Patents

Literature

193results about How to "Guaranteed performance indicators" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Diluent enabling stability for acridinium ester antigen-antibody conjugate and preparation method of diluent

ActiveCN105628914ANot easy to hydrolyzeExtended shelf lifeBiological testingPreservativeAntibody conjugate

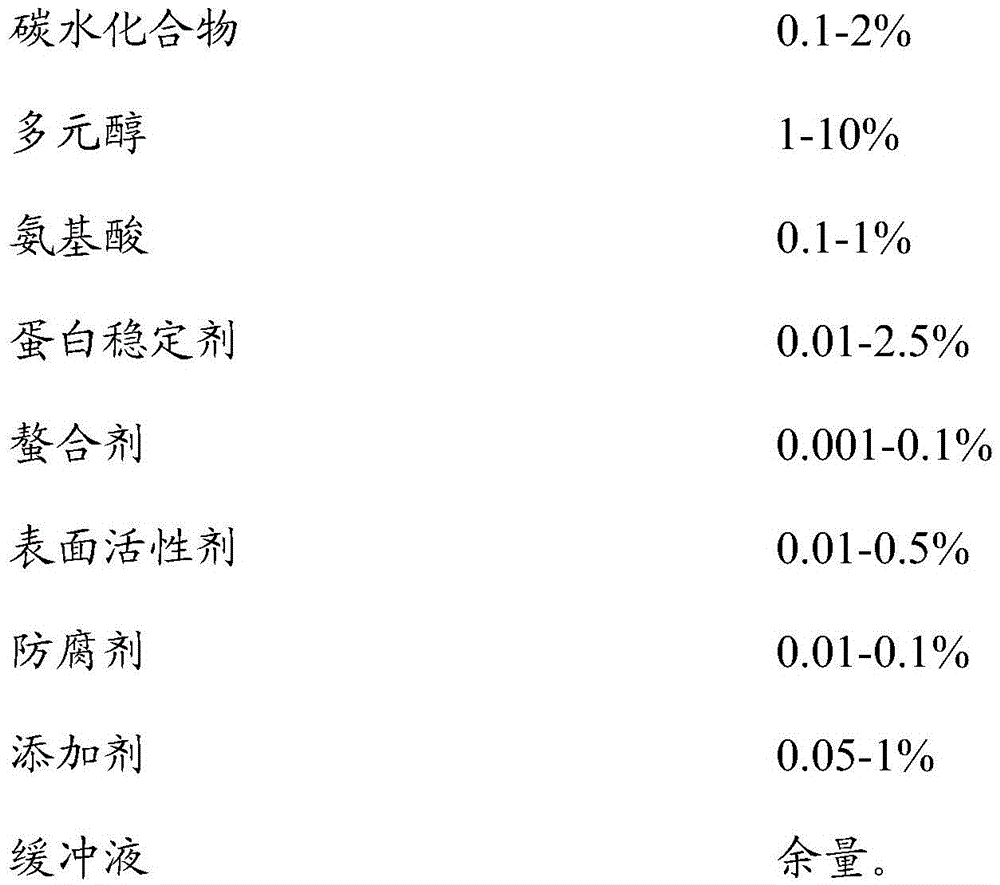

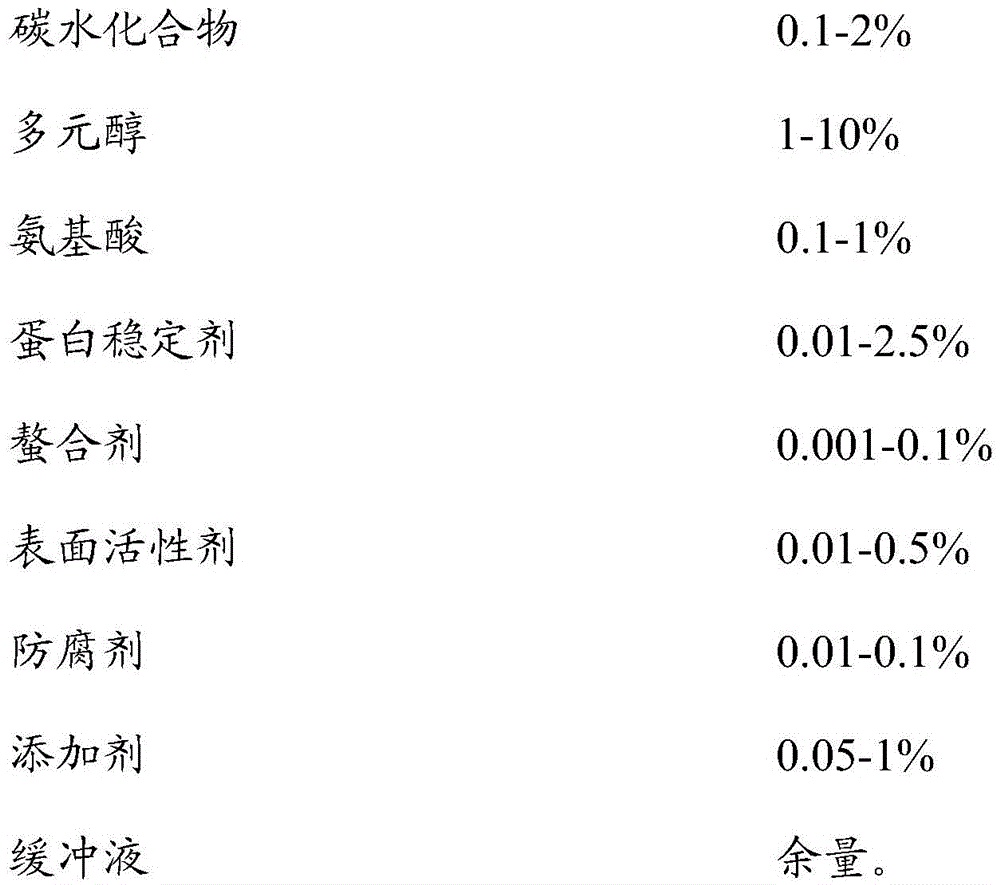

The invention discloses a diluent enabling stability for acridinium ester antigen-antibody conjugate. The diluent is prepared by adding a carbohydrate, polyalcohol, amino acids, a protein stabilizer, a chelating agent, a surfactant, a preservative and an additive into a buffer solution; the diluent prepared by the invention overcomes the defect that acridinium ester is unstable and easily hydrolyzes in the buffer solution, can protect the acridinium ester antigen-antibody conjugate to improve its stability and prolong its service life, and also can be fully used in in-vivo diagnostic kits.

Owner:GUANGZHOU KEFEN BIOTECH CO LTD

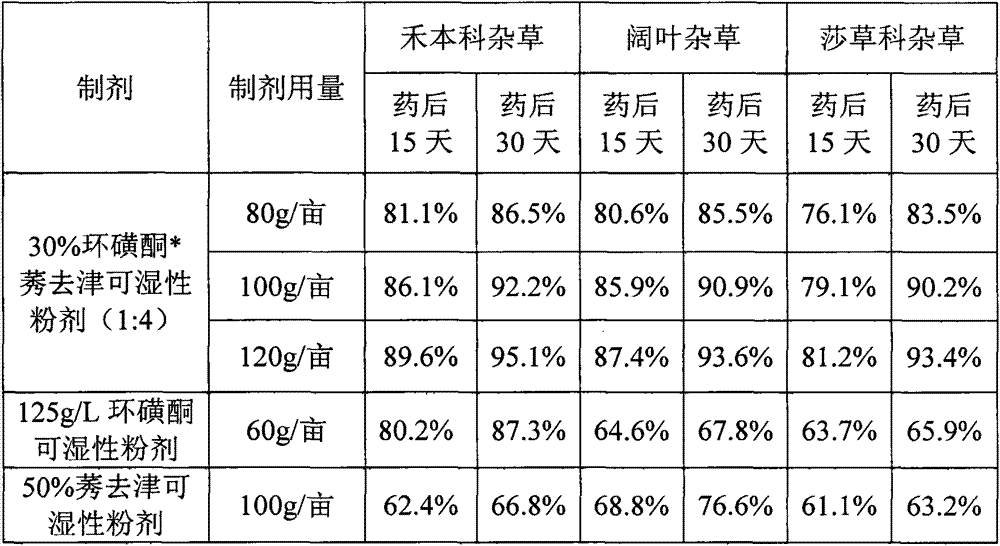

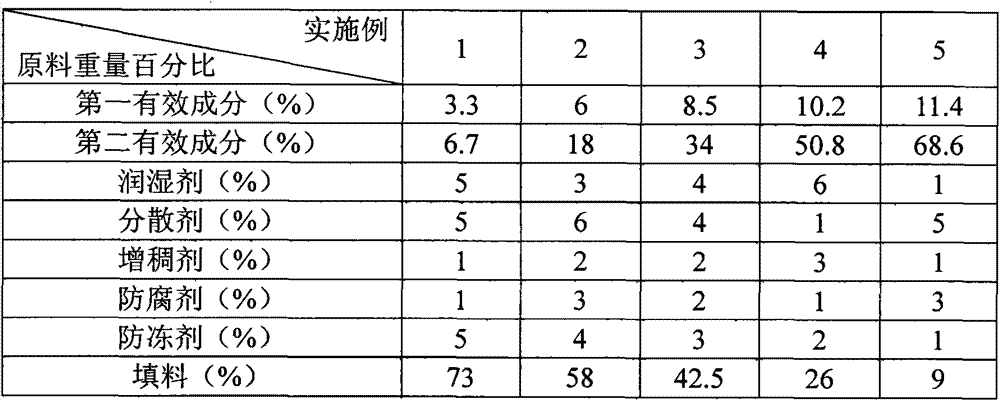

Tembotrions compound cornfield herbicide

InactiveCN103392710ADelay drug resistanceSignificant synergies in prevention and controlBiocideAnimal repellantsMCPAFluroxypyr

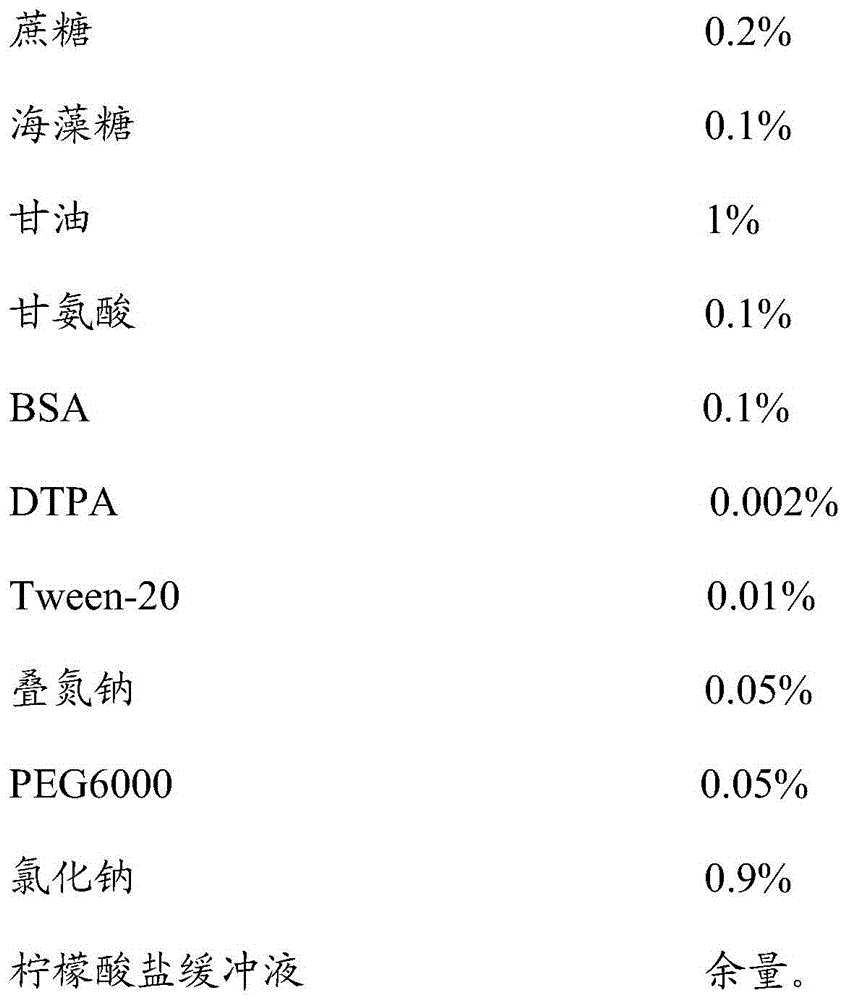

The invention discloses a tembotrions compound cornfield herbicide. According to the adopted technical scheme, the herbicide comprises the following components in percentage by weight: 5-80 percent of effective components, 5-15 percent of auxiliaries and 5-80 percent of filler, wherein a first effective component is tembotrions, and a second effective component is any one of atrazine, terbuthylazine / nicosulfuron, foramsulfuron, rimsulfuron / fluroxypyr, MCPA-Na / mesotrione, sulcotrione and topramezone; the weight ratio of the first effective component to the second effective component is (1:8)-(8:1). The technical effect is that multiple grassy weeds, broadleaf weeds and cyperaceae weeds which can be prevented by the independent tembotrions can be also prevented by the tembotrions compound cornfield herbicide; furthermore, a prevention effect for part of grassy weeds and part of broadleaf weeds is improved, the herbicide controlling spectrum is expanded, the safety to the corns is improved, the drug using amount is reduced, the prevention and treatment cost is reduced, and the pollution to the environment is reduced.

Owner:河北博嘉农业有限公司

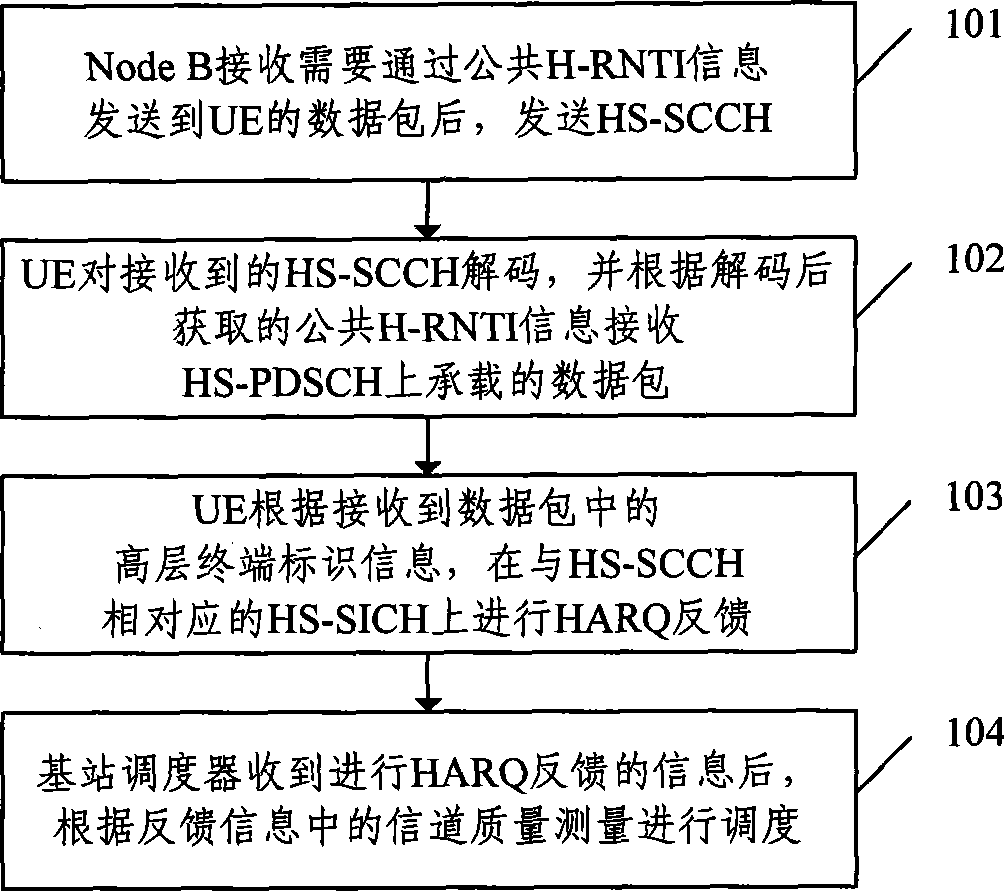

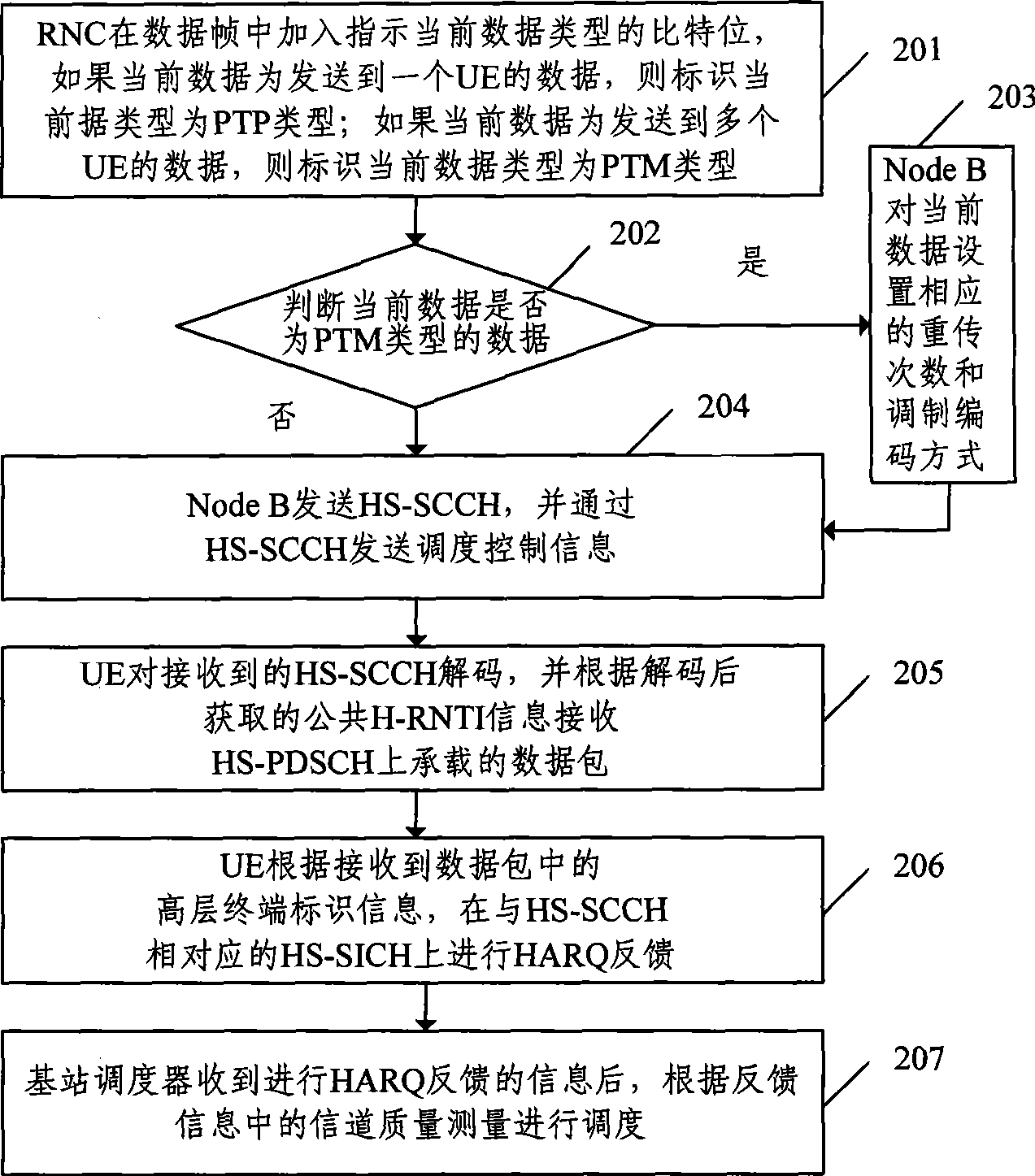

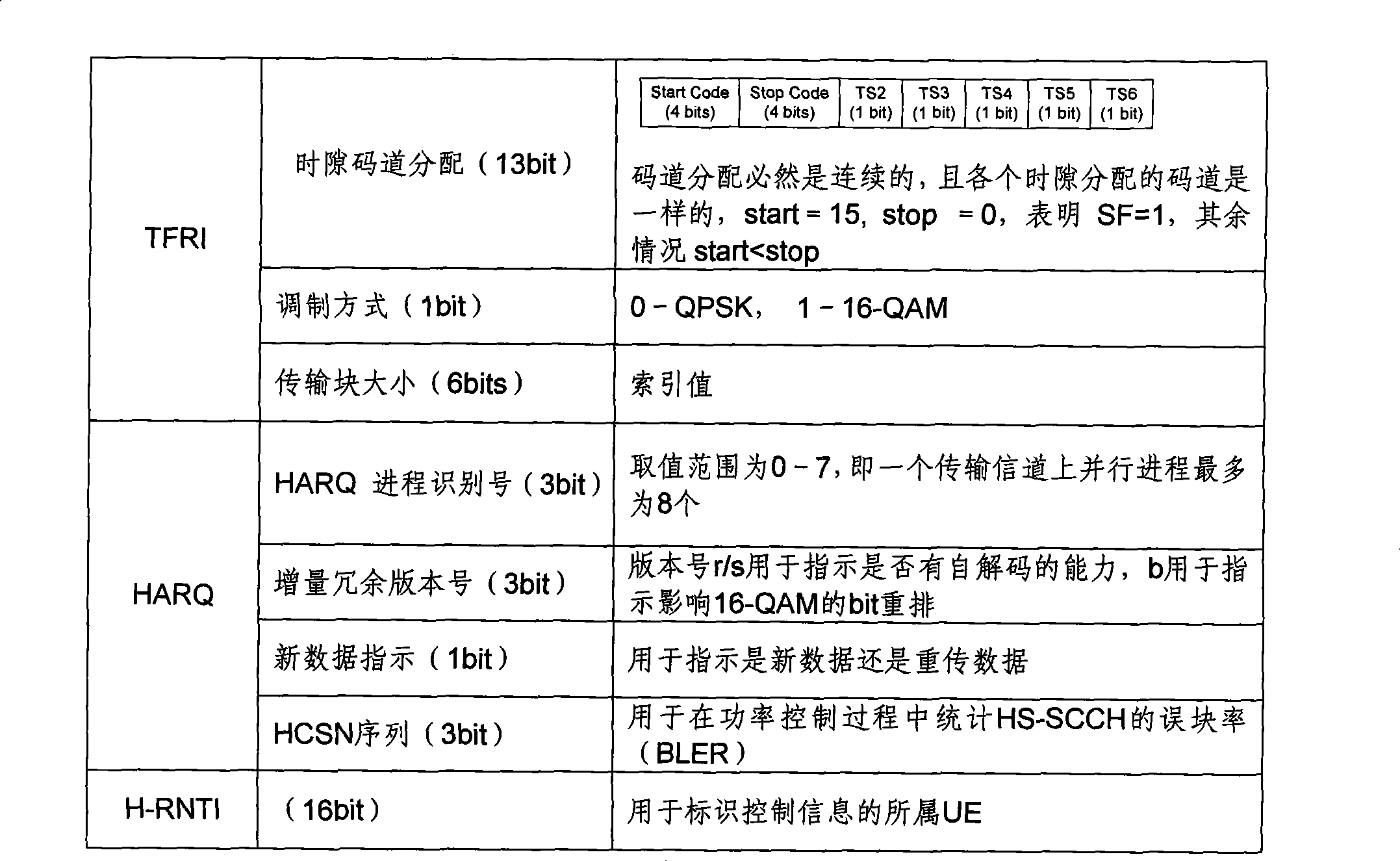

Method, system and device for implementing hybrid automatic request retransmission feedback mechanism

InactiveCN101399644AGuaranteed performance indicatorsImprove throughputError prevention/detection by using return channelNetwork packetControl channel

The invention discloses a method for realizing a hybrid automatic request repeat feedback mechanism. The method comprises the following steps: a base station transmits a shared control channel (HS-SCCH) of a high-speed downlink shared channel, and a downlink scheduling control channel of high-speed downlink packet access; a terminal decodes the received HS-SCCH, and receives a data packet loaded on a high-speed physical downlink shared channel; and the terminal carries out hybrid automatic request repeat feedback on a shared information channel (HS-SICH) corresponding to the HS-SCCH and an uplink feedback channel of high-speed downlink packet access. The invention also discloses a system and base station side / terminal side equipment for realizing the hybrid automatic request repeat feedback mechanism. By adopting the method, the system and the equipment, information can be fed back on the HS-SICH.

Owner:CHINA ACAD OF TELECOMM TECH

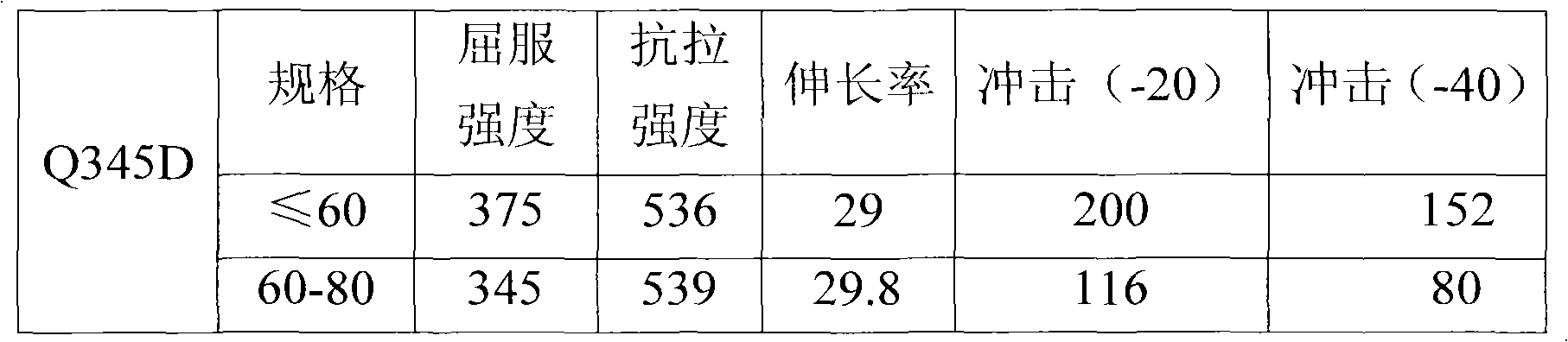

Low-alloy Q345D thick plate produced without adding micro-alloy elements and production method thereof

ActiveCN102080181AGuaranteed purityGuaranteed Performance RequirementsTemperature control deviceThick plateDegasser

The invention discloses a low-alloy Q345D thick plate produced without adding micro-alloy elements and a production method thereof. The method disclosed by the invention is characterized in that on the premise of not adopting vacuum decarburization equipment such as an RH and the like, through using the existing equipment such as a VD (vacuum degasser) and the like of enterprises, the requirements for smelting low-carbon steel plates and extreme low carbon steel plates are met, therefore, under the condition that the profits of the enterprises at the present stage are not high, a heavy investment in large-scale equipment replacement and remodeling is avoided, thereby saving the investment for the enterprises, completely using the existing equipment of the enterprises, greatly reducing the capital investment of the enterprises at the present stage, and providing abundant preparation time for equipment replacement after the market situation takes a favorable turn in the future and the profits of the enterprises are improved.

Owner:NANYANG HANYE SPECIAL STEEL CO LTD

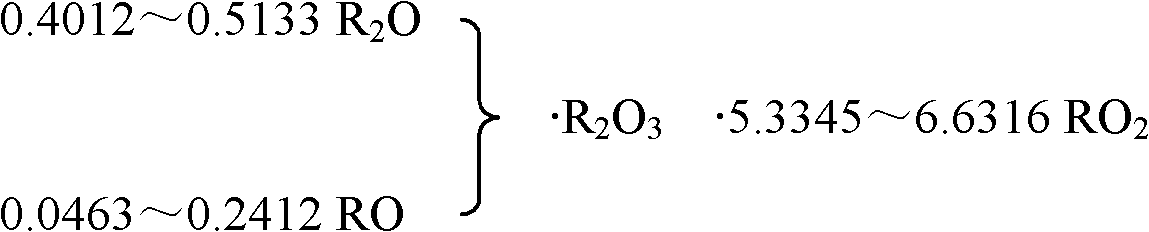

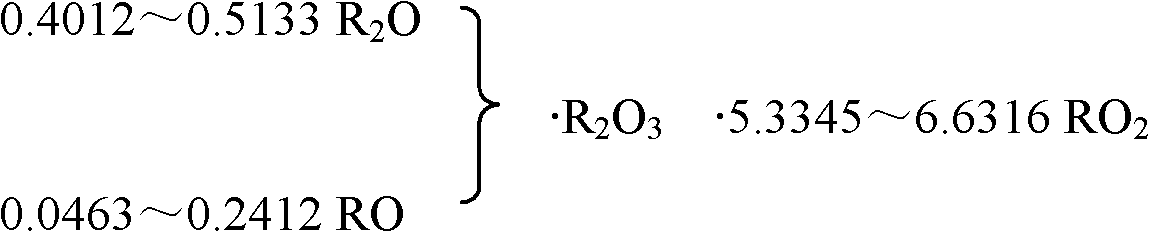

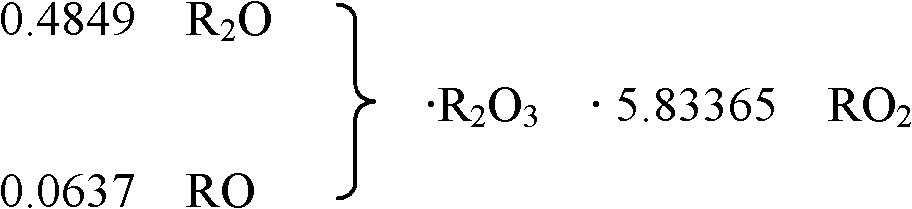

Ceramic brick produced by using rare earth tailings and production method thereof

ActiveCN102515695AIncrease profitLower sintering temperatureCeramic materials productionClaywaresSocial benefitsBrick

The invention discloses a ceramic brick prepared by rare earth tailings, wherein a base substrate of the ceramic brick comprises 55-80 wt% of the rare earth tailings, 5-15 wt% of plastic clay, and 10-30 wt% of fusing agent. The invention also discloses a production method of the ceramic brick. According to the invention, the utilization rate of the rare earth tailings is greatly raised, simultaneously the sintering temperature of a product is reduced, the range of the sintering temperature is enlarged, and guarantees for guaranteeing all performance indexes and quality of the product are provided; and the recycling of the rare earth tailings is effectively realized, and the production cost is reduced. The invention is beneficial for protecting environment and promoting the sustainable development of industry production, and has important economic benefits and social benefits.

Owner:JINGDEZHEN CERAMIC INSTITUTE

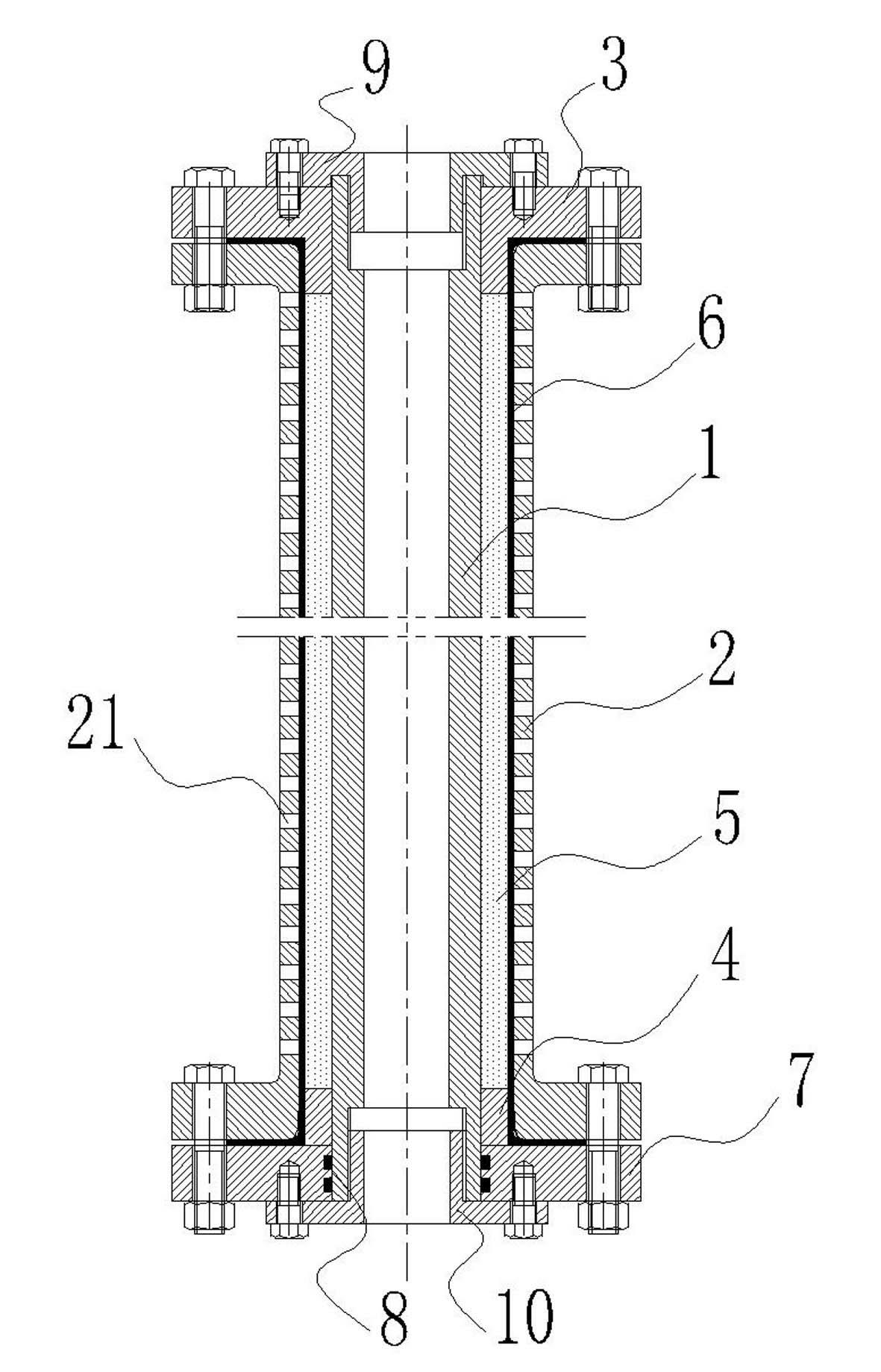

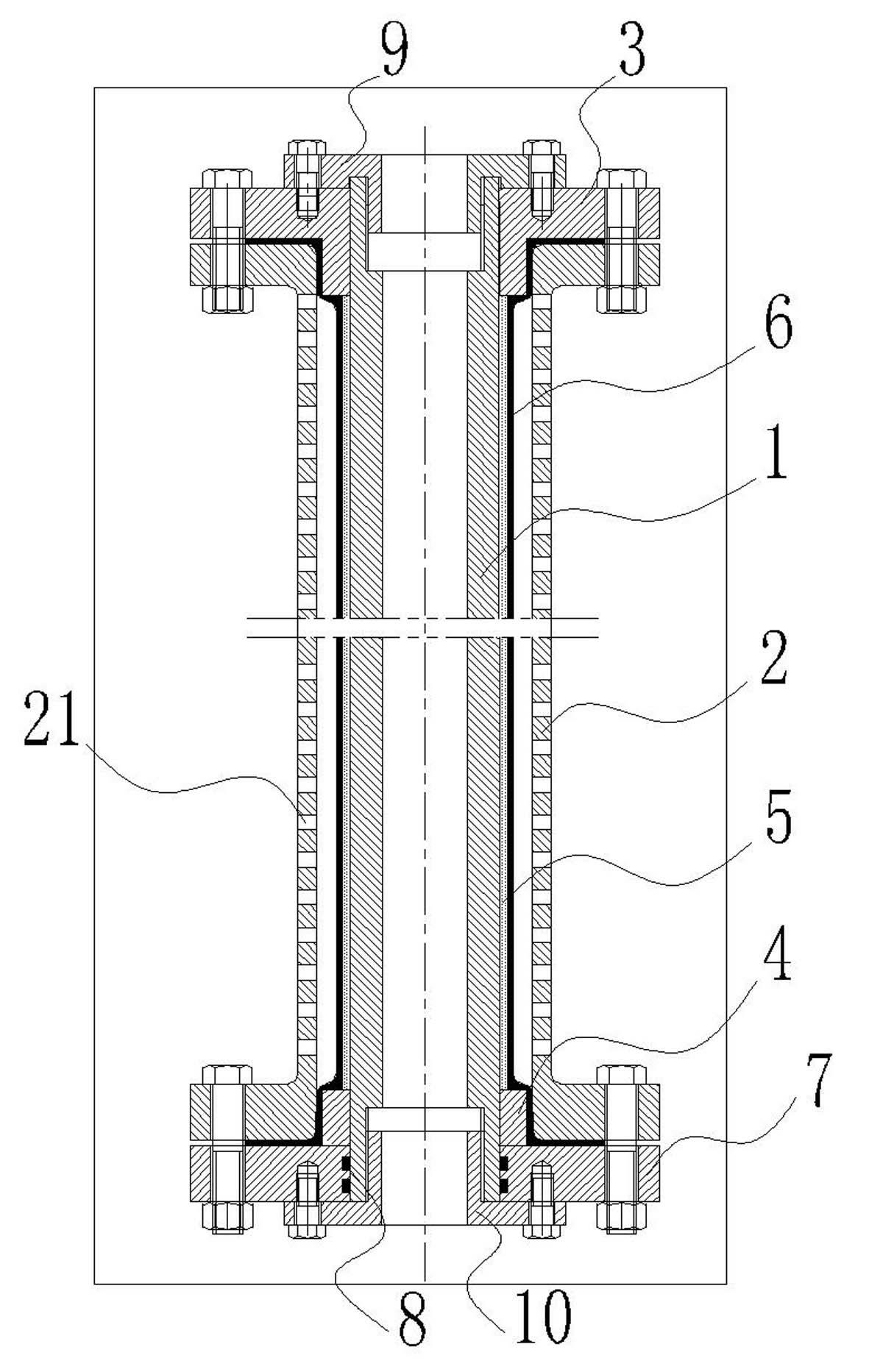

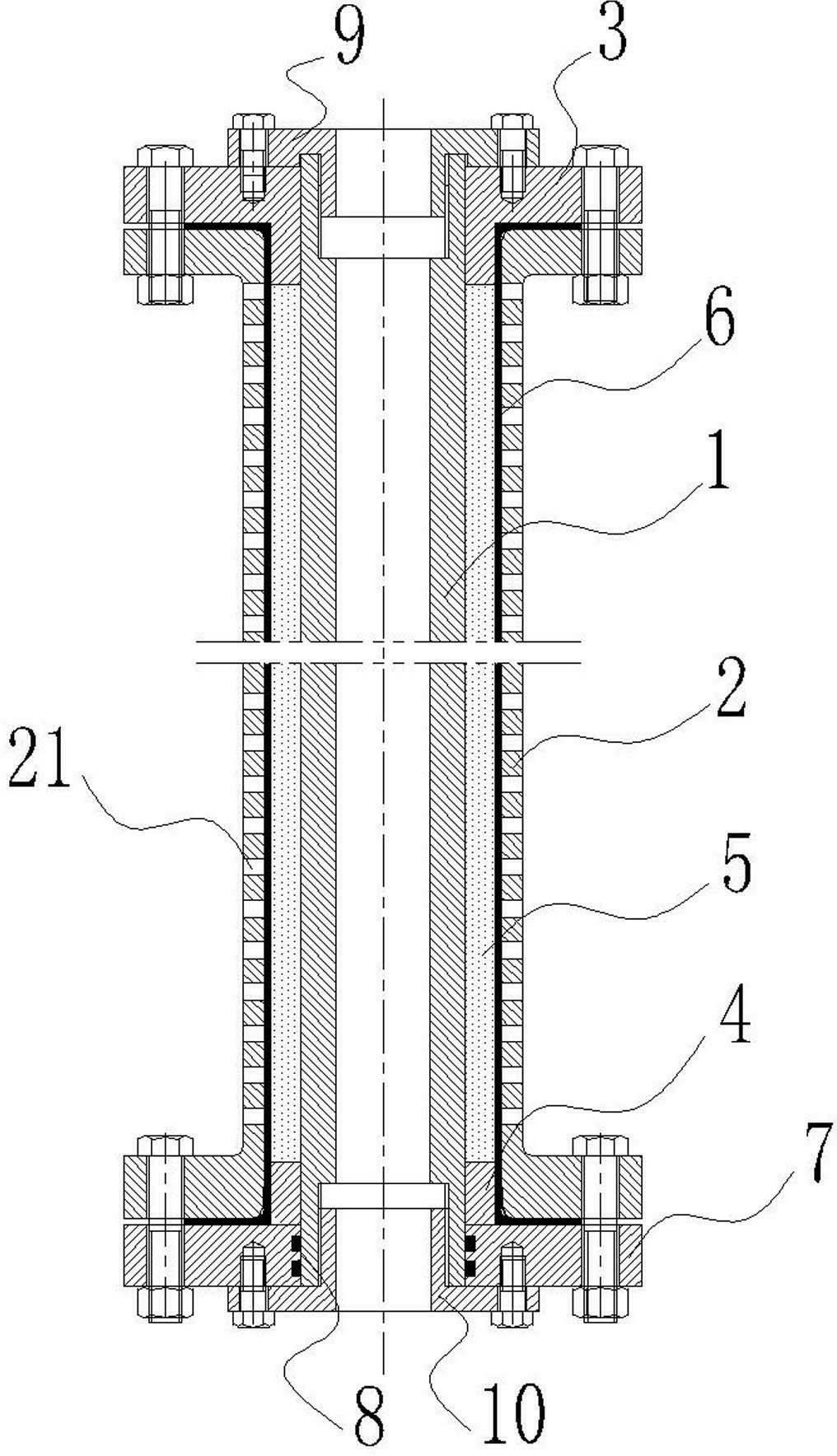

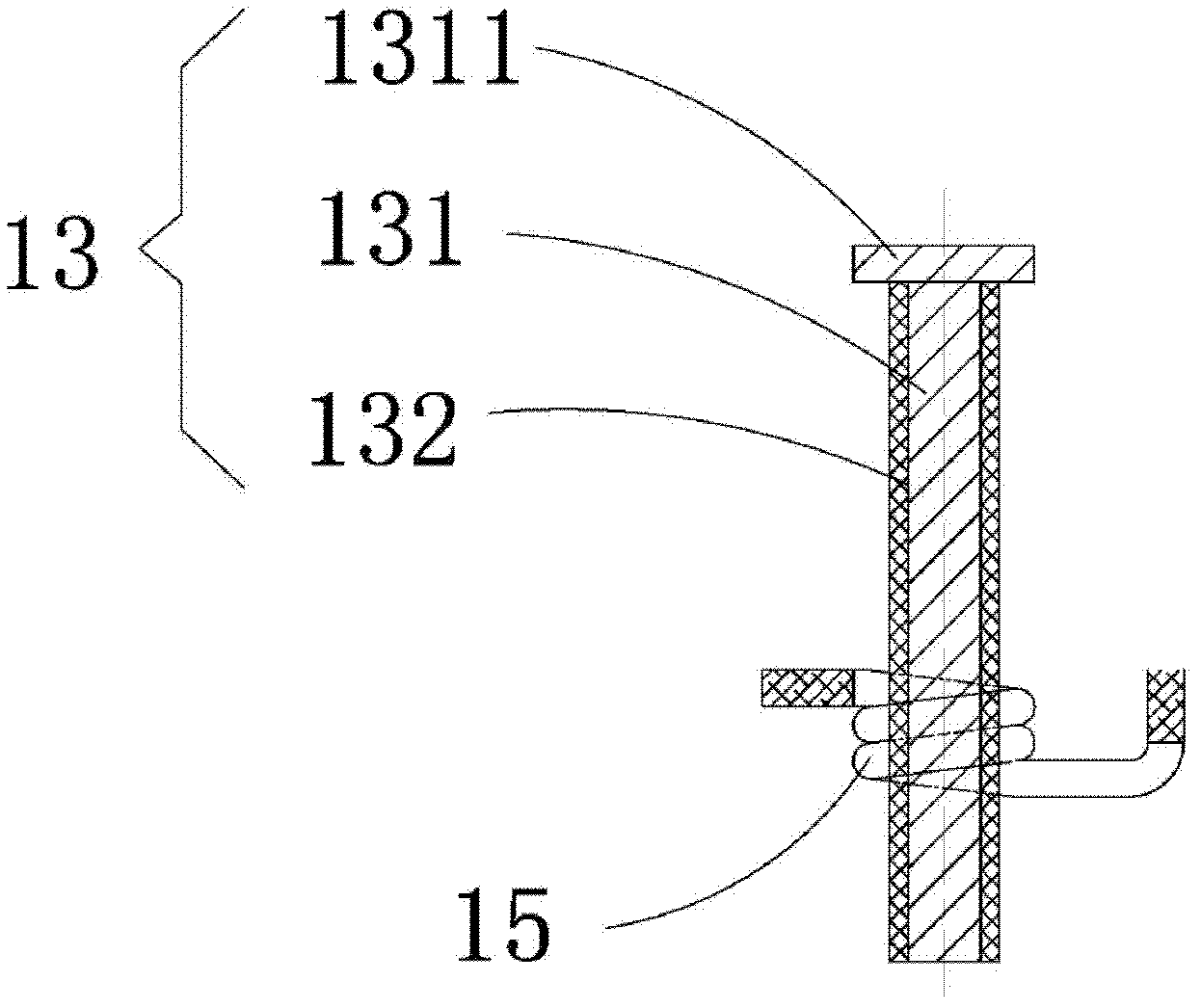

Polytetrafluoroethylene isostatic pressure molding device and pipeline lining method by aid of same

ActiveCN102632578AImprove product qualityHigh densityTubular articlesMoulding deviceComposite material

The invention discloses a lining molding device used on chemical equipment and a lining method, and provides a polytetrafluoroethylene isostatic pressure molding device and a lining method. The polytetrafluoroethylene isostatic pressure molding device is smart in conception and fine in performance, a pipe molded by the aid of the polytetrafluoroethylene isostatic pressure molding device is high in strength, and the polytetrafluoroethylene pipe can be tightly lined in a pipeline by the aid of the lining method, and the technical problems of low polytetrafluoroethylene lining density, poor tensile strength and permeation resistance and the like due to insufficient molding pressure of an existing polytetrafluoroethylene molded pipe of the prior are solved. The method includes integrally placing a mold below the liquid level of a high-pressure cabin of an isostatic pressure machine; pressurizing the high-pressure cabin to process pressure and leading a polytetrafluoroethylene blank to be in cold press molding; adopting an isostatic pressure process; sintering a blank part released from the mold, drawing down the blank part, and placing the blank part into the pipeline; realizing memory rebounding of a polytetrafluoroethylene pipe blank after heating; and leading the polytetrafluoroethylene pipe lining to be lined in the pipeline. The lining is fine in high-temperature resistance and high-pressure resistance, and full-vacuum service requirements under the condition with high temperature of 232 DEG C are met.

Owner:四达氟塑股份有限公司

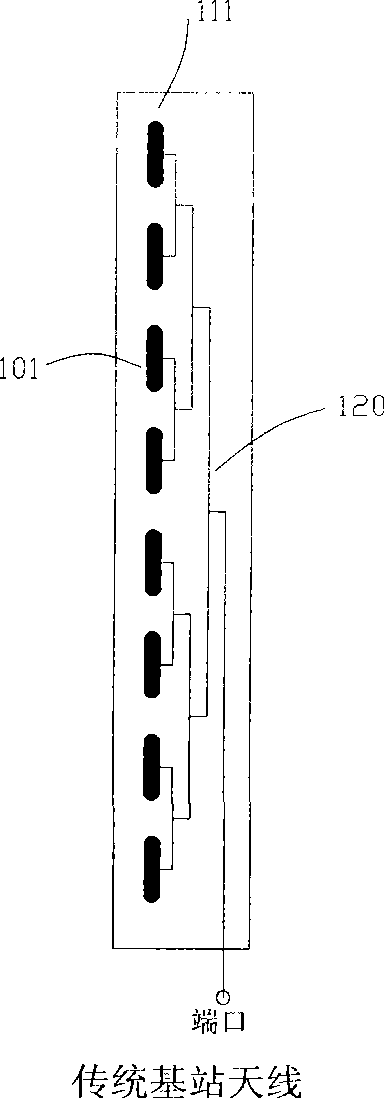

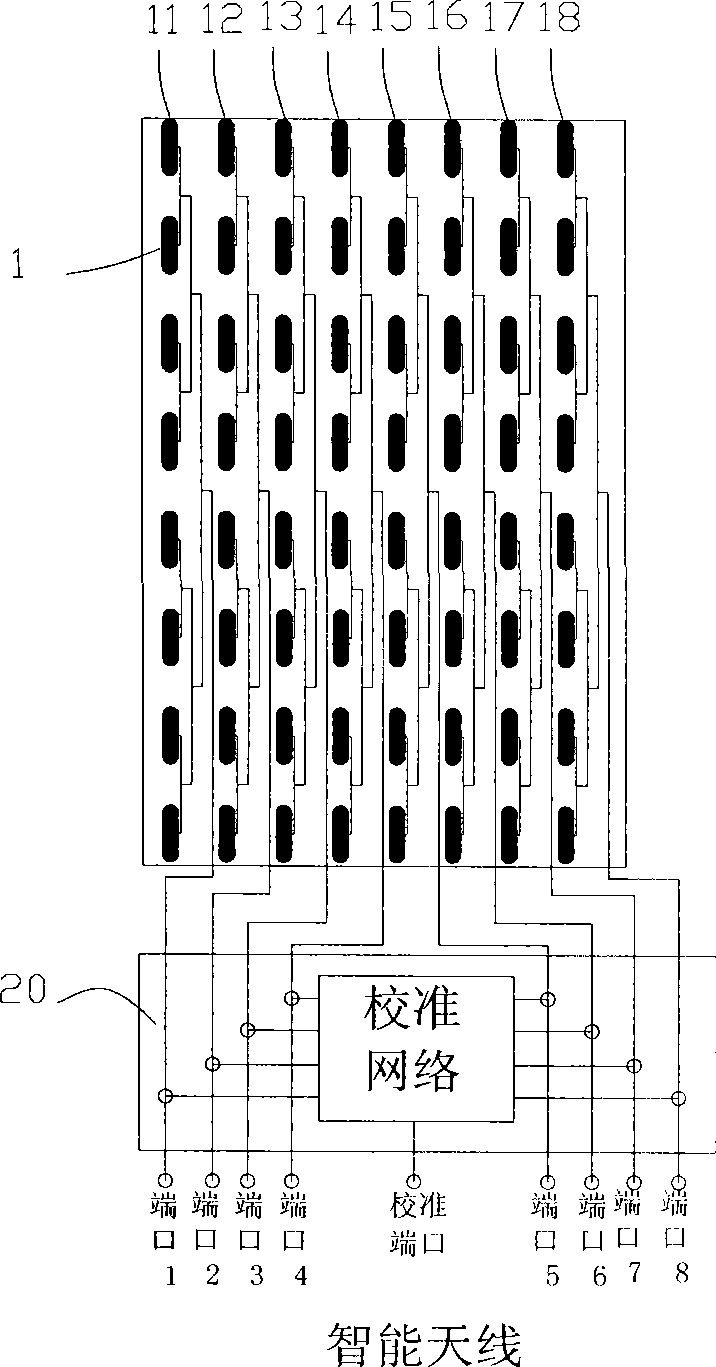

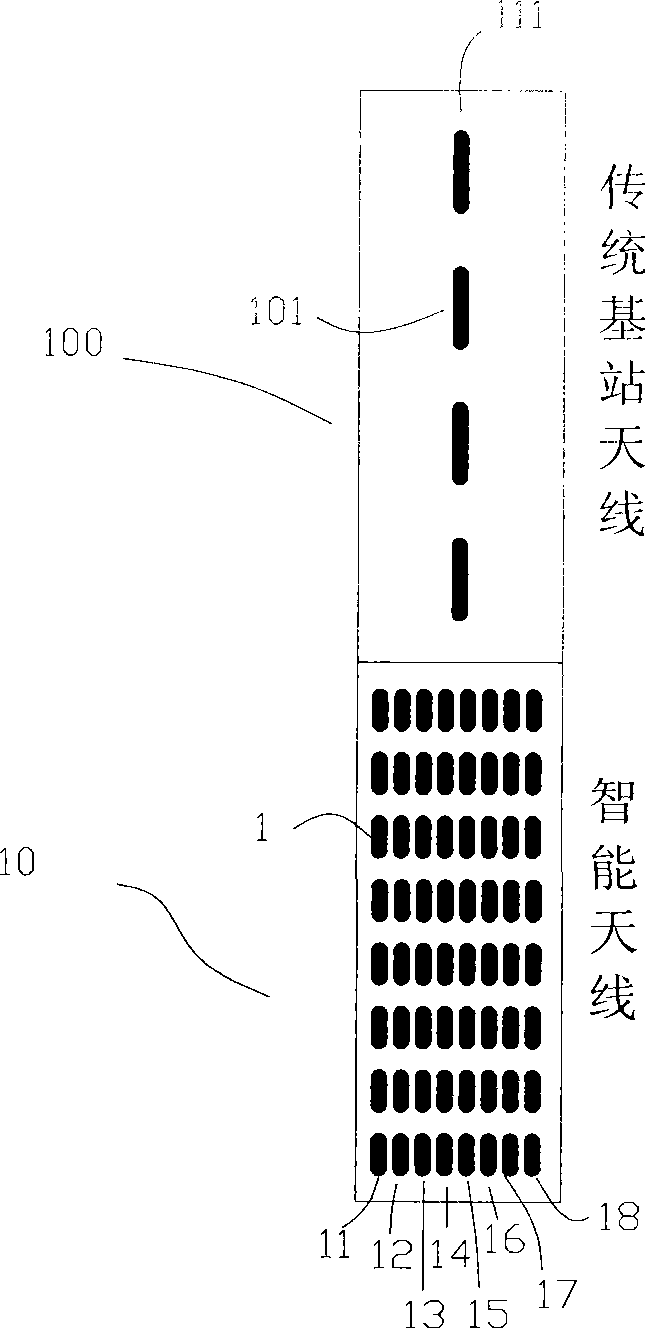

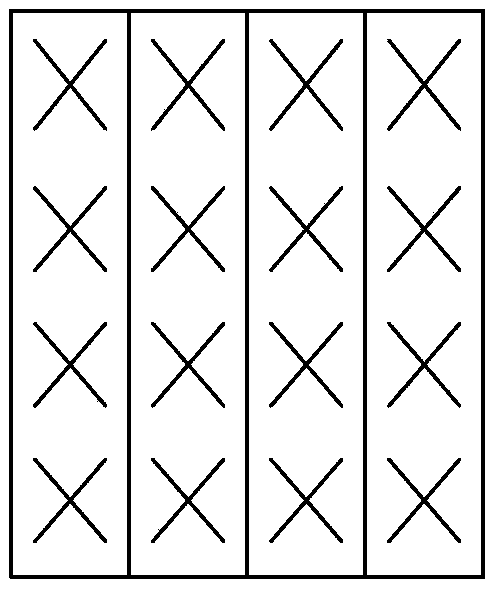

Multisystem covolume antenna

ActiveCN101465473AAchieve compactnessImprove compatibilitySpatial transmit diversityAntenna arraysTD-SCDMAPerformance index

The invention discloses a multi-system community antenna, comprising a main antenna array which at least comprises two antenna array elements for sending and receiving communication signals at a first frequency band together, and the antenna array element is composed of at least two radiating units; at least a secondary antenna array which at least comprises one antenna array element for sending and receiving independent frequency bands different from the first frequency band, and the antenna array element is composed of at least two radiating units; and a shared reflecting plate for arranging the main antenna array and the secondary antenna array and being used as a shared reflector of the main antenna array and the secondary antenna array; in each antenna array element of the main antenna array and unequal phase distribution feeding is carried out between the radiating units. The multi-system community antenna realizes effective integration of the traditional base-station antennas and the TD-SCDMA intelligent antennas; in addition, the compaction of the antenna is realized on the premise of ensuring performance index, thus ensuring the safety and practicability of the community antenna.

Owner:COMBA TELECOM TECH (GUANGZHOU) CO LTD +1

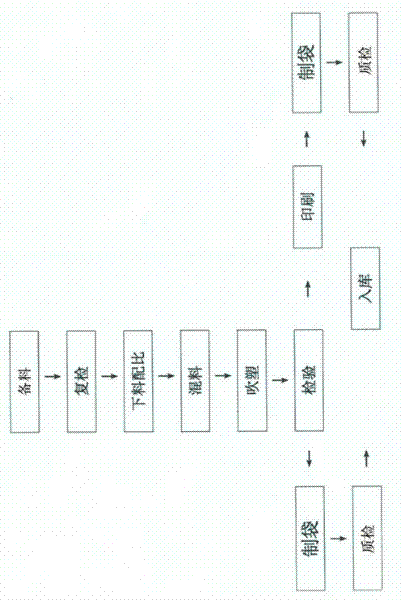

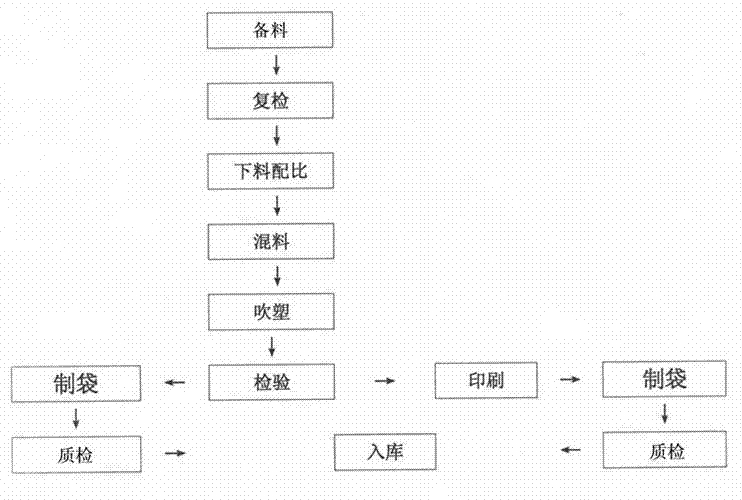

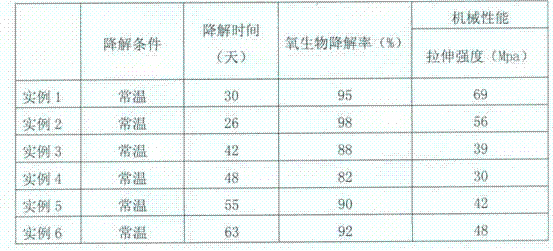

Degradable plastic film and production method thereof

The invention relates to a degradable plastic film, which is characterized by comprising the following components in part by weight: 50 to 80 parts of film-grade polyethylene, 20 to 50 parts of film-grade polyactic acid, 2 to 10 parts of plasticizer and 1 part of heat stabilizer. A preparation method comprises the following steps of: preparing, rechecking, blanking, mixing, performing blow molding, inspecting, making a bag, performing quality inspection and warehousing. The degradable plastic film can be automatically decomposed at the environment temperature of higher than 55 DEG C or under the action of oxygen enrichment or microorganisms; the discarded film can be completely degraded and digested by the microorganisms in the natural world to generate carbon dioxide and water, and the polyactic acid is ideal completely degradable plastic; and degradable plastic with different degradation speeds can be prepared by blending the film-grade polyactic acid with film-grade polyethylene plastic. The degradable plastic film can be produced by the ordinary plastic film blowing machine, film-grade polyethylene particles and the film-grade polyactic acid can be uniformly mixed during production, and the degradable plastic film can be blown by the plastic film blowing machine.

Owner:开原市升达塑料彩印厂

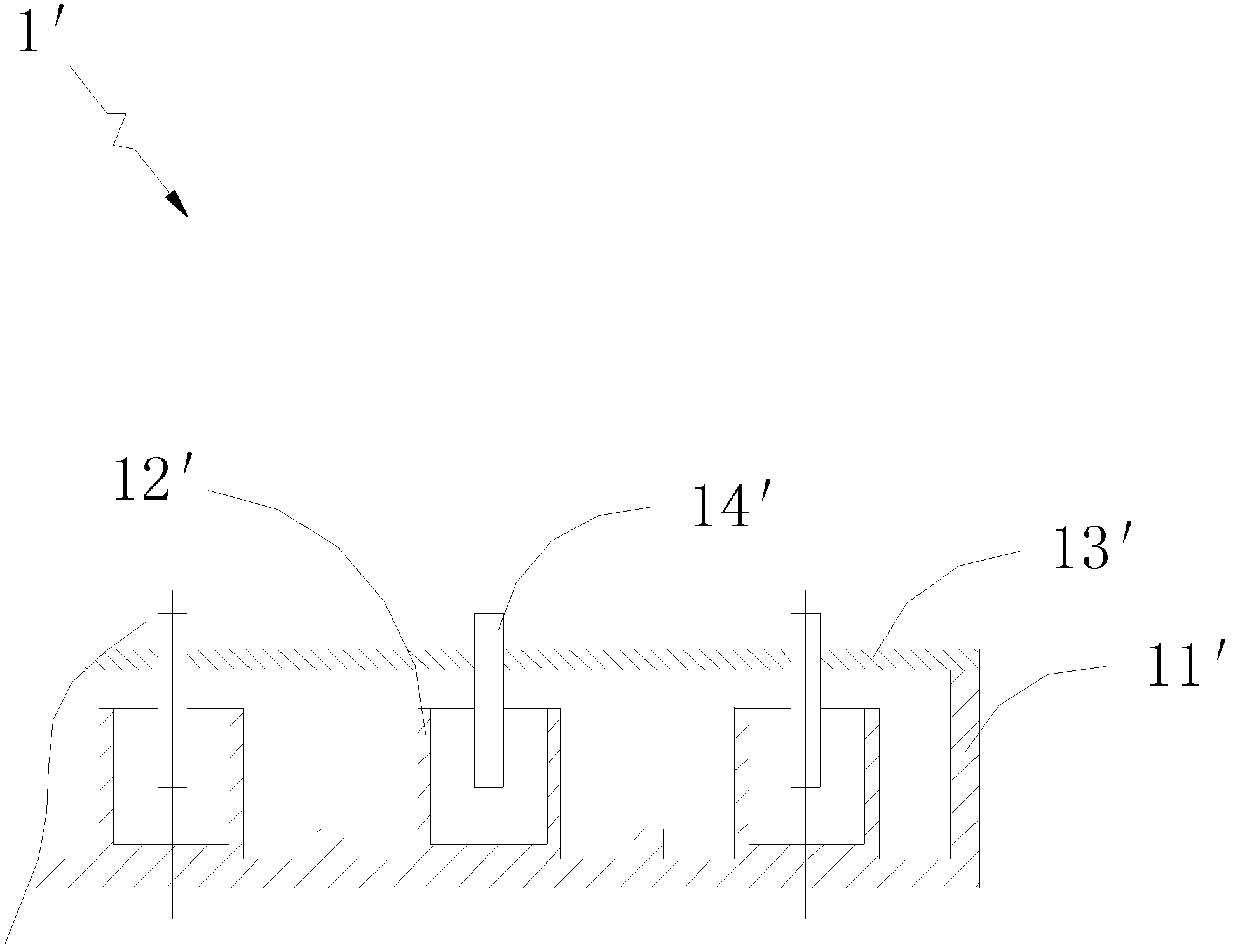

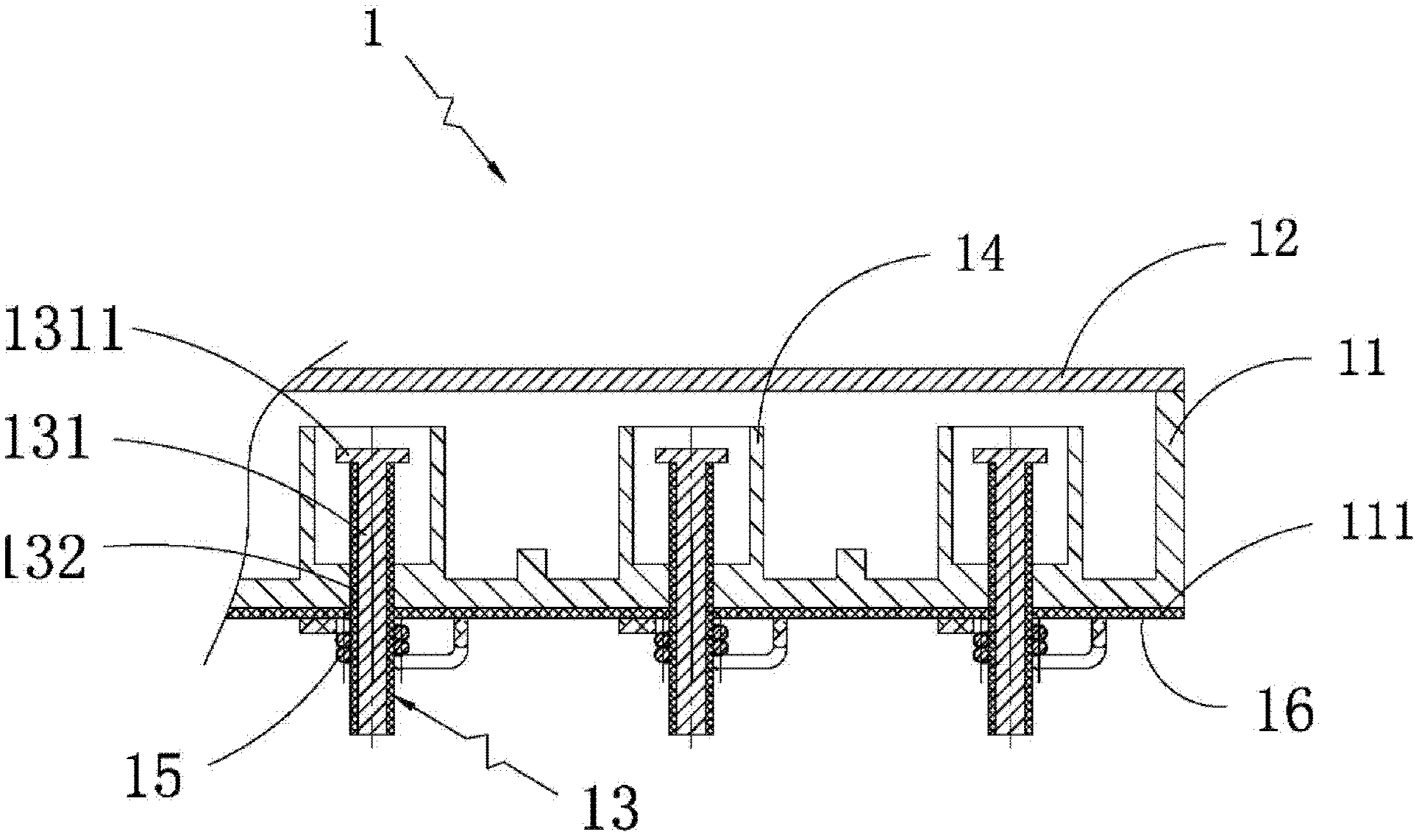

Tunable filter

InactiveCN102324601AAchieve frequency tunabilityMiniaturizationWaveguide type devicesMulti bandCoupling

The invention provides a tunable filter comprising a cavity, a cover plate which is assembled on the cavity and a plurality of tuning screw rods; at least two resonators are arranged in the cavity; every tuning screw rod respectively penetrates through each resonator; inductor devices capable of adjusting the coupling quantity between the tuning screw rods and the cover plate and the resonators are arranged; and the inductor devices are wound on the tuning screw rods. An electromagnetic field in an inductor is changed by changing the current which flows through the inductor or the direction of the current, so that a multi-band filtering function can be realized without manual debugging, performance indexes of the filter are guaranteed under different frequency while the filter is tunable, the frequency of the filter is tunable, the product cost is greatly reduced while the same functions are realized, the size is reduced, the material cost is reduced, simultaneously the workload of debugging and assembly is reduced, the miniaturization of the product is realized, and social resources are greatly saved.

Owner:MOBILE ANTENNA TECH SHENZHEN

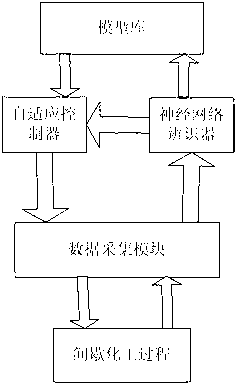

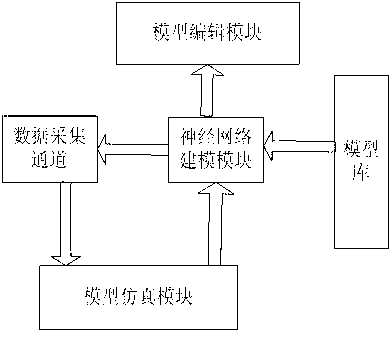

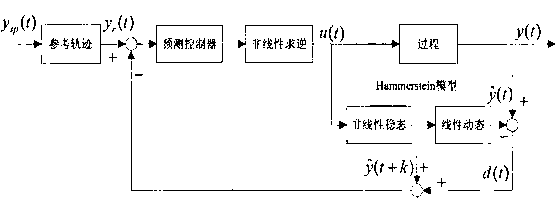

Adaptive prediction control method based on Hammerstein model

ActiveCN103268069APrecise and effective controlReduce energy consumptionAdaptive controlModel parametersControl system

The invention discloses an adaptive prediction control method based on the Hammerstein model. The adaptive prediction control method based on the Hammerstein model specifically comprises a first step that a data collection channel collects technological parameter values in the process of intermittent chemical production in real time and conducts data pre-processing, a second step that the processed data are transmitted to a neural network identifier, modeling is conducted by the neural network identifier, and the established model is revised in a simulating mode, a third step that a mixed adaptive prediction controller reads model parameters, and generates a control parameter to control motions of an executing mechanism, and a fourth step that a control algorithm is achieved. According to the adaptive prediction control method based on the Hammerstein model, a control system is designed through the control method based on the Hammerstein model, a nonlinear inversion element is introduced, prediction strategy is designed aiming at a linear element, and then the actual controlled quantity is determined through solving of a nonlinear algebraic equation set. Therefore, the calculated quantity of on-line optimization is reduced, and precise effective control over the intermittent chemical process is achieved.

Owner:溧阳常大技术转移中心有限公司

High speed steel finishing roll of wire bar mill and manufacturing method of high speed steel finishing roll

ActiveCN104384193AEvenly distributedImprove bindingRollsMetal rolling arrangementsCrack resistanceChemical composition

The invention discloses a high speed steel finishing roll of a wire bar mill and a manufacturing method of the high speed steel finishing roll, belonging to the technical field of machining and casting. The finishing roll consists of a roll neck and a roll body comprising a working layer, a primary core and a core part; the working layer comprises the following chemical components: 1.50-2.50 percent of C, 0.40-1.00 percent of Si, 0.40-0.80 percent of Mn, less than or equal to 0.03 percent of P, less than or equal to 0.03 percent of S, 4.0-8.0 percent of Cr, 0.50-1.00 percent of Ni, 5.00-8.00 percent of Mo and 5.00-8.00 percent of V. In the casting process, the casting temperature and the rotating speed of a centrifuge can be controlled by adopting manners of high-temperature discharge from a furnace, low-temperature casting, high-speed mold filling and slow-down solidification. According to the high speed steel finishing roll and the manufacturing method of the high speed steel finishing roll, the adaptability of high speed steel materials on bar rolling can be effectively solved by reasonable design of alloy components and the processing technology, and the wear resistance and the millimeter rolling quantity of the roll are improved; in addition, the high speed steel finishing roll has favorable thermal crack resistance, and the working efficiency of a heavy and medium plate mill can be greatly improved.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

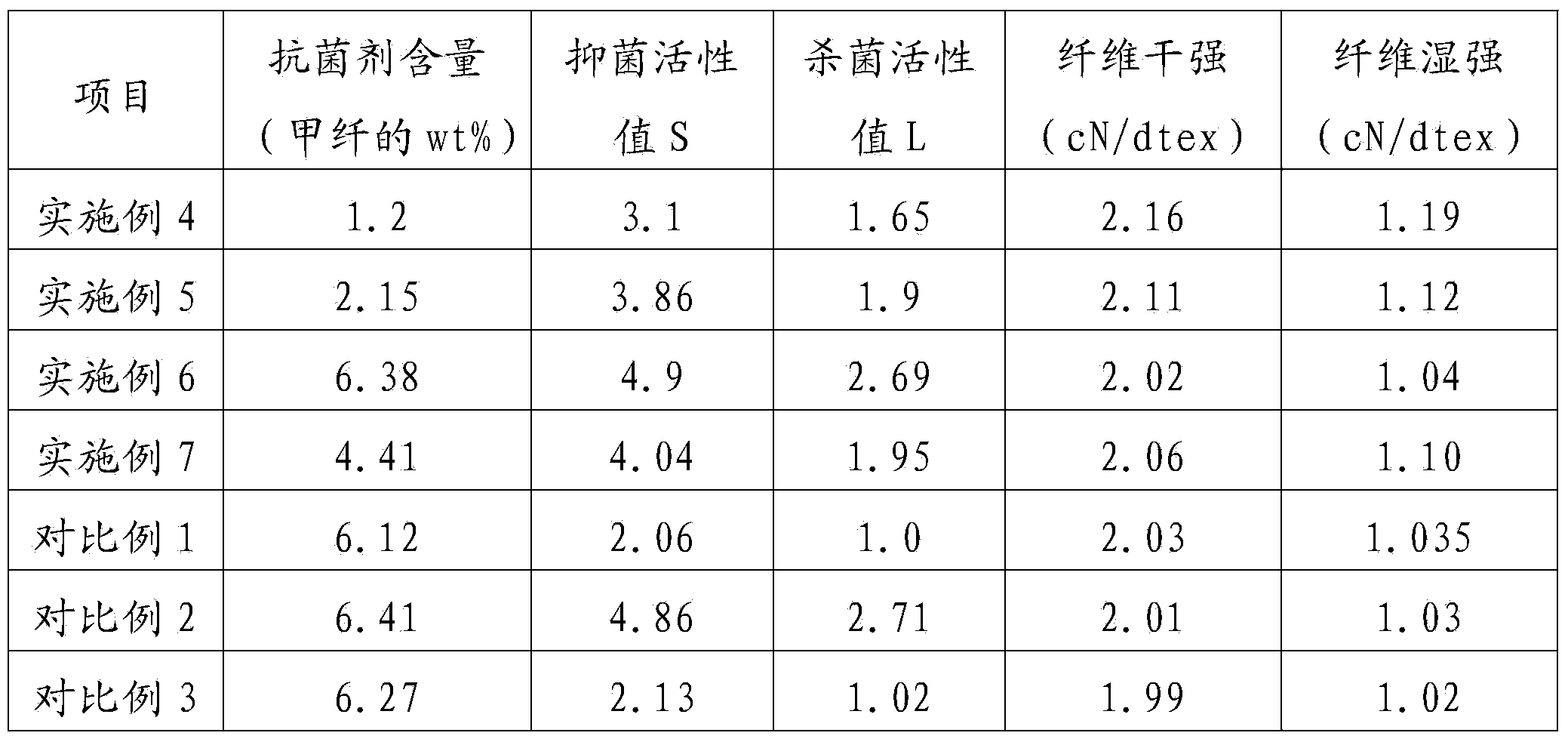

Antibacterial regenerated cellulose fiber and preparation method thereof

ActiveCN103668520ABiodegradablePromote degradationArtificial filaments from viscoseWet spinning methodsBiocompatibility TestingCellulose fiber

The invention discloses an antibacterial regenerated cellulose fiber and a preparation method thereof, and the antibacterial cellulose fiber contains 0.5 ~ 10wt% of chitosan quaternary ammonium salt, the preparation method comprises the following steps: (1) preparing the chitosan quaternary ammonium salt with deionized water and sodium hydroxide into an antibacterial solution; (2) using cellulose pulp as a raw material to prepare spinning viscose; (3) adding the antibacterial solution to a viscose solution of any step from the yellowing step to before spinning, with the adding amount of the chitosan quaternary ammonium salt being 0.5 ~ 10% of the weight of alpha cellulose in the viscose solution, to obtain an antibacterial spinning viscose solution; and (4) obtaining the antibacterial regenerated cellulose fiber by coagulating bath spinning and drawing molding of the antibacterial spinning viscose solution, and then refining and drying. The antibacterial regenerated cellulose fiber simultaneously has biodegradability, biocompatibility, safety and antibacterial property and other excellent properties, and has better moisture absorption and moisture preservation, crease resistance and softness.

Owner:赛得利(盐城)纤维有限公司

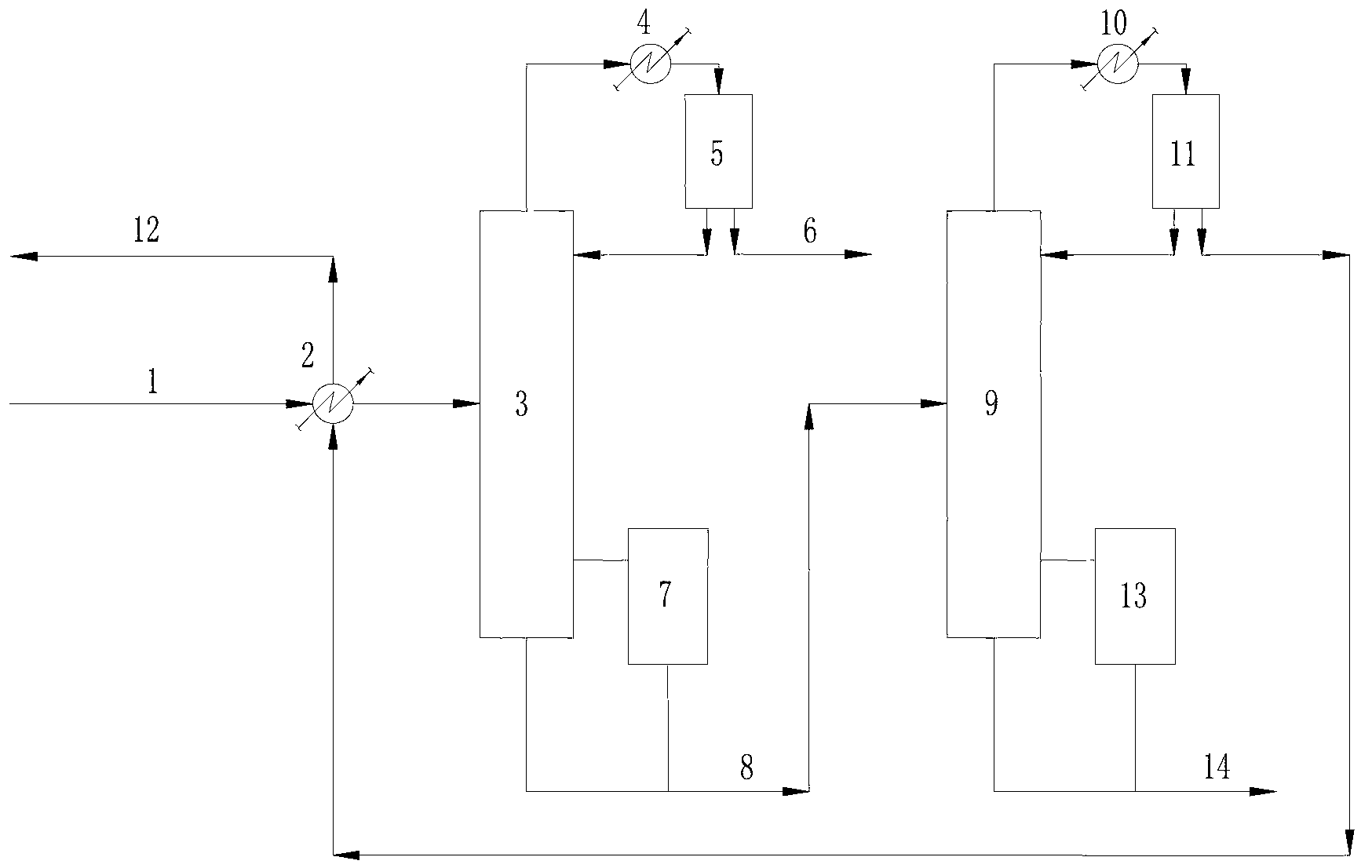

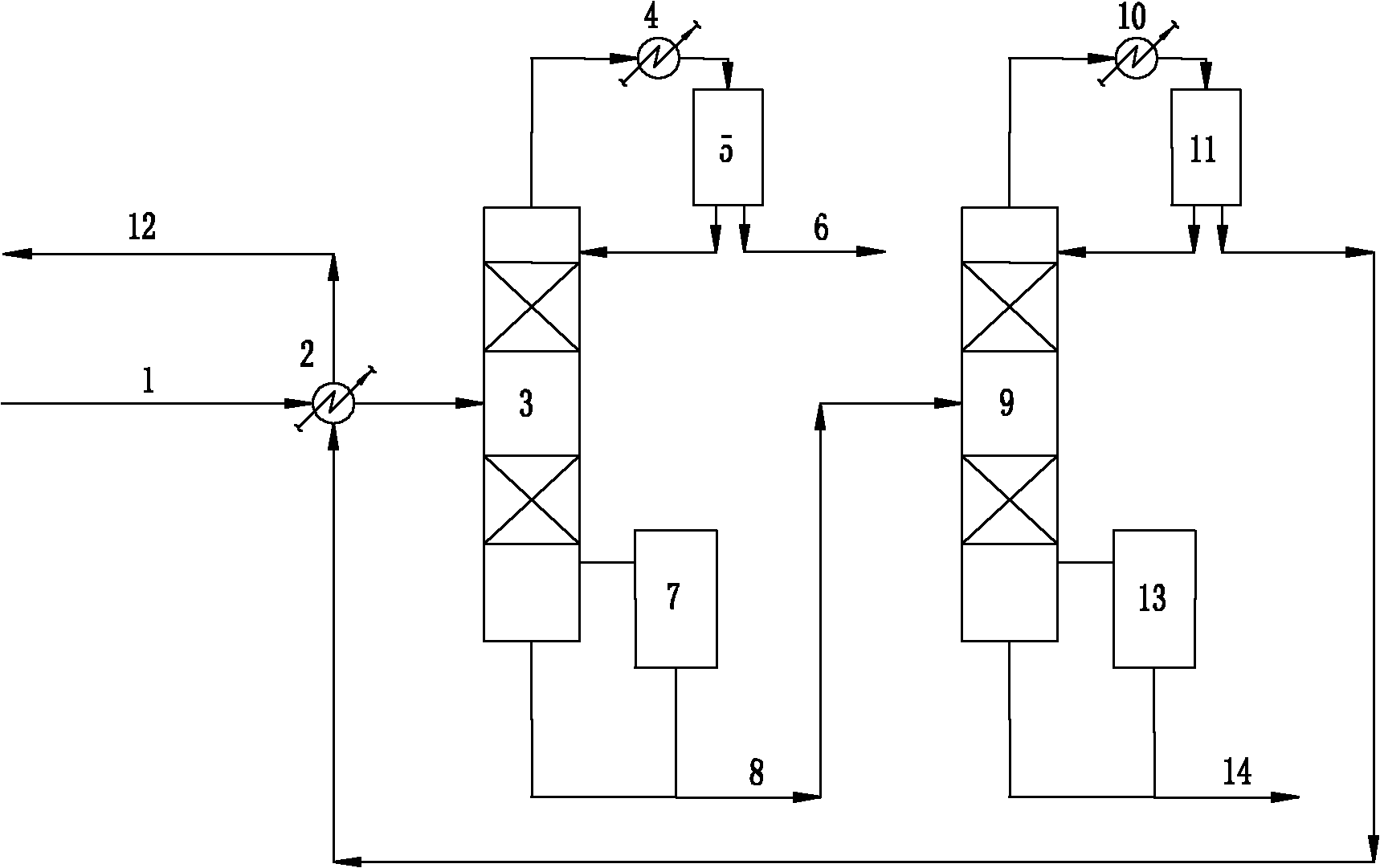

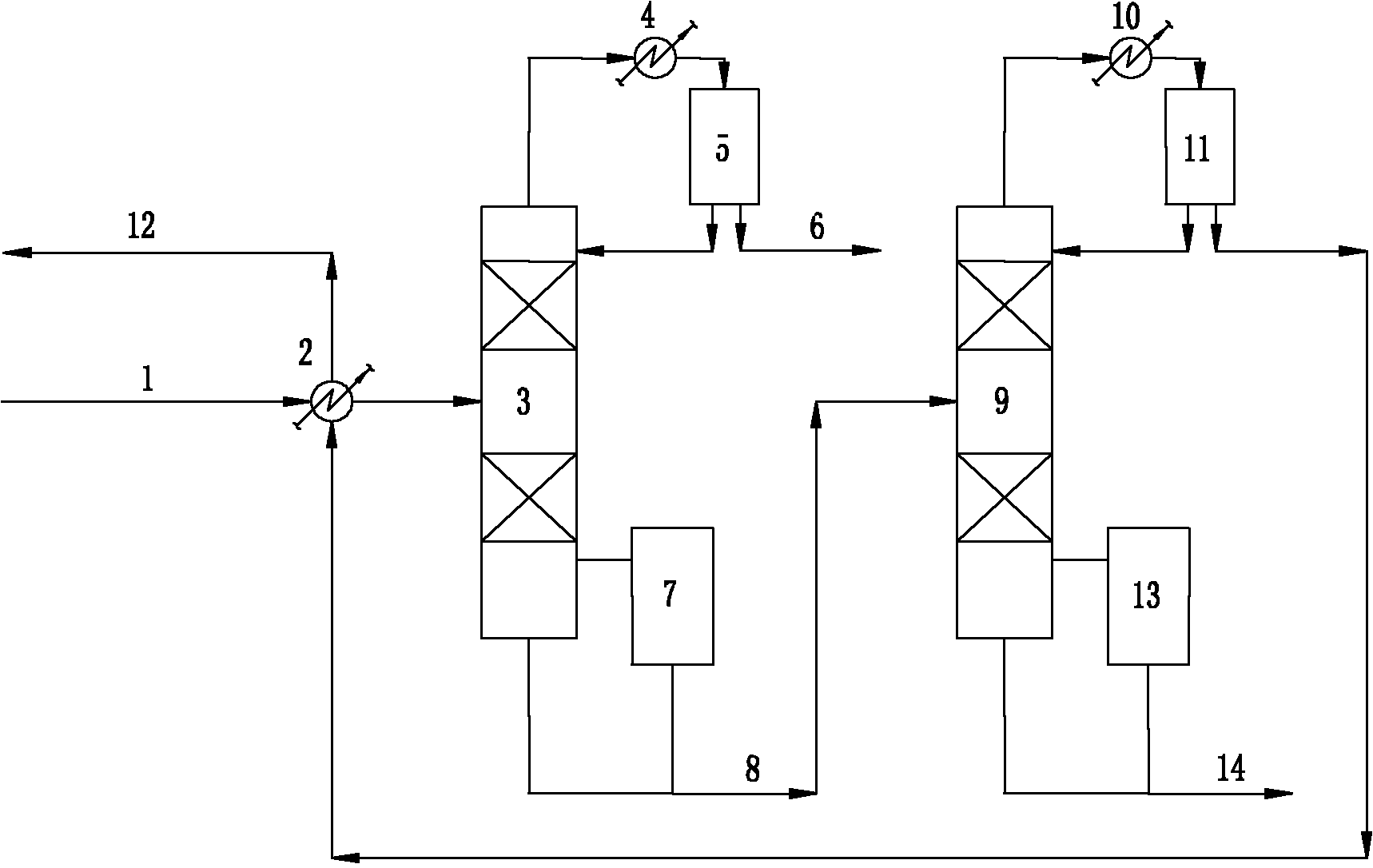

Titanium tetrachloride purification system and method

InactiveCN103011268APlay the role of heat exchangeReduce energy consumptionTitanium halidesTetrachloridePurification methods

The invention relates to a titanium tetrachloride purification system and a titanium tetrachloride purification method, wherein raw titanium tetrachloride material liquid treated by a vanadium removal process is subjected to heat exchange by a preheater and then flows into the middle of a de-light rectifying tower to remove impure light components such as SiCl4 and lose a little amount of titanium tetrachloride; the material flow at the tower bottom contains rather pure titanium tetrachloride and flows into the middle of a de-heavy rectifying tower to remove heavy components such as AlCl3 and FeCl3 and lose a little amount of the titanium tetrachloride; and highly pure titanium tetrachloride is obtained at the top of the tower. The operation pressure at the top of the de-light rectifying tower is the normal pressure, the reflux ratio is 60.0-80.0, and the theoretical stage number is 16-22 in total; and the operation pressure at the top of the de-heavy rectifying tower is the normal pressure, the reflux ratio is 1.0-1.2, and the theoretical stage number is 16-22 in total. The purity of the highly pure titanium tetrachloride is at least 99.99%, and the product recycling rate in the process is higher than 97.0%.

Owner:TIANJIN UNIV

System and method for rectifying and purifying food grade ethyl lactate into electronic grade ethyl lactate

InactiveCN102320969AReduce energy consumptionReduce decompositionOrganic compound preparationCarboxylic acid esters preparationEthyl esterMoisture

The invention discloses a system and method for rectifying and purifying food grade ethyl lactate into electronic grade ethyl lactate. The method comprises the following steps of: performing heat exchange on a food grade ethyl lactate feed solution with a raw material preheater, and making the food grade ethyl lactate feed solution enter the middle part of a lightness-removing column; removing a small quantity of impurity light components and losing a small amount of ethyl lactate; making tower kettle material flow which contains pure ethyl lactate enter the middle part of a weight-removing column; and removing heavy components such as heavy metals and the like and losing a small amount of ethyl lactate to obtain an electronic grade ethyl lactate product on the top of the column, wherein the column top operation pressure of the htness-removing column is 15.0-20.0Kpa, the column bottom operation temperature is 101.0-107.9 DEG C, the reflux ratio is 80.0-120.0, and the theoretical grade is 80-120; the column top operation pressure of the weight-removing column is 6.7-8.0KPa, the column bottom operation temperature is 87.4-90.4 DEG C, the reflux ratio is 3.0-10.0, and the theoretical grade is 90-120 DEG C; the product purity of the electronic grade ethyl lactate is more than or equal to 99.5 percent, the total metal content is less than 100 ppb, the moisture is less than 0.05 percent, and the acidity is less than 0.05 percent; and the product recovering rate in the process is more than 98.0 percent.

Owner:TIANJIN UNIV

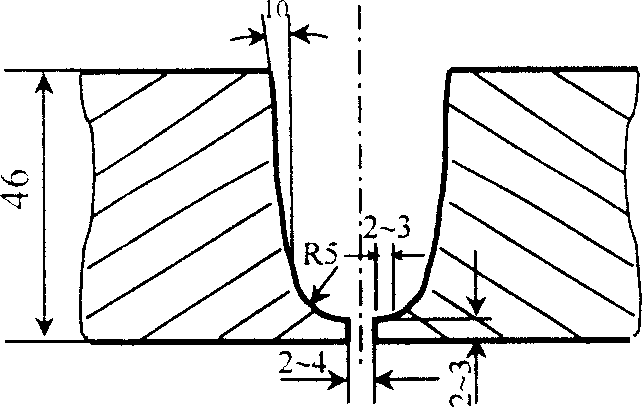

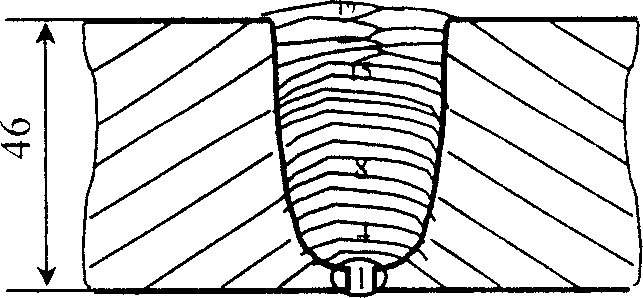

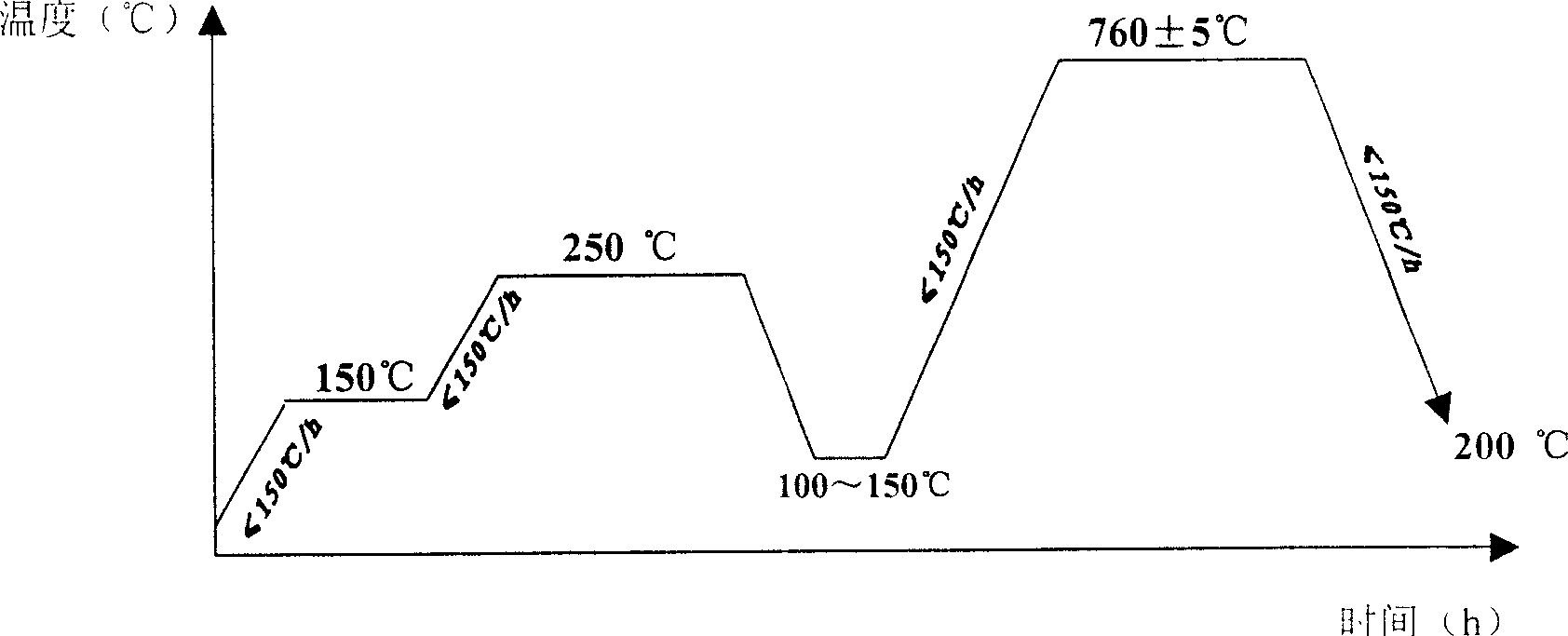

P91 steel welding method

InactiveCN1721118AIncreasing the thicknessReduce thicknessArc welding apparatusBack-fireThermal insulation

This invention provides welding method for P91 steel with basic steps of preheating, back welding with TGS-9CbªŽ2.4 solder wire, filler welding with C9MVªŽ2.5, C9MVªŽ3.2 welding rod and parameters of current 75-140A, welding time for every layer 6-21min, welding preheating temperature 150Deg and welding layer-to-layer temperature 200-300Deg, thermal insulation and thermal treatment. The technique progress can be found from: 1. increase welding current and speed about one times compared with generated method; 2. change layer bead arrangement, decrease welding bead and welding layer thickness convenient to operate, avoid dead angle, prevent welding bug; use layer-to-layer back fire effect to improve metal structure and performance of welding line; 3. come to welding operation standardization and process programming benefit for training and management to workers.

Owner:石家庄电力工业学校焊接培训中心

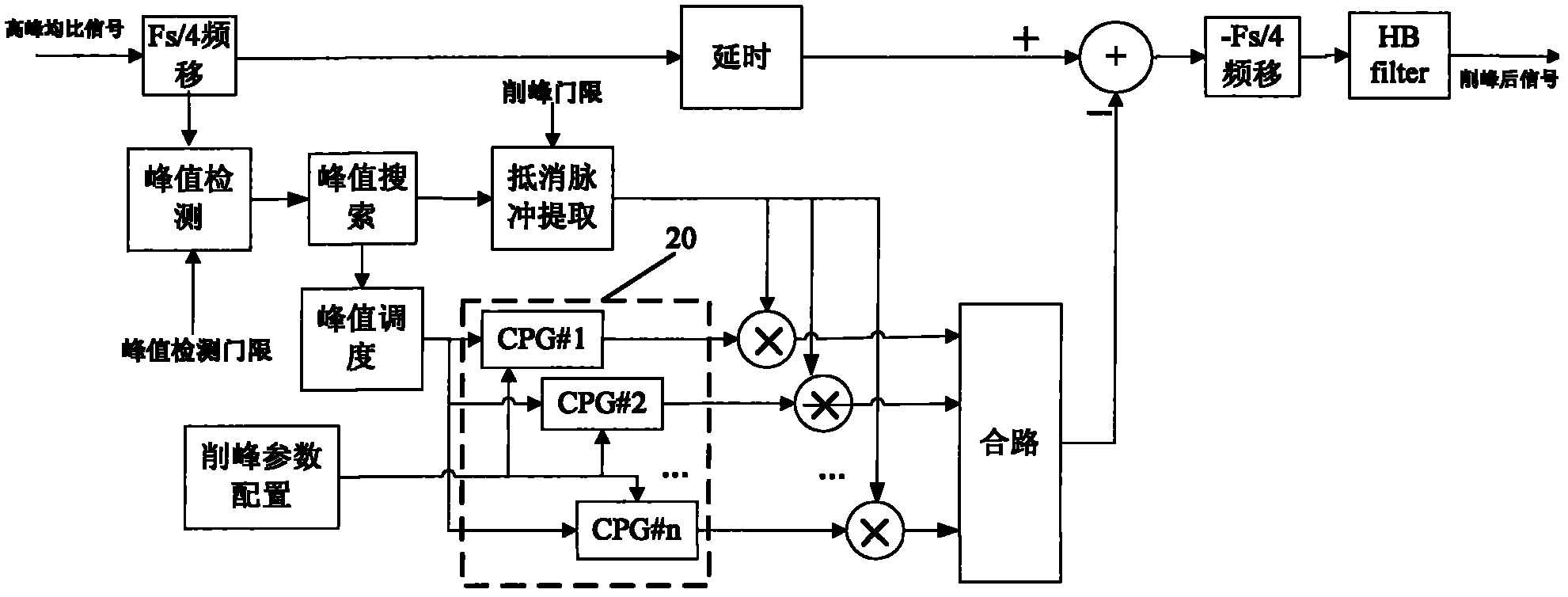

Despiking coefficient update method and device suitable for frequency hopping and power fluctuation system

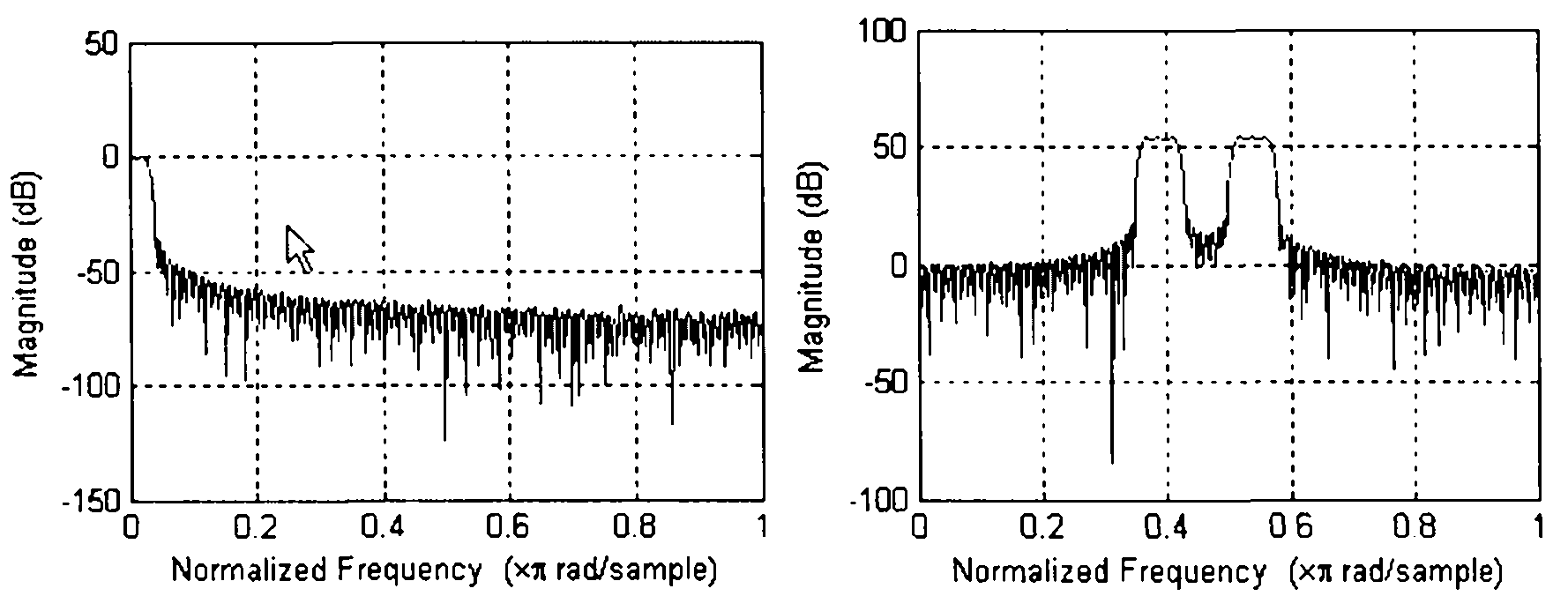

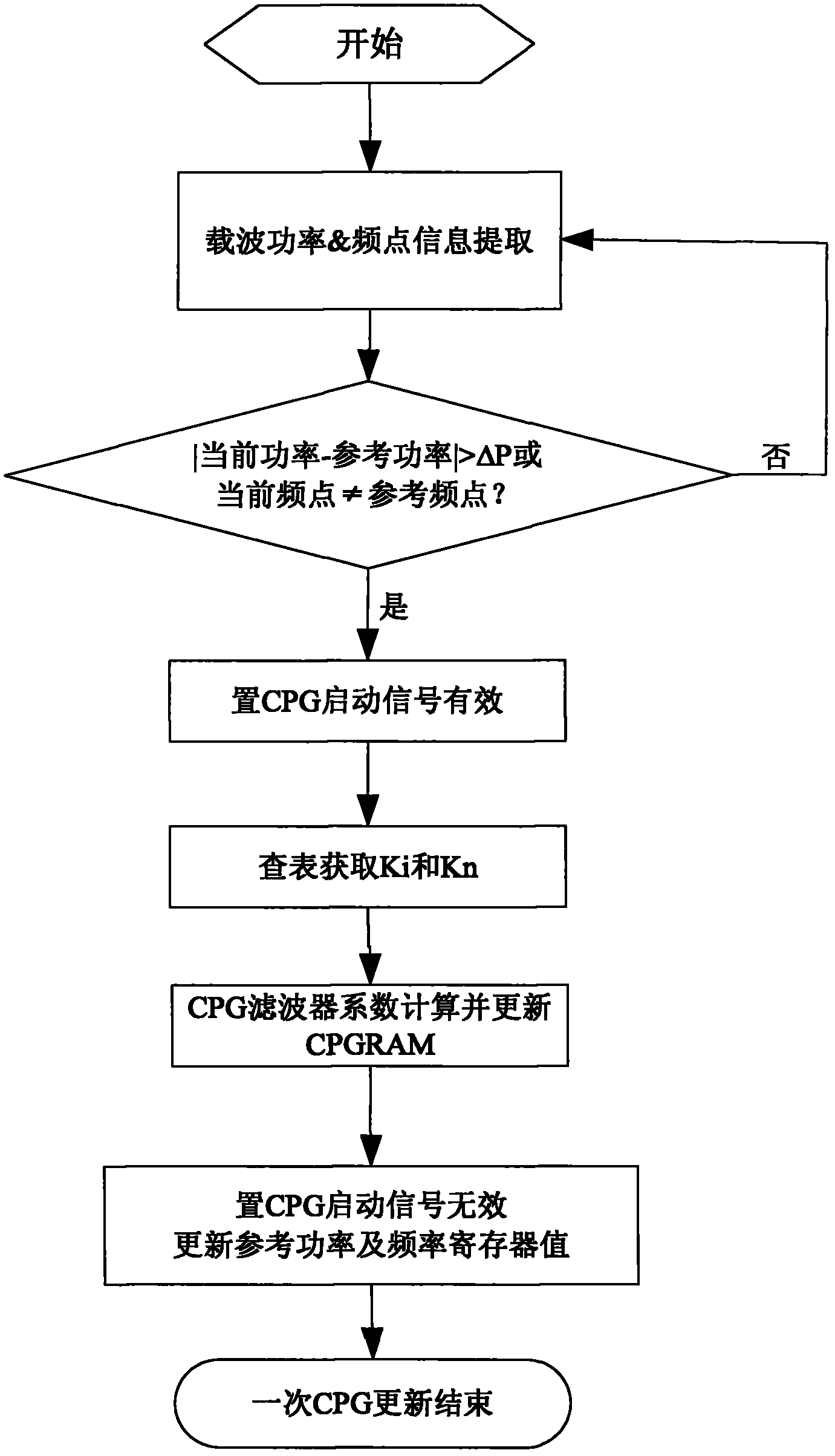

ActiveCN101986636AGuaranteed peak clipping performance indicatorsGuaranteed performance indicatorsMulti-frequency code systemsTransmitter/receiver shaping networksTime domainRelative variation

The invention discloses a despiking coefficient update method and device suitable for a frequency hopping and power fluctuation system. The method comprises the following steps: when any carrier frequency point varies or the relative variation of the carrier power thereof is more than a set value, an offset pulse shaping filter coefficient is generated and the starting signal is updated; the filter power weighted correction factor of each carrier is determined according to the frequency variation of each carrier, the power-weighting calculation of the prototype filter coefficient of each carrier is performed; the cosine signal corresponding to each filter frequency point is generated according to the input frequency control word and phase control word of each carrier, time-domain multiplication-accumulation treatment is performed to the synchronized cosine signal and corrected prototype filter coefficient to obtain the offset pulse shaping filter coefficient; and the normalization, gain compensation and quantification treatment of the offset pulse shaping filter coefficient are performed, and the currently used offset pulse shaping filter coefficient of the system is updated. By adopting the invention, the despiking performance index of the system is matched with the static despiking performance index.

Owner:ZTE CORP

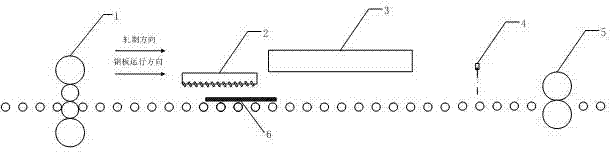

Ultra fast cooling and conventional laminar flow cooling method for medium plate

ActiveCN102513383AVarious control modesAchieve high cooling rate processWork treatment devicesMetal rolling arrangementsSheet steelUltra fast

The invention discloses an ultra fast cooling and conventional laminar flow cooling method for a medium plate, comprising the steps of rolling to obtain a medium plate of 40-100mm; positively and quickly air cooling the medium plate by delivering through a post-rolling cooling device to a straightening machine, inversing a transmission roller motor after the medium plate is straightened, so that the plate is subjected to quick air cooling by the post-rolling cooling device and returned to a post-rolling roller before an ultra fast cooling device by the post-rolling cooling device; controlling a program which calculates the water cooling procedure according to the cooling starting step, ultra fast cooling stopping step, laminar flow cooling stopping step and self-tempering temperature of the rolling process of the medium plate; controlling the ultra fast cooling device or / and a conventional laminar flow cooling device by a process instruction to carry out the cooling program corresponding to the steel plate; allowing the steel plate to pass through the cooling device and the straightening machine and sending to a cooling bed. Great cooling speed, sectional cooling and cooling speed big range adjustable process is realized by using the method provided in the invention, by use of the ultra fast cooling device alone or in combination with the laminar flow cooling.

Owner:NORTHEASTERN UNIV

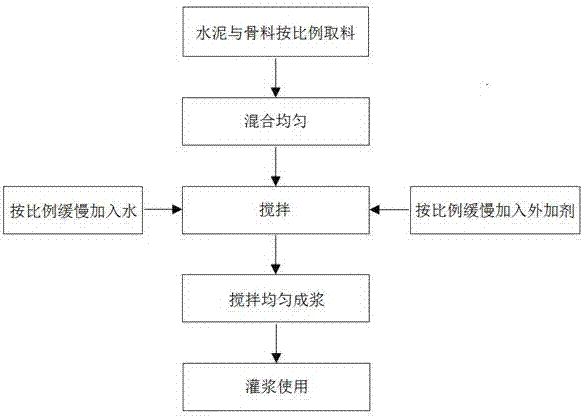

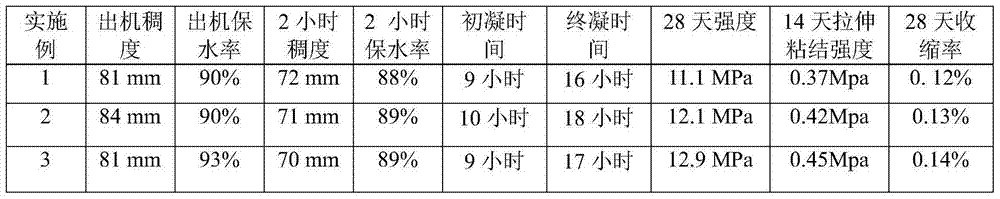

High-performance assembling type construction reinforcing steel bar sleeve grouting material and using method thereof

The invention discloses a high-performance assembling type construction reinforcing steel bar sleeve grouting material and a using method thereof, and belongs to the technical field of building materials. The grouting material consists of the following components in parts by mass: 80 to 100 parts of cement, 0 to 80 parts of quartz sand, 10 to 100 parts of mountain sand or river sand, 5 to 15 partsof an expanding agent, 0 to 1 part of a set retarder, 0.5 to 3 parts of a water reducing agent, 0 to 1 part of a defoaming agent and 15 to 80 parts of steel slag powder. When the grouting material isused, the cement, the quartz sand and steel slag are uniformly mixed in proportion first, then 2 to 3 times of water is added slowly, the materials are stirred, the expanding agent, the set retarder,the water reducing agent and the defoaming agent are added in proportion in a stirring process, and after the materials are stirred uniformly into the grouting material, the grouting material can beused. According to the grouting material, the quartz sand is partially or completely replaced by adopting the river sand or the mountain sand, the using of complex admixtures is reduced, and industrial waste steel slag is added, so that the performance of the grouting material can be maintained, and meanwhile, the cost is greatly reduced; therefore, the grouting material is suitable to be widely applied in an assembling type construction reinforcing steel bar sleeve grouting material.

Owner:云南鼎安翔农业产业发展股份有限公司

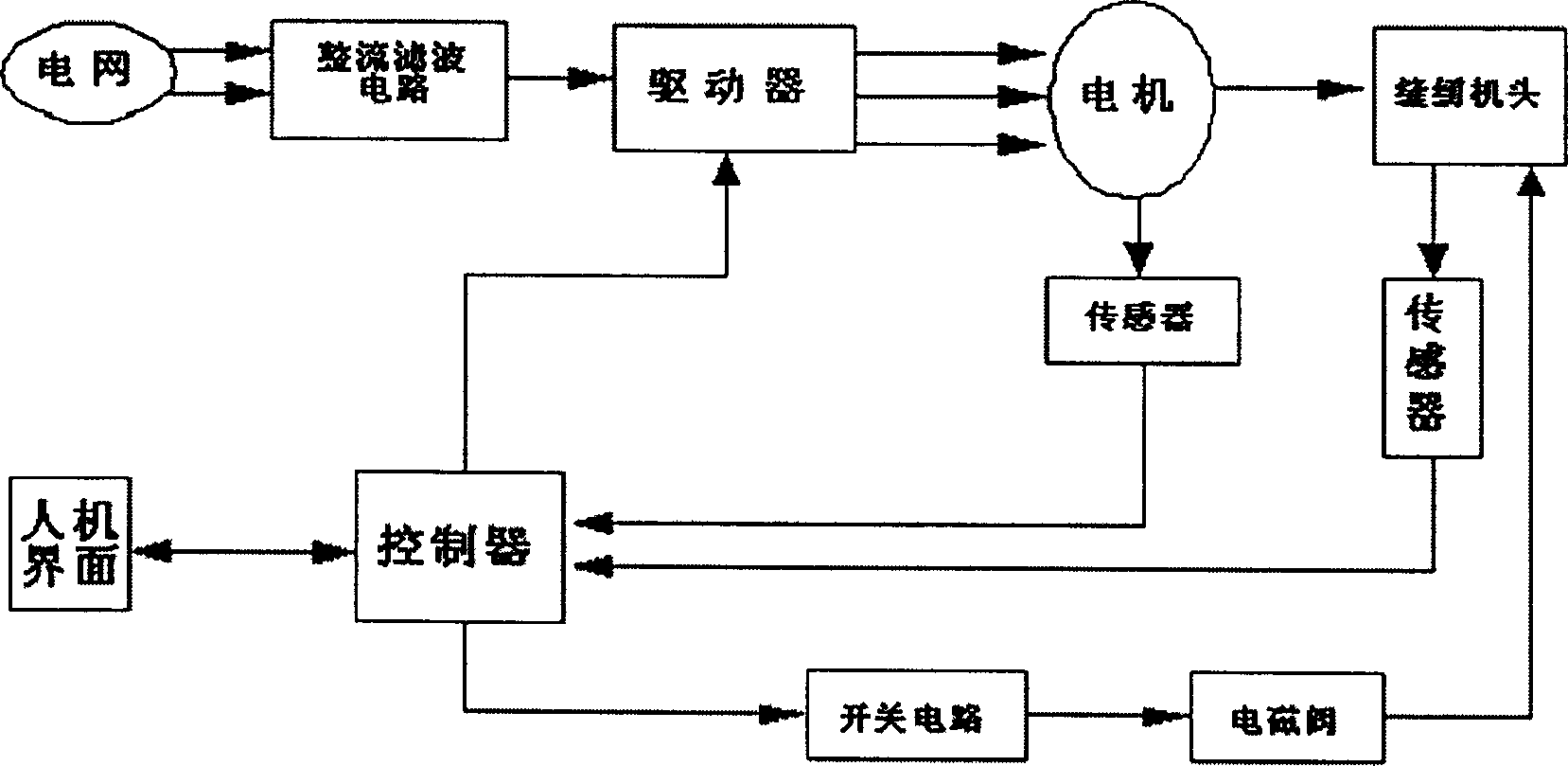

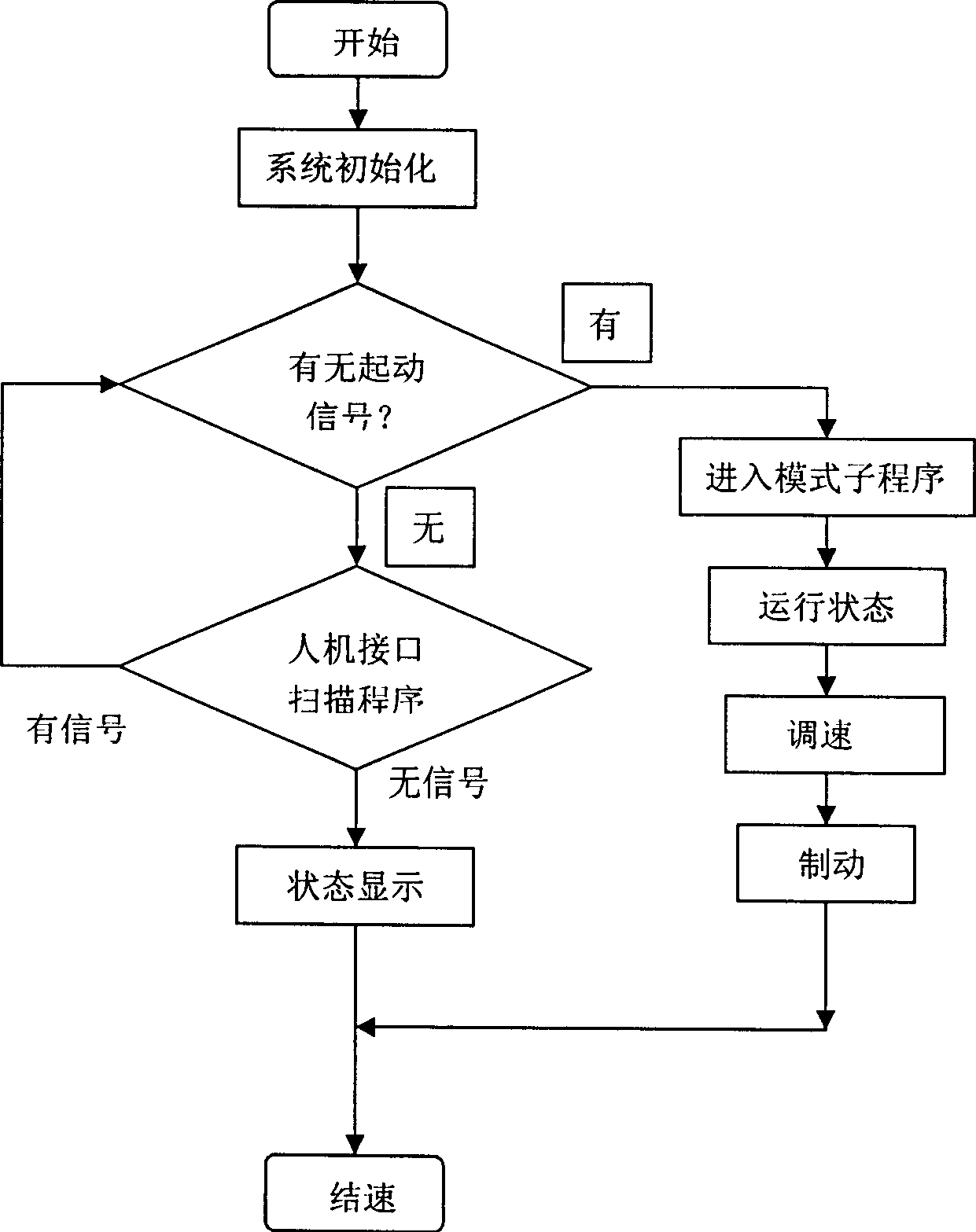

Servo system for sewing machine

InactiveCN1702222AImprove power utilizationHigh speedSewing-machine control devicesHuman–machine interfaceMan machine

This invention relates to a seamer follow-up system, which applies the three-phase continuous brushless current dynamo. The dynamo is connected with an electrified wire netting through the rectifier filter circuit and the driver, and connected with the seamer head, in addition to the controller through the sensor, while the seamer head connects to the controller through the sensor, and the controller export connects to the driver and the seamer head through the switch circuit and the magnetic valve, the input information of the controller is acquired by the man-machine interface.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

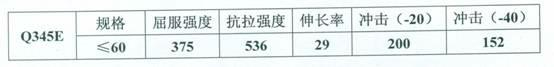

Low-alloy Q345E medium plate and production process thereof

InactiveCN102041442AGuaranteed matching of strength and plasticityLow heating temperatureTemperature control deviceProcess efficiency improvementAlloy elementSteel plates

The invention discloses a low-alloy Q345E medium plate produced without adding micro-alloy element and a production process thereof. The low-alloy Q345E medium plate comprises the following chemical components in percentage by weight: 0.13-0.19% of C, 0.20-0.50% of Si, 1.30-1.60% of Mn, less than or equal to 0.020% of P, less than or equal to 0.010% of S, 0.015-0.050% of Als, and the balance of Fe and residual elements. The process disclosed by the invention comprises the following steps: KR (knotted reactor) hot metal pretreatment of high-quality hot metal, processing with a top-bottom combined blowing converter, LF ((ladle furnace) refining, casting blank stack cooling, processing with a heating furnace, rolling, ACC (accelerated cooling) laminar flow cooling, processing with a hot straightener, stack cooling, finishing, external inspection, flaw detection and storage. The invention has the beneficial effects that: compared with the traditional Q345E, precious alloys such as Nb, Ti and the like are not added without changing the carbon equivalent, all performance indexes of Q345E are guaranteed, and the production cost is remarkably reduced.

Owner:NANYANG HANYE SPECIAL STEEL CO LTD

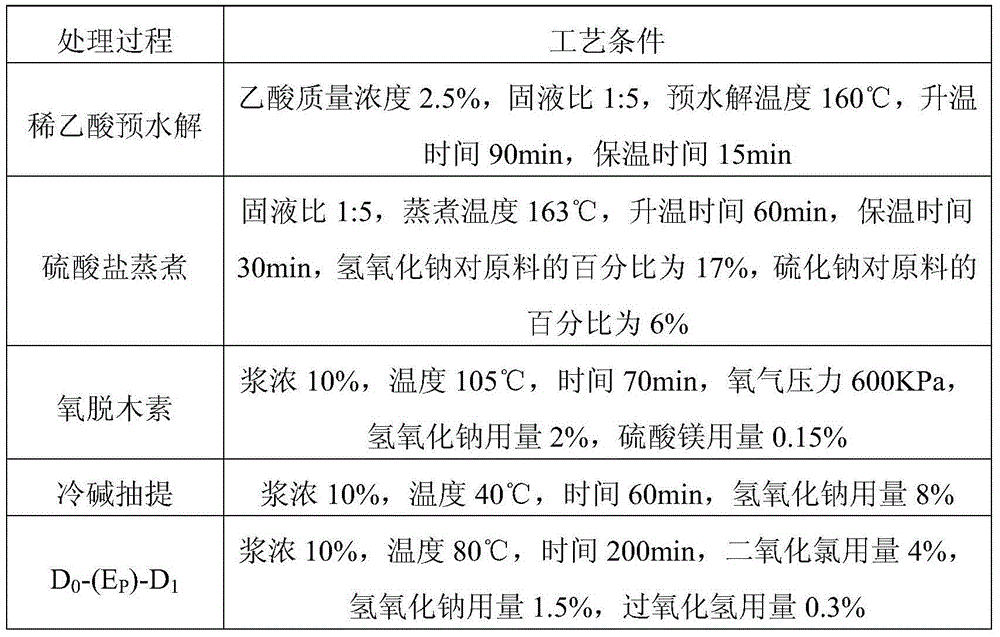

Preparation method of bamboo dissolving pulp

InactiveCN104153229AHigh yieldWeak acidPretreatment with acid reacting compoundsPulp bleachingAcetic acidSulfate

The invention discloses a preparation method of bamboo dissolving pulp. The preparation method disclosed by the invention comprises bamboos as the raw material and comprises the following steps: pre-hydrolyzing bamboo chips through diluted acetic acid, stewing the pre-hydrolyzed raw material with sulphate, processing pulp through oxygen delignification, extracting the pulp with cold caustic, bleaching with D0-(EP)-D1, and thus obtaining the bamboo dissolving pulp. The prepared bamboo dissolving pulp is more than 90% of ISO (International Standardization Organization) in whiteness, more than 92% in content of alpha-cellulose, 959 ml / g in intrinsic viscosity, 3.23% in content of pentosan, 0.11% in content of ash, and 38% in yield; compared with the yield of 30-35% in the common process currently, the yield of the bamboo dissolving pulp disclosed by the invention is at least increased by 3-8%, and therefore, the preparation method of the bamboo dissolving pulp disclosed by the invention has great economic benefit.

Owner:SOUTH CHINA UNIV OF TECH

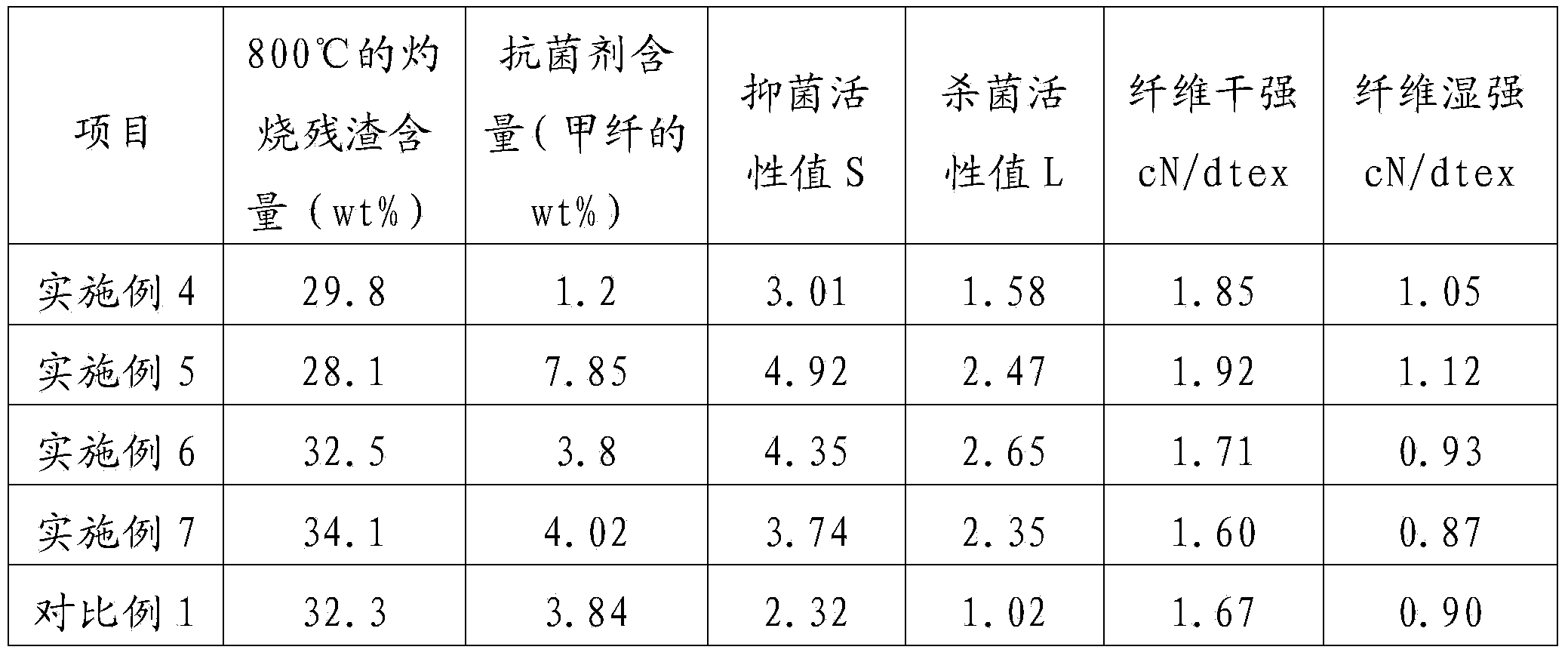

Functional composite fiber and preparation method thereof

ActiveCN103643332AGood antibacterial effectPromote degradationArtificial filaments from viscoseWet spinning methodsCellulose pulpSilicon dioxide

The invention discloses a functional composite fiber and a preparation method thereof. The functional composite fiber comprises 15wt%-45wt% of silicon dioxide and 0.5wt%-10wt% of chitosan quaternary ammonium salt. The preparation method comprises the following steps: (1) preparing an antiseptic solution from the chitosan quaternary ammonium salt, deionized water and sodium hydroxide; (2) preparing alkali cellulose from cellulose pulp, yellowing the alkali cellulose and dissolving the yellowed alkali cellulose in a sodium hydroxide solution of the silicon dioxide, wherein the solid content of spinning viscose containing silicon dioxide is 9.5wt%-11.5wt%; (3) adding the antiseptic solution into the viscose solution containing silicon dioxide in any step from yellowing to spinning to prepare a blended viscose solution, wherein the weight of the chitosan quaternary ammonium salt in the added antiseptic solution accounts for 0.5%-10% of that of the solid in the viscose solution; and (4) performing spinning forming and after-treating on the blended viscose solution to obtain the functional composite fiber. The functional composite fiber prepared by the method has both flame retardant and antibacterial properties.

Owner:赛得利(盐城)纤维有限公司

Method for producing diamond circular saw film base body for mine

InactiveCN101439557AReduce consumptionExpand the scope of processingStone-like material working toolsFilm baseCircular saw

The invention relates to a method for producing a saw blade, in particular to a method for producing a diamond round saw blade substrate used in a mine. The method comprises the steps as follows: materials selecting: straight carbon steel, spring steel and cutlery steel hot rolling medium plate are selected; baiting: the outer diameter of a blank is equal to the outer diameter of a finished product plus 22mm or plus 28mm; central hole drilling: the hole diameter is Phi 50-Phi 90mm; coarse leveling; coarse grinding: a centreless grinder is used for grinding the two side surfaces of the blank to be smoothing, and 0.5-0.8mm of excess is reserved based on the finished product; saw teeth, a fabrication hole and a transmission hole are formed by cutting by laser; central hole finish machining: a boring is used for processing the central hole to the final size; excircle finish machining: a grinding machine tool is used for processing the outer diameter of the saw blade to the final size; smoothing; accurate grinding: the centreless grinder is used for grinding the saw blade to the thickness size required in the drawing; refined smoothing: final correction is carried out on the saw blade after accurate grinding, and the planeness, the total runout and the stress of the saw blade is adjusted comprehensively until the product is qualified. The invention has the advantages of reducing cost and processing difficulty, saving heat-processing equipment, saving energy and being environment-friendly.

Owner:TANGSHAN METALLURGICAL SAW BLADE

Novel high-speed train pantograph sliding block material

InactiveCN102618771AMeet the performance requirements of the pantograph sliderMeet performance requirementsNon-rotary current collectorContactsOperational costsPerformance index

The invention relates to a novel high-speed train pantograph sliding block material, belonging to the technical field of metallic functional materials. The novel high-speed train pantograph sliding block material is characterized in that the alloy material comprises the following compositions in mass percent: 7-13 percent of Ti3SiC2, 0.9-3.1 percent of C and the balance of Cu. A pantograph sliding block which is made of the material provided by the invention has the advantages of excellent friction antifriction performance, good self-lubricating performance, good conductive performance, good arc burning loss resistance, good weather resistance, higher strength and rigidity, simple manufacturing process, good machining performance and low cost. When the material is used for a conductive system of a high-speed train, the conductive system can adapt to severe environments such as high temperature, high speed, heavy load, large impact and poor lubrication, the performance indexes of the high-speed train sliding block are realized, and the material is of a great practical significance to guaranteeing the safety and the normal work of the train and reducing the operating cost of a high-speed railway system.

Owner:TONGJI UNIV

Wet-mixed masonry mortar prepared by adopting aggregate chips

ActiveCN104496327AEasy to get materialsLow priceSolid waste managementCarboxymethyl celluloseSodium Bentonite

The invention discloses wet-mixed masonry mortar prepared by adopting aggregate chips. The wet-mixed masonry mortar comprises the following components in parts by weight: 18-22 parts of cement, 6-8 parts of pulverized fuel ash, 5-7 parts of mineral powder, 22-25 parts of water, 135-145 parts of aggregate chips and 0.5-2.0 parts of a mortar admixture, wherein the particle size of the aggregate chips is not more than 4.75mm; the mountain flour in the aggregate chips accounts for 2-3 percent by weight; the mortar admixture serves as a thickening agent; the thickening agent comprises the following components in parts by weight: 2-4 parts of a sulfonic acid type air entraining agent, 10-20 parts of a melamine water reducing agent, 1-3 parts of soft sugar, 1-3 parts of a water repellent, 4-6 parts of sodium carboxymethyl cellulose and 40-60 parts of sodium bentonite. The machine-made sand and river sand are replaced by residual aggregate chips after stone processing, the aggregate chips are readily available and low in price, the resources are reasonably utilized, the environmental pollution caused by waste aggregate chips is reduced, and the production cost of the mortar is reduced.

Owner:青岛磊鑫混凝土有限公司

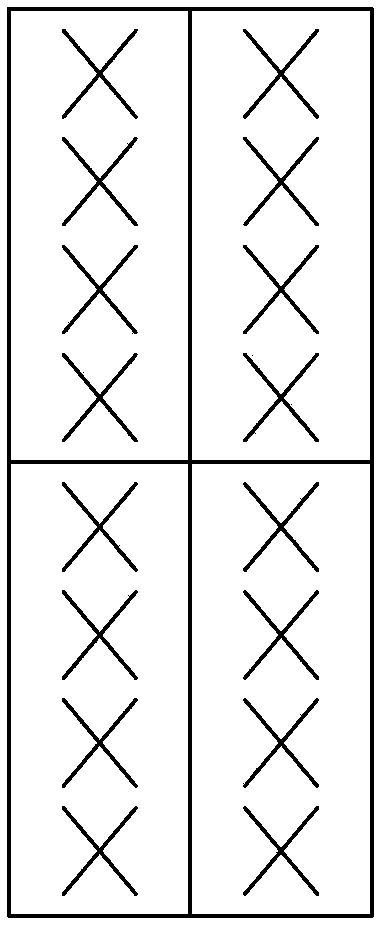

Multi-input multi-output antenna device

ActiveCN104143698AGuaranteed performance indicatorsImprove applicabilityRadiating elements structural formsPolarised antenna unit combinationsMulti inputElectricity

The invention relates to a multi-input multi-output antenna device. The multi-input multi-output antenna device comprises a baffle board, at least two first dual-polarization array antennas, at least two second dual-polarization array antennas, a feed printed circuit board and a fixed beamforming network, wherein the feed printed circuit board is fixed to a first face of the baffle board, the at least two first dual-polarization array antennas and the at least two second dual-polarization array antennas are fixed to a second face of the baffle board and are connected with the feed printed circuit board, the fixed beamforming network is fixed to the baffle board, the at least two first dual-polarization array antennas and the at least two second dual-polarization array antennas are arranged in an upper and lower mode, and ports, in the +45-degree polarization direction, of the at least two second dual-polarization array antennas and ports, in the -45-degree polarization direction, of the at least two second dual-polarization array antennas form a +45-degree composite beam and a -45-degree composite beam respectively through the fixed beamforming network. According to the multi-input multi-output antenna device, while original performance indexes can be ensured, applicability of application is improved.

Owner:CHINA TELECOM CORP LTD

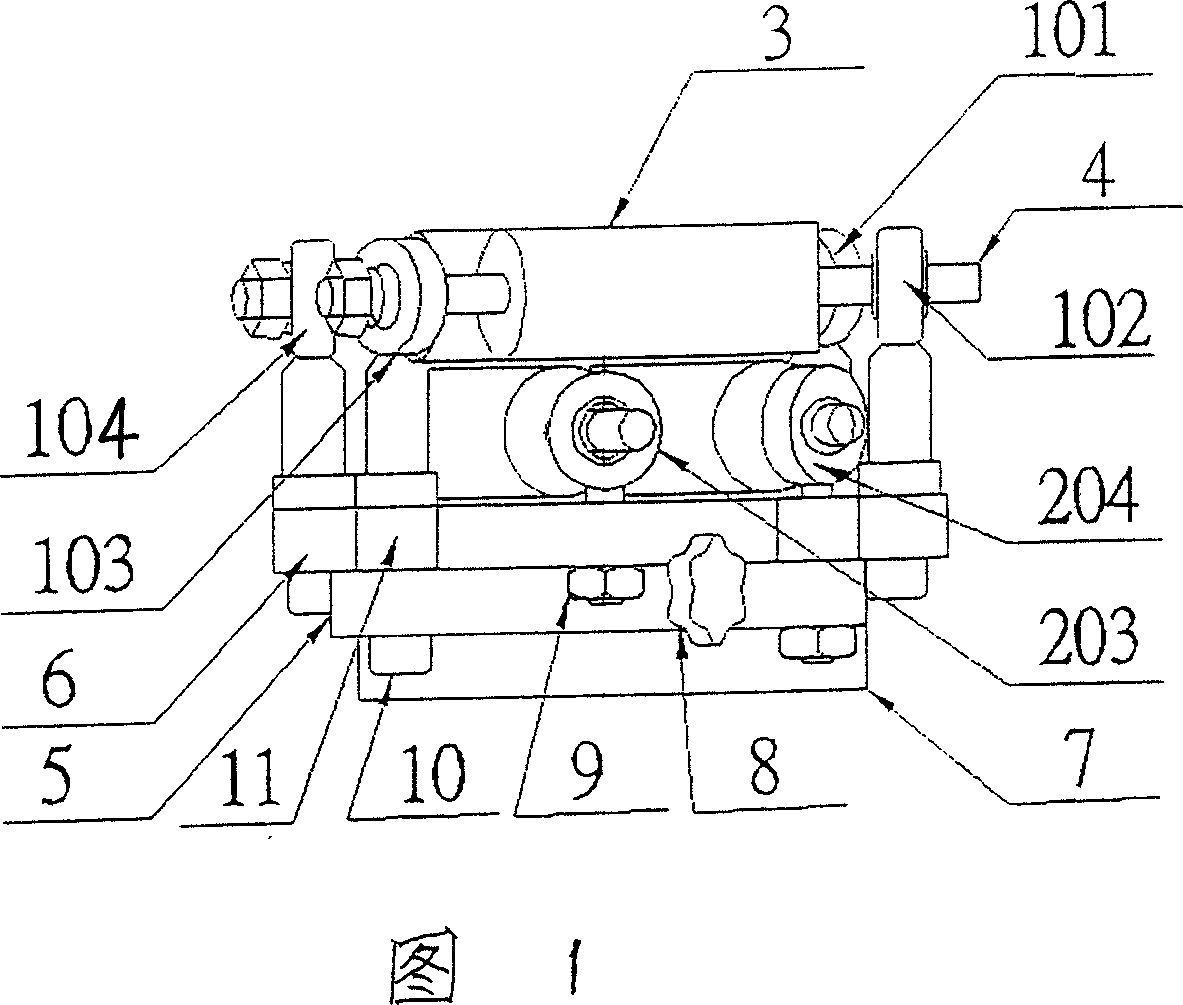

Cable positioning clamping device and regulation

InactiveCN1933039AGuaranteed performance indicatorsNo frequent replacementCable/conductor manufactureEngineeringSelf-assembly

Cable location and holding equipment and adjust method use for single twist cabling machine and cage stranger. Existing technology adopts eye mould or three guiding rolls, but its adjust isn't easy and the eye mould easily wear out with friction and warm up. In this paper, a well style cable location and holding equipment is made up of four active guiding rolls and relates to inner rifled self-assembly pole-end joint bearing, outside rifled self-assembly pole-end joint bearing, guiding roll combination,guiding roll axes,active seat,up and down fix seat and revolving handle bolt. During the adjust, positive and negative revolving active seat adjusts cable passing hole, adjusts the foursquare hole in the middle of well style made up by parallel guiding roll axes. It saves cost and adjusts easily with credible operation and without continually changing eye mould. Four idler pulleys in well style move with credible with small friction and without warm up to keep each capability of credible.

Owner:百通赫思曼工业(苏州)有限公司

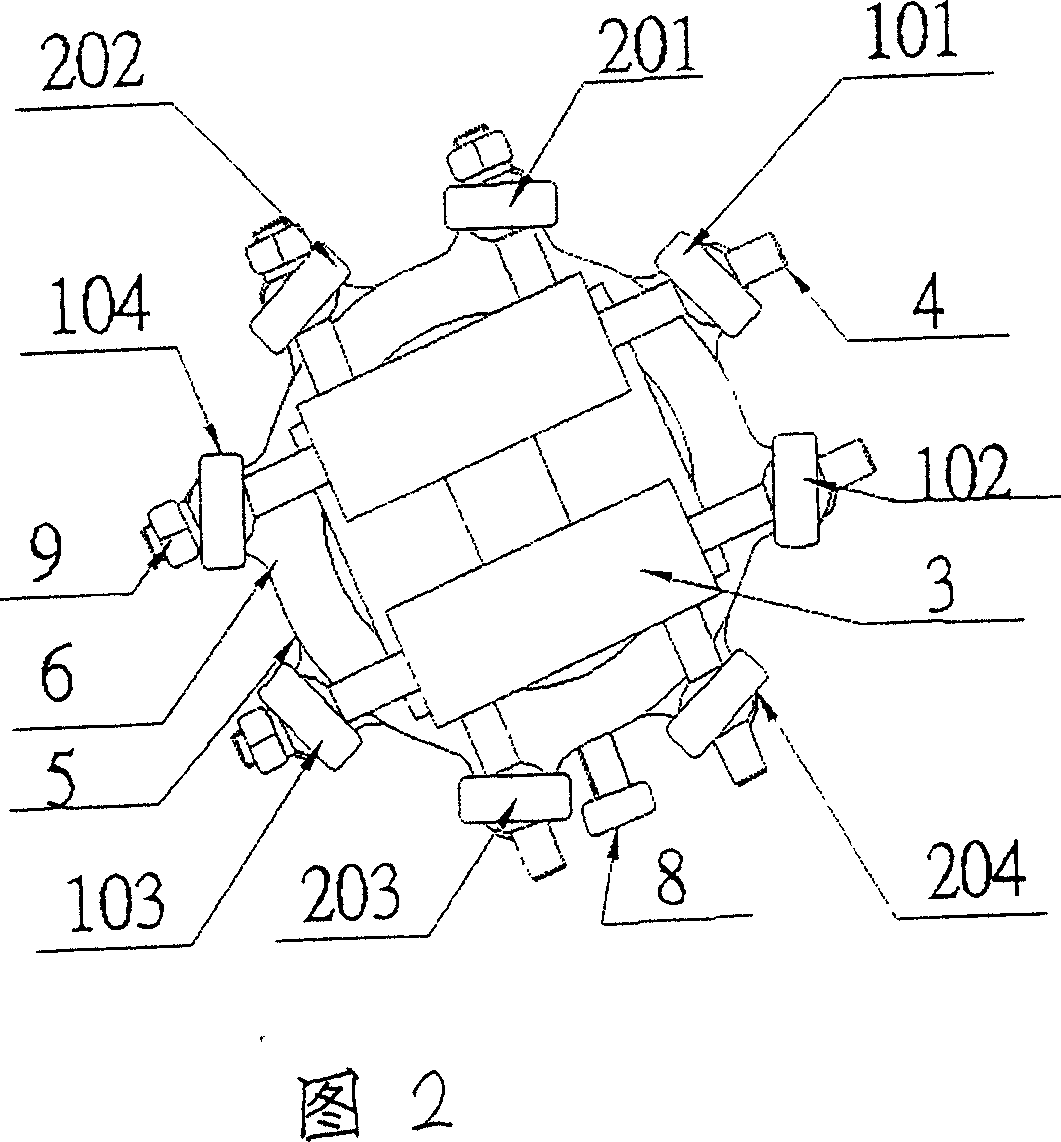

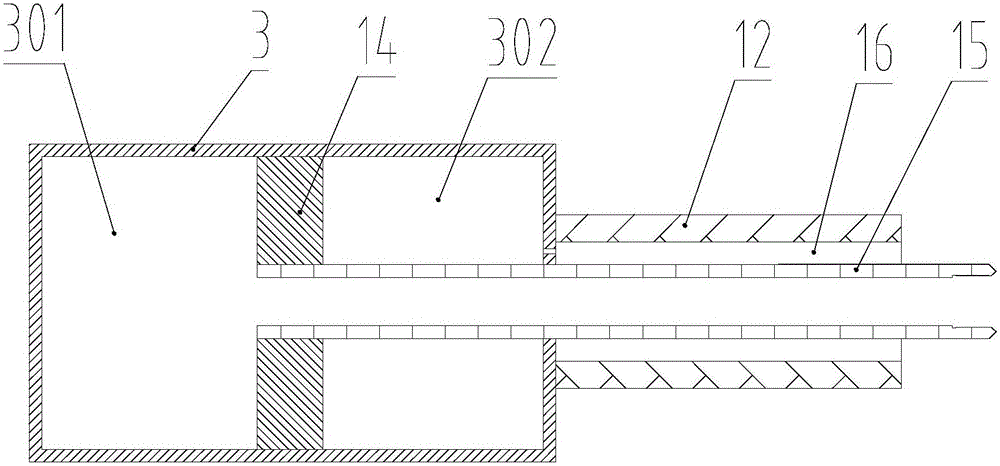

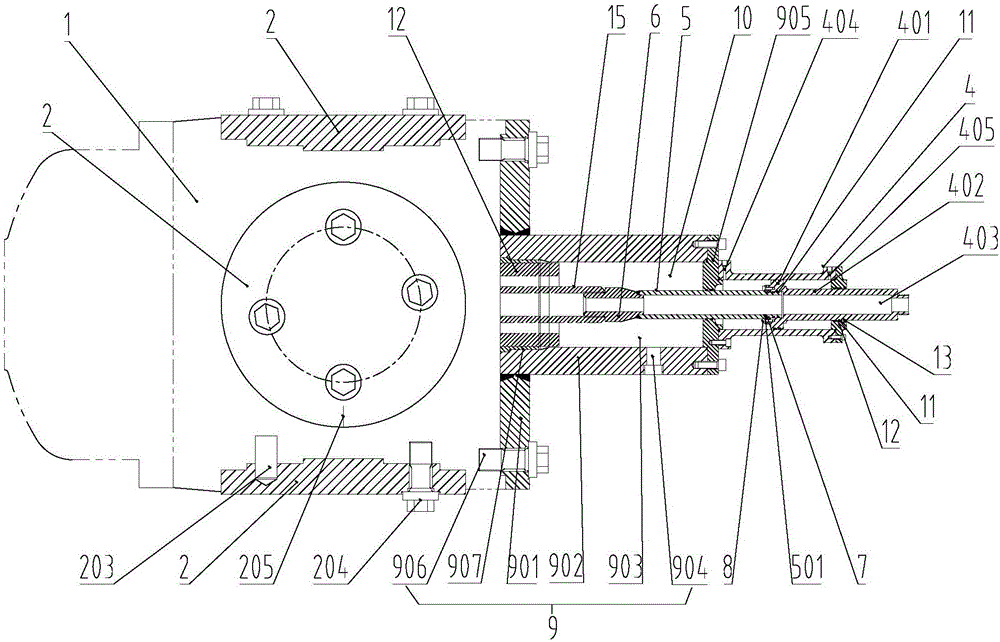

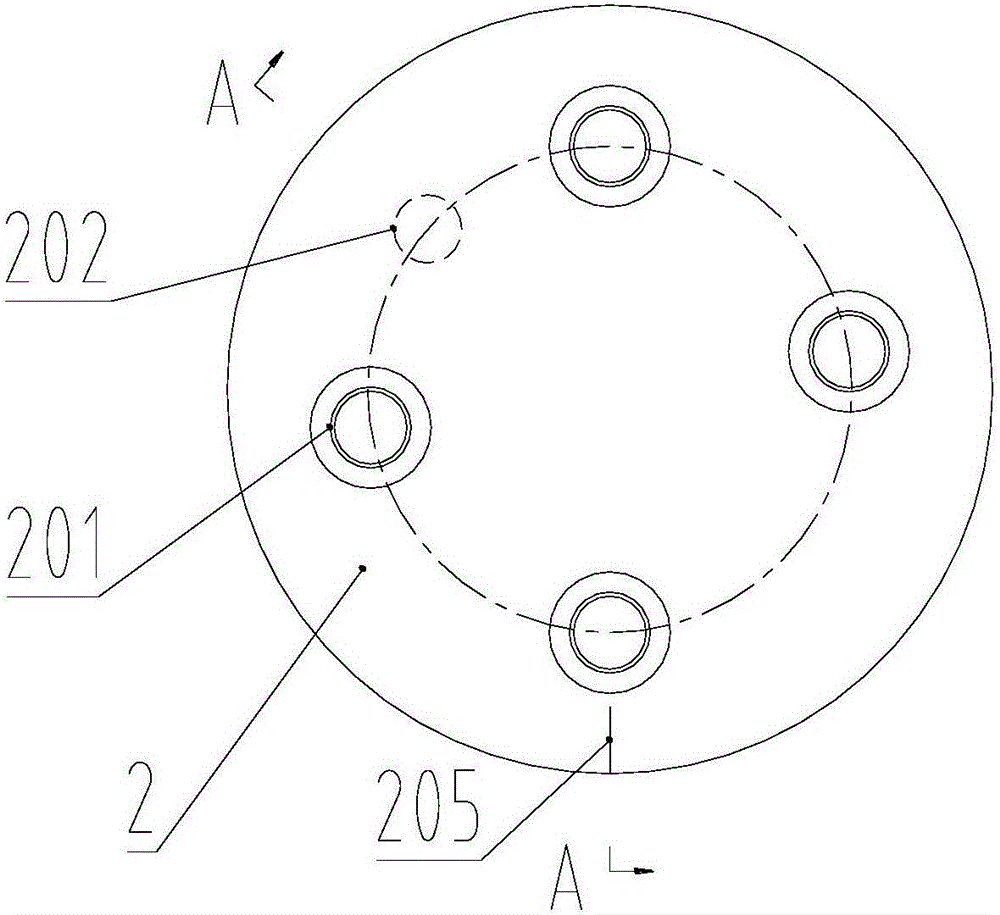

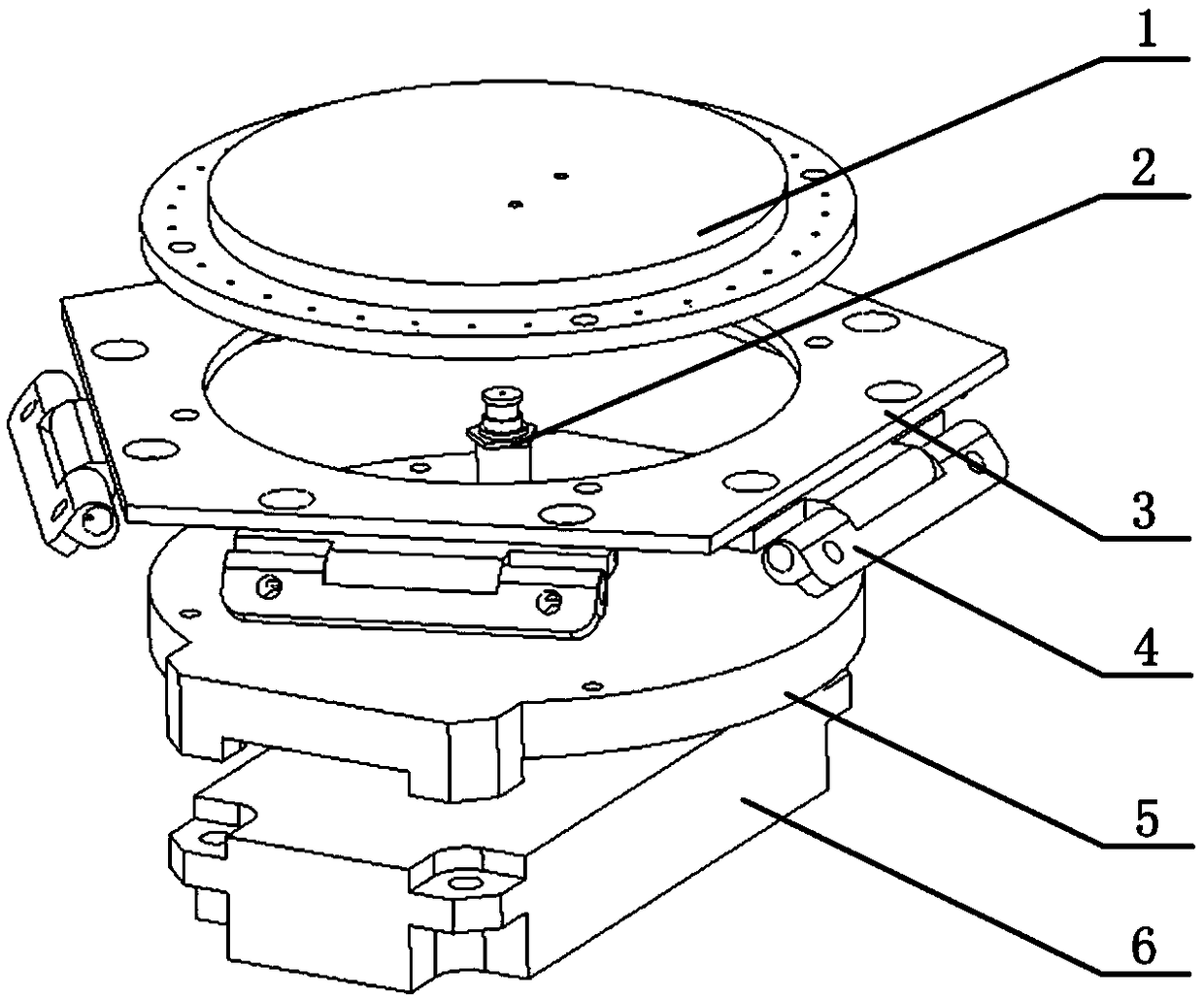

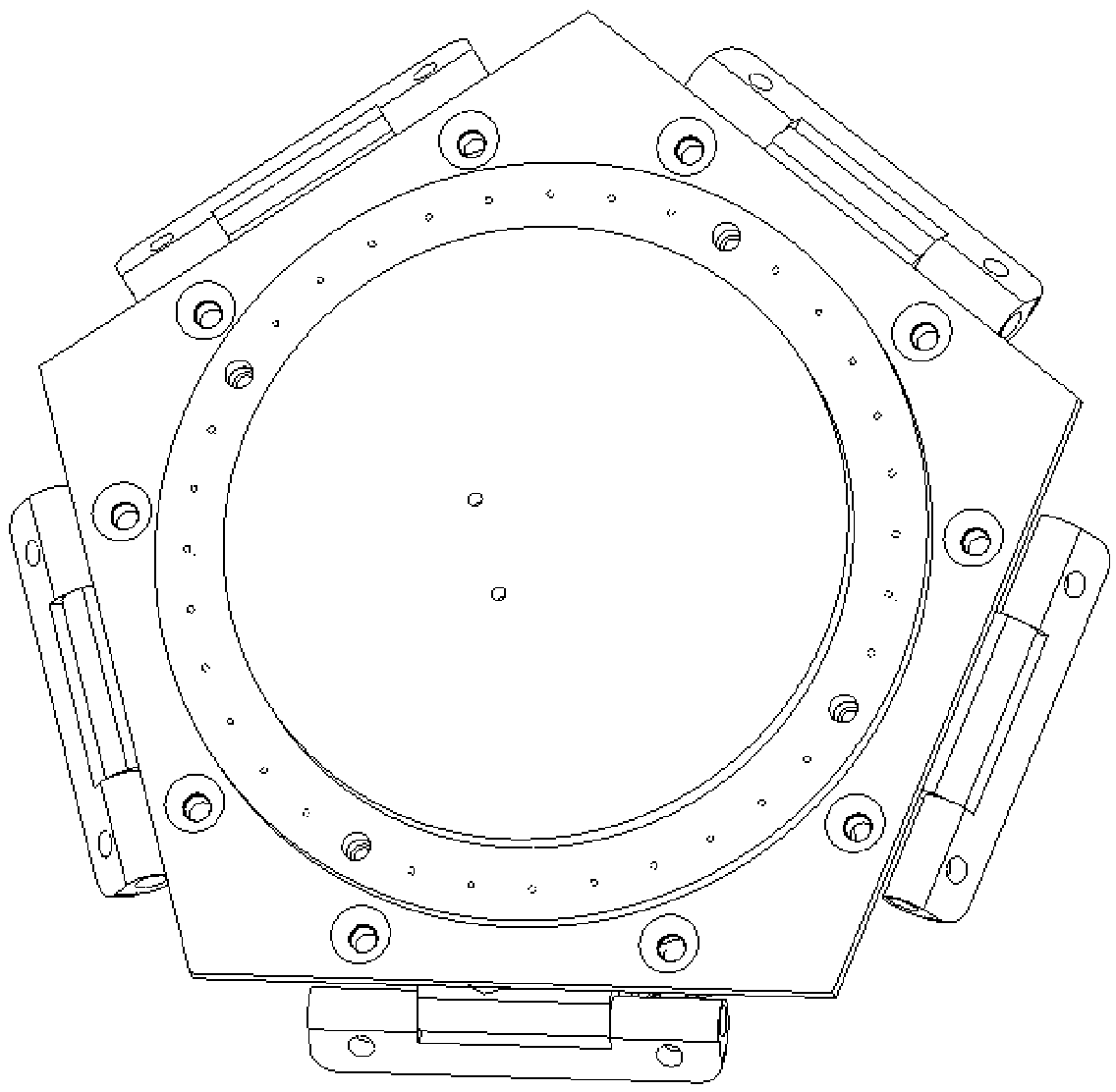

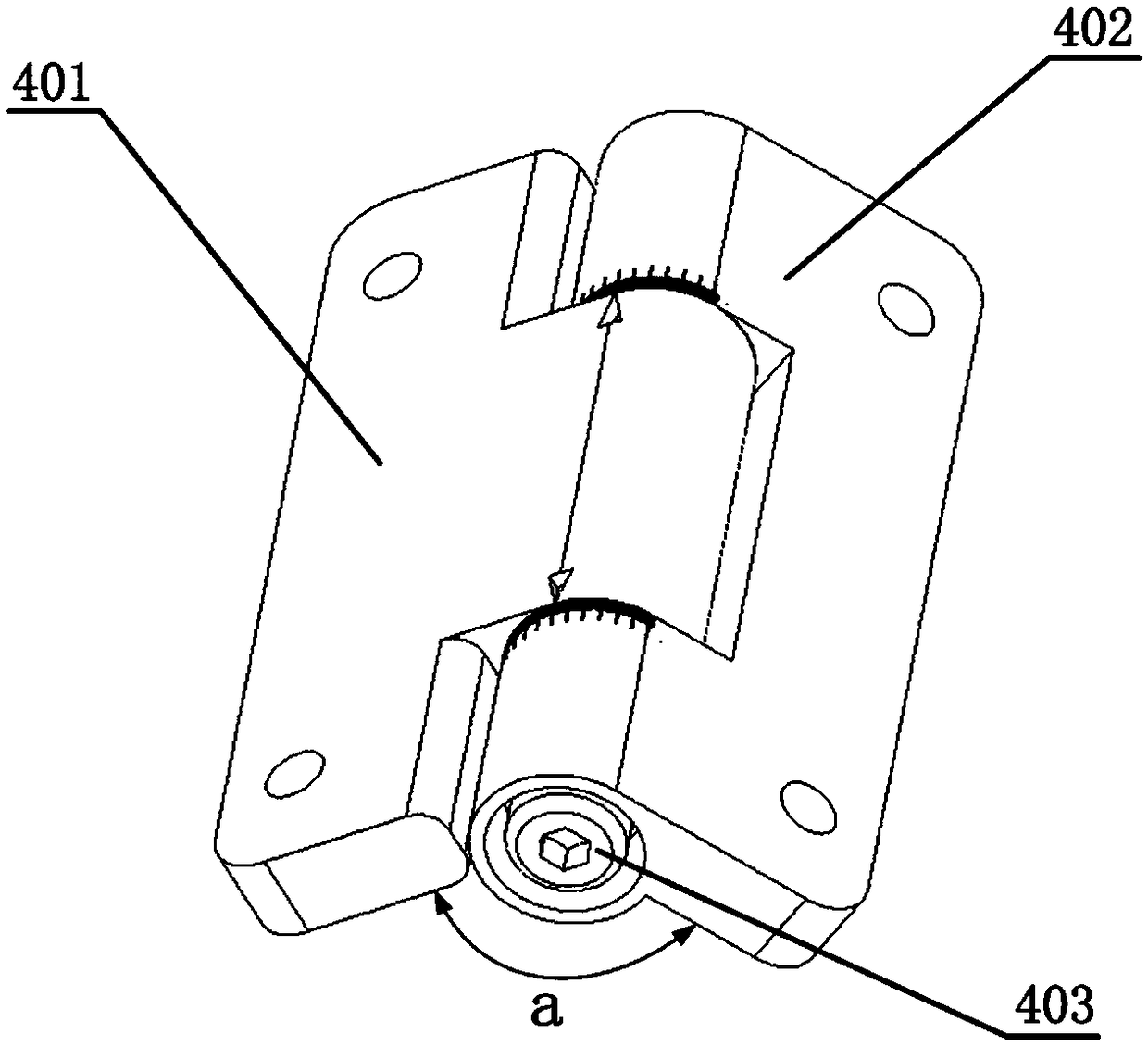

Controllable-pitch propeller hub test device

ActiveCN106546421AChange pitchGuaranteed performance indicatorsMachine part testingPerformance indexOil transportation

The present invention discloses a controllable-pitch propeller hub test device and belongs to the marine machinery field. The device comprises a connecting flange, a connecting oil pipe, a control oil cylinder and a plurality of flange plates; the plurality of flange plates are suitable for being mounted on a hub to be tested so as to be used for simulating blade pitch varying; the connecting flange is suitable for being mounted on an end surface of the hub to be tested and is provided with an oil transportation cavity with an oil transportation opening, wherein the oil transportation cavity is suitable for being communicated with the reverse oil cavity of a pitch varying oil cylinder; one end of the connecting oil pipe is suitable for being connected with and communicated with an oil transportation pipe in the hub to be tested; the control oil cylinder is mounted on the oil transportation cavity; the other end of the connecting oil pipe is connected with the piston of the control oil cylinder; one end of a piston rod is fixedly connected with the piston, and the other end of the piston rod extends out from the control oil cylinder; and a transportation oil channel communicated with the connecting oil pipe is arranged in the piston rod. With the controllable-pitch propeller hub test device of the invention adopted, simulation testing can be performed on an assembled integrated product, so that it can be ensure that the performance index of the product can meet design requirements and use requirements.

Owner:WUHAN MARINE MACHINERY PLANT

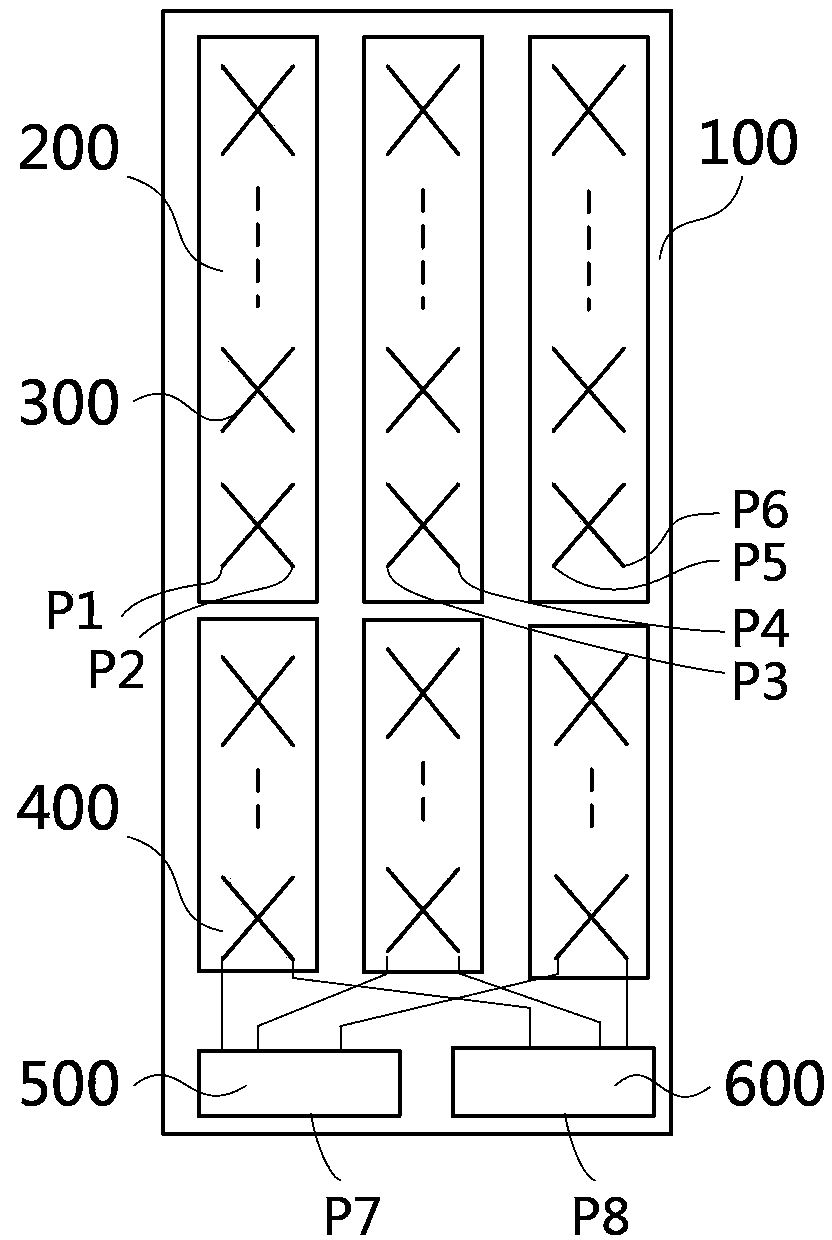

Splicable antenna module for wide area coverage

ActiveCN108832249ALow costEasy to assembleAntenna supports/mountingsAntenna arrays manufactureWide areaEngineering

The invention relates to a splicable antenna module for wide area coverage. The module comprises a radiation unit, a radio frequency connector, an N-polygon splicing substrate, an angle adjustable splicing connector, a heat dissipation module and a TR module, wherein the angle adjustable splicing connector comprises a splicing connector 1, a splicing connector 2 and a rotation locking mechanism. The invention provides a splicable mechanical, electric and thermal integrated design antenna module. The N-polygon splicing substrate is a mounting fixed substrate of the radiation unit, the angle adjustable splicing connector and the heat dissipation module and also is a splicing configuration basis of splicing the antenna module into a plane or a conformal shape. By adjusting the angle a of theangle adjustable splicing connector, the splicing angle requirement of the array antenna can be achieved. The quick splicing of a frameless plane and a conformal array antenna and the angle adjustmentof the conformal antenna are achieved. The size of the antenna module can be adjusted according to needs, thus the overall size of the spliced array antenna is adjustable, and the antenna module is versatile.

Owner:XIAN INSTITUE OF SPACE RADIO TECH

Process for preparing square deflecting magnetic core and material thereof

ActiveCN1547234AReduce manufacturing costGuaranteed performance indicatorsMagnetic deflection device manufactureInorganic material magnetismTelevision receiversElectron

The invention discloses a manufacturing method for a kind of square deflection magnetism core and the materials. 1) the Fe2O3, ZnO, Mn3O4, ...MgO, and additives CuO, Bi2O3 elements are blended, prebaked, and reacted with solid phase, the compound generates the ferrite phase after being prebaked; 2) the prebaked material are grinded into pulp with particle size less than phi1.8ª–m, then the additives are added in and carries on the atomization pelleting; 3) the particles are blended and pressed, formed in the automatic presser and special model; 4) uses the flat board or bake bearing base process to carry on oriented baking. The merits of the invention are: 1) it uses cheap materials ferric oxide, with current manufacturing device and special process, it decreases the cost greatly, the key technology parameter is upgraded; 2) PF design makes the magnetic flow area and the density distributed more reasonable, it upgrades the articulation and resolution of the screen; 3)( upgrades the deflection efficiency of negative transmitting pipe of the television receiver, reduces the idle work consumption of the electron beam deflection.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com