Antibacterial regenerated cellulose fiber and preparation method thereof

A technology of regenerated cellulose and α cellulose, which is applied in the direction of spinning solution preparation, wet spinning method, artificial filament made of viscose, etc., can solve the problems of long production process, large equipment investment and complicated process, etc. Achieve good antibacterial effect, good moisture absorption and moisturizing, long-lasting effect of antibacterial function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

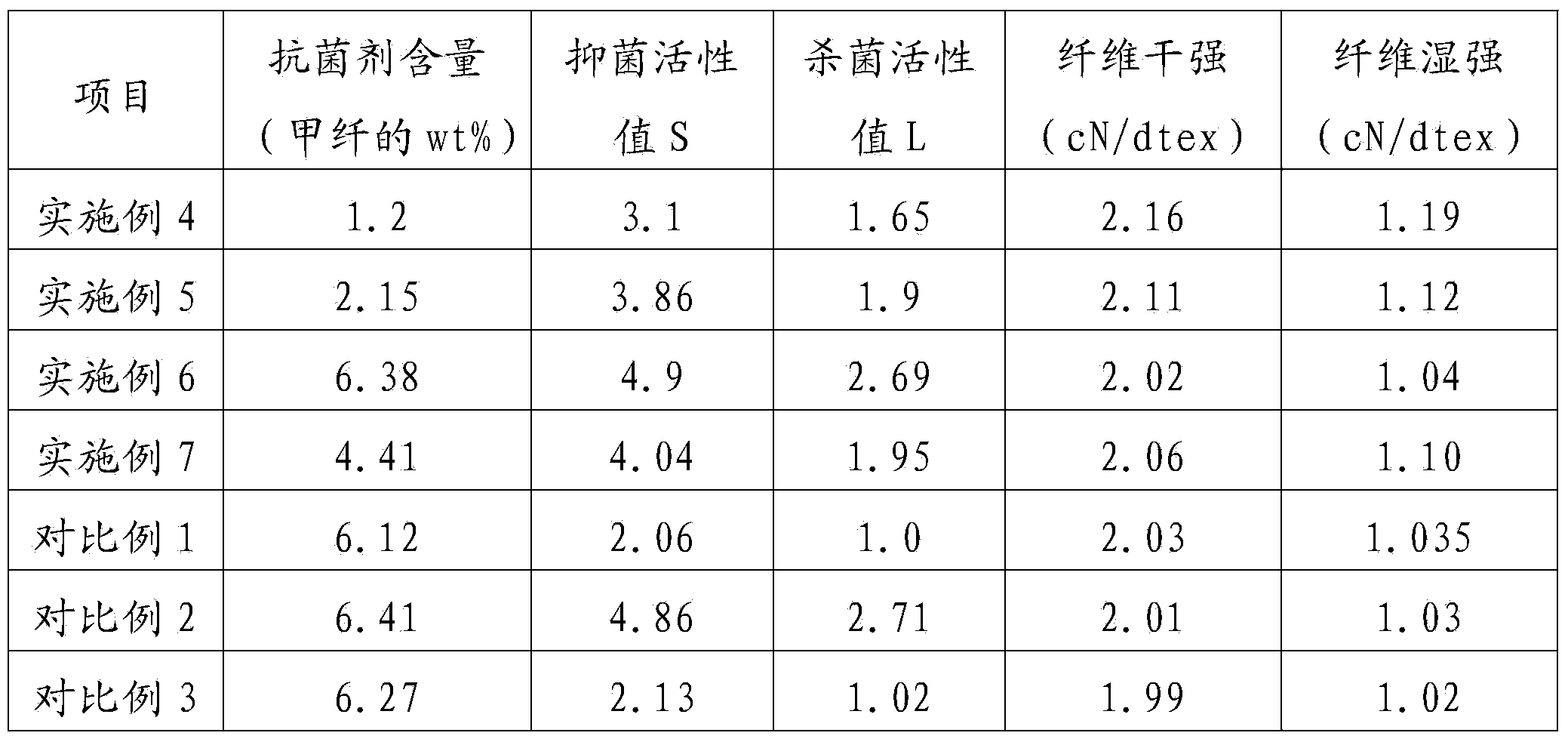

Examples

Embodiment 1

[0031] An antibacterial regenerated cellulose fiber, containing 1.5wt% chitosan quaternary ammonium salt in the described antibacterial regenerated cellulose fiber, the substitution degree of the chitosan quaternary ammonium salt is 85%, and the antibacterial regenerated cellulose fiber The antibacterial activity value is 3.2, and the bactericidal activity value is 1.55.

Embodiment 2

[0033]An antibacterial regenerated cellulose fiber, containing 3.5wt% hydroxypropyltrimethylammonium chloride chitosan in the described antibacterial regenerated cellulose fiber, the substitution of the hydroxypropyltrimethylammonium chloride chitosan The antibacterial regenerated cellulose fiber has a bacteriostasis activity value of 4.2 and a bactericidal activity value of 2.58.

Embodiment 3

[0035] A kind of antibacterial regenerated cellulose fiber, containing 7.5wt% hydroxypropyl alkyl dimethyl ammonium chloride chitosan in the described antibacterial regenerated cellulose fiber, described hydroxypropyl trimethyl ammonium chloride chitosan The substitution degree of the antibacterial regenerated cellulose fiber is 92%, and the antibacterial activity value of the antibacterial regenerated cellulose fiber is 3.95, and the bactericidal activity value is 1.9.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com