Functional composite fiber and preparation method thereof

A composite fiber and functional technology, applied in spinning solution preparation, chemical post-treatment of cellulose/protein artificial filament, wet spinning method, etc., can solve the problems of no research and reports, and achieve good antibacterial effect and antibacterial effect Long-lasting function, good moisture absorption and moisturizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

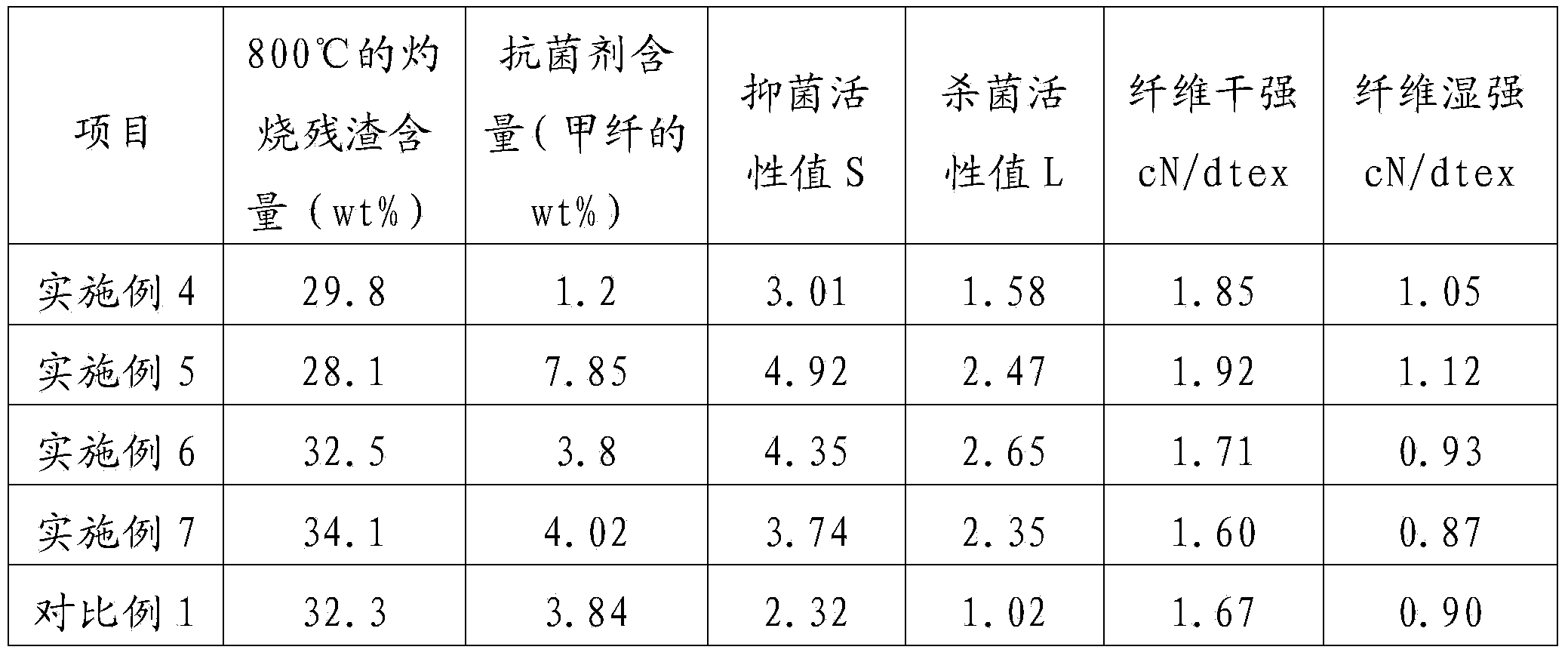

Examples

Embodiment 1

[0035] A functional composite fiber, which contains: 20wt% silicon dioxide, 8.5wt% hydroxypropyl ammonium chloride chitosan, and 86% substitution degree of chitosan quaternary ammonium salt.

Embodiment 2

[0037] A functional composite fiber, which contains: 25wt% silicon dioxide, 5.5wt% hydroxypropyltrimethylammonium chloride chitosan, the hydroxypropyltrimethylammonium chloride shell The degree of substitution of polysaccharides is 88.5%.

Embodiment 3

[0039] A functional composite fiber, which contains: 32wt% silicon dioxide, 1.0wt% hydroxypropyl alkyl dimethyl ammonium chloride chitosan, the hydroxypropyl alkyl dimethyl The substitution degree of ammonium chloride chitosan is 82%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com