Pre-wetting size vat device of pre-wetting sizing machine

A sizing machine and sizing tank technology is applied in textile processing machine accessories, textile material processing, continuous processing of textile materials, etc. , the effect of the yarn direction is reasonable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with embodiment (accompanying drawing):

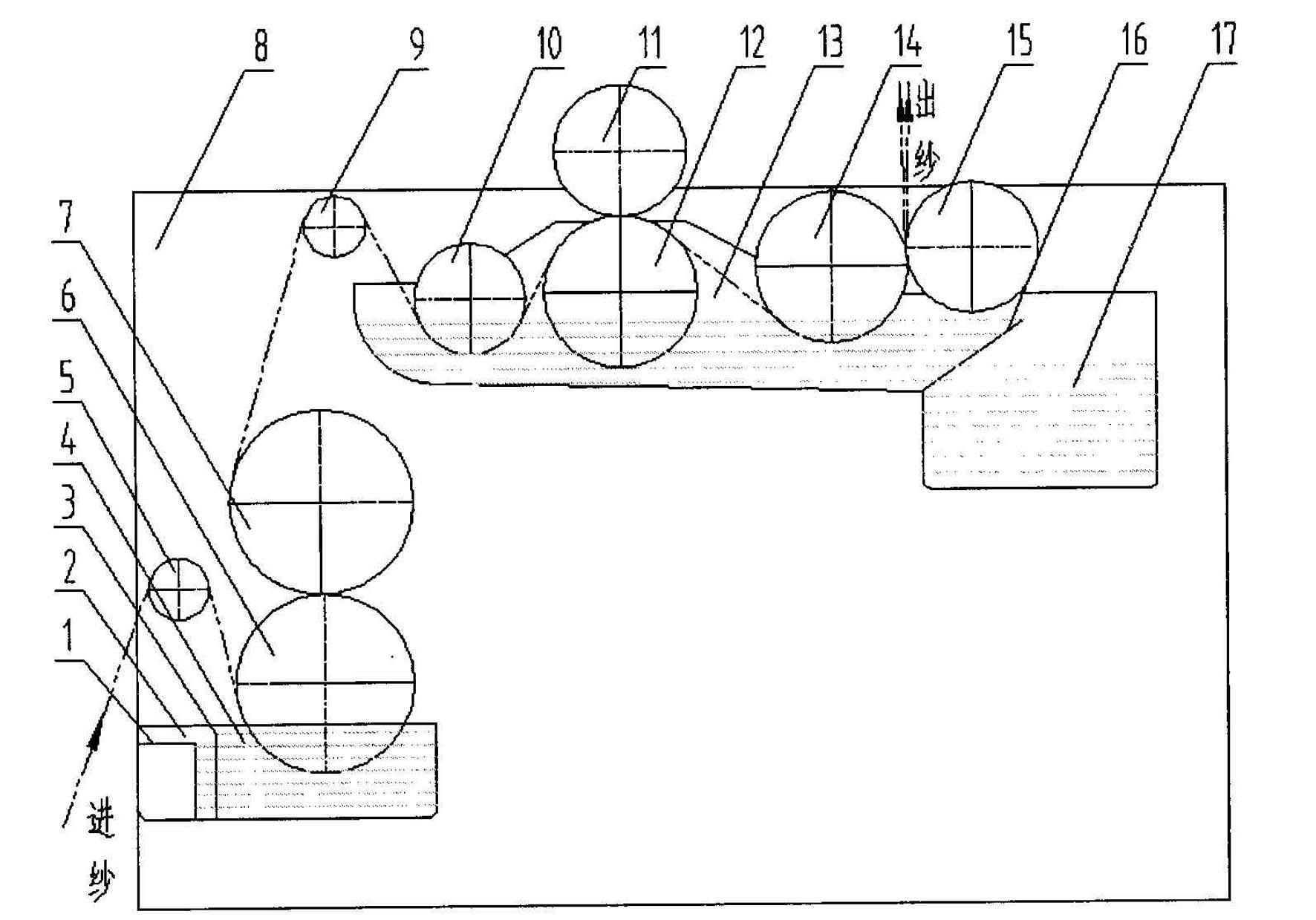

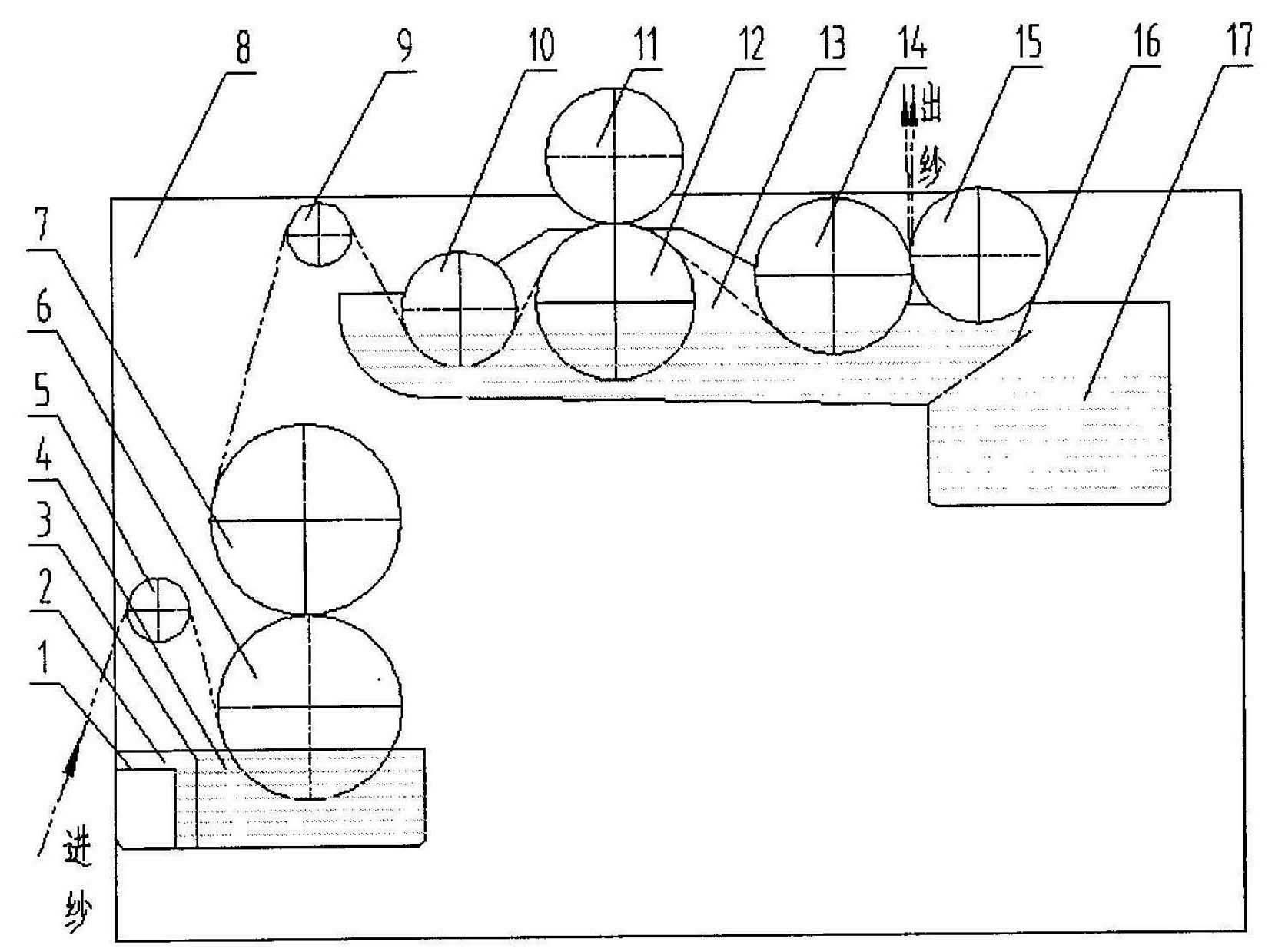

[0014] Such as figure 1 As shown, the pre-wet size tank device suitable for pre-wet sizing machines of the present invention includes a frame (8), a main size tank (13) installed on the upper part of the frame, and a machine mounted on the front and lower side of the main size tank (13). The main water tank (4) on the rack, and the guide rollers (5), upper water rollers (6), water rolling rollers (7), yarn guide rollers (9), Immersion roll (10), first sizing roll (12), second sizing roll (14), first sizing roll (11) above the first sizing roll (12), second sizing roll (14) The second pressure roller (15) on the rear side; the guide roller (9) is set on the frame (8) located in front of the main size tank (13); the guide roller (5) and the upper water The roll (6) and the rolling water roll (7) are set above the main water tank (4) and within the range of ±15°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com