Patents

Literature

56 results about "Propyl vinyl ether" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Conductive composition and production method thereof, antistatic coating material, antistatic coating, antistatic film, optical filter, and optical information recording medium, and capacitors and production method thereof

ActiveUS20060062958A1Improve conductivityImprove heat stabilityHybrid capacitor electrolytesHybrid capacitor electrodesVinyl etherConductive polymer

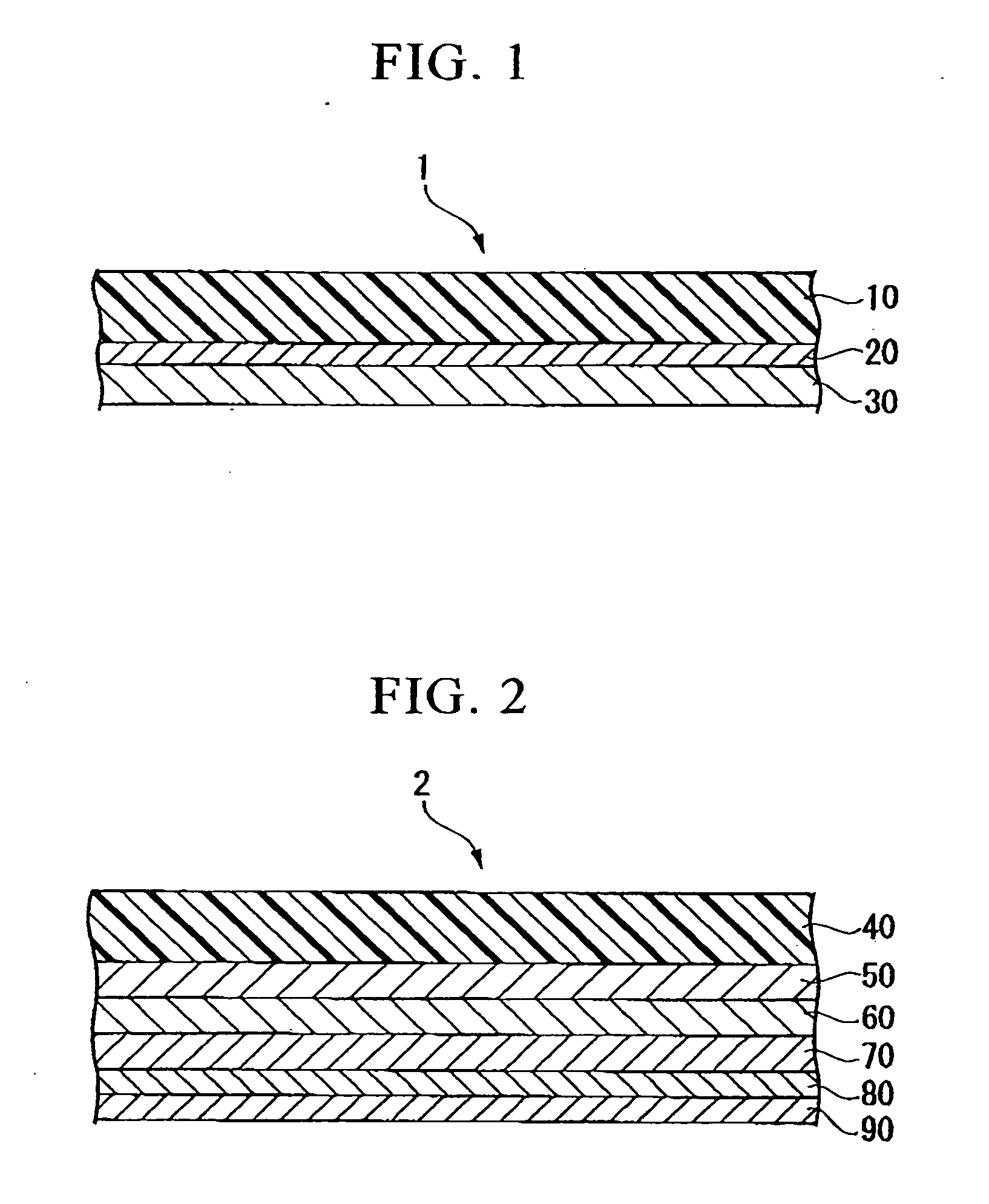

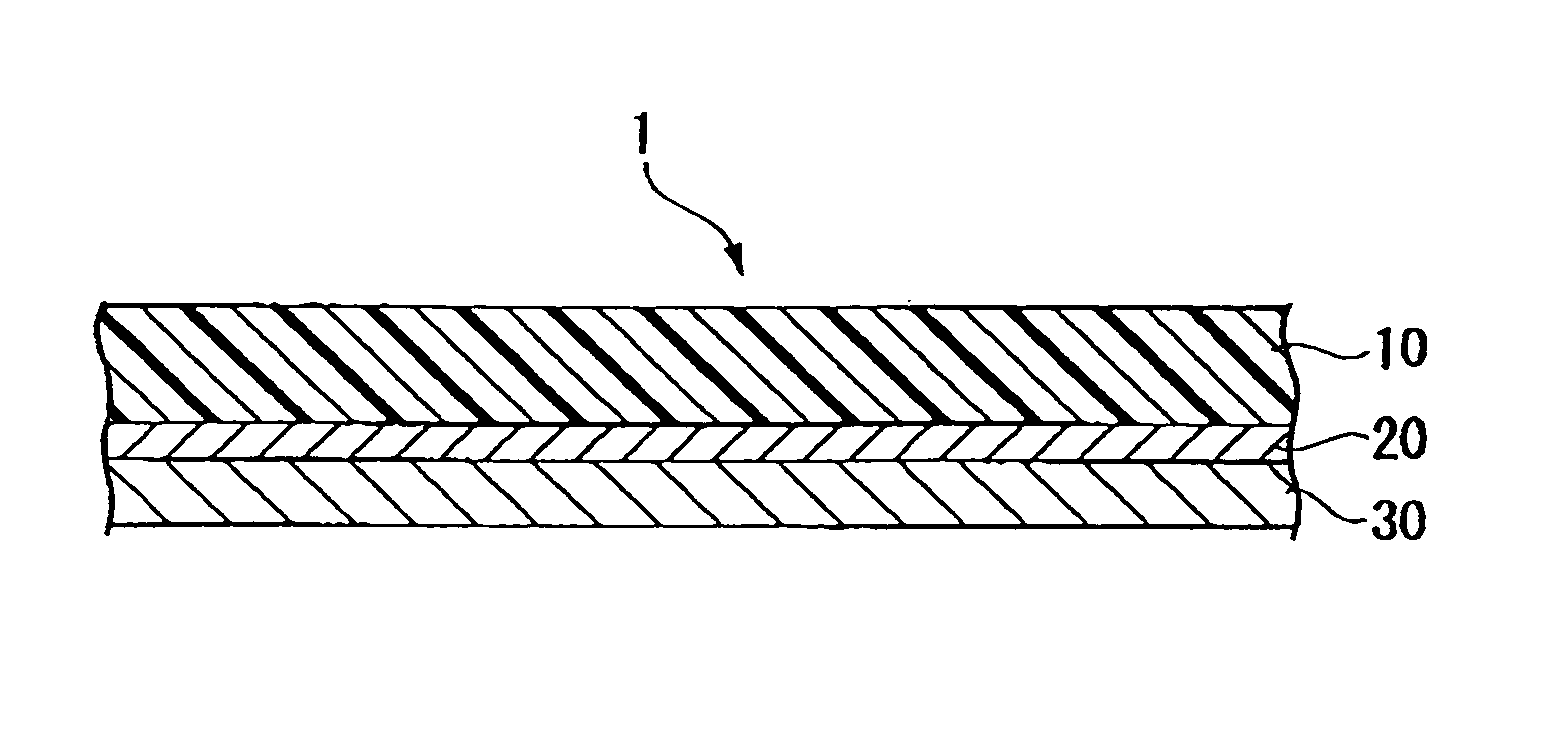

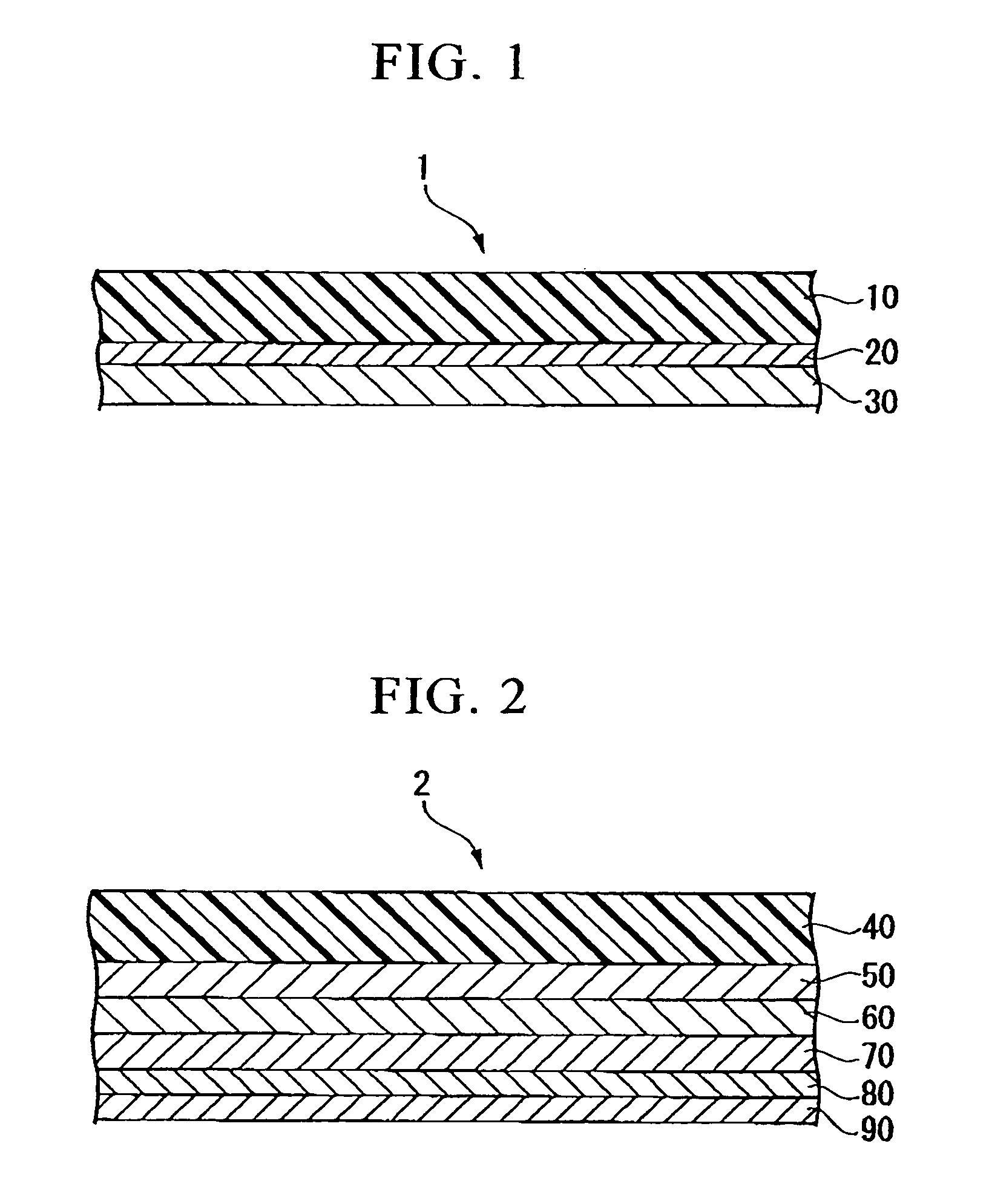

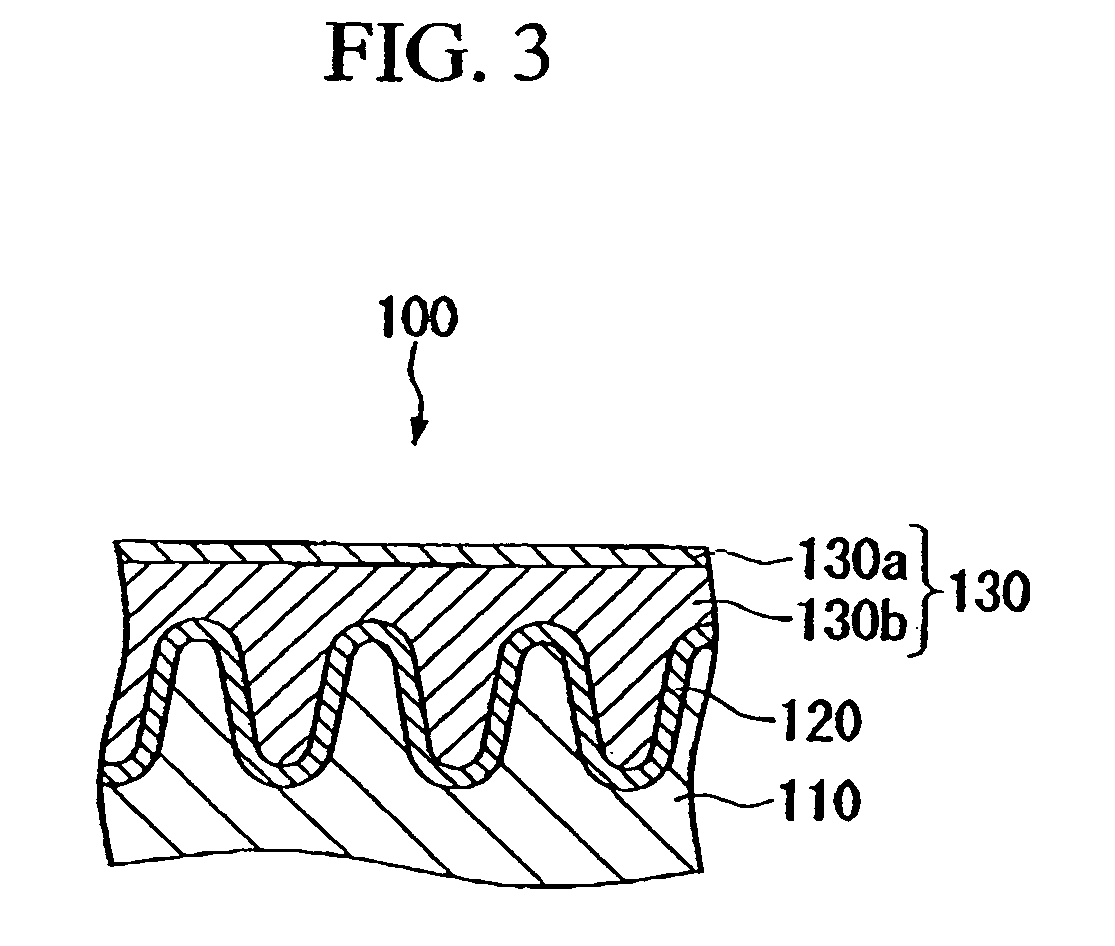

A conductive composition comprises a π conjugated conductive polymer, a dopant composed of polyanion, and at least one crosslinking site forming compound selected from (a) compounds having a glycidyl group and (b) compounds having a hydroxyl group and one selected from the group consisting of allyl, vinyl ether, methacryl, acryl methacrylamide, and acrylamide groups. An antistatic coating material comprises a π conjugated conductive polymer, polyanion, at least one crosslinking site forming compound selected form the above (a) and (b), and a solvent. An antistatic coating is formed by applying the above-mentioned antistatic coating material. In a capacitor comprising an anode composed of a valve metal porous body; a dielectric layer formed by oxidizing the suds of the anode; and a cathode formed on the dielectric lays, the cathode has a solid electrolyte layer formed by crosslinking complexes of a π conjugated conductive polymer and a dopant composed of a polyanion.

Owner:SHIN-ETSU POLYMER CO LTD

Novel ionic conduction membrane for chlor-alkali industry and preparation method thereof

The invention belongs to the technical field of ionic membranes and particularly relates to a novel ionic conduction membrane for chlor-alkali industry. The membrane consists of a perfluorosulfonate ion-exchange resin based membrane, a porous reinforcing material and a surface layer formed by mixing microparticles of fluorine-containing resin and particles of an inorganic compound. The particles of the inorganic compound are selected from one or more of oxides, hydroxides and nitrides of group IV-A, group IV-B, group V-B, iron, cobalt, nickel, chromium, manganese or boron. The microparticles of fluorine-containing resin comprise one or more of microparticles of polytetrafluoroethylene, microparticles of PFA (Polyfluoroalkoxy), microparticles of polyfluorinated ethylene propylene, microparticles of polyfluorinated propyl vinyl ether or microparticles of polyvinylidene fluoride. The ionic conduction membrane for chlor-alkali industry can stably and efficiently treat alkali chloride solutions with wide concentration range and is suitable for operation in a zero polar distance electrolytic bath under a novel electric current density condition, so that the product purity is high. The invention further provides a preparation method of the ionic conduction membrane and the preparation method is simple and reasonable in process and easy for industrialized production.

Owner:SHANDONG DONGYUE POLYMER MATERIAL

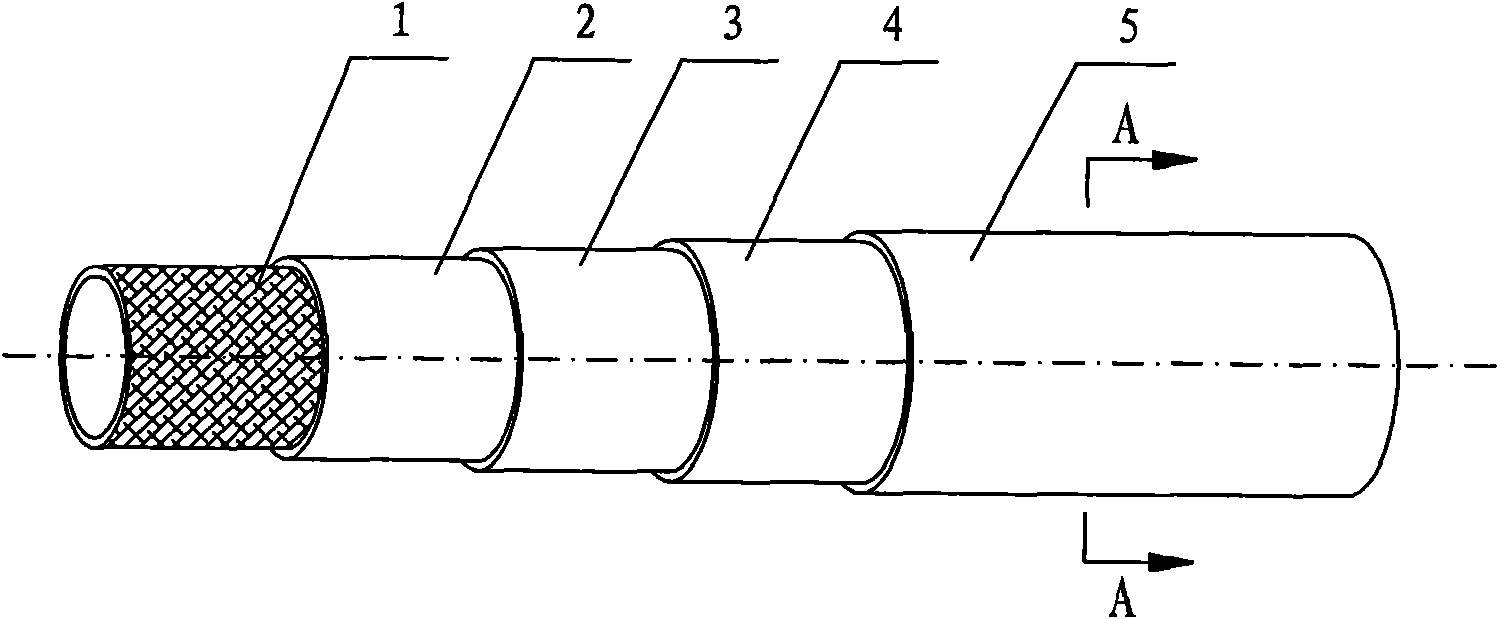

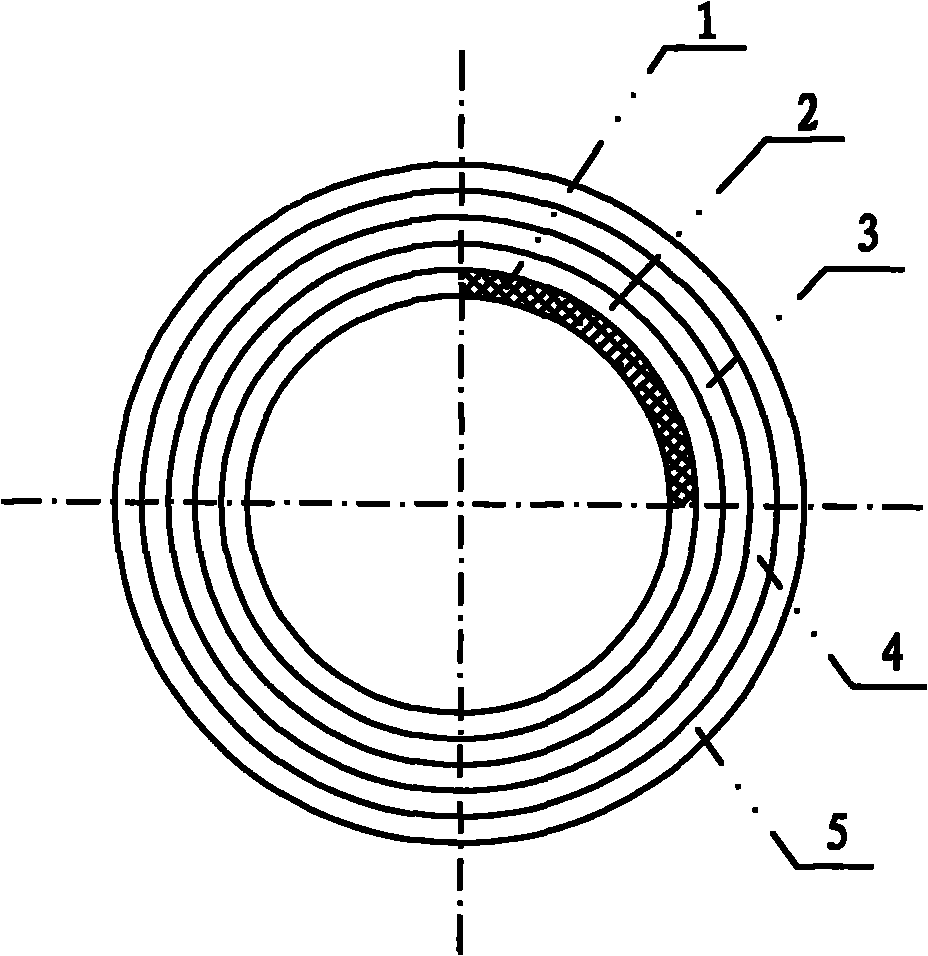

Perfluoroether composite air condition hose and preparation method thereof

InactiveCN102042446AMeet anti-seepage requirementsChemically resistantFlexible pipesRubber materialVulcanization

Owner:GUANGDONG MIDEA ELECTRIC APPLIANCES CO LTD

Method for preparing suspension modified polytetrafluoroethylene

The invention discloses a method for preparing floating modified polytetrafluror-ethylene (PTFE) by adding a secondary comonomer which is perfluro propyl vinyl ether. Activator used in the method can be persulfate of alkali metals or alkaline-earth metals and a redox initiation system. The reaction temperature changes within a range of 5 DEG C -90 DEG C and the pressure is between 0.5-2.0MPa based on different activating system. The perfluro propyl vinyl ether is added by a vacuum absorption way, so as to avoid using perfluro octoate.

Owner:SHANGHAI 3F NEW MATERIAL TECH CO LTD

Conductive composition and production method thereof, antistatic coating material, antistatic coating, antistatic film, optical filter, and optical information recording medium, and capacitors and production method thereof

ActiveUS7683109B2High conductivity and flexibility and adhesion to baseSimple manufacturing methodHybrid capacitor electrolytesClosuresVinyl etherPolymer science

A conductive composition comprises a π conjugated conductive polymer, a dopant composed of polyanion, and at least one crosslinking site forming compound selected from (a) compounds having a glycidyl group and (b) compounds having a hydroxyl group and one selected from the group consisting of allyl, vinyl ether, methacryl, acryl methacrylamide, and acrylamide groups. An antistatic coating material comprises a π conjugated conductive polymer, polyanion, at least one crosslinking site forming compound selected form the above (a) and (b), and a solvent. An antistatic coating is formed by applying the above-mentioned antistatic coating material. In a capacitor comprising an anode composed of a valve metal porous body; a dielectric layer formed by oxidizing the suds of the anode; and a cathode formed on the dielectric layer, the cathode has a solid electrolyte layer formed by crosslinking complexes of a π conjugated conductive polymer and a dopant composed of a polyanion.

Owner:SHIN-ETSU POLYMER CO LTD

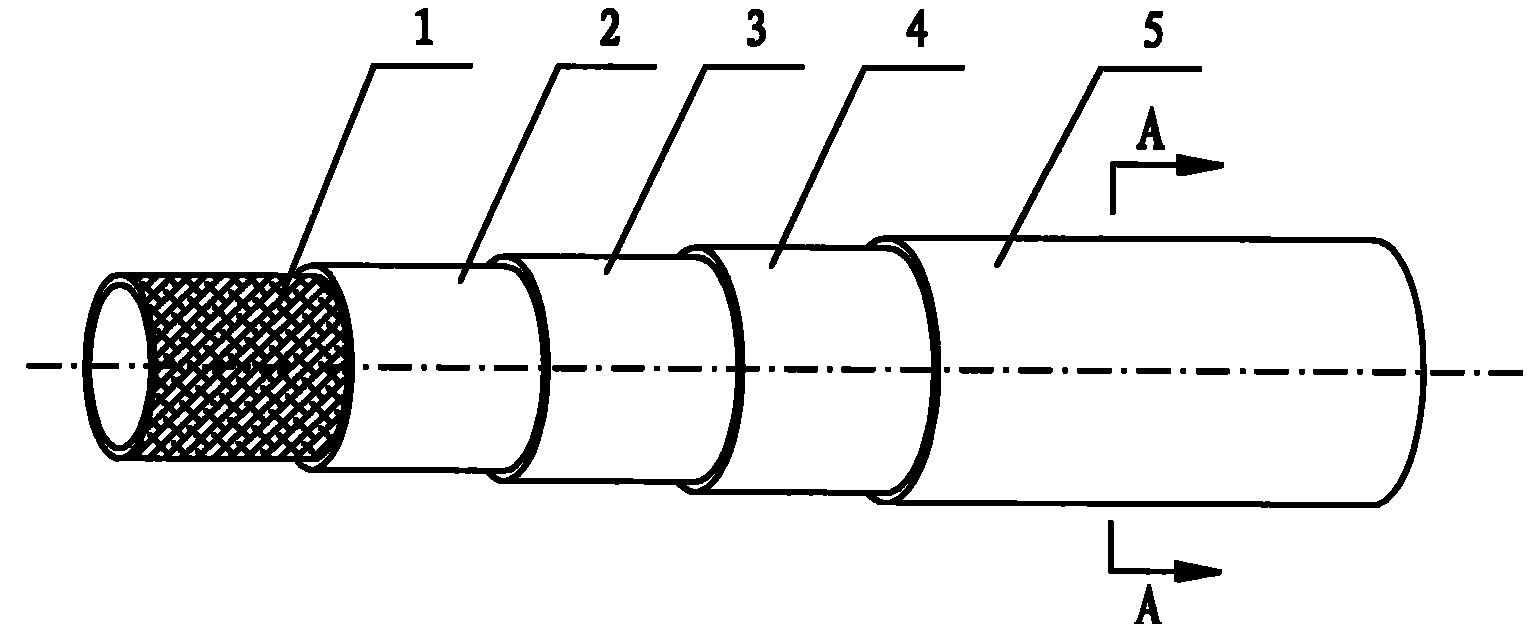

Perfluoro copolymers of tetrafluoroethylene and perflouro alkyl vinyl ethers

In preparing a fluorinated thermoplastic with good flex life, high thermal conductivity and low average spherolite diameter from tetrafluoroethylene and perfluoro n-alkyl vinyl ether, perfluoro 2-propoxyalkyl vinyl ether is additionally incorporated into the fluorinated thermoplastic. A semicrystalline, thermoplastically processable copolymer is prepared, made from units of the tetrafluoroethylene, from 2 to 10% by weight of units of perfluoro n-propyl vinyl ether and from 0.1 to 6% by weight of units of perfluoro 2-propoxypropyl vinyl ether. The novel copolymer preferably contains fewer than 70 unstable end groups per 106 carbon atoms, has thermal conductivity of at least 0.19 W / mK at 23° C. and has a smooth surface with an average spherolite diameter of <5 mum. The novel terpolymer is suitable for extrusion of hose, in particular for heat exchangers, and also for ultrahigh-purity applications.

Owner:3M INNOVATIVE PROPERTIES CO

Hinge with insulated wire for electronic devices

InactiveUS7592406B2Provide capabilitySatisfy lifeDigital data processing detailsInsulatorsHexafluoropropyleneFluoropolymer

The combination of a hinge and an insulated wire is provided, wherein the hinge is capable of closing and opening to an angle of at least 90°, the insulated wire being secured by the hinge so as to fold when said hinge is closed and to unfold when said hinge is opened, the insulation on the wire comprising fluoropolymer, such as tetrafluoroethylene / -hexafluoropropylene copolymer or tetrafluoroethylene / perfluoro(methyl vinyl ether) / perfluoro(propyl vinyl ether) copolymer, each polymer having a melting point of 260 to 290° C. and MIT Flex Life of at least about 15,000 cycles, the hinge being useful in such electronic devices as a laptop computer or a clamshell cell phone, attaching the keyboard and screen portion to one another, the insulation being capable of repeated opening and closing of the hinge without cracking of the insulation.

Owner:THE CHEMOURS CO FC LLC

Perfluoro copolymers of tetrafluoroethylene and perflouro alkyl vinyl ethers

In preparing a fluorinated thermoplastic with good flex life, high thermal conductivity and low average spherolite diameter from tetrafluoroethylene and perfluoro n-alkyl vinyl ether, perfluoro 2-propoxyalkyl vinyl ether is additionally incorporated into the fluorinated thermoplastic. A semicrystalline, thermoplastically processable copolymer is prepared, made from units of the tetrafluoroethylene, from 2 to 10% by weight of units of perfluoro n-propyl vinyl ether and from 0.1 to 6% by weight of units of perfluoro 2-propoxypropyl vinyl ether. The novel copolymer preferably contains fewer than 70 unstable end groups per 10<6 >carbon atoms, has thermal conductivity of at least 0.19 W / mK at 23° C. and has a smooth surface with an average spherolite diameter of <5 mum. The novel terpolymer is suitable for extrusion of hose, in particular for heat exchangers, and also for ultrahigh-purity applications.

Owner:3M INNOVATIVE PROPERTIES CO

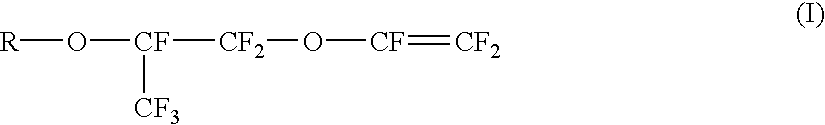

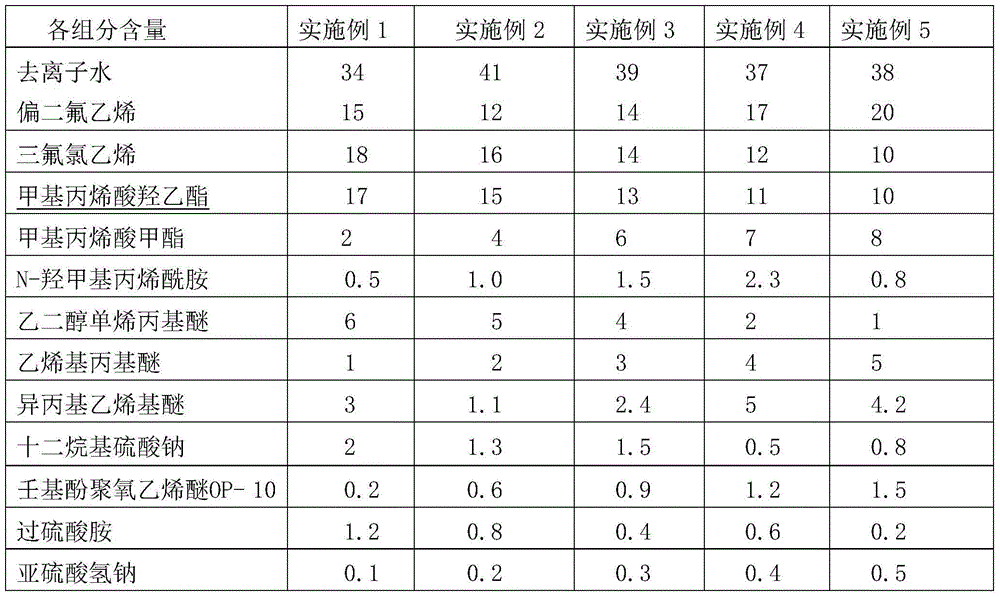

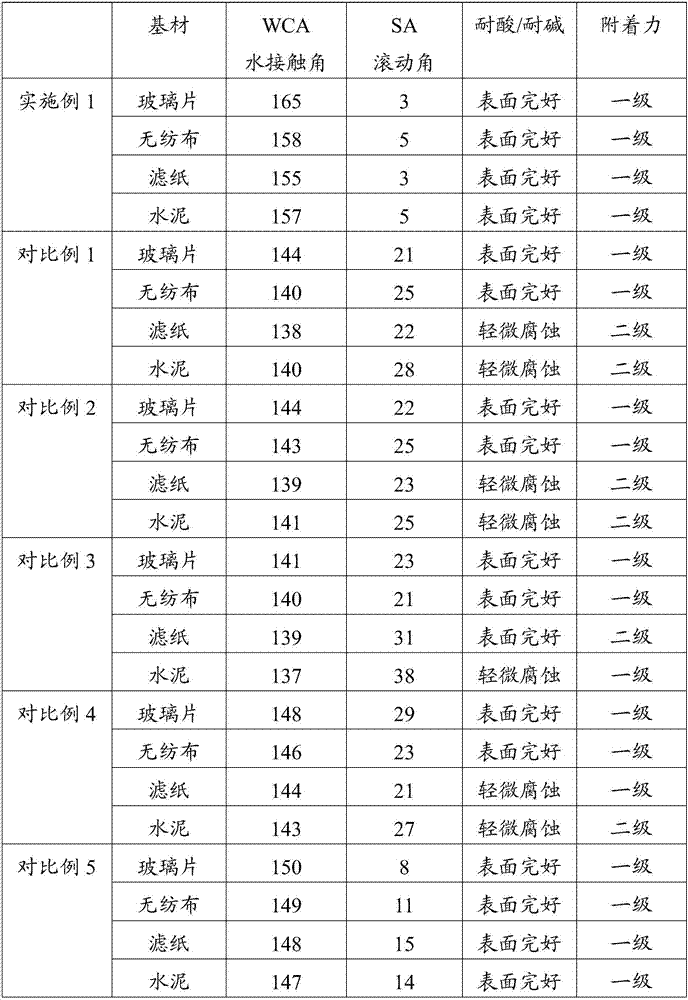

Environment-friendly hydrophilic elastic fluorocarbon building emulsion and preparation method thereof

InactiveCN104059446AGood flexibilityGood weather resistanceCoatingsVinyl ether(Hydroxyethyl)methacrylate

The invention discloses environment-friendly type hydrophilic elastic fluorocarbon building emulsion and a preparation method thereof. The emulsion consists of the following components in percentage by weight: 34-41% of deionized water, 12-20% of polyvinylidene fluoride, 10-18% of trifluorochlor oethylene, 10-17% of hydroxyethyl methylacrylate, 2-8% of methyl methacrylate, 0.5-2.3% of N-hydroxymethyl acrylamide, 1-6% of ethylene glycol monoene propyl ether, 1-5% of vinyl propyl ether, 1.1-5% of isopropyl vinyl ether, 0.2-1.5% of nonylphenol polyoxyethylene ether OP-10, 0.2-1.2% of ammonium persulfate, 0.1-0.5% of sodium hydrogen sulfite and 0.5-2% of lauryl sodium sulfate. The preparation method comprises the step of firstly, emulsifying and then pouring the emulsified emulsion into a reaction kettle for carrying out reaction. The emulsion disclosed by the invention is environmental friendly, has the advantages of excellent comprehensive performances such as ultra-long weather resistance, acid and alkaline resistance, dirt resistance, chemical resistance, strong adhesion force, good softness, scrubbing resistance, good elongation at break and good tensile strength.

Owner:JIANGSU UNIV OF SCI & TECH

Preparation method for special low-temperature-resistant fluororubber

InactiveCN105111353AImprove surface activityEasy to useOrganic chemistryOrganic compound preparationVinyl etherGas phase

The present invention discloses a preparation method for special low-temperature resistant fluororubber. The method comprises: in a pressure resistant reactor, adding deionized water and special fluoroether carboxylate as a surfactant; after deoxidation of the reactor, performing heating and stirring; introducing vapor fluorine-containing monomers that comprises the following materials in percentage by weight: 20%-70% of vinylidene fluoride, 10%-40% of hexafluoropropene, 0%-70% of tetrafluoroethylene and 0%-40% of other selectable comonomer that is one of the monomers or a combination of more than one monomers selected from: perfluoro methyl vinyl ether, perfluoro ethyl vinyl ether, perfluoro propyl vinyl ether, fluoroethylene, ethylene, propylene, trifluoroethylene, chlorotrifluoroethylene, difluoro dichloroethylene, 3,3,3-trifluoropropene, and perfluoroalkyl ethylene; and then adding a free radical initiator to prepare the fluororubber, wherein the reaction temperature is controlled at 20-140 DEG C, and the reaction pressure is controlled at 1-50 atmospheric pressure, and the concentration of the special fluoroether carboxylate in the final emulsion product is 0.01%-3%.

Owner:江苏梅兰化工有限公司 +2

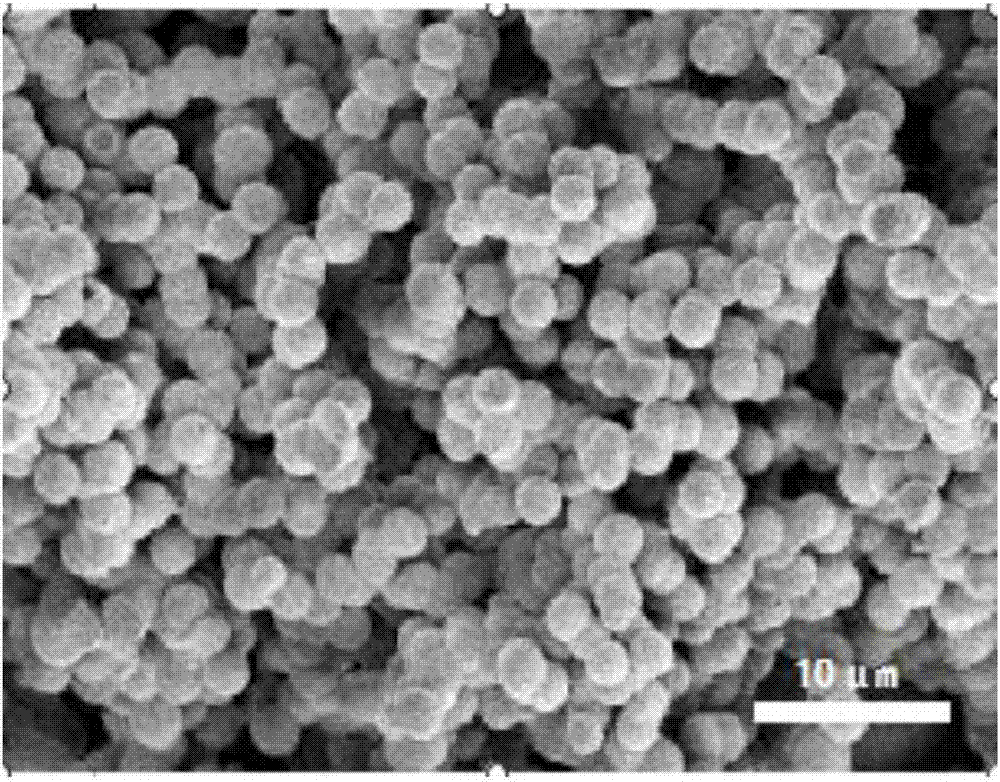

Preparation method and application of super-hydrophobic fluorine-containing block copolymer microspheres

The invention provides a preparation method and application of a super-hydrophobic fluorine-containing block copolymer microspheres and belongs to the field of preparation of polymer materials. The method for preparing the microspheres comprises the following steps: with perfluoroalky iodide as a chain transfer agent, preparing a scCO2 hydrophobic poly(vinylidene fluoride-co-heptafluoropropyl trifluorovinyl ether) macro-chain transfer agent in a reactor by adopting controlled free radical polymerization with iodine-containing compounds in which the polymerization condition is close to that in traditional industrial production; and with scCO2 as a solvent, adding a fluorinated acrylate monomer for reaction continuously, thereby obtaining the super-hydrophobic fluorine-containing block copolymer microspheres. According to the method disclosed by the invention, the super-hydrophobic fluorine-containing block copolymer microspheres are directly prepared in scCO2 through a polymerization-induced self-assembly process by adopting a one-step process, the operating steps are less, the polymerization reaction condition is close to that in the traditional industrial production, and the product is controllable in molecular weight and narrow in molecular weight distribution and can effectively solve the environmental problem brought by usage of an organic solvent and a dispersing agent.

Owner:UNIV OF JINAN

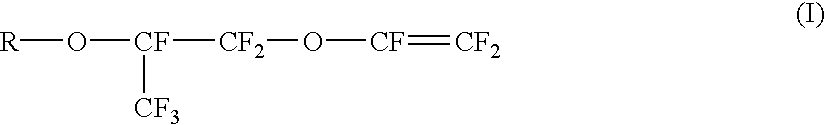

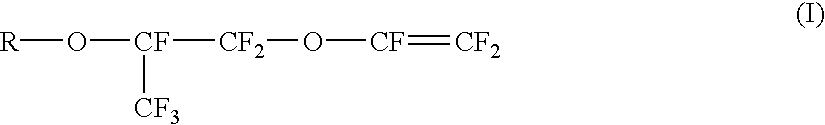

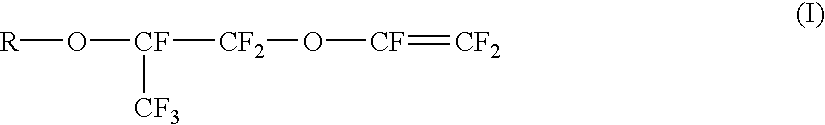

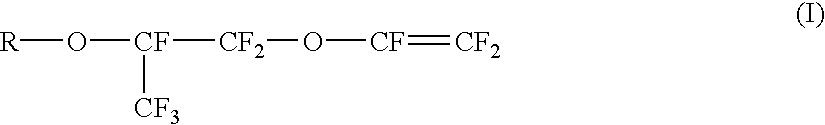

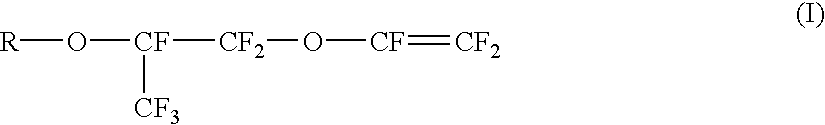

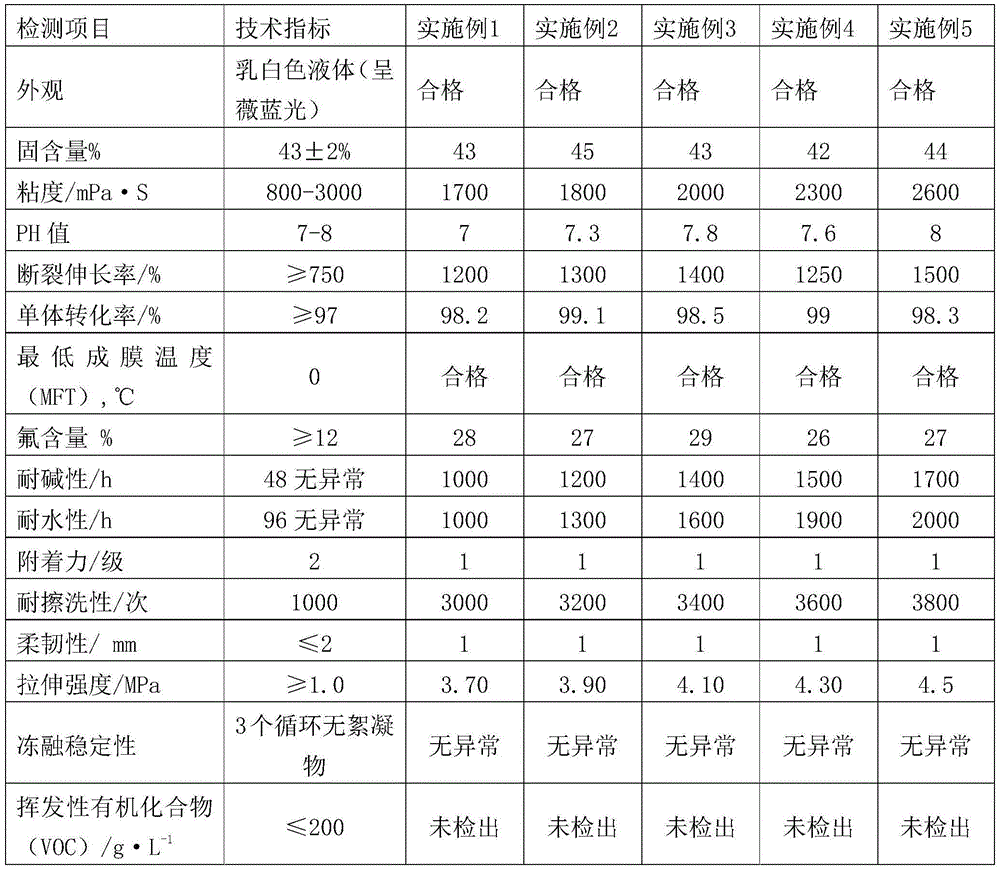

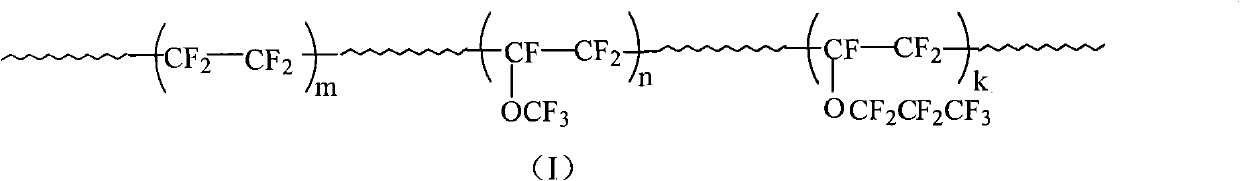

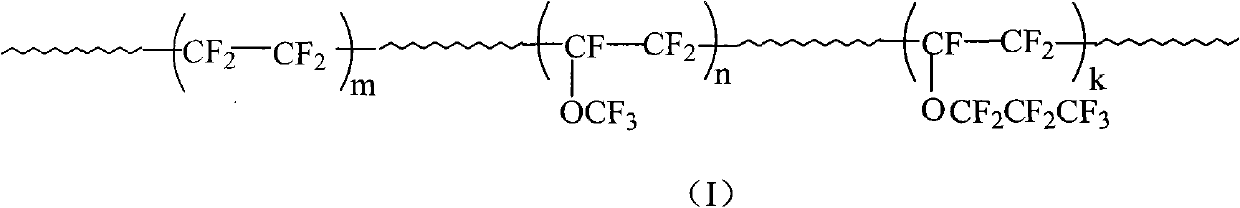

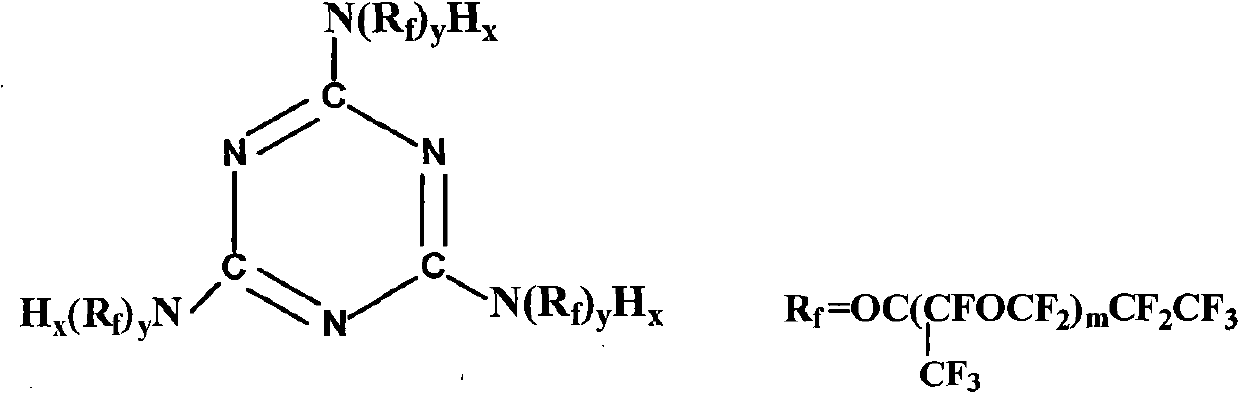

Tetrafluoroethylene triple perfluorinated resin and application thereof as ion-exchange membrane reinforcing material

ActiveCN101775097AReduce crystallinityReduce melt viscositySemi-permeable membranesOrganic diaphragmsAlkali ionsTextile technology

The invention discloses a fluorine-containing polymer and application thereof as an ion-exchange membrane reinforcing material. The fluorine-containing polymer is tetrafluoroethylene triple perfluorinated resin with a structure of Formula (I) as shown in the attached picture, which is prepared by polymerization of tetrafluoroethylene, a perfluorinated methyl vinyl ether monomer and a perfluorinated propyl vinyl ether monomer initiated by free radicals in the presence of a dispersant, a solvent and an initiator. The fluorine-containing polymer fiber can be prepared through melt spinning with a melt-spinning device and can be woven into fiber nets through the textile technology so as to be used as reinforcing nets for proton exchange membranes and chlor-alkali ion-exchange membranes, thereby achieving the function of enhancing the membrane strength.

Owner:SHANDONG DONGYUE WEILAI HYDROGEN ENERGY MATERIAL CO LTD

Fluorocopolymer

A fluorocopolymer which comprises repeating units (a) based on tetrafluoroethylene, repeating units (b) based on perfluoro(methyl vinyl ether) and repeating units (c) based on perfluoro(propyl vinyl ether) in a molar ratio of (a) / (b) / (c) of 40 to 70 / 3 to 57 / 3 to 57. The fluorocoplymer is a perfluoroelastomer which is excellent in low temperature characteristics, heat resistance and chemical resistance.

Owner:ASAHI GLASS CO LTD

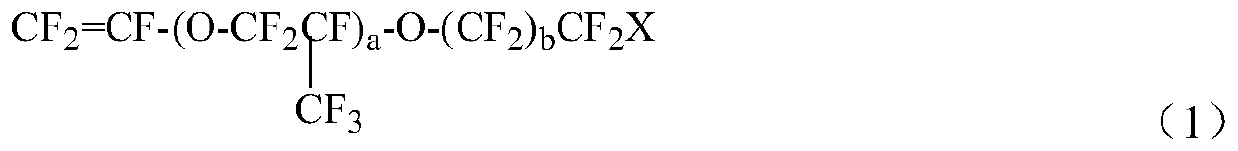

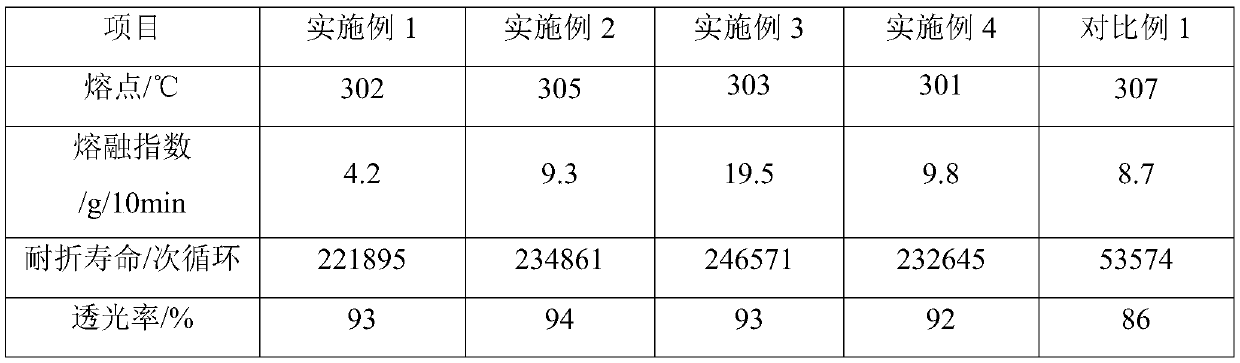

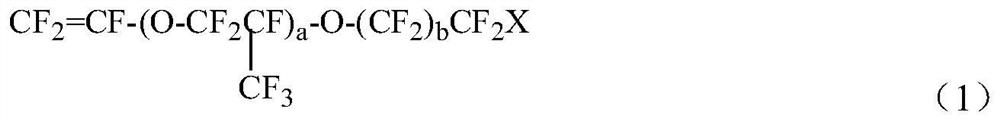

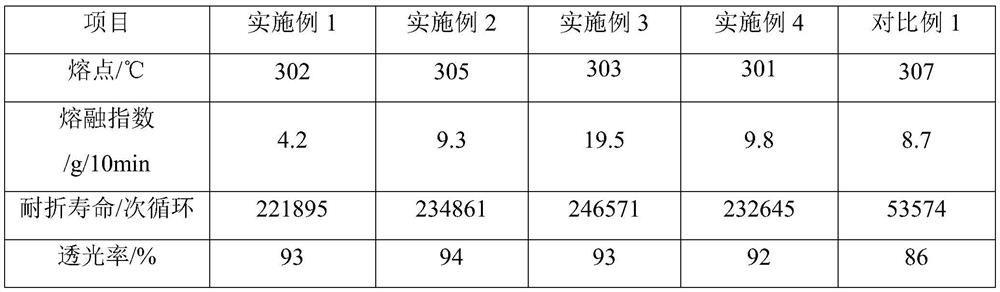

Tetrafluoroethylene copolymer and preparation method thereof

The invention belongs to the field of fluorine-containing polymer materials, and particularly relates to a tetrafluoroethylene copolymer and a preparation method thereof. The tetrafluoroethylene copolymer is a terpolymer comprising 90-98 wt% of tetrafluoroethylene, 1-7 wt% of perfluoro-n-propyl vinyl ether and 1-3 wt% of perfluoro-propenyl alkoxy ether with a CF<2>=CFCF<2>[OCF<2>CF(CF<3>)]<n>OR<f>structure or a hydrogen-containing derivative thereof, wherein n is an integer of 0-5, and R<f> is a perfluoroalkyl group provided with 1-5 carbon atoms or the derivative containing hydrogen atoms. The tetrafluoroethylene copolymer has good melting fluidity and thermal stability, high flexibility, high transparency and high surface finish. A green environment-friendly solvent is adopted in the preparation method, and damage to the atmospheric ozone layer is avoided, energy is saved, and the environment is protected.

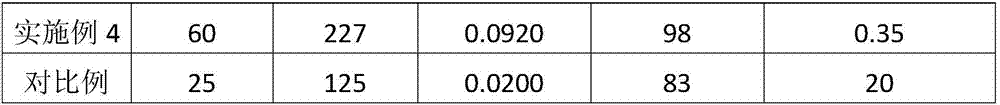

Owner:SHANDONG HUAXIA SHENZHOU NEW MATERIAL

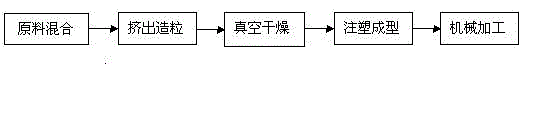

Process method for thermoplastic soft magnetic supramolecular material assembled by complexing subject and object

ActiveCN102199331AImprove mechanical propertiesImprove thermal stabilityOrganic/organic-metallic materials magnetismElectrical polarityMolecular materials

The invention relates to a process method for a thermoplastic soft magnetic supramolecular material assembled by complexing a subject and an object, which belongs to the field of magnetic materials and high molecular materials. The invention relates to a subject provider which is formed by the complex assembly of a tetrafluoroethylene and a perfluoro-n-propyl-vinyl ether copolymer as the subject and the object of the supramolecular material; under the conditions of high temperature and high pressure, a subject-object complex assembled system is formed by absorbing cations or soft magnetic nanometer granules with polarities. After the complex assembly of the subject and the object is completed, washing and drying are carried out, and finally, secondary granulation is carried out by utilizing a vacuum double-screw extrusion machine so as to split a terminal group; and the extruded granules are the thermoplastic soft magnetic supramolecular material product assembled by complexing the subject and the object. The thermoplastic soft magnetic supramolecular material product disclosed by the invention has the advantages of customized magnetic conductive performance, superior electrical performance, fine mechanical performance, fine processability, chemical resistance and thermostability.

Owner:YUNNAN INFINE NEO MATERIAL

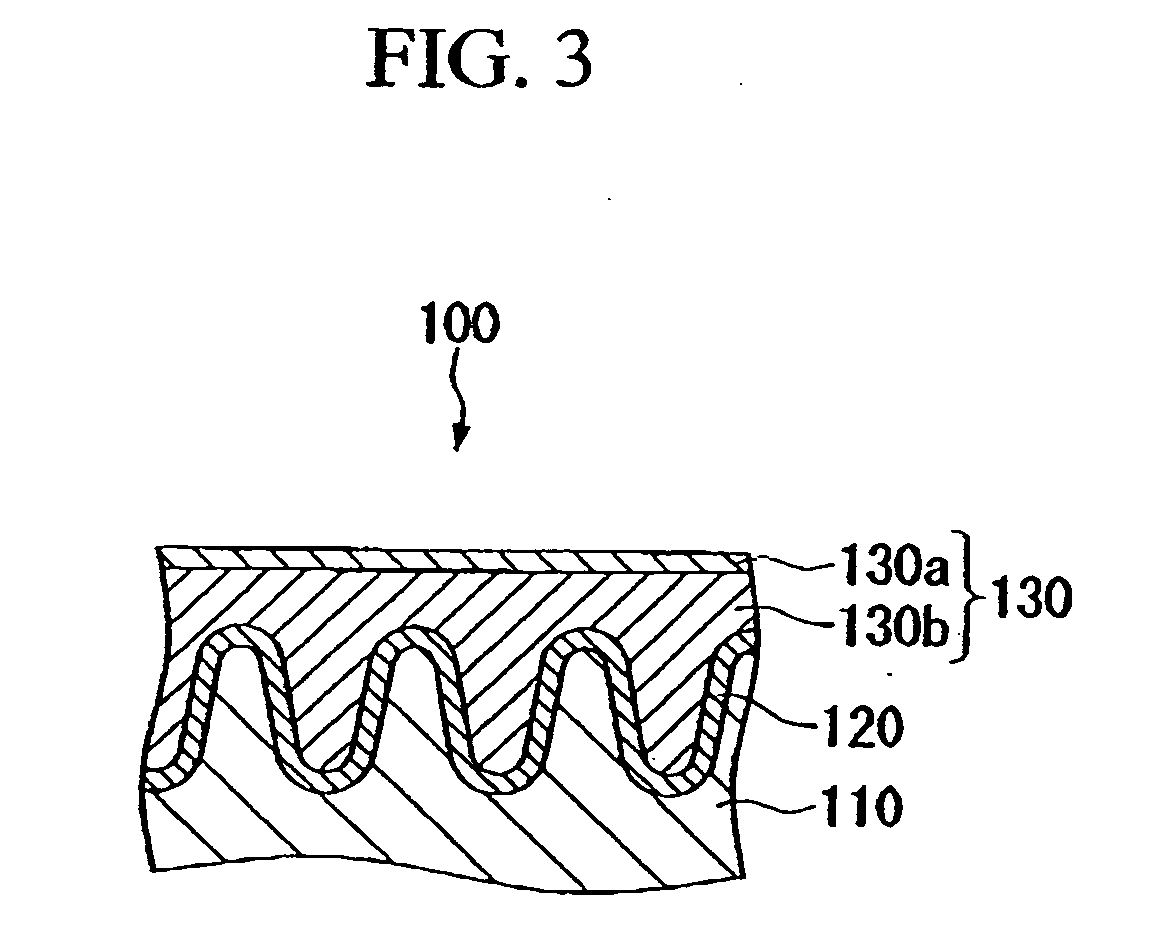

Process for preparing fluorine-containing high polymer high frequency circuit board material by hydrothermal method

ActiveCN102350825AGood adhesionMeet needsSynthetic resin layered productsCircuit susbtrate materialsDielectricVinyl ether

The invention relates to a process for preparing a fluorine-containing high polymer high frequency circuit board material by a hydrothermal method, which belongs to the high frequency circuit substrate material field. The method comprises the following steps: uniformly mixing a polytetrafluoroethylene emulsion (PTFE), a fluoroethylenepropylene emulsion (FEP) and a polyfluoroalkoxy emulsion (PFA), adding salts, then adding a molecule guiding agent and a molecular weight regulator, uniformly mixing, adding in a reaction vessel for performing hydrothermal reaction to complete high-molecular secondary polymerization, acquiring a substance of dielectric inorganic compound nanoparticles coated with high-molecular, filtering, washing, drying, removing end group, sintering, rolling, cladding copper to obtain the high frequency circuit board material with different dielectric constants finally. The prepared high frequency circuit board is capable of satisfying each basic index of the high frequency circuit board, and has the advantages of adjustable dielectric constant, low loss, good mechanical property and the like; the dielectric constant can be adjusted by the circuit board according to the generated dielectric inorganic compound content, the range of the dielectric constant is 2-35 which can satisfy the different requirements.

Owner:YUNNAN INFINE NEO MATERIAL

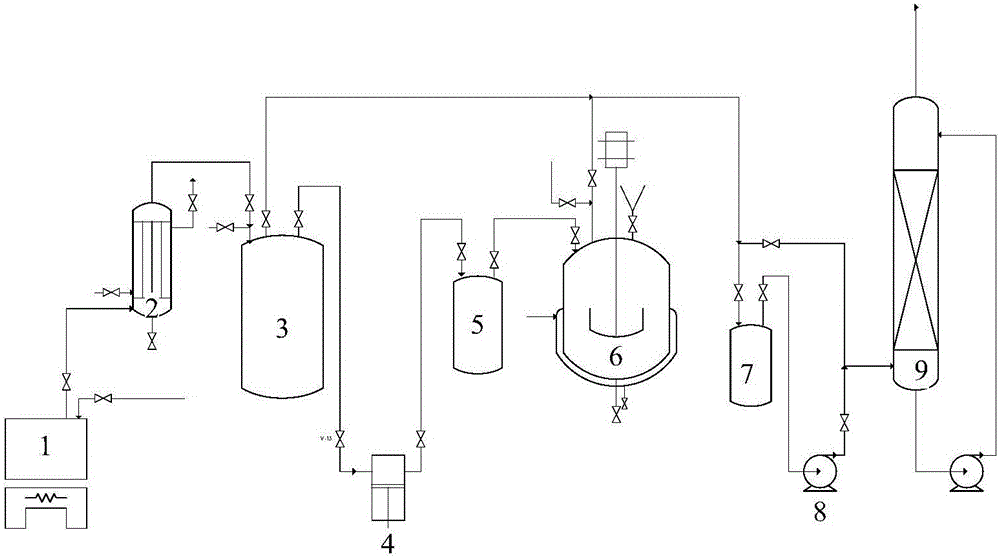

Device used for treating unstable terminal group of fluorine-containing polymer and a process for treating same

The invention relates to a device used for treating an unstable terminal group of a fluorine-containing polymer. The device comprises a fluorine-preparing electrolyzer, a hydrogen fluoride freezing remover, a fluorine gas collecting tank, a diaphragm compressor, a fluorine and nitrogen mixed gas high-pressure storage tank and a high-pressure reaction tank, wherein the gas outlet of the high-pressure reaction tank is connected with one gas outlet pipeline of the fluorine gas collecting tank. A process for treating the unstable terminal group of the fluorine-containing polymer concretely comprises the following steps: (1) refinement and collection of fluorine gas; (2) preparation and pressurization of fluorine and nitrogen mixed gas; and (3) fluorination of the unstable terminal group of the fluorine-containing polymer. The device and process for fluorination provided by the invention can realize fluorination directing at different fluorine-containing polymers (like polytetrafluoroethylene PTFE, fluorinated ethylene propylene FEP and a tetrafluoroethylene and heptafluoropropyl trifluorovinyl ether copolymer PFA), has extremely extensive applicability and good fluorination effects, and is applicable to great popularization in the fluorine chemical industry.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

Fluoropolymers resistant to stress cracking

The invention provides a fluorothermoplastic composition comprising interpolymerized units derived from about 94 to about 97.5 mole percent (mol %) tetrafluoroethylene (TFE), about 2 to about 3 mol % perfluoro (propyl vinyl ether) (PPVE), and about 0.5 to about 3 mol % hexafluoropropylene (HFP). The invention also provides a fluorothermoplastic composition comprising interpolymerized units derived from about 94 to about 97 mol % TFE, about 0.75 to about 3 mol % PPVE, and about 1.5 to about 3.5 mol % HFP. These fluorothermoplastic compositions have a flex life that fits the equation: log(flex life cycles)>=0.71+4.0*(MFI<(-0.294)>), a method of making fluorothermoplastic compositions, a method of improving stress crack resistance, and fluorothermoplastic articles.

Owner:3M INNOVATIVE PROPERTIES CO

Modified polytetrafluoroethylene, preparation method of modified polytetrafluoroethylene and application of modified polytetrafluoroethylene to high frequency connector

The invention provides a modified polytetrafluoroethylene, a preparation method of the modified polytetrafluoroethylene and application of the modified polytetrafluoroethylene to a high frequency connector. The modified polytetrafluoroethylene is obtained through polymerization reaction of tetrafluoroethylene and perfluoropropoxyethylene; a side group is introduced into a molecular chain of the polytetrafluoroethylene; crystallinity and melt viscosity of the polytetrafluoroethylene are reduced; and when original excellent performance of the polytetrafluoroethylene is basically kept, processing performance of the polytetrafluoroethylene is improved to enable the modified polytetrafluoroethylene to be formed by injection molding, so that the production process is simplified and the production efficiency is improved. When the high frequency connector is produced, the injection molding can be carried out in one step and the post processing step is omitted.

Owner:NANJING COMPTECH COMPOSITES CORP +1

Fluorinated terpolymer

InactiveUS7009017B2Distinguished mechanical strengthDistinguished transparencyPropyl vinyl etherEthyl vinyl ether

A fluorine-containing terpolymer with distinguished transparency and strength at ordinary temperature and at elevated temperatures when heated, which comprises 20–98% by weight of tetrafluoroethylene, 1–40% by weight of perfluoro(ethyl vinyl ether) and 1–40% by weight of perfluoro(propyl vinyl ether) and has a specific melt viscosity of 0.1×103–110×103 Pa·s (372° C.). The fluorine-containing terpolymer preferably has a comonomer ratio of perfluoro(propyl vinyl ether) to perfluoro(ethyl vinyl ether) of 1.0 or more by weight.

Owner:UNIMATEC CO LTD

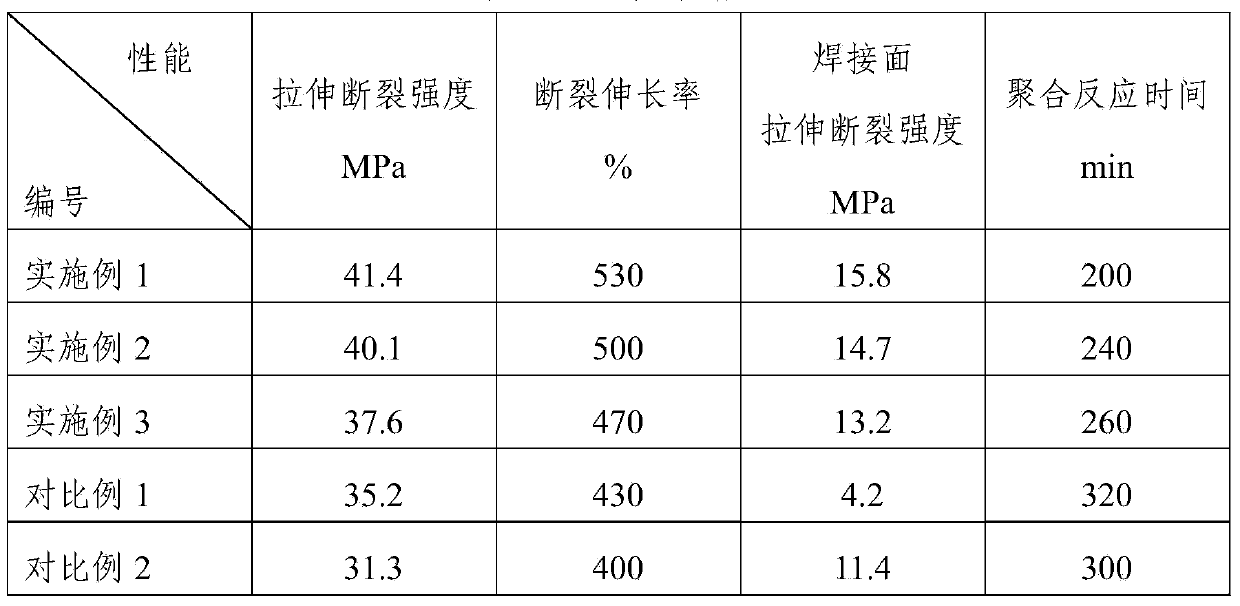

Modified PTFE (Polytetrafluoroethylene) suspension resin with high welding property and preparation method of modified PTFE suspension resin

The invention relates to a modified PTFE (Polytetrafluoroethylene) suspension resin which comprises the following components in parts by weight: 3500-6000 parts of tetrafluoroethylene, 0.2-1.5 parts of oxidizing agent, 0.1-0.5 part of dispersion agent, 1-8 parts of buffer salt, 0.02-0.15 parts of reducing agent, and 30-70 parts of perfluor propyl vinyl ether. By regulating the adding steps of polymerization monomers, the reaction process is effectively controlled, the obtained polymer is compact in structure and low in porosity, and the welding property and the electrical property of the polymer are improved.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

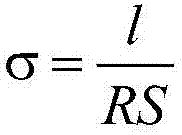

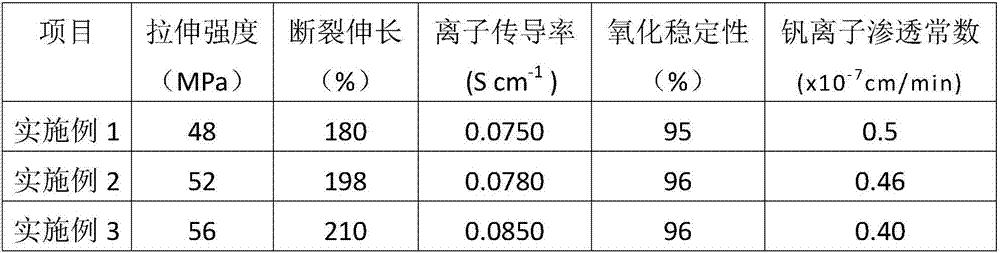

Triazine derivative-based separator for vanadium battery and preparation method of separator

ActiveCN107978769ASimple manufacturing methodLow equipment requirementsRegenerative fuel cellsVinyl etherUltraviolet lights

The invention discloses a triazine derivative-based separator for a vanadium battery and a preparation method of the separator. The preparation method comprises the steps of firstly, adding 2,4-diamino-6-phenyl-1,3,5-triazine and 2-chloroethyl vinyl ether into an organic solvent, performing uniform mixing, performing stirring and backflow reaction for 6-8 hours under 30-40 DEG C, performing rotaryevaporation under 40-50 DEG C to remove a solvent, sequentially washing the product with ethyl ether and ethyl acetate for 3-5 times, performing rotary evaporation under 40-50 DEG C to remove the solvent so as to prepare a polymerization triazine derivative; and mixing the polymerization triazine derivative, a polymerization monomer, heptafluoropropyl trifluorovinyl ether, an emulsifier and a light initiator, dropping the mixture onto a glass plate, placing the glass plate under ultraviolet light of 200-250 nanometers in nitrogen or inert gas atmosphere for irradiation for 45-55 minutes, andgenerating polymerization reaction to obtain a polymer membrane. The preparation method is simple and practical, the separator is more excellent in mechanical property, ultraviolet aging resistance and chemical stability, higher in ion conductivity, better in vanadium resistance, and is green and environmental-friendly, and no toxic raw material is used during the preparation process.

Owner:太湖县市场监督检验所(太湖县功能膜检测研究院)

A kind of modified ptfe suspension resin with high weldability and preparation method thereof

The invention relates to a modified PTFE (Polytetrafluoroethylene) suspension resin which comprises the following components in parts by weight: 3500-6000 parts of tetrafluoroethylene, 0.2-1.5 parts of oxidizing agent, 0.1-0.5 part of dispersion agent, 1-8 parts of buffer salt, 0.02-0.15 parts of reducing agent, and 30-70 parts of perfluor propyl vinyl ether. By regulating the adding steps of polymerization monomers, the reaction process is effectively controlled, the obtained polymer is compact in structure and low in porosity, and the welding property and the electrical property of the polymer are improved.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

Preparation of styrene light diffusing agent

The invention discloses preparation of a styrene light diffusing agent. Fluorine-containing monomers such as heptafluoropropyl trifluorovinyl ether are introduced in styrene polymerization for a polymerization reaction, and then the styrene light diffusing agent is obtained.

Owner:王金明

Teflon engineering plastics having preservative effect

The invention discloses Teflon engineering plastics having a preservative effect. The Teflon engineering plastics include polytetrafluoroethylene, copolymer of perfluoro propyl vinyl ether and polytetrafluoroethylene, fluorinated ethylene propylene copolymer, isopentane, paraffin, disodium bisulfate, succinic acid peroxide and potassium persulfate. The Teflon engineering plastics having the preservative effect can be used for a long time without corroding, use time of the Teflon engineering plastics is effectively prolonged, the Teflon engineering plastics do not need to be often replaced, the cost in use is reduced, and the Teflon engineering plastics sell easily.

Owner:SUZHOU NEW DISTRICT TEFLON PLASTIC PRODS FACTORY

Process for preparing fluorine-containing high polymer high frequency circuit board material by hydrothermal method

ActiveCN102350825BGood adhesionMeet needsSynthetic resin layered productsCircuit susbtrate materialsDielectricVinyl ether

The invention relates to a process for preparing a fluorine-containing high polymer high frequency circuit board material by a hydrothermal method, which belongs to the high frequency circuit substrate material field. The method comprises the following steps: uniformly mixing a polytetrafluoroethylene emulsion (PTFE), a fluoroethylenepropylene emulsion (FEP) and a polyfluoroalkoxy emulsion (PFA), adding salts, then adding a molecule guiding agent and a molecular weight regulator, uniformly mixing, adding in a reaction vessel for performing hydrothermal reaction to complete high-molecular secondary polymerization, acquiring a substance of dielectric inorganic compound nanoparticles coated with high-molecular, filtering, washing, drying, removing end group, sintering, rolling, cladding copper to obtain the high frequency circuit board material with different dielectric constants finally. The prepared high frequency circuit board is capable of satisfying each basic index of the high frequency circuit board, and has the advantages of adjustable dielectric constant, low loss, good mechanical property and the like; the dielectric constant can be adjusted by the circuit board according to the generated dielectric inorganic compound content, the range of the dielectric constant is 2-35 which can satisfy the different requirements.

Owner:YUNNAN INFINE NEO MATERIAL

Method for recovering perfluoro-2-(2-sulfuryl fluoride ethyoxyl) propyl vinyl ether in polymer

PendingCN113583293AImprove recycling efficiencyReduce difficultyOrganic chemistryOrganic compound preparationVinyl etherPhysical chemistry

The invention discloses a method for recovering perfluoro-2-(2-sulfuryl fluoride ethyoxyl) propyl vinyl ether in a polymer, which comprises the following steps: (1) stirring and mixing the polymer containing the perfluoro-2-(2-sulfuryl fluoride ethyoxyl) propyl vinyl ether with an extracting agent, extracting, and filtering to obtain an extracting solution; (2) adjusting the pH value of the extraction solution to 5-8 by using an alkaline solution, filtering to obtain filtrate, and standing and layering the filtrate to obtain an organic layer; (3) carrying out normal-pressure rectification on the organic layer under the protection of nitrogen to obtain the recovered extracting agent and tower bottoms; and (4) carrying out reduced pressure rectification on the tower bottoms under the protection of a stabilizer to obtain the perfluoro-2-(2-sulfuryl fluoride ethyoxyl) propyl vinyl ether. The method has the advantages of simple process, high efficiency, economy and environmental protection.

Owner:JUHUA GROUP TECH CENT

Polyether-containing leather brightener composition

InactiveCN106085246AIncrease brightnessImprove wettabilityPolishing compositionsLeather surface finishingImideWax

The patent relates to a polyether-containing leather brightener composition, which is composed of trimethoxysilane propyl vinyl ether, organosilicon glycol interpolymer wax, perfluoropolyether oil, perfluoroalkyl ethyl acrylates, polyisobutylene and N-butyl-N-methylpyrrolidinium bis(trifluoromethyl sulfonyl)imide.

Owner:王金明

Tetrafluoroethylene-based copolymer and its preparation method

The invention belongs to the field of fluorine-containing polymer materials, and particularly relates to a tetrafluoroethylene copolymer and a preparation method thereof. The tetrafluoroethylene copolymer is a terpolymer comprising 90-98 wt% of tetrafluoroethylene, 1-7 wt% of perfluoro-n-propyl vinyl ether and 1-3 wt% of perfluoro-propenyl alkoxy ether with a CF<2>=CFCF<2>[OCF<2>CF(CF<3>)]<n>OR<f>structure or a hydrogen-containing derivative thereof, wherein n is an integer of 0-5, and R<f> is a perfluoroalkyl group provided with 1-5 carbon atoms or the derivative containing hydrogen atoms. The tetrafluoroethylene copolymer has good melting fluidity and thermal stability, high flexibility, high transparency and high surface finish. A green environment-friendly solvent is adopted in the preparation method, and damage to the atmospheric ozone layer is avoided, energy is saved, and the environment is protected.

Owner:SHANDONG HUAXIA SHENZHOU NEW MATERIAL

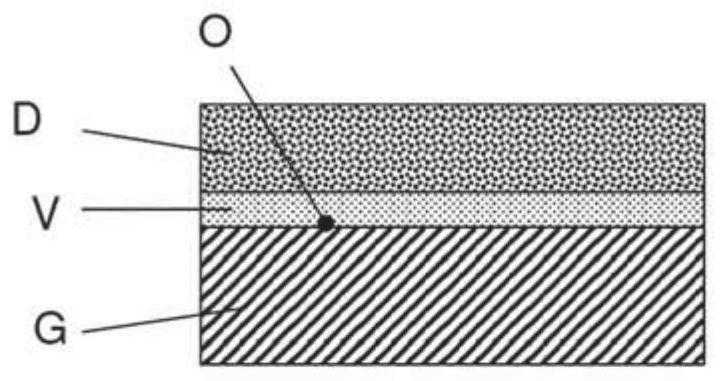

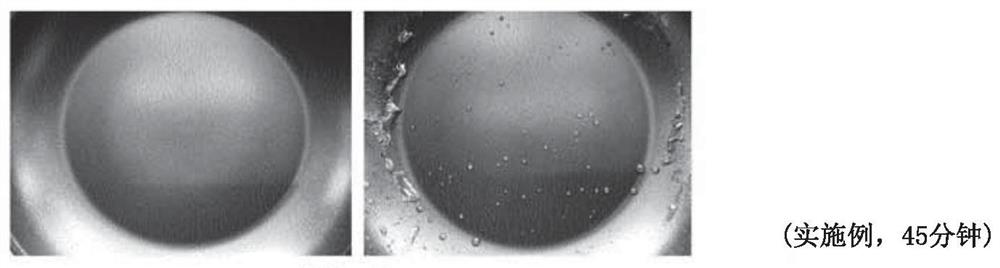

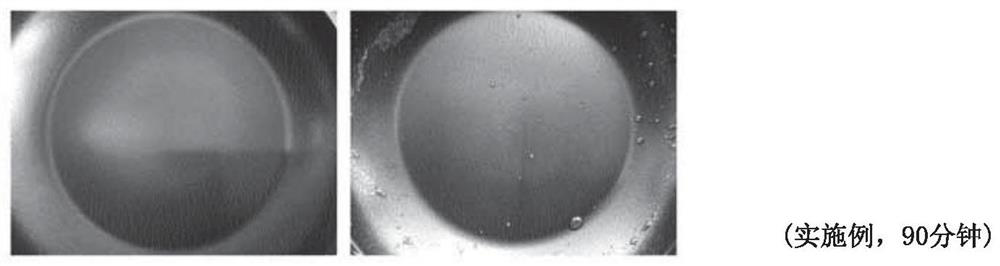

Non-stick coating and method for production thereof

PendingCN112399812ANon-stick and durableGood wear resistanceCooking-vessel materialsCoatingsVinyl etherPolymer science

The invention relates to a non-stick coating for an article, having at least one bonding agent layer (V) applied to a surface of the article and a top layer (D), disposed over the bonding agent layer,wherein the bonding agent layer has a dry film layer thickness of 5 to 25 mum, and the top layer has a dry film layer thickness of 10 to 65 mum. In order to obtain an improved combination of non-stick effect and abrasion resistance, according to the invention the top layer contains 95 to 100 wgt.-% PTFE and, as applicable, up to 5 wgt.-% pigments, relative to the total solids content of the top layer, and is free of fluoropolymers which can be melt-processed, and the PTFE contained comprises between 100 wgt.-% of a high-molecular modified PTFE, which contains < 1 wgt.-% perfluoro propyl vinylether (PPVE) as a modified co-monomer and was obtained by emulsion polymerization. In a method for applying the non-stick coating, the bonding agent layer is applied in liquid form as a first aqueousdispersion to the surface of the article and then heat-dried, then the top layer is applied in the form of a second aqueous dispersion and the layers are bonded by subsequent drying and fusion to each other and to the surface of the article, wherein the second dispersion is free of fluoropolymers which can be melt-processed and is free of low-molecular PTFE.

Owner:工业漆股份公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com