Cable positioning clamping device and regulation

A clamping device and cable technology, which is applied in the direction of cable/conductor manufacturing, electrical components, circuits, etc., can solve the problems that the 360-degree circumferential force of the cable cannot be guaranteed to be uniform, affect the wrapping quality, and restrict the production speed, etc. , to achieve the effect of small friction, no temperature rise and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

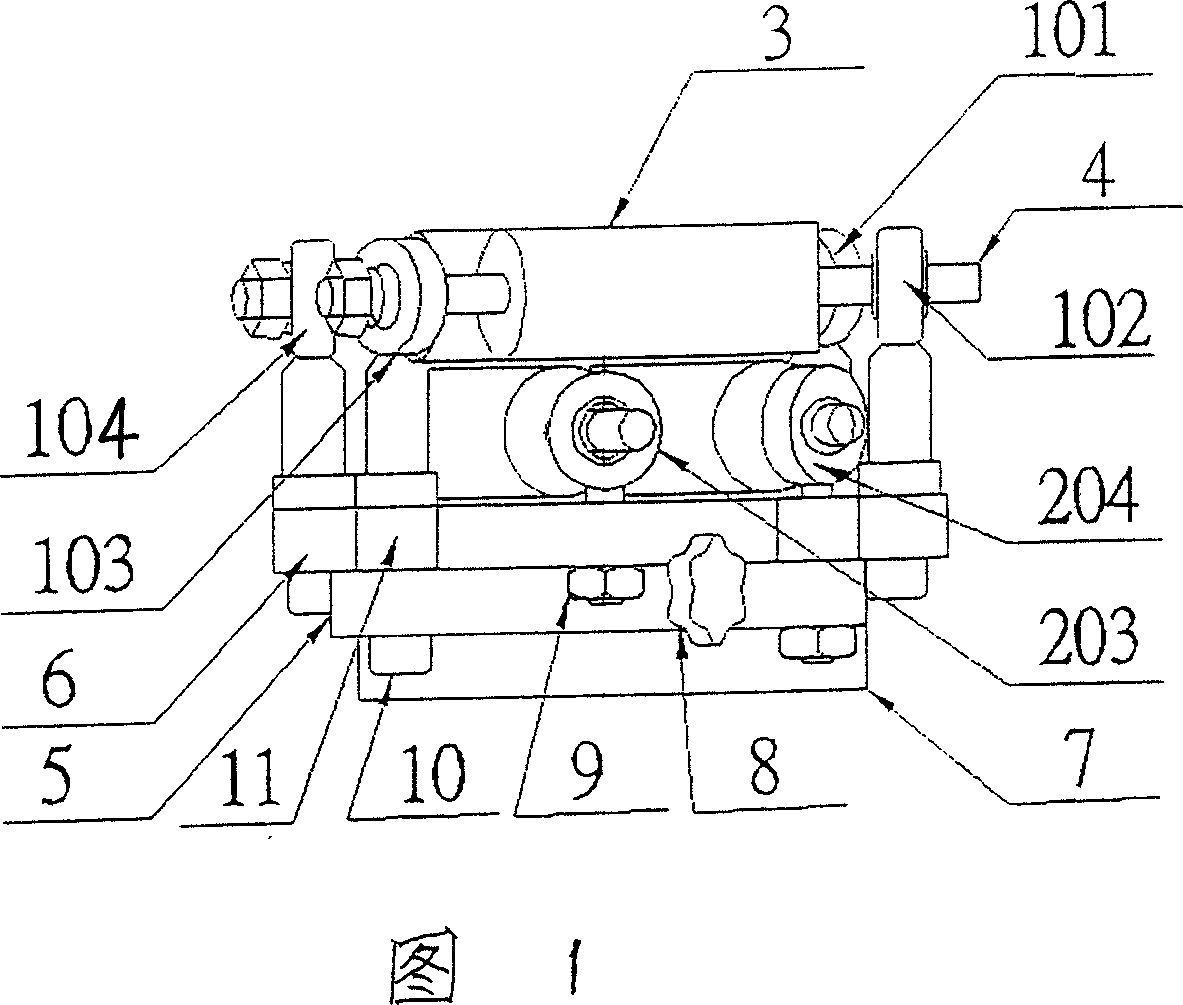

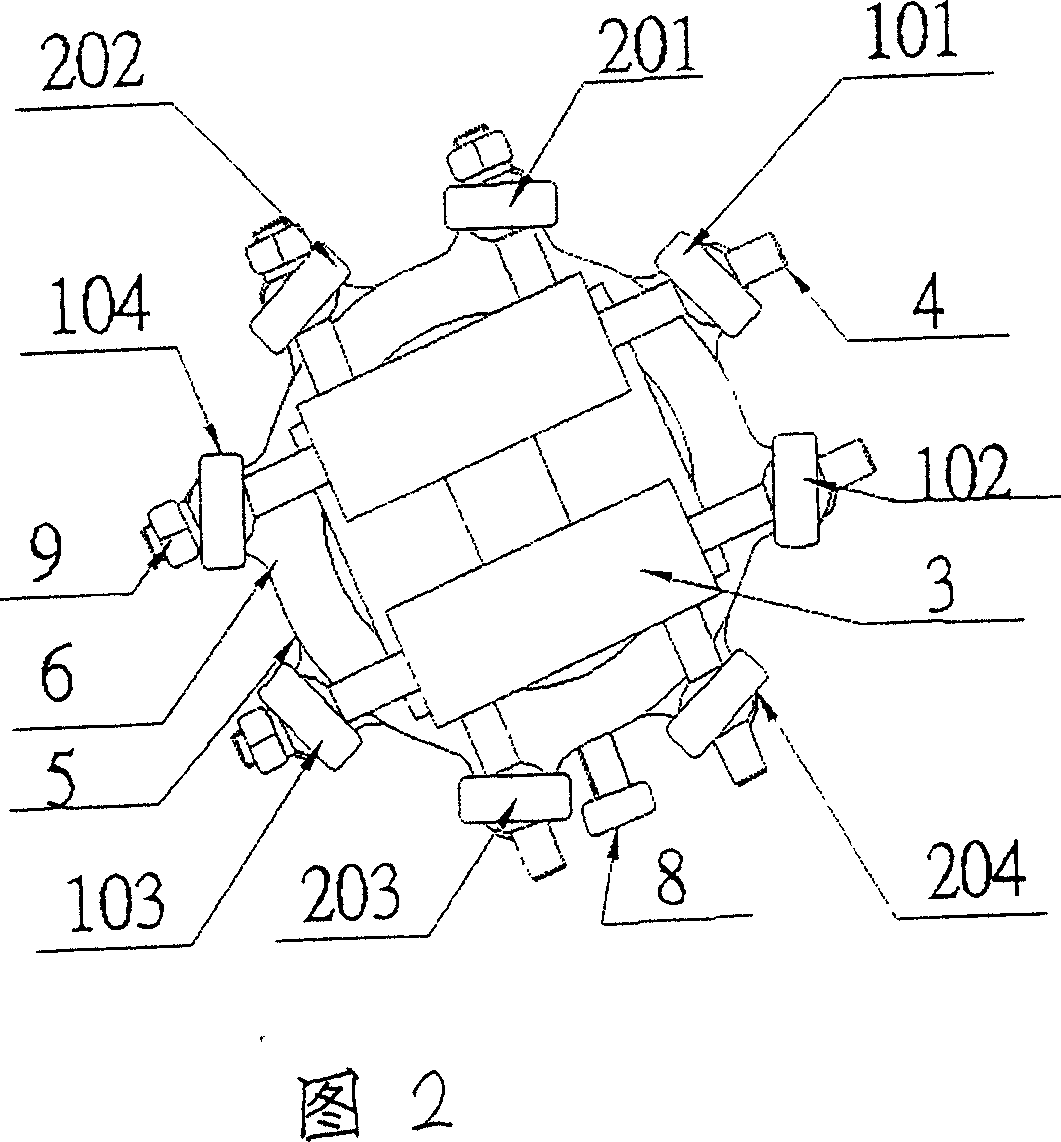

[0009] The present invention will be further described with reference to accompanying drawing 1 and Fig. 2 and embodiment:

[0010] This embodiment is a cable positioning and clamping device with a well-shaped guide wheel frame whose through hole diameter can be adjusted within the range of 0 mm to 28 mm. All components are installed according to the structure in the accompanying drawings. Among them: joint bearings 201, 203, 102, and 104 are installed on the fixed seat 6 with an outer diameter of φ80mm, an inner hole of φ36mm, a thickness of 20mm (including ring-shaped steps with a thickness of 10mm and φ60mm), and a distance between the center holes of the upper and lower or left and right lugs of 93mm. On, the joint bearings 202, 204, 101, 103 are installed on the movable seat 5 with an outer diameter of φ80mm, an inner hole of φ60mm, a thickness of 10mm, and a distance between the center holes of the upper and lower or left and right lugs of 93mm. A washer 11 with an outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com