Seamless pipe four-roller type hot sizing stand

A technology of seamless steel pipe and sizing machine, which is applied in the direction of metal rolling stand, metal rolling mill stand, driving device for metal rolling mill, etc. , to achieve the effect of convenient use, compact structure and reasonable structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

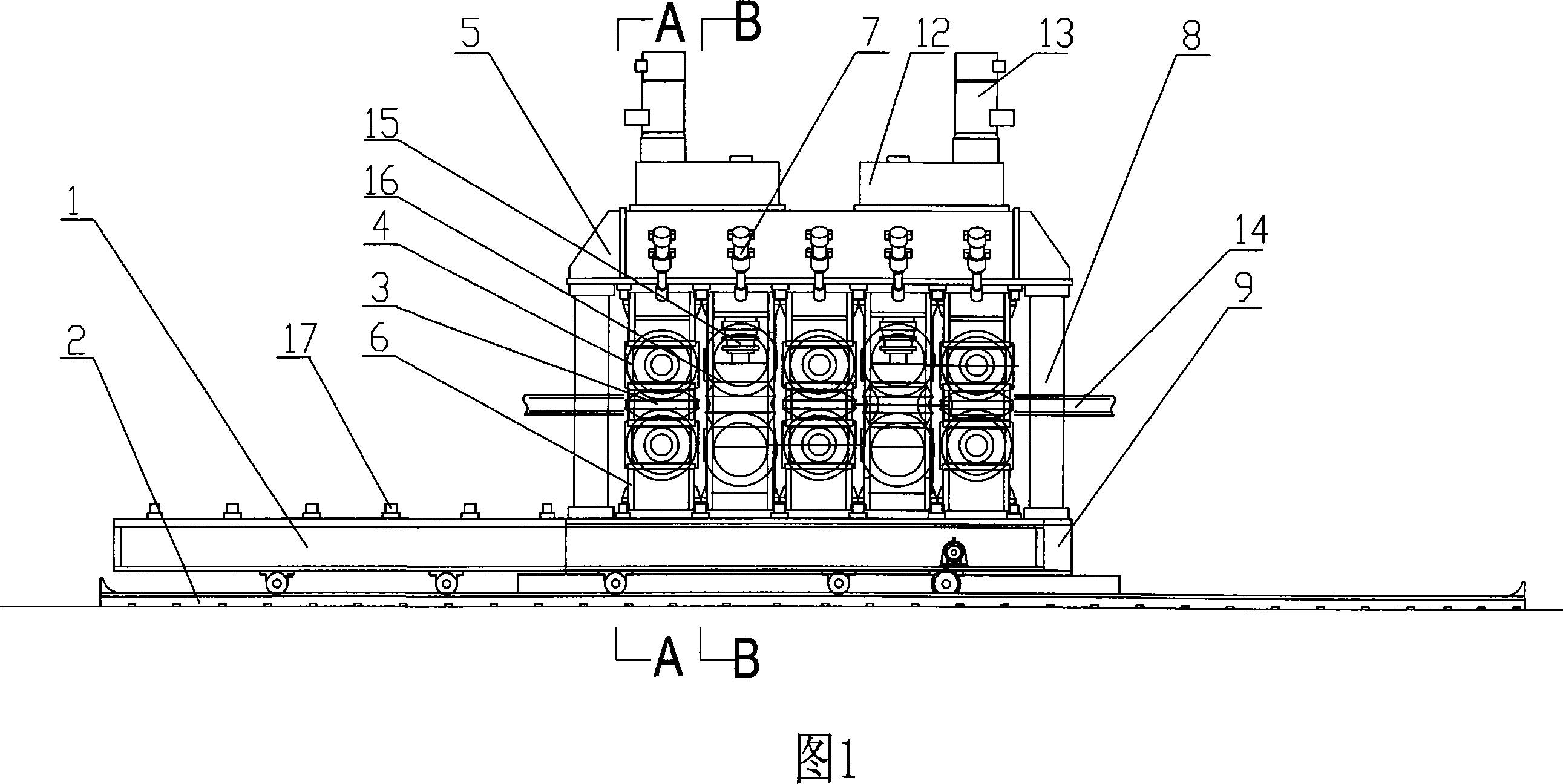

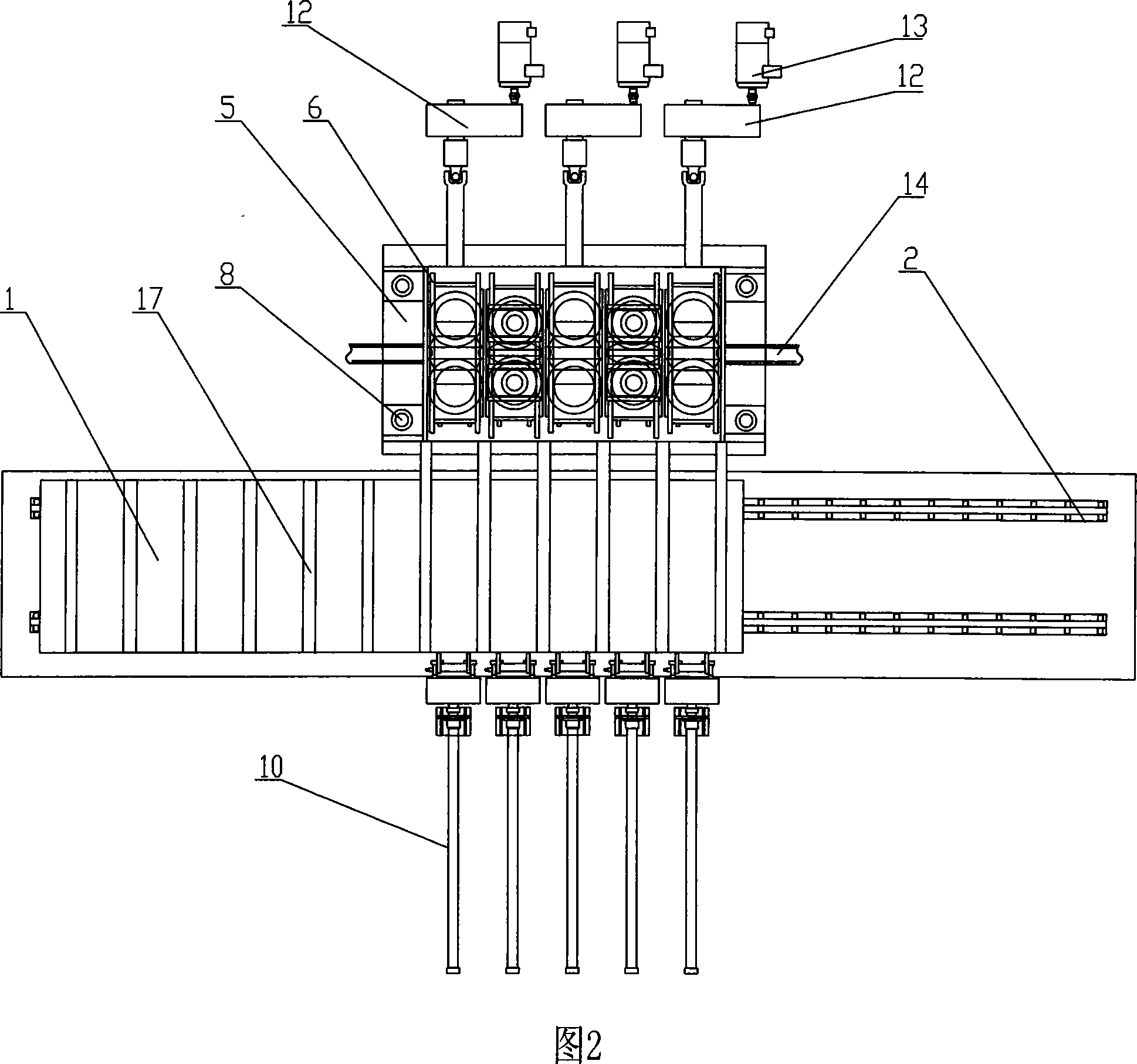

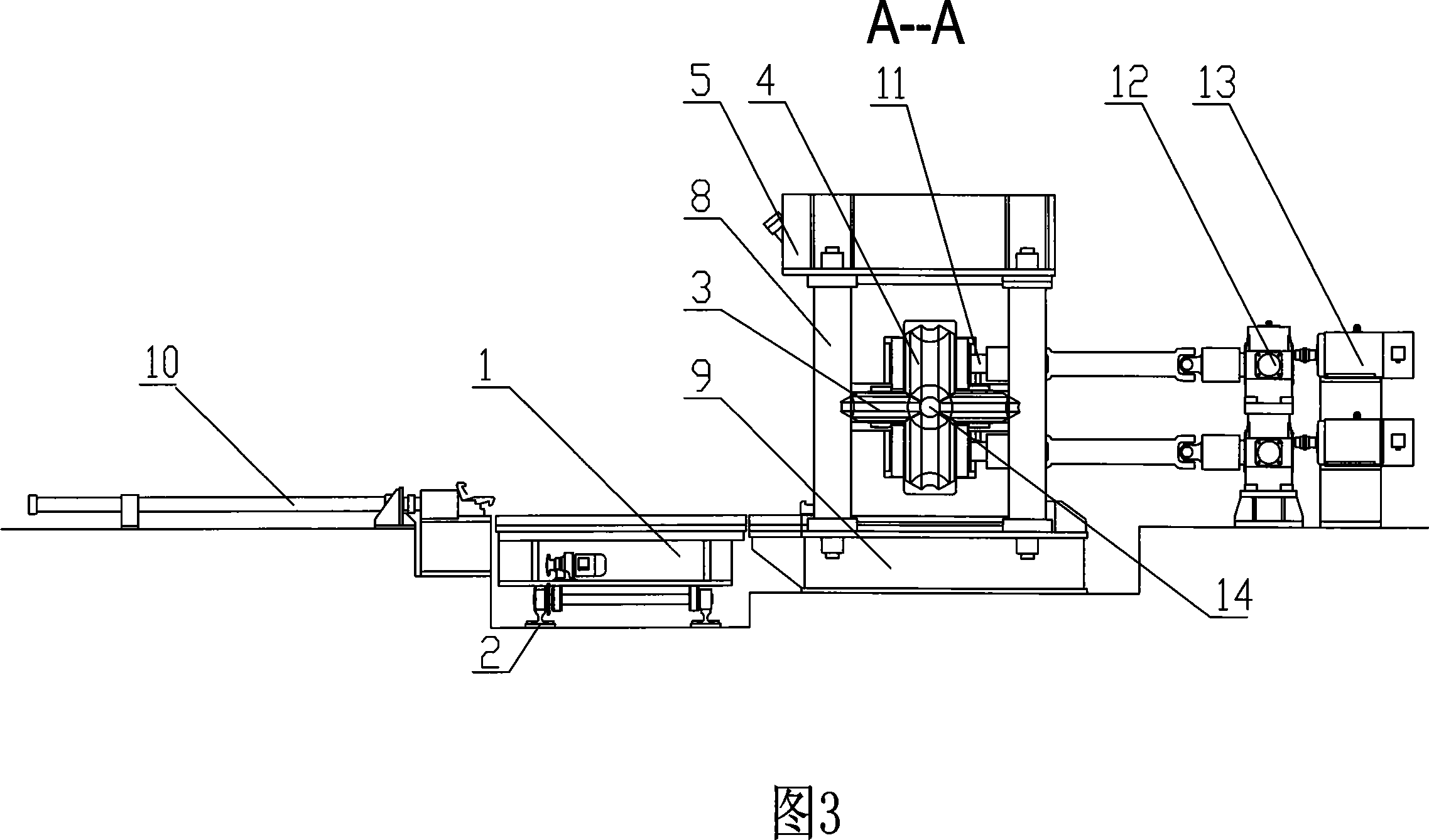

[0022] Shown in Fig. 1, 2, 3 is the concrete embodiment of the present invention, and it is the seamless steel pipe four-roller heat sizing machine that is installed on the ∮ 325~700mm seamless steel pipe production line; Car 1, the sizing main engine, is characterized in that: the sizing main engine is installed on the rear side of the track 2, and the sizing main engine is composed of a frame, a horizontal sizing roller group, and a side sizing roller group. The base 9 and the column 8 are in use. 1. Crossbeams 5 are connected to each other to form the base 9 of the square frame, and three groups of horizontal sizing roller groups and two groups of side-standing sizing roller groups are installed in sequence, and each group of horizontal sizing machines is composed of a frame 6. Flat roller 4 with large fan angle, vertical roller 3 with small fan angle, roller shaft 11 and transmission mechanism, corresponding to the position of the processed tube 14, installed in the frame 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com