Servo system for sewing machine

A servo system and sewing machine technology, applied in the field of servo systems, can solve the problems of low transmission speed of control chips, complex electrical circuits, large volume, etc., and achieve the effects of smooth braking, low noise and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

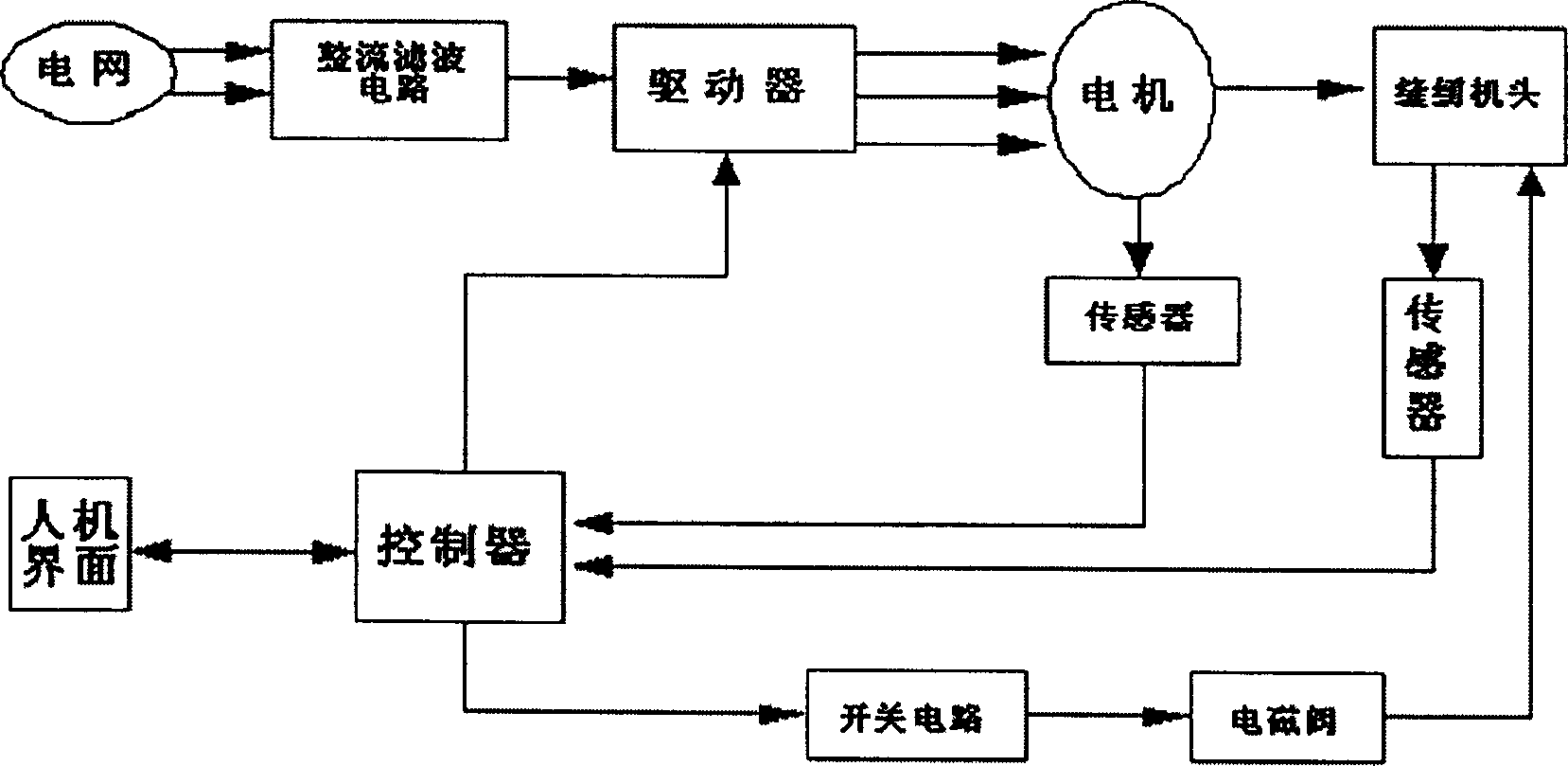

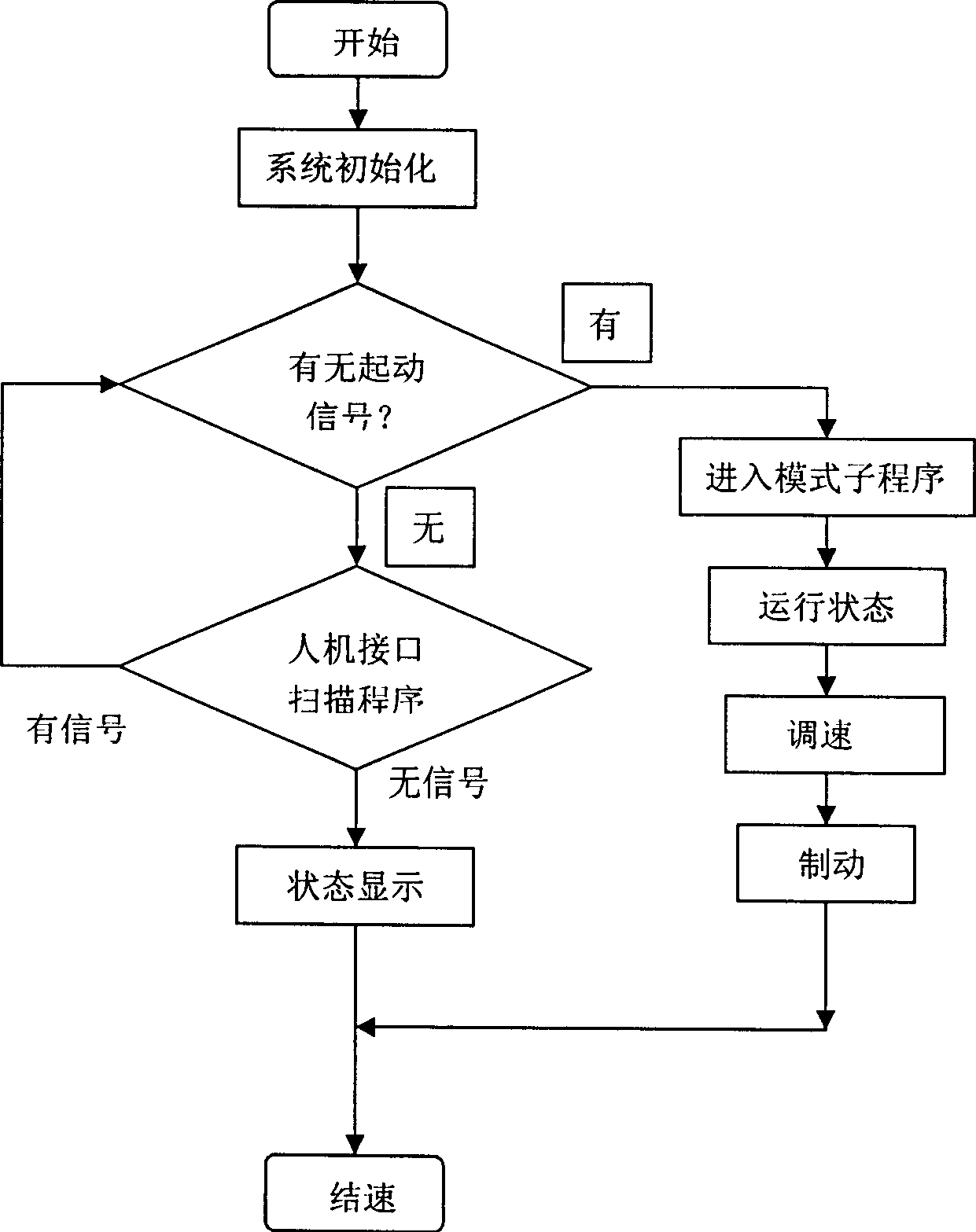

[0037] figure 1 The present invention shown includes: a rectifying and filtering circuit, a driver, a motor, a sewing machine head, a sensor, a man-machine interface, a controller, a switch circuit and a solenoid valve. Among them: the power grid is connected to the motor through a rectification filter circuit and the driver; the motor is connected to the sewing machine head; the motor is connected to the controller through the sensor, and the sewing machine head is connected to the controller through the sensor; the output of the controller is connected to the driver, and the output of the controller is connected to the sewing machine head through the switching circuit and the solenoid valve . The controller is connected with the man-machine interface to obtain input information. When working: the power grid transmits electric energy to the driver through the rectification and filtering circuit. When the controller receives the set input information, it sends a command signa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com