Patents

Literature

139results about How to "Good blending" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

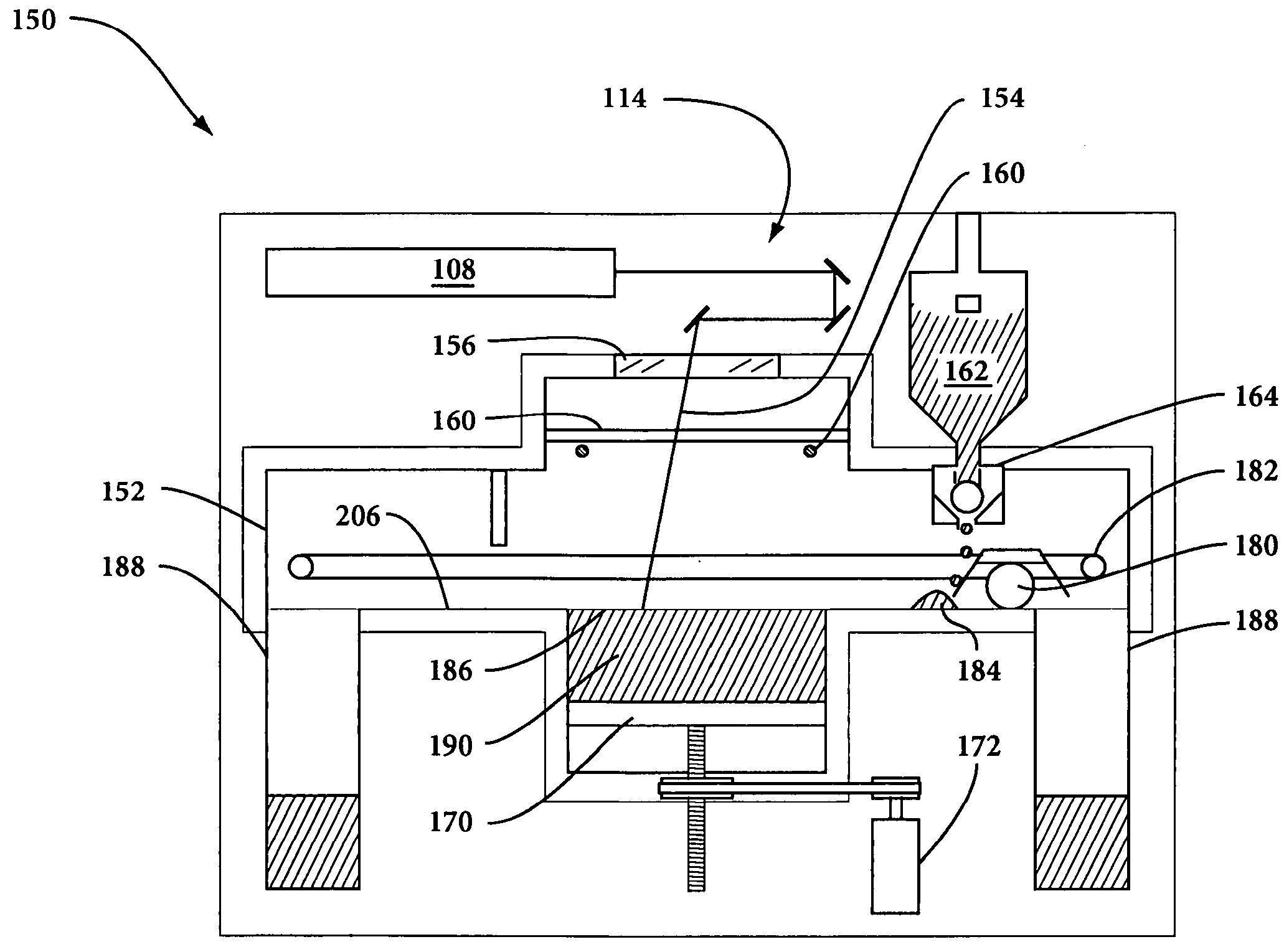

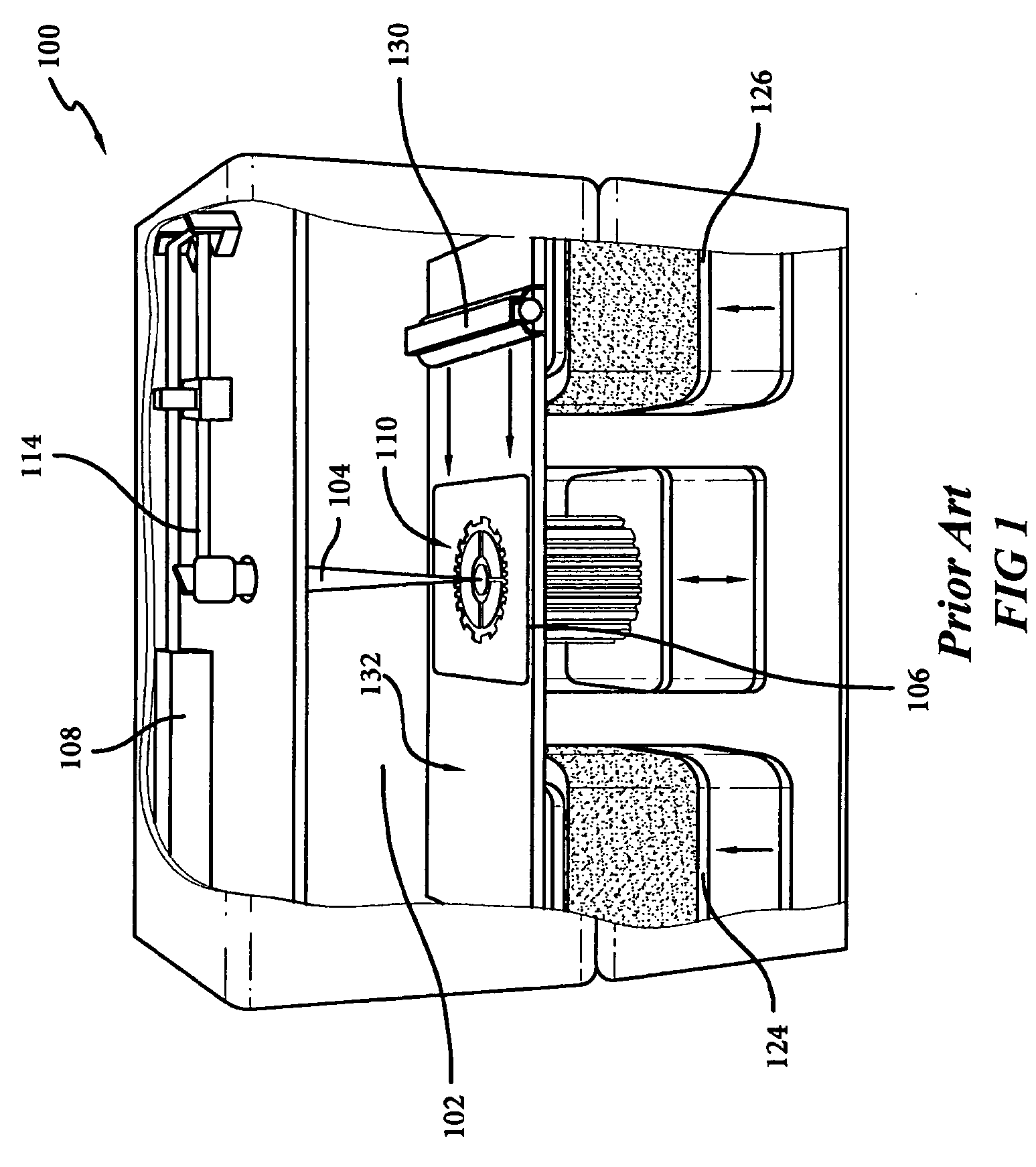

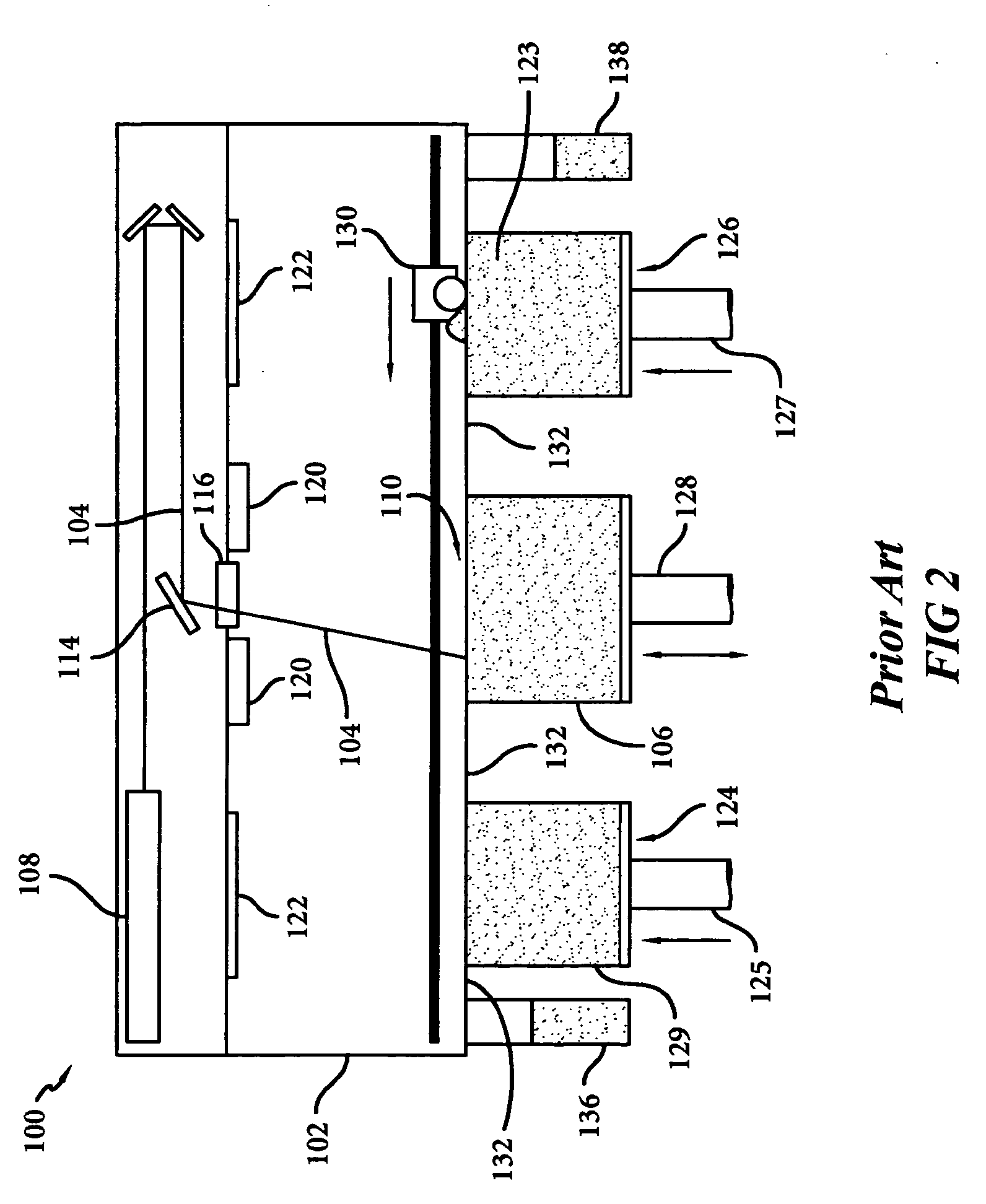

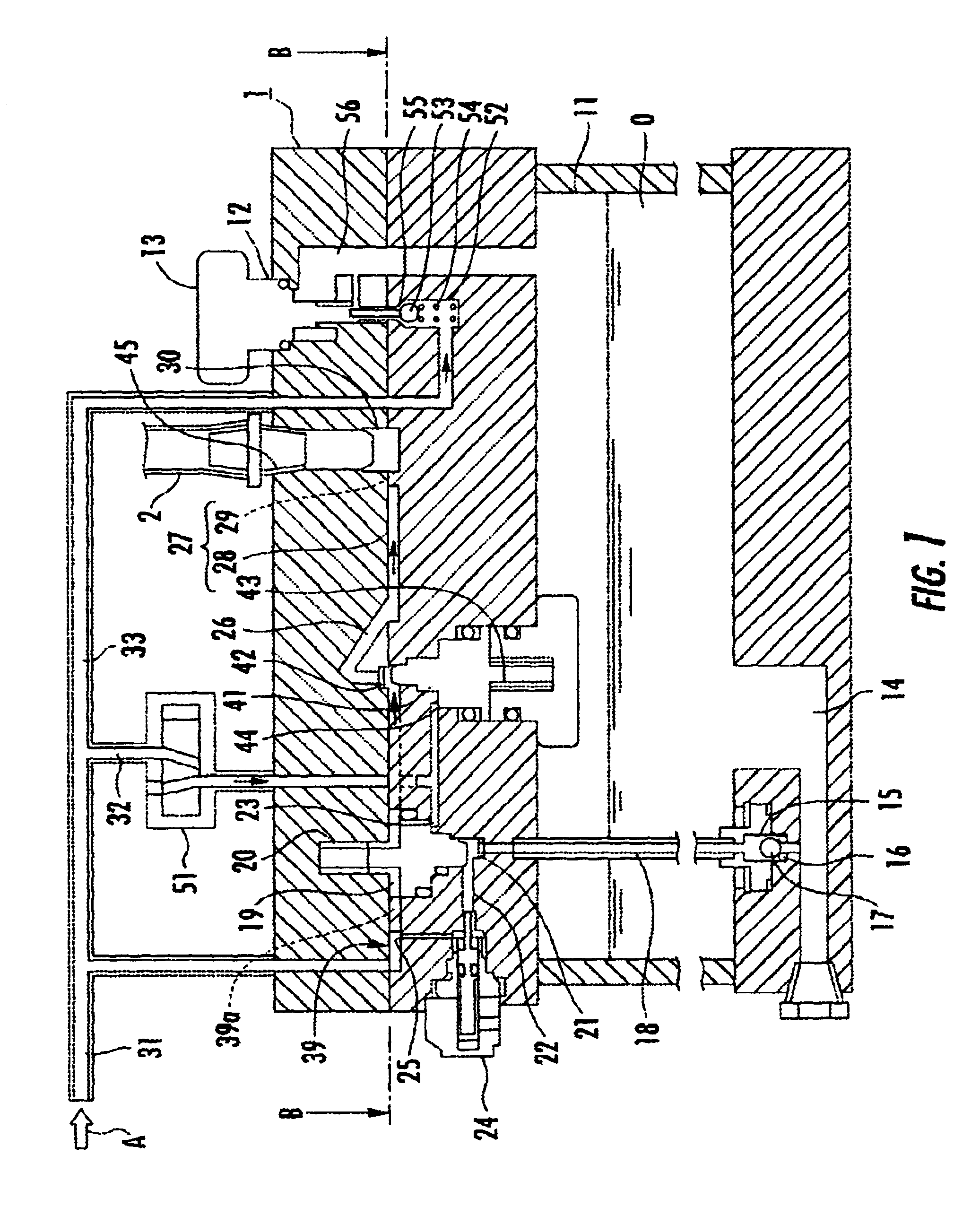

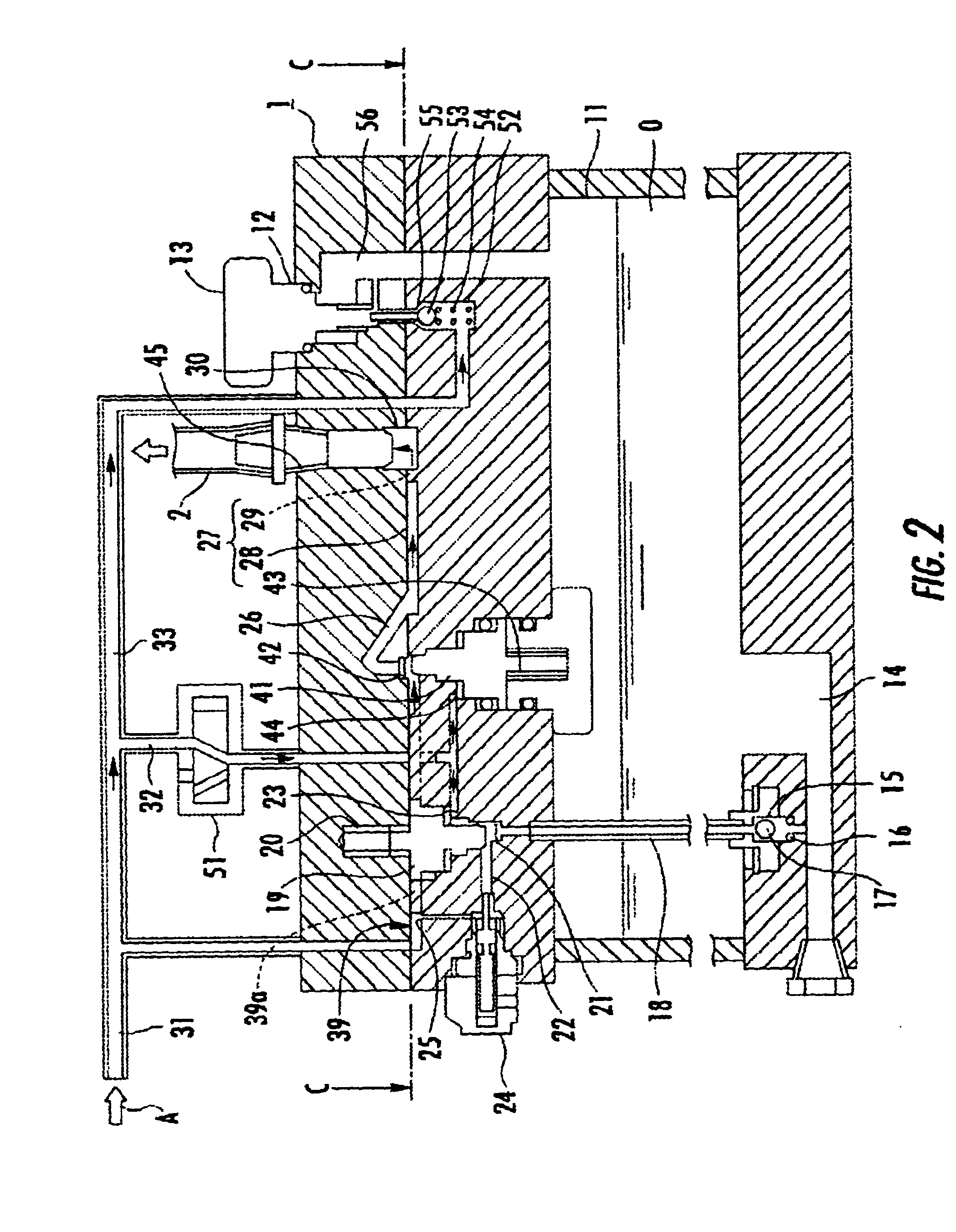

Selective Laser Sintering Powder Recycle System

ActiveUS20090169664A1Good blendingReduce powder lossFlow mixersTransportation and packagingSelective laser sinteringMetallurgy

A method and apparatus for forming three-dimensional objects by laser sintering that includes the use of dense phase pneumatic conveying to internally recycle overflow powder, and to thoroughly blend overflow, recovered and virgin powder to provide a consistent powder feed mix to a laser sintering machine. Overflow powder from the laser sintering machine is recovered and recycled back into the laser sintering machine for reuse. The approach results in a compact and reliable powder recycle system with complete blending and minimum attrition to the handled powder.

Owner:3D SYST INC

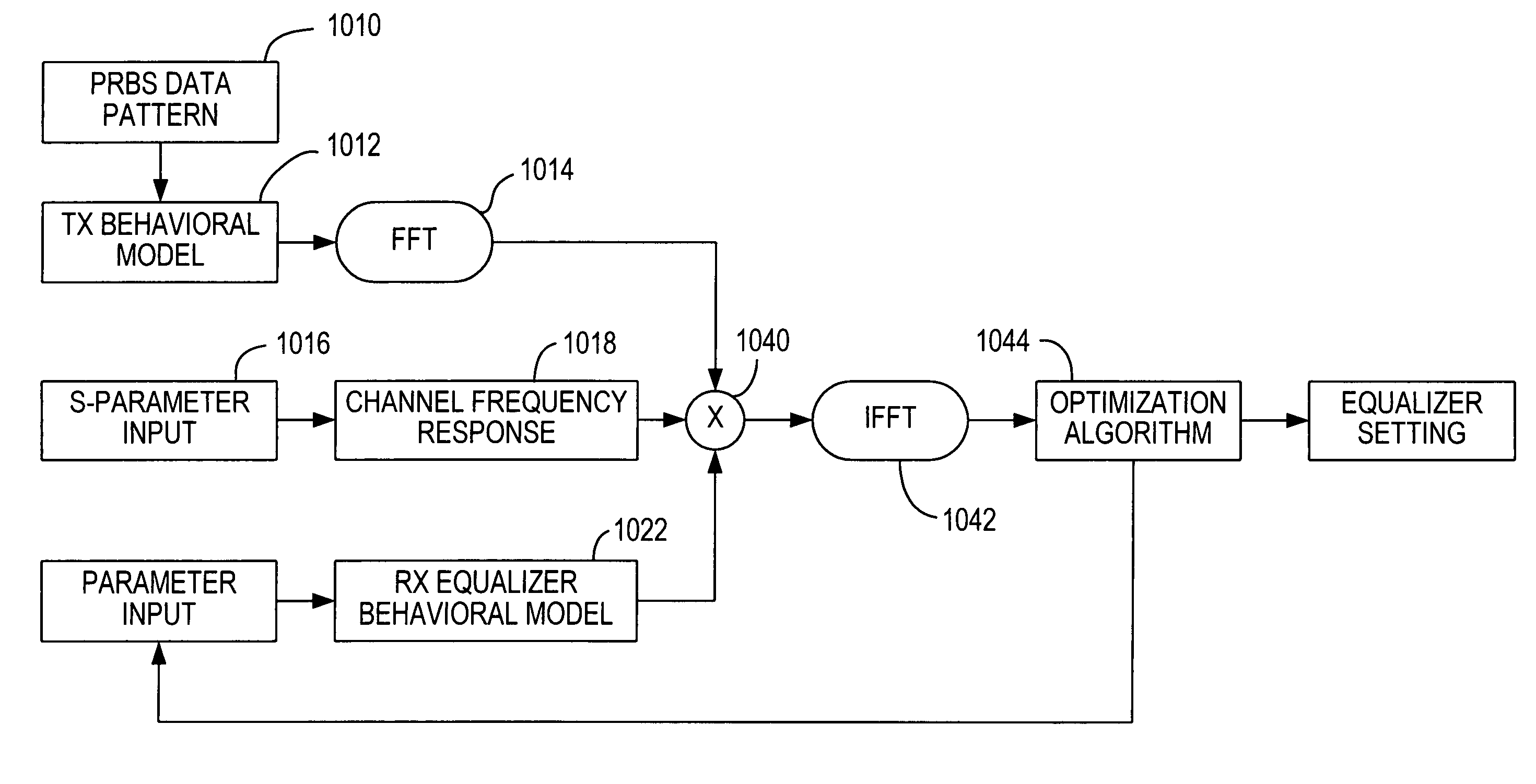

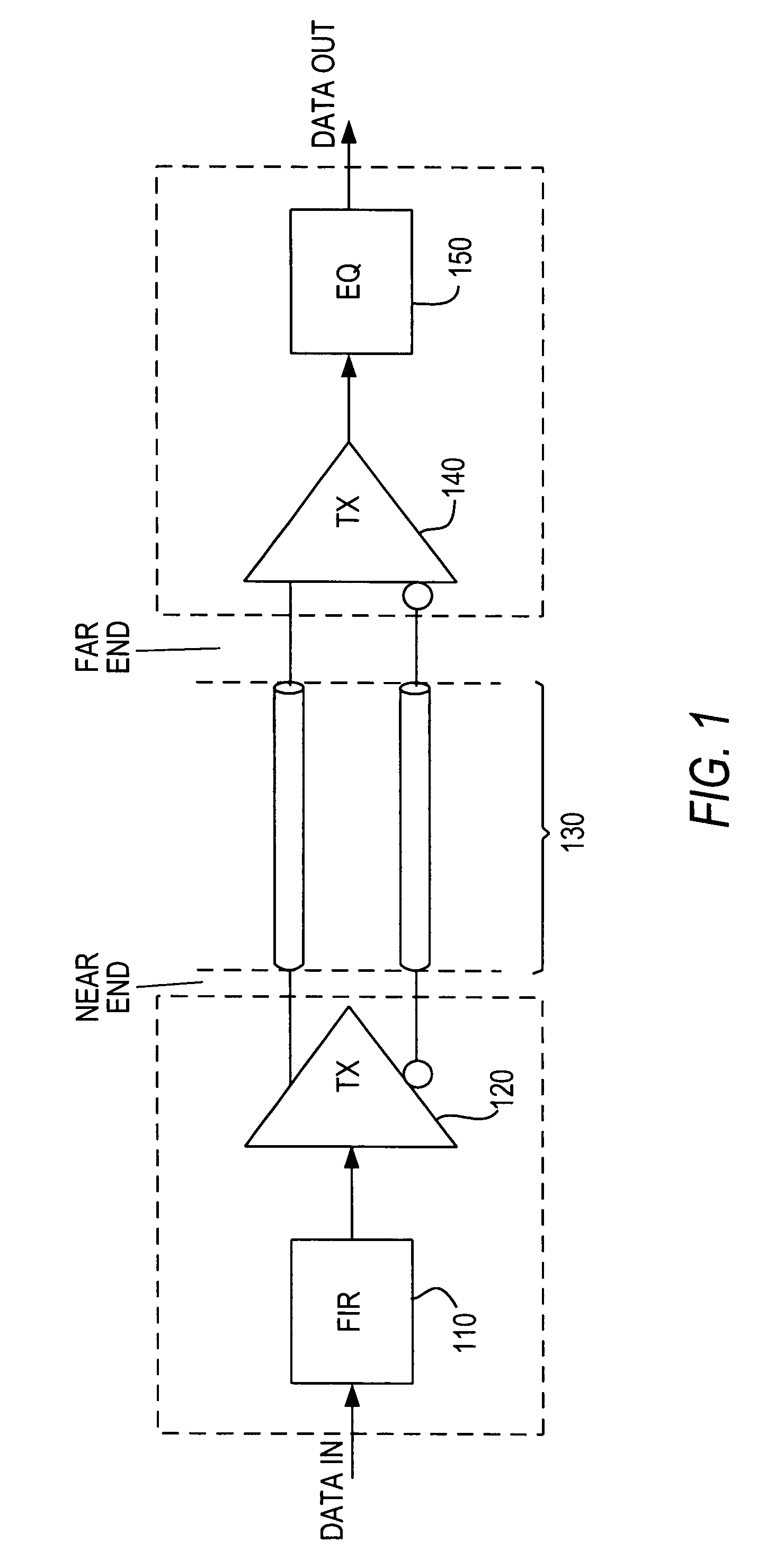

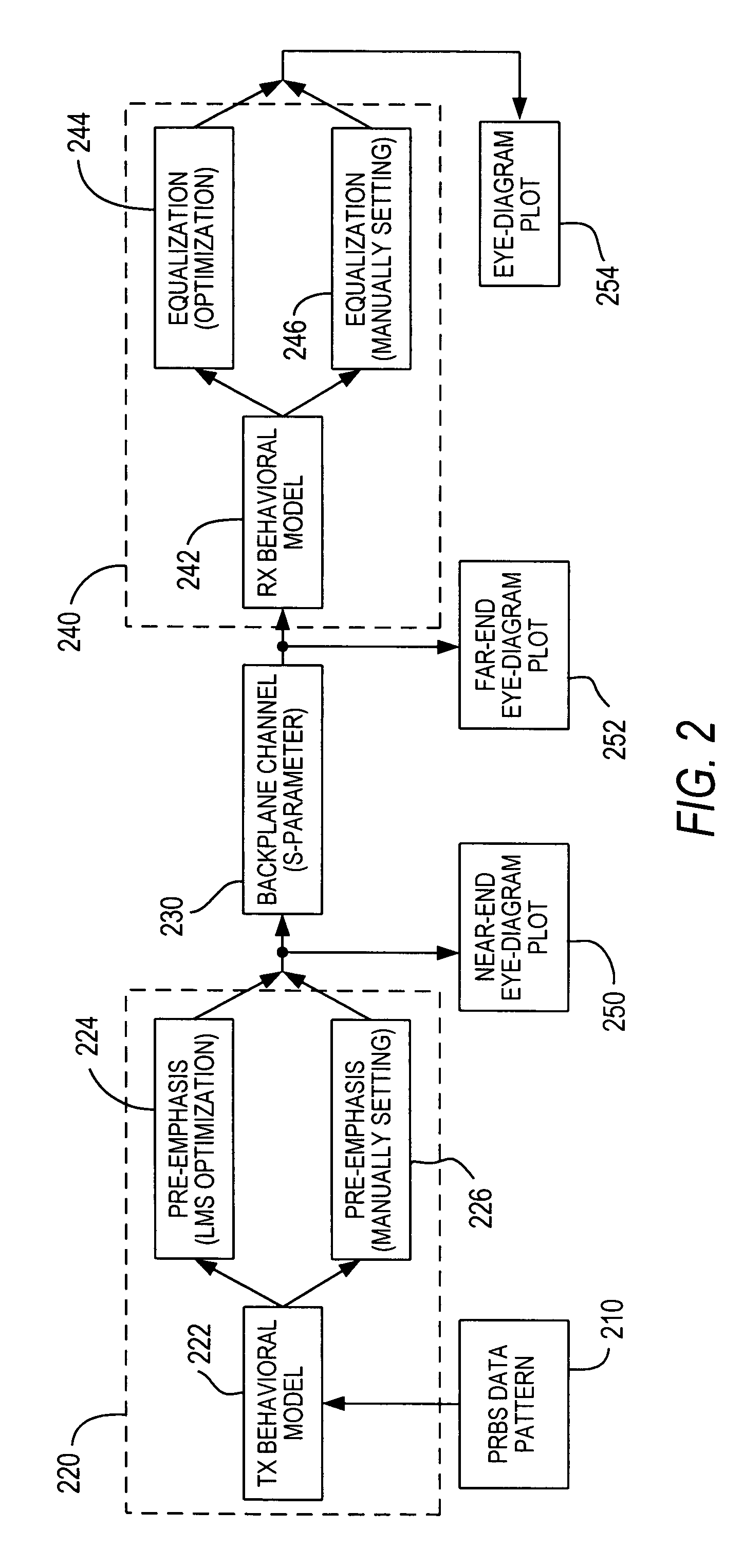

Systems and methods for simulating link performance

InactiveUS7693691B1Less-processing-power intensiveTradeoff is reduced accuracyAnalogue computers for electric apparatusComputation using non-denominational number representationTransceiverSimulation

Systems and methods for accurately and quickly simulating link performance of a transceiver operating with any given transmission medium are provided. Accurate and quick link simulations may be provided using a link simulation platform. The link simulation platform may simulate link performance using transceiver behavioral models (e.g., transmitter and receiver behavioral models) that incorporate silicon level parameters, which parameters enable the behavioral models to substantially emulate the actual behavior of the transceiver portions of the link.

Owner:ALTERA CORP

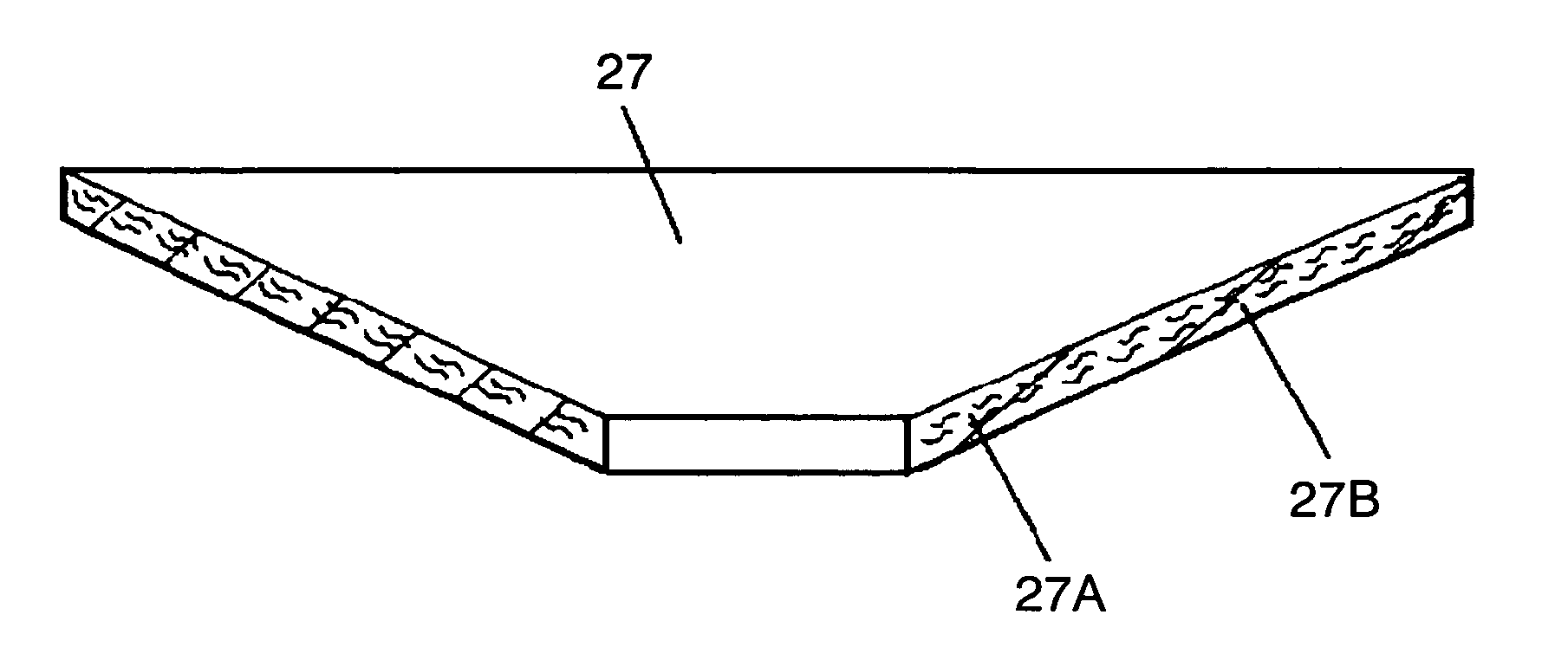

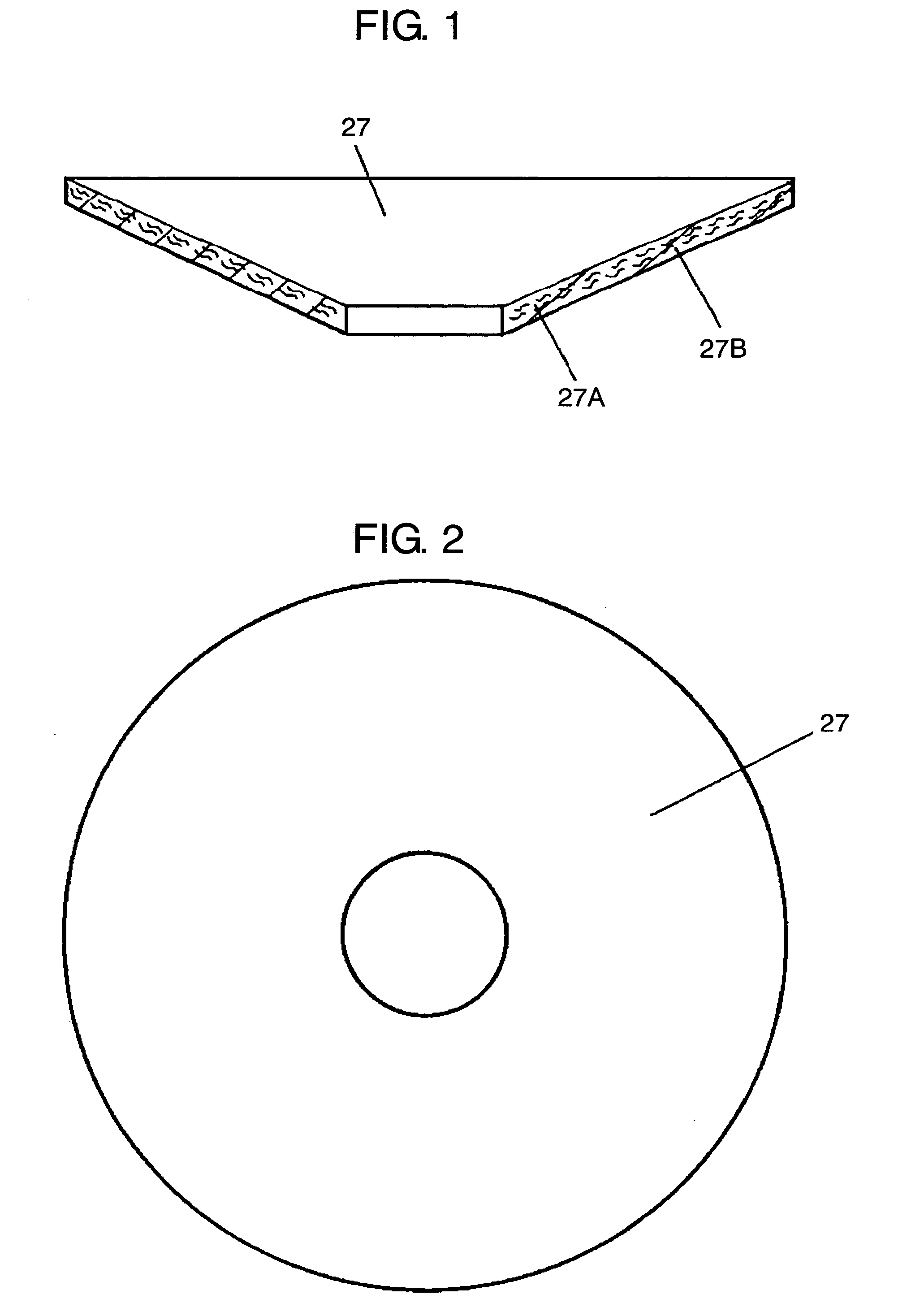

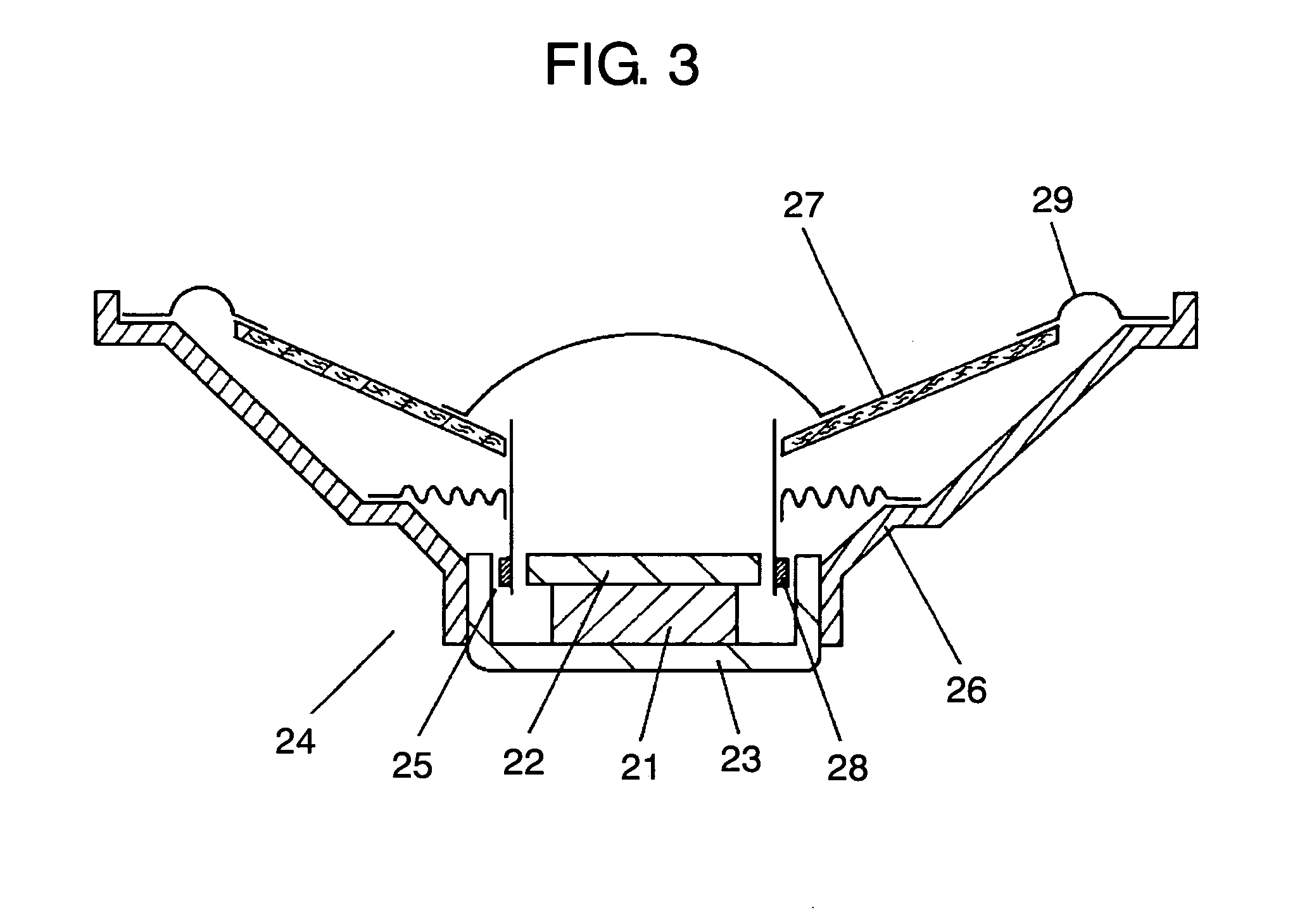

Speaker, speaker-use diaphragm, dust cap, production methods and production devices for them

InactiveUS20070131478A1The degree of freedom becomes largerNice appearanceFibre diaphragmsPolymeric diaphragmsFiberProduction rate

A speaker diaphragm or a dust cap formed by injection molding a mixture at least containing a resin material and a fiber material. The speaker diaphragm or the dust cap combines the advantages of both a paper diaphragm and a resin diaphragm. The advantage of a paper diaphragm is a large degree of freedom in setting physical properties. The advantages of a resin diaphragm are being excellent in moisture resistance reliability, strength, external appearance, productivity and dimension stability.

Owner:PANASONIC CORP

Adhesive of flexible epoxy resin and latent dihydrazide

Flexible epoxy-based adhesive compositions which remain Theologically stable at room temperature in an uncured state comprise: (a) at least one flexible polyepoxide resin having a hardness not exceeding a durometer Shore D reading of 45 when cured with a stoichiometric amount of diethylene triamine ("DETA"); and (b) a substantially stoichiometric amount of at least one latent epoxy resin curing agent. Optionally, the adhesive composition may also incorporate one or more semi-flexible resins. Other optional components include fillers, thixotropic agents, and flexibilizers. The adhesive composition provicdes an epoxy-based adhesive composition that is storable for weeks as a single component mixture at room temperature, curable at temperatures ranging from about 100° C. to 125° C. in less than two hours, and flexible upon curing to temperatures as low as minus 50° C., exhibiting a durometer Shore A of less than about 95.

Owner:OL SECURITY LIABILITY CO

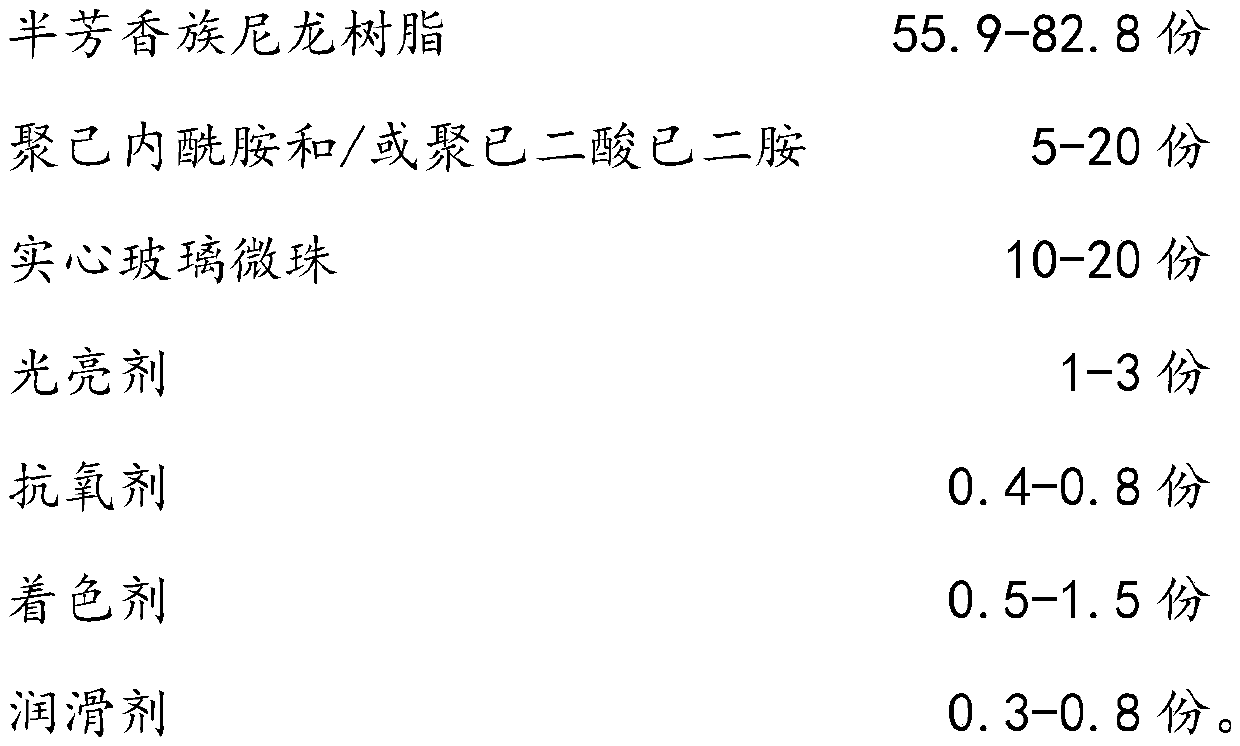

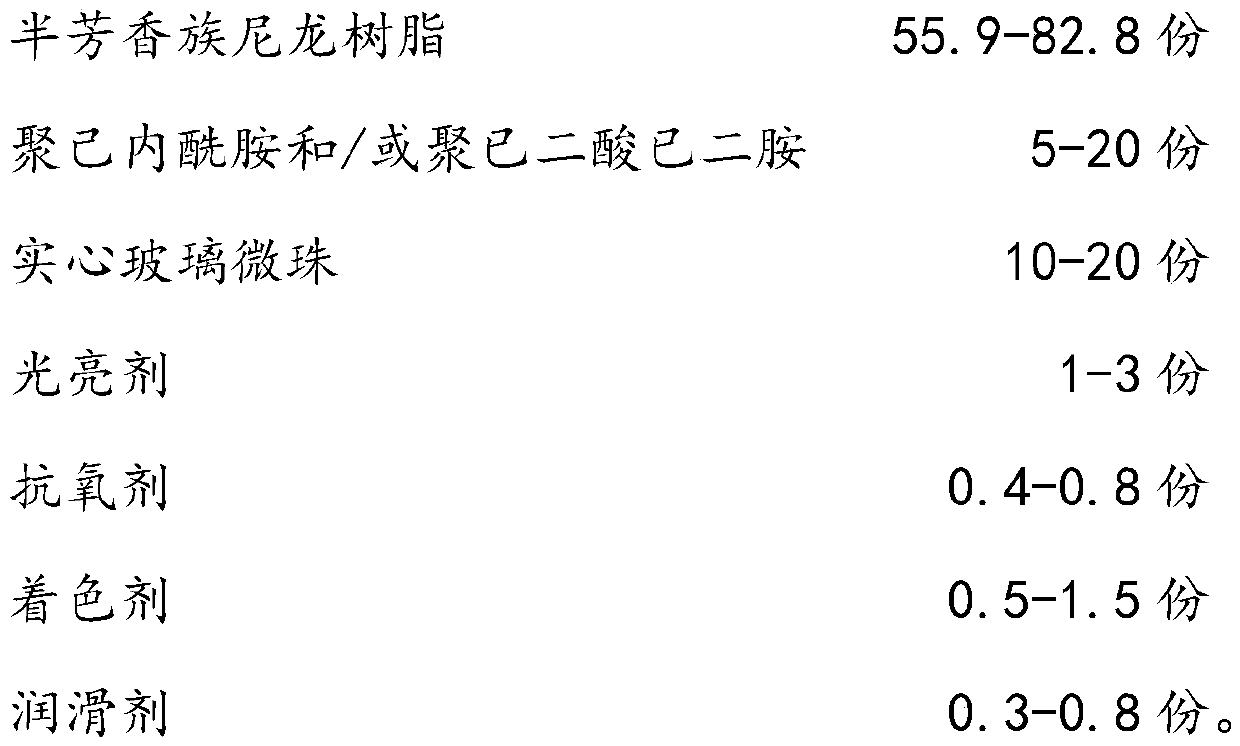

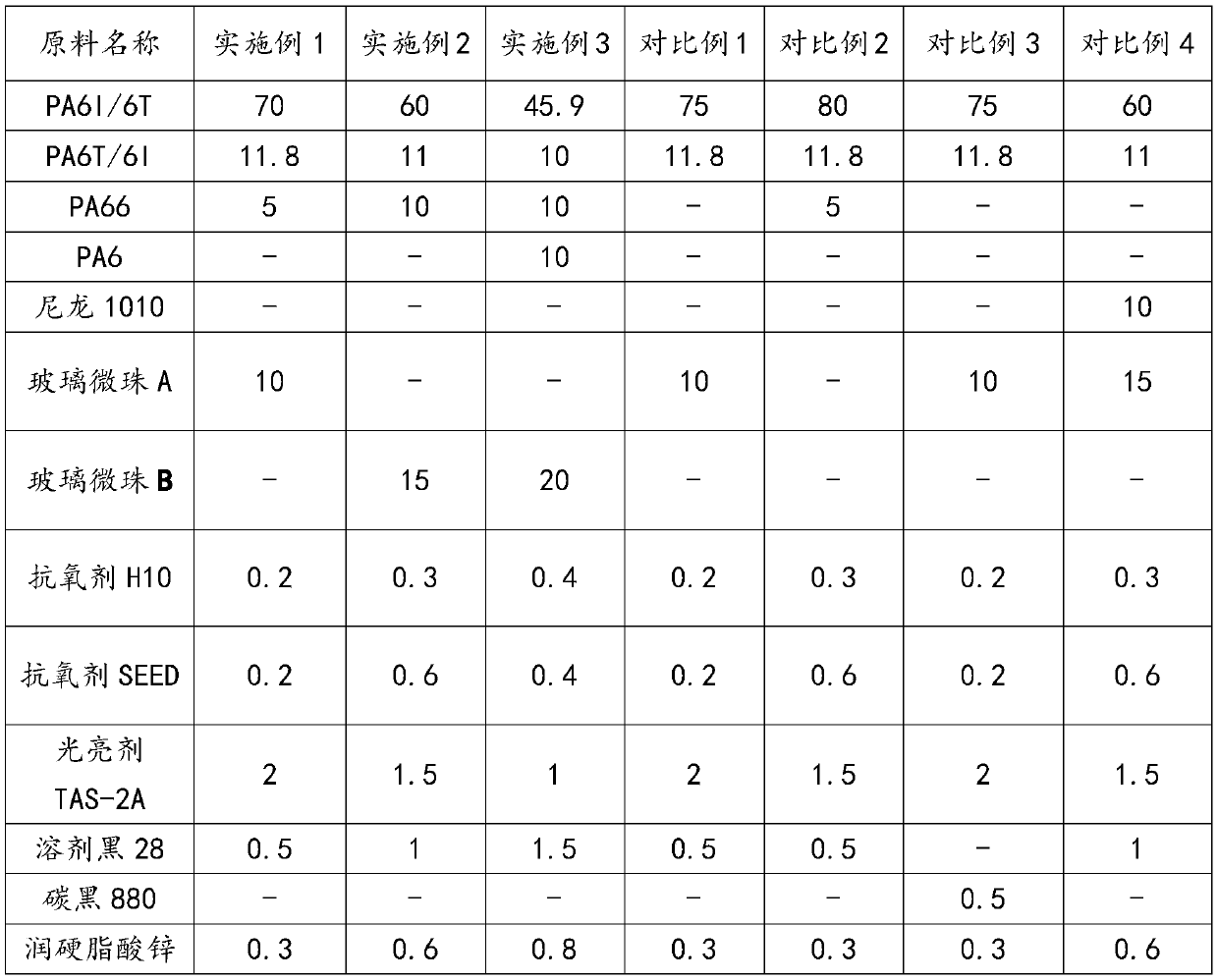

Heatproof spraying-free high-gloss nylon material and preparation method thereof

The invention relates to the field of automobile material preparation, and especially relates to a heatproof spraying-free high-gloss nylon material and a preparation method thereof. The nylon material is composed of following raw materials in parts by weight: 55.9 to 82.8 parts of semi-aromatic nylon resin, 5 to 20 parts of polycaprolactam and / or poly(nylon 66), 10 to 20 parts of solid glass bead, 1 to 3 parts of brightener, 0.4 to 0.8 part of antioxidant, 0.5 to 1.5 parts of coloring agent, and 0.3 to 0.8 part of lubricant. The provided nylon material is mainly made of semi-aromatic nylon resin; the matrix is in a highly transparent glass state; compared with other automobile spraying-free black decorative materials, such as PMMA, ABS, and the like, and the provided nylon material has abetter dyeing performance and a better temperature tolerant property, is capable of forming a highly bright and black coating, and is resistant to scratching, chemical products, and impact. The provided nylon material does not need any complicated spraying technology, the cost is reduced, and moreover, the nylon material is healthy and environmentally friendly and has an important practical value.

Owner:JINYOUNG XIAMEN ADVANCED MATERIALS TECH CO LTD

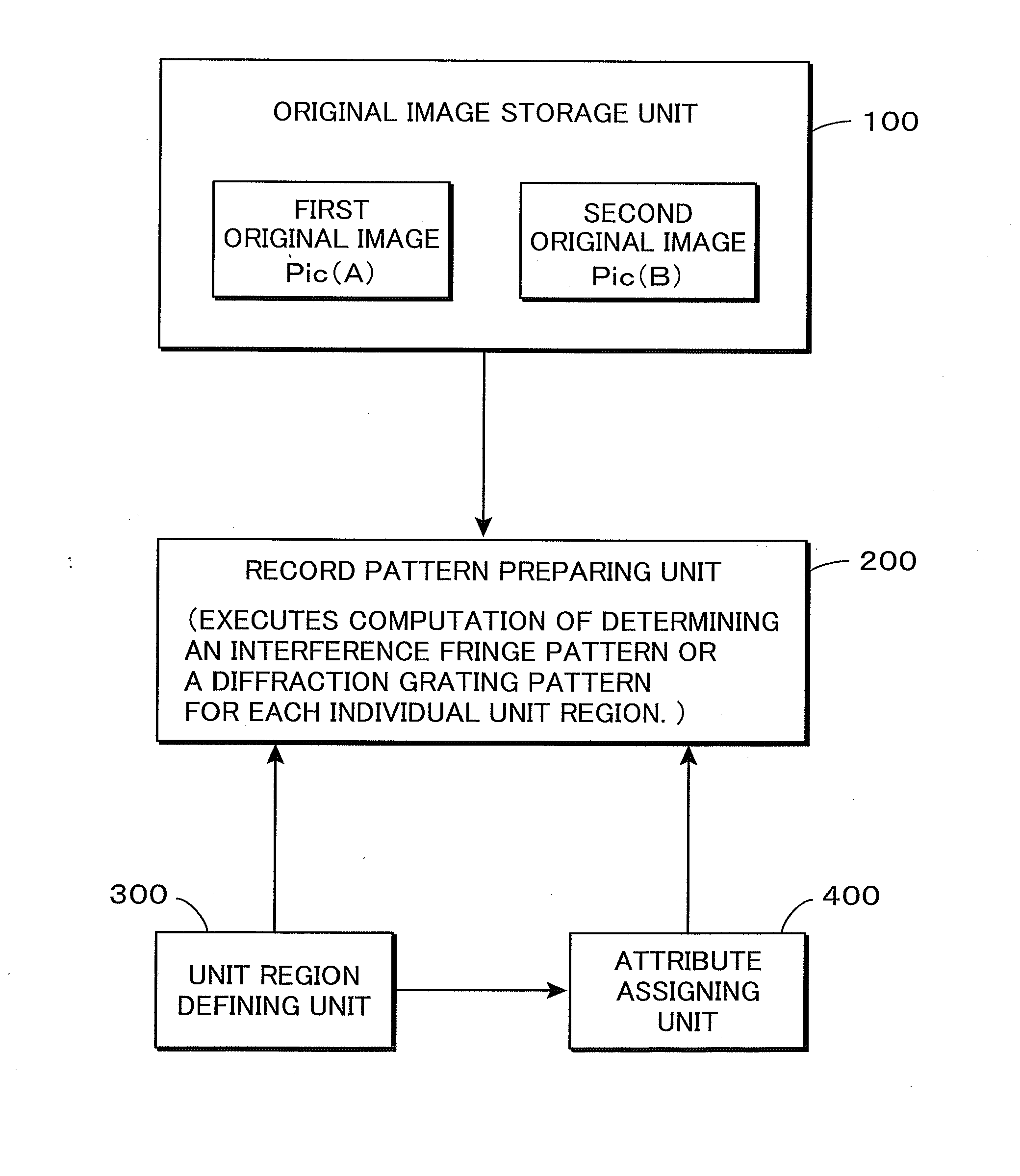

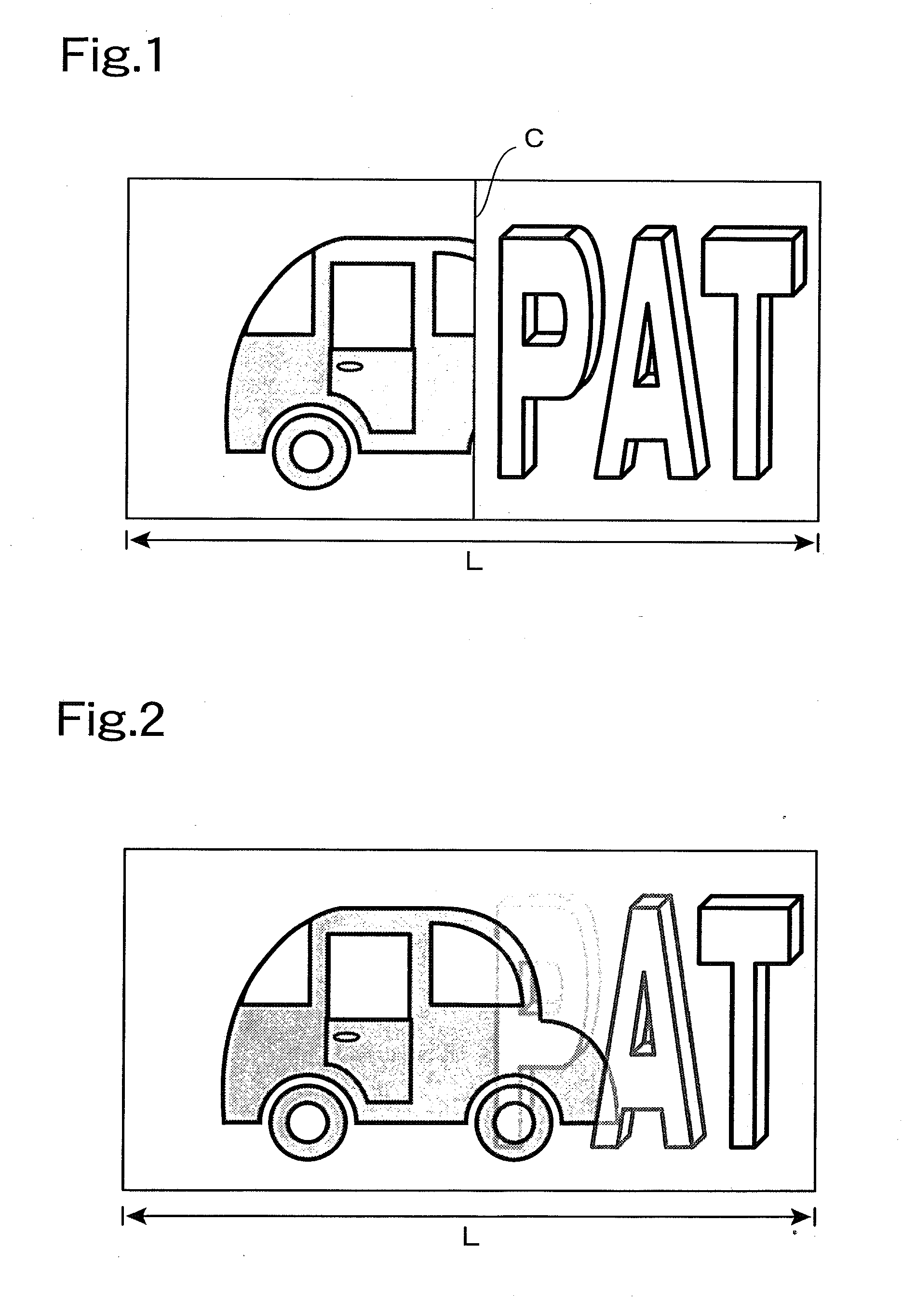

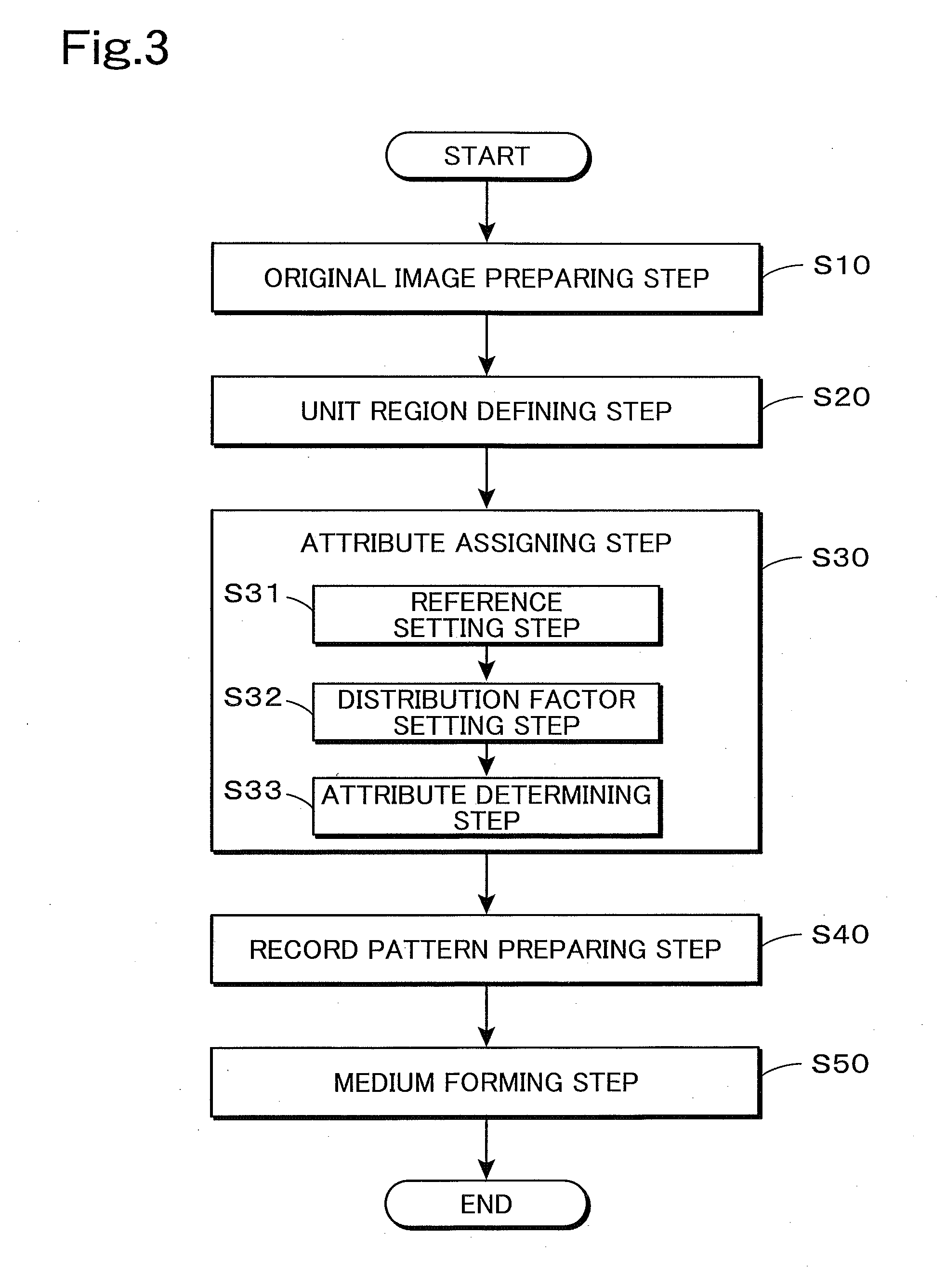

Method for preparing a hologram recording medium

ActiveUS20110267664A1Good blendingHolographic object characteristicsInformation cardsComputer scienceRecording media

Two original images to be recorded are prepared as data (S10). A plurality of unit regions, each having an adequate area to record interference fringes of visible light, are defined and positioned on a hologram recording surface (S20). A gradation pattern, with which appearance probabilities of two record attributes gradually change in space, is overlapped onto the recording surface, and to each unit region, one of either record attributes is assigned according to the appearance probabilities of the respective record attributes at each individual position (S30). In each unit region, to which the first record attribute is assigned, the first original image is recorded as an interference fringe pattern, a diffraction grating pattern, or a scattering structure pattern, and in each unit region, to which the second record attribute is assigned, the second original image is recorded as an interference fringe pattern, a diffraction grating pattern, or a scattering structure pattern (S40), and a record pattern is formed on a physical medium (S50).

Owner:DAI NIPPON PRINTING CO LTD

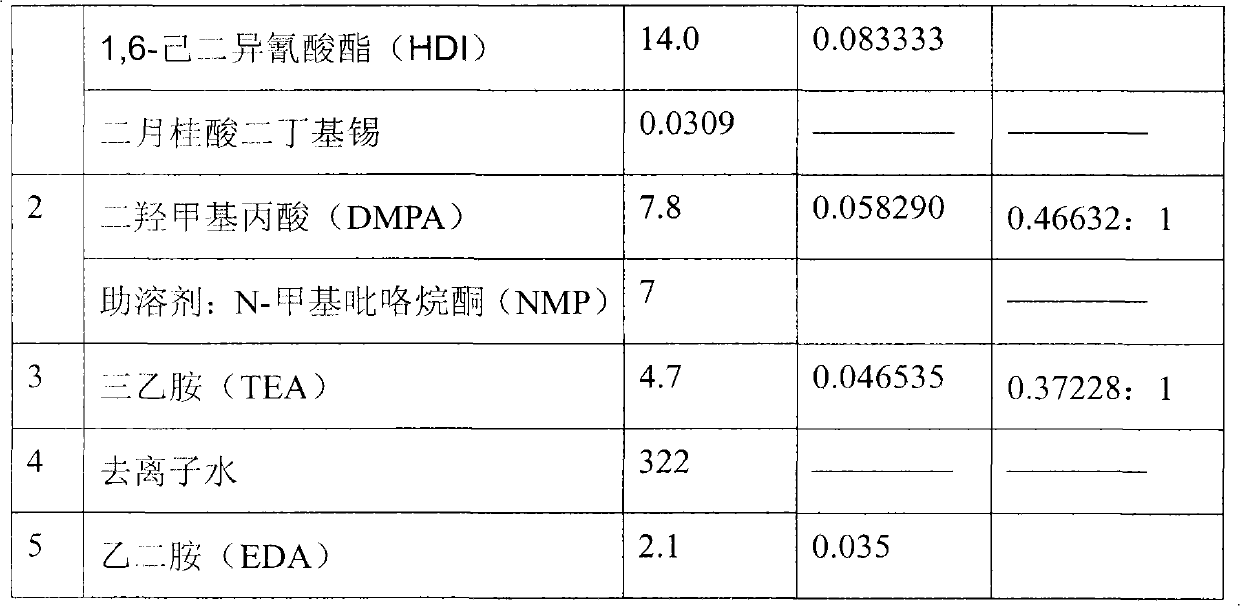

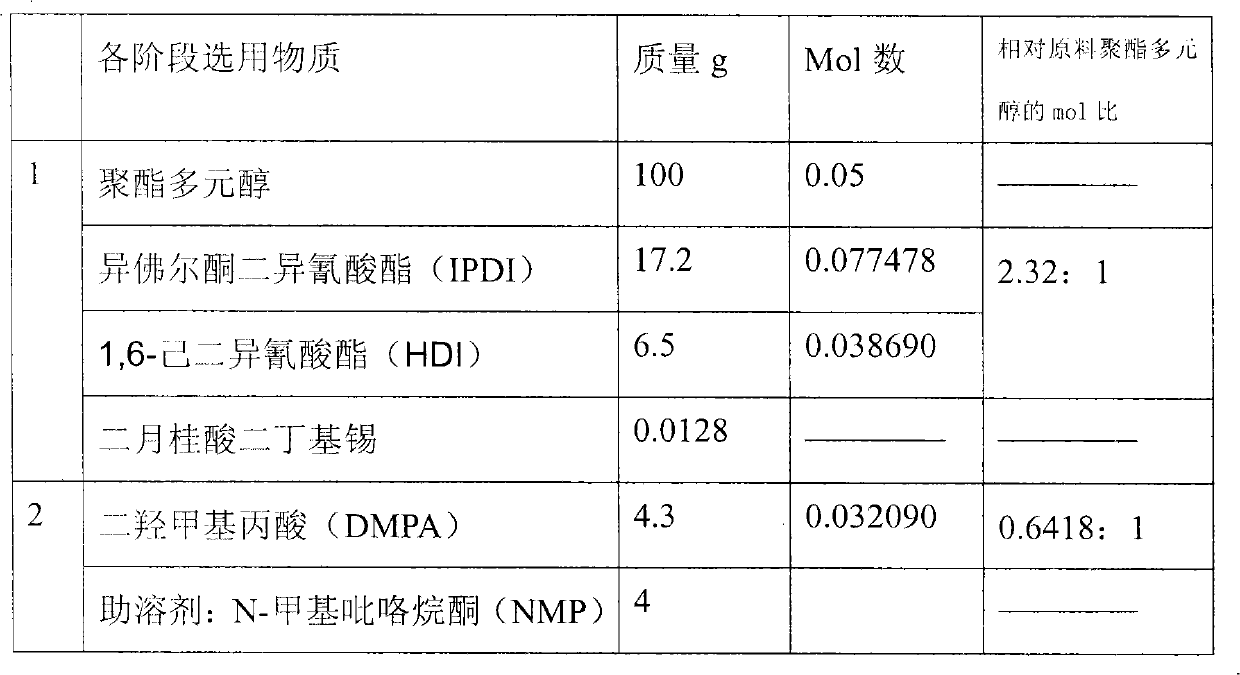

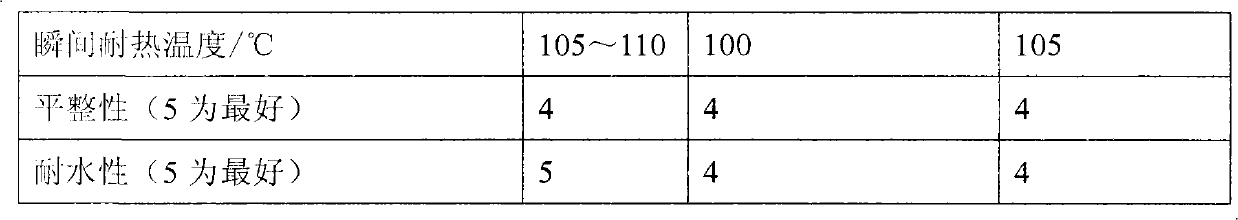

Preparation method and application of aqueous polyurethane latex as vacuum plastic-absorption adhesive

ActiveCN101921381ASimple processReduce dosagePolyureas/polyurethane adhesivesPrepolymerBonding strength

The invention relates to a preparation method and application of aqueous polyurethane latex as a vacuum plastic-absorption adhesive in the field of fine polymer materials. The preparation method comprises the following steps of: (1) making polyester polyol and isocyanate as raw materials react in the presence of a catalyst to obtain a prepolymer, wherein the molar ratio of the polyester polyol tothe isocyanate is 2-2.35:1, and the catalyst accounts for 0.01% of the total weight of the prepolymer; (2) adding dimethylolpropionic acid containing a hydrophilic group compound, simultaneously adding N-methylpyrrolidone as a cosolvent and making the mixture to react to obtain a product, wherein the addition of the cosolvent accounts for 1%-3% of the total weight of the latex; (3) adding triethylamine for neutralization reaction, adding deionized water, and then emulsifying; and (4) adding an amine chain expander and then dispersing to obtain the aqueous polyurethane latex. The product prepared in the method has the advantages of low cost, stable viscosity, moderate activation temperature, good blending performance and better high-temperature resistance and bonding strength and can be applied as the vacuum plastic-absorption adhesive.

Owner:上海英诺威化学有限公司 +1

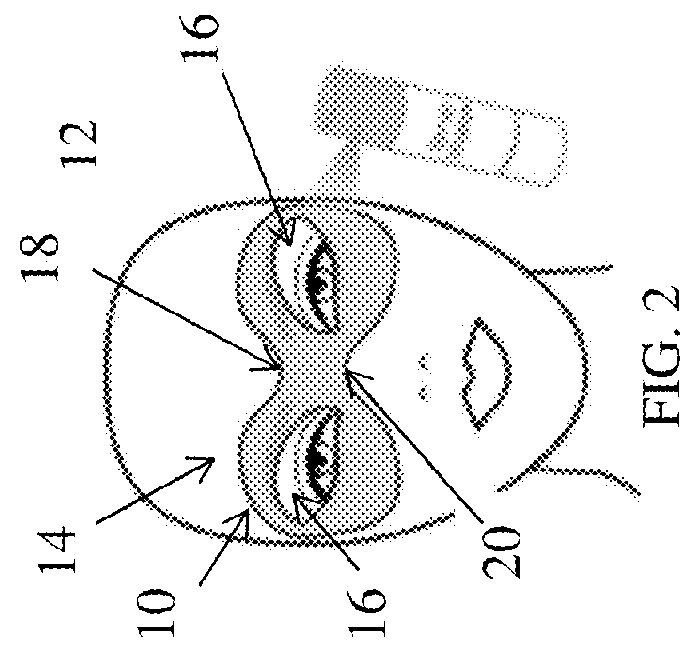

Eye makeup device

InactiveUS20160051033A1Good blendingEasy maintenanceCurling devicesPackaging toiletriesEyelidOptometry

An eye makeup device including a covering that can be placed near or over the eyes of a person to guide application of eye color to the upper eyelids of the person. The covering has an inner side for facing the person's skin and an outer side. The inner side is formed from a material that is sufficiently flexible to follow the surface topology of the person's face around the eye region and also sufficiently tacky to stay in place on the person's skin.

Owner:AND B

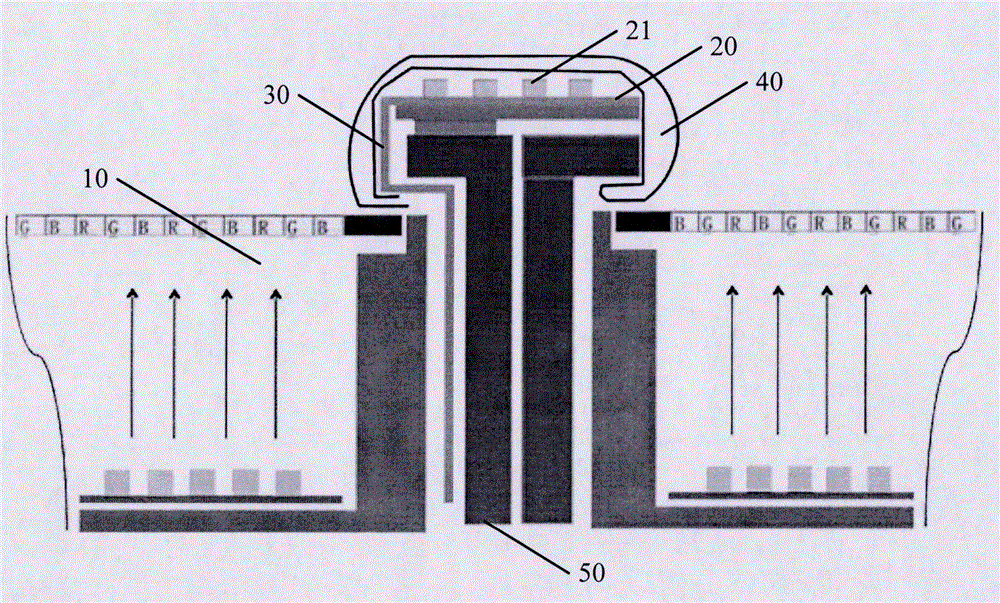

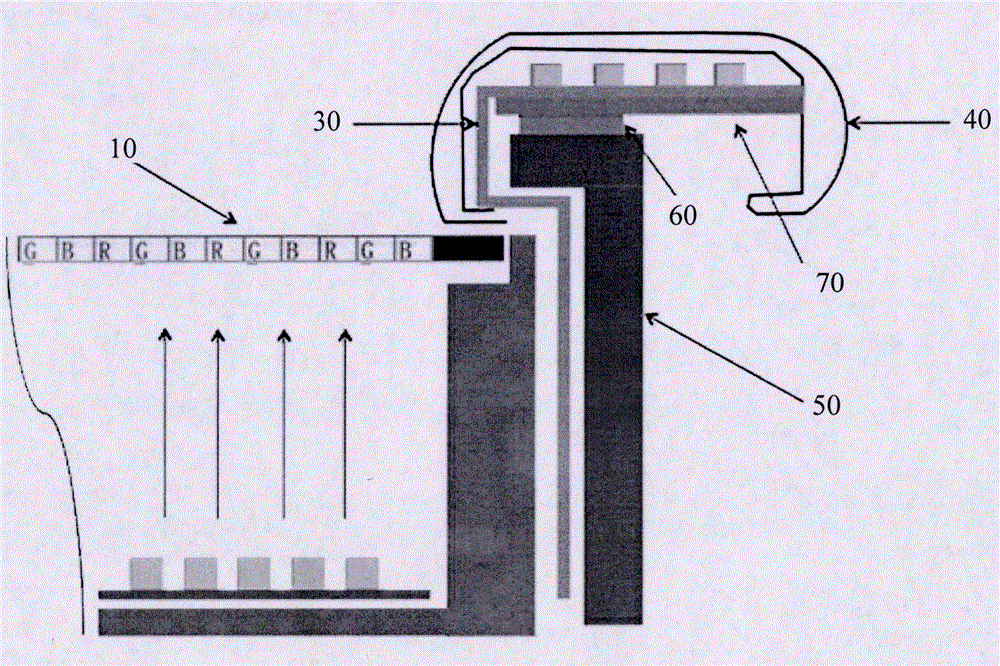

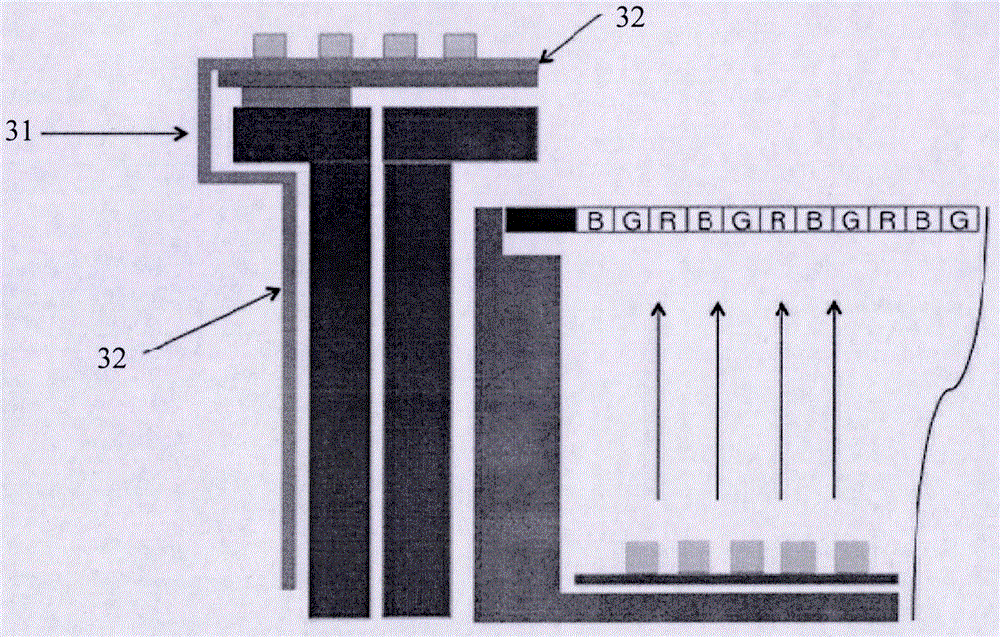

Display structure for eliminating splicing seams of edges of flat display screens and integrated structure

InactiveCN106842711AWell mixedIncrease the light output angleStatic indicating devicesNon-linear opticsFlexible circuitsEngineering

The invention discloses a display structure for eliminating seams at the edge of a flat panel display. A flexible circuit board is arranged on the upper part of a metal frame and its side surfaces, and the flexible circuit board extends along the inner side of the metal frame to the flat panel display. Inside, and connected with the internal electrical appliances of the flat panel display; the luminous body is fixedly connected to the flexible circuit board located on the upper part of the metal frame, and forms a light strip with this part of the flexible circuit board; on the light strip A lampshade is arranged on the outside; the lampshade is used as the display surface of the display structure, and together with the display area of the flat panel display screen, the original input video image is displayed. Correspondingly, the present invention also provides an integrated structure of multiple flat display screens using the display structure provided by the present invention. The technical solution provided by the invention can significantly integrate the splicing seams during the splicing of flat panel display screens, and truly achieve a "seamless" splicing effect.

Owner:韩玉君 +2

Polylactic acid resin composition

InactiveUS8044134B2High viscosityIncrease resistanceOrganic dyesDyeing processMachine partsHeat resistance

Owner:LOTTE ADVANCED MATERIALS CO LTD

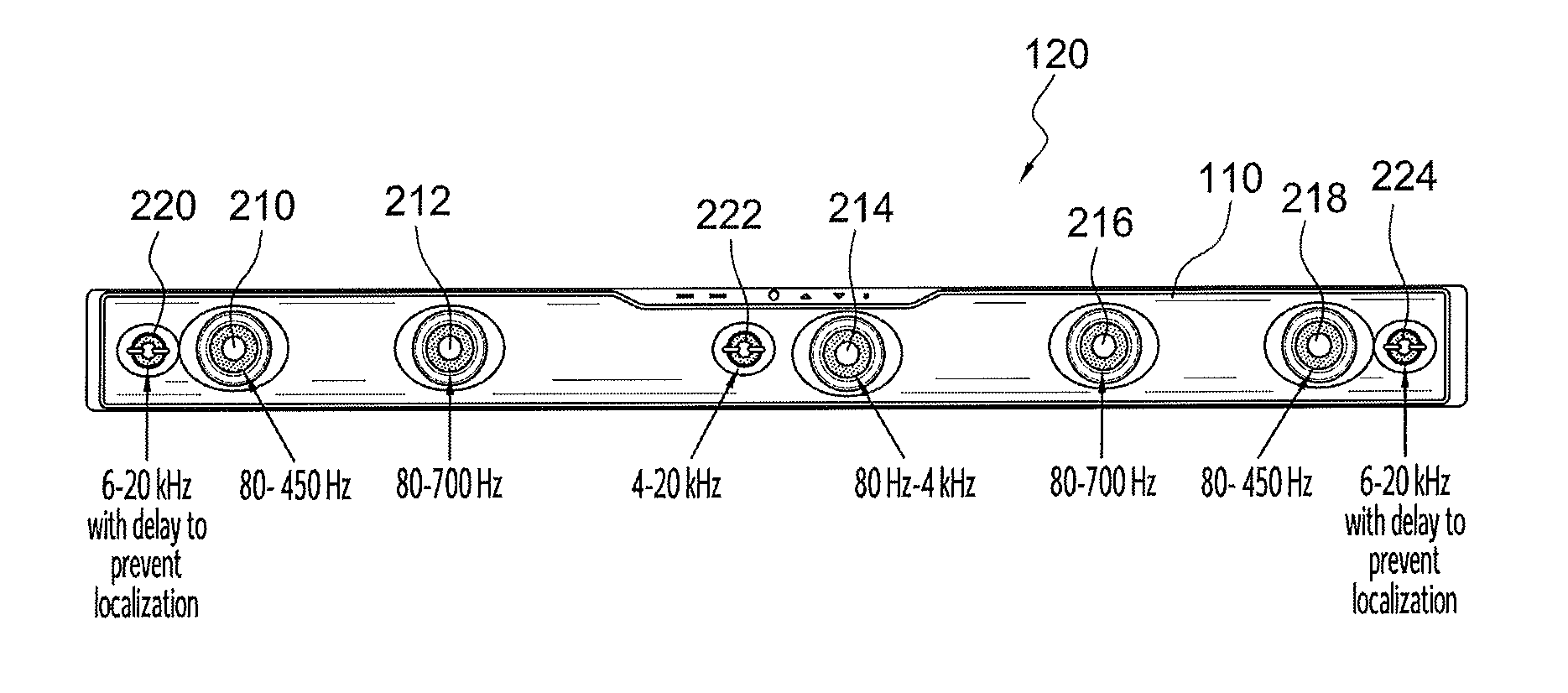

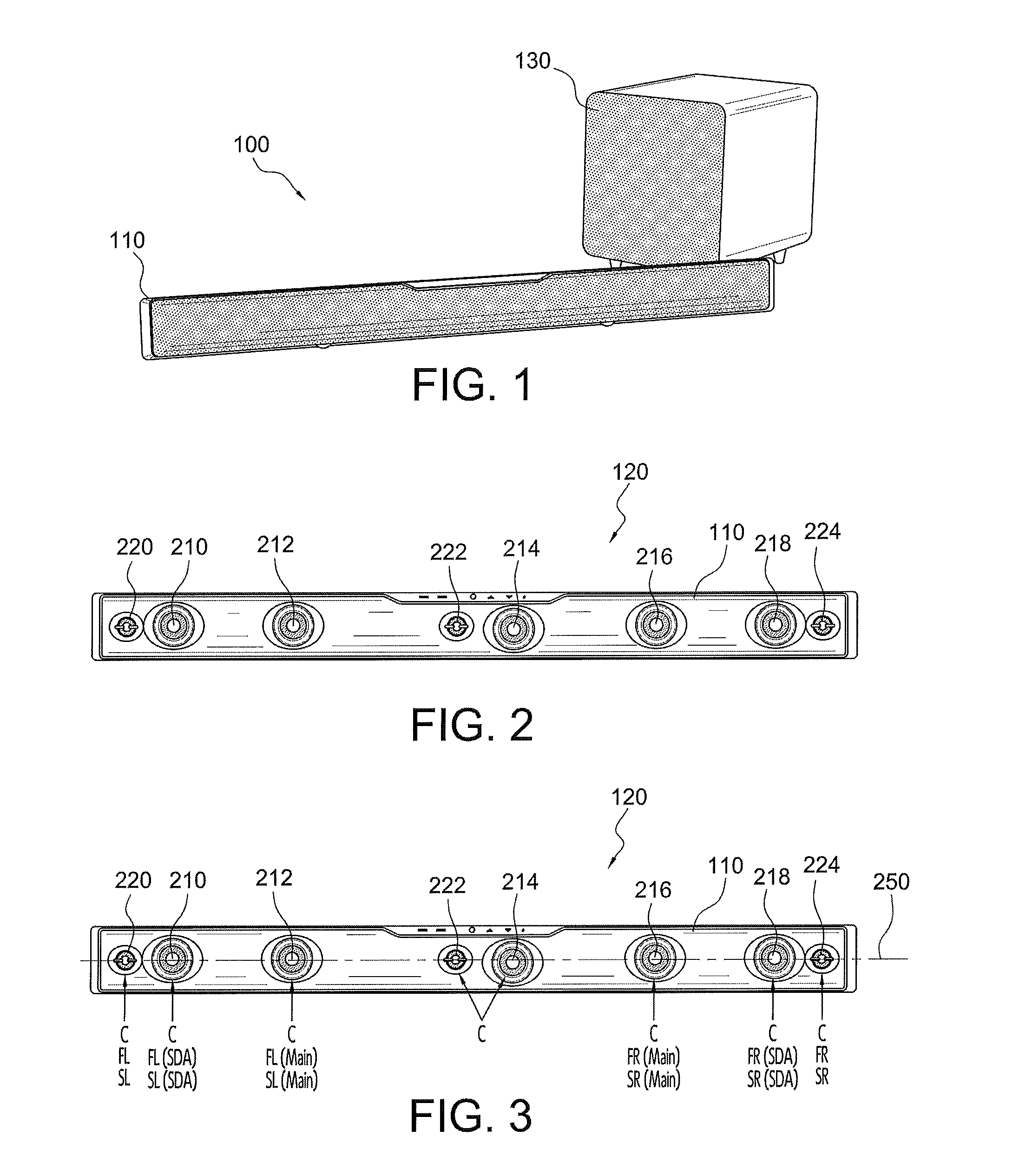

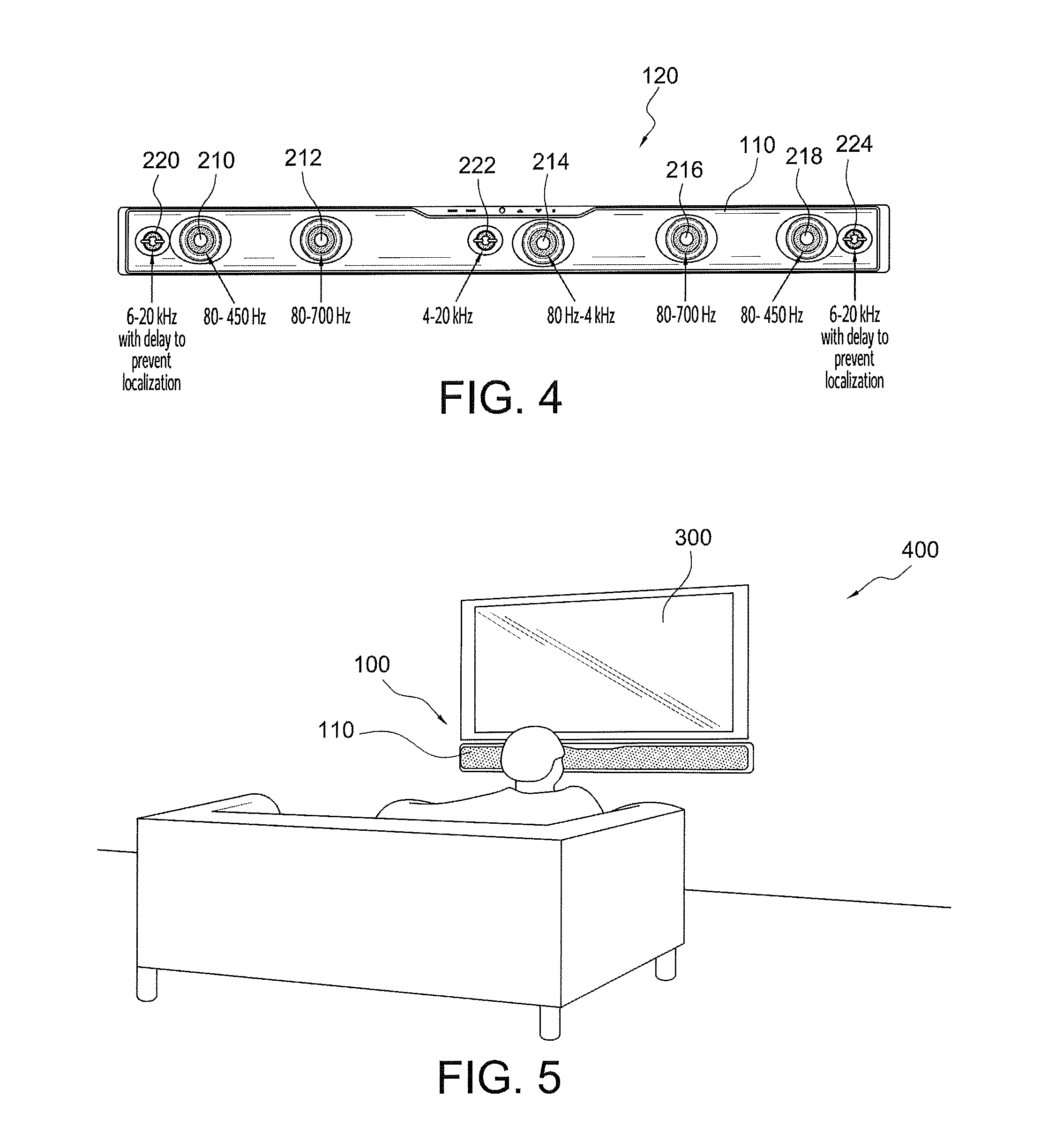

Method and System for Optimizing Center Channel Performance in a Single Enclosure Multi-Element Loudspeaker Line Array

ActiveUS20150189439A1Improve fidelityImprove intelligibilityTransducers for sound channels pluralityStereophonic circuit arrangementsCLARITYVocal tract

A multi-element single enclosure loudspeaker system uses all of the available driver elements in a linear array of loudspeaker drivers for purposes of reproducing center channel program material, whether discrete within a multichannel mix (such as Dolby Digital 5.1™) or derived from a 2-channel mixdown via any appropriate means (such as SRS™ or Dolby ProLogic™ algorithms), in a manner that provides optimized intelligibility of dialog, improved overall clarity, natural timbre and dynamics of music or other effects and wide bandwidth for a wide range of seating / viewing locations for (domestic) home theater environments.

Owner:STAROBIN BRADLEY M

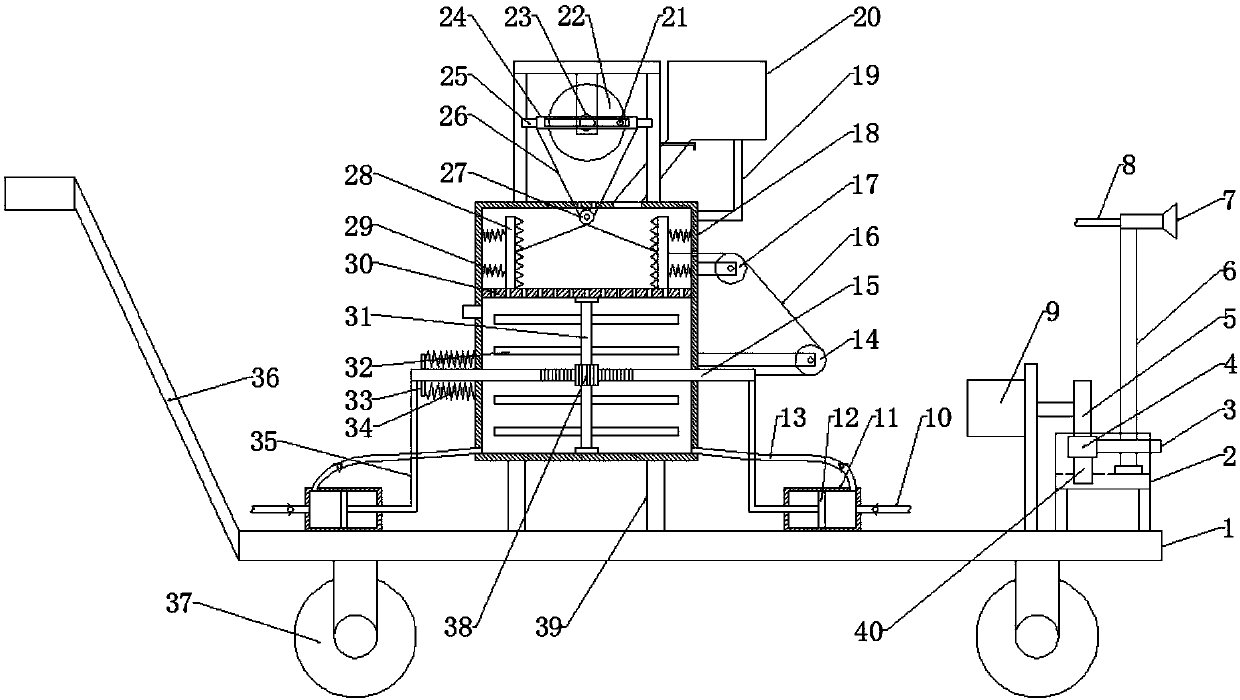

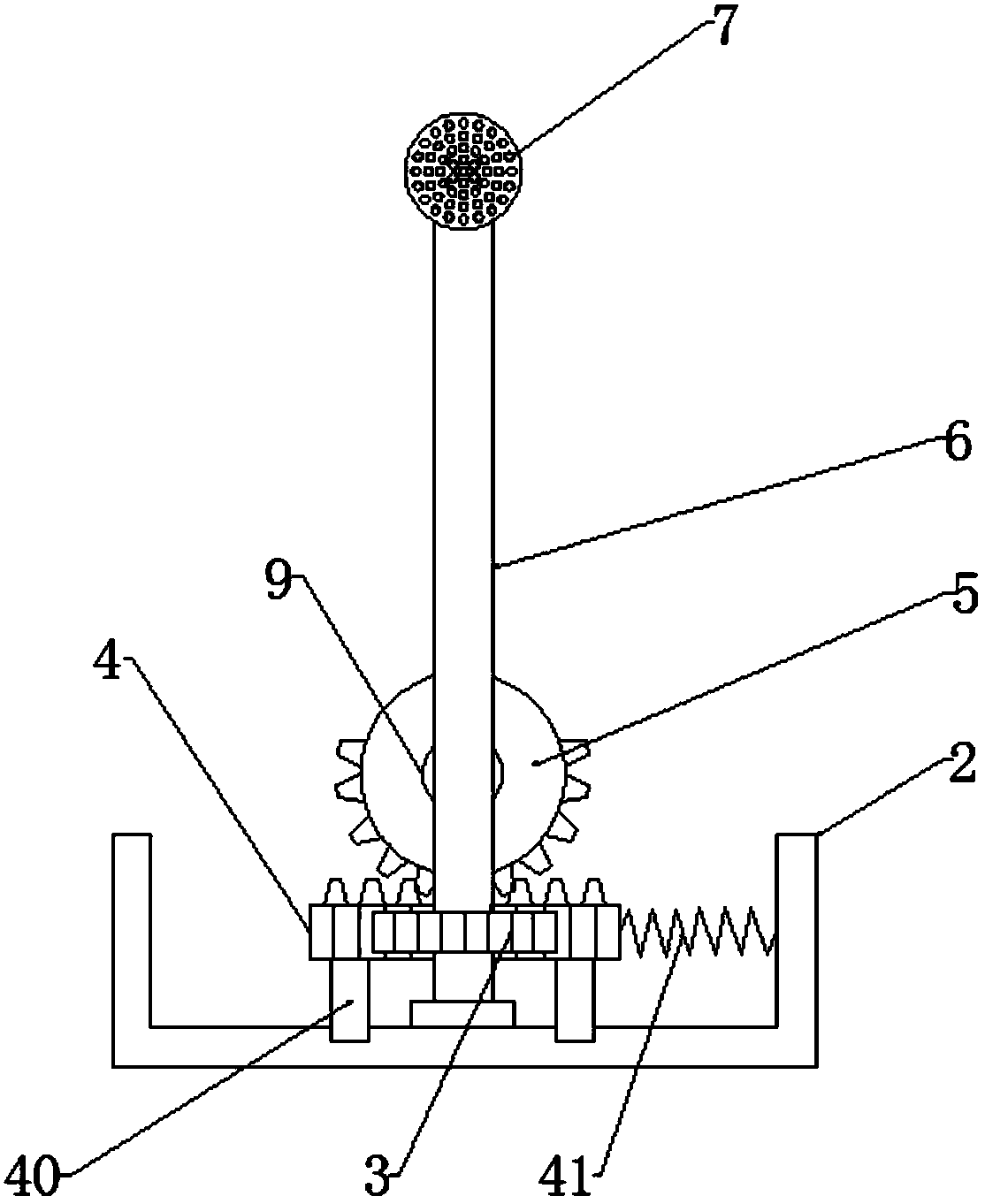

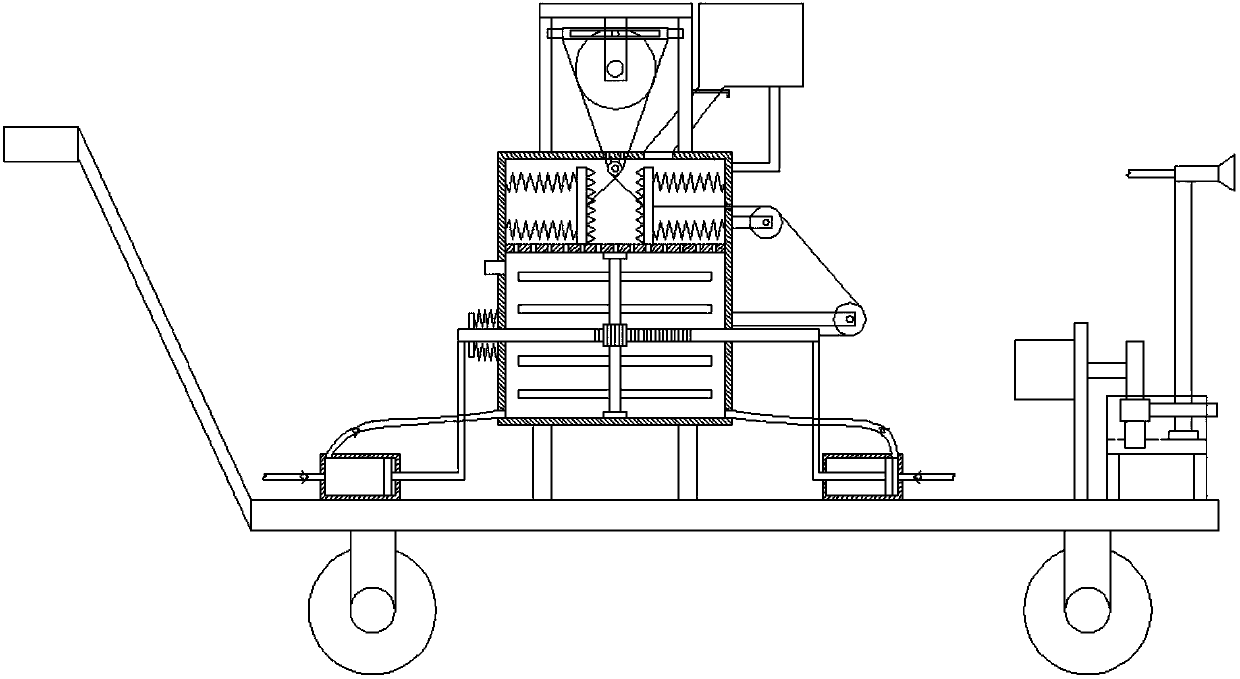

Efficient watering and fertilization device for agriculture

InactiveCN107580847AIncrease profitImprove preparation efficiencyPressurised distribution of liquid fertiliserGear wheelAgricultural engineering

The invention discloses an efficient watering and fertilization device for agriculture. The device comprises a base plate, a box, a first motor, a disc, a movable rod, a fertilizer hopper, a crushingplate, a first spring, a first haulage rope, a second haulage rope, a first tooth bar, a second spring, a first rotating shaft, a first gear, an agitator arm, spraying mechanisms and a fertilization mechanism. With the arrangement of the first motor, the disc, the movable rod, the first haulage rope and the crushing plate, a solid granular fertilizer is repeatedly crushed, and then the solid fertilizer is better dissolved in water and utilization rate of the fertilizer is raised. With the arrangement of the second haulage rope, the first tooth bar, the first gear, the second spring, the firstrotating shaft and the agitator arm for cooperation, the agitator arm rotates in the forward and reverse directions such that water and the fertilizer are better integrated and fertilizer water preparation efficiency is raised. With the arrangement of two spraying mechanisms, continuous spraying is realized. With the arrangement of the fertilization mechanism, a nozzle can rotate a certain angle in both forward and reverse directions such that spraying range is widened, fertilization efficiency is raised and labor of workers is reduced.

Owner:临泉县生产力促进中心

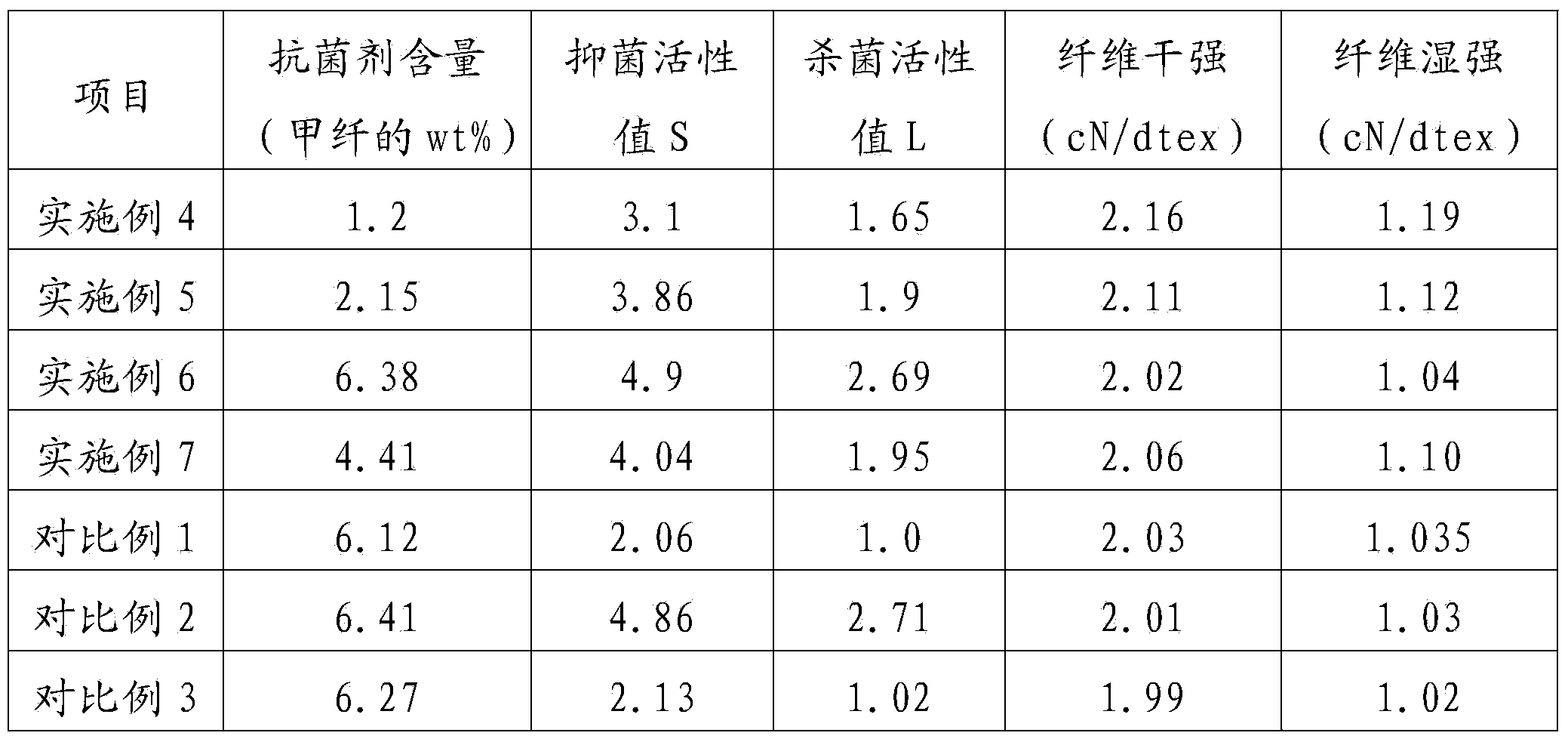

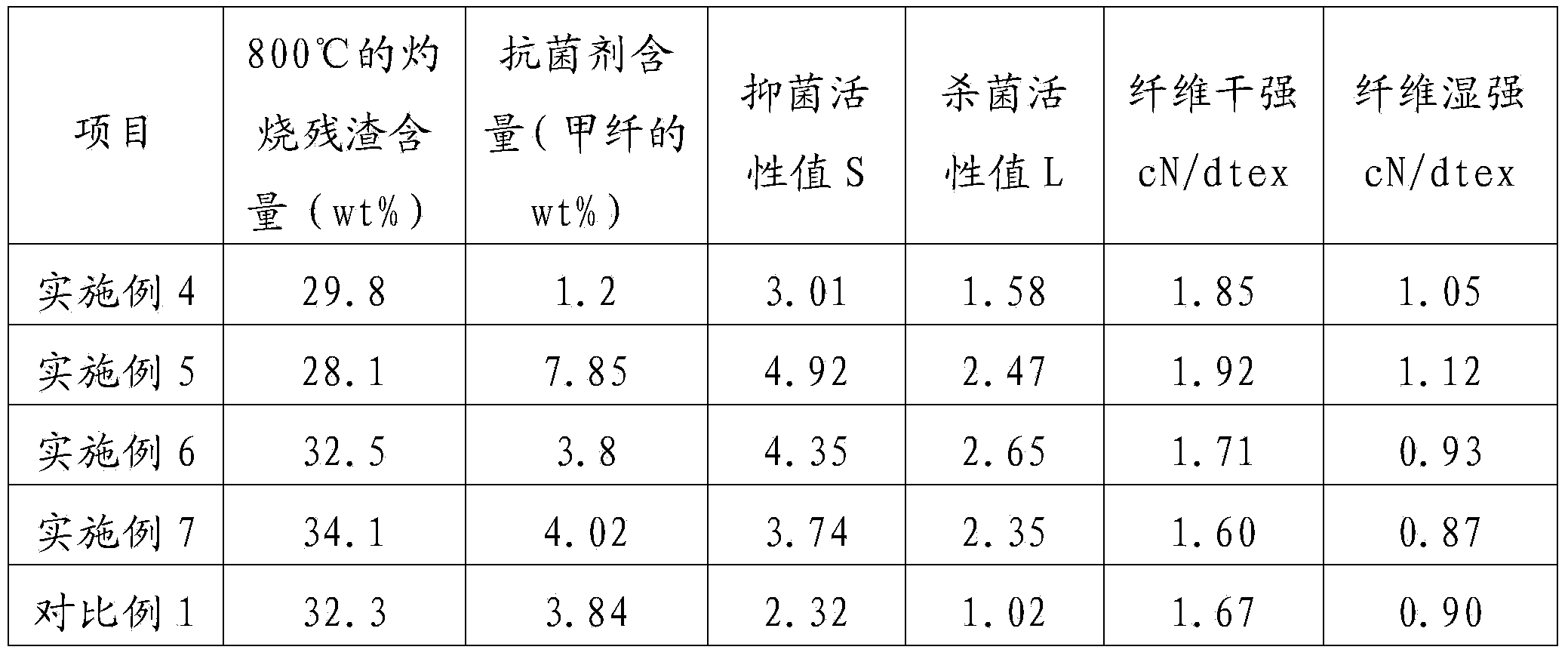

Antibacterial regenerated cellulose fiber and preparation method thereof

ActiveCN103668520ABiodegradablePromote degradationArtificial filaments from viscoseWet spinning methodsBiocompatibility TestingCellulose fiber

The invention discloses an antibacterial regenerated cellulose fiber and a preparation method thereof, and the antibacterial cellulose fiber contains 0.5 ~ 10wt% of chitosan quaternary ammonium salt, the preparation method comprises the following steps: (1) preparing the chitosan quaternary ammonium salt with deionized water and sodium hydroxide into an antibacterial solution; (2) using cellulose pulp as a raw material to prepare spinning viscose; (3) adding the antibacterial solution to a viscose solution of any step from the yellowing step to before spinning, with the adding amount of the chitosan quaternary ammonium salt being 0.5 ~ 10% of the weight of alpha cellulose in the viscose solution, to obtain an antibacterial spinning viscose solution; and (4) obtaining the antibacterial regenerated cellulose fiber by coagulating bath spinning and drawing molding of the antibacterial spinning viscose solution, and then refining and drying. The antibacterial regenerated cellulose fiber simultaneously has biodegradability, biocompatibility, safety and antibacterial property and other excellent properties, and has better moisture absorption and moisture preservation, crease resistance and softness.

Owner:赛得利(盐城)纤维有限公司

Method of preparing soy protein/cellulosic composite fiber with high protein inventory

InactiveCN101509156AImprove protectionImprove securityConjugated cellulose/protein artificial filamentsProtein solutionCellulose

The invention provides a preparation method for soyabean protein / cellulose composite fiber with high protein inventory, belonging to the material field. In the method, sodium hydroxide / sulfourea / urea mixed aqueous solution is used as the solvent for dissolving cellulose to prepare high concentrated cellulose solution, separated soyabean protein is pretreated by the hydroxide / sulfourea / urea mixed aqueous solution to obtain suspending liquid, and sodium hydroxide is added into the obtained suspending liquid for direct dissolution to obtain soyabean protein solution; the cellulose solution and the soyabean protein solution are mixed in proportion and stirred to obtain composite solution, and the composite solution is treated by defoaming, spinning by a spinning machine, solidifying, drafting, washing, drying, oil-applying and winding to prepare soyabean protein / cellulose composite fiber with excellent mechanical property and high protein inventory. The production process avoids the technique of viscose process which is lengthy, complex and seriously polluting.

Owner:DONGHUA UNIV

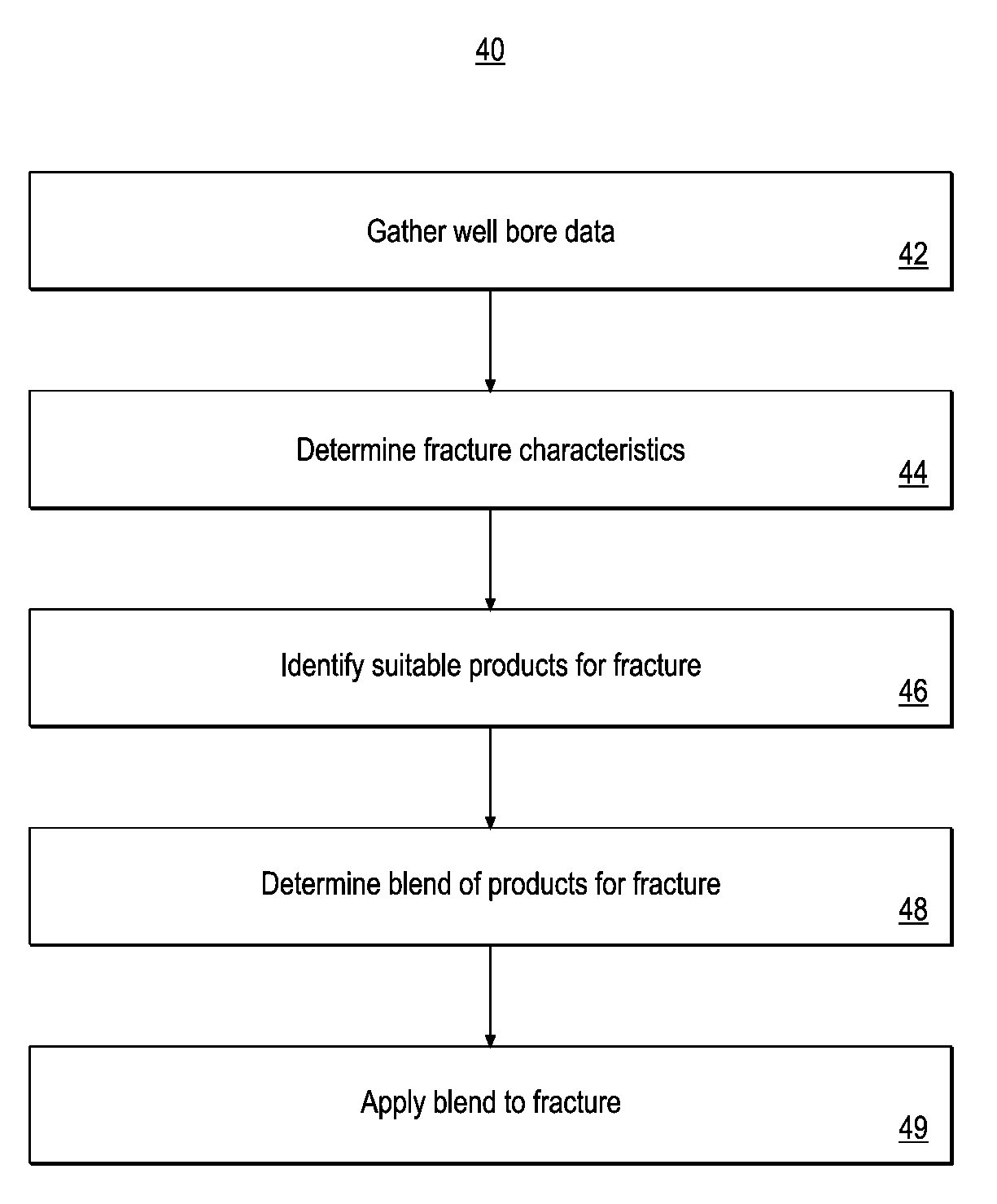

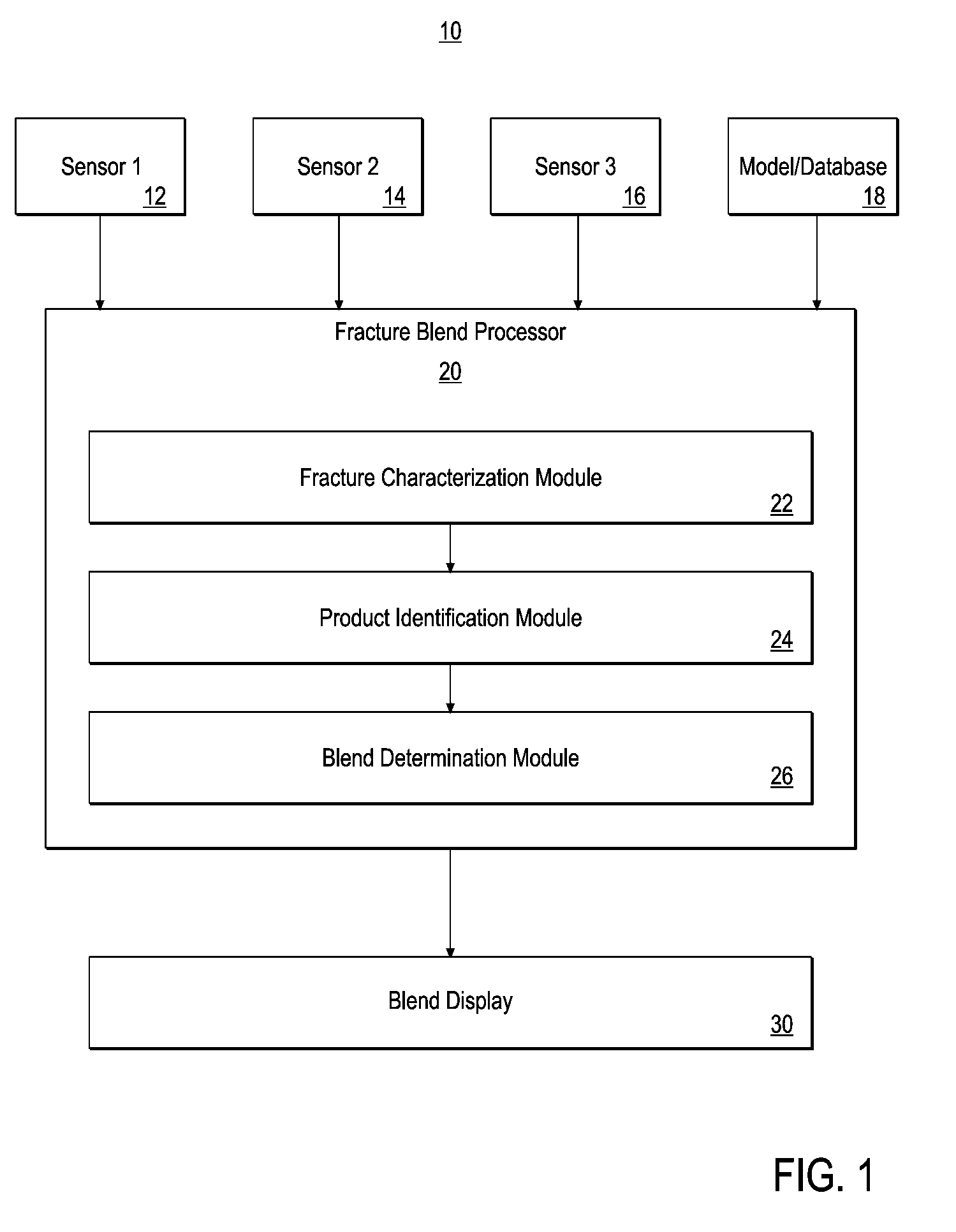

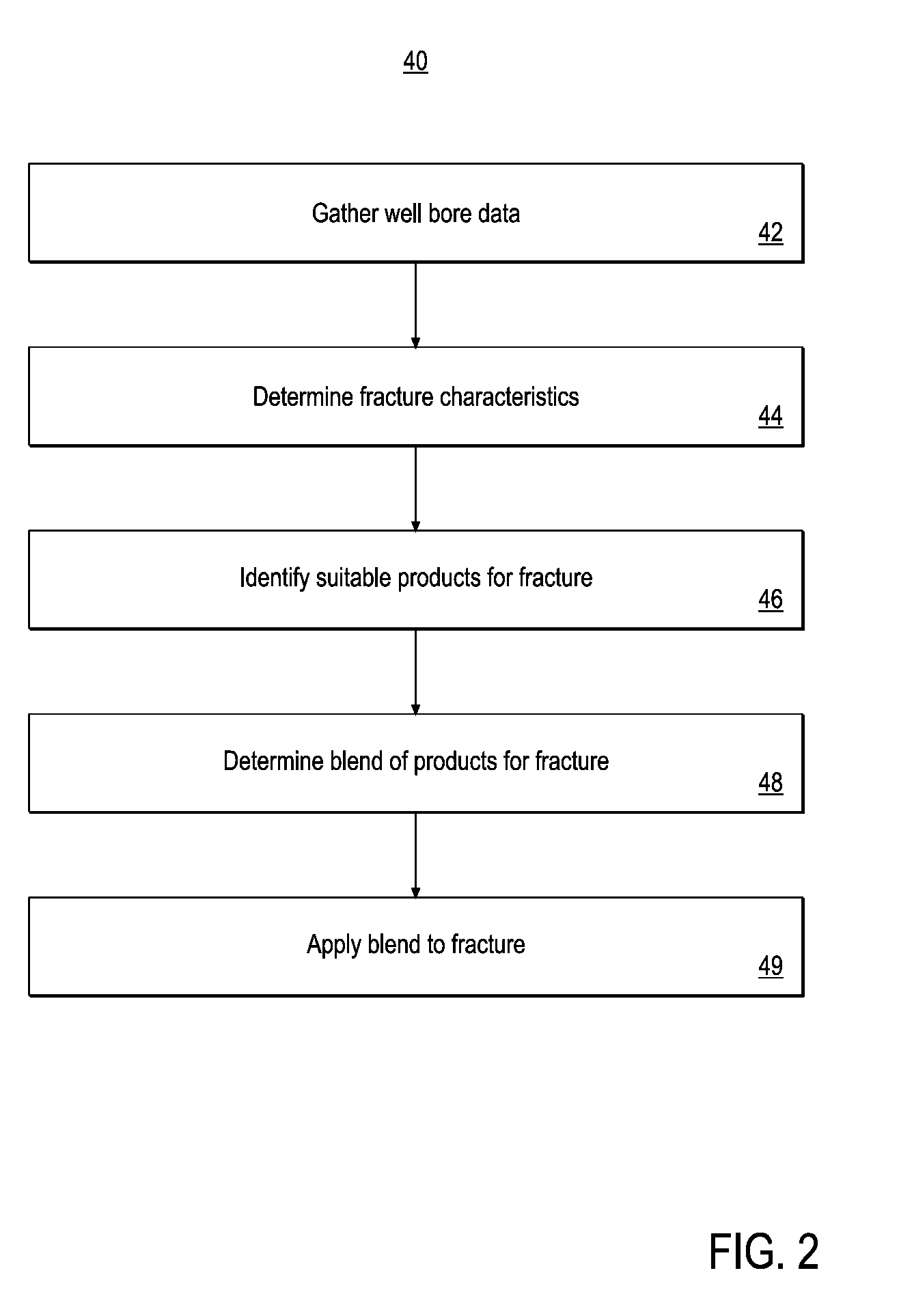

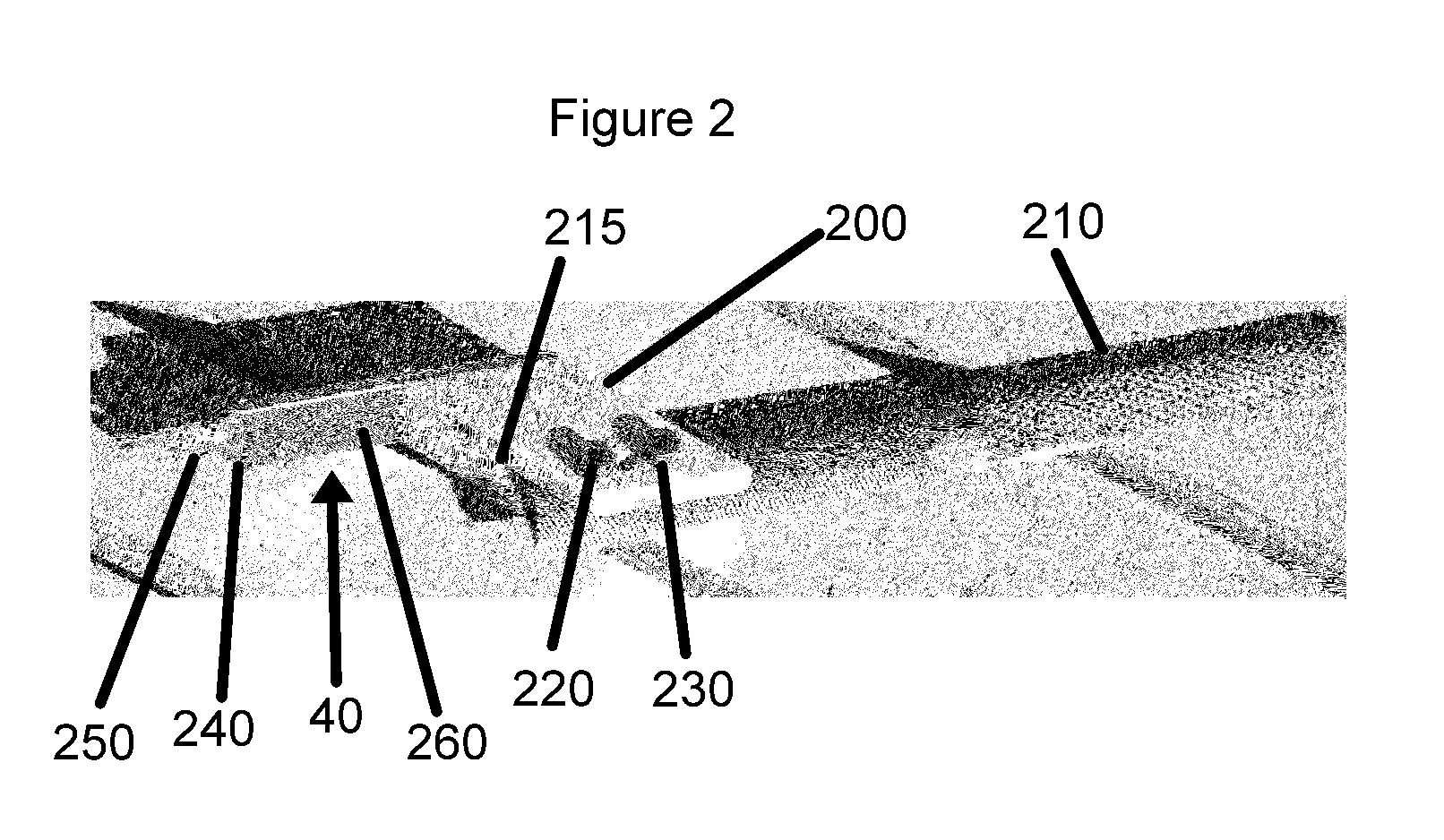

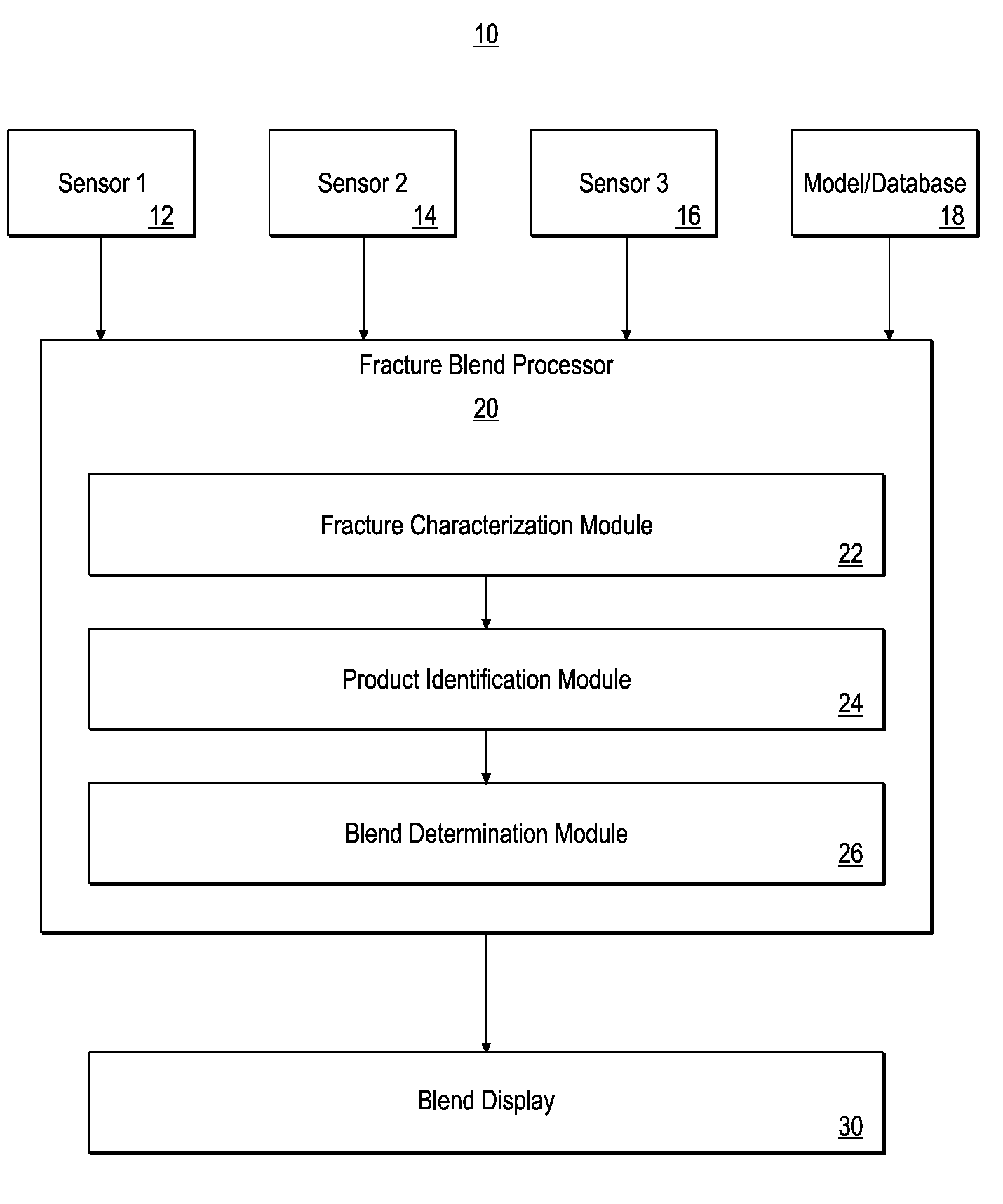

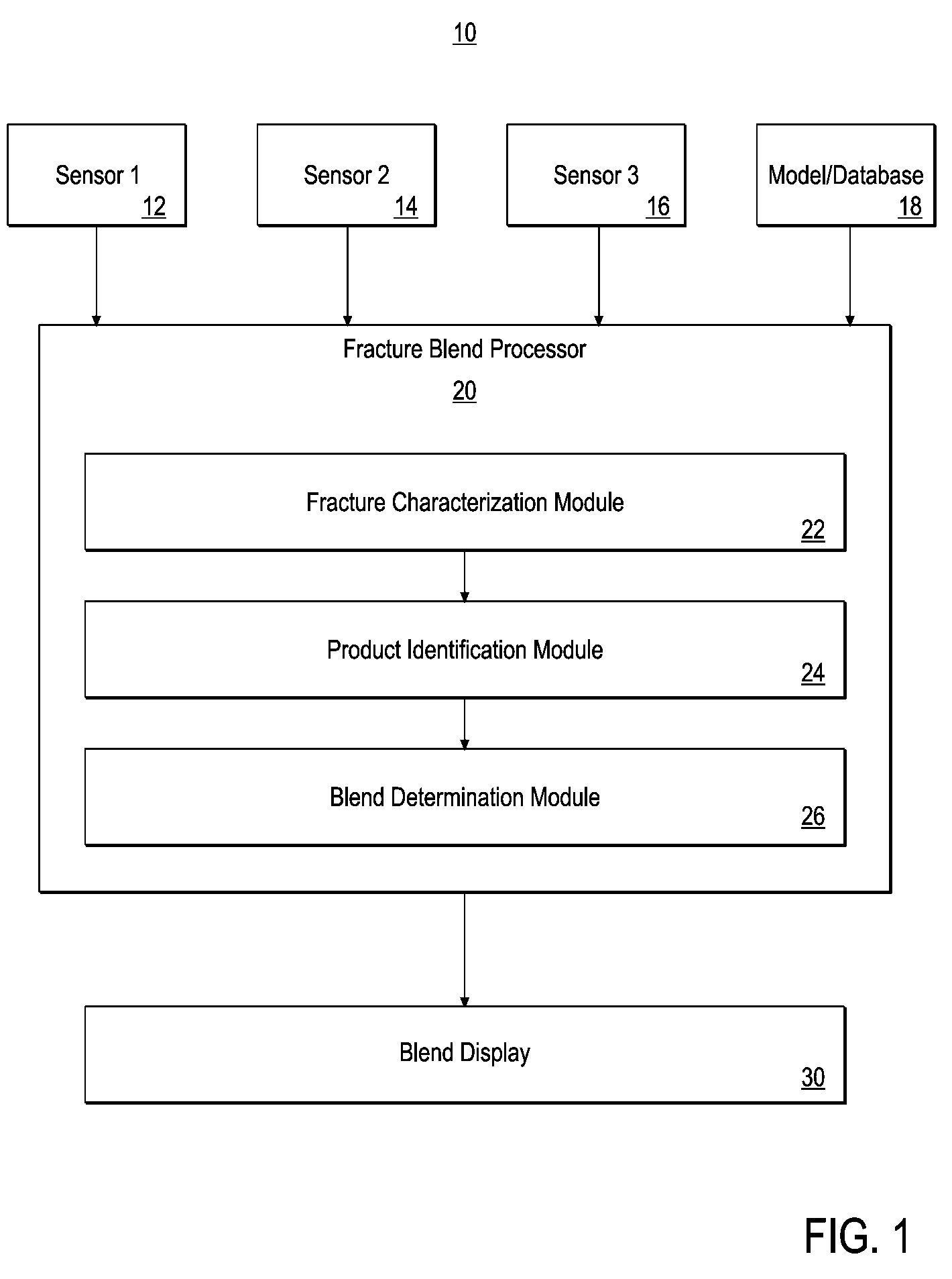

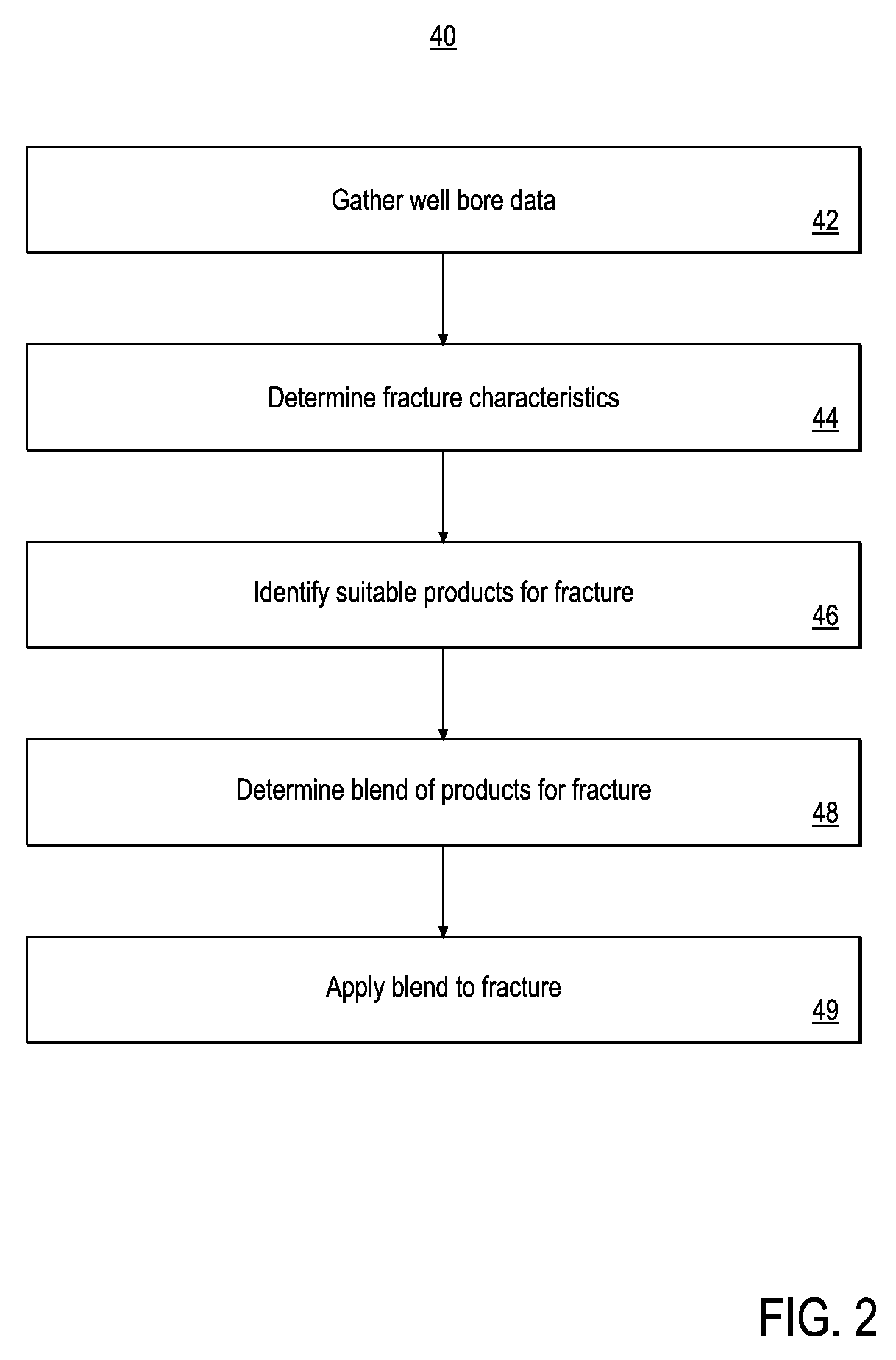

System and method for minimizing lost circulation

InactiveUS20100250204A1Minimize circulationReduce the amount of wasteComputation using non-denominational number representationFlushingData sourceAnalysis tools

A system and method is provided for minimizing lost circulation associated with the operation of a subterranean reservoir. The system includes one or more sources, such as earth modeling and fracture analysis tools, for providing data representative of a fracture formation in the reservoir, and a computer processor in communication with the data sources for determining an appropriate blend of lost circulation material products for application to the fracture formation. The computer processor is programmed with computer readable code for selecting a plurality of candidate products for application to the fracture formation, and for mathematically determining an optimized blend of the selected products. By applying the optimized blend, material and labor costs associated with well operation can be significantly reduced.

Owner:CHEVROU USA INC

Toxin-expelling weight-reducing flower cake and preparation method thereof

The invention relates to a toxin-expelling weight-reducing flower cake and a preparation method thereof. The flower cake comprises the following raw materials by weight: 15%-50% of pollen, 20%-70% of glutinous rice flour or flour, 1%-2% of bifidus factors, 10%-20% of oil, 2%-10% of water, 2%-5% of other auxiliary materials, 0.1%-0.5% of vanillin, and 0.05%-0.2% of aspartame. The toxin-expelling weight-reducing flower cake is obtained by mixing and braising the above raw materials. The toxin-expelling weight-reducing flower cake obtained by the method in the invention has flower fragrance and agreeable sweet taste, has bowel-relaxing and toxin-expelling efficacy, can reach the effect of maintaining beauty and keeping young after long-term eating, and is convenient for both eating and carrying. Toxin-expelling weight-reducing flower cake series products can be manufactured according to different taste and functions of flowers.

Owner:云南龙润茶业集团有限公司

Preparation method of tiles with imitated natural stone grains

ActiveCN105819904AGood blendingThe decorative effect is clear and realisticCeramic tilesMaterials science

The invention provides a preparation method of tiles with imitated natural stone grains.The preparation method comprises the following steps that 1, color pastes are prepared, wherein the pastes of at least two colors are prepared by selecting common raw materials for ceramic bodies and adding ceramic pigments through wet ball milling; 2 premixing is conducted, wherein the color pastes are unevenly mixed to obtain an uneven paste; 3, the uneven paste is applied to tile green bodies to form pattern layers; 4, the tile green bodies obtained in the step 3 are placed in a kiln for sintering, and then the tiles with the imitated natural stone grains are obtained.According to the preparation method, strip-shaped intersection or staggered mixing is formed between the color pastes through an uneven mixing method, the paste is applied to the pattern layers formed on the tile green bodies, multiple different pattern grains such as a strip shape, a flocculent shape and a pinnate shape can be presented, the prepared tiles with the imitated natural stone grains have the decorative effects of different patterns and lines, the grains are rich and diverse, different in style and clear and vivid in effect, and therefore the diversity of the decorative effect is improved.

Owner:FOSHAN DONGPENG CERAMIC +3

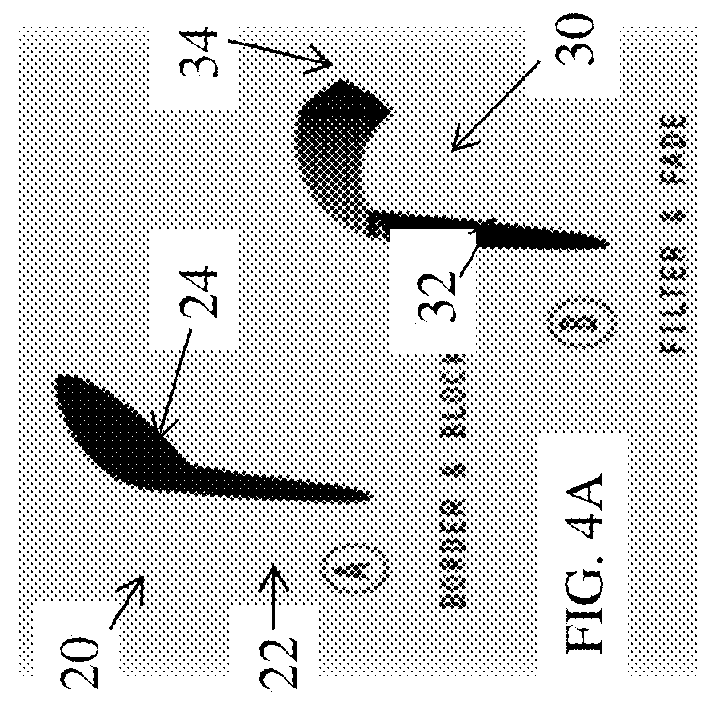

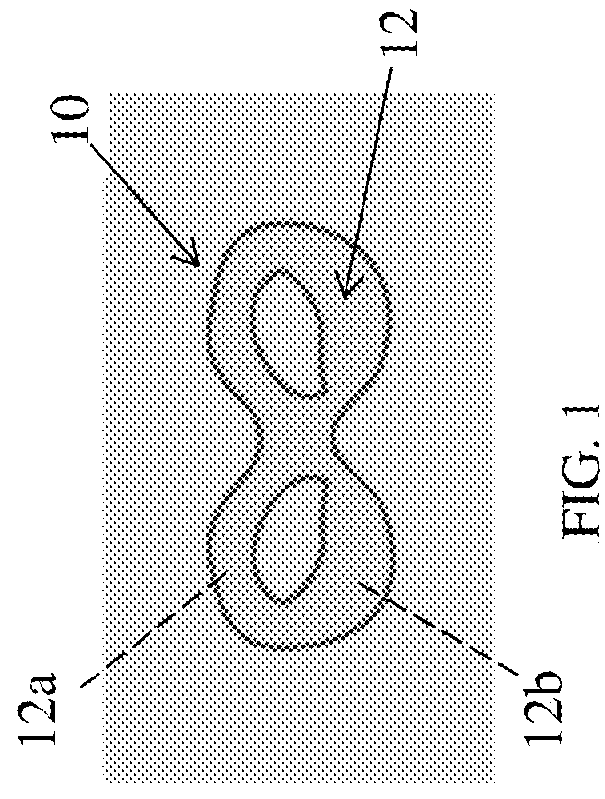

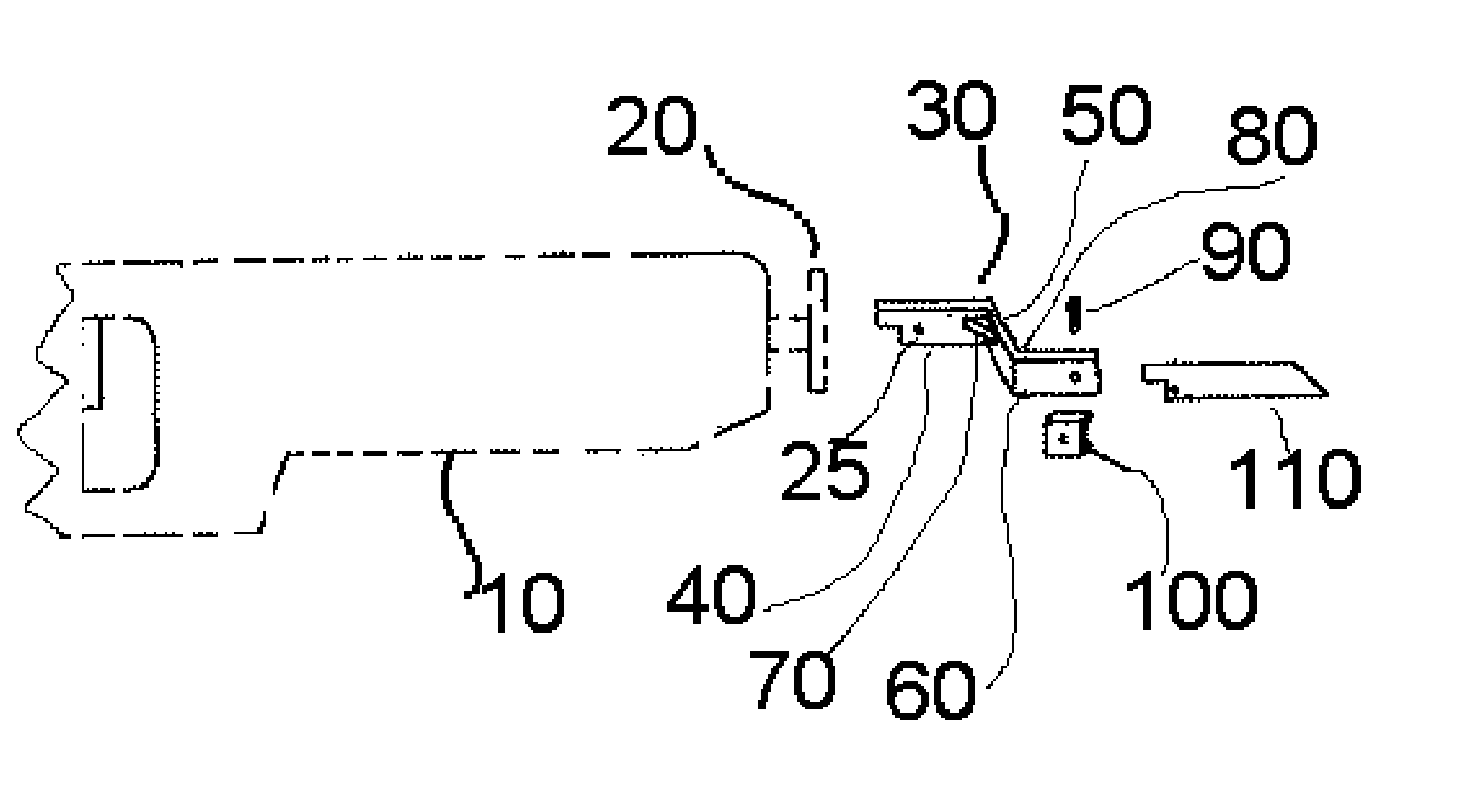

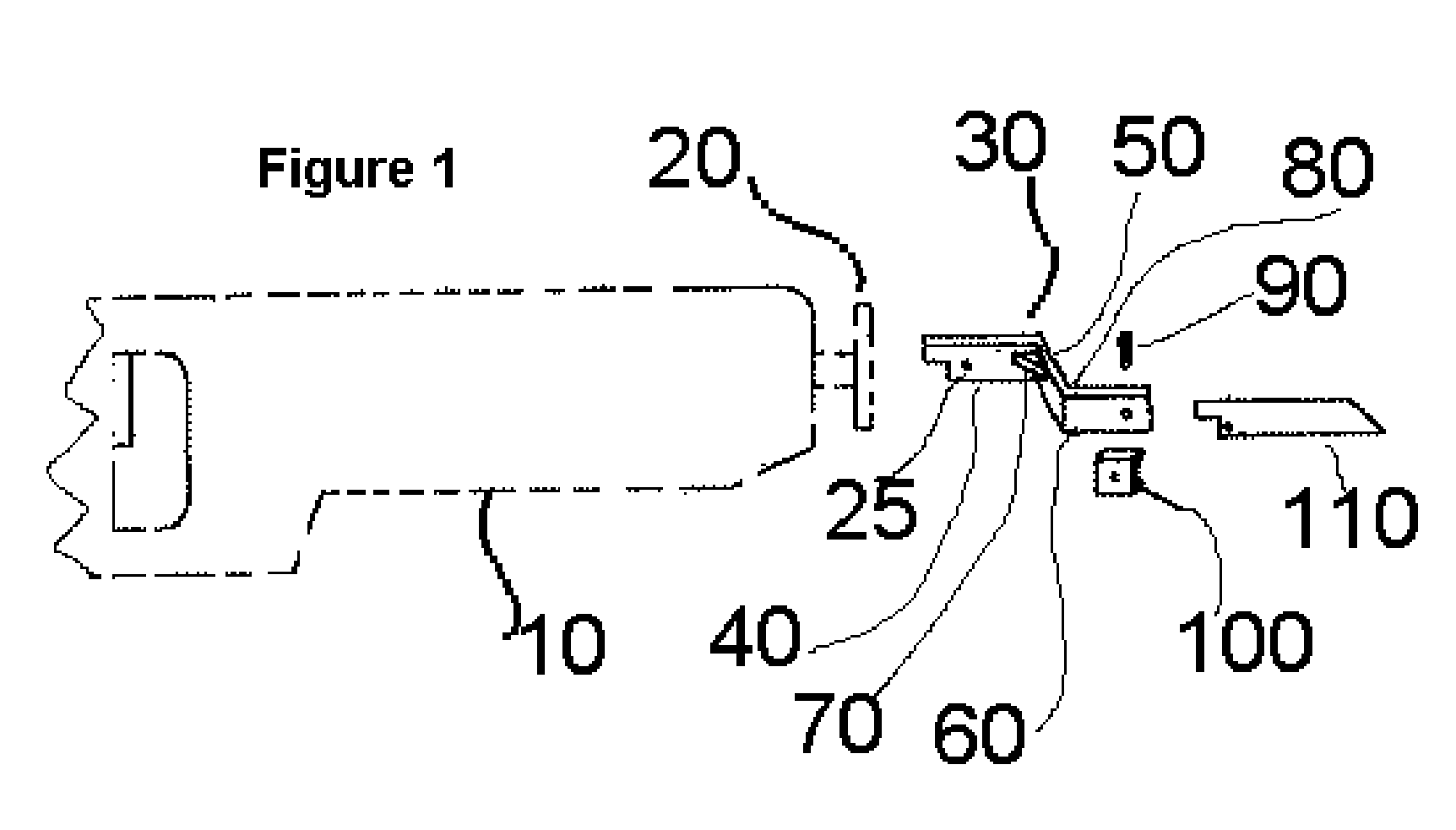

Orbital reciprocating saw

A simple attachment for a reciprocating tool that will effectuate the ability to do a flush cut in an inexpensive and simple manner which is neither too rigid, nor not rigid enough. This is effectuated by providing an insert which fits into the reciprocating tool in the same fashion as a regular blade. The present invention then offsets the placement of a blade, sander, file, or other tool by as many inches as wished by the user. The blade, sander, file, or other tool is held rigid through the use of a 45 degree bracket spanning the distance from the original plane to the offset plane, or via a single or compound trapezoid design.

Owner:SHIRE THE

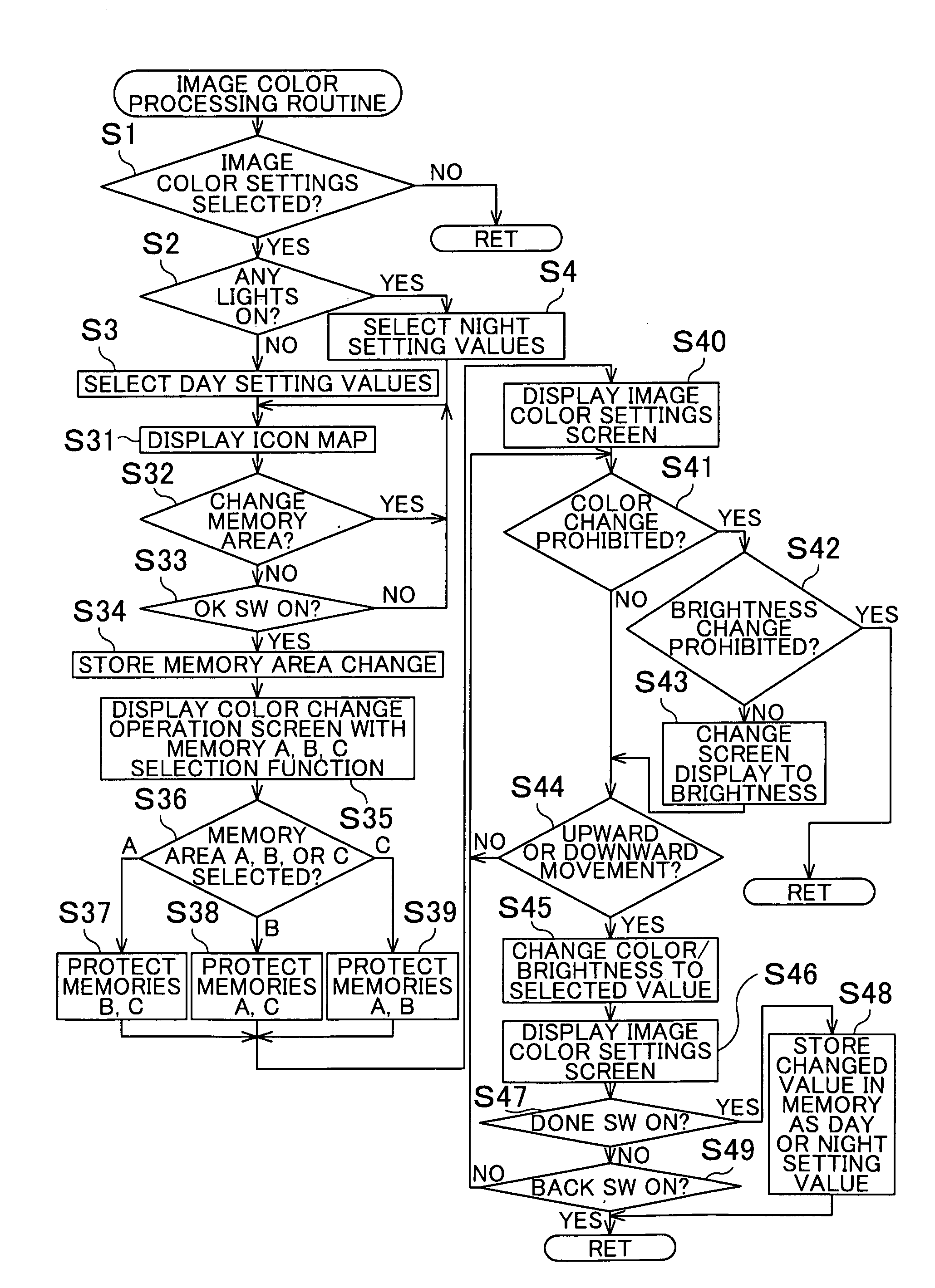

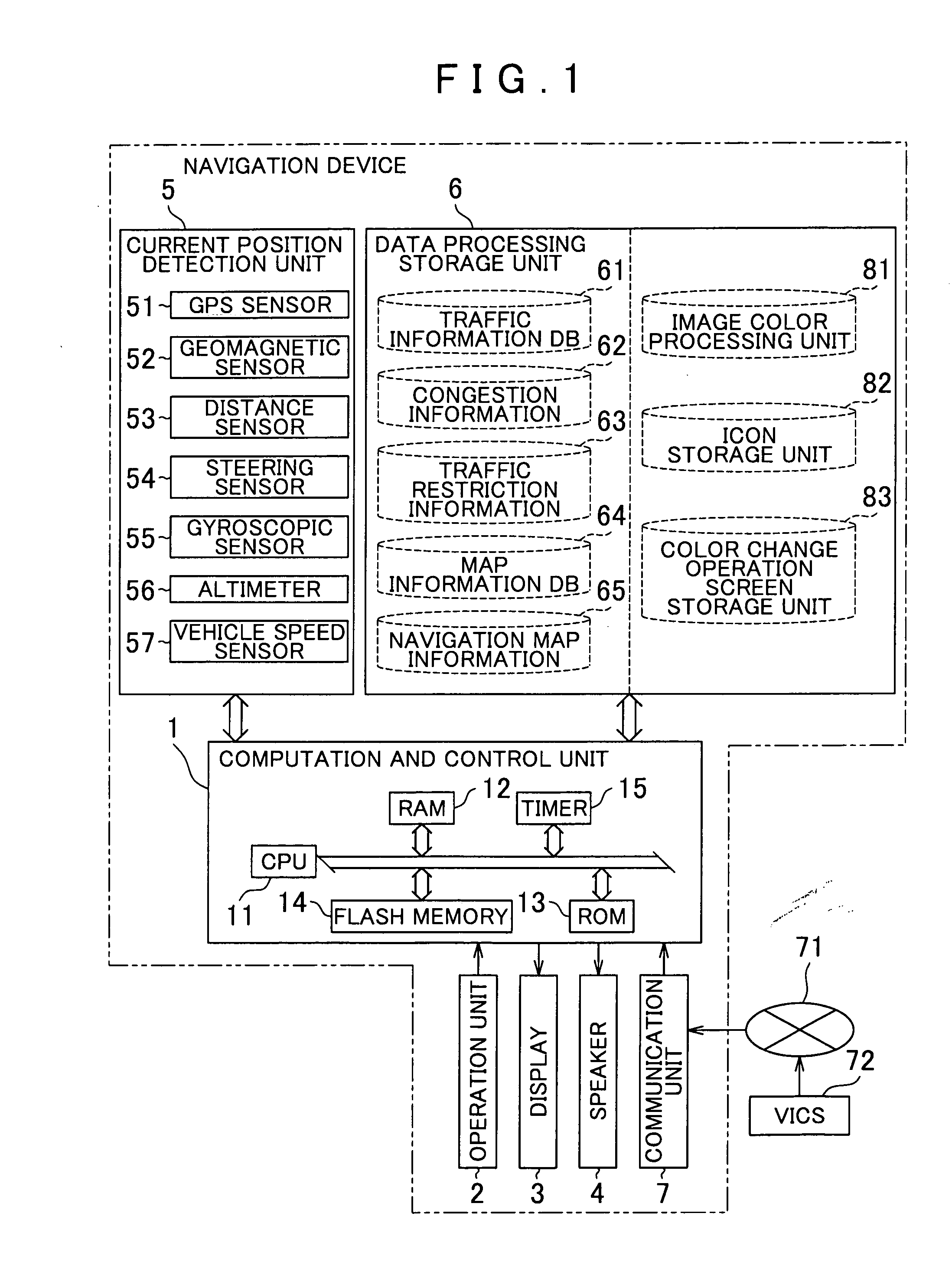

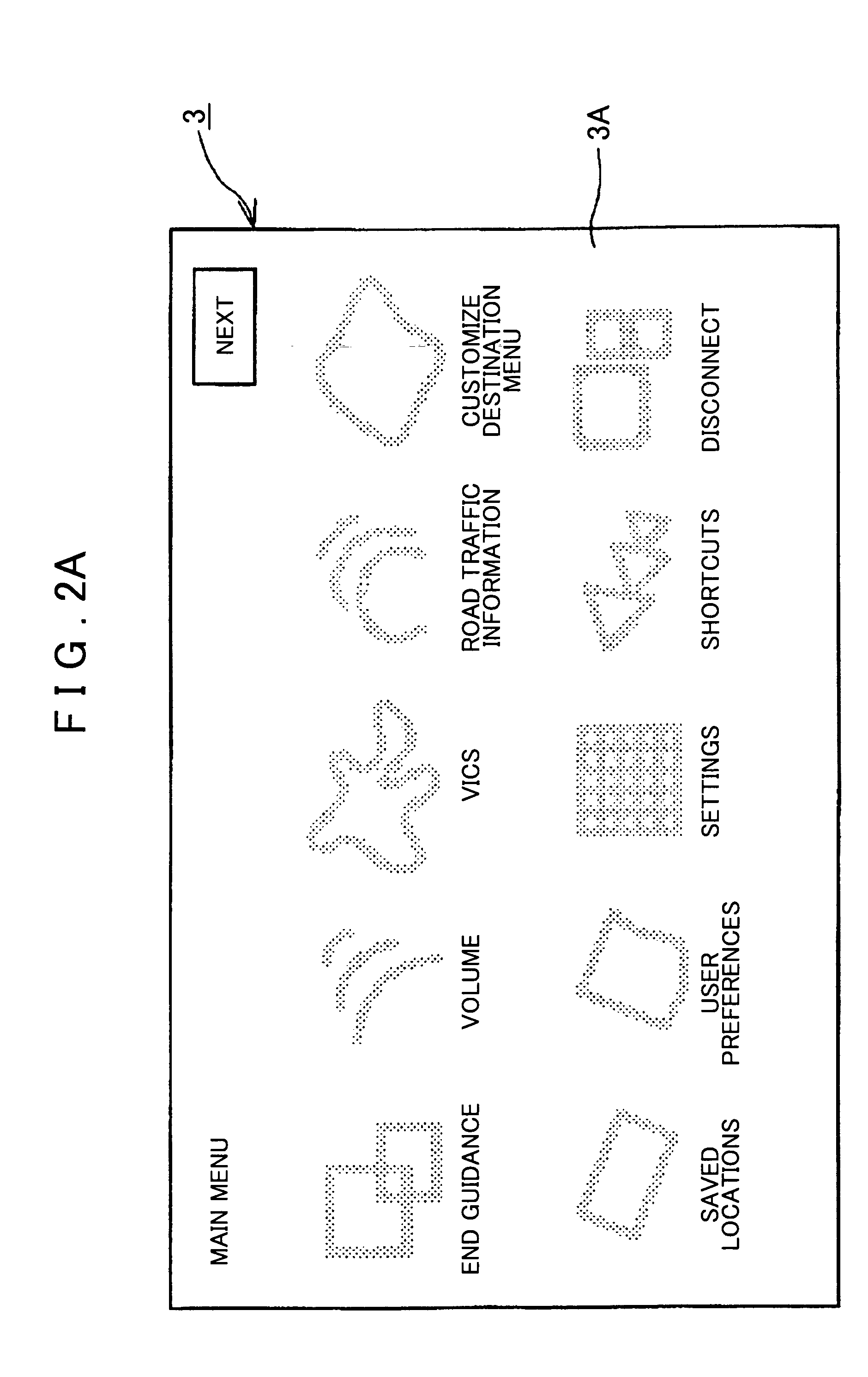

Navigation device

InactiveUS20100274476A1Adjust moreGood blendingInstruments for road network navigationRoad vehicles traffic controlComputer graphics (images)Map design

A vehicle owner can express a display screen that displays a map in a color that matches an interior design. On a map view screen that displays a map for route guidance on a display screen, icons that indicate current navigation functions, and icons that indicate touch switches that are operated to change current navigation functions are displayed. A color change operation screen is used to change the color of the icons that indicate navigation functions and the icons that are operated to change navigation functions on the display screen. Accordingly, the display screen can be expressed in colors that match the interior design of the vehicle. Moreover, the colors of the map view screen used for route guidance do not change; only the icons that indicate navigation functions and icons that are operated to change navigation functions are changed. The general map colors are thus maintained according to natural usage conditions that blend into the overall design.

Owner:AISIN AW CO LTD

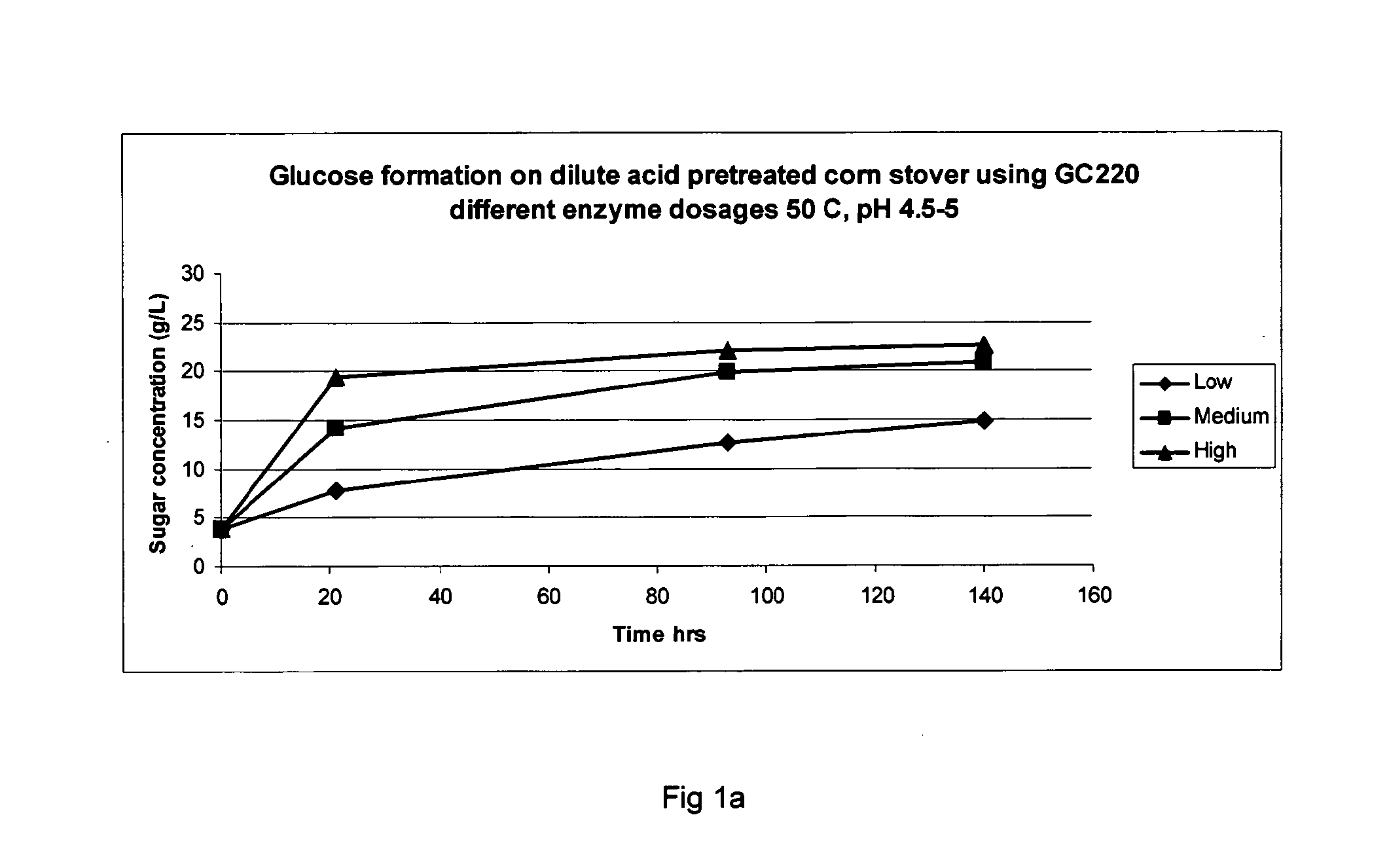

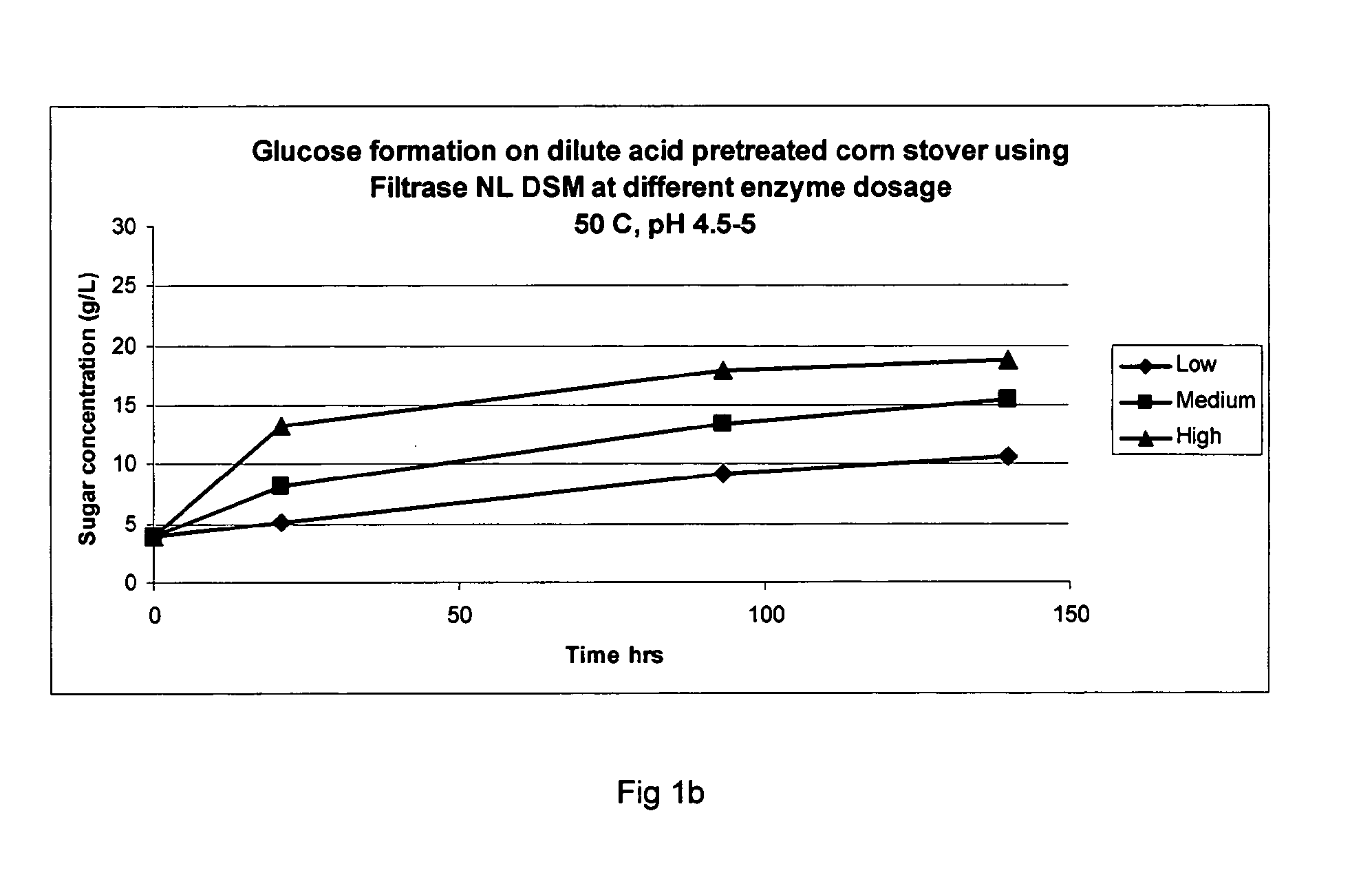

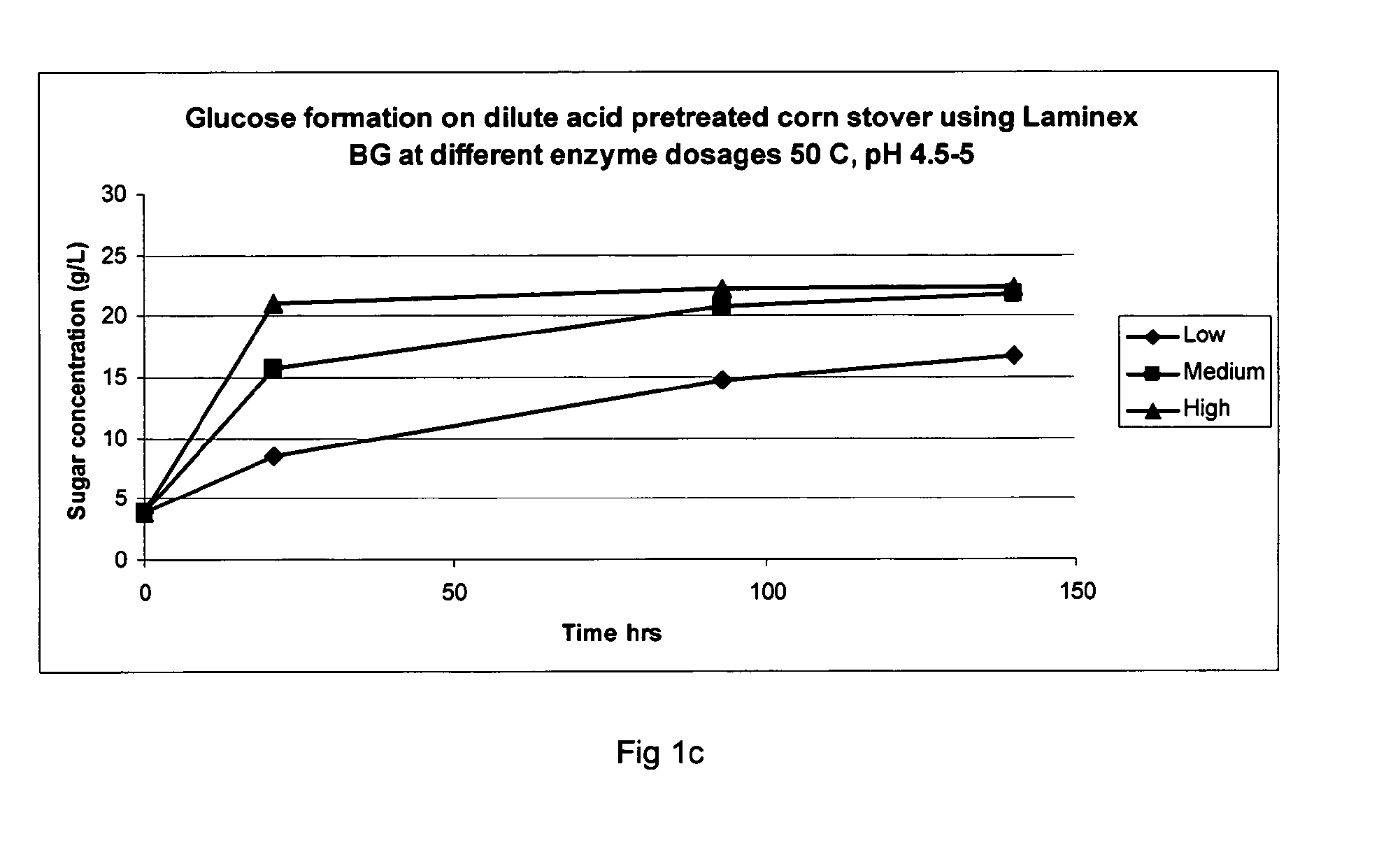

Degradation of lignocellulosic material

ActiveUS20110143402A1Efficient hydrolysisHigh specific activityBiofuelsEnzymesCellulaseHemicellulose

The present invention describes a method for the treatment of lignocellulosic material which method comprises contacting said lignocellulosic material with a composition comprising two or more enzyme activities, said enzyme activities being cellulase and / or hemicellulase activities, wherein the pH during the treatment is about 4.5 or lower, and the treatment is carried out at a dry matter content of 15% or more.

Owner:DSM IP ASSETS BV

BOPET (Biaxial oriented Polyethylene Terephthalate) ultraviolet shielding master batch and manufacturing method thereof

ActiveCN107418159AEasy to prepareImprove filtering effectArtifical filament manufactureMonocomponent polyamides artificial filamentPolyethylene terephthalate glycolHigh-speed grinding

The invention relates to BOPET (Biaxial oriented Polyethylene Terephthalate) ultraviolet shielding master batch. The BOPET ultraviolet shielding master batch is prepared from the following raw materials in parts by weight: 70 to 90 parts of polyethylene terephthalate, 1 to 5 parts of a dispersant, 5 to 20 parts of a coloring agent, 10 to 20 parts of a nano-grade ultraviolet absorbent and 5 to 10 parts of meta-aramid fibers. According to the BOPET ultraviolet shielding master batch provided by the invention, the coloring agent is ground through a high-speed grinding machine; the aramid fibers are added and the nano-grade ultraviolet absorbent is matched, so that a dispersion effect of the coloring agent and the ultraviolet absorbent is good; meanwhile, the fibers are also dispersed well and have no tangling phenomenon; the filtering performance is good and a BOPET ultraviolet shielding film prepared from the BOPET ultraviolet shielding master batch has a ultraviolet shielding rejection rate reaching 100 percent, and the film haze is less than 2; the master batch is used for producing the BOPET ultraviolet shielding film; a net replacing period is long, and film-forming performance is good. The invention further relates to a preparation method of the BOPET ultraviolet shielding master batch.

Owner:广东彩艳股份有限公司

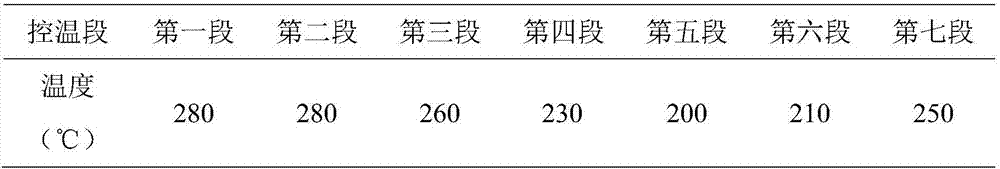

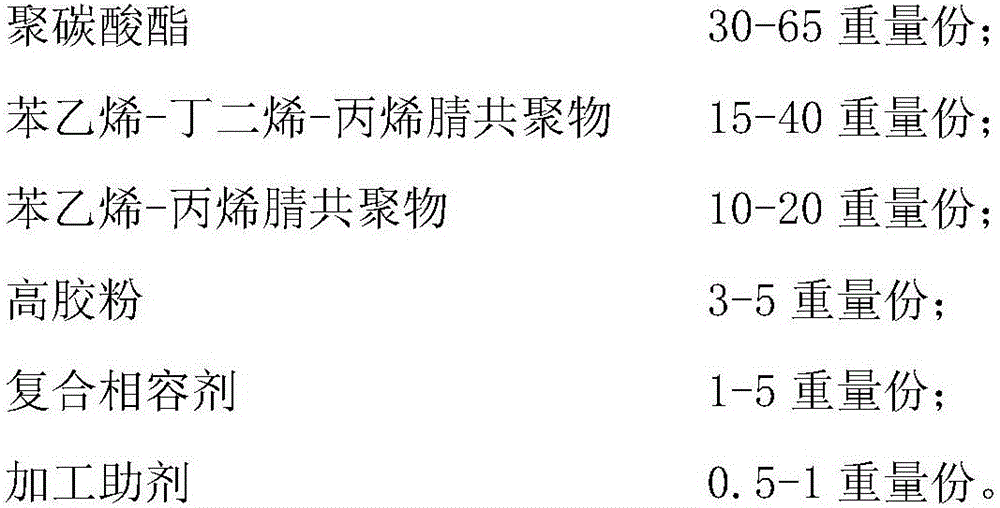

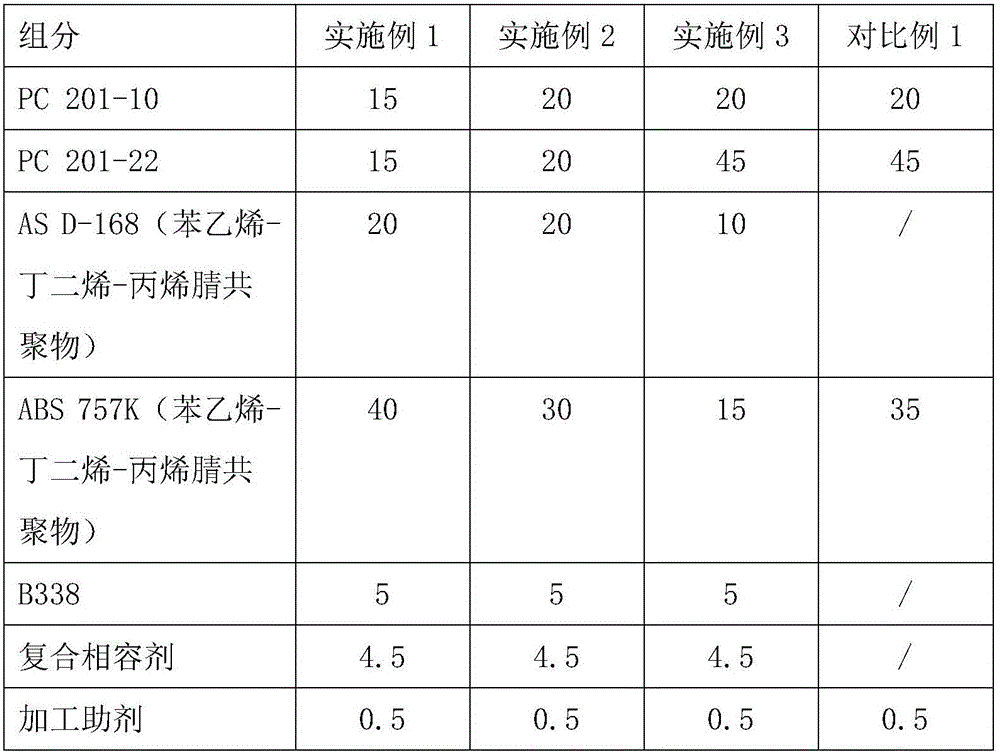

PC/ABS alloy material with high welding strength

The invention provides a PC / ABS alloy material with high welding strength. The PC / ABS alloy material is prepared from, by weight, 30-65 parts of polycarbonate, 15-40 parts of styrene-butadiene-acrylonitrile copolymer, 10-20 parts of styrene-acrylonitrile copolymer, 3-5 parts of high rubber powder, 1-5 parts of compatilizer and 0.5-1 part of processing auxiliaries. The invention provides a preparing method for the PC / ABS alloy material with high welding strength. The invention further provides application of the PC / ABS alloy material with high welding strength to automotive upholstery (like an instrument board), domestic appliance and other components. The alloy material obtained through the method is excellent in physical property and high in welding strength, and can be used in automotive upholstery, domestic appliance and other components.

Owner:中广核俊尔(上海)新材料有限公司

Functional composite fiber and preparation method thereof

ActiveCN103643332AGood antibacterial effectPromote degradationArtificial filaments from viscoseWet spinning methodsCellulose pulpSilicon dioxide

The invention discloses a functional composite fiber and a preparation method thereof. The functional composite fiber comprises 15wt%-45wt% of silicon dioxide and 0.5wt%-10wt% of chitosan quaternary ammonium salt. The preparation method comprises the following steps: (1) preparing an antiseptic solution from the chitosan quaternary ammonium salt, deionized water and sodium hydroxide; (2) preparing alkali cellulose from cellulose pulp, yellowing the alkali cellulose and dissolving the yellowed alkali cellulose in a sodium hydroxide solution of the silicon dioxide, wherein the solid content of spinning viscose containing silicon dioxide is 9.5wt%-11.5wt%; (3) adding the antiseptic solution into the viscose solution containing silicon dioxide in any step from yellowing to spinning to prepare a blended viscose solution, wherein the weight of the chitosan quaternary ammonium salt in the added antiseptic solution accounts for 0.5%-10% of that of the solid in the viscose solution; and (4) performing spinning forming and after-treating on the blended viscose solution to obtain the functional composite fiber. The functional composite fiber prepared by the method has both flame retardant and antibacterial properties.

Owner:赛得利(盐城)纤维有限公司

Injection-moldable conductive heat-conduction modified fluoroplastic material and preparation method and application thereof

ActiveCN104927271AGood electrical and thermal conductivityWide range of applicationsIn situ polymerizationInjection moulding

The invention relates to an injection-moldable conductive heat-conduction modified fluoroplastic material which is prepared from the following components in parts by weight: 50 to 100 parts of conductive heat-conduction modified basic fluoroplastic, 10 to 30 parts of an auxiliary material, 0 to 20 parts of a filling material and 5 to 30 parts of a processing auxiliary. The conductive heat conduction modified basic fluoroplastic is formed by performing in-situ polymerization on tetrafluoroethylene, perfluoro propyl vinyl ether, a conductive heat-conduction medium material and the auxiliary. The injection-moldable conductive heat-conduction modified fluoroplastic material has the beneficial effects that according to the prepared fluoroplastic, the conductive heat-conduction medium material is added in the polymerization process; by adoption of an in-situ polymerization technology, the volume resistivity (about 103 to 104) of the material is greatly reduced, and the heat conduction performance is improved (the heat conduction coefficient is greater than 3W / (m.K)), so that the injection-moldable conductive heat-conduction modified fluoroplastic material is higher in conductivity and heat conduction performance on the basis of chemical resistance and aging resistance. The technology is simple, the production efficiency is high, and no pollution waste is produced.

Owner:青岛科凯达橡塑有限公司

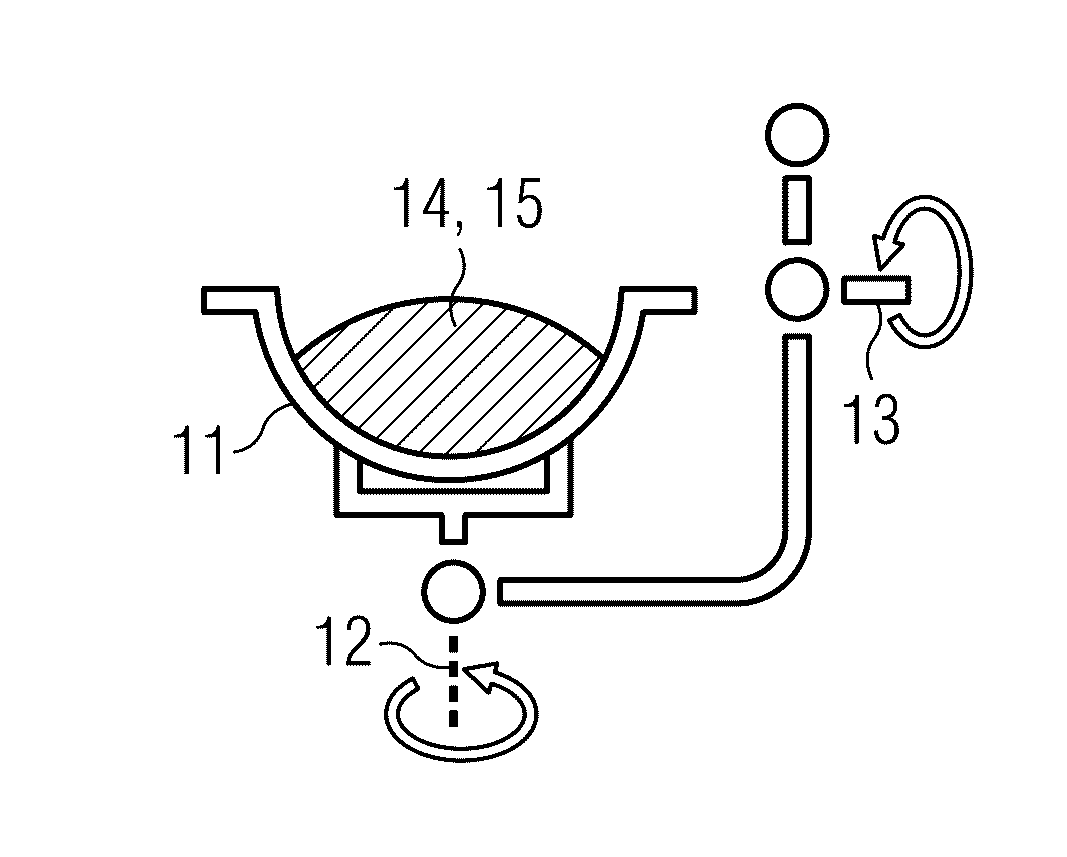

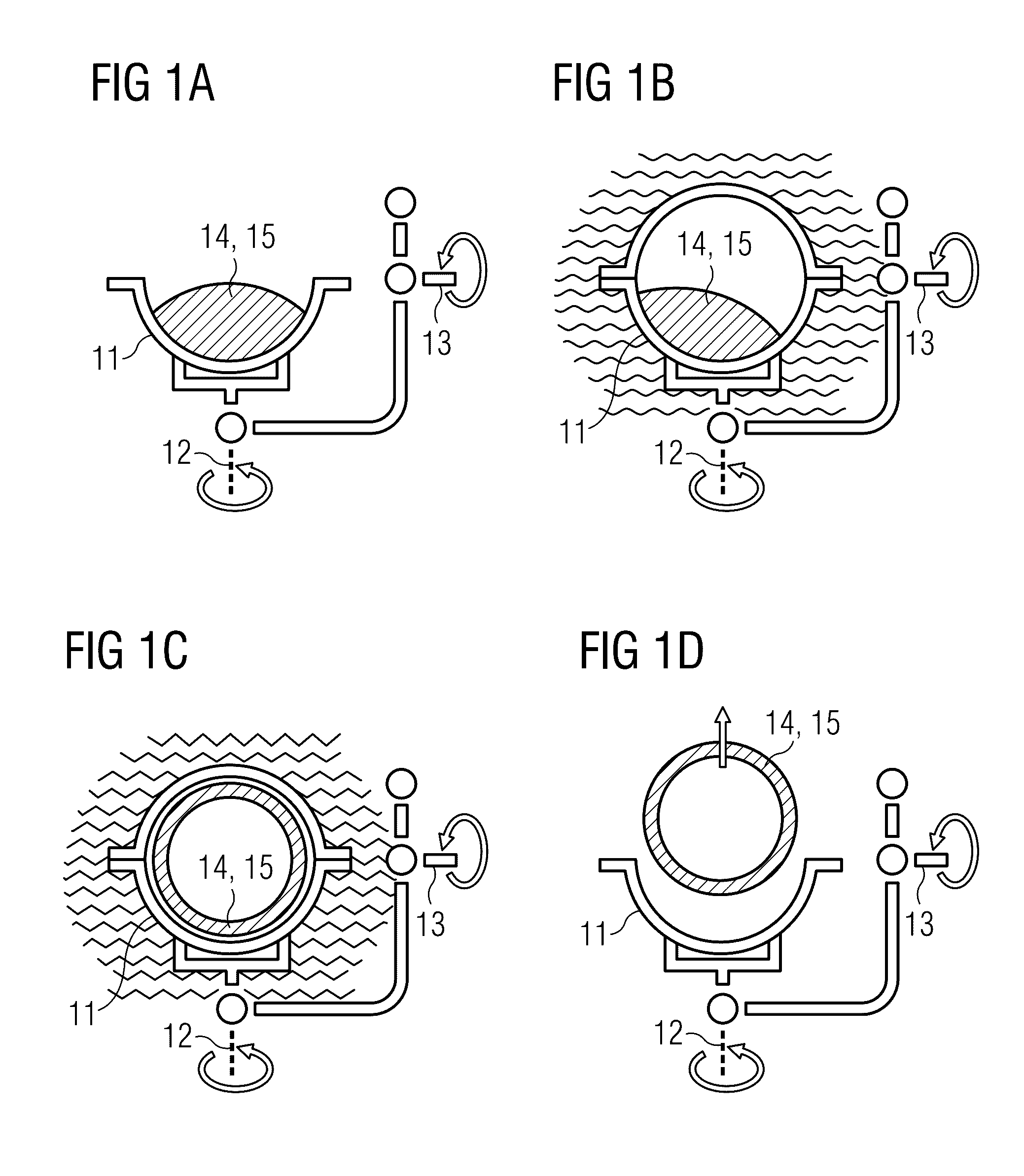

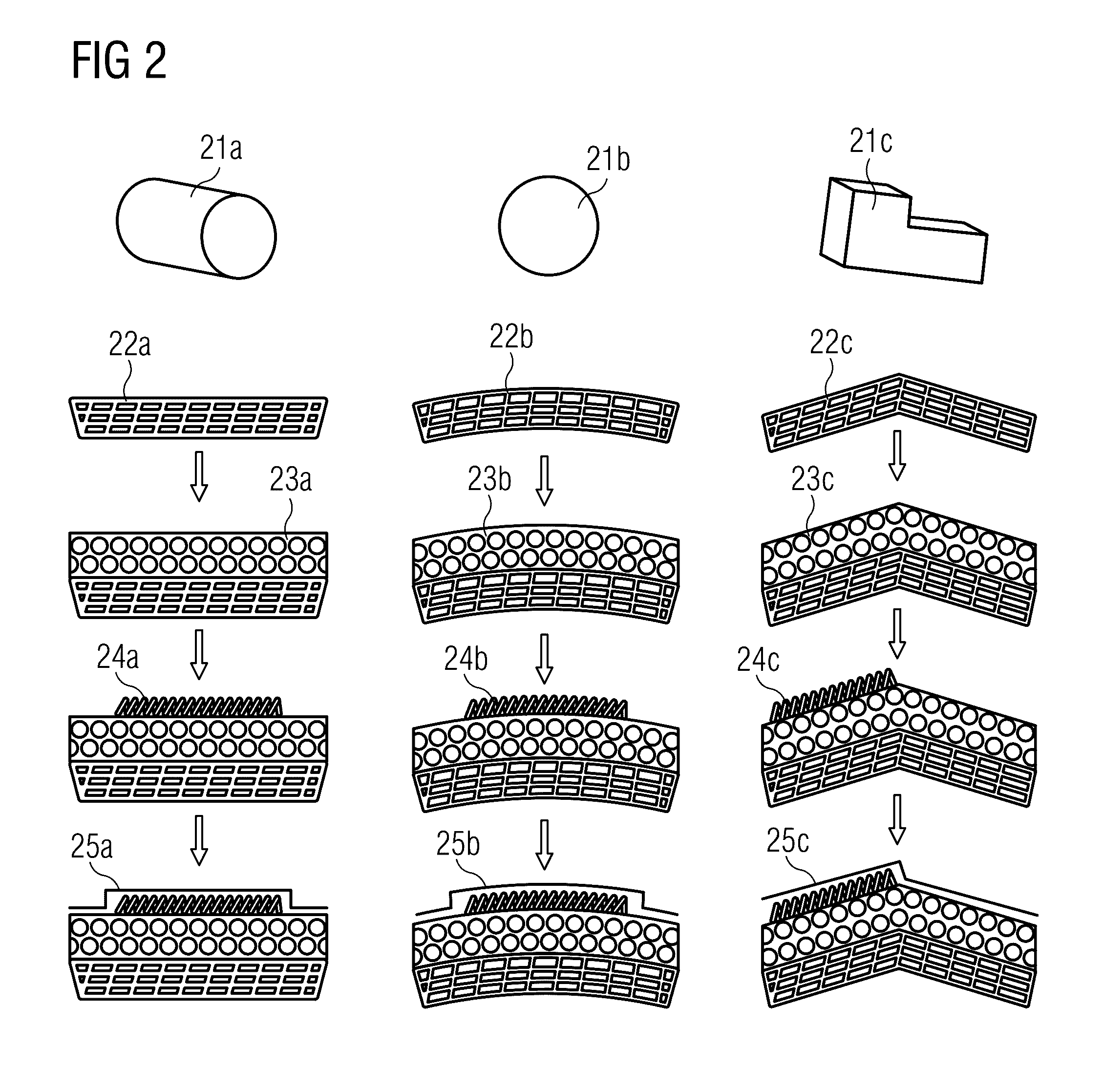

Method for manufacturing a three-dimensional composite object

PendingUS20160346964A1Desired stabilityEvenly distributedHollow inflatable ballsDomestic articlesComposite objectCasting mold

Methods for manufacturing a three-dimensional composite object, especially a sports article, comprising the steps: preparing a rotatable casting mold; filling a first material into the casting mold; filling a second material into the casting mold, wherein at least one of the materials is a polymer material; moving the casting mold; and adapting of at least one process parameter during the performance of one or more of the preceding steps, so that a homogeneous distribution of the second material in the manufactured composite object is achieved.

Owner:ADIDAS

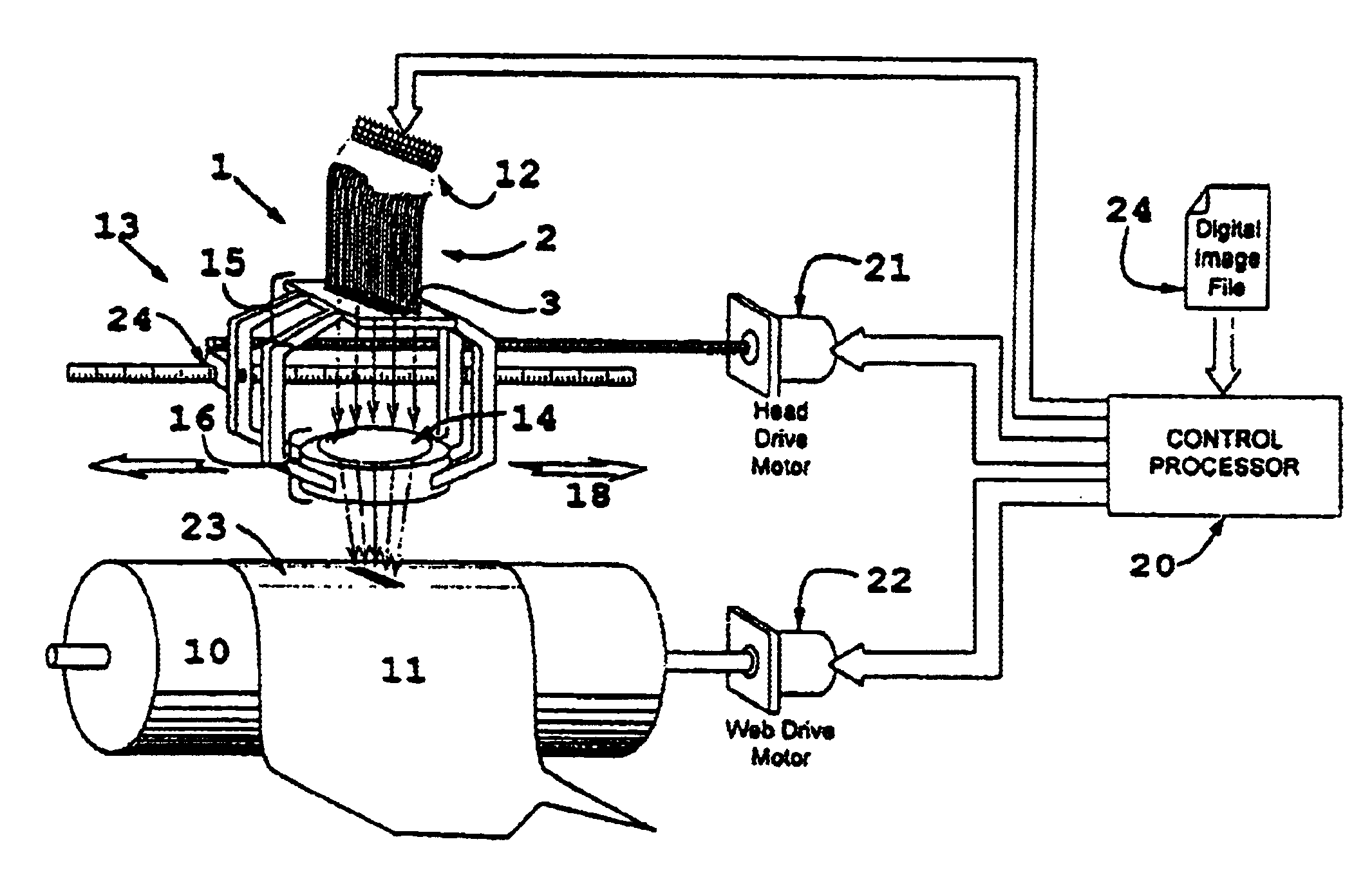

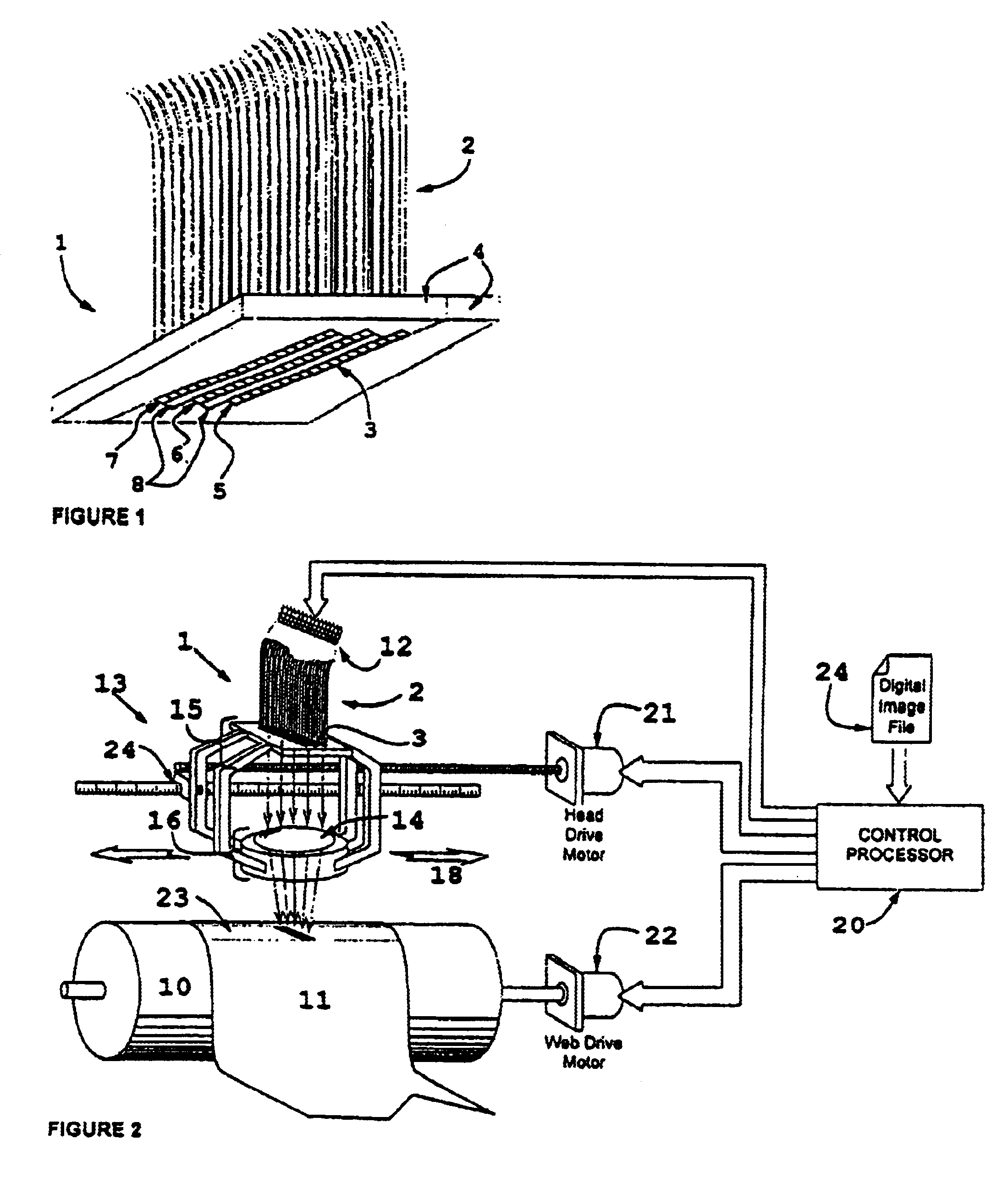

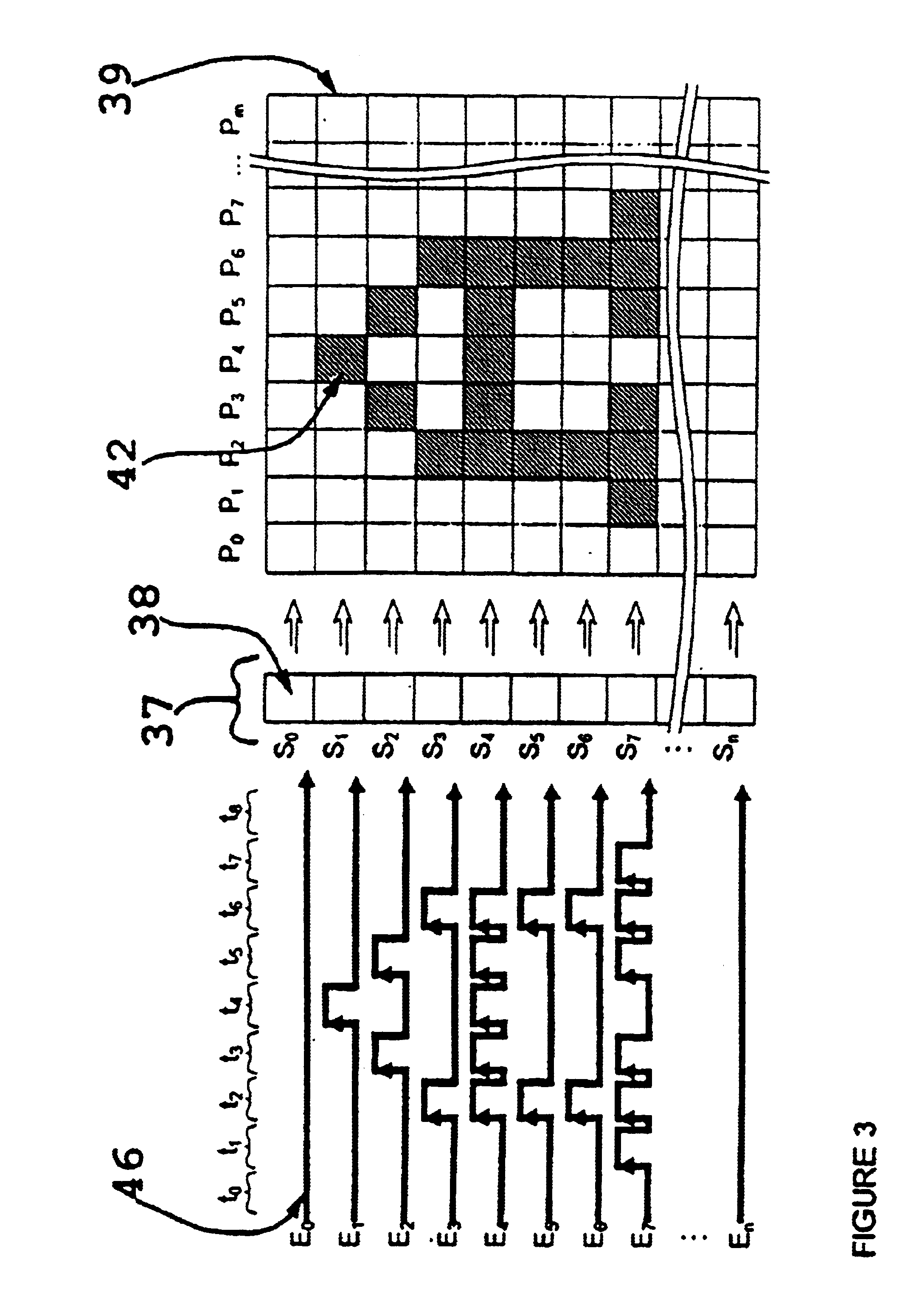

Method and apparatus for recording digital images on photosensitive material

InactiveUS6917447B2High qualityLow costDigitally marking record carriersInking apparatusLight sourceLight spectrum

The present invention is directed to a method and apparatus for exposing photosensitive material to form high quality continuous tone and / or color images thereon. The preferred apparatus includes an imaging head comprised of a plurality of red light sources, a plurality of green light sources, and a plurality of blue light sources. The light produced by said green light sources is passed through a first filter having a narrow spectral transmission characteristic in the green spectral range. Similarly, the light produced by said blue light sources is passed through a second filter having a narrow spectral transmission characteristic in the blue spectral range.

Owner:BOQART ZAC +1

System and method for minimizing lost circulation

InactiveUS8271246B2Minimizing lost circulationGood blendingComputation using non-denominational number representationFlushingData sourceAnalysis tools

A system and method is provided for minimizing lost circulation associated with the operation of a subterranean reservoir. The system includes one or more sources, such as earth modeling and fracture analysis tools, for providing data representative of a fracture formation in the reservoir, and a computer processor in communication with the data sources for determining an appropriate blend of lost circulation material products for application to the fracture formation. The computer processor is programmed with computer readable code for selecting a plurality of candidate products for application to the fracture formation, and for mathematically determining an optimized blend of the selected products. By applying the optimized blend, material and labor costs associated with well operation can be significantly reduced.

Owner:CHEVROU USA INC

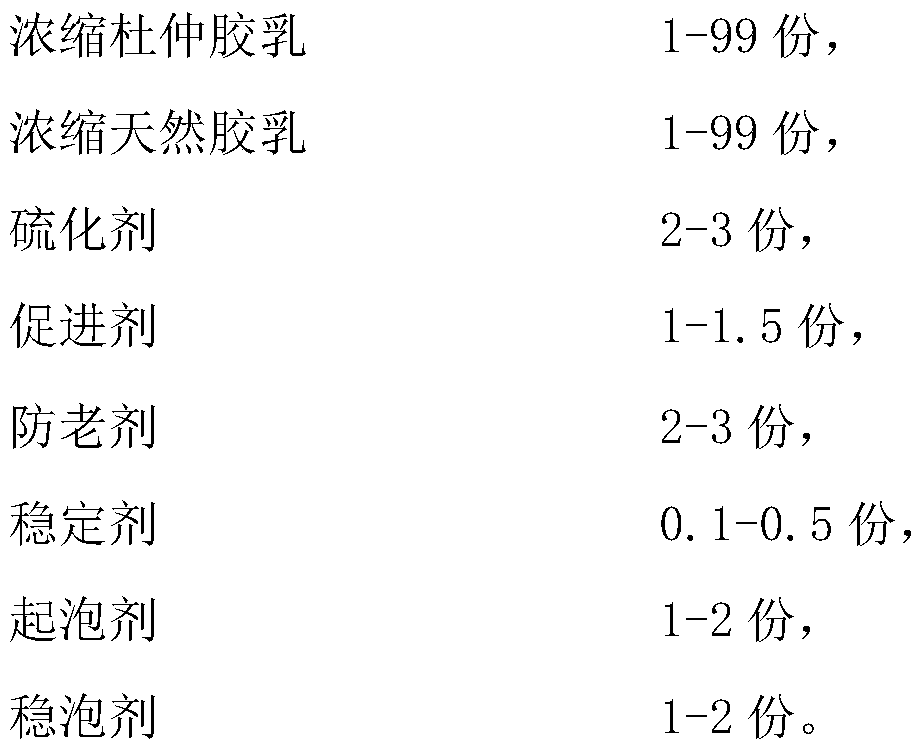

Gutta-percha/natural latex sponge product and preparation method thereof

ActiveCN110437510ASignificant technological progressHigh total solid contentFoaming agentGutta-percha

The invention provides a gutta-percha / natural latex sponge product. The gutta-percha / natural latex sponge product is prepared from the following components: gutta-percha emulsion, natural latex, a vulcanizing agent, an active agent, an accelerant, an antiager, a filler, a stabilizer, a PH value adjust, a gelatinizer, a foaming agent, a foam stabilizer, and a blowing agent in proportion, and the gutta-percha emulsion and the natural latex are correspondingly concentration emulsion. A preparation method of the gutta-percha / natural latex sponge product comprises the steps that first, the gutta-percha emulsion and the natural latex are mixed in proportion, deammoniation is conducted through a simultaneous ongoing method of mechanical stirring and air drafting, thenvarious kinds of powder typeauxiliaries and emulsifying oil auxiliaries which are grinded into dispersoid are added into a mixture latex material, after ripening, air is inflated under the mechanical stirring, foam is generatedto expand foam, after foaming, the foam is solidified with the gelatinizer, after vulcanization, washing and dewatering and drying of the solidified foam, the gutta-percha / natural latex sponge is obtained. According to the gutta-percha / natural latex sponge product and the preparation method thereof, successfully development of the gutta-percha / natural latex sponge product expands application prospects of gutta-percha, and promotes the technical progress of the gutta-percha.

Owner:CHEMCHINA ZHUZHOU RUBBER RES & DESIGN INST

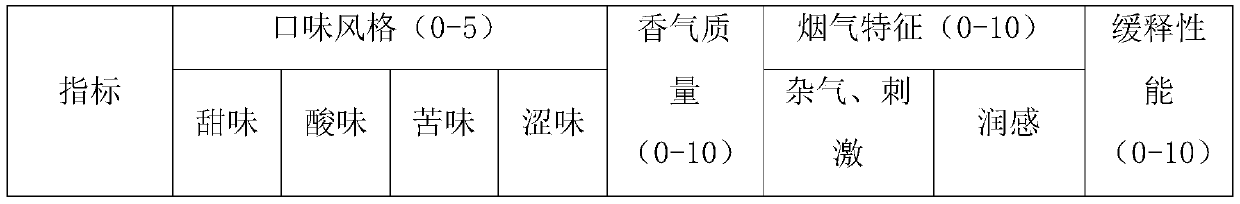

Cigarette dry bead filter rod capable of improving sweet feeling of cigarettes

ActiveCN110226774ANo astringencyRich and sweet aromaCigar manufactureTobacco smoke filtersMolecular sieveHippophae rhamnoides fruit

The invention discloses a cigarette dry bead filter rod capable of improving the sweetness of cigarettes. The circumference of the bottom surface of a nozzle rod is 24mm. A dry bead with the diameterthereof to be 3.25 + / -0.15 mm is loaded on the middle section of a tow. The dry bead takes a zeolite molecular sieve as a main raw material. The hippophae rhamnoides fruit composite extract for improving the sweetness of cigarettes is adsorbed on the dry bead. Due to the porous structure of the dry bead, in the cigarette smoking process, the essence is slowly and uniformly released along with smoke and is not combusted. Therefore, the diversity of smoking taste is improved. Meanwhile, the sweetening and moistening effect can be achieved.

Owner:CHINA TOBACCO JIANGXI IND CO LTD

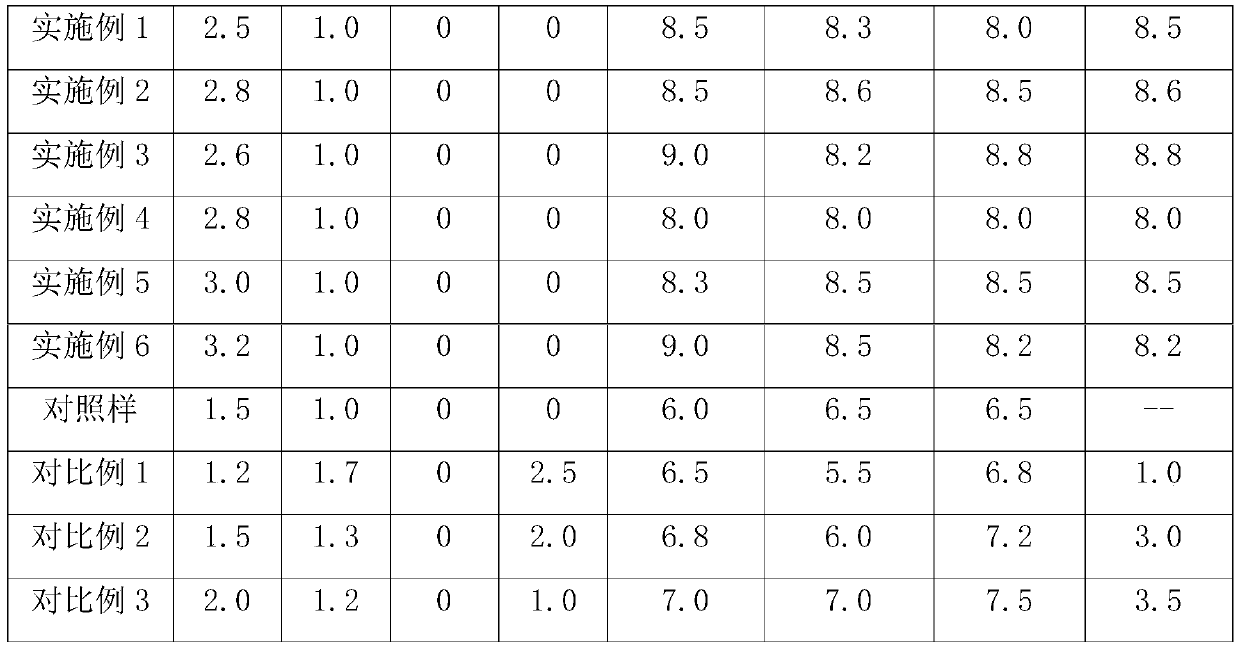

Oil mist discharger

InactiveUS6622942B2Reduce manufacturing costSimple structureSpray nozzlesFire rescueDifferential pressureOil mist

An oil mist discharger (1) is disclosed. The oil mist discharger (1) utilizes a flow regulator (27) which comprises a main passage (28), sub-passages (29) and an agitation chamber (30). Differential pressure between air and oil is created and utilized in drawing oil into an oil feed chamber (39) to be mixed with air. The oil-containing air is sent to the flow regulator (27) and fed into the agitation chamber (30) via the main passage (28) and sub-passages (29) in jet streams to be transformed into a well blended oil mist, which is discharged from a discharge nozzle.

Owner:TANAKA IMPORT GROUP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com