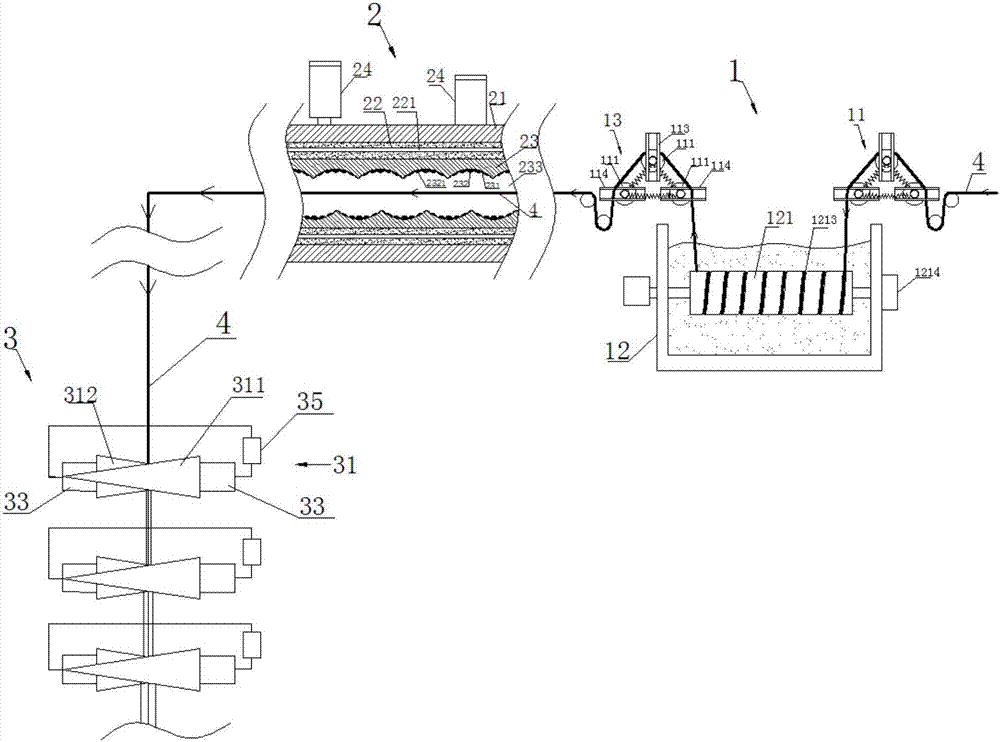

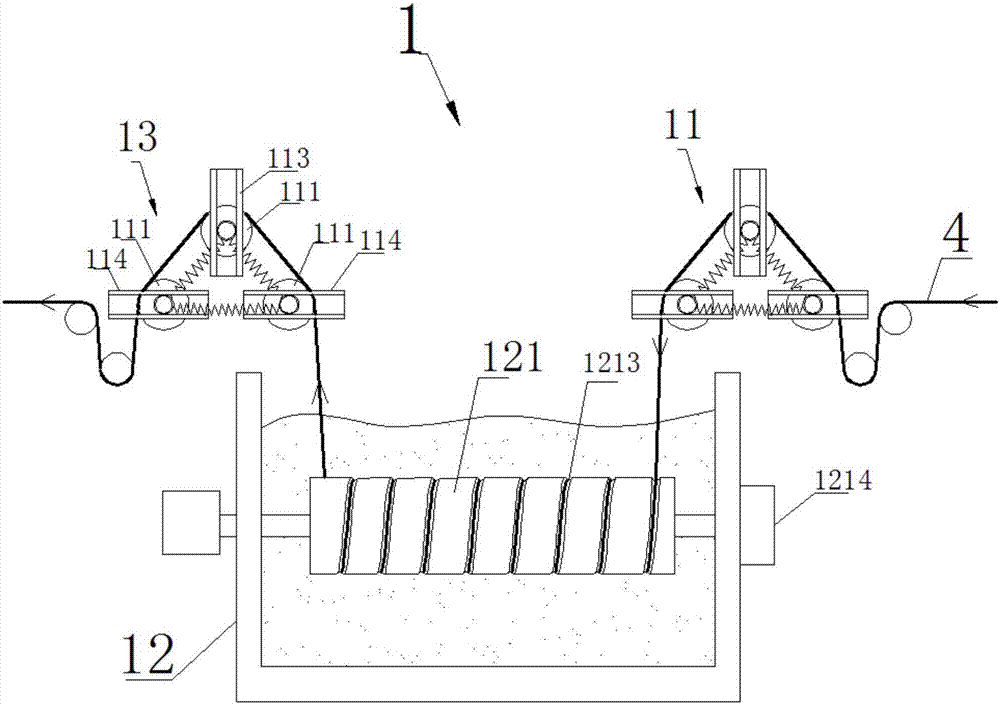

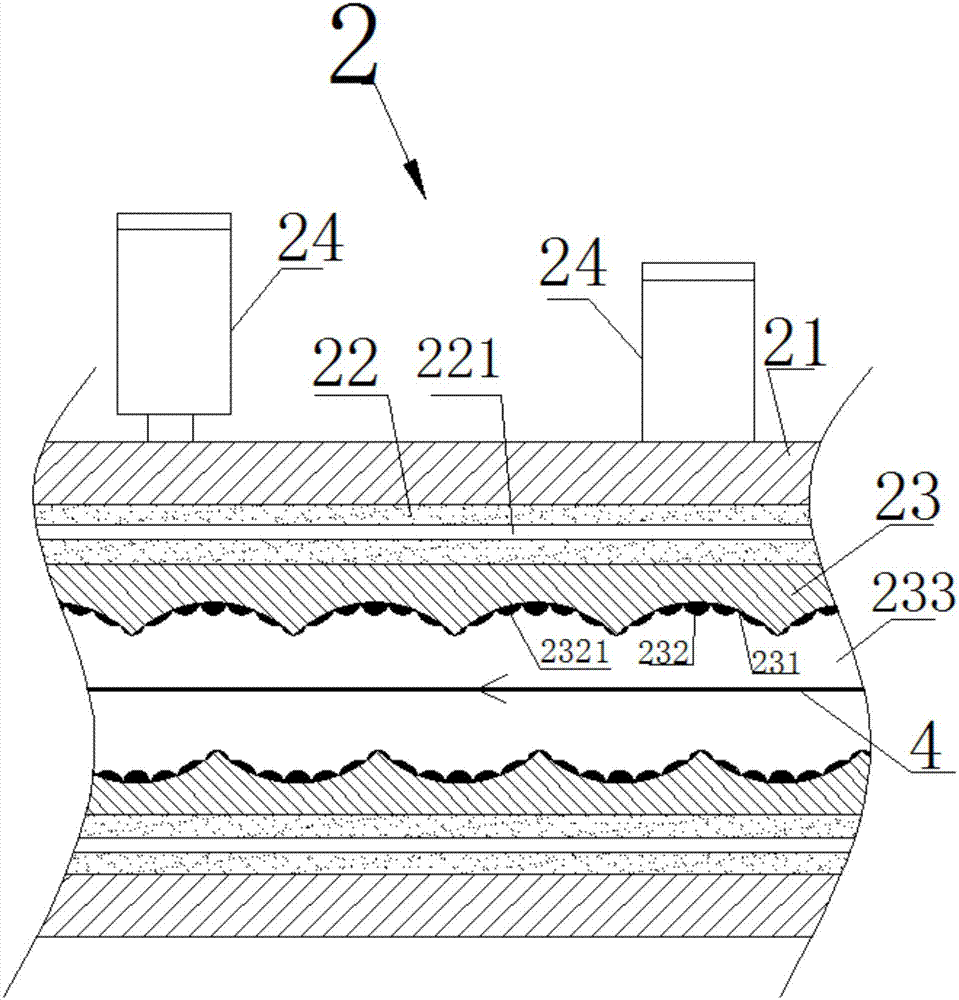

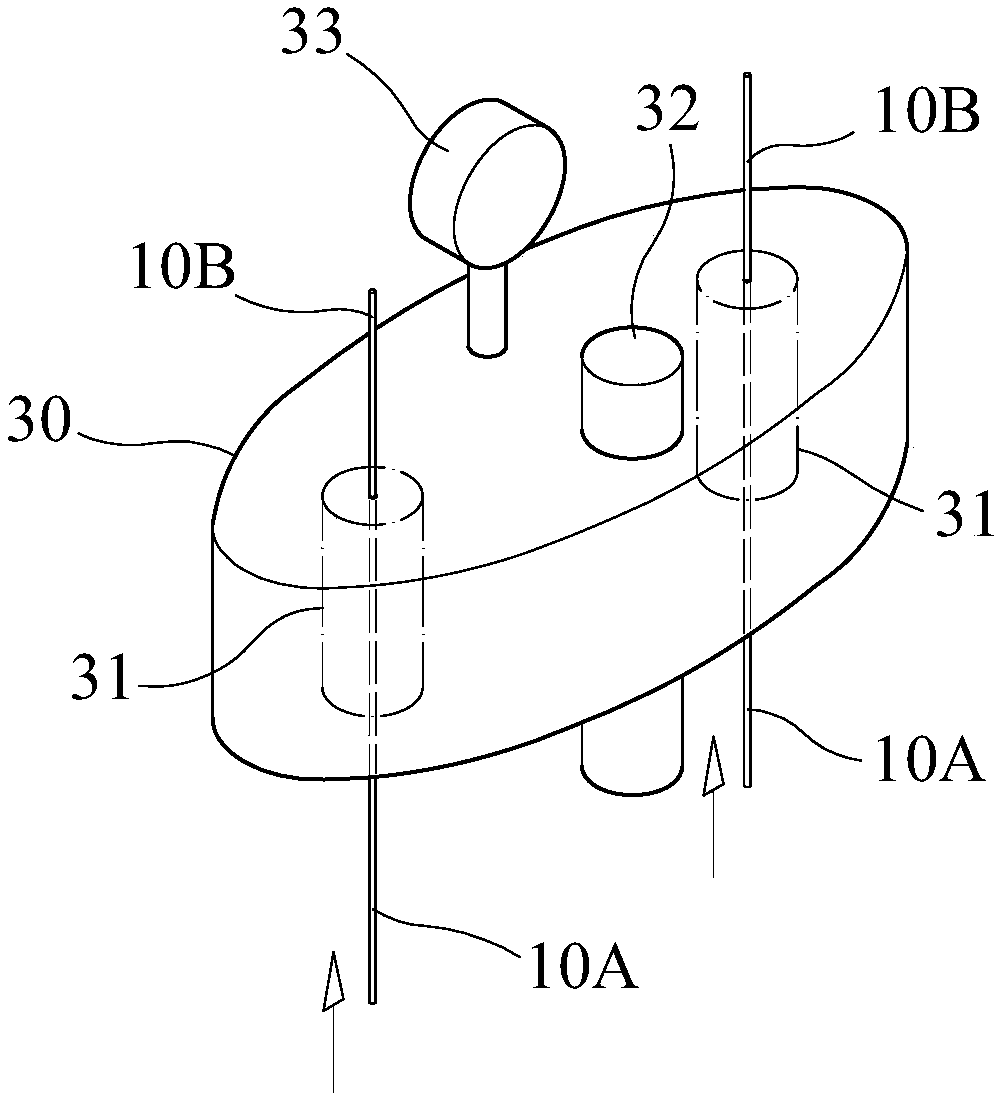

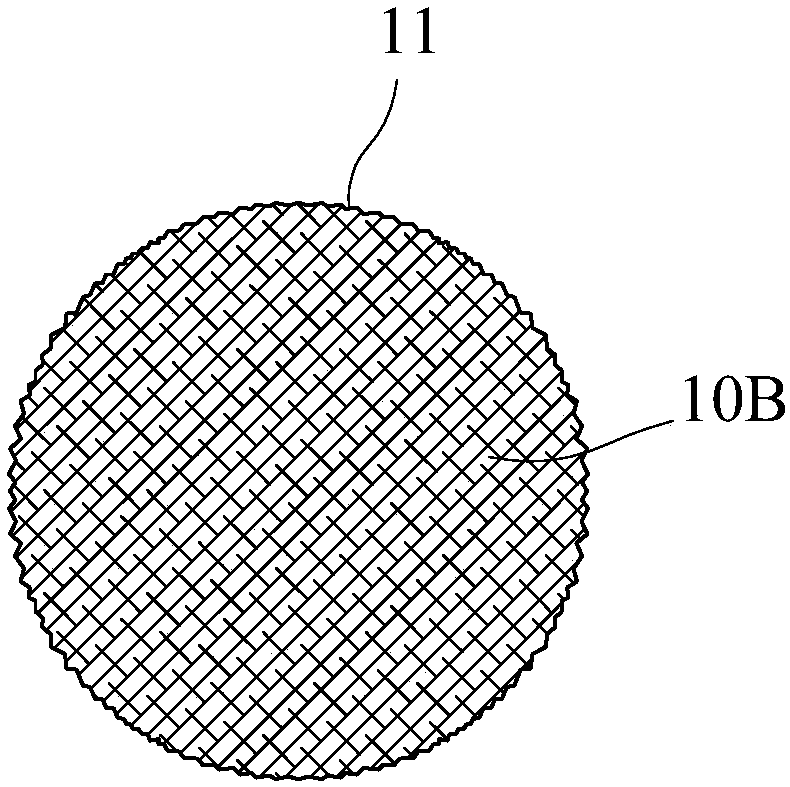

Yarn processing device

PendingCN106988050ASpeed up dryingEasy to separateLiquid/gas/vapor removalTextile treatment machine arrangementsYarnThermal radiation

The invention relates to a yarn processing device. The device comprises a sizing mechanism, a drying mechanism and a separation mechanism which are sequentially arranged in the yarn moving direction. The sizing mechanism comprises a sizing fluid box; a rotational sizing roller is horizontally arranged in the sizing fluid box; the sizing roller comprises a cylindrical ultrasonic transducer and a cylindrical rubber layer, the cylindrical rubber layer is tightly attached to the ultrasonic transducer, and the ultrasonic transducer is sleeved with the cylindrical rubber layer; a spiral yarn path is arranged on the outer circumferential face of the rubber layer and used for yarn routing; the drying mechanism comprises a cylindrical heat radiation base layer; a drying cavity penetrating in the axial direction of the heat radiation base layer is defined by the heat radiation base layer; a plurality of concave base arc surfaces are densely arranged on the inner wall of the heat radiation base layer; in the drying cavity, two opposite base arc surfaces are arranged in a staggered mode. The yarn processing device can effectively improve the sizing, drying and separating effects, the production efficiency is improved, and the yarn processing quality is ensured.

Owner:泉州市睿敏机电技术有限公司

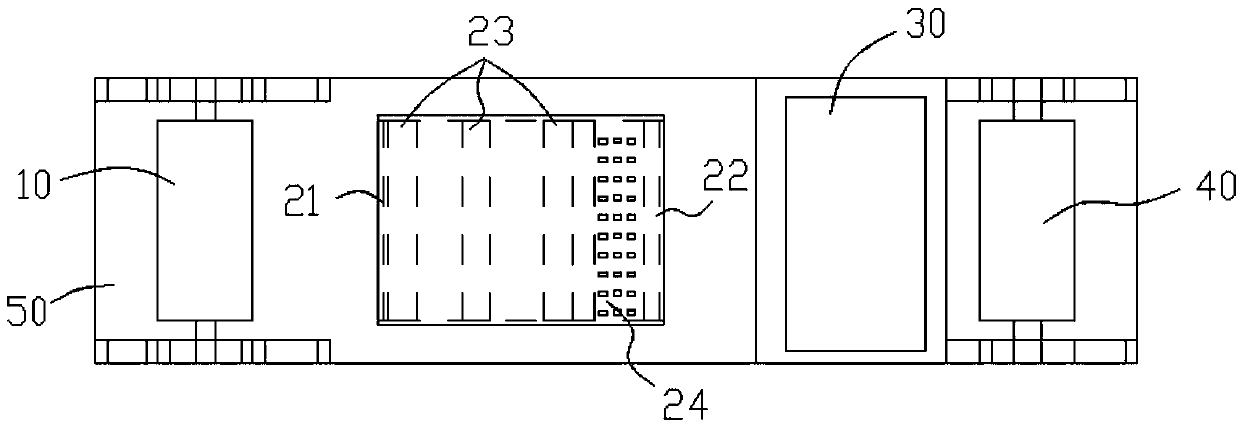

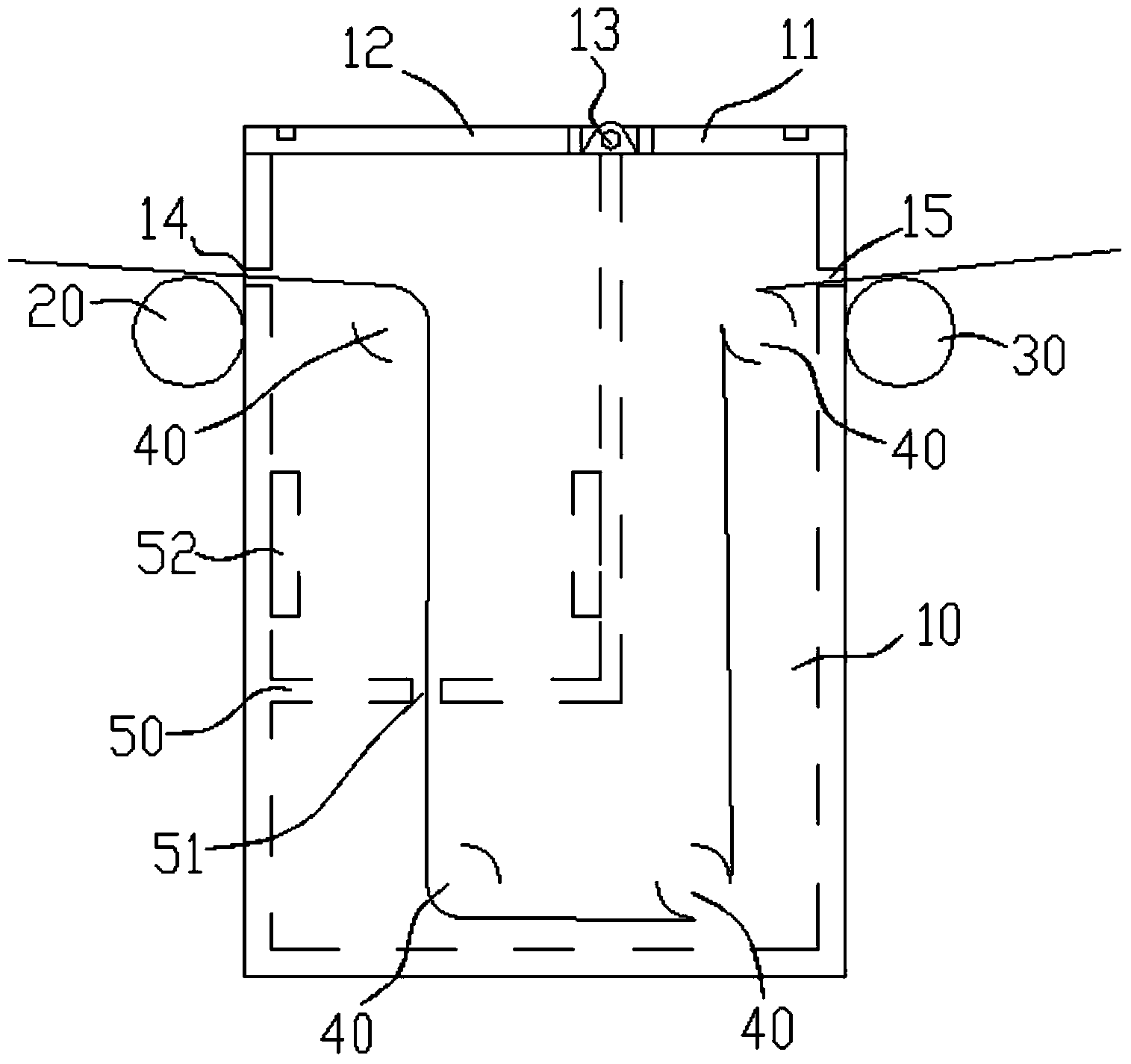

Novel sizing device

ActiveCN103981660ATake advantage ofImprove sizing qualityTextile treatment machine arrangementsLiquid/gas/vapor textile treatmentMechanical engineeringSizing

The invention discloses a novel sizing device. The novel sizing device comprises a box body, the box body is of a cavity-type structure and is divided into an upper cavity and a lower cavity through a partition plate, the upper cavity and the lower cavity are communicate through a connecting opening in the bottom end face of the partition plate, an inlet end is arranged on one lateral wall of the lower cavity, one side of the inlet end is provided with a cloth unrolling roller, an outlet end is arranged on the lateral wall, opposite to the inlet end, of the upper cavity, a cloth rolling roller is arranged on one side of the outlet end, and a top cover is arranged on the top end face of the box body. A plurality of cloth rollers are arranged in the lower cavity, the cloth rollers are located at the bottom of the inlet end and the bottom of the lower cavity respectively, the upper cavity is communicated with the lower cavity through the connecting opening, the cloth rollers are arranged over the connecting opening, the installation height of the cloth rollers is equal to the installation height of the outlet end, the two lateral walls of the upper cavity are respectively provided with a heating device, and the installation height of the heating devices is located between the bottom end face of the partition plate and the outlet end. The novel sizing device is small in occupied space and even in sizing.

Owner:江苏盛泰克纺织印染有限公司

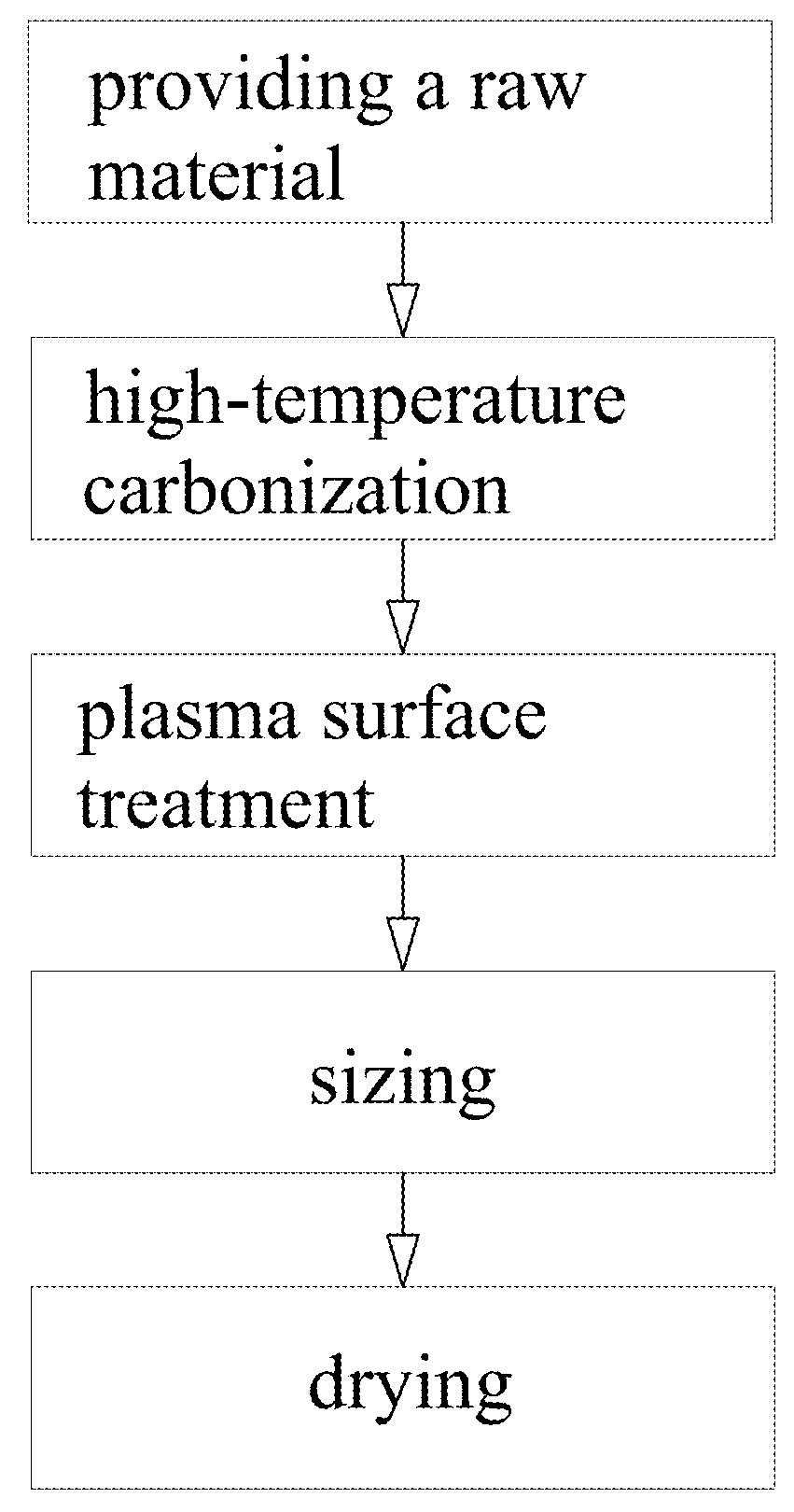

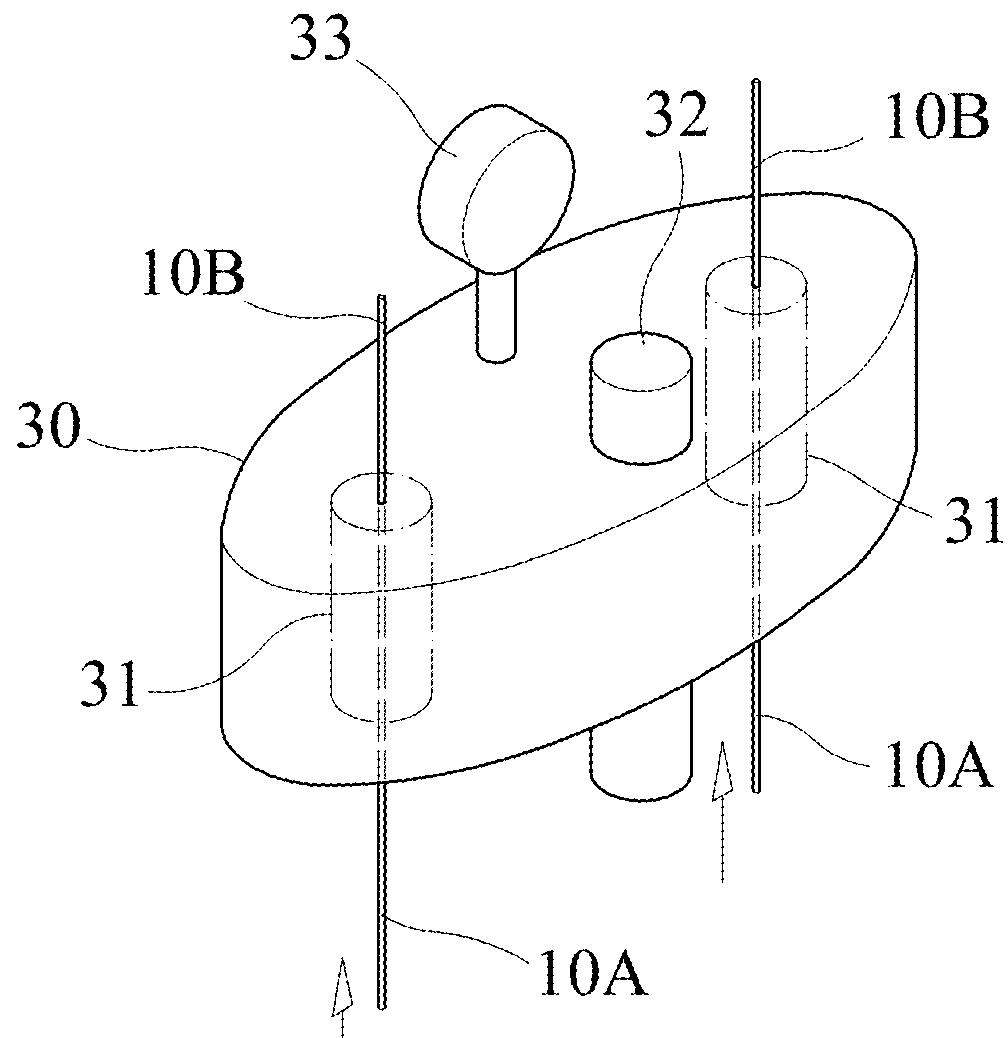

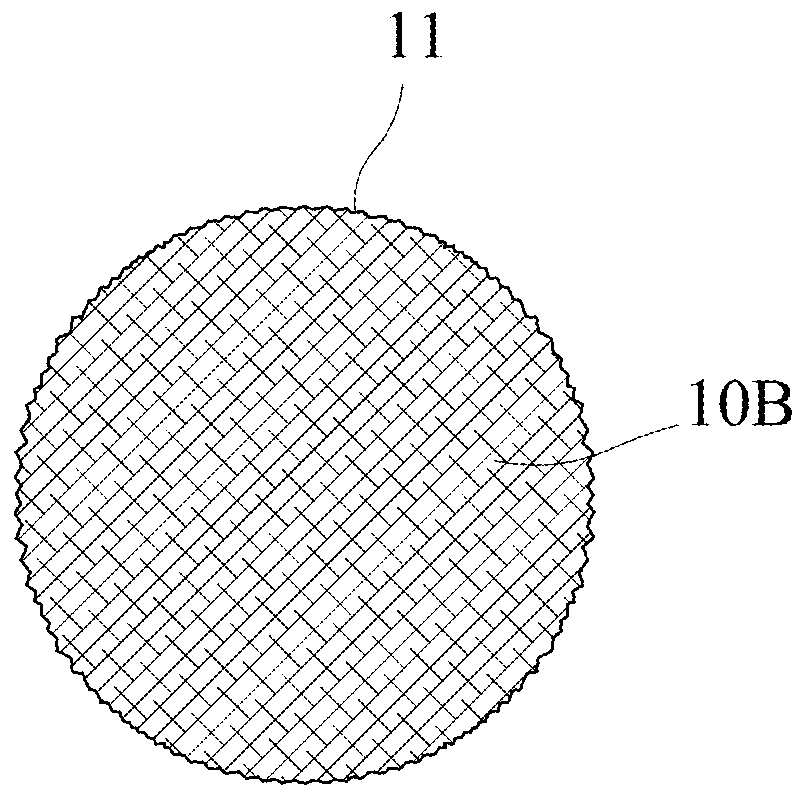

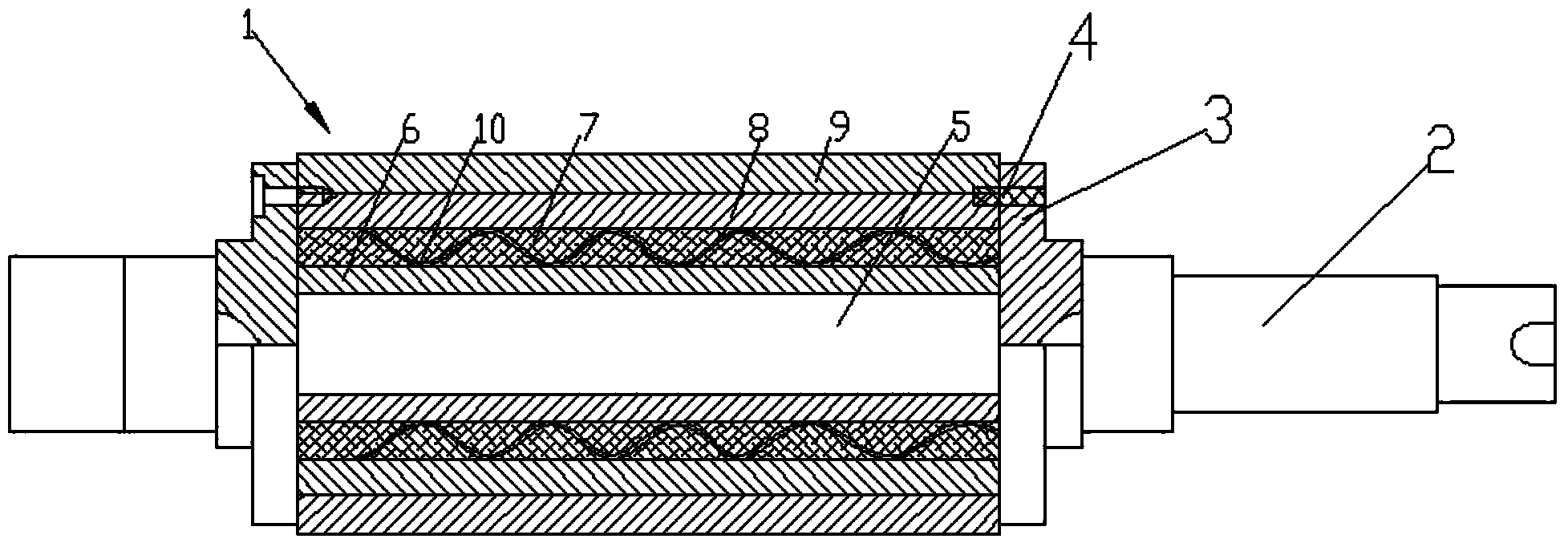

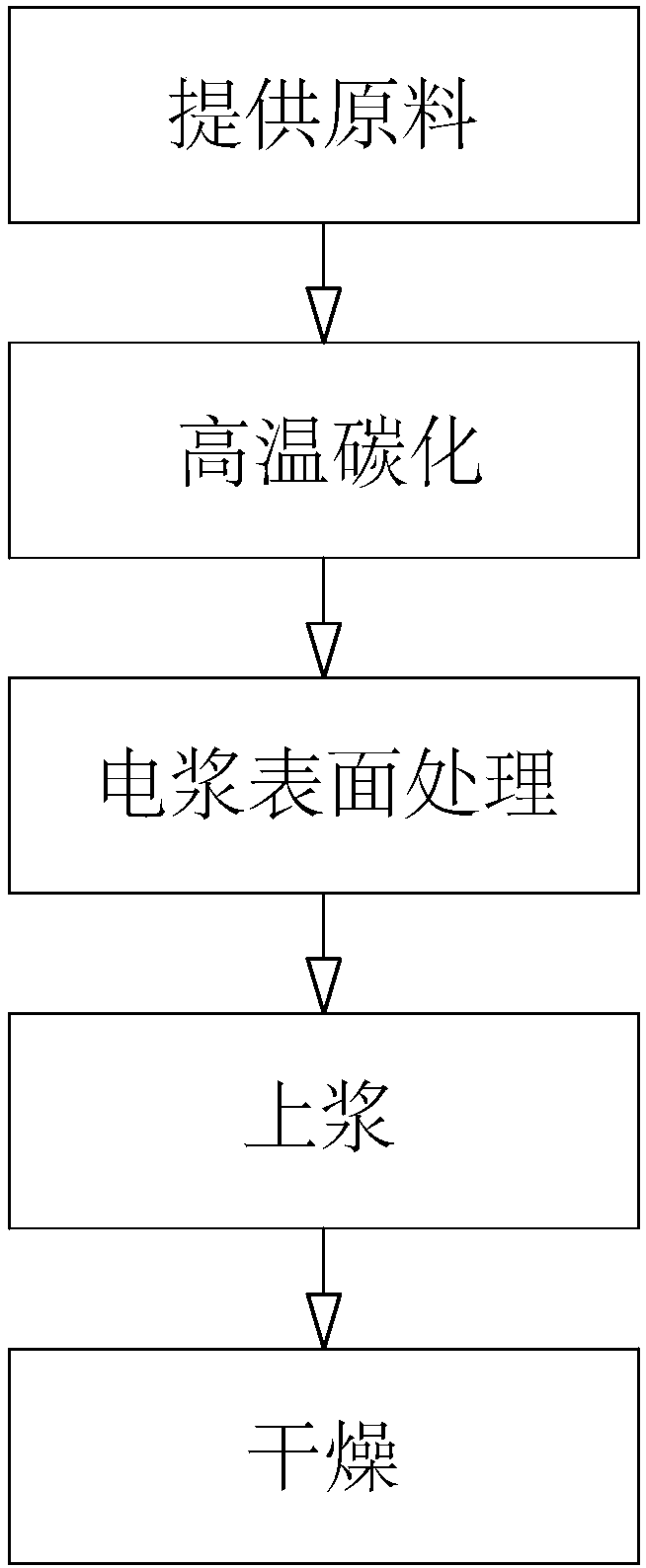

Carbon fiber manufacturing method

InactiveUS20180179696A1Enhanced interface bindingReduce carbon costRadio/micro wave fibre treatmentCarbon fibresFiber bundleCarbon fibers

A carbon fiber manufacturing method is provided. A carbon fiber precursor fiber bundle is performed with a high-temperature carbonization step to form a carbon fiber, and then the carbon fiber is performed with a plasma surface treatment so that the surface of the carbon fiber is formed with a plasma-modified configuration which is relatively rougher. Finally, the surface of the carbon fiber is coated with a resin oiling agent to obtain the carbon fiber having the resin oiling agent thereon. Particularly, through a plasma surface treatment step, the surface of the carbon fiber is roughened and provided with functional groups, which is beneficial to enhance the interface bonding of the resin oiling agent and the carbon fiber. The structure of the carbon fiber is more stable and reliable. The cost of the carbon fiber production equipment and the working time can be reduced effectively.

Owner:UHT UNITECH

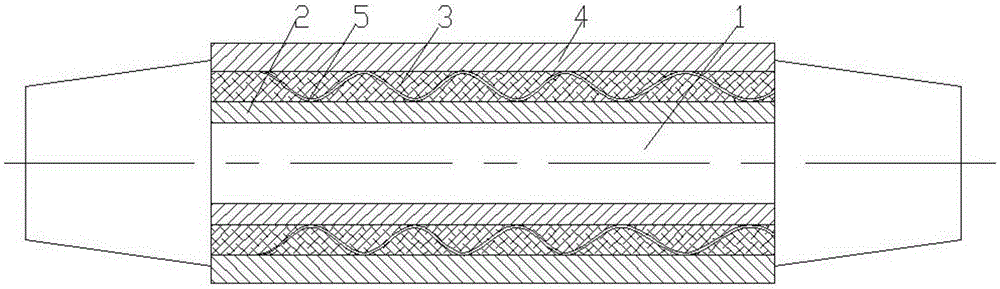

Extrusion roller for sizing machine

ActiveCN104404729AReduce stressAvoid damageLiquid/gas/vapor removal by squeezing rollersTextile treatment rollersYarnSurface layer

The invention discloses an extrusion roller for a sizing machine. The extrusion roller mainly comprises three parts, namely, a roller body as well as two end shaft structures detachably arranged at two ends of the roller body, wherein the roller body adopts a hollow structure, and the two end shafts are inserted in and connected onto end surfaces of the roller body respectively and then locked on the end surfaces of the roller body by chucks at ends of the end shafts through fasteners; the roller body comprises a metal roller core and a rubber layer, the rubber layer mainly comprises four parts, namely, a bottom rubber layer, a buffer rubber layer, a surface buffer layer and a surface layer, and a gap layer is arranged in the buffer rubber layer; the gap layer is in a waved hole shape, and one end surface of the buffer rubber layer extends inwards to form a non-through blind hole structure; the gap layer is filled with hot air. With the adoption of the extrusion roller, the size film integrity is increased, hairiness is stuck, and the sizing quality is improved; the buffer rubber layer is filled with the hot air, so that the friction coefficient of the surface layer is increased, relative motion is reduced, yarn damage caused by slippage is avoided, uniform sizing is realized, the soakage and coverage are good, and the sizing quality is improved.

Owner:SUZHOU ZHONGTUO PATENT OPERATION MANAGEMENT CO LTD

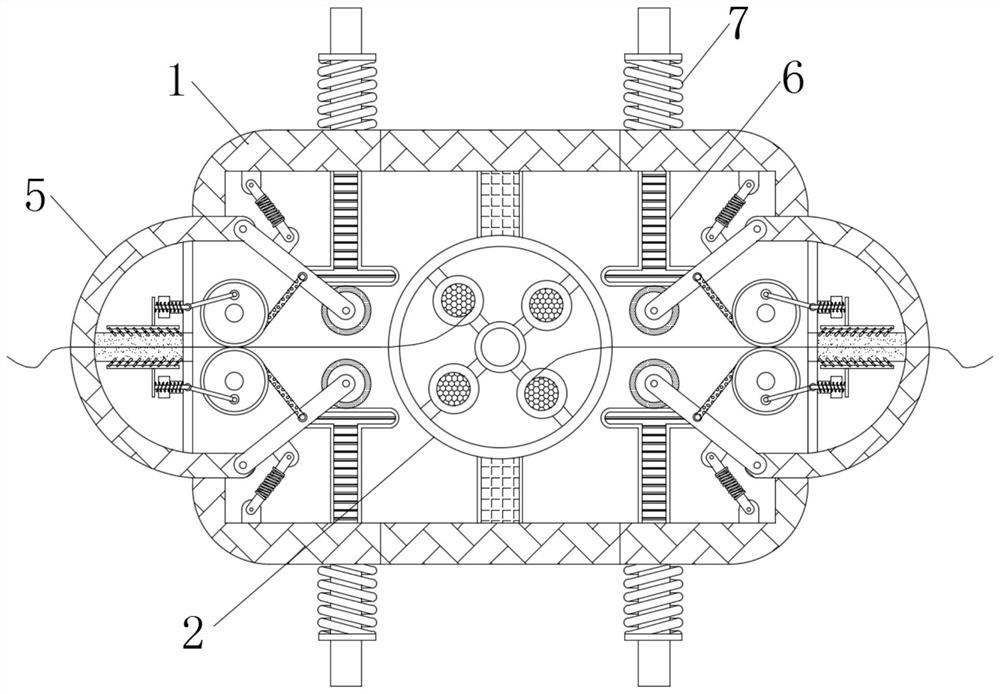

Uniform spraying based textile yarn uniform sizing and setting device

ActiveCN111334953AGuarantee the quality of sizingReduce cleanup burdenFibre cleaning/openingTextile treatment machine arrangementsTextile yarnIndustrial engineering

The invention discloses a uniform spraying based textile yarn uniform sizing and setting device in the technical field of textile yarns. The device comprises a base; the left side of the top of the base is fixedly provided with a treatment shell; the top of an inner cavity of the treatment shell is provided with a dust extraction mechanism; the middle of the inner cavity of the treatment shell issymmetrically provided with clean spraying mechanisms with the same structure in a longitudinally staggered manner; the outer wall of the back side of the treatment shell is provided with clean spraying driving mechanisms matched with the two groups of clean spraying mechanisms; the treatment shell is internally provided with a filtering part; the right side of the top of the base is provided witha setting shell; and the top of an inner cavity of the setting shell is provided with a setting drying part. The device is provided with the clean spraying mechanisms and the clean spraying driving mechanisms, so that removed burrs and impurities can be extracted, the subsequent sizing liquid cleaning burden is reduced, and the subsequent yarn sizing quality is ensured; and the two groups of clean spraying mechanisms are arranged to realize two-sided uniform sizing of the textile yarns, so that the sizing quality and the sizing efficiency are improved.

Owner:重庆华智天下科技有限公司

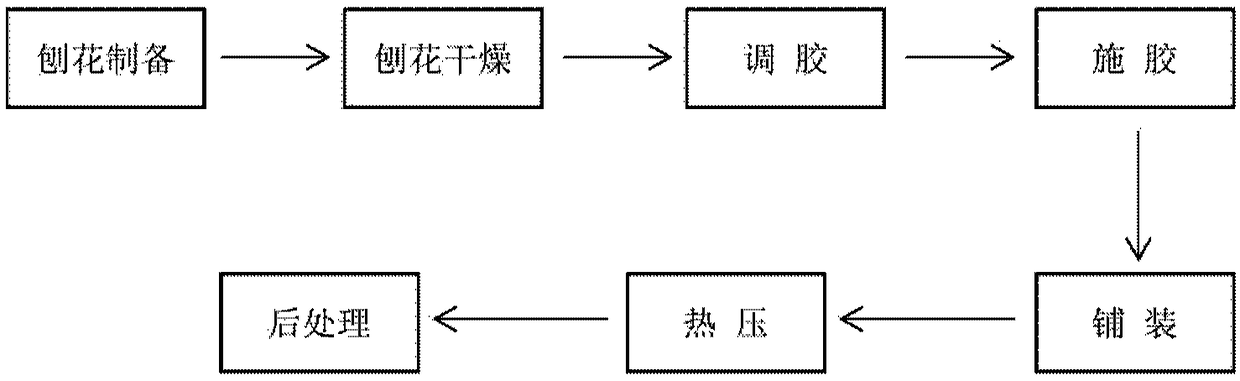

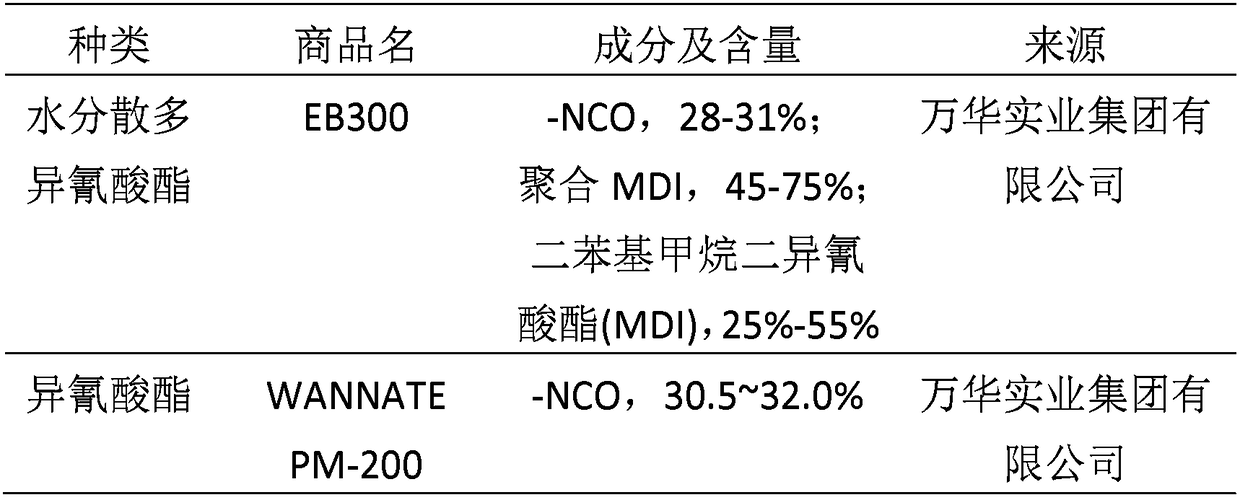

Chipboard and production method thereof

InactiveCN108162123AGuaranteed performance indicatorsSpray evenlyWood working apparatusFlat articlesWood shavingsSurface layer

The invention provides a non-formaldehyde chipboard and a production method thereof. The non-formaldehyde chipboard comprises surface layers and a core layer clamped by the surface layers, wherein thesurface layers comprise straw shavings and non-formaldehyde adhesives, the core layer comprises wood shavings and non-formaldehyde adhesives, the non-formaldehyde adhesives are aqueous dispersion polyisocyanates, and the content of the aqueous dispersion polyisocyanates in the surface layers and the core layer accounts for 3-6% of the weight.

Owner:WANHUA ECOBOARD INTEGRATED EQUIP CO LTD

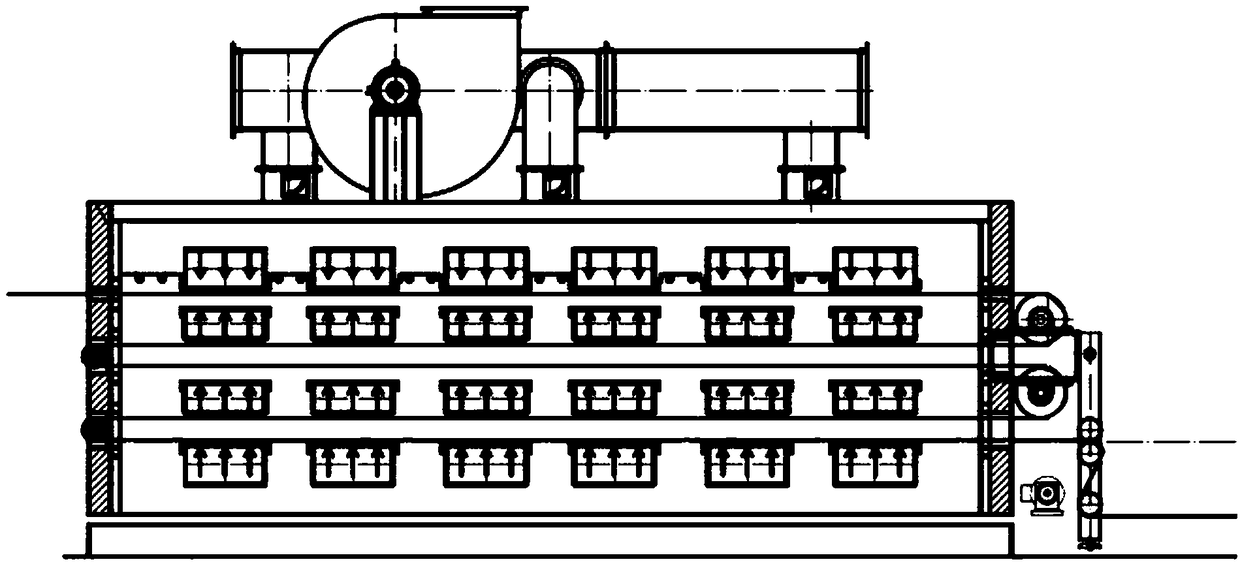

Front drying system used for multi-cylinder long mesh paper machine

The invention discloses a front drying system used for a multi-cylinder long mesh paper machine, and belongs to the field of accessories of paper making equipment. The total number of drying cylinders of the front drying system is increased by 10%-50% than that of drying cylinders of a front drying portion of a traditional front drying system with the same width and the same vehicle speed. A reinforced drying device can be arranged at an outlet of a front drying portion; high padding paper pulp can be made into paper meeting standard requirements; the front drying system has the advantages that drying time is long, the drying effect is good, paper can be sufficiently dried and dehydrated, follow-up glue applying of paper is facilitated, and quality of finished product paper is high; problems of the traditional front drying system are solved; the front drying system is one of the important procedures in successful development of the multi-cylinder long mesh paper machine used for production of high padding paper pulp.

Owner:GUONENG PAPER IND +1

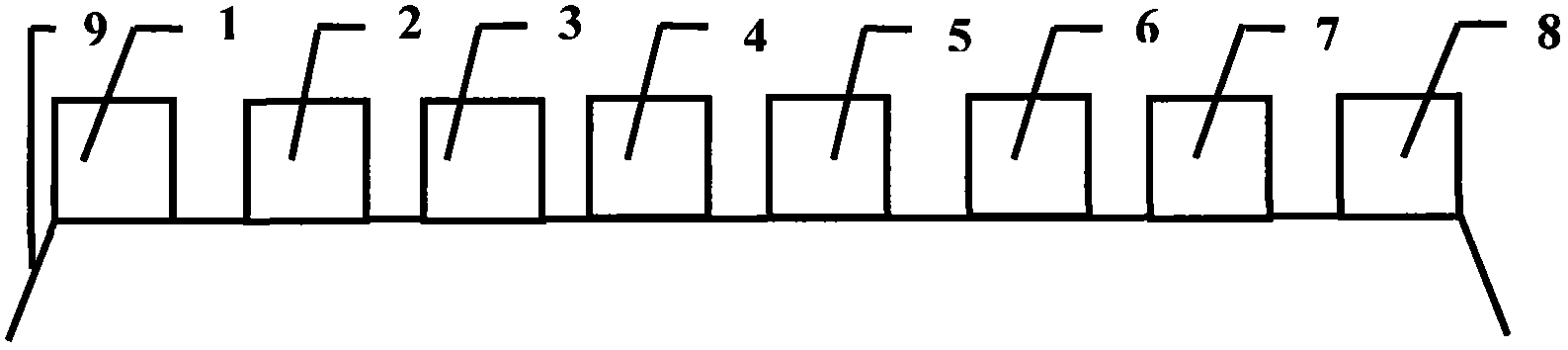

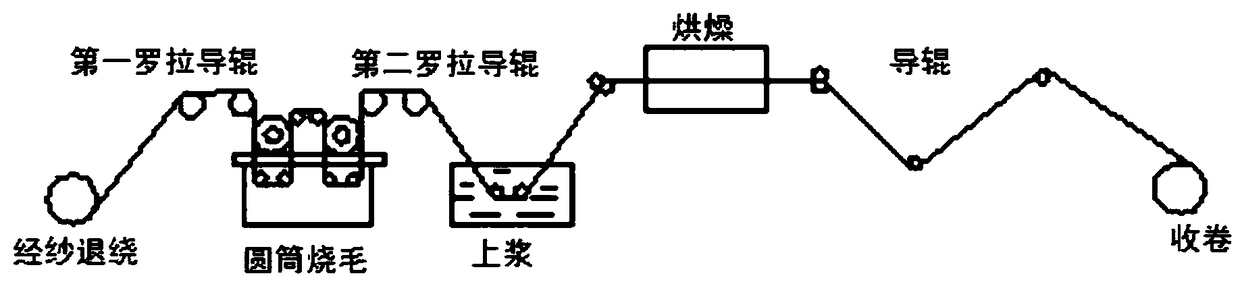

Roller singeing and sizing process for purified cotton warp

InactiveCN108754958ARemove completelyShorten the lengthSucessive textile treatmentsVegetal fibresYarnPulp and paper industry

The invention discloses a roller singeing and sizing process for purified cotton warp. The process includes the following steps of backing-off of the warp, guidance by first rollers, roller singeing,guidance by a second roller, sizing, drying, guidance by rollers and rolling. A singeing device is added before sizing of the warp, and fur of the warp is burnt before sizing; since the fur of the warp is all exposed outside relative to a fabric, by making the warp be fully in contact with the singeing device, the purpose of completely removing the fur can be achieved. The fur scale of a fabric woven by the beam warp which is subjected to singeing can reach 4th-5th level, and the pilling resistance can reach the 4th level or above.

Owner:IANGSU COLLEGE OF ENG & TECH

Method for producing carbonized fiber

InactiveCN108149483AImprove sizing qualityStable structureRadio/micro wave fibre treatmentCarbon fibresFiberCarbon fibers

The invention discloses a method for producing a carbonized fiber. The method mainly comprises the following steps: performing high-temperature carbonization on a carbon fiber precursor fiber beam soas to obtain a carbonized fiber, further performing plasma treatment on the carbonized fiber so as to obtain a relatively roughened plasma modified structure on the surface of the carbonized fiber, and finally covering the surface of the carbonized fiber with a resin oil agent, thereby obtaining the carbonized fiber with the resin oil agent on the surface. Particularly, through a plasma surface treatment step, the surface of the carbonized surface is roughened; in addition, functional groups on the surface are enriched, high-quality interface combination of the carbonized fiber and the resin oil agent is achieved, furthermore the carbonized fiber which is relatively stable and reliable in structure is achieved, the cost of carbonized fiber equipment is effectively reduced, and the operation time can be effectively shortened.

Owner:UHT UNITECH

Production process for starching-free quick-frozen fillets

PendingCN111406907AIncrease productivityImprove qualityFish washing/descalingMeat/fish preservation by freezing/coolingEngineeringFish fillet

The invention discloses a production process for starching-free quick-frozen fillets. The production process comprises the following steps: taking fresh live fish, putting the fresh live fish into a water tank, carrying out standing, and manually scaling the fish and removing the heads of the fish; removing middle bones of the cleaned fish, trimming fish flesh, and cutting the fish flesh into large fillets; placing the cut large fillets in clear water for rinsing of bloody water; fishing out the cleaned large fillets, filtering out water on the surfaces of the fillets, and soaking the filletsin a container containing a fishy-smell removing liquid; absorbing water on the surfaces of the fish fillets through absorbent paper, and cutting the treated large fish fillets into small fish fillets; lifting and feeding the small fillets and paste into a vacuum starching machine; uniformly mixing the paste with the small fillets by using the vacuum starching machine; and weighing and packaging the starched fillets, and introducing the packaged fillets into a liquid nitrogen instant freezer for quick-freezing. The invention belongs to the technical field of quick-frozen fillets. The production process for the starching-free quick-frozen fillets achieves the purposes of realizing quick starching of the fillets, accelerating the production efficiency of the quick-frozen fillets, achieving aquick freshness locking effect and improving the quality of the fillets.

Owner:长牌食品(江苏)有限公司

Vacuum stirring starching machine applied to quick-frozen fish slice processing

PendingCN111296544AAvoid stackingEasy dischargeHollow article cleaningFish processingMechanical engineeringElectrical and Electronics engineering

The invention discloses a vacuum stirring starching machine applied to quick-frozen fish slice processing. The machine comprises a supporting base plate, wherein a supporting connecting rod is in rotatable connection to the right side of the top end of the supporting base plate, a bearing is fixedly connected to the top end of the supporting connecting rod, a transmission shaft passes through inside of the bearing and is connected in a rotatable manner, a starching enclosure is fixedly connected to the left axis of the transmission shaft, a seal door plank is disposed at a left outlet of the starching enclosure, inner stirring blades are fixedly and uniformly connected to the internal surface of the starching enclosure, a vacuum generator is fixedly connected to the right side of the top end outside the starching enclosure, a washing mechanism is fixedly connected to the top of the starching enclosure, a limiting rolling groove is fixedly connected to the left side outside the starching enclosure, and an adjustment and control mechanism is fixedly connected to the left side of the top of the supporting base plate. The invention relates to the technical field of quick-frozen fish slices. The vacuum stirring starching machine applied to quick-frozen fish slice processing realizes the purposes of increasing fish slice starching efficiency, improving starching quality and facilitating manual operations.

Owner:长牌食品(江苏)有限公司

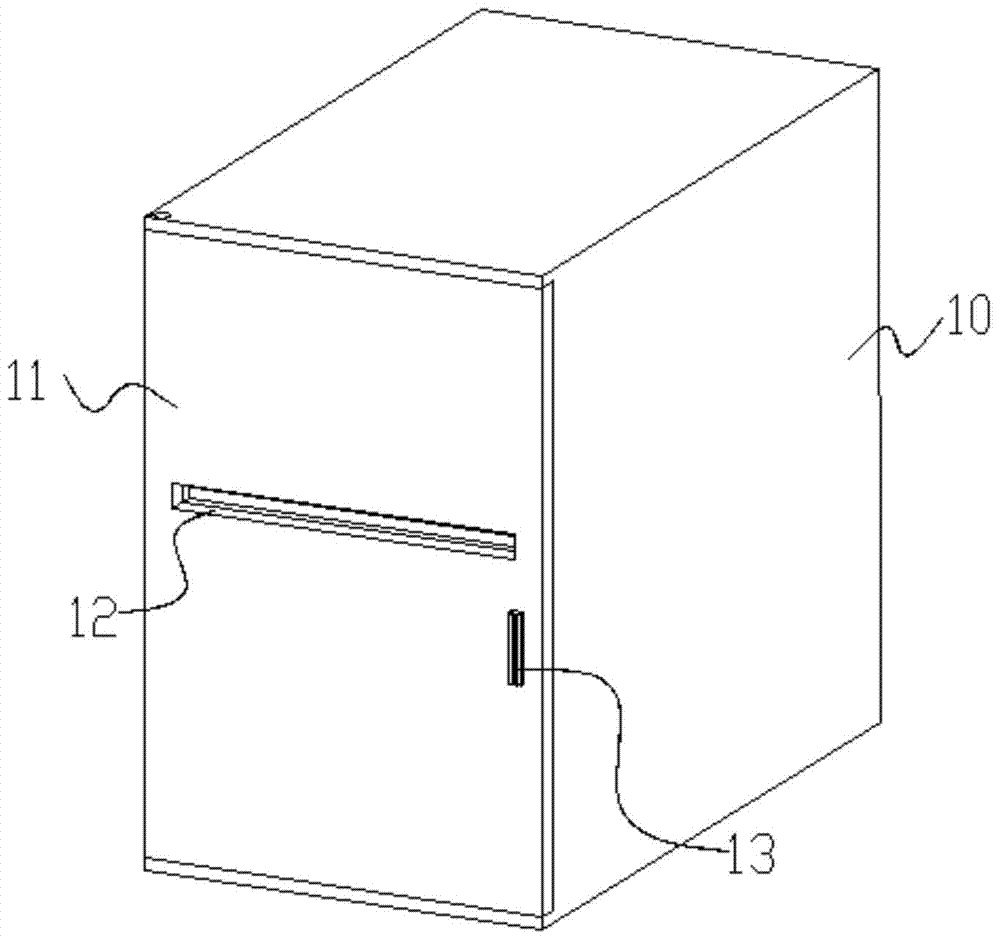

Sizing device

InactiveCN104120578AReduce distanceEasy to joinLiquid/gas/vapor removalTextile treatment machine arrangementsEngineeringSizing

The invention discloses a sizing device. The sizing device comprises a drying case. One side face of the drying case is provided with a drying case feed port. The other side face, opposite to the drying case feed port, of the drying case is provided with a drying case discharge port. The side face where the drying case feed port is located is a drying case door sheet. The drying case door sheet is hinged to a case body of the drying case through a door spindle. A sizing storage box is arranged in the drying case. The side face, close to the drying case door sheet, of the sizing storage box is provided with a sizing storage box feed port, and the other side face, opposite to the sizing storage box feed port, of the sizing storage box is provided with a sizing storage box discharge port. A plurality of sizing rollers are fixedly arranged in the sizing storage box. A plurality of cloth rollers are arranged on the outer side of the sizing storage box and located between the sizing storage box discharge port and the drying case discharge port. An air heater is arranged over the cloth rollers. The air heater is fixedly arranged on the top end face in the drying case. The sizing device has the advantages of being small in occupied area, uniform in sizing, good in sizing quality and simple in structure.

Owner:HANDAN XIANGYUAN SPEICAL FIBERS CO LTD

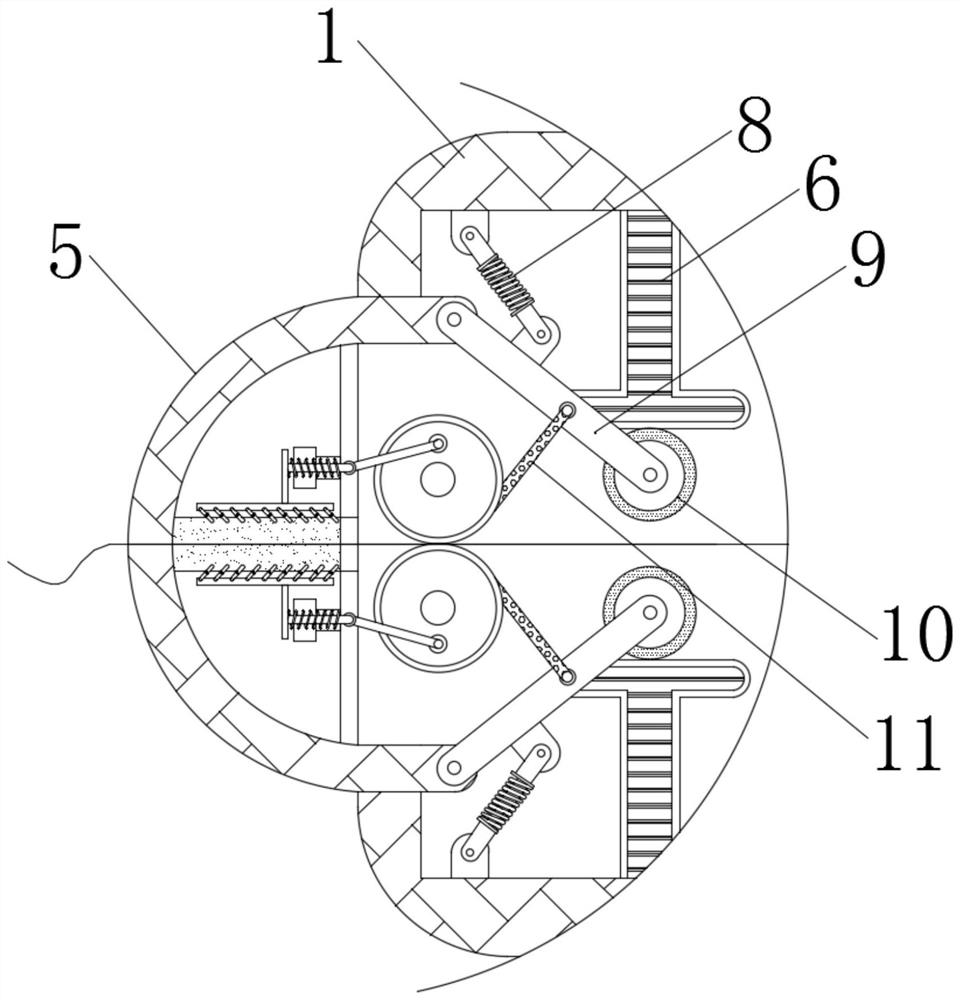

Textile yarn sizing device for clothing manufacturing

PendingCN114045616AImprove qualityImprove sizing qualityLiquid/gas/vapor treatment machines driving mechanismsLiquid/gas/vapor removal by suctionTextile yarnManufacturing engineering

The invention relates to the technical field of clothing manufacturing, and discloses a textile yarn sizing device for clothing manufacturing. The device comprises a winding frame, a winding disc is movably connected in the winding frame, a supporting rod is fixedly connected to the inner wall of the winding disc, a winding column is movably connected to the outer surface of the supporting rod, dredging mechanisms are fixedly connected to the two sides of the interior of the winding frame correspondingly, a pressing plate is movably connected to the inner wall of the winding frame in an embedded mode, the winding disc can rotate in the winding frame, the multiple winding columns can wind multiple silk threads at the same time, a shaft disc circularly pushes and pulls a shaft rod up and down in the rotating process, sponge layers on the outer surfaces of the squeezing rollers in contact with the upper side and the lower side of the yarn extrude each other, size absorbed by the sponge layers on the outer surfaces of the squeezing rollers is discharged, the sponge layers on the outer surfaces of the squeezing rollers are in an unsaturated state all the time, redundant size on the surface of the yarn after sizing can be absorbed easily, the sizing quality of the yarn can be improved easily, and the clothing manufacturing quality is improved.

Owner:浙江山海数字信息科技有限公司

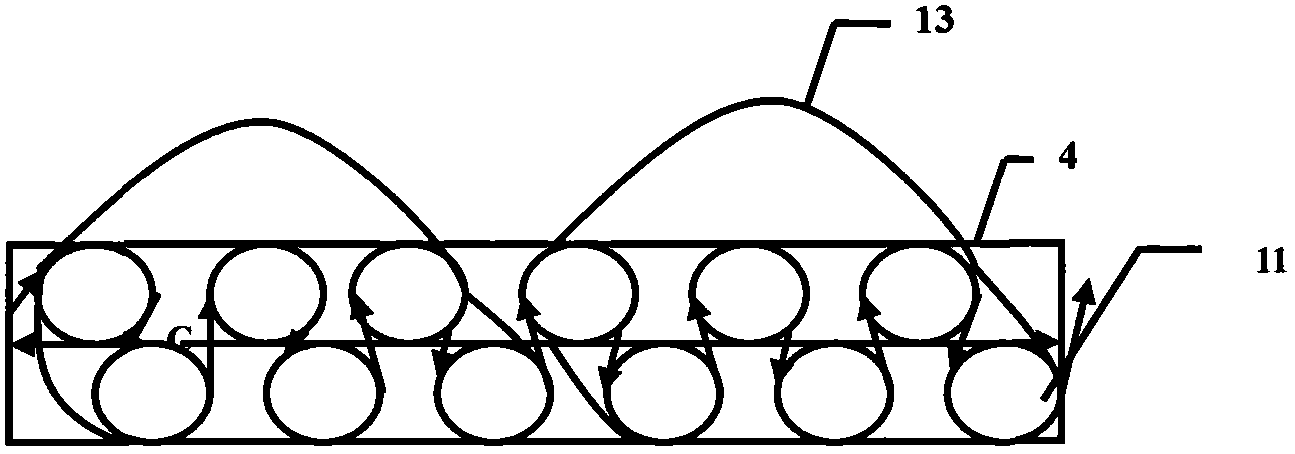

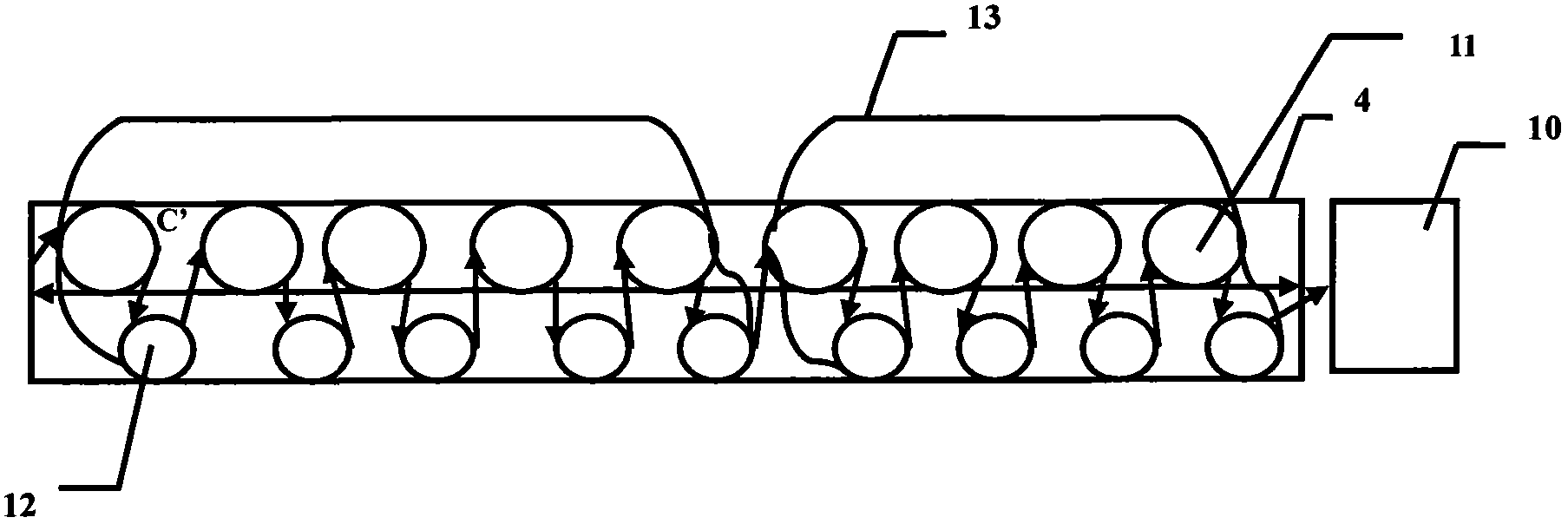

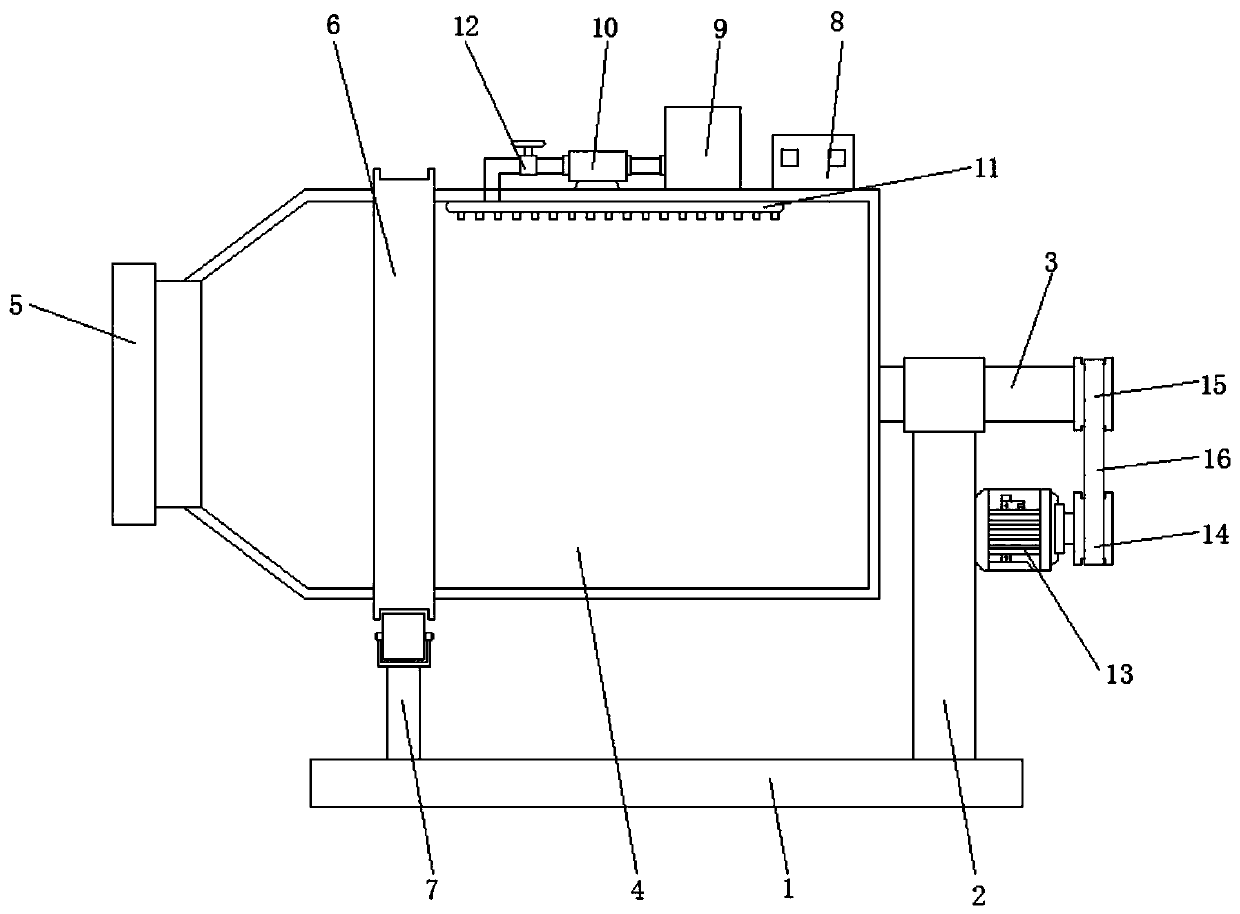

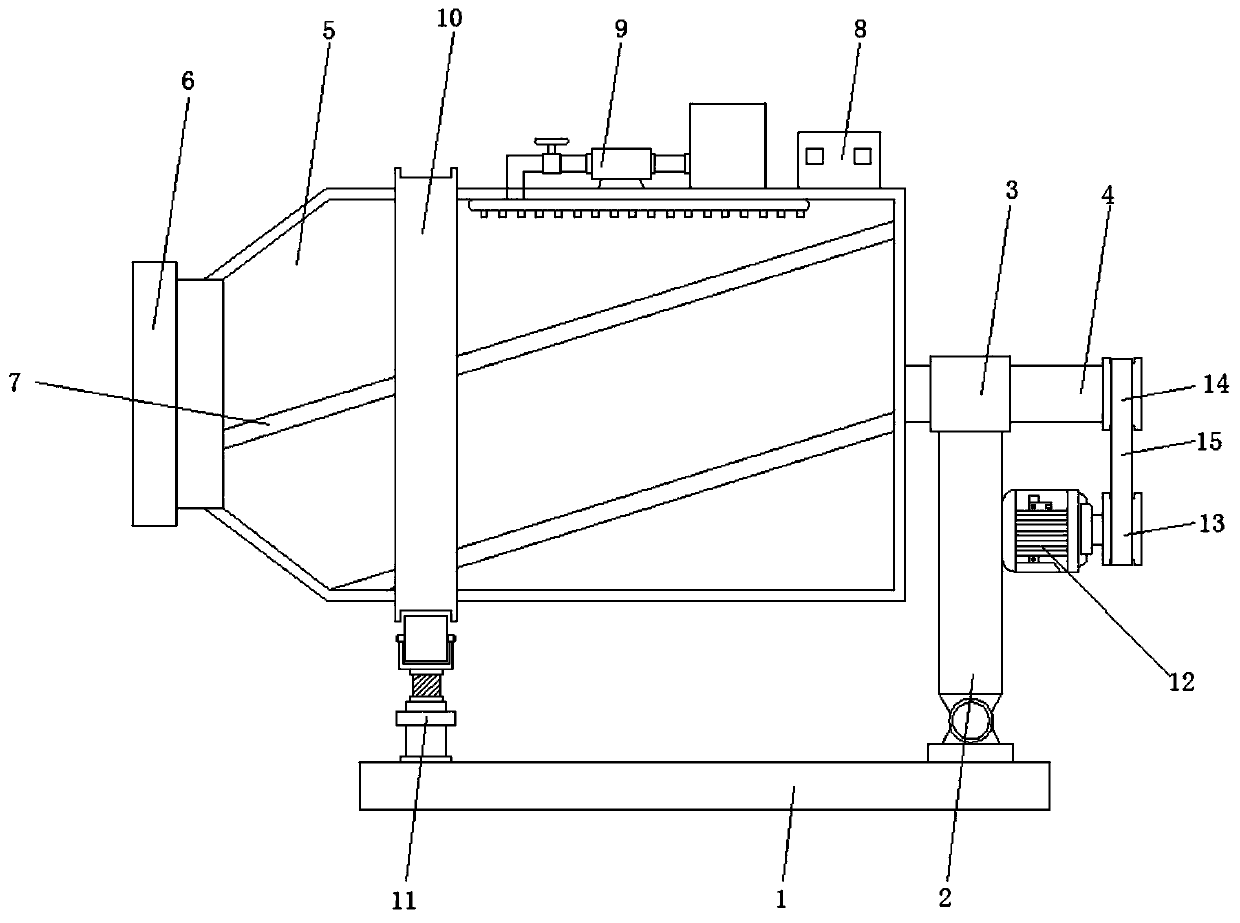

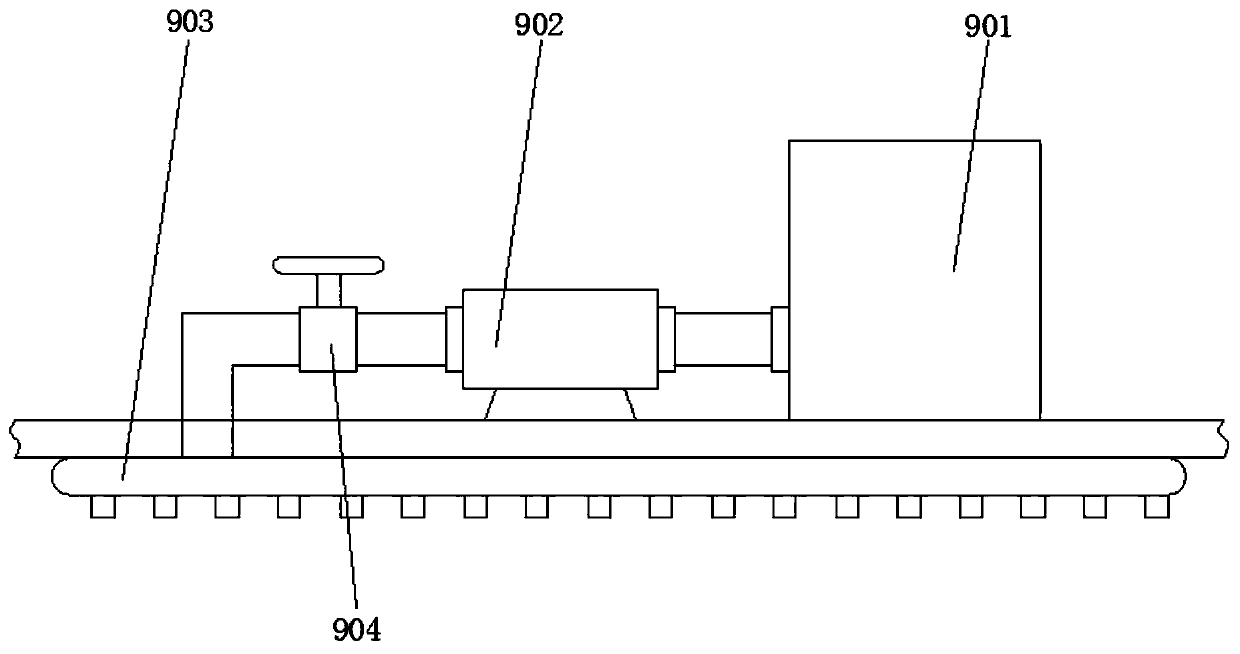

Temperature-controlled circular sizing deVice for sizing agent tanks of slasher

PendingCN108677417AImprove sizing qualityIncrease circulation flowTextile treatment machine arrangementsLiquid/gas/vapor yarns/filaments treatmentTemperature controlPulp and paper industry

The inVention discloses a temperature-controlled circular sizing deVice for sizing agent tanks of a slasher. The sizing deVice comprises the lower size agent tank for heating a sizing agent, a circulation pump for driVing circulate sizing of a deVice body, at least two filters, a size spraying deVice and the upper size agent tank, wherein the lower size agent tank is connected with the circulationpump, the filters are connected with the circulation pump, the size spraying deVice is connected with the circulation pump, and the upper size agent tank corresponds to the size spraying deVice and cooperates with the size spraying deVice. The temperature of the sizing agent is maintained in the sizing process, impurities and contaminants in the sizing agent are filtered out, the circulating flowrate of the sizing agent is increased, the sizing effect is improVed, degradation due to poor sizing is aVoided, and the sizing quality of warp is improVed.

Owner:TAIJIA GLASS FIBER

A fourdrinier multi-cylinder paper machine for producing high-filler paper

InactiveCN103669097BEnhanced effect of low vacuum dehydrationIncrease the number ofDryer sectionMachine wet endPaper sheetDehydration

The invention discloses a multi-cylinder long mesh paper machine used for producing high-filler paper. Compared with a traditional multi-cylinder long mesh paper machine with the same width and the same speed, the whole multi-cylinder long mesh paper machine is 8-25 meters longer, the mesh portion is 4-6 meters longer, the front drying system portion is 5-15 meters longer, and the rear drying system portion is 1-1.5 meters longer. Accordingly, corresponding structures are changed, the problem that the traditional paper machine can not manufacture cultural paper which meets the standards through high-filler paper pulp is solved, and the multi-cylinder long mesh paper machine has the advantages of being long in dehydration time, high in dehydration efficiency, good in dehydration quality, low in investment, good in drying effect and high in paper product quality.

Owner:GUONENG PAPER IND +1

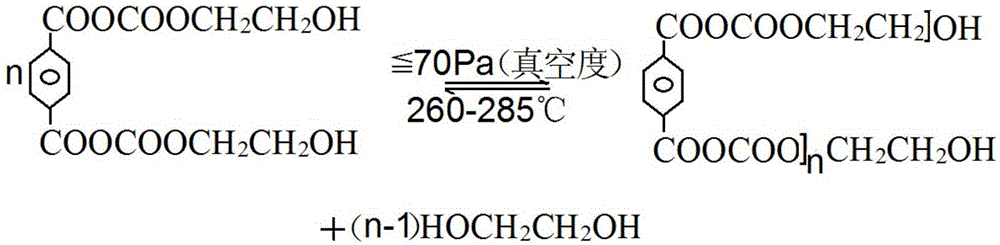

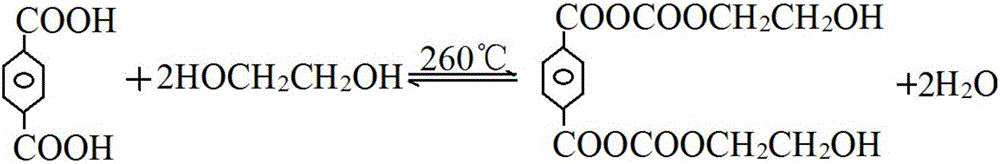

Aliphatic aqueous polyester graft copolymer, adhesion accelerant for improving adhesion strength on terylene fibers by starch slurry, and preparation method thereof

The present invention relates to the field of materials, especially to a slurry for textile warp sizing, and discloses an aliphatic aqueous polyester graft copolymer and a preparation method for an adhesion accelerant for improving adhesion strength on terylene fibers by a starch slurry, wherein the main chain of the graft copolymer is a random copolymer of hydrophobic polyester chain segment aliphatic dicarboxylic acid diol ester and hydrophilic polyester chain segment aliphatic dicarboxylic acid (1,2-dihydroxy-3-propylsulfonate)ester, the graft branch chain is a random copolymer of acrylamide and a vinyl carboxylate, and the adhesion accelerant comprises, by weight, 15-28% of an aliphatic aqueous polyester graft copolymer, 1-6% of a hydroxyl plasticizer, 1-8% of an amino plasticizer, and the balance of water . The preparation process comprises: firstly synthesizing an aliphatic aqueous polyester main chain, carrying out graft copolymerization of the aliphatic aqueous polyester main chain and a hydrophilic vinyl monomer, and finally dissolving plasticizers in the aqueous slurry of the graft copolymer to obtain the adhesion accelerant.

Owner:西达(无锡)生物科技有限公司 +1

A sizing device for textile

ActiveCN103993442BFully absorbedUniform sizeTextile treatment containersLiquid/gas/vapor textile treatmentBristleBrush device

Owner:启东市丰武农副产品专业合作社

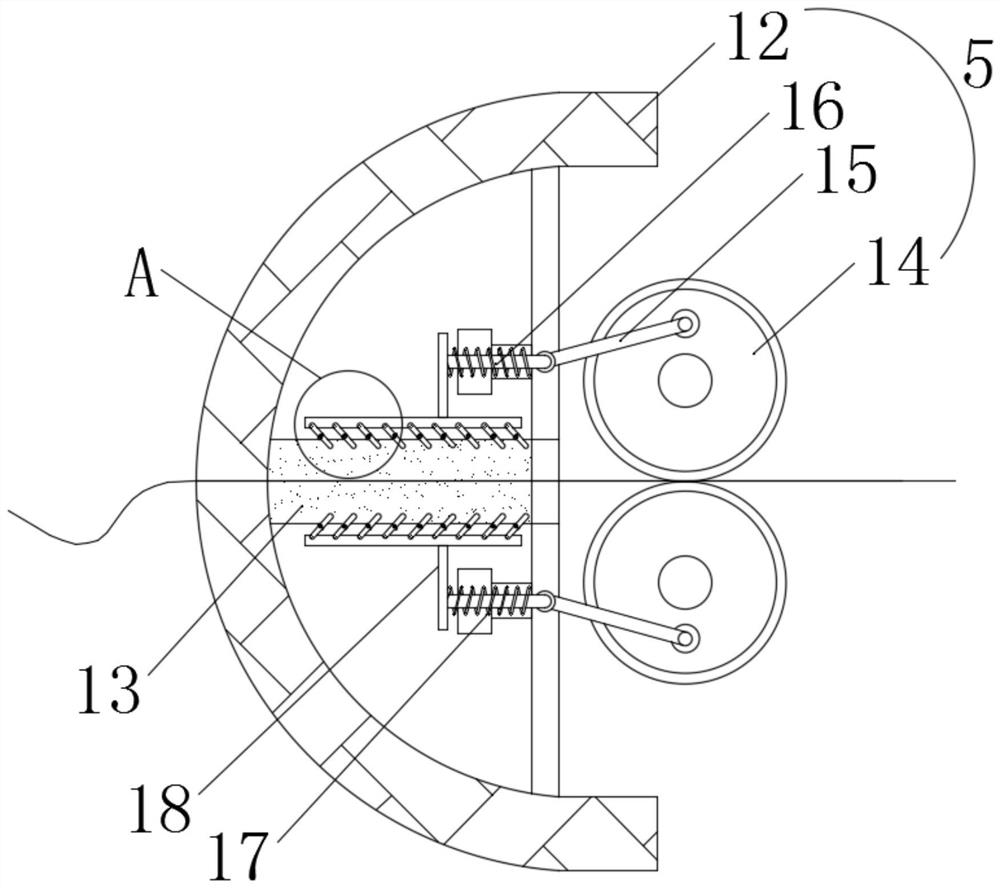

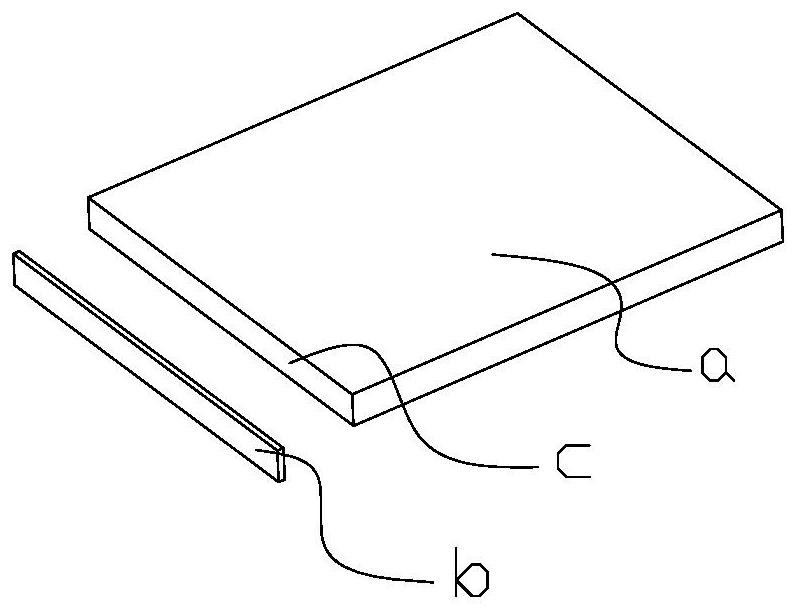

Furniture woodworking board gluing device and method

InactiveCN112060244AAvoid the problem of insufficient sizingImprove sizing qualityAdhesive application devicesAdhesive glueIndustrial engineering

The invention relates to the field of woodworking board processing, in particular to a furniture woodworking board gluing device and method. The device comprises a glue supply mechanism and a glue extrusion mechanism, wherein the glue supply mechanism and the glue extrusion mechanism can be fixed on a rack. The input end of the glue supply mechanism is connected with a glue inlet, and the output end of the glue supply mechanism is connected with the input end of the glue extrusion mechanism. The output end of the glue extrusion mechanism makes contact with the side edge of a board. The glue supply mechanism is used for providing quantitative glue for the glue extrusion mechanism. The glue extrusion mechanism is used for coating the side edge of the board with the glue. According to the device, by arranging the glue extrusion mechanism, the side edge of the board is fully glued, and the gluing quality of the side edge of the board is guaranteed.

Owner:林利

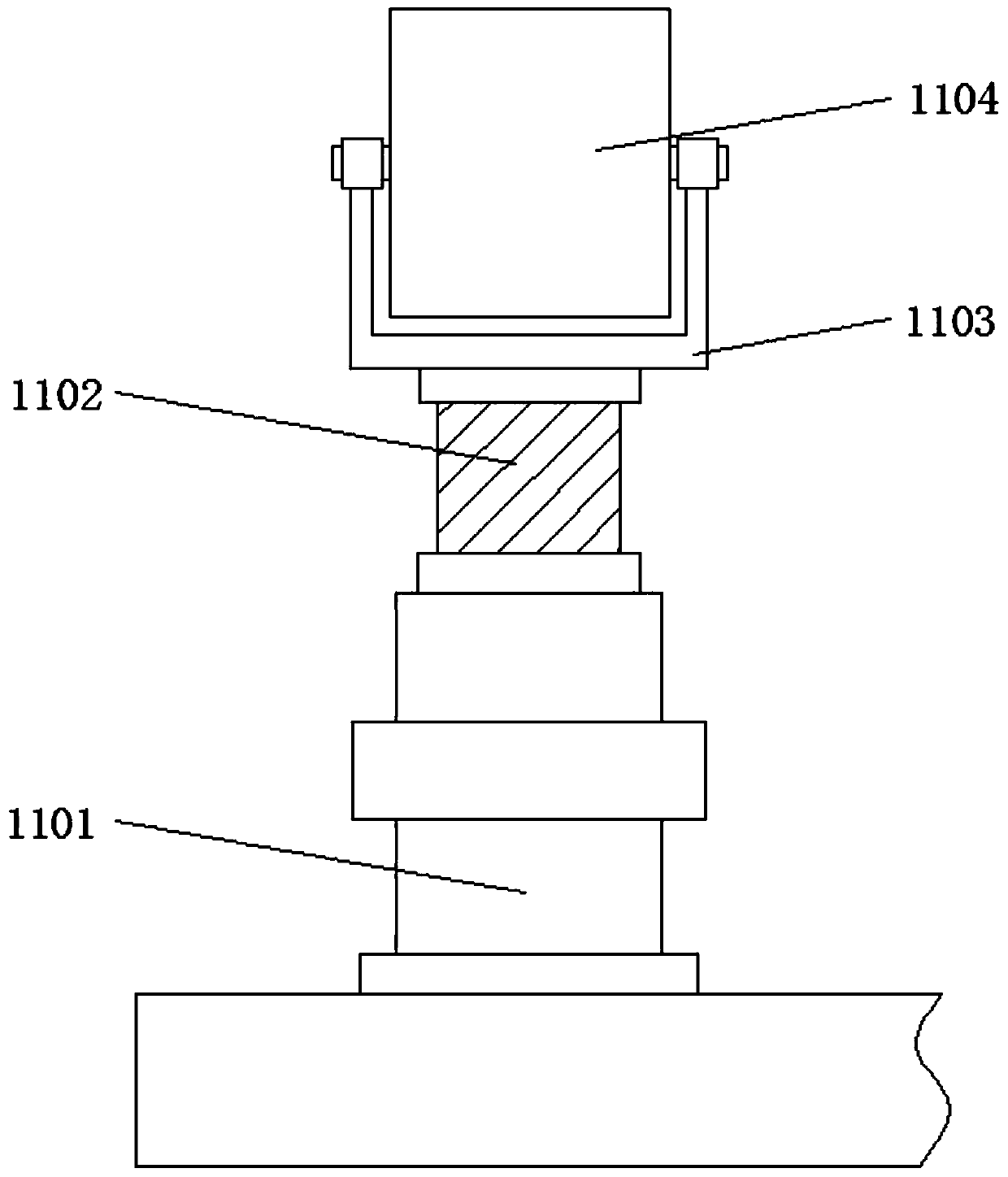

A low-position pressure roller

ActiveCN104452154BIncrease coefficient of frictionAvoid damageTextile treatment rollersYarnSurface layer

The invention discloses a low squeezing roller. The low squeezing roller comprises a metal roller core and a rubber layer, wherein the rubber layer is mainly composed of a bottom rubber layer, a buffering rubber layer and a surface layer, a gap layer is arranged in the buffering rubber layer and in a wavy hole shape, extends inwards from one end face of the buffering rubber layer and is of an impassable blind hole structure, and the gap layer is filled with hot airflow. According to the low squeezing roller in the scheme, sizing is uniform, soakage and superimposition are good, yarn permeation, consideration and enhancement of superimposition, reduction of horizontal stripe starch lumps and side laitance are obviously improved, the sizing film integrity is improved, yarn hairness is appressed, and the sizing quality is improved.

Owner:SUZHOU ZHONGTUO PATENT OPERATION MANAGEMENT CO LTD

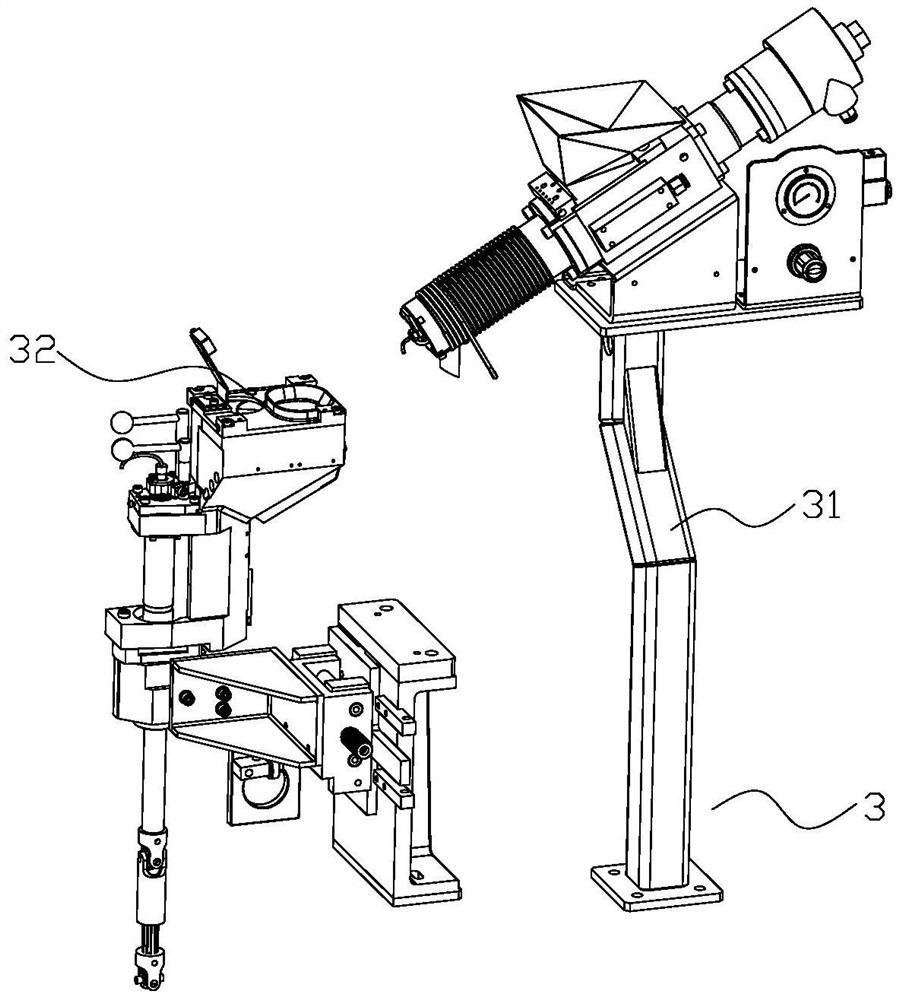

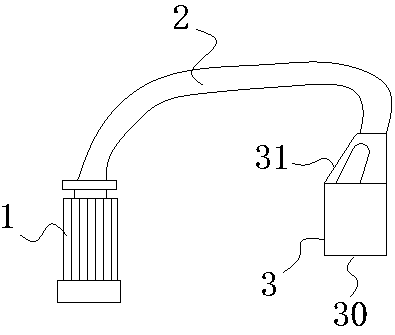

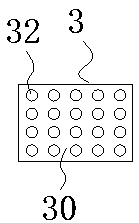

Sizing agent spraying machine

InactiveCN109403593AImprove efficiencyImprove sizing qualityBuilding constructionsPulp and paper industrySizing

The invention provides a sizing agent spraying machine. According to the sizing agent spraying machine, sizing can be carried out in a spraying mode, so that sizing efficiency and sizing quality are improved. The sizing agent spraying machine comprises a centrifugal pump for sizing agents, a discharge outlet of the centrifugal pump is connected with a spraying barrel through a pipeline, a handle is arranged at the joint of the spraying barrel and the pipeline, and a plurality of spraying holes are formed in the end surface of the spraying barrel in an array mode. When the sizing agent sprayingmachine is in use, proper cement sand sizing agents are firstly stirred out through a size barrel, and then the centrifugal pump is put into the size barrel for pumping the sizing agents directly; asthe cement sand sizing agents used for tile tiling are relatively fine sizing agents, so that the purpose of pumping the sizing agents can be achieved by adopting a common centrifugal pump; and afterthe sizing agents are pumped by the centrifugal pump, the sizing agents enter the spraying barrel through the pipeline and are uniformly sprayed out from the spraying holes on the end face of the spraying barrel. When workers construct, only the handle is needed to be held to drive the spraying barrel to spray the sizing agents on the back surface of a ceramic tile or on the tiling surface of theceramic tile, the quantity of the sprayed sizing agents is easy to control, and the sizing efficiency is high.

Owner:刘英武

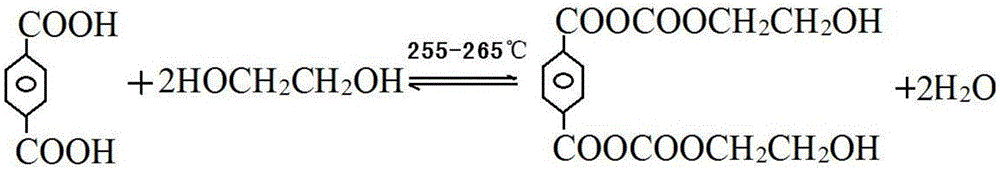

A kind of production method of environment-friendly size polyester for fabric sizing

The invention provides a production method of an environment-friendly polyester slurry. The production method comprises the following steps: (1) putting right amounts of ethylene glycol and terephthalic acid into a slurrying kettle, and stirring into a slurry; (2) carrying out esterification reaction on the slurry in an esterification kettle at 255-265 DEG C, sending the water generated by esterification and volatile ethylene glycol into a fractionating column to perform separation, and controlling the column top temperature by a column top condenser water inlet regulating valve and an external reflux regulating valve, thereby separating out the esterification water; weighing the obtained esterification water, and judging that the esterification reaction is finished when the weighed water is greater than or equal to 95 wt% of the theoretical generated water; (3) polycondensation reaction: carrying out two steps in a vacuum state, and judging the end point of the polycondensation reaction according to the stirring power of the polycondensation reaction kettle; and (4) granulating or slicing. The production method has the advantages of simple technique and stable operation. By adopting the process of judging the end point of the polycondensation reaction according to the stirring power of the polycondensation reaction kettle, the production method is simple, feasible and easy to operate in mass production, and saves the human resources and material resources.

Owner:湖北尚助化学有限公司

Squeeze roll for sizing machine

ActiveCN104404729BReduce stressAvoid damageLiquid/gas/vapor removal by squeezing rollersTextile treatment rollersYarnSurface layer

The invention discloses an extrusion roller for a sizing machine. The extrusion roller mainly comprises three parts, namely, a roller body as well as two end shaft structures detachably arranged at two ends of the roller body, wherein the roller body adopts a hollow structure, and the two end shafts are inserted in and connected onto end surfaces of the roller body respectively and then locked on the end surfaces of the roller body by chucks at ends of the end shafts through fasteners; the roller body comprises a metal roller core and a rubber layer, the rubber layer mainly comprises four parts, namely, a bottom rubber layer, a buffer rubber layer, a surface buffer layer and a surface layer, and a gap layer is arranged in the buffer rubber layer; the gap layer is in a waved hole shape, and one end surface of the buffer rubber layer extends inwards to form a non-through blind hole structure; the gap layer is filled with hot air. With the adoption of the extrusion roller, the size film integrity is increased, hairiness is stuck, and the sizing quality is improved; the buffer rubber layer is filled with the hot air, so that the friction coefficient of the surface layer is increased, relative motion is reduced, yarn damage caused by slippage is avoided, uniform sizing is realized, the soakage and coverage are good, and the sizing quality is improved.

Owner:SUZHOU ZHONGTUO PATENT OPERATION MANAGEMENT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com