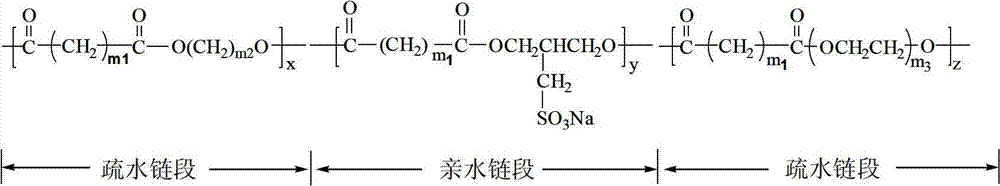

Aliphatic aqueous polyester graft copolymer, adhesion accelerant for improving adhesion strength on terylene fibers by starch slurry, and preparation method thereof

A technology of graft copolymer and water-based polyester, which is applied in the field of aliphatic water-based polyester graft copolymer, adhesion promoter and preparation for improving the bonding strength of starch size to polyester fiber, and can solve the problem of interface damage and impact Warp reinforcement, wear resistance and hairiness reduction rate, poor toughness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] (1) Preparation of the main chain of aliphatic water-based polyester: 118.1 parts by weight of succinic acid, 23.3 parts by weight of ethylene glycol, and 57.85 parts by weight of sodium 1,2-dihydroxy-3-propanesulfonate were added to the polymerization reactor. 31.83 parts by weight of ethylene glycol and 1 part by weight of zinc acetate were heated under nitrogen protection, and the stirring device was started immediately after the reactants in the kettle were melted. The molar ratio of succinic acid, ethylene glycol, ethylene acetal and sodium 1,2-dihydroxy-3-propanesulfonate was 1:0.375:0.3:0.325.

[0055] When the temperature rises to 130-160°C, care should be taken to control the heating rate to avoid the fractionation column head temperature exceeding 100°C. Then the temperature of the material was gradually raised to 200 °C, and the pressure in the kettle was gradually reduced to 12-20 mmHg by a decompression device, and then the reaction was stirred at 200-210 °...

Embodiment 2

[0060] (1) Preparation of the main chain of aliphatic water-based polyester: 118.1 parts by weight of succinic acid, 37.24 parts by weight of ethylene glycol, 22.53 parts by weight of ethylene glycol, 1,2-dihydroxy-3 -44.5 parts by weight of sodium propanesulfonate and 0.45 parts by weight of zinc acetate, heated under nitrogen protection, and the stirring device was started immediately after the reactants in the kettle were melted, and the reaction was controlled as in Example 1. The molar ratio of succinic acid, ethylene glycol, ethylene glycol, and sodium 1,2-dihydroxy-3-propanesulfonate is 1:0.6:0.15:0.25.

[0061]After 32 hours of reaction, the product appeared serious "climbing" phenomenon, the reaction was terminated by cooling, nitrogen was filled to eliminate the vacuum, and the linear polyester main chain of the granular aliphatic water-based polyester graft copolymer was obtained by casting and dicing. The prepared water-based linear polyester main chain structure i...

Embodiment 3

[0066] Ⅰ. Preparation of the main chain of aliphatic water-based polyester: add 146.1 parts by weight of adipic acid, 7.448 parts by weight of ethylene glycol, 50.93 parts by weight of ethylene glycol, 1,2-dihydroxy-3- 71.20 parts by weight of sodium propanesulfonate and 2.20 parts by weight of zinc acetate were heated under nitrogen protection, and the stirring device was started immediately after the reactants in the kettle were melted. The reaction was controlled as in Example 1. The molar ratio of adipic acid, ethylene glycol, ethylene acetal and sodium 1,2-dihydroxy-3-propanesulfonate was 1:0.12:0.48:0.4.

[0067] After 36 hours of reaction, the product appeared serious "climbing" phenomenon, the reaction was terminated by cooling, nitrogen was filled to eliminate the vacuum, and the linear polyester main chain of the granular aliphatic water-based polyester graft copolymer was obtained by casting and dicing. The prepared water-based linear polyester main chain structure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adhesive strength | aaaaa | aaaaa |

| Adhesive strength | aaaaa | aaaaa |

| Adhesive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com