Patents

Literature

64results about How to "Satisfy life" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-temperature resisting methyl vinyl silicone rubber

The invention discloses high-temperature resisting methyl vinyl silicone rubber as well as a prescription and a preparation process thereof. The high-temperature resisting modified silicon rubber material which has more than 300 DEG C of application temperature and can not crack when according with requirements of 550 DEG C, 4mm distance and high-temperature radiation for more than 12 minutes is prepared by adopting the following steps of: adding cerium oxide and polymide into the prescription in which methyl vinyl silicon crude rubber is taken as a rubber raw material to improve the heat-resisting temperature, adding hydroxy silicone oil, dimethyl silicon oil and a silane coupling agent to improve the oil-resisting performance, adding precipitation method white carbon black and gas-phase method white carbon black to improve the tearing-resistance strength, adding quartz power and kieselguhr to improve the tensile strength and matching technical schemes of the preparation process. The high-temperature resisting methyl vinyl silicone rubber overcomes the problems and the defects of poor high-temperature and aging resistance performance and short service life of the common silicone rubber in the prior art, satisfies the special requirements for the heat-resisting performance, the electrical strength and the mechanical strength of automotive rubber products, and ensures that the silicone rubber products achieve the aims of improving the high-temperature resistance performance and prolonging the service life.

Owner:NINGBO GUANGMING RUBBER & PLASTIC

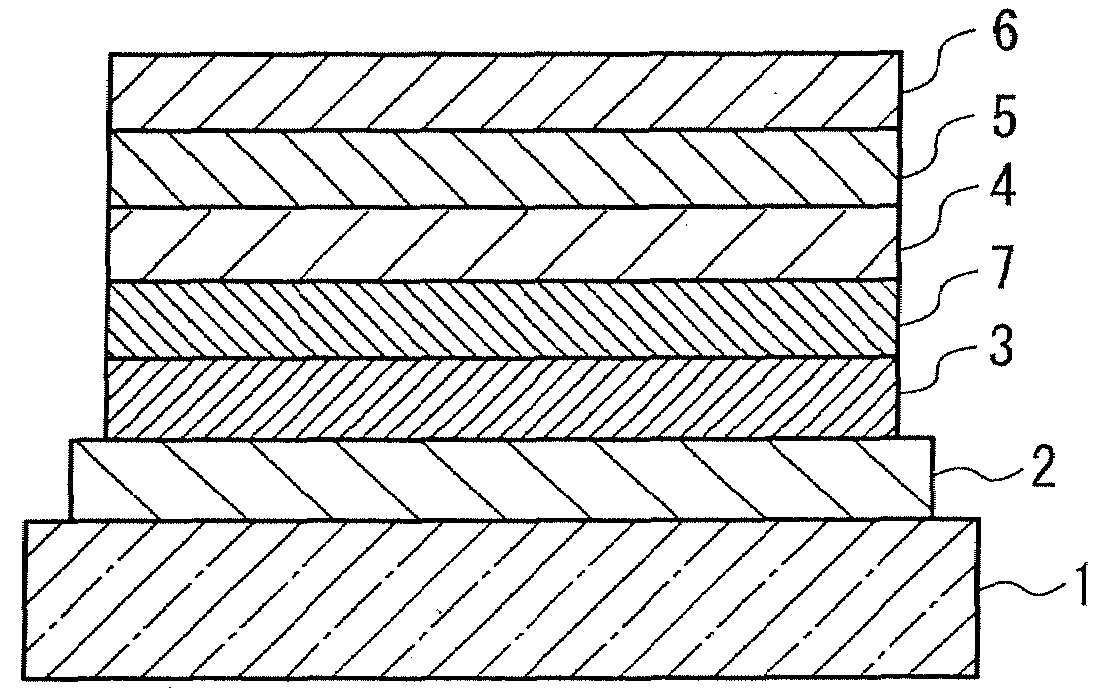

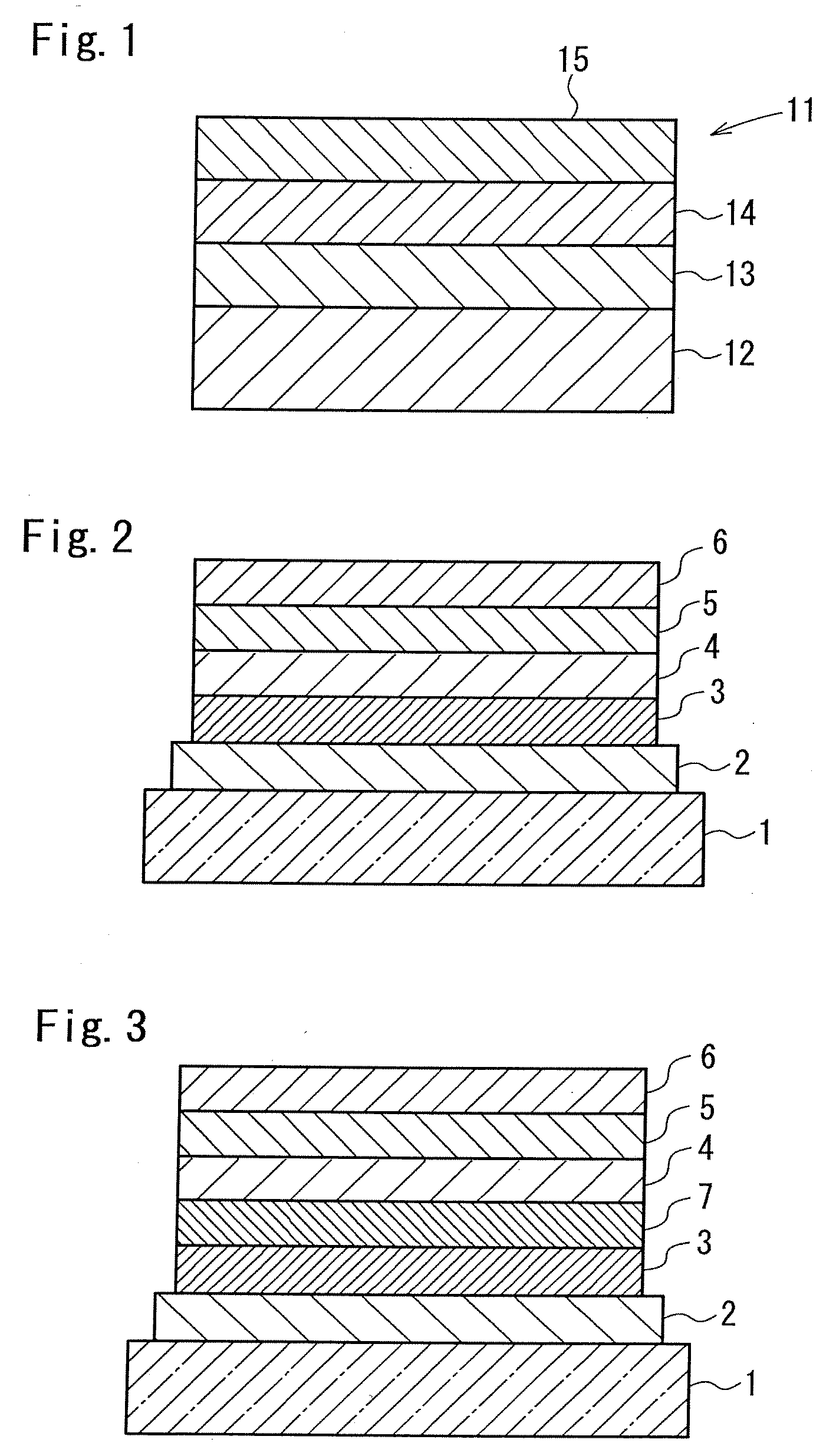

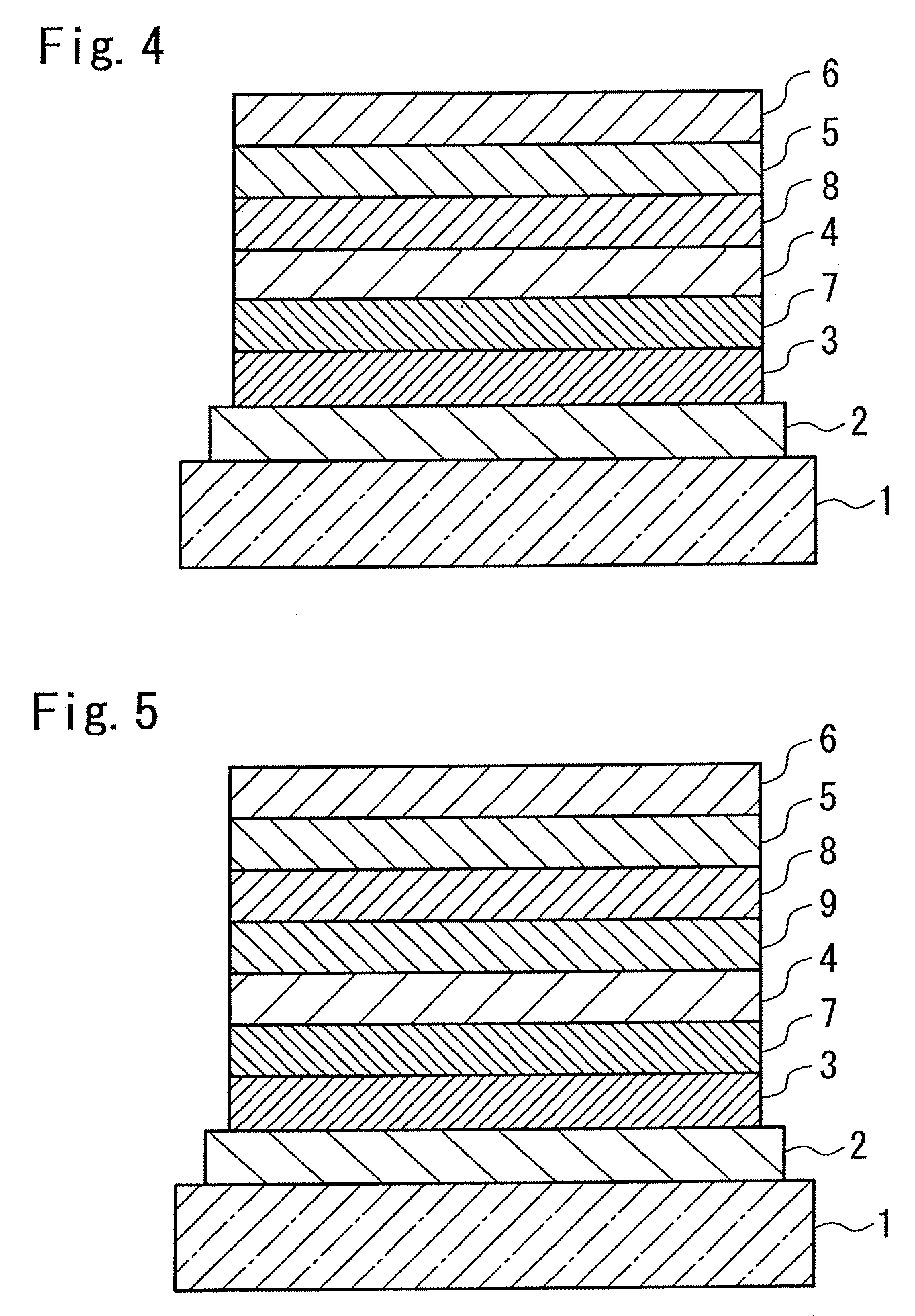

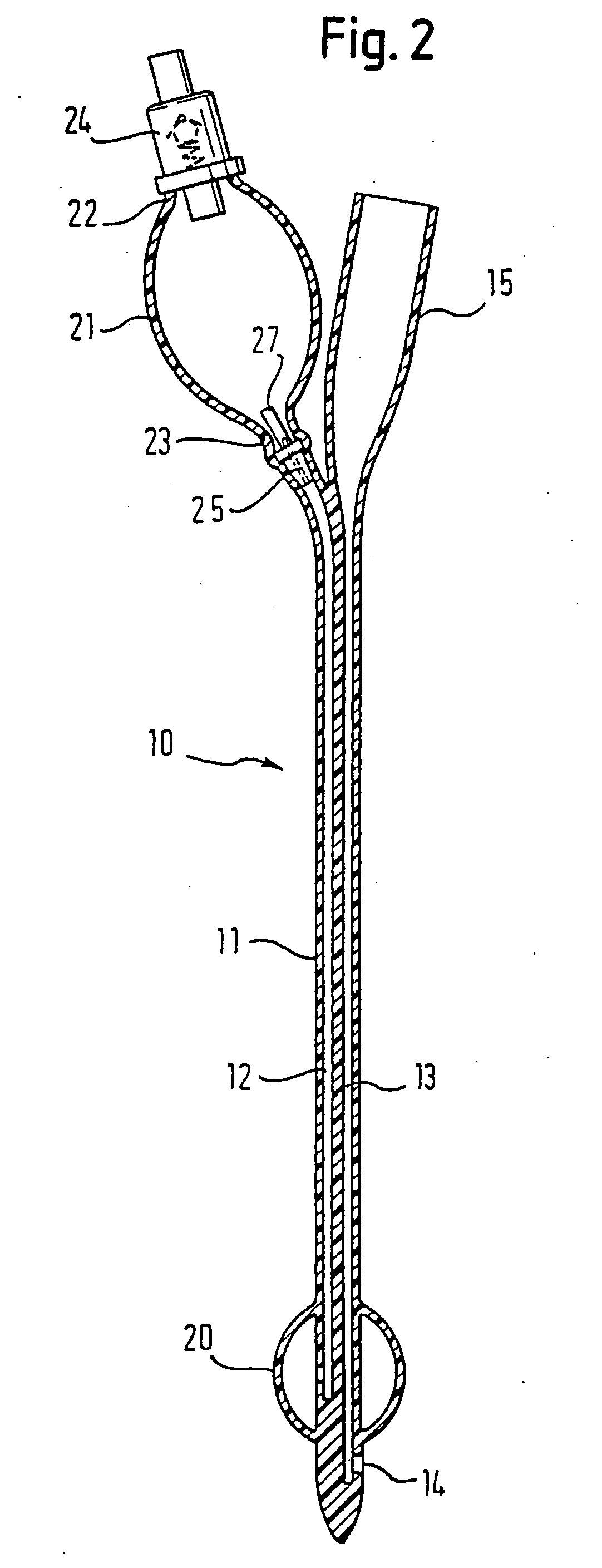

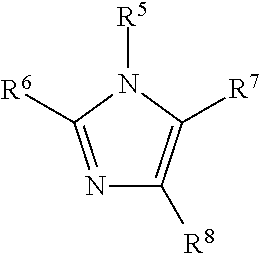

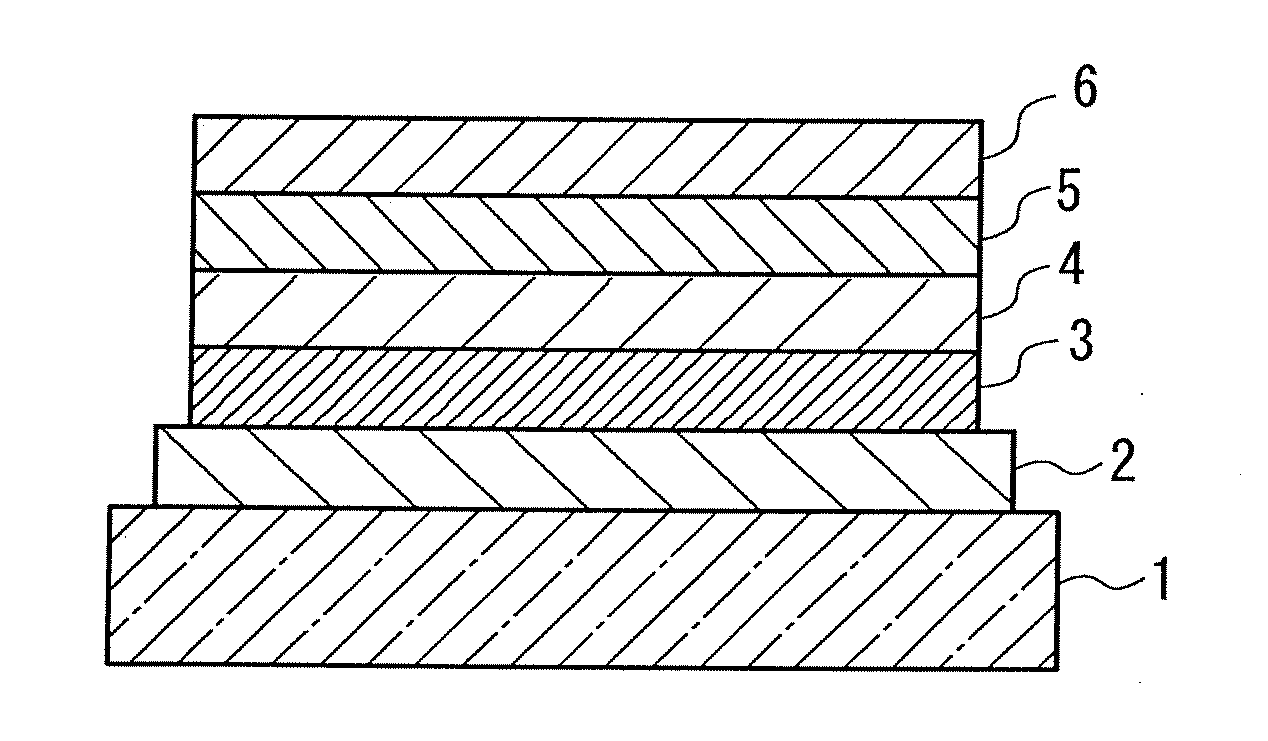

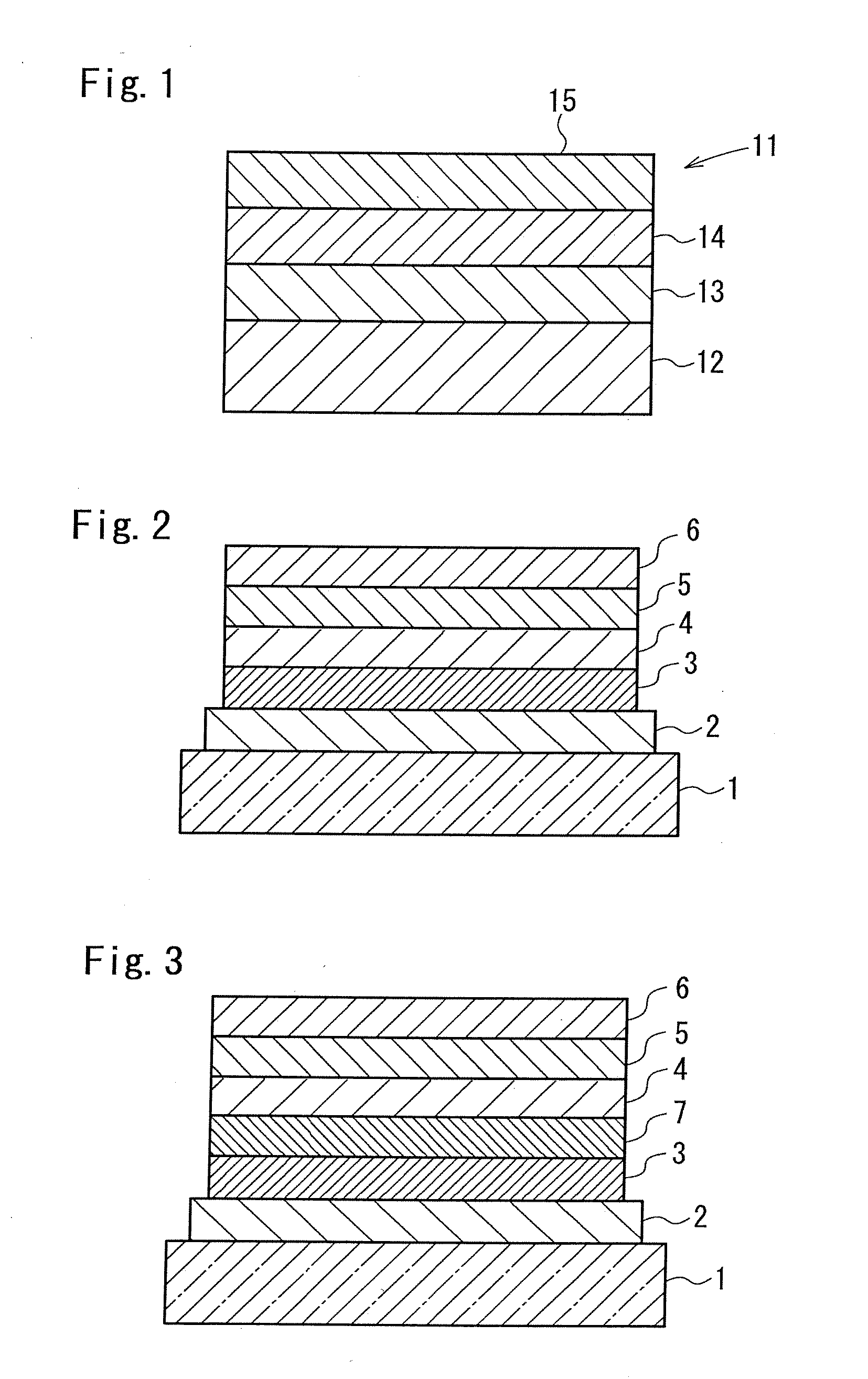

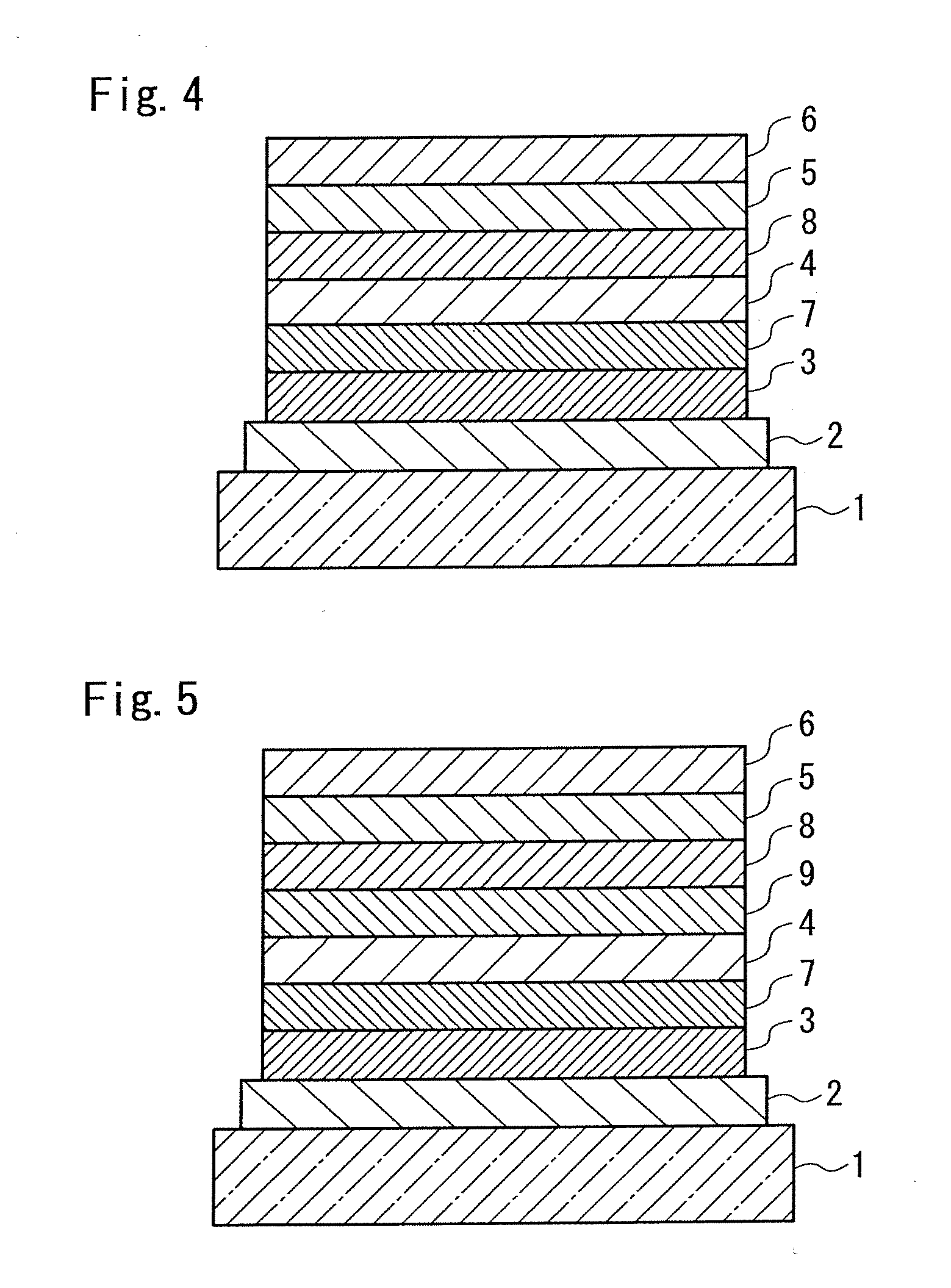

Organic electric field light emitting element and production therefor

ActiveUS20090066223A1Good luminous efficiencySatisfactory operating lifeDischarge tube luminescnet screensElectroluminescent light sourcesOrganic electroluminescenceSolvent

A composition for an organic electroluminescent device is a composition for forming an organic light emitting layer of an organic electroluminescent device by wet coating process. The composition contains a phosphorescent material, a charge transport material, and a solvent, in which the phosphorescent material and the charge transport material are each an unpolymerized organic compound, and the first oxidation potential of the phosphorescent material ED+, the first reduction potential of the phosphorescent material ED−, the first oxidation potential of the charge transporting material ET+, and the first reduction potential of the charge transporting material ET− satisfy the following condition: ET−+0.1≦ED−<ET+≦ED+−0.1 or ED−+0.1≦ET−<ED+≦ET+0.1.

Owner:MITSUBISHI CHEM CORP

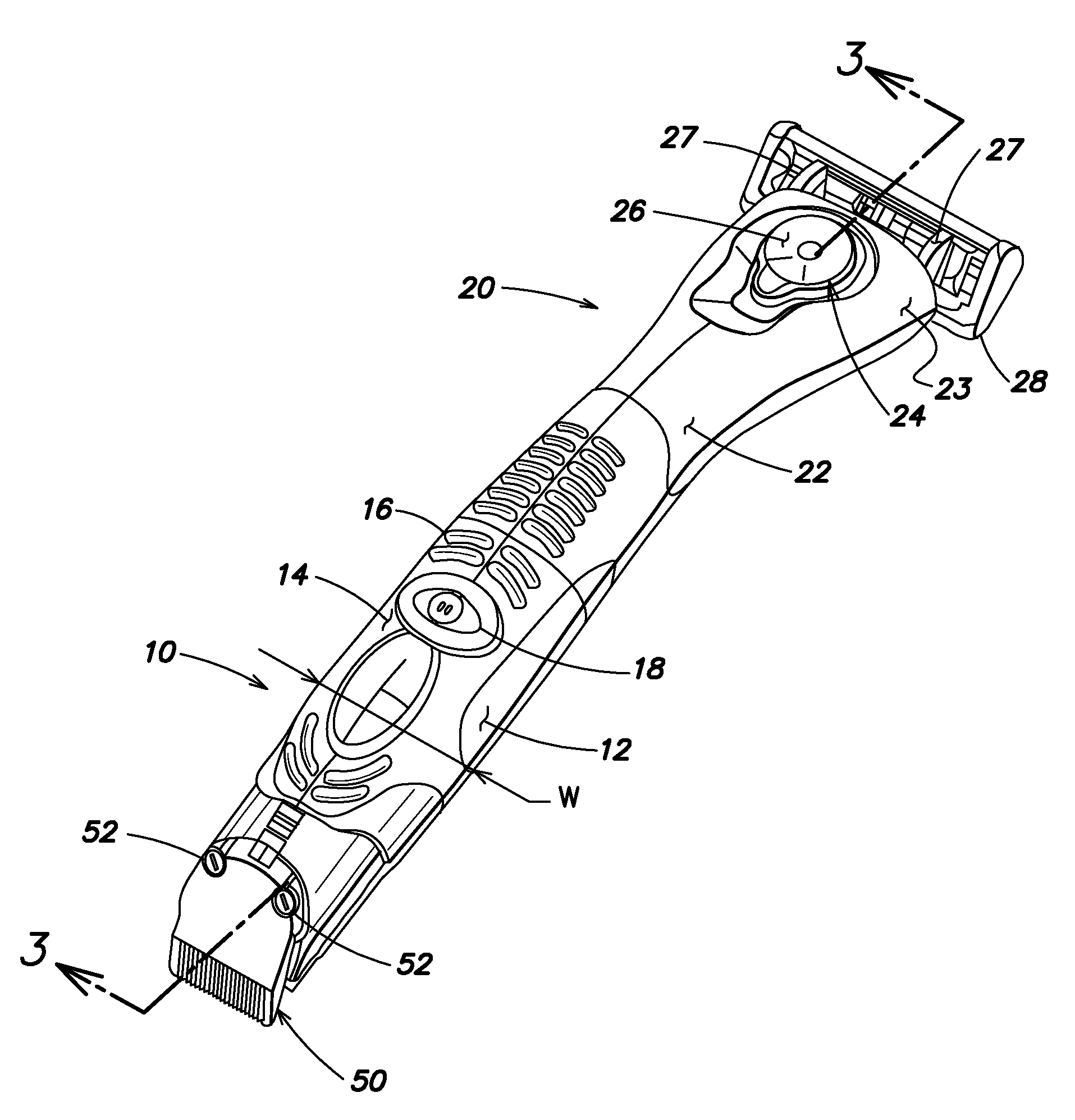

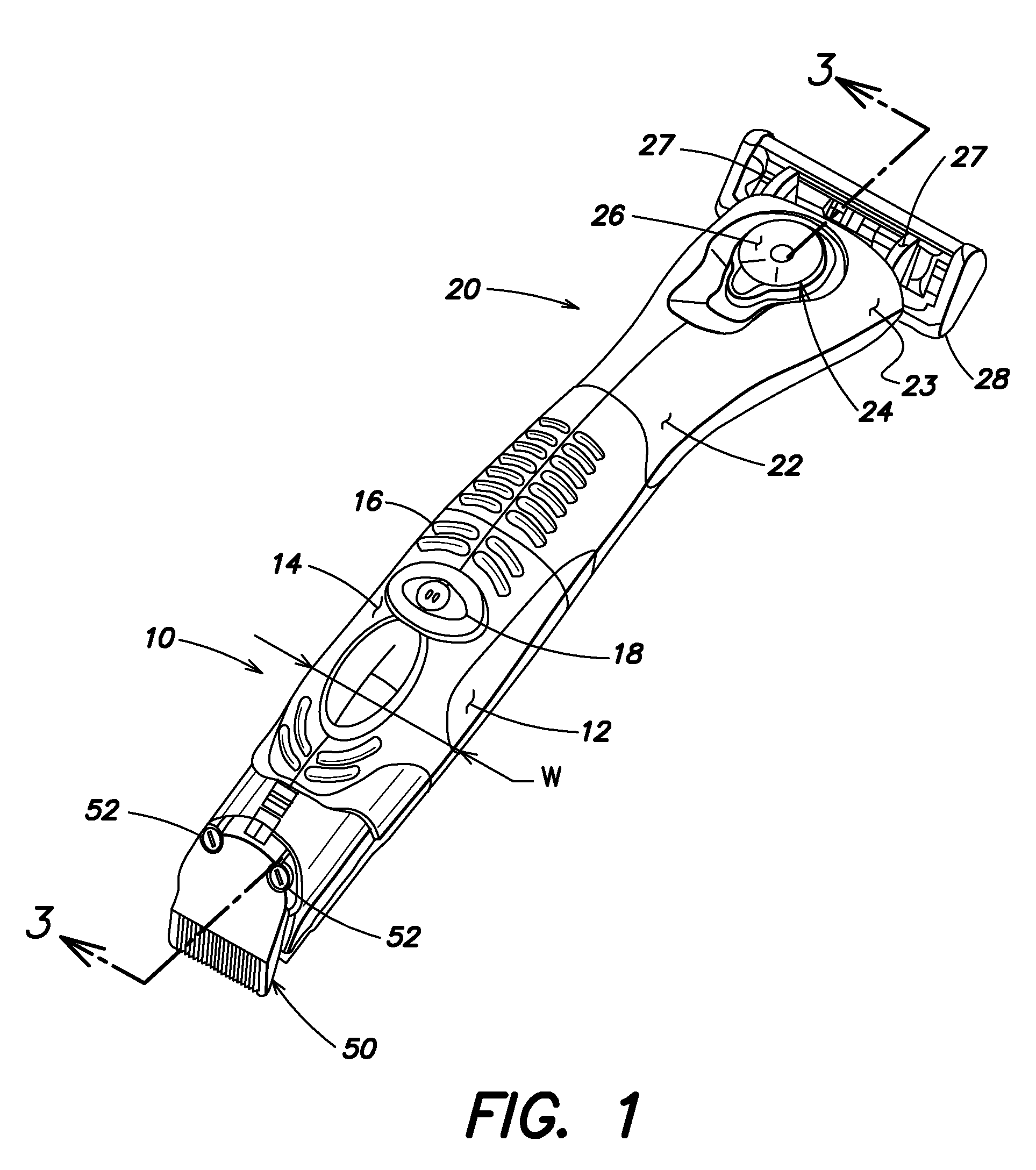

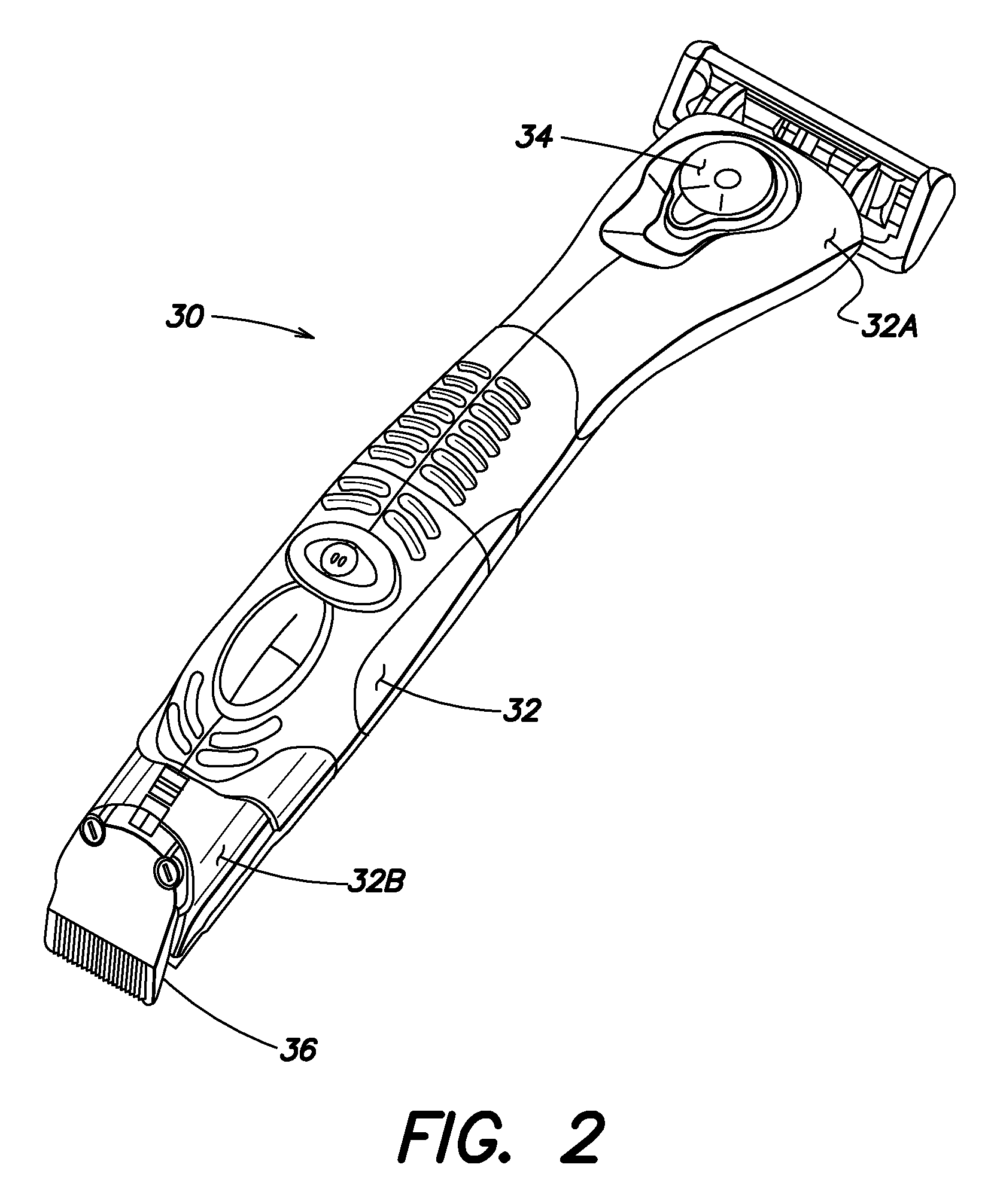

Grooming tool assembly

InactiveUS20090000124A1Peak efficiency of motorLife of batteryMetal working apparatusEngineeringKnife blades

A battery powered grooming tool is provided that includes a safety razor assembly adjoined to a hair trimmer assembly. Both assemblies include a housing. The housings may be separable or may be integrally formed. The trimmer assembly includes a motor operably connected to a moving toothed blade. The motor has a diameter less than 18 mm, a peak efficiency greater than 55% and an output torque greater than 0.8 mNm at peak efficiency. The grooming tool has a width less than 25 mm and a mass less than 80 g and the grooming tool is ergonomically familiar to a typical safety razor user.

Owner:EVEREADY BATTERY CO INC

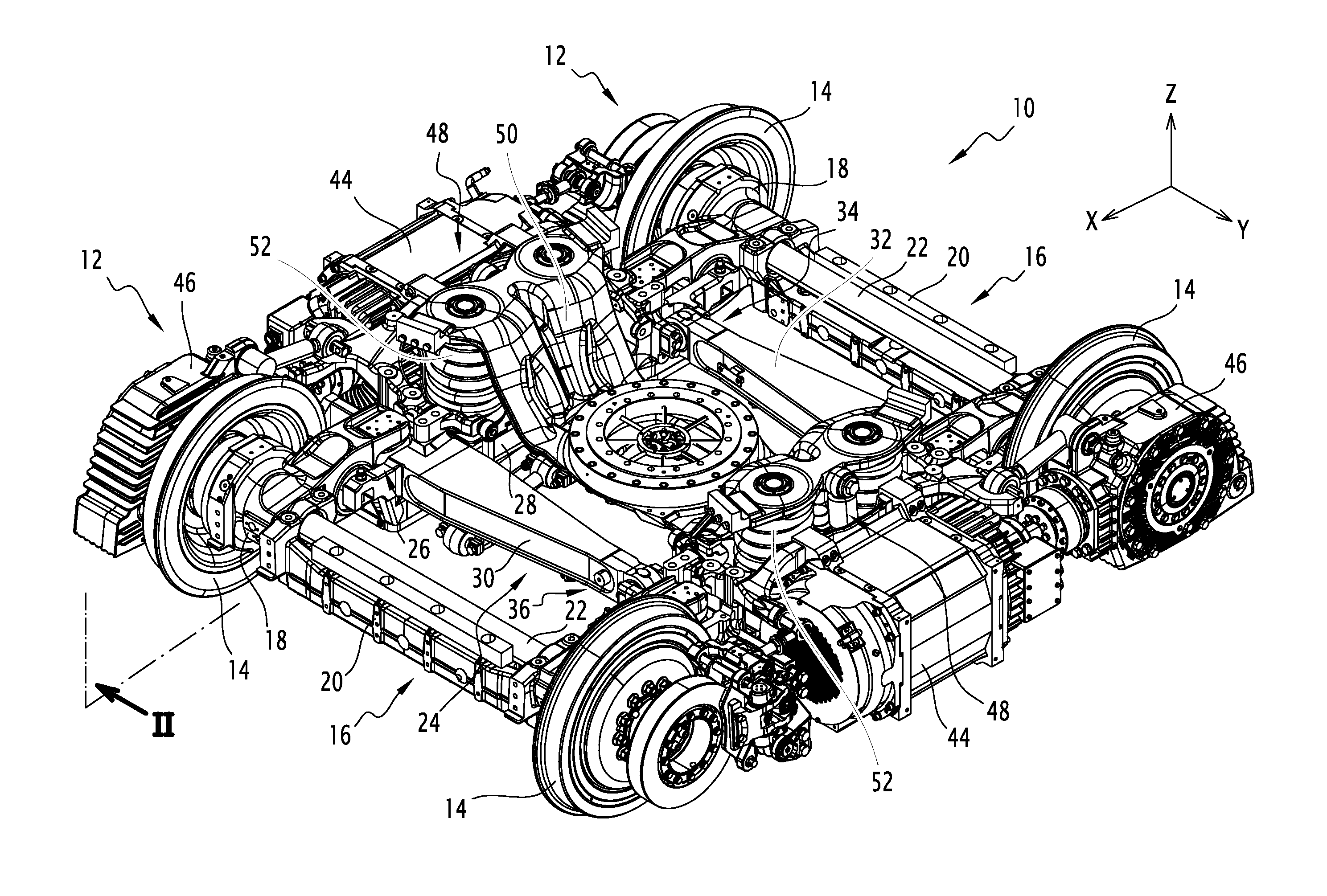

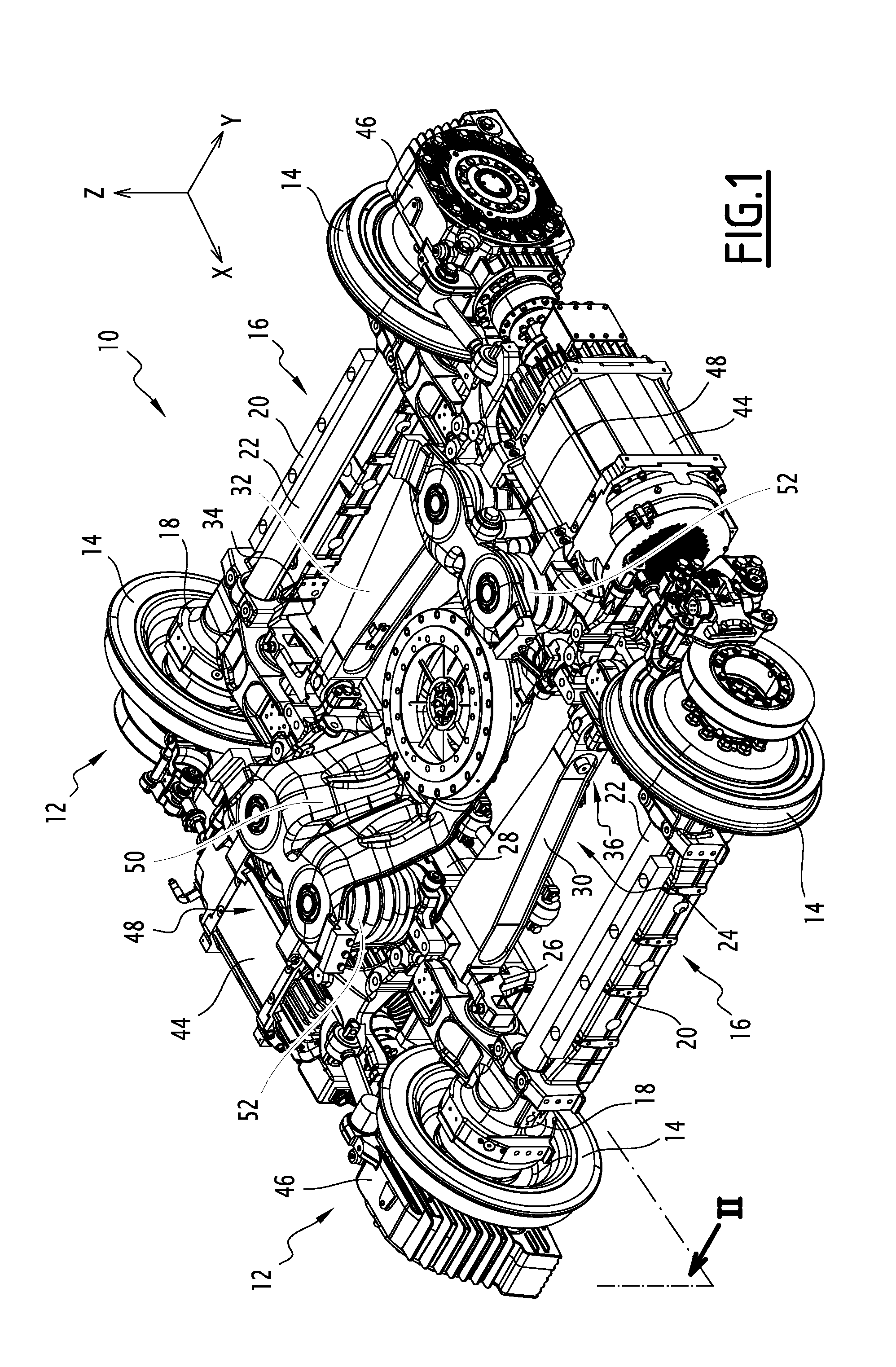

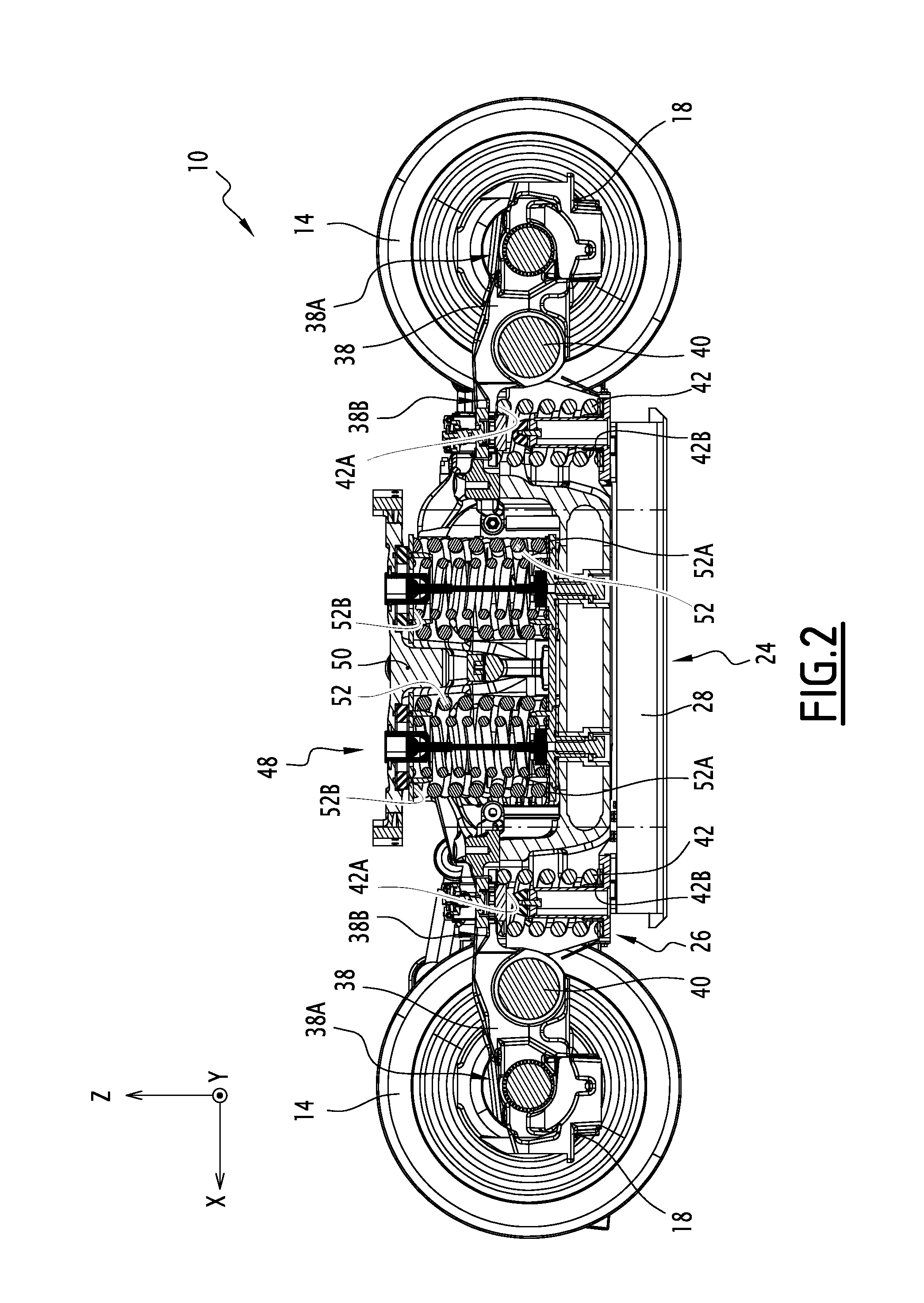

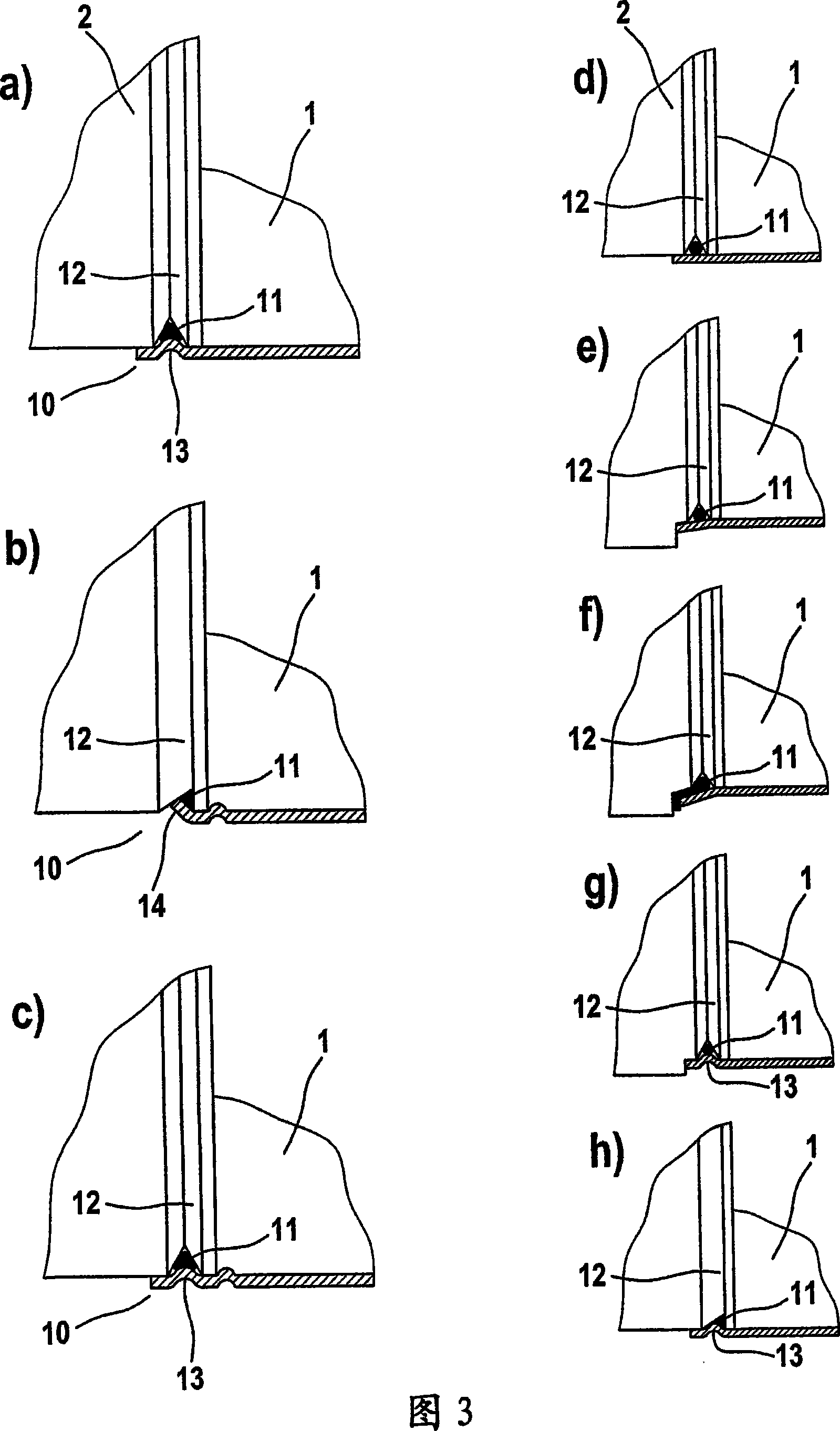

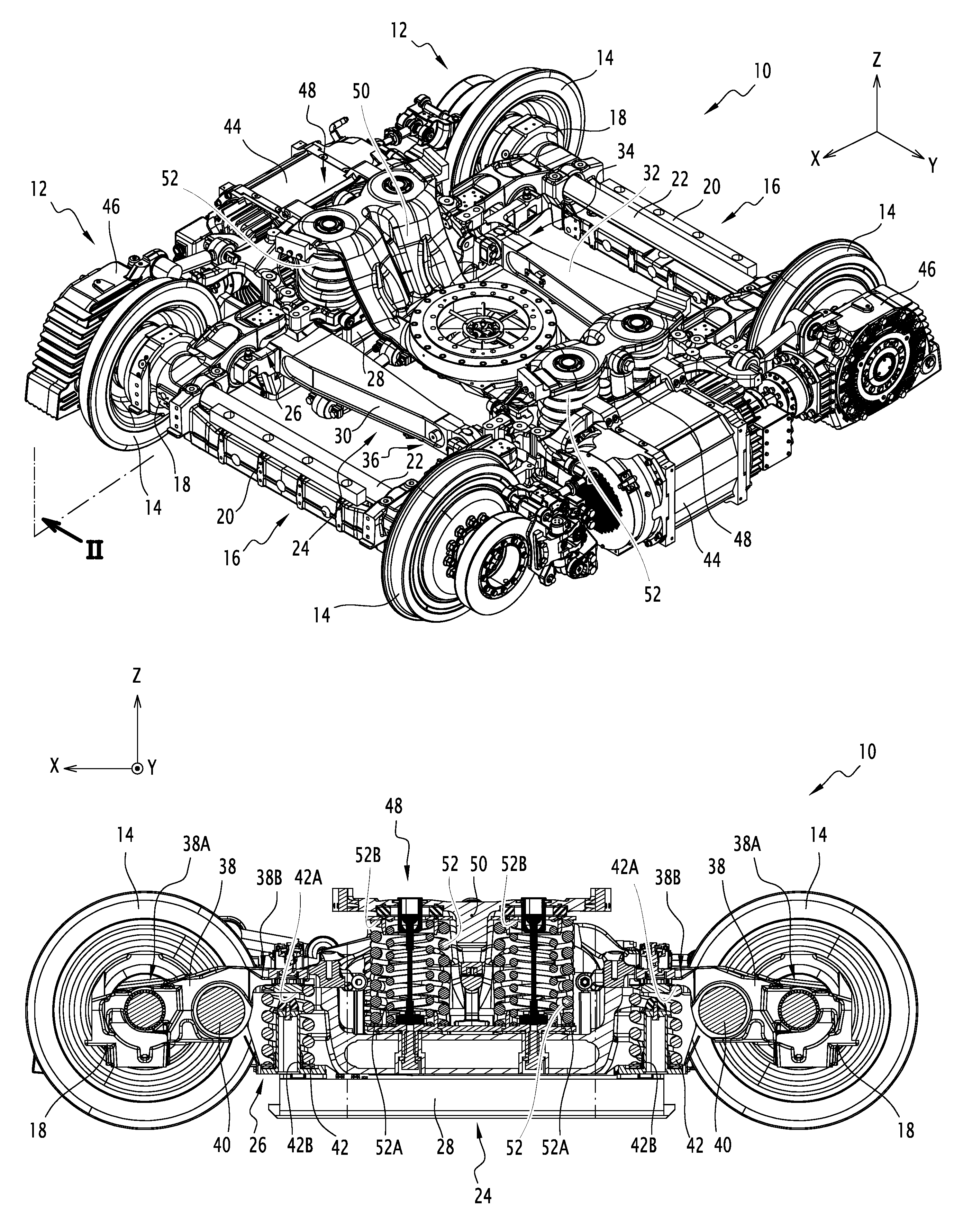

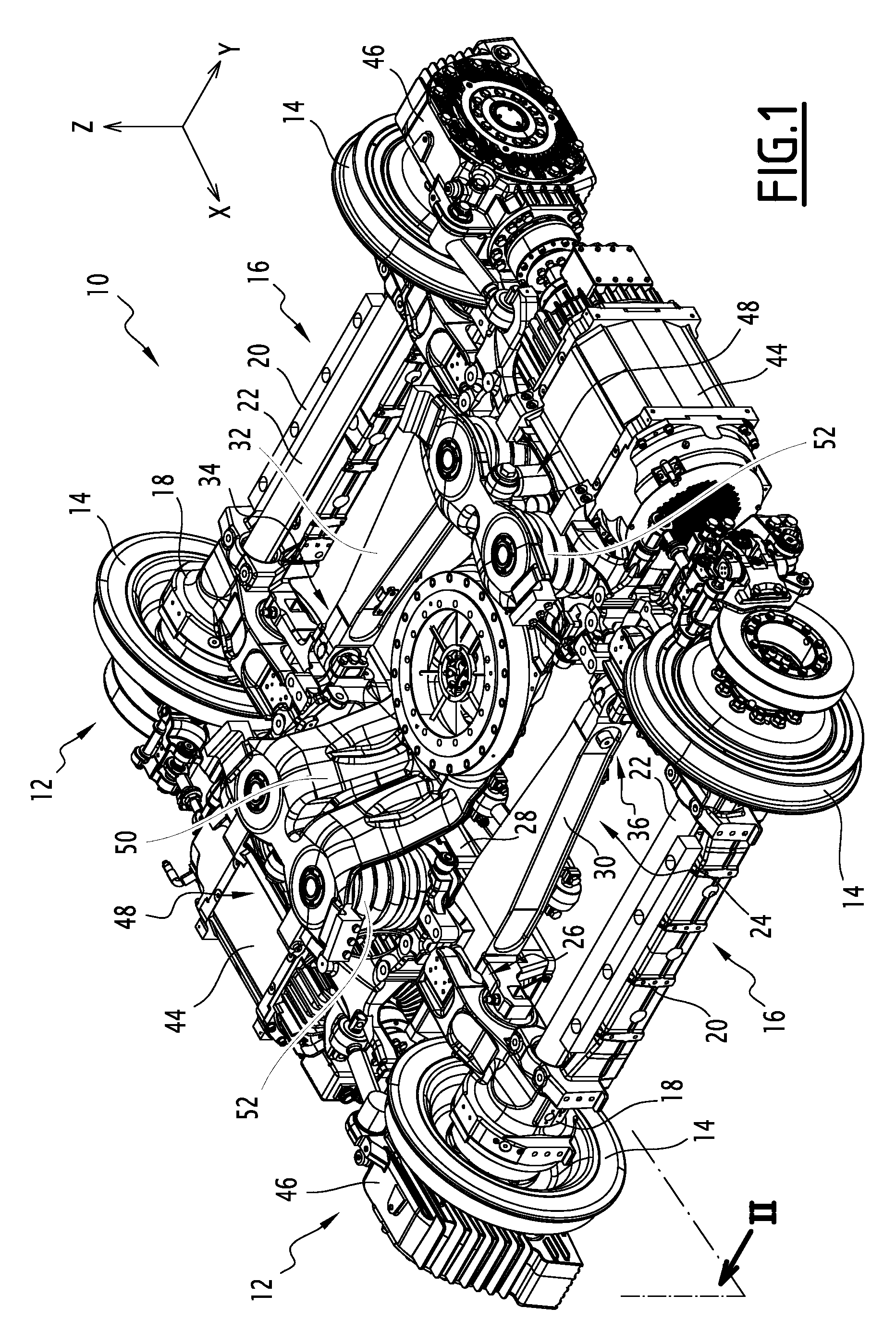

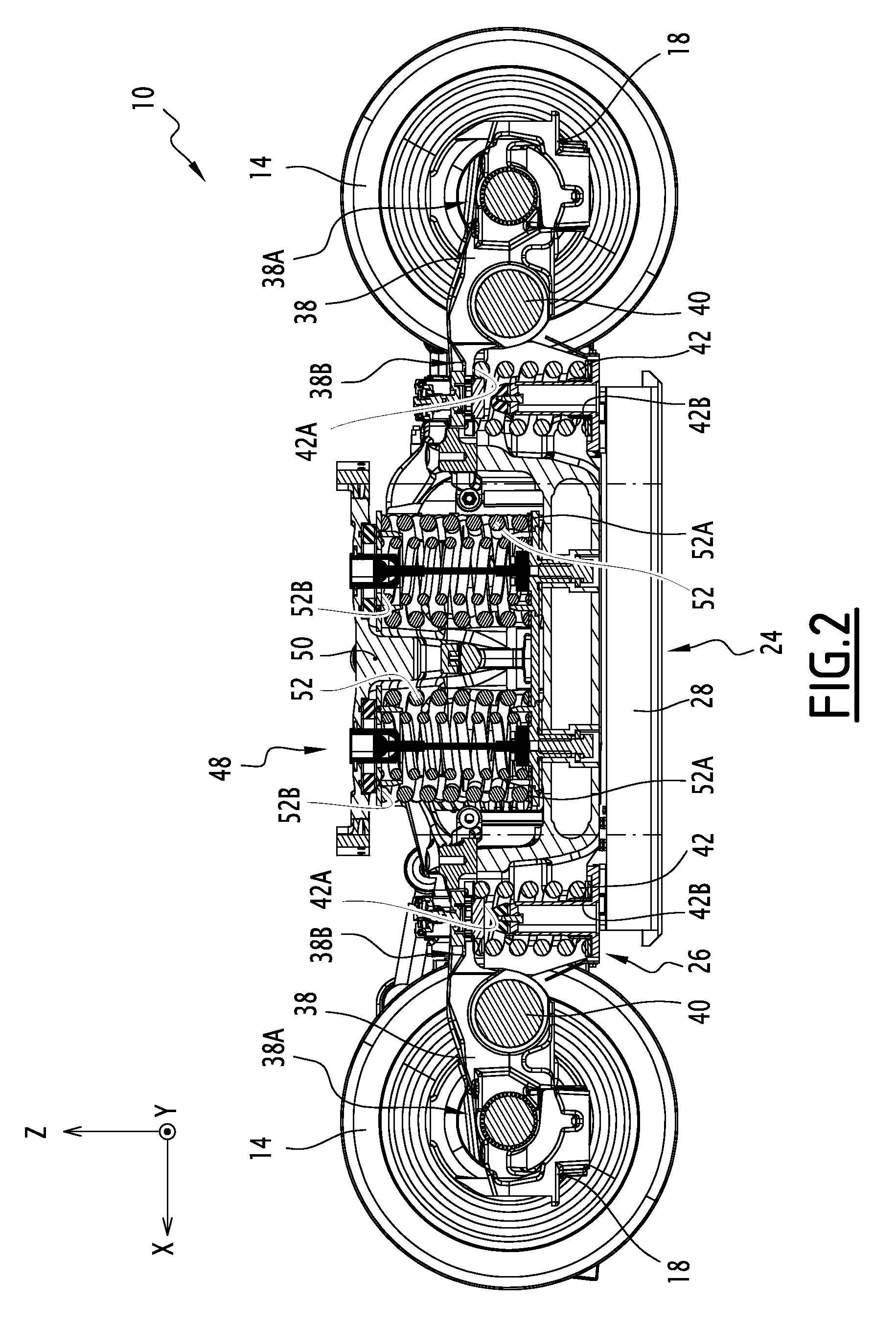

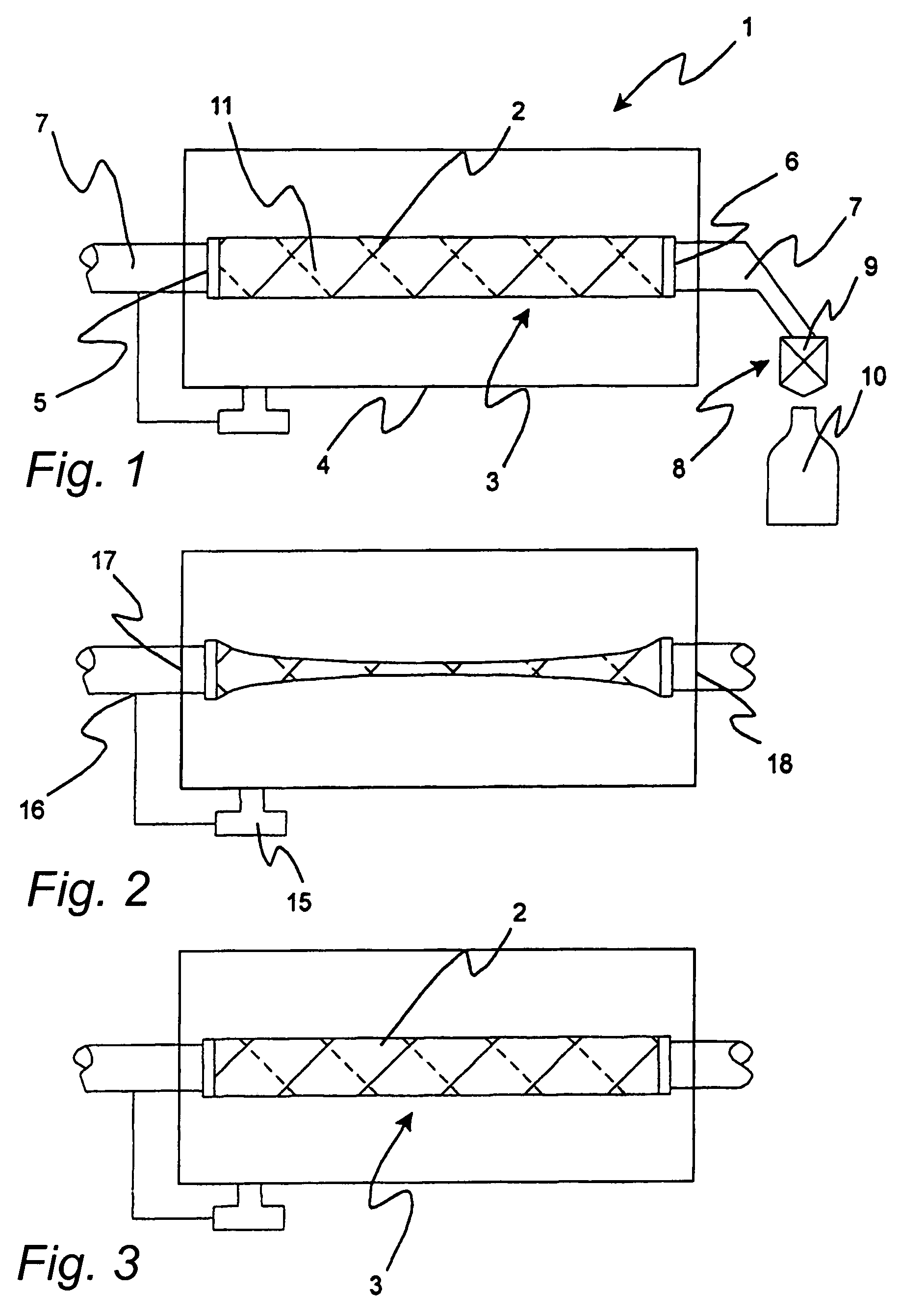

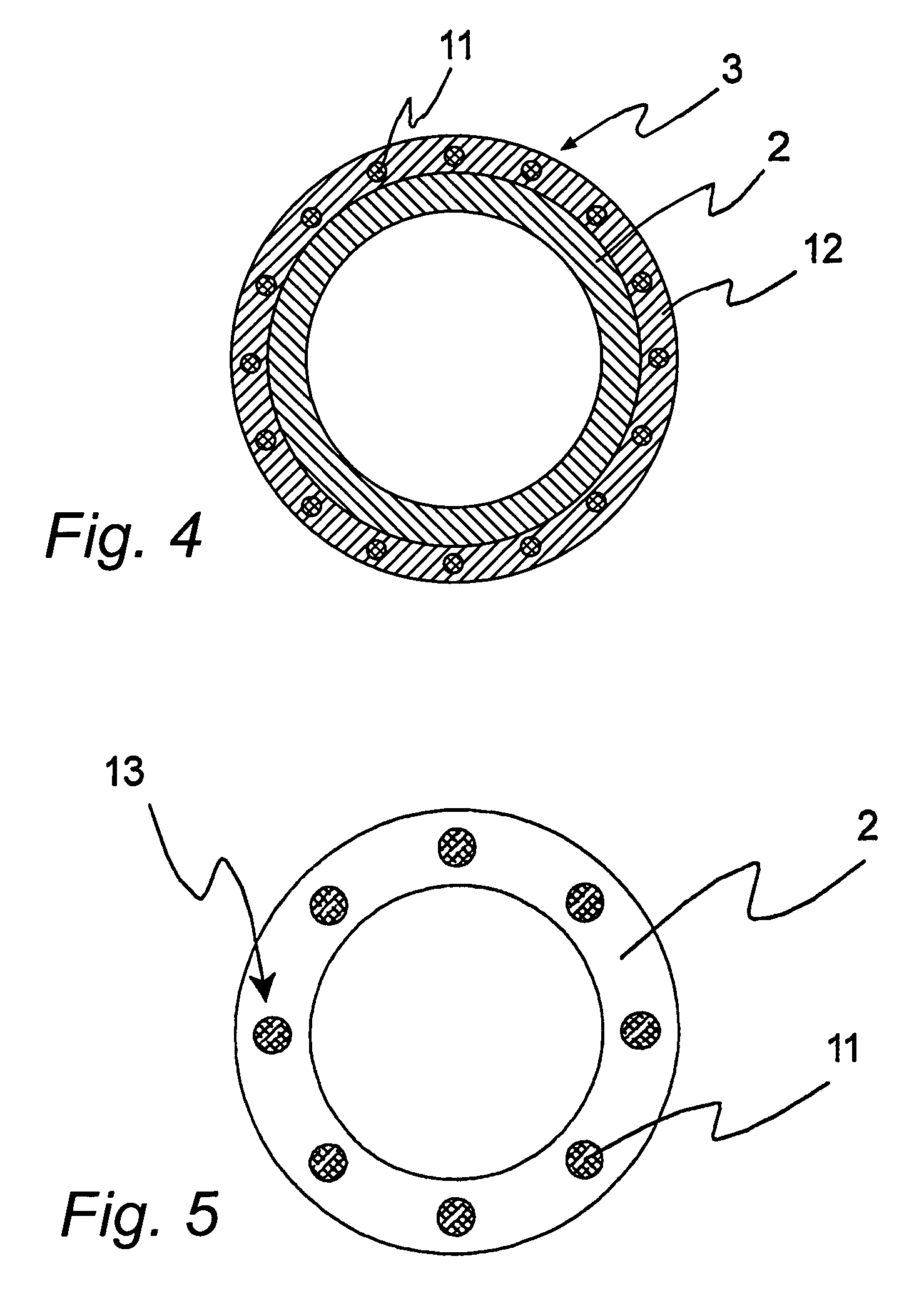

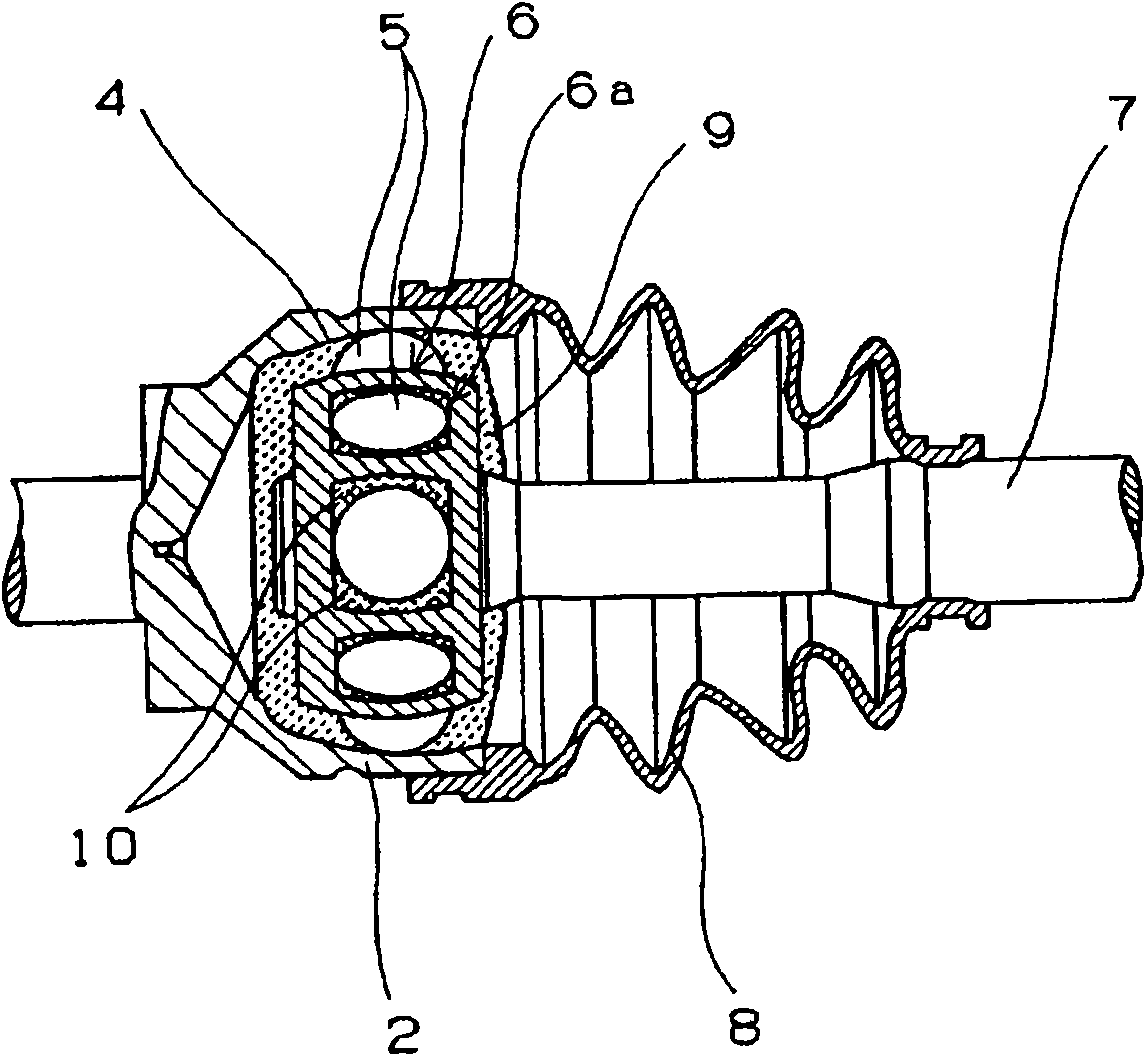

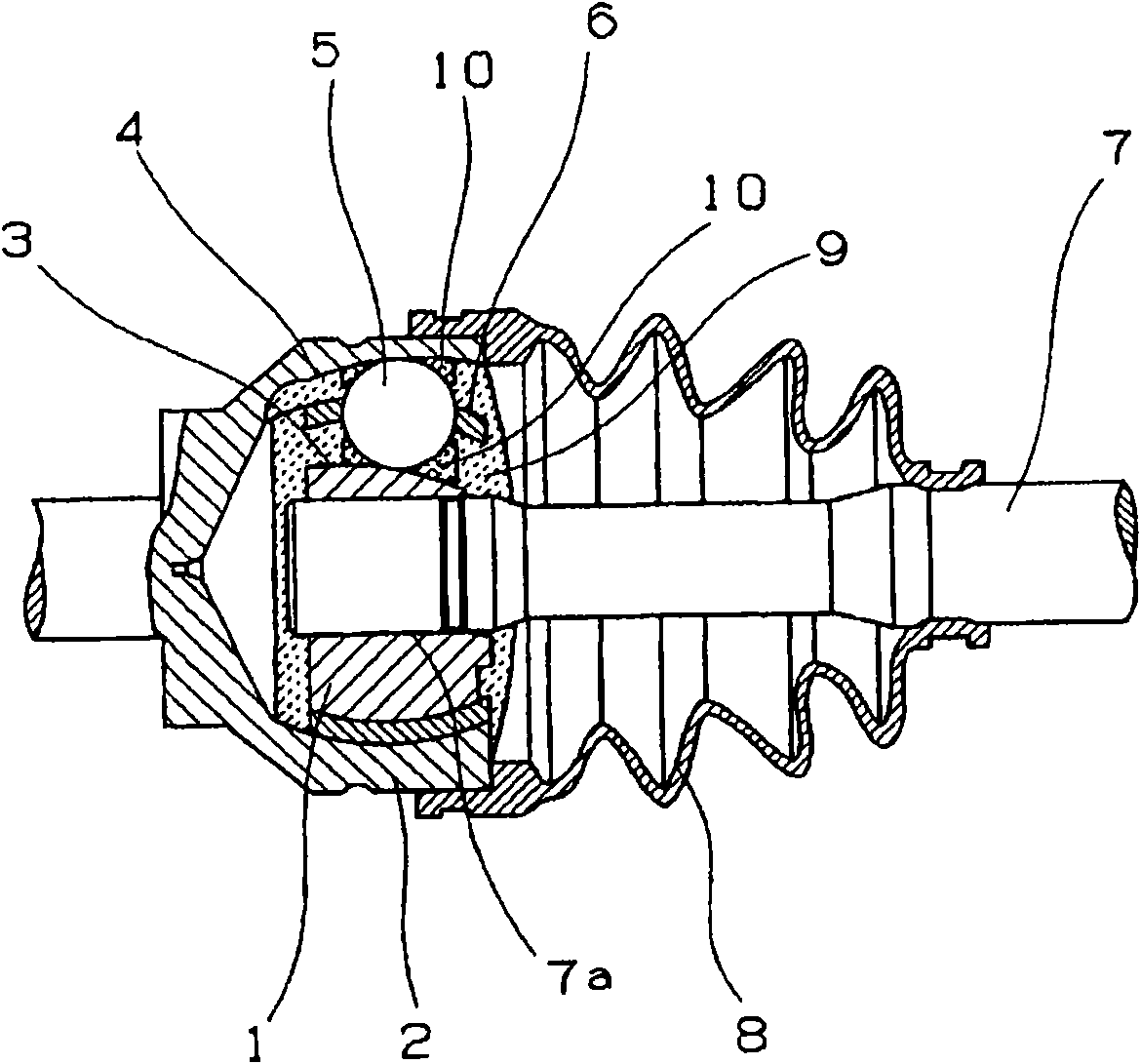

Bogie for Railway Vehicle with a Suspension System

ActiveUS20130333590A1Satisfactory service lifeReduced vertical space requirementsBogiesTramway vehiclesBogieCoil spring

A bogie is provided. The bogie includes two pairs of wheels, the wheels of each pair are connected to each other by an axle structure, this axle structure includes, for each wheel, an axle box. The bogie includes an articulated chassis, each axle structure is supported by the chassis by way of the primary suspension device. The primary suspension device includes, for each wheel, an arm extending substantially longitudinally between a first end that is integrally joined with the axle box associated with this wheel, and a second free end. The arm is articulated between the first and second ends about a pivot connection with the chassis. For each arm, a primary helical spring extends between a first seat provided on the second end of the arm, and a second seat carried by the chassis.

Owner:ALSTOM TRANSPORT TECH SAS

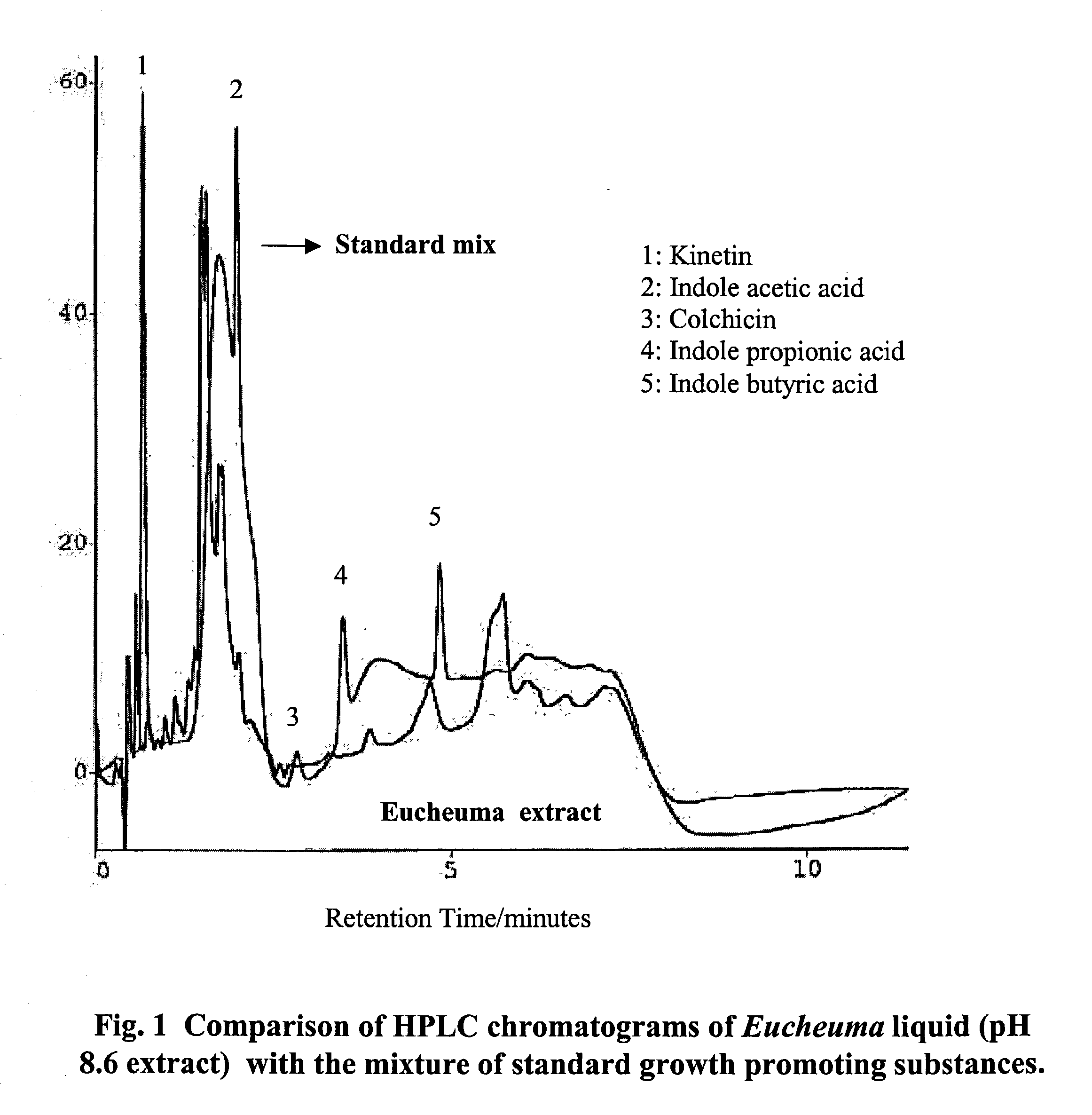

Integrated method for production of carrageenan and liquid fertiliser from fresh seaweeds

InactiveUS20040031302A1Raw materials are simpleArea minimizationBiocideAnimal repellantsKappa-CarrageenanCost of transport

An integrated method is developed to utilise to a maximum extent the fresh biomass of seaweeds such as Kappaphycus alvarezii that can be crushed to release sap and where the sap is useful as a potent liquid fertilizer after suitable treatment with additives and dilution while the residue is a superior raw material for extraction of kappa-carrageenan, thereby enhancing the value of the seaweed. Other advantages of the invention include a reduced drying time and drying area to obtain the raw material for kappa-carrageenan production in dry and storable form, a reduced cost of transporting and storing this raw material because of its lesser bulk, easier handling due to its free flowing granular nature, and its direct use for gel preparation in certain applications.

Owner:COUNCIL OF SCI & IND RES

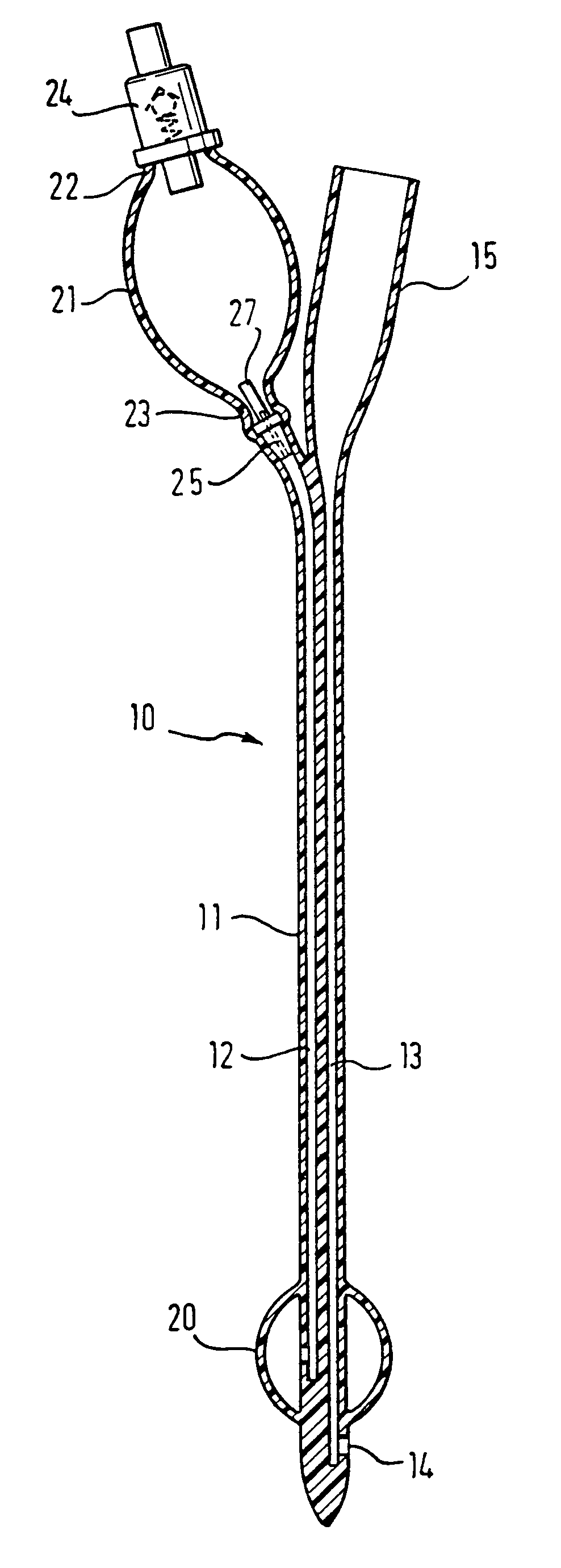

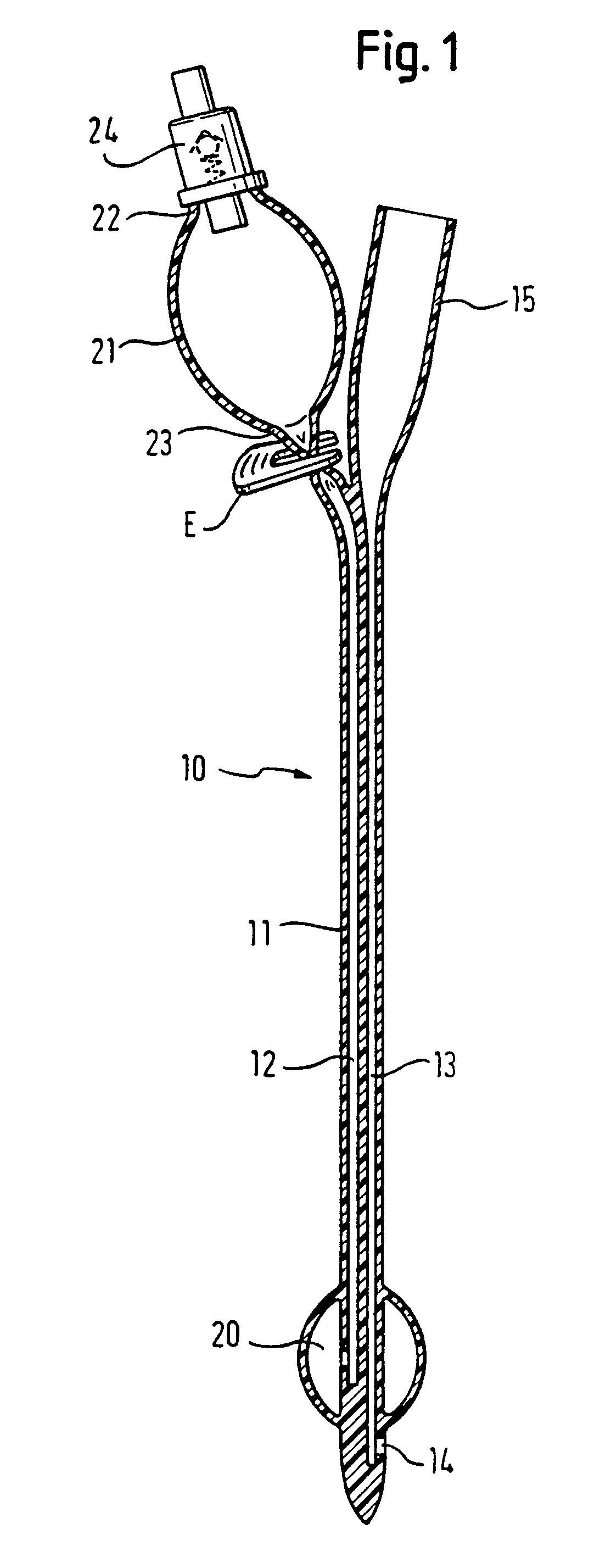

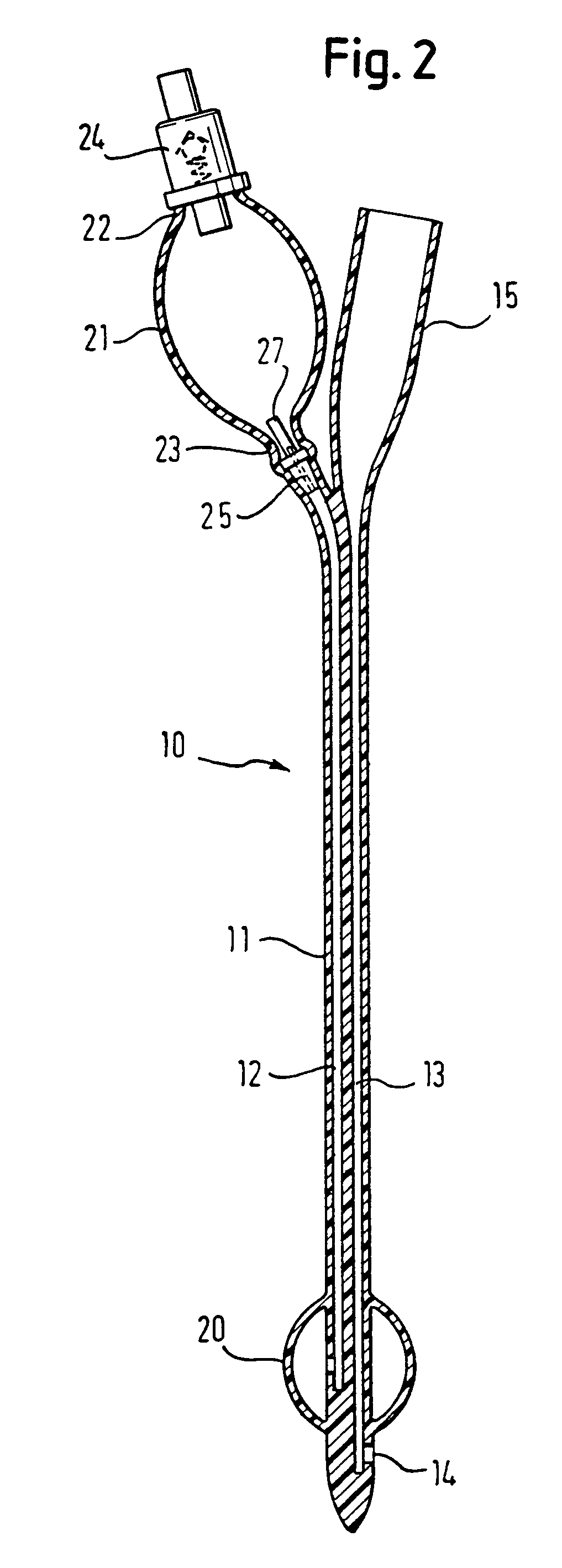

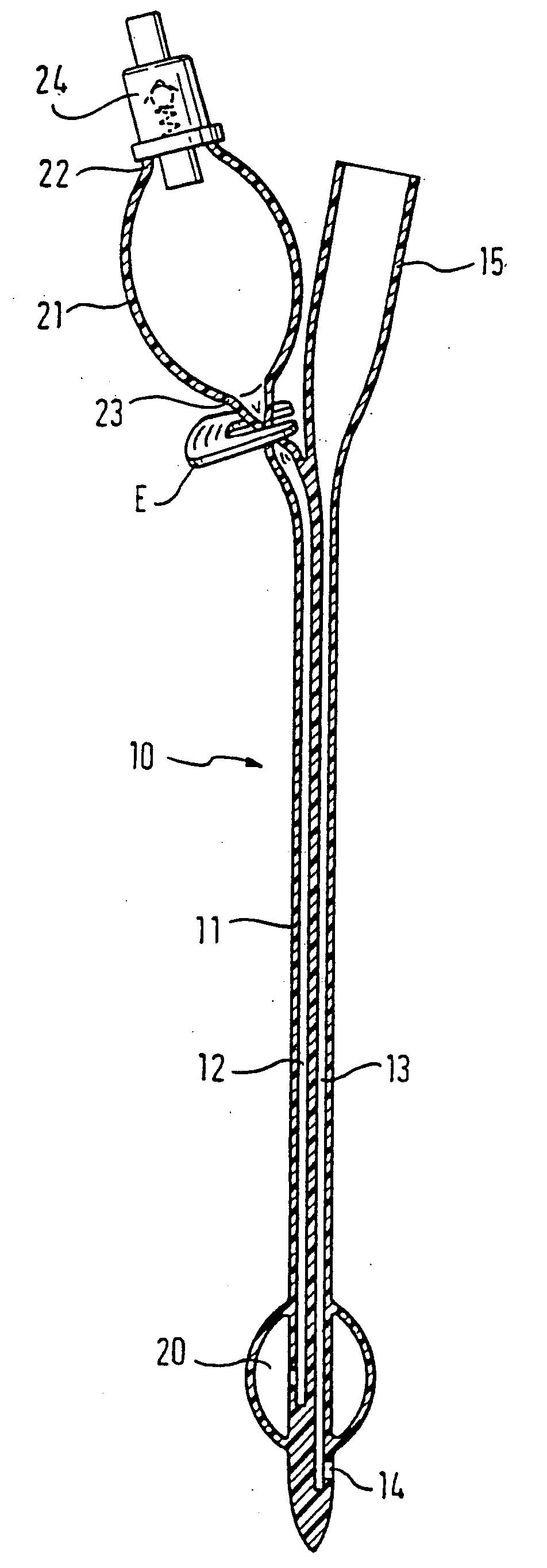

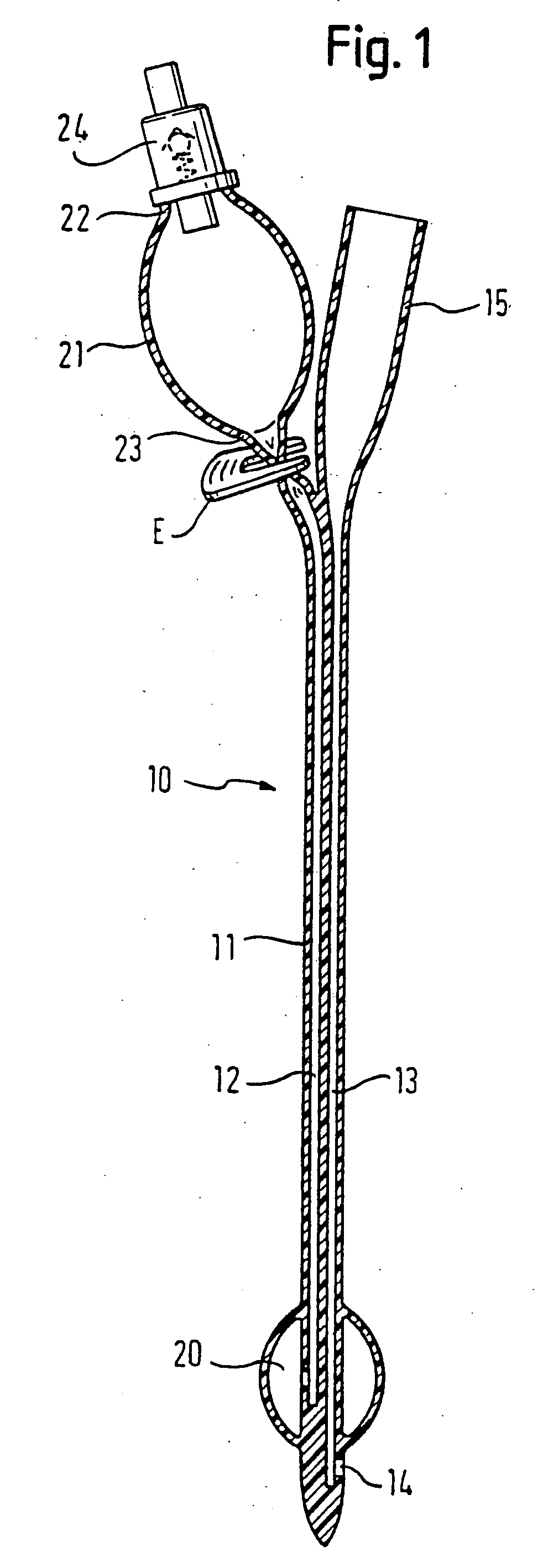

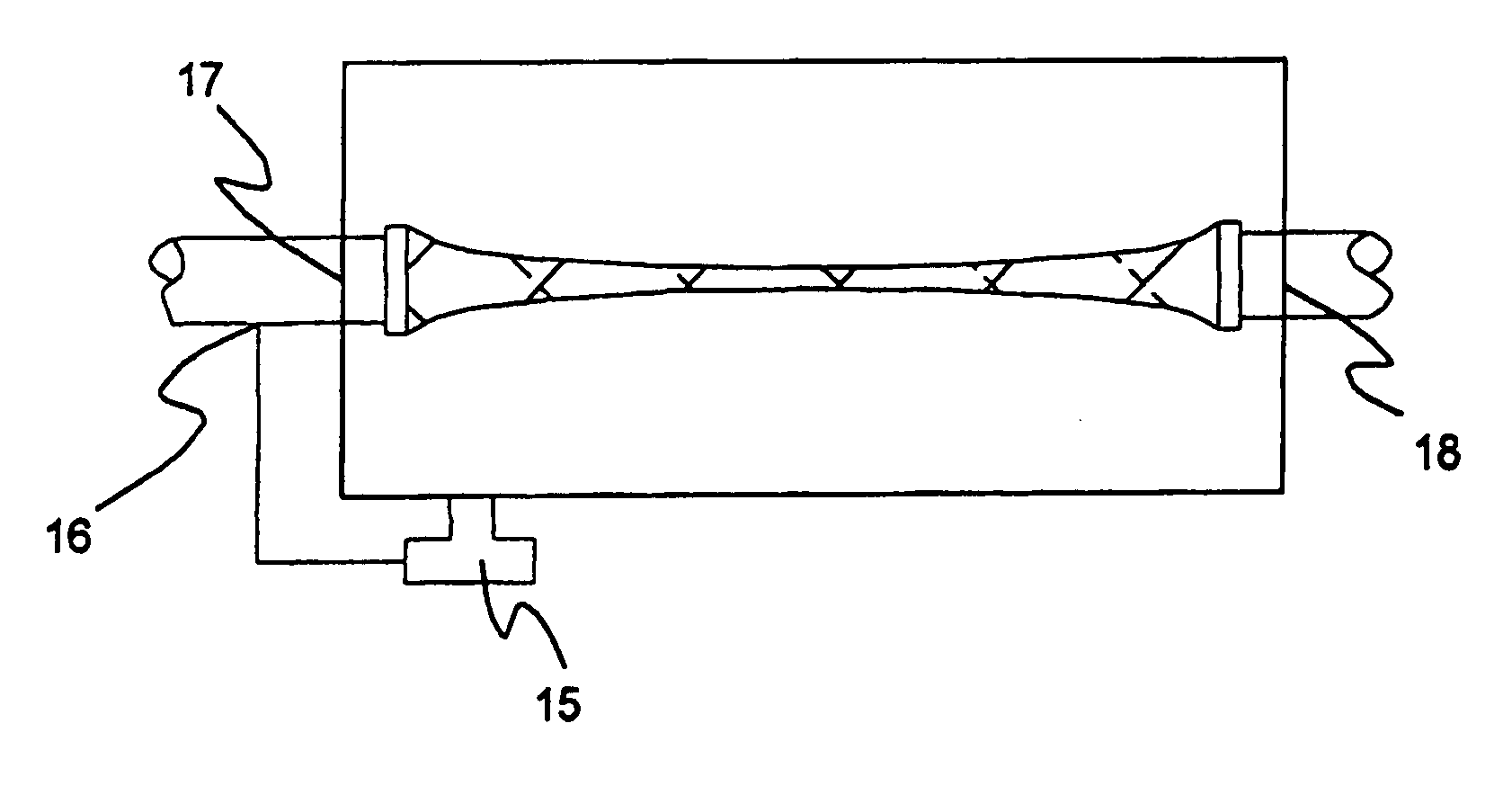

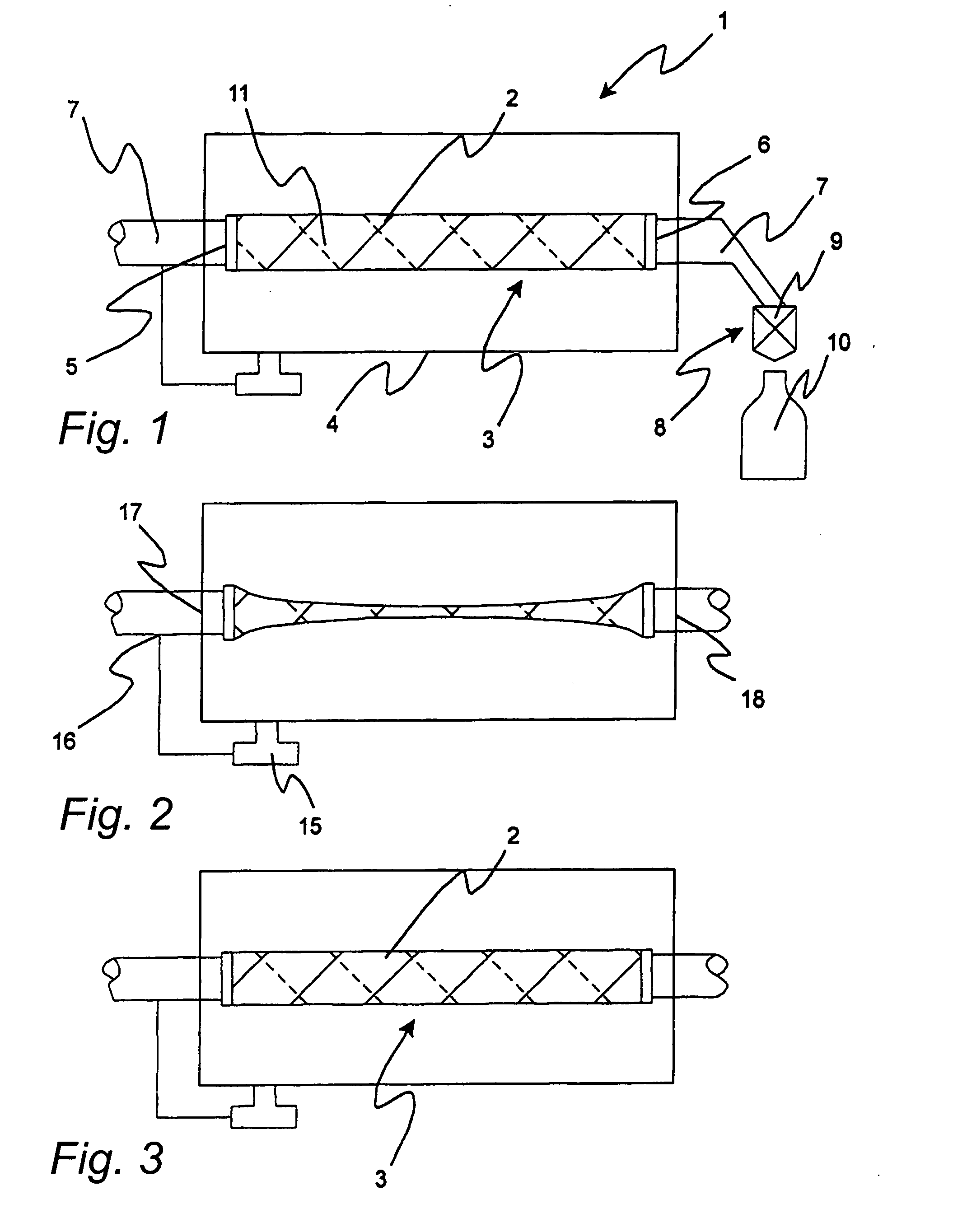

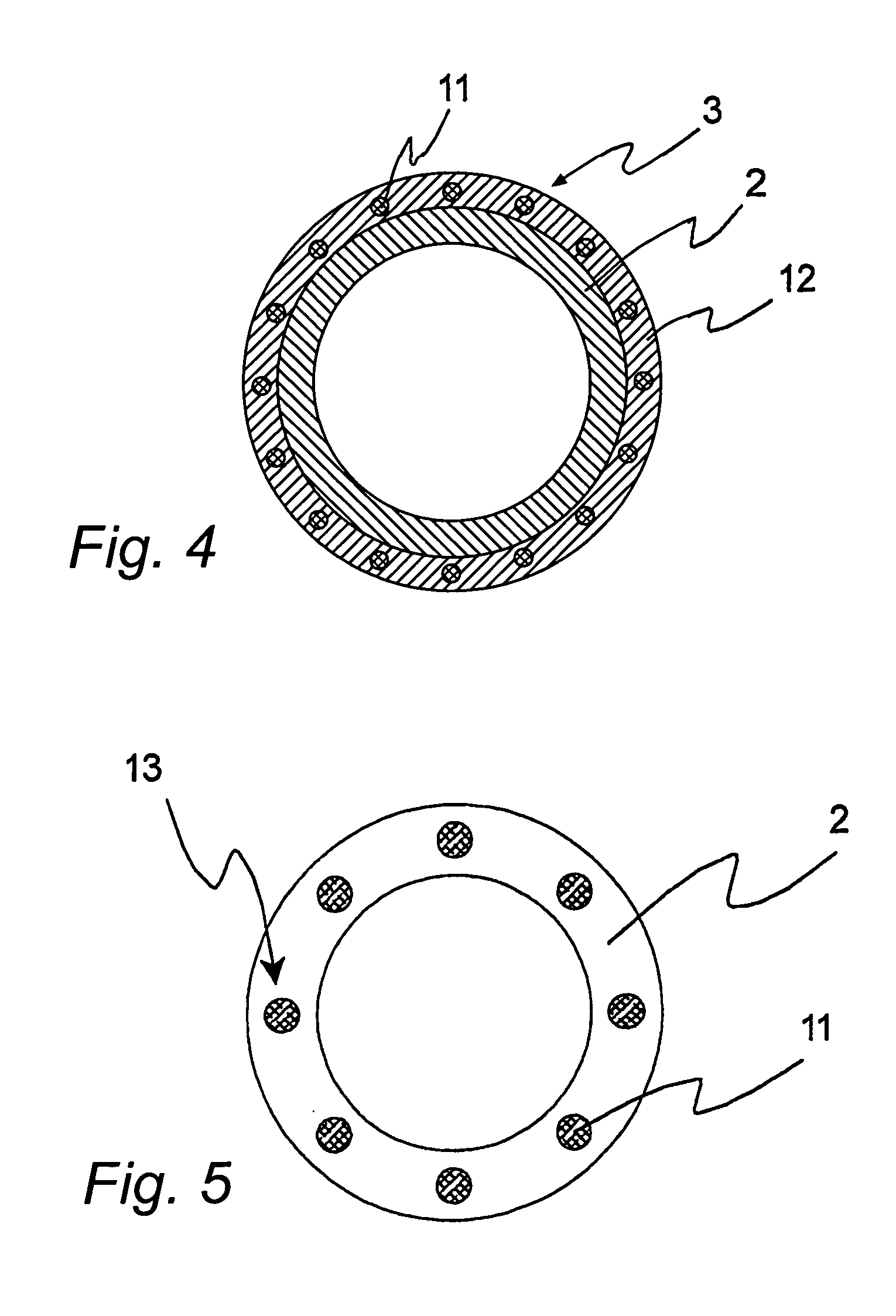

Medical device with elastomeric bulb

In a pre-filled Foley catheter for urine drainage, the conventional clip for releasing sterile water from a bulb (21) at the proximal end of the catheter, to fill the anchor bulb (20) at the distal end of the device, is replaced by a plug (25) which has an annular portion connected to a thin stem (27) by a circle of weakness. Snapping the stem (27) from the annulus provides a tactile signal through the opaque latex lumen that the catheter has been actuated. There is no separate clip to be disposed of. The interface between the latex and the plug remains undisturbed. Further improvement in the shelf-life and convenience of use of the catheter is delivered by the use of a sleeve, which can be of shrink-wrap material, around the bulb (21) and optionally also around the drain coupling (15) of the catheter. Apparatus for placing the plug and the sleeve is also described.

Owner:CR BARD INC

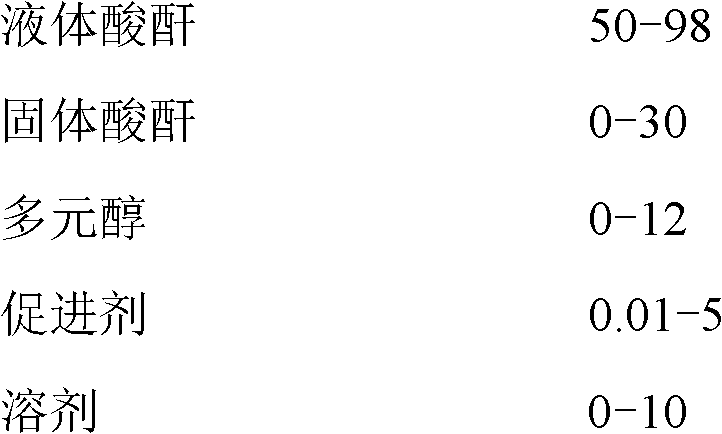

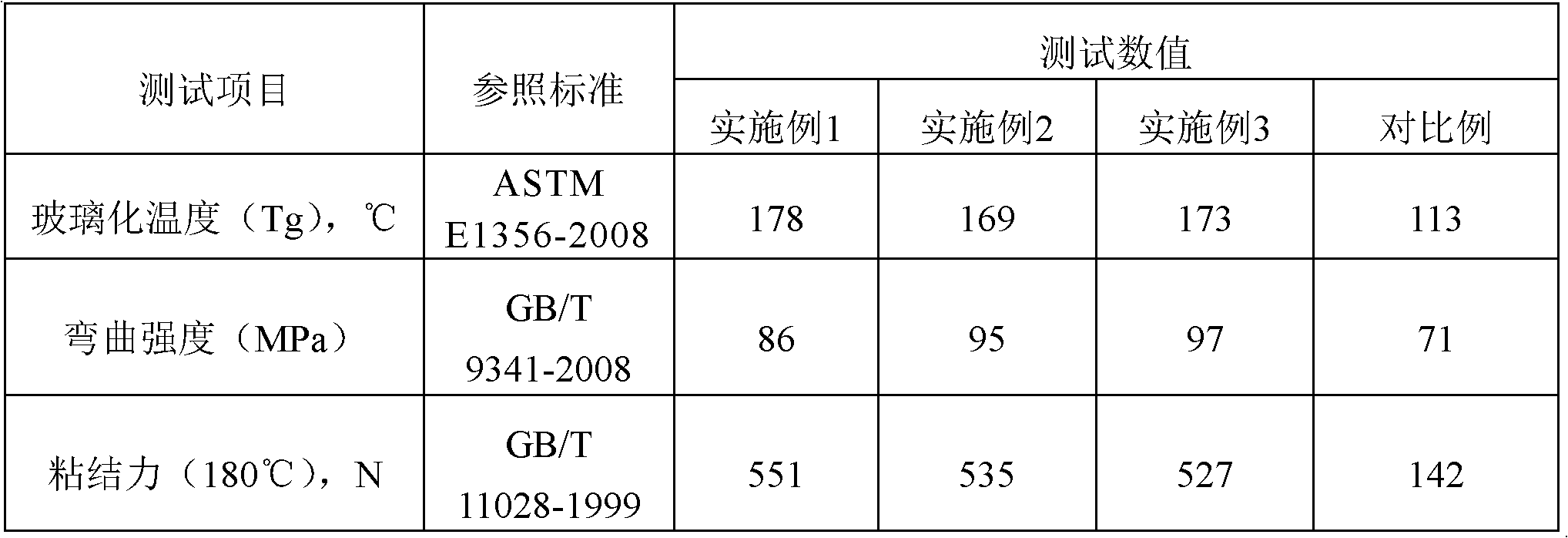

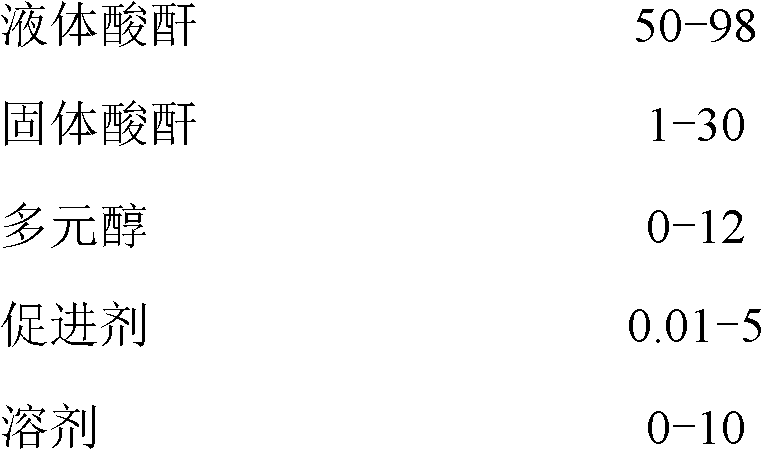

Epoxy resin adhesive for impregnation with high heat resistance and preparation method thereof

ActiveCN102643621AHigh mechanical strengthImprove electrical performanceNon-macromolecular adhesive additivesEpoxy resin adhesivesInsulation systemGlass transition

The invention relates to a epoxy resin adhesive with high heat resistance, which is obtained by mixing of modified epoxy resin with the viscosity of 1000-30000mPa.s and a curing agent with the viscosity of 100-3000mPa.s under the room temperature of more than 20 DEG C according to the mass ratio of 1:0.5-1:1.2. The epoxy resin adhesive is obtained by mixing of modified epoxy resin and the heat-resistant acid anhydride curing agents as the main raw materials, the mechanical strength and electric property of cured resin is enhanced by the modified epoxy resin and applied to dropping impregnation resin for motor rotor with high heat resistance requirement to obtain an insulation system with high fullness, good heat resistance (the glass transition temperature is 160-200 DEG C), high adhesivestrength and bright surface, so that the requirements of life tests and impact tests during high speed rotation of an automobile motor are met.

Owner:ZHEJIANG RONGTAI TECH ENTERPRISE

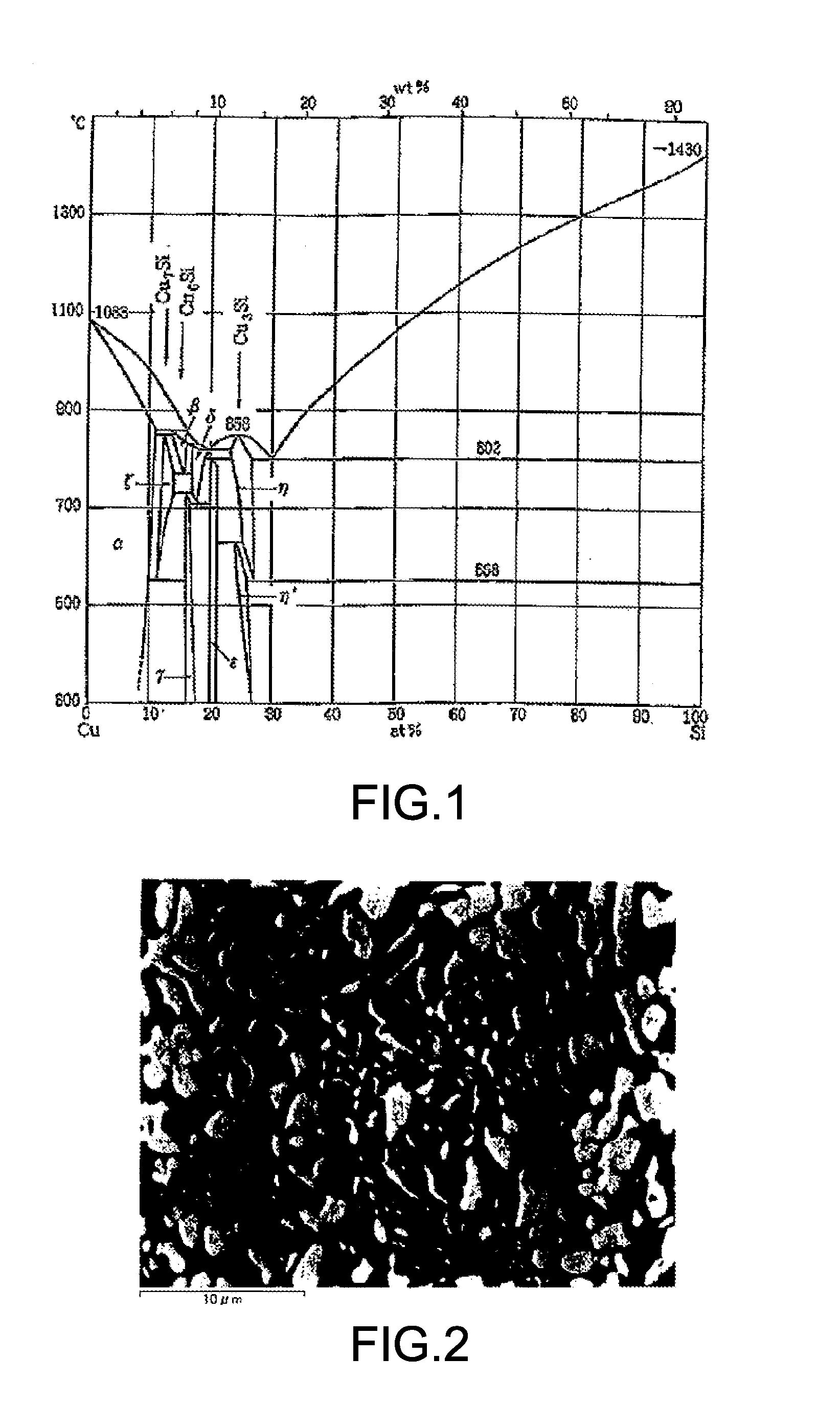

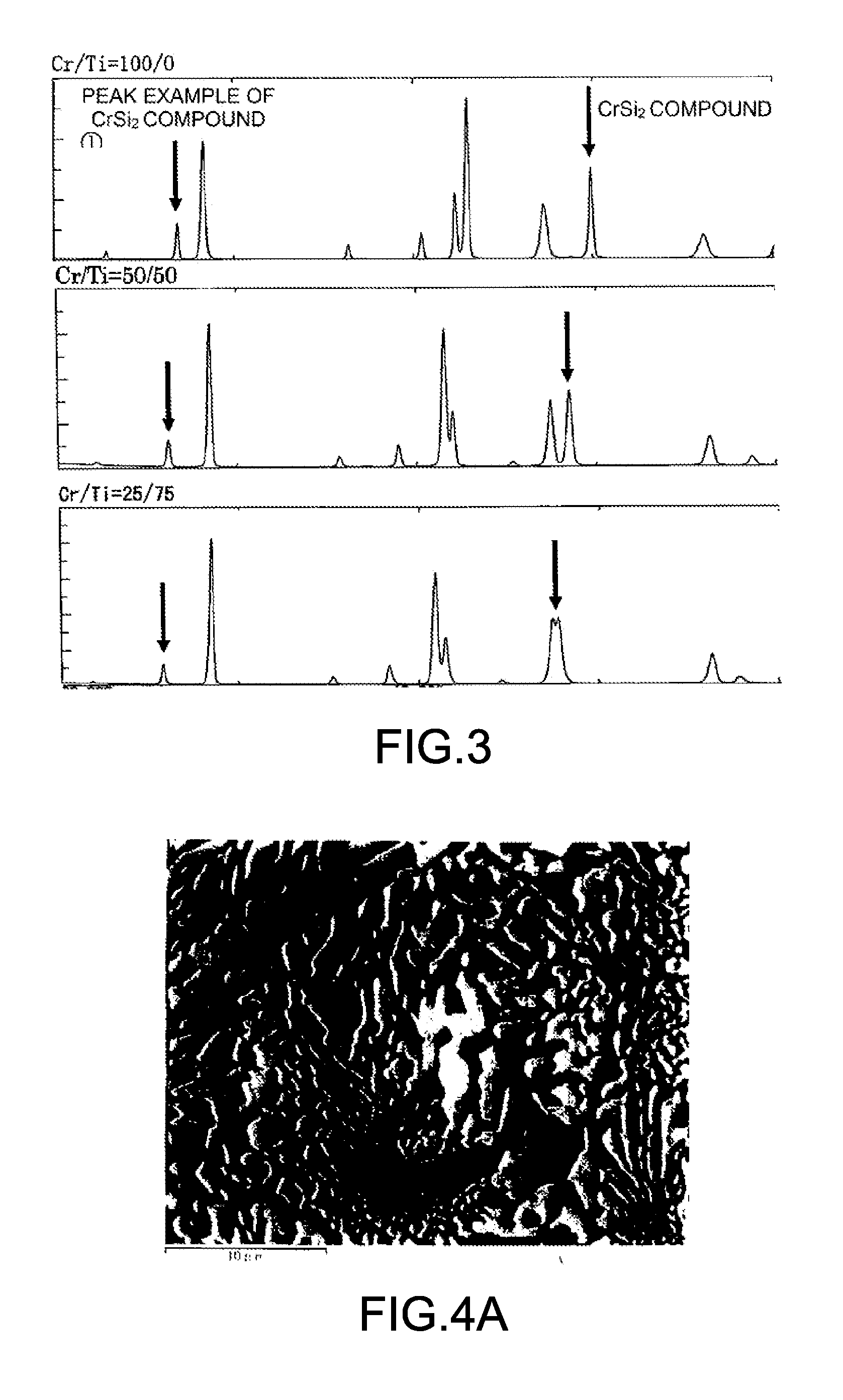

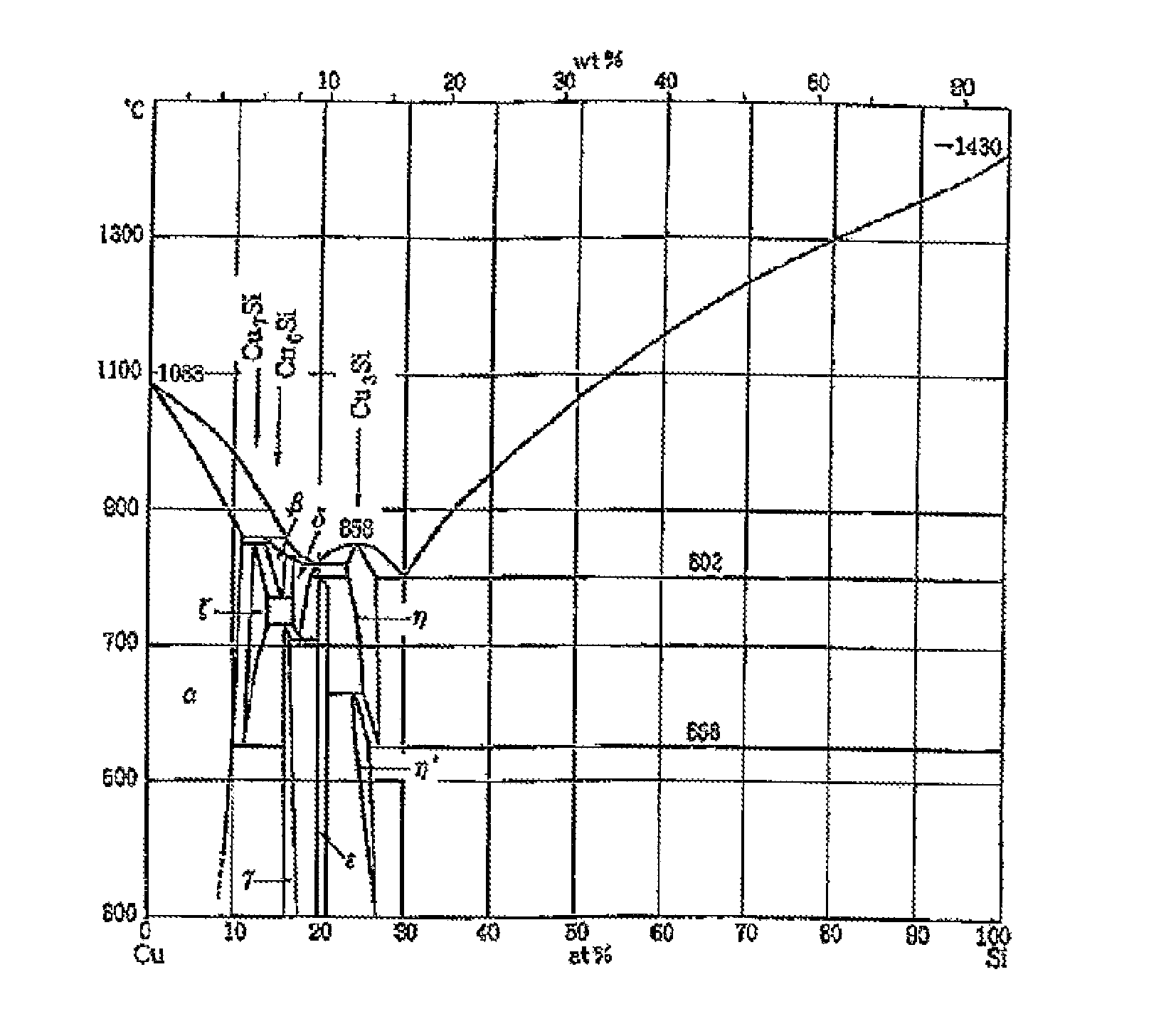

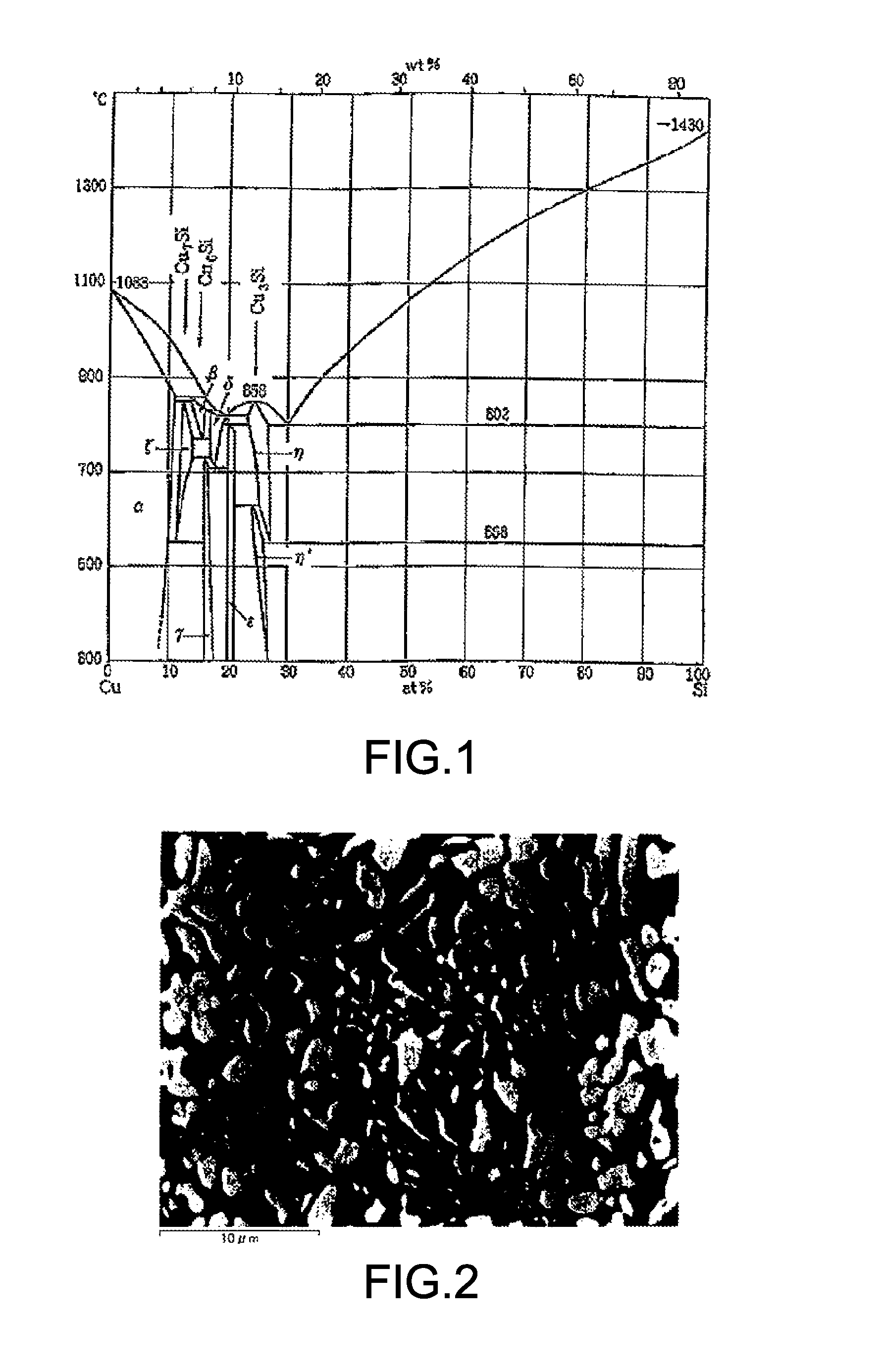

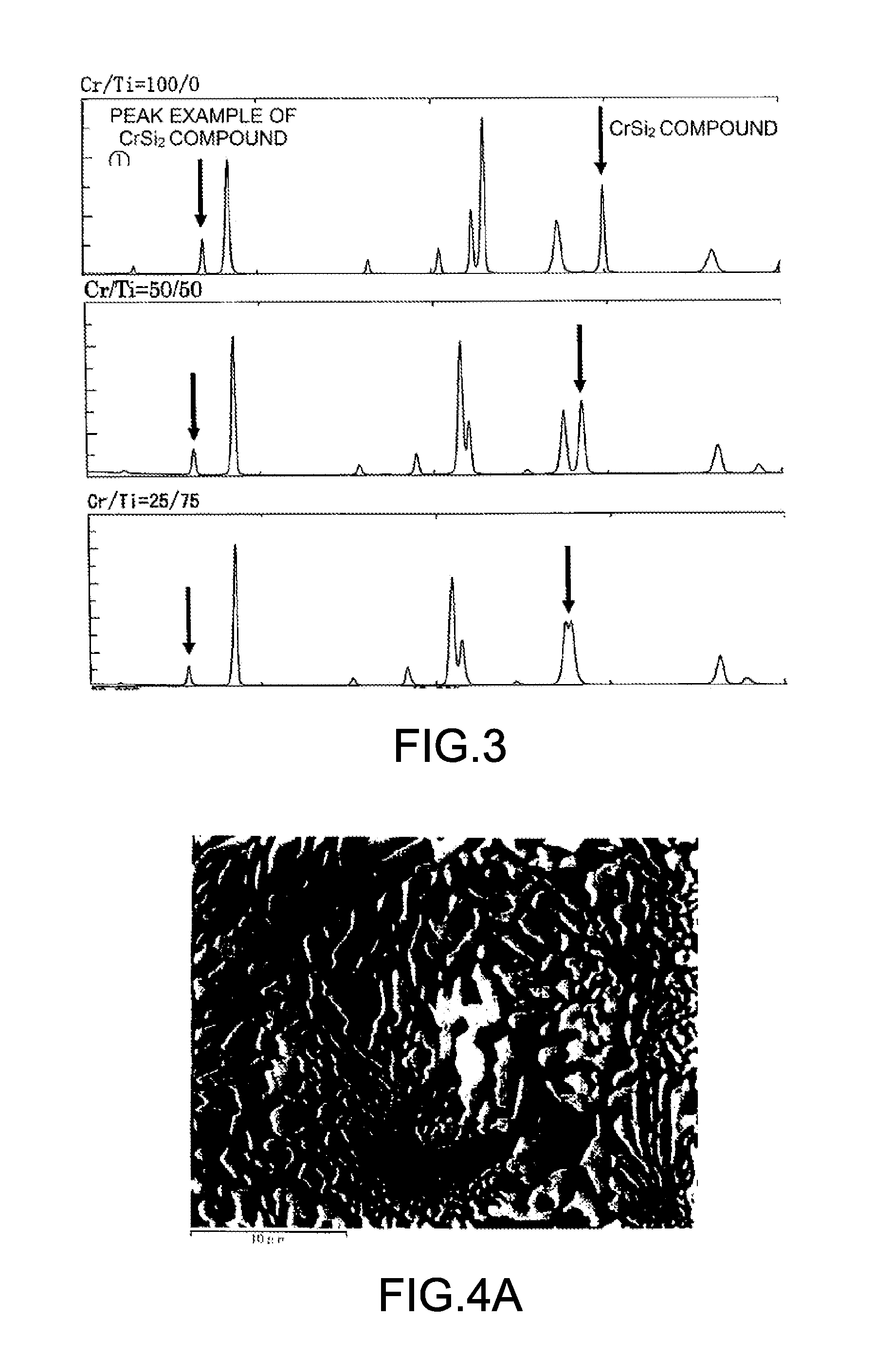

Si-Based-Alloy Anode Material

ActiveUS20140370386A1Superior charge discharge propertyExtend cycle lifeNegative electrodesNon-aqueous electrolyte accumulator electrodesIonSingle phase

Disclosed is a Si-based alloy anode material for lithium ion secondary batteries, including an alloy phase with a Si principal phase including Si and a compound phase including two or more elements, which includes a first additional element A selected from Ti, V, Cr, Mn, Fe, Co, Ni, Cu, Zr, Nb and Mg and a low-melting second additional element B selected from S, Se, Te, Sn, In, Ga, Pb, Bi, Zn, Al. This compound phase includes (i) a first compound phase including Si and the first additional element A; a second compound phase including the first additional element A and the second additional element B; and one or both of a third compound phase including two or more of the second additional elements B and a single phase of the second additional element B.

Owner:SANYO SPECIAL STEEL COMPANY

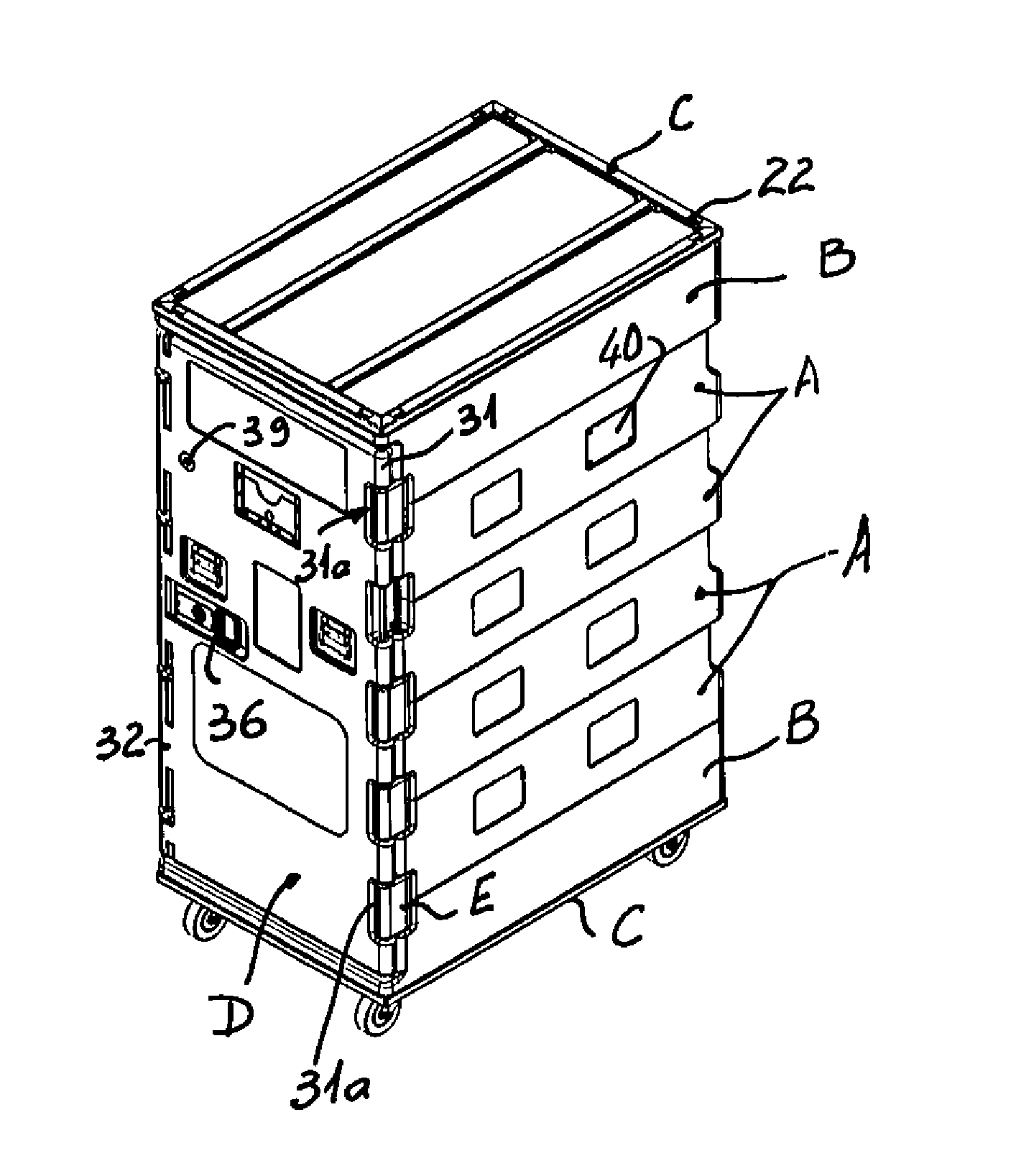

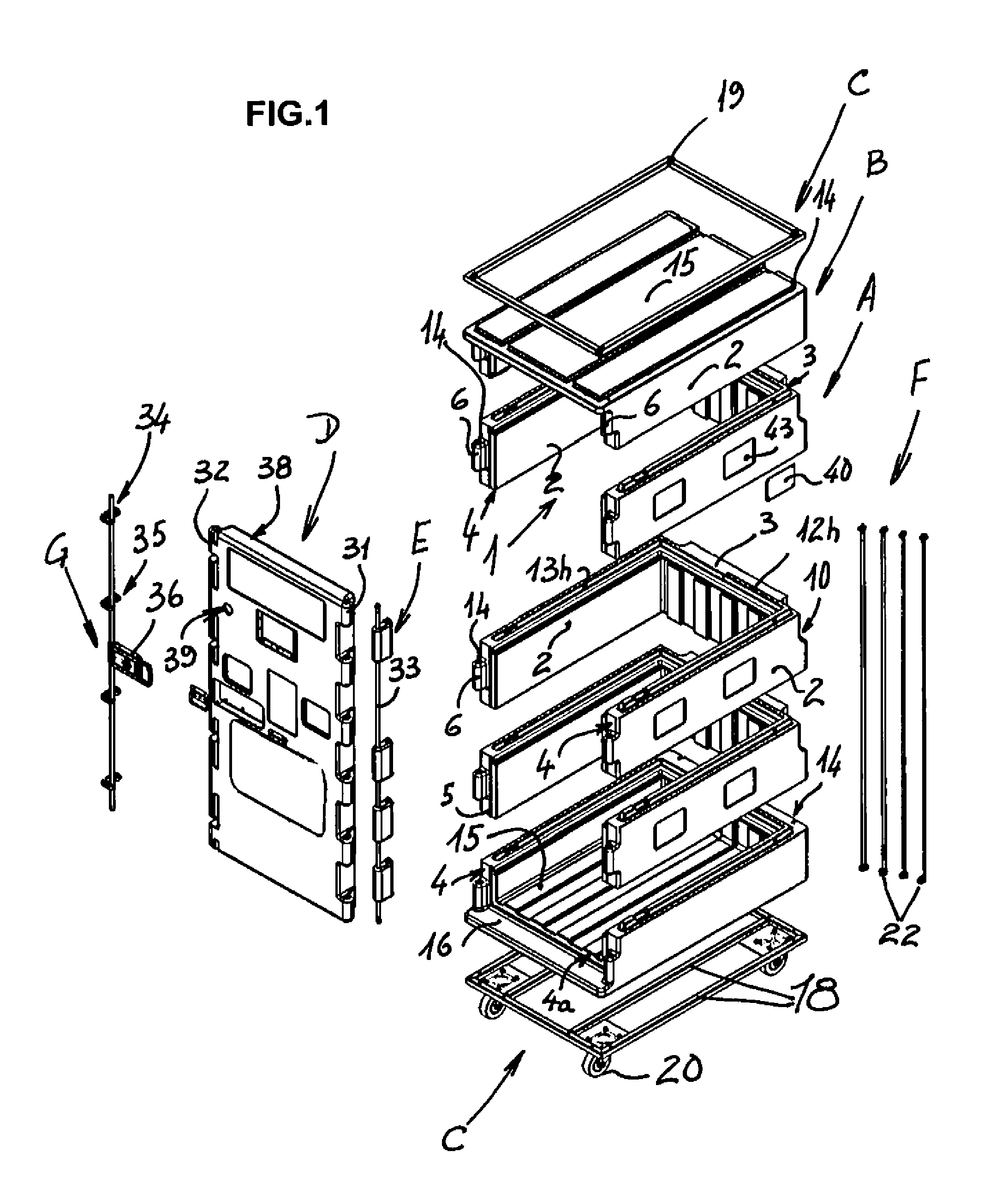

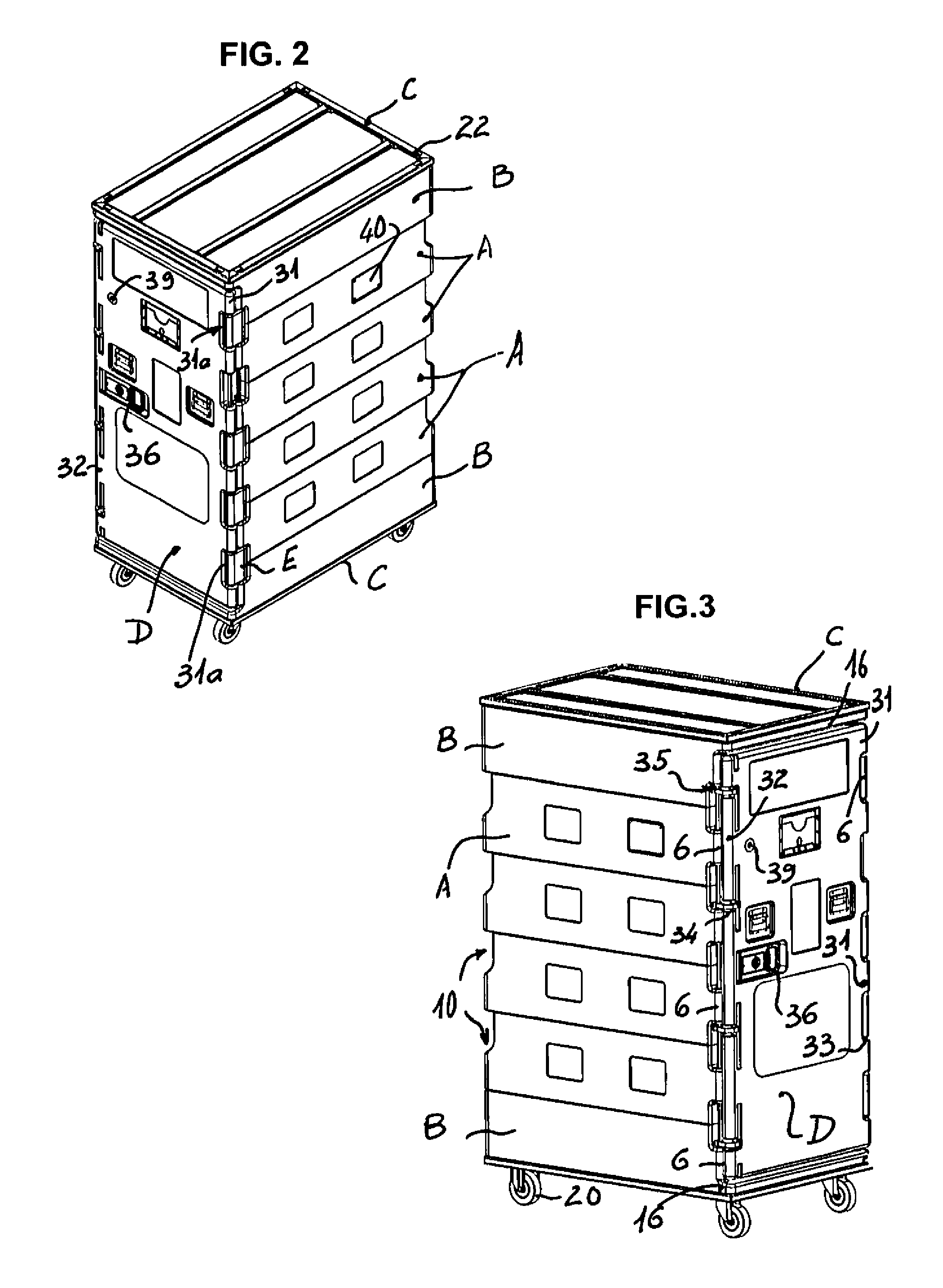

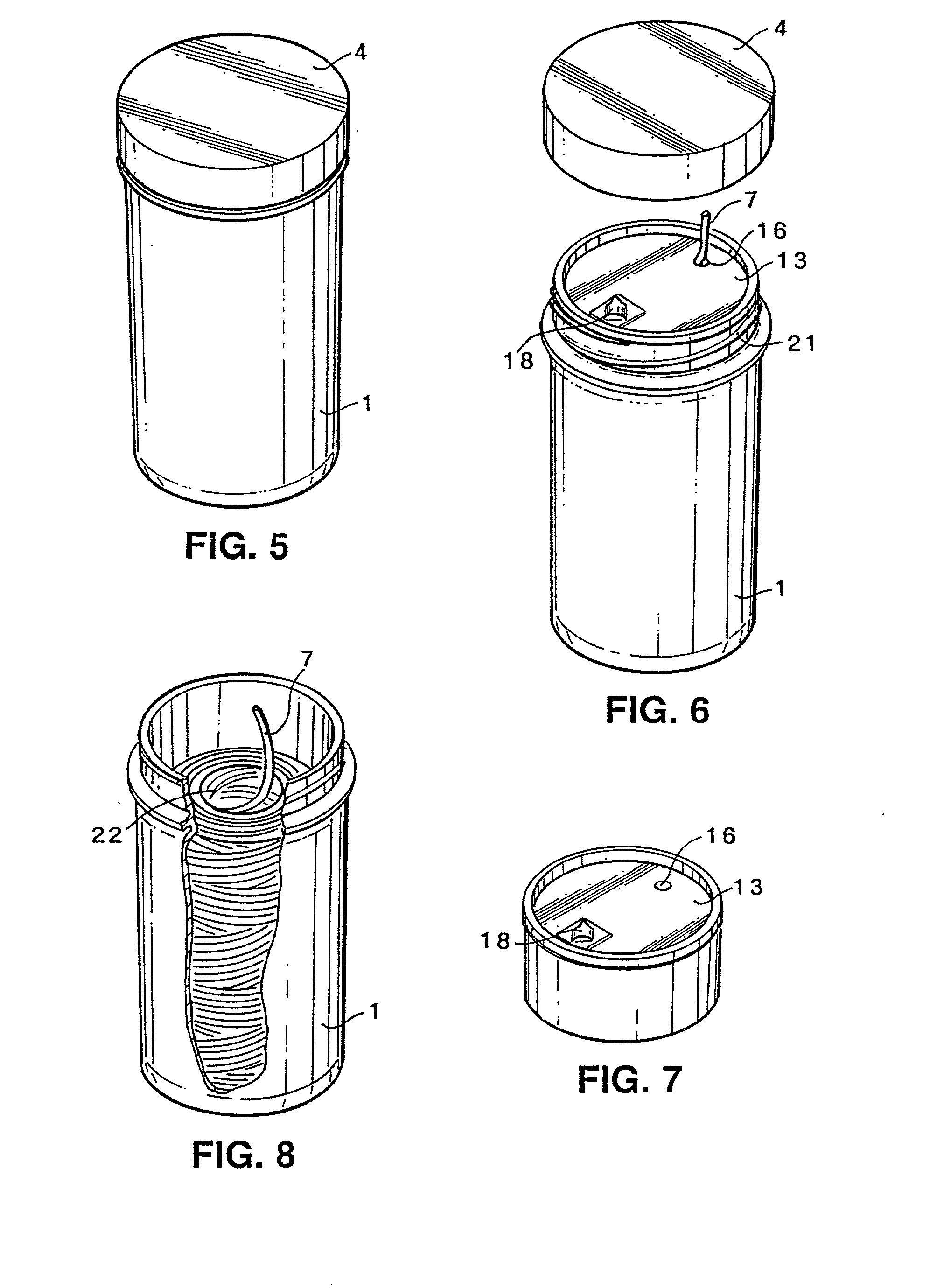

Isothermal Container For Preserving Of Various Materials

InactiveUS20160370082A1Simple waySatisfy lifeLighting and heating apparatusVentilationEngineeringCompressive strength

This container includes an insulating body, a door made of an insulating material, and mechanism for locking the door in the closed position. A multi-component container having a volume adaptable on demand, less heavy and less expensive, whilst having good resistance to wear and to blows. This body is formed by stacking body elements which are made of an insulating material and which are each generally U-shaped, the ends of the wings thereof defining the access opening, the elements being inserted between end elements which, having the same U-shaped cross-section as these but being closed at one side by a bottom, are reinforced by independent metal frames which exert thereon a compressive strength which is produced by metal clamping rods. These extend between the two frames and pass through the body elements and the end elements via holes.

Owner:OLIVO SA

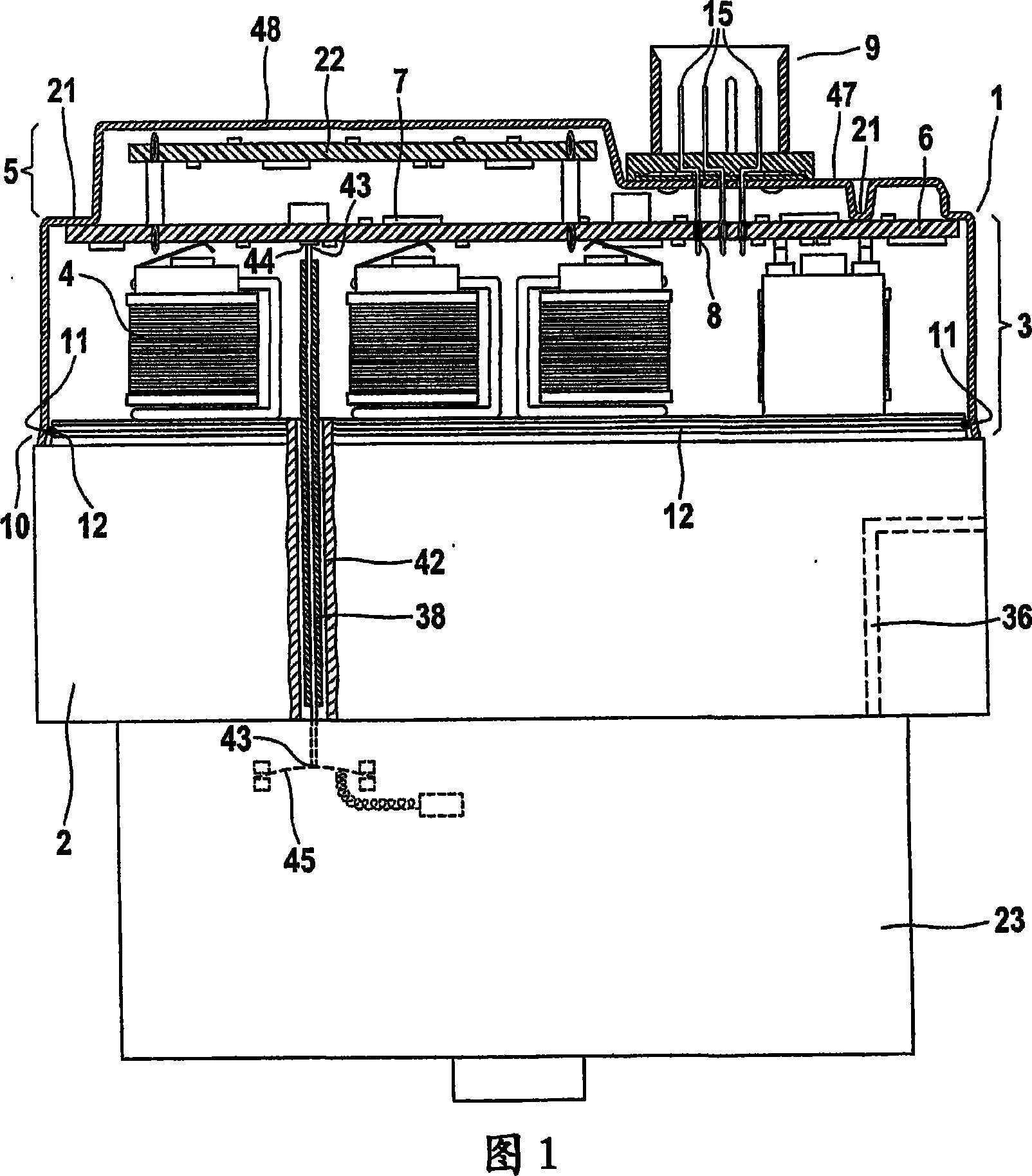

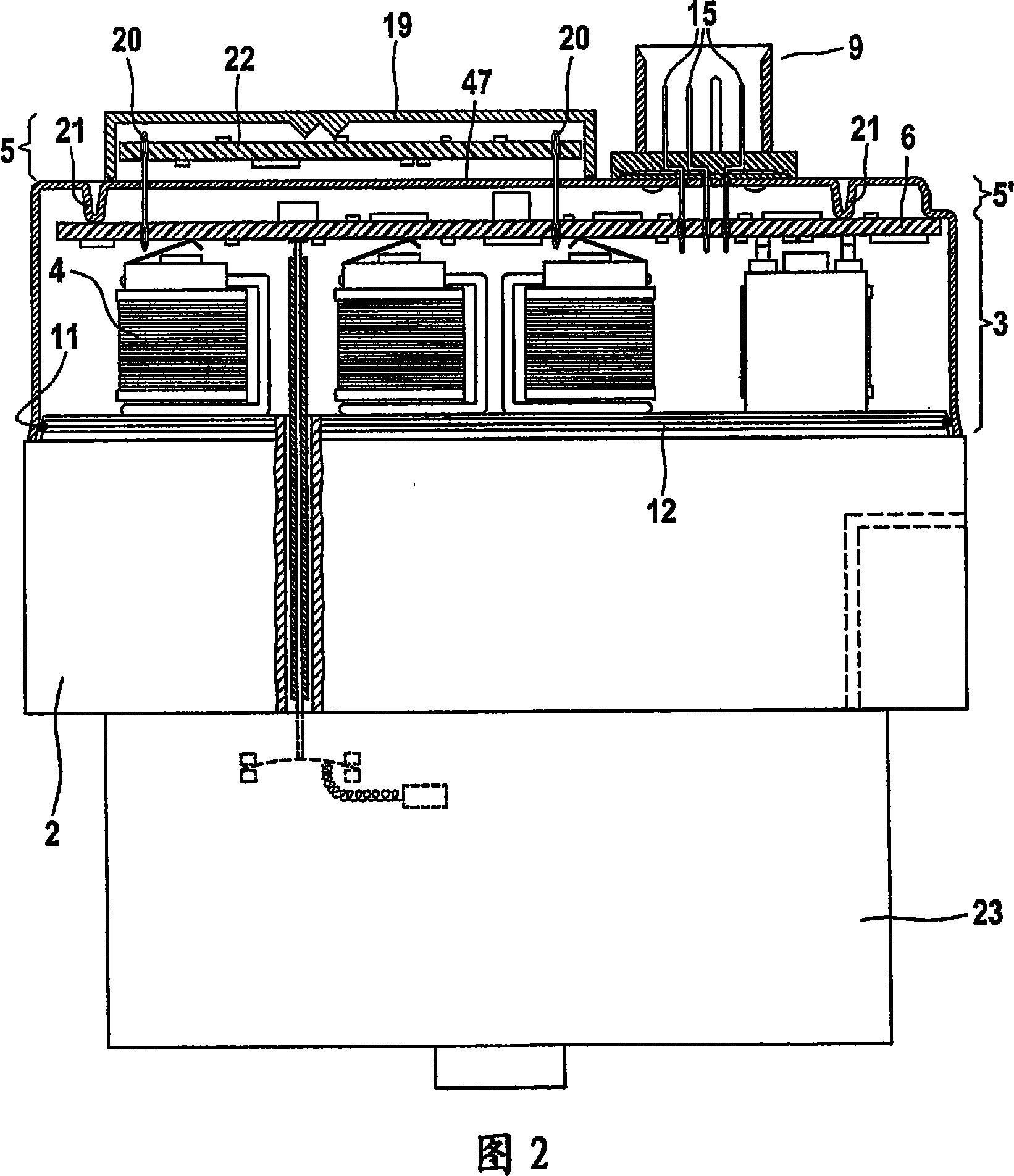

Electrohydraulic pressure control device for automotive brake systems

InactiveCN101084142AMeet electromechanical requirementsMeet the mechanical strengthBraking componentsElectrical apparatus contructional detailsEngineeringElectron

The present invention relates to a electrohydraulic pressure control device for vehicle braking system. The device comprises a electron control unit (1) connecting with hydraulic pressure component (2). The control unit comprises a shell volume area (3) which can contain multiple valve loops (4), a shell cover area (5, 5') of the control unit shell, at least a first print circuit board (6) which is arranged with electric and / or electronic component as well as a electric coupling device (8) of conjugation plug, at least an adapter (38) of a motor unit which is used to joint hydraulic pressure unit, the adapter extends and passes through the hydraulic pressure component. The adapter comprises one or more electric pressure contact points (43) on one end or two, the electric pressure contact points push down on one or more interfaces (44, 45) through elastic force.

Owner:CONTINENTAL TEVES AG & CO OHG

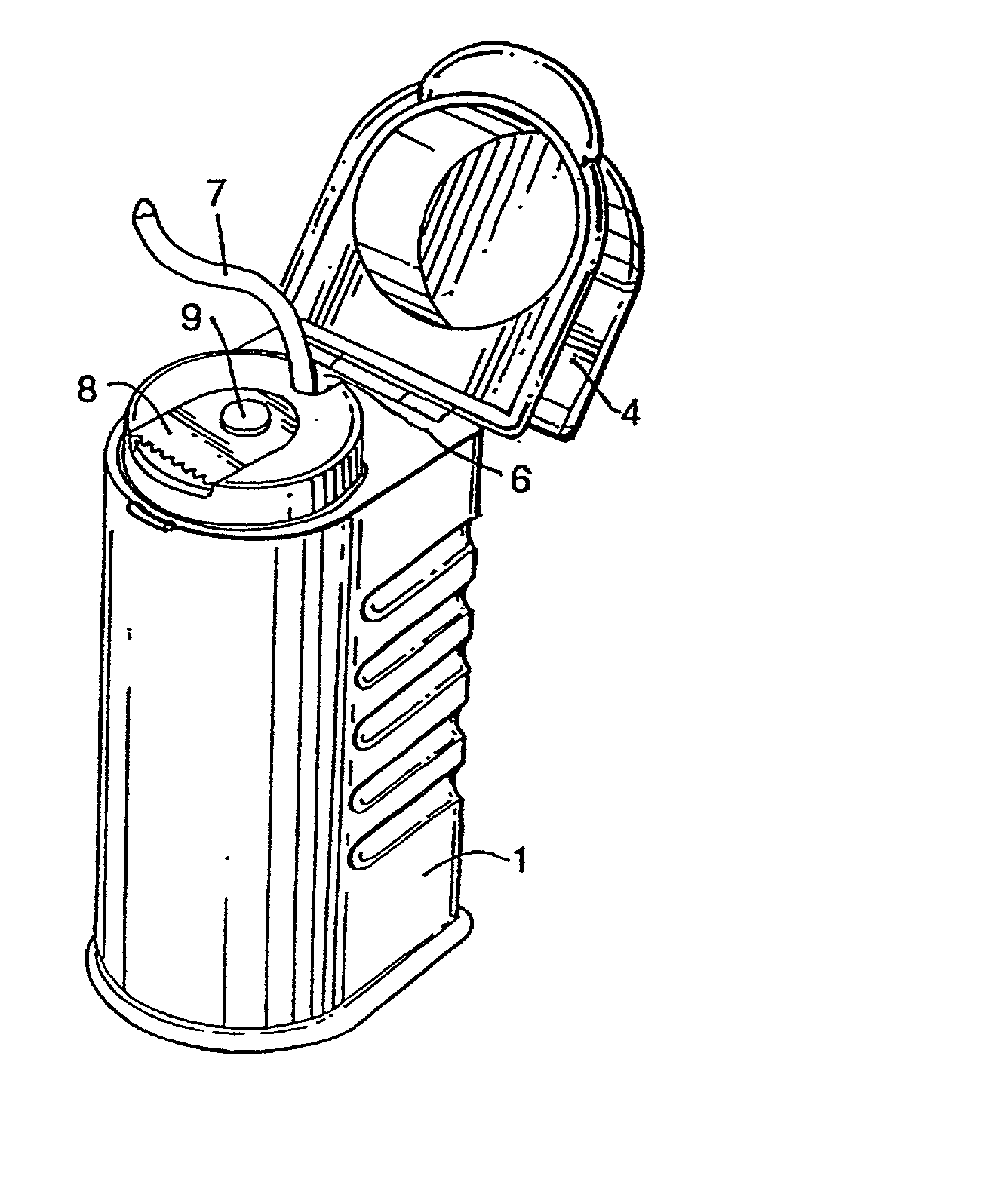

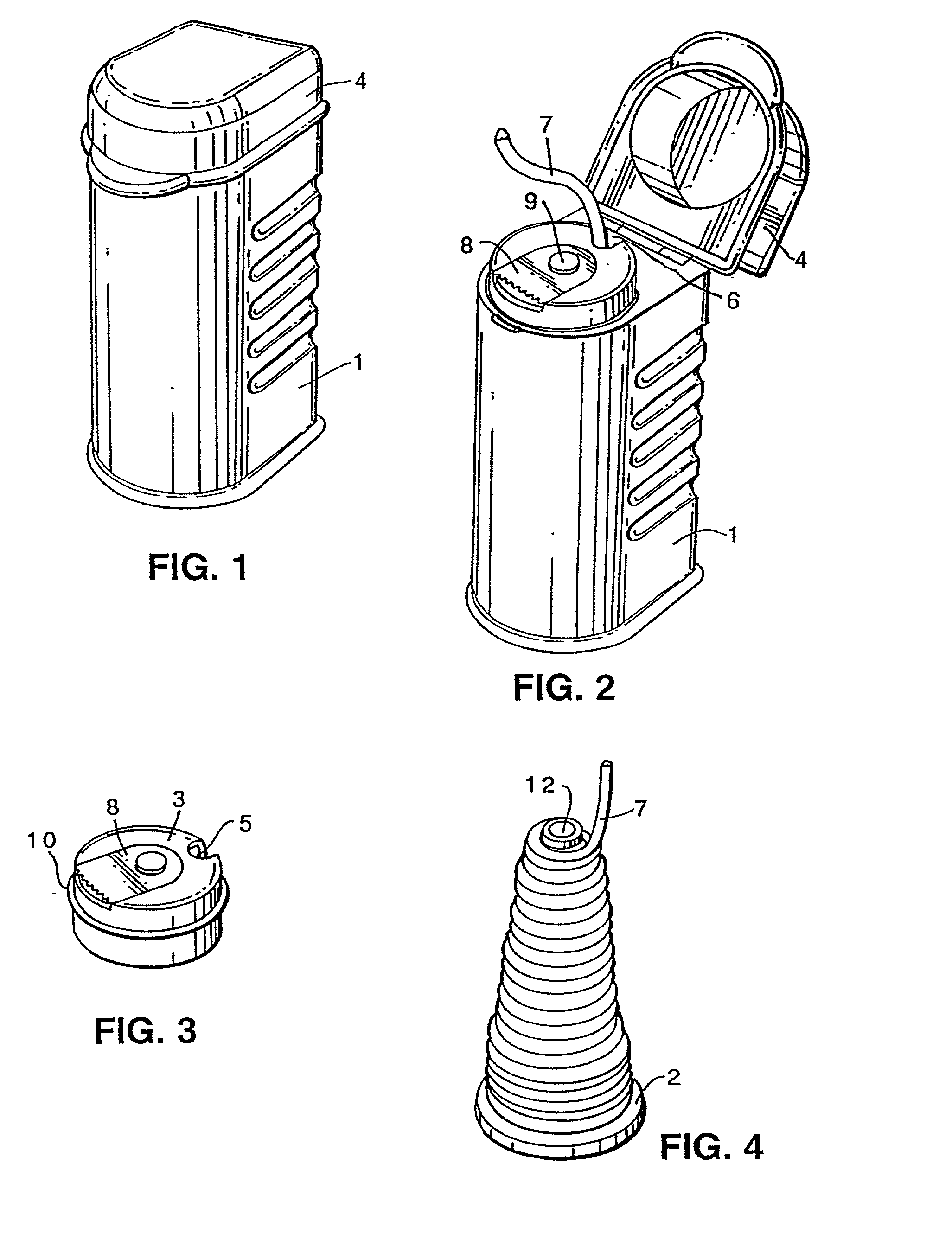

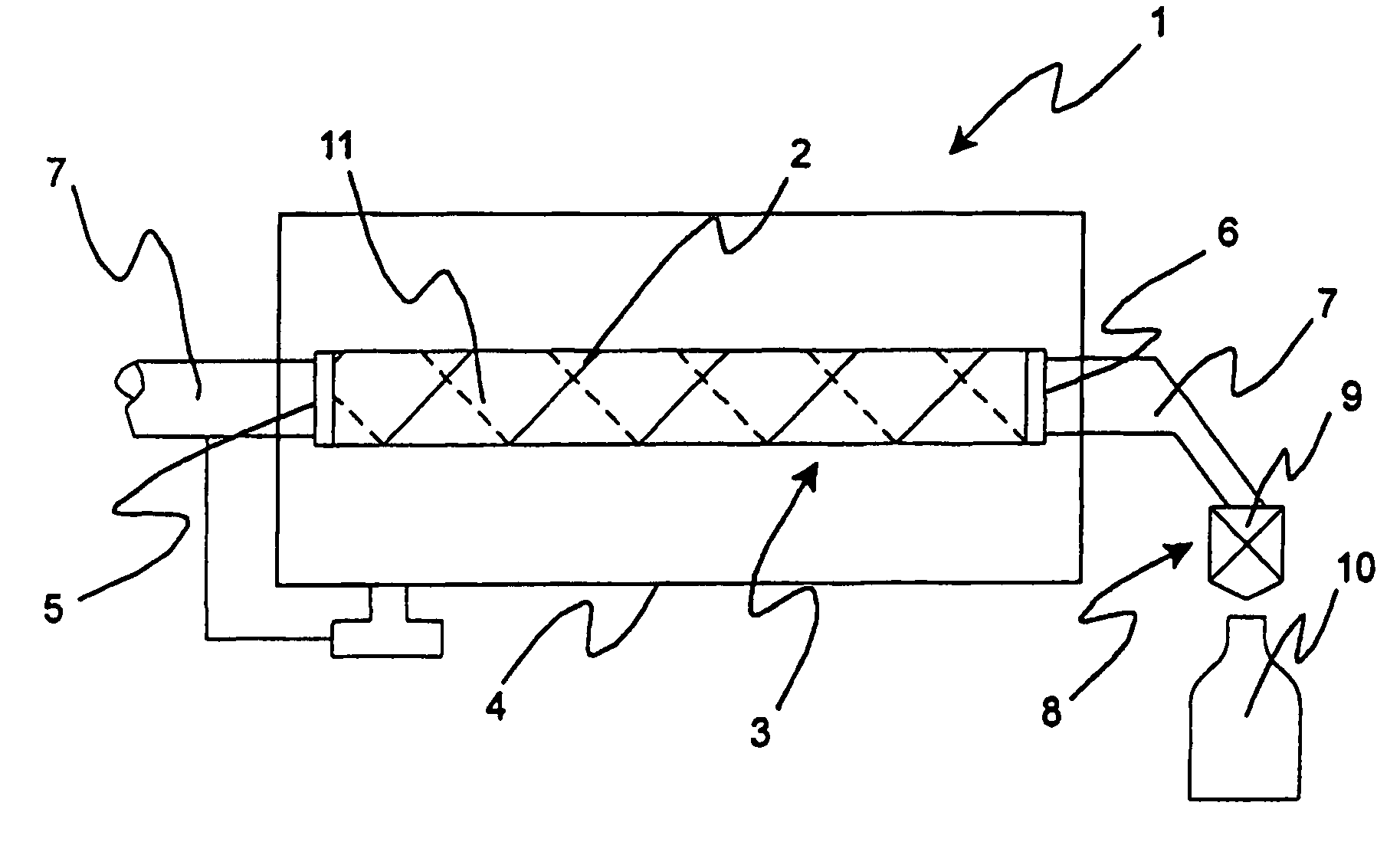

Material for sealing threaded pipe joints, and dispenser therefor

InactiveUS20020190481A1Improve sealingGive mechanical strengthSleeve/socket jointsEngine sealsYarnThreaded pipe

An article of manufacture which comprises a material for sealing threaded pipe joints comprising a multifilament yarn ready-coated with a joint sealing composition and packaged in a dispenser from which the coated yarn may be supplied for direct application to a threaded area of a pipe.

Owner:HENKEL IP & HOLDING GMBH

Medical device with elastomeric bulb

InactiveUS20060135951A1Satisfy lifeReduced effectivenessStentsBalloon catheterSterile waterFoley catheter

In a pre-filled Foley catheter for urine drainage, the conventional clip for releasing sterile water from a bulb (21) at the proximal end of the catheter, to fill the anchor bulb (20) at the distal end of the device, is replaced by a plug (25) which has an annular portion connected to a thin stem (27) by a circle of weakness. Snapping the stem (27) from the annulus provides a tactile signal through the opaque latex lumen that the catheter has been actuated. There is no separate clip to be disposed of. The interface between the latex and the plug remains undisturbed. Further improvement in the shelf- life and convenience of use of the catheter is delivered by the use of a sleeve, which can be of shrink-wrap material, around the bulb (21) and optionally also around the drain coupling (15) of the catheter. Apparatus for placing the plug and the sleeve is also described.

Owner:CR BARD INC

Method for forming coating film and coated article

ActiveUS20140227534A1Improve curing effectSatisfactory pot lifeSynthetic resin layered productsPretreated surfacesOrganometallic catalysisAcrylic resin

An object of the present invention is to provide a method for forming a multilayer coating film, the method making it possible to obtain, with excellent curability at low temperatures and in a short period of time, a multilayer coating film exhibiting an excellent finished appearance. The present invention provides a method for forming a multilayer coating film, wherein a substrate is sequentially coated with at least one layer of one or more base coating compositions, and with one or more clear coating compositions, the method being characterized by utilizing a clear coating composition containing a hydroxy-containing acrylic resin (A) having a hydroxy value in a specific range; a polyisocyanate compound (B) having a viscosity in a specific range; and an organometallic catalyst (C) containing a metallic compound (C1) in which the metal is a member selected from the group consisting of zinc, tin, zirconium, bismuth, lead, cobalt, manganese, titanium, aluminum, and molybdenum, and an amidine compound (C2).

Owner:KANSAI PAINT CO LTD

Bogie for railway vehicle with a suspension system

ActiveUS9096240B2Satisfy lifeReduced vertical space requirementsBogiesTramway vehiclesBogieCoil spring

A bogie is provided. The bogie includes two pairs of wheels, the wheels of each pair are connected to each other by an axle structure, this axle structure includes, for each wheel, an axle box. The bogie includes an articulated chassis, each axle structure is supported by the chassis by way of the primary suspension device. The primary suspension device includes, for each wheel, an arm extending substantially longitudinally between a first end that is integrally joined with the axle box associated with this wheel, and a second free end. The arm is articulated between the first and second ends about a pivot connection with the chassis. For each arm, a primary helical spring extends between a first seat provided on the second end of the arm, and a second seat carried by the chassis.

Owner:ALSTOM TRANSPORT TECH SAS

Hinge with insulated wire for electronic devices

InactiveUS7592406B2Provide capabilitySatisfy lifeDigital data processing detailsInsulatorsHexafluoropropyleneFluoropolymer

The combination of a hinge and an insulated wire is provided, wherein the hinge is capable of closing and opening to an angle of at least 90°, the insulated wire being secured by the hinge so as to fold when said hinge is closed and to unfold when said hinge is opened, the insulation on the wire comprising fluoropolymer, such as tetrafluoroethylene / -hexafluoropropylene copolymer or tetrafluoroethylene / perfluoro(methyl vinyl ether) / perfluoro(propyl vinyl ether) copolymer, each polymer having a melting point of 260 to 290° C. and MIT Flex Life of at least about 15,000 cycles, the hinge being useful in such electronic devices as a laptop computer or a clamshell cell phone, attaching the keyboard and screen portion to one another, the insulation being capable of repeated opening and closing of the hinge without cracking of the insulation.

Owner:THE CHEMOURS CO FC LLC

Device for compensating for pressure drop

InactiveUS7066211B2Satisfy lifeEasy to cleanAircraft componentsFilling using counterpressureCollapsible tubeEngineering

The invention relates to a device for compensating for pressure drop in a product pipe through which a liquid flows, and a system comprising such a device. The device comprises a collapsible tube portion, which is connectible to the product pipe, and is characterised by a limiting means, which is adapted to counteract stretching of the tube portion in the circumferential direction and which is adapted to allow free collapsing of the tube portion.

Owner:ECOLEAN

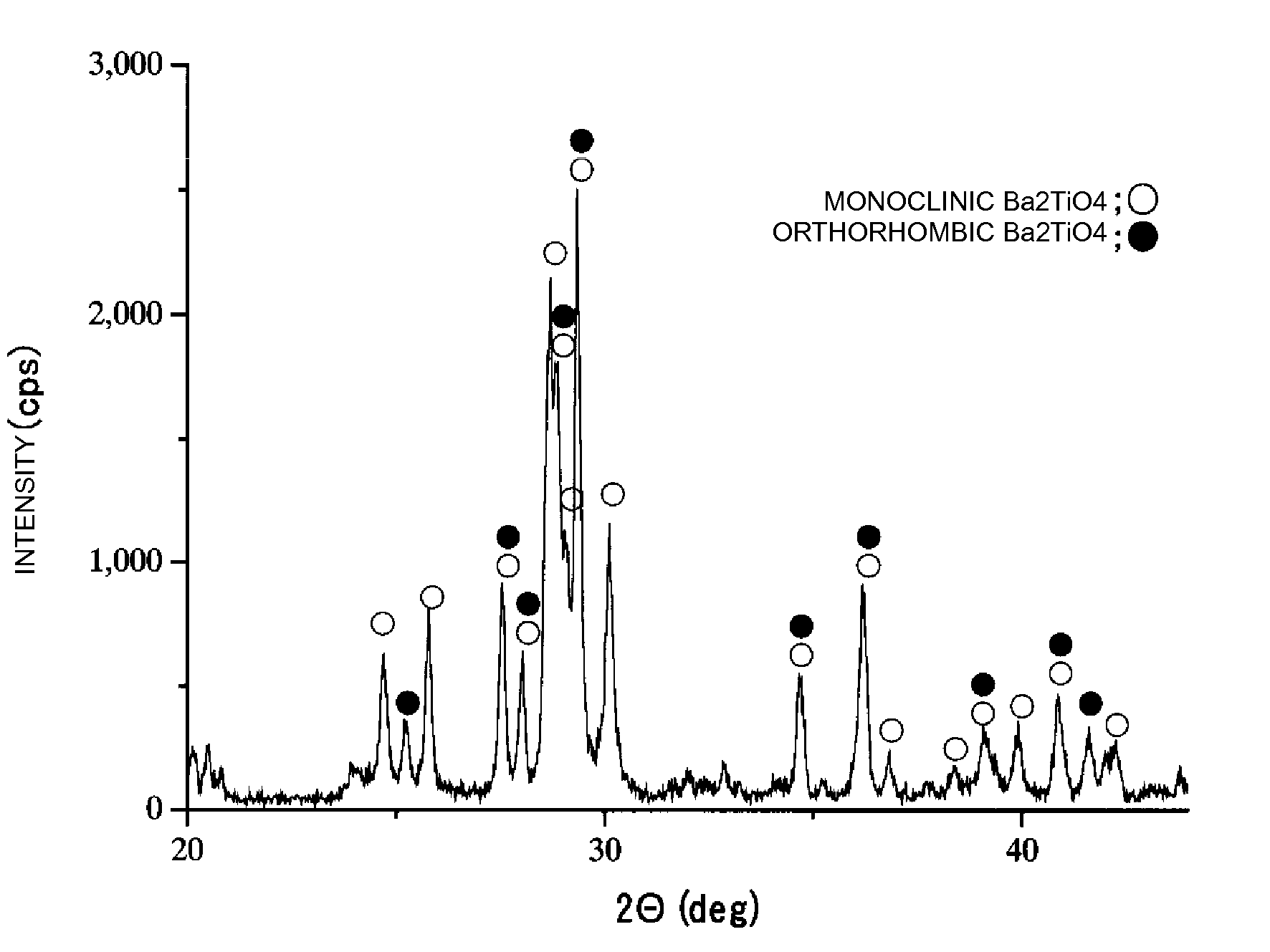

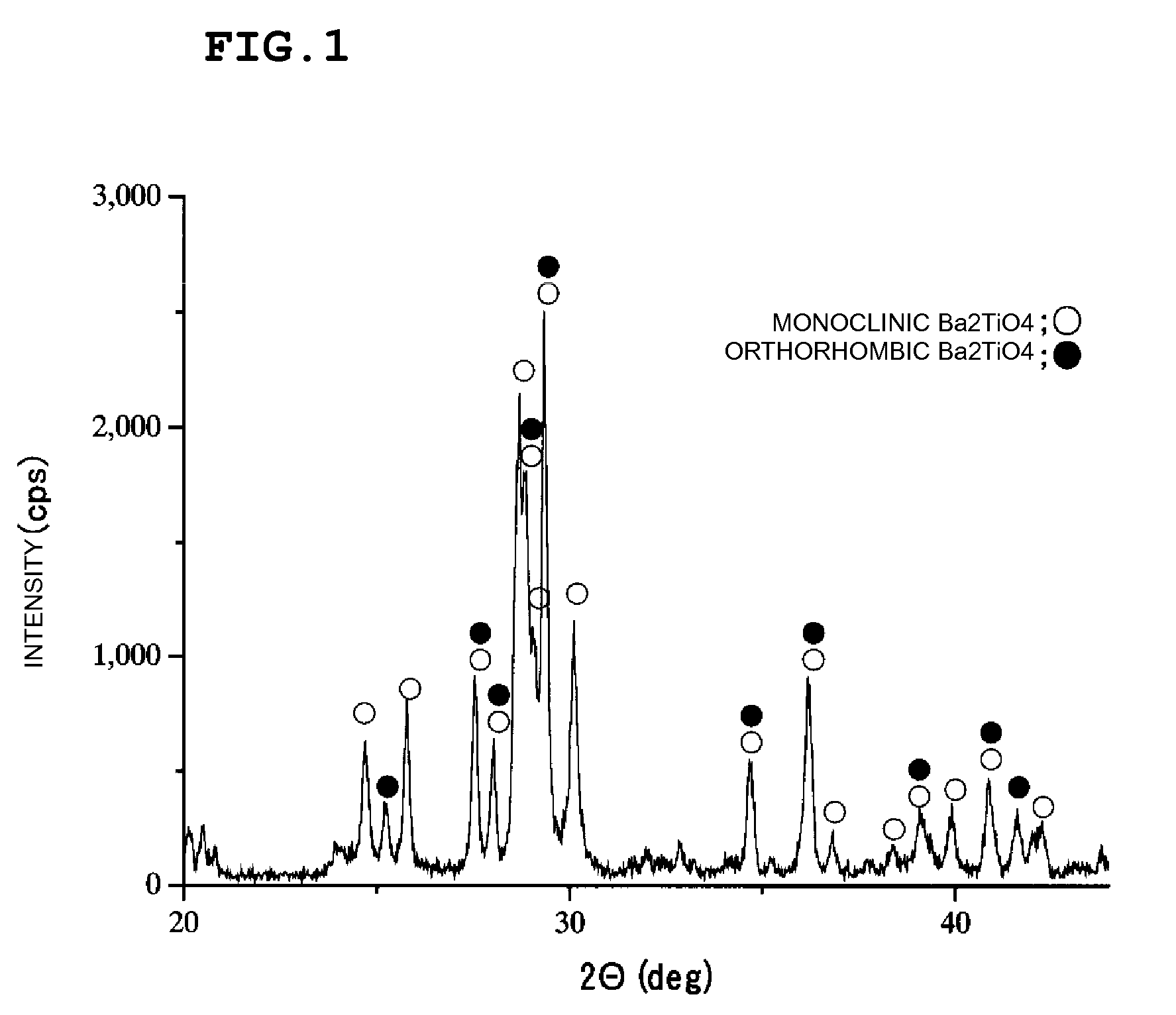

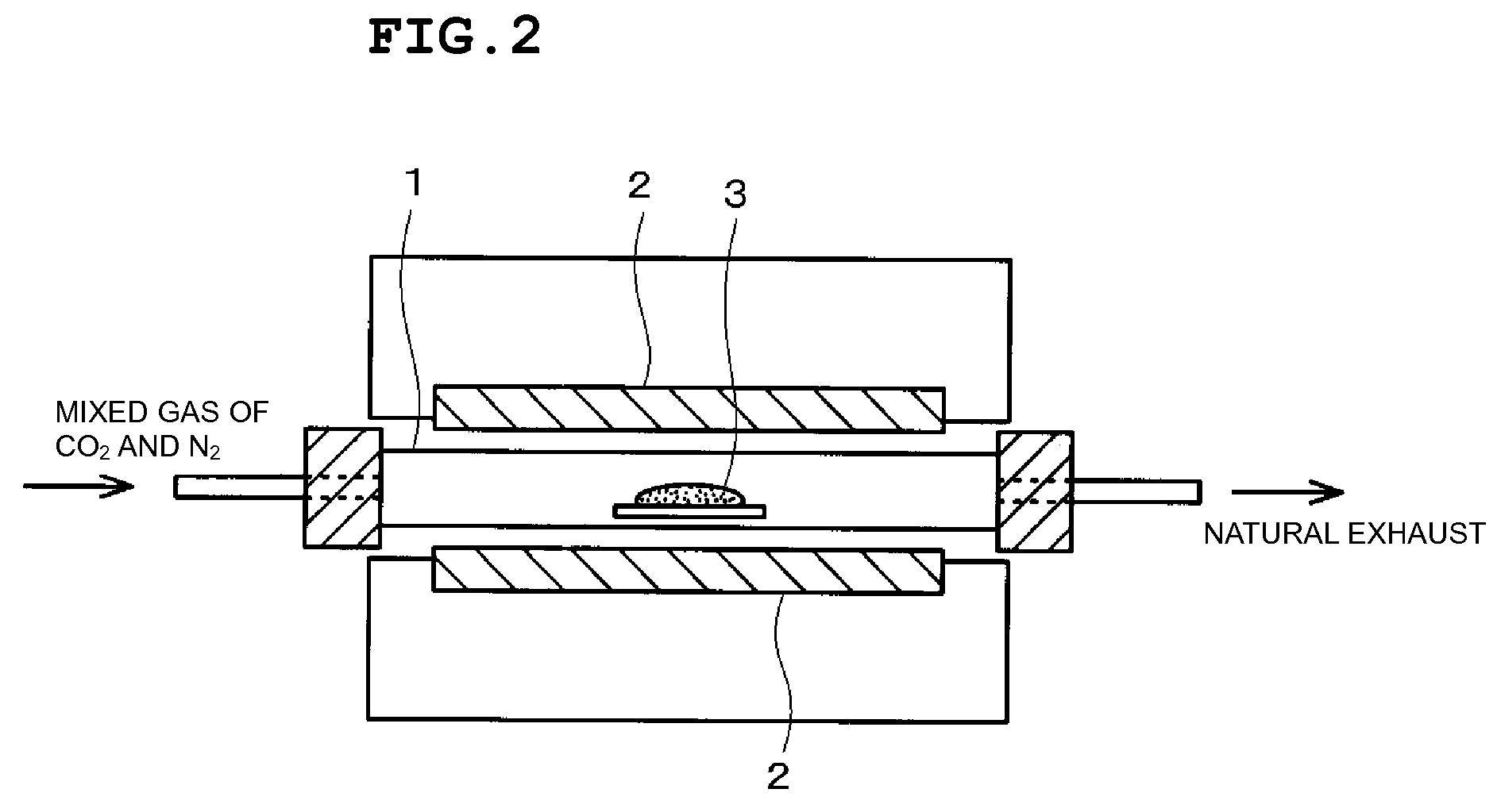

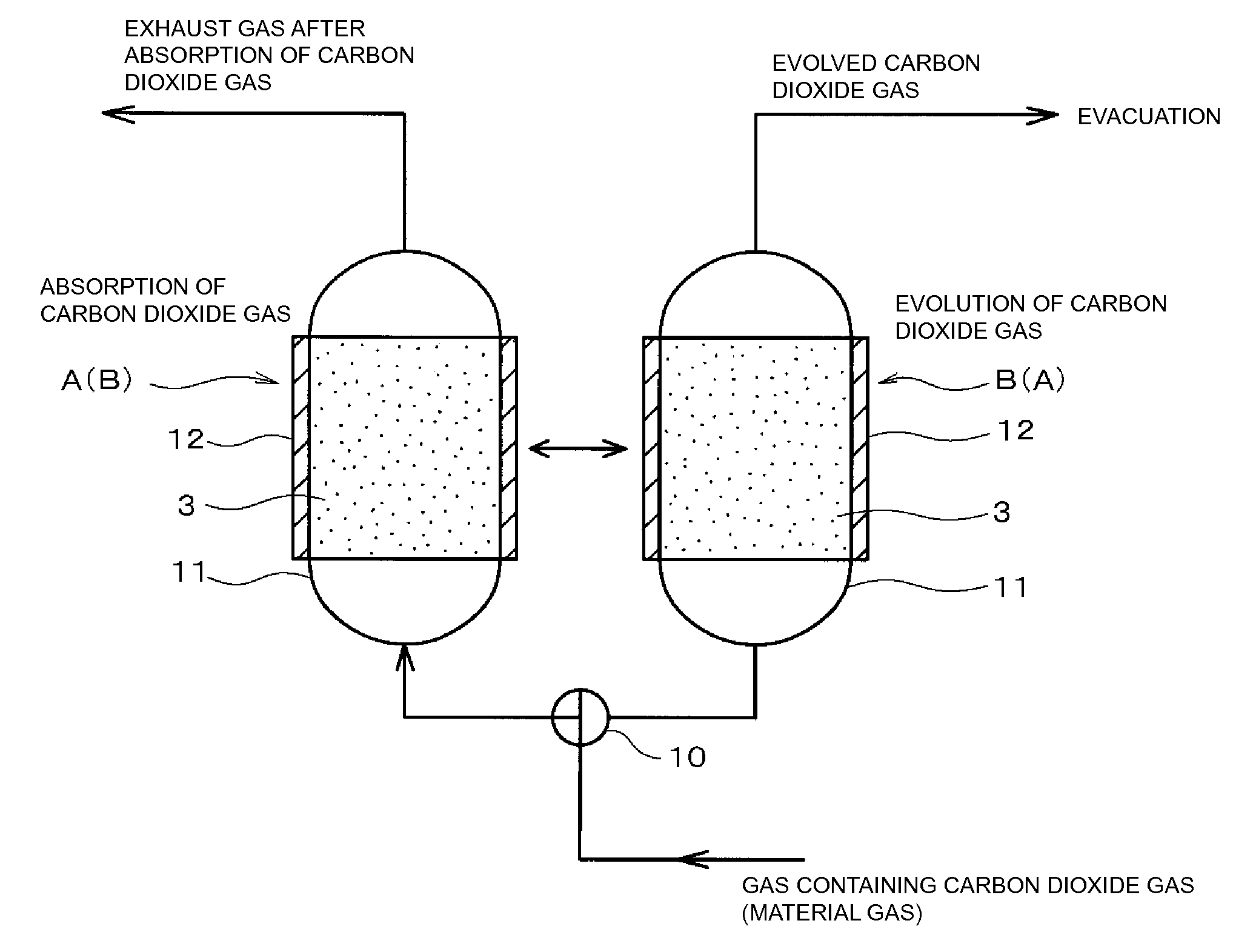

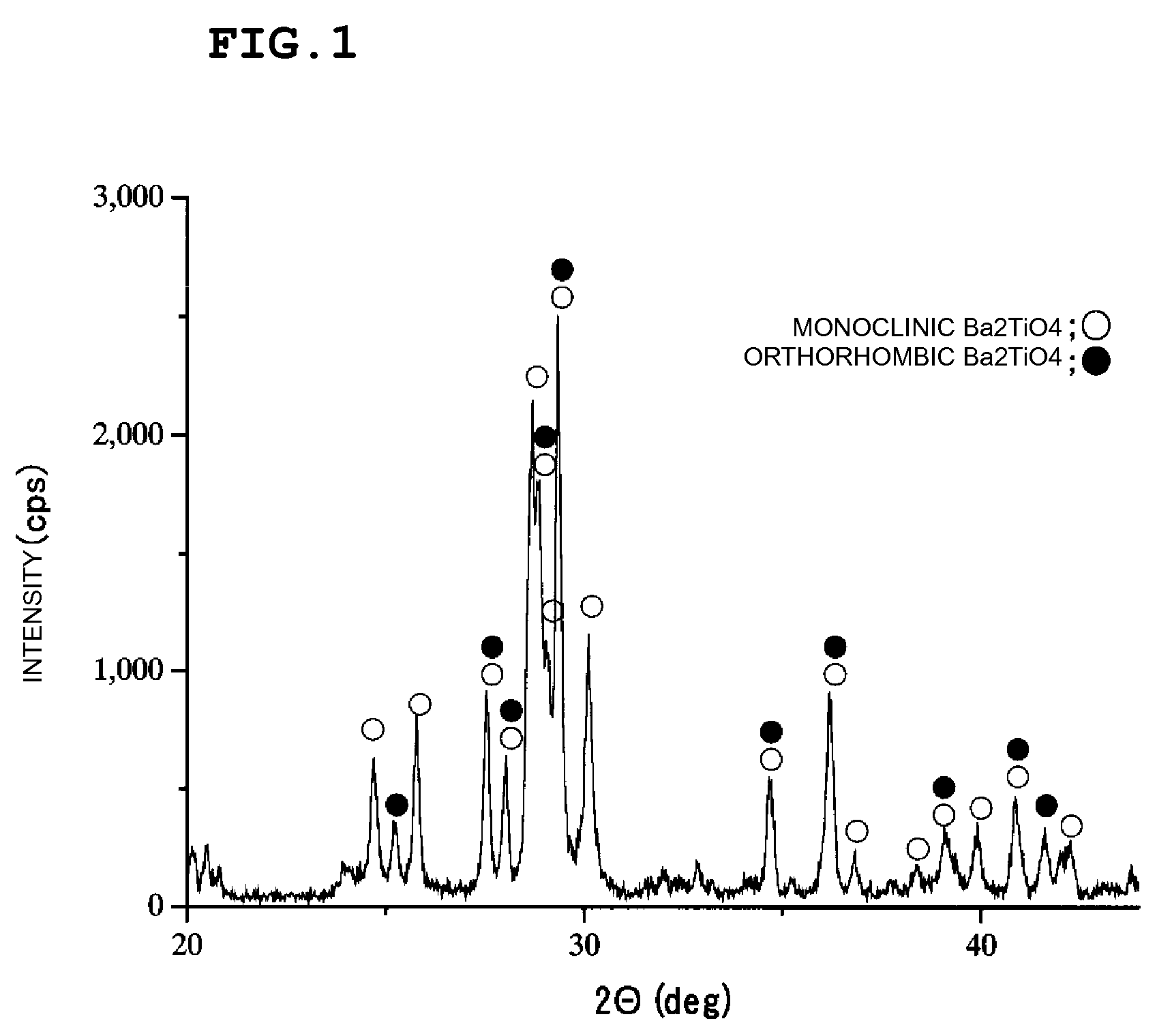

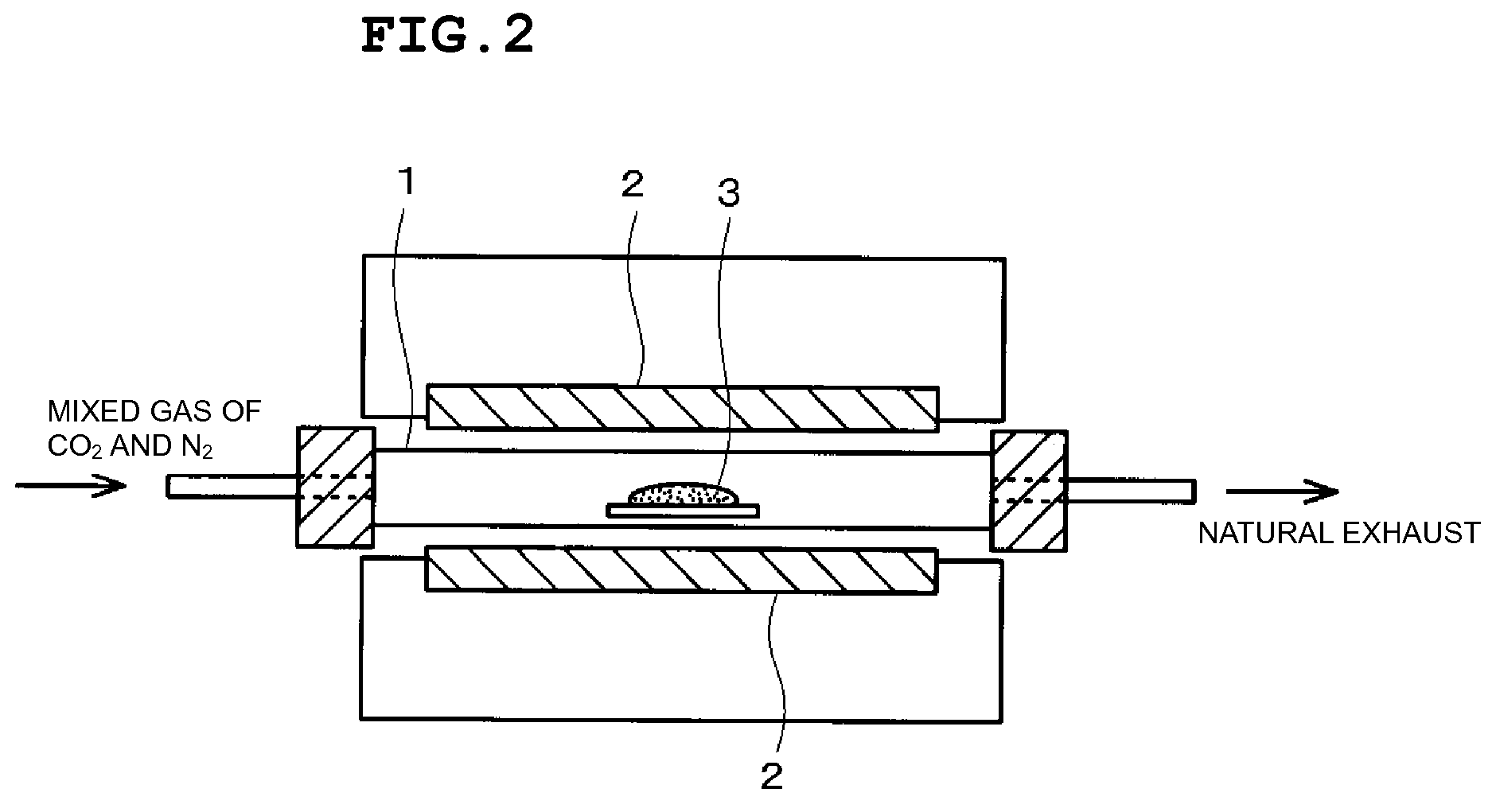

Carbon-dioxide-gas absorber, method for separating carbon-dioxide-gas using carbon-dioxide-gas absorber, and apparatus for separating carbon-dioxide-gas including carbon-dioxide-gas absorber

ActiveUS20070125229A1Reduce bloatSatisfactory service lifeAlkaline earth titanatesIsotope separationStrontium carbonateComposite oxide

A carbon-dioxide-gas absorber includes a composite oxide as a main component, the composite oxide including Ti and a constituent X that is at least one of Sr and Ba, and the composite oxide having an (X / Ti) of about 1.8 to about 2.2 on a molar basis. A substance having a perovskite structure and having an (X / Ti) of about 0.9 to about 1.1 or at least one selected from green sheets, green sheet wastes, green-sheet-laminate wastes, and precursors of green sheets including the substance is fired in the presence of at least one of strontium carbonate and barium carbonate. An apparatus includes a carbon-dioxide-gas-absorbing mechanical unit A that allows a carbon-dioxide-gas absorber to absorb a carbon dioxide gas at about 1.0×104 to about 1.0×106 Pa and at about 500° C. to about 900° C.; and a carbon-dioxide-gas-evolving mechanical unit B that evolves the absorbed carbon dioxide gas at about 1000 Pa or less and at at least about 750° C.

Owner:MURATA MFG CO LTD

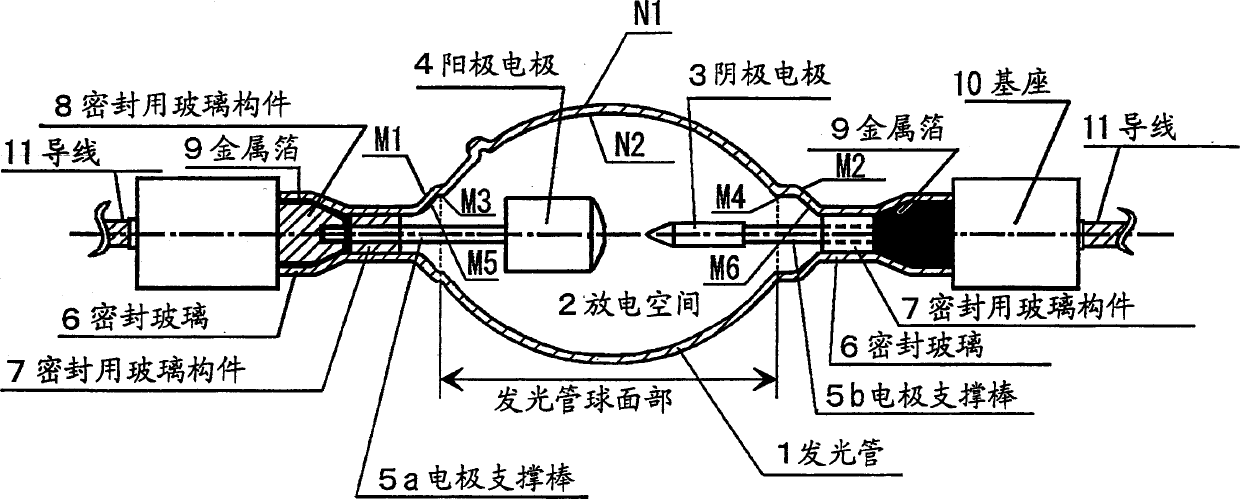

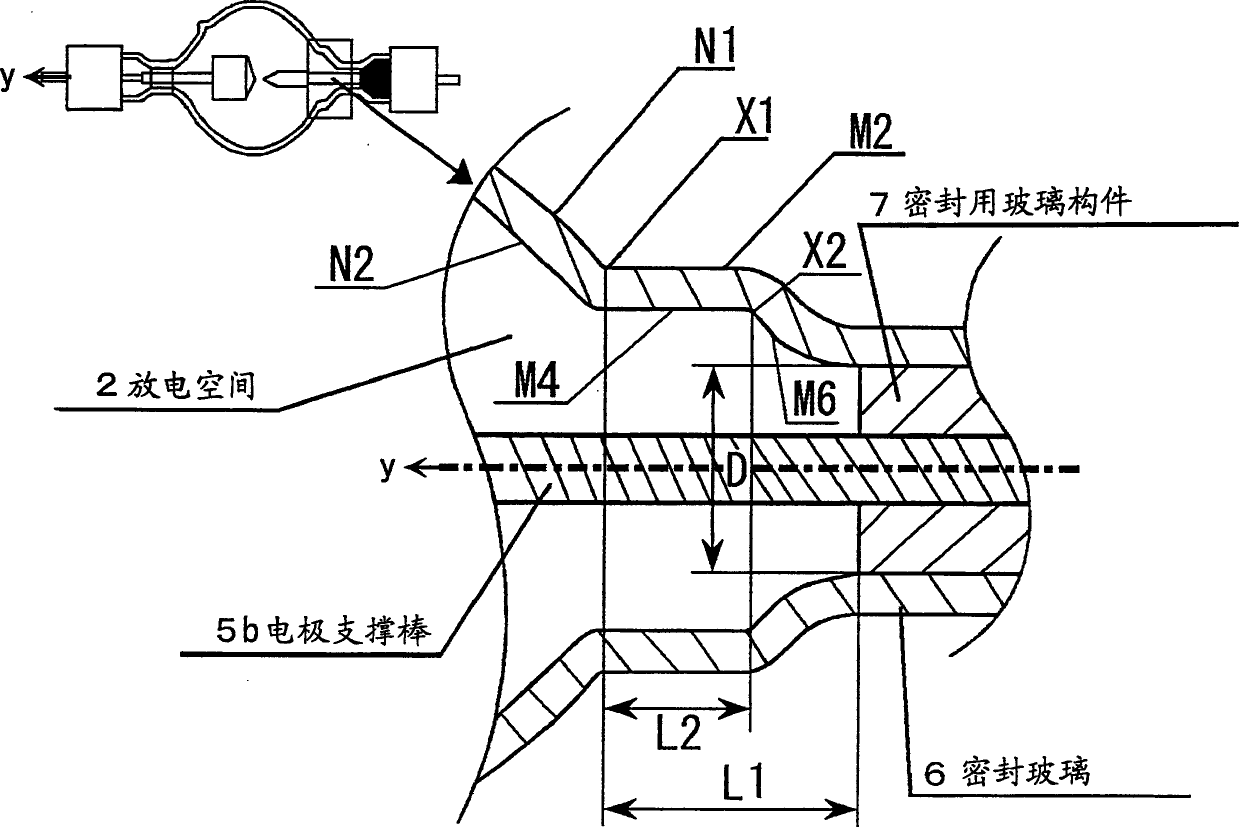

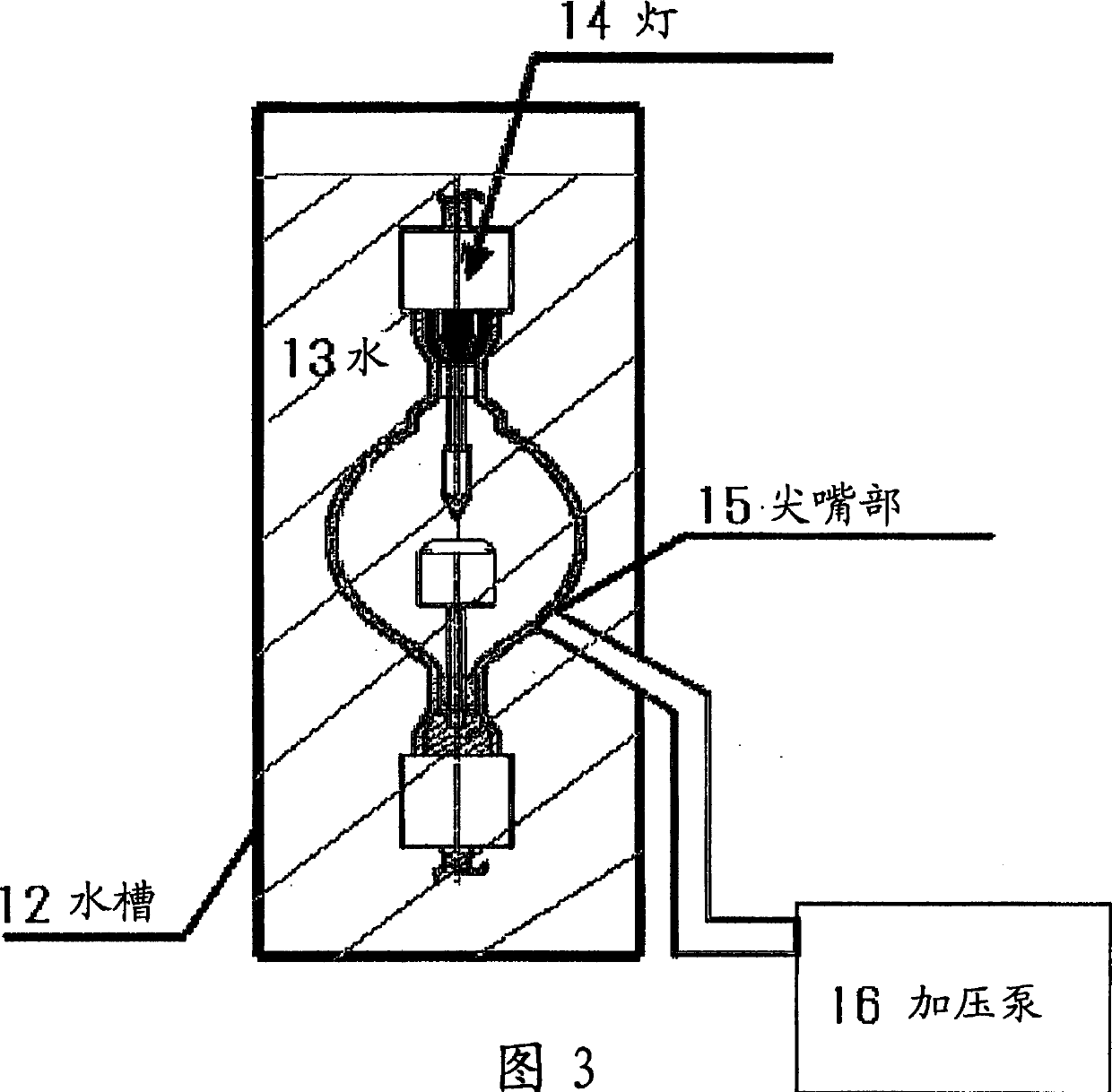

Short arc type discharge lamp

ActiveCN1794412ASatisfy the ascending characteristicSatisfy the irradianceHigh-pressure discharge lampsGas discharge lamp detailsInternal pressureEngineering

Object: To prevent the burst during lighting of short-arc discharge lamp with lighting inner pressure from 2.0 MPa to 3.0 MPa, satisfying well the characteristics of rise-time, irradiance and lifetime of lamp. Resolution: Cathode 3 and anode 4 are arranged in the discharge space 2 of the light tube 1 of short-arc discharge lamp. Rare gas and mercury are enclosed in the discharge space 2. L1 (mm) is the length from the edge of the spherical part of the light tube to the front edge of the sealing glass member 7. D (mm) is the diameter of the sealing glass member 7. P (MPa) is the inner pressure at lighting of the lamp. Under this condition, the shape of the lamp is decided to fulfill the inequality formula D<(-0.38*P+1.79)*L1+(-3.32*P+24.3). Moreover, the thickness of the sealing glass 6 is from 3.0 mm to 5.0 mm in the range L2 from the spherical edge X1 of the light tube to the point X2 where the inner surfaces of different curvature meet. And also, the input electric power to the lamp is in the range from 5 kW to 25 kW.

Owner:ORC MFG

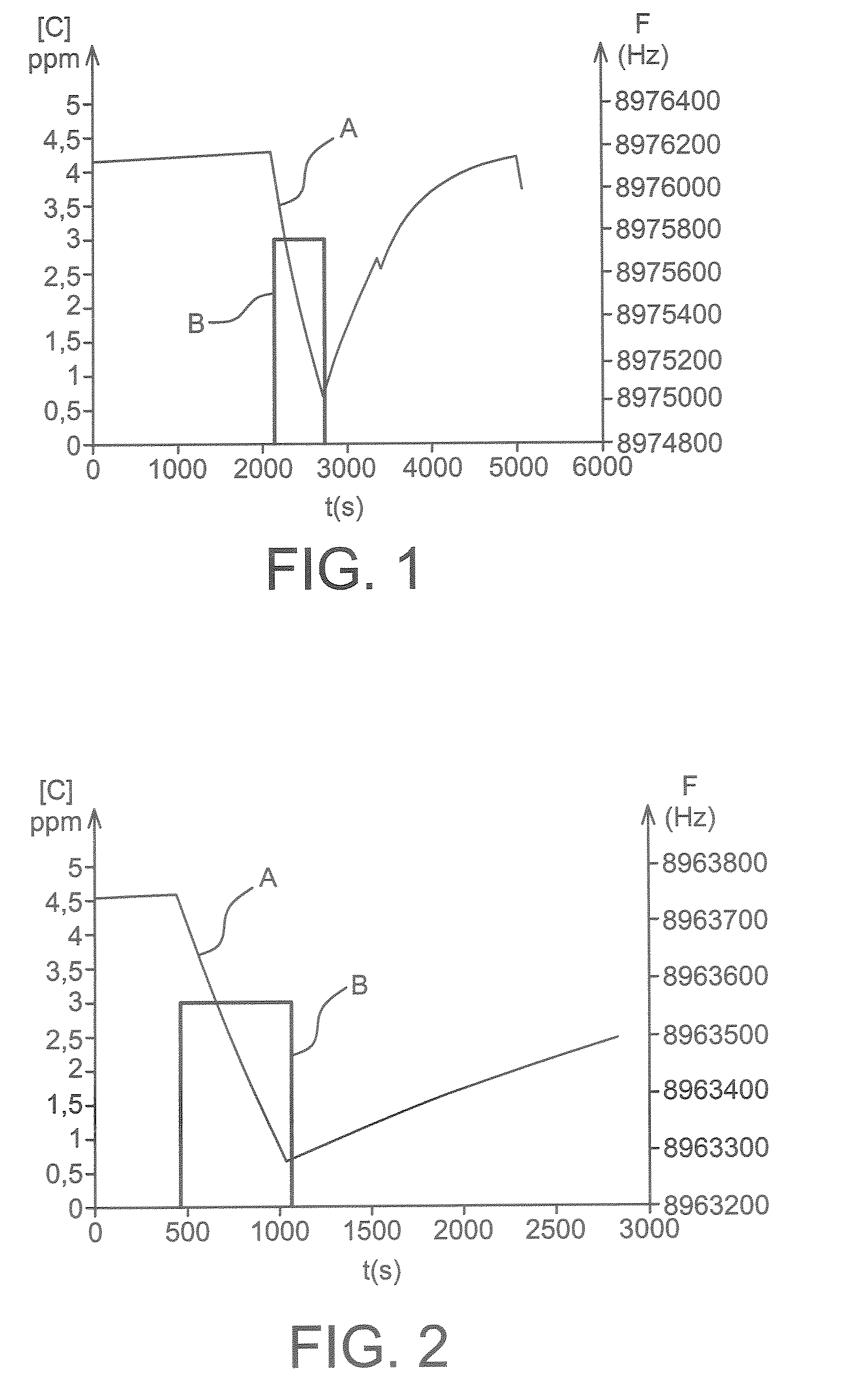

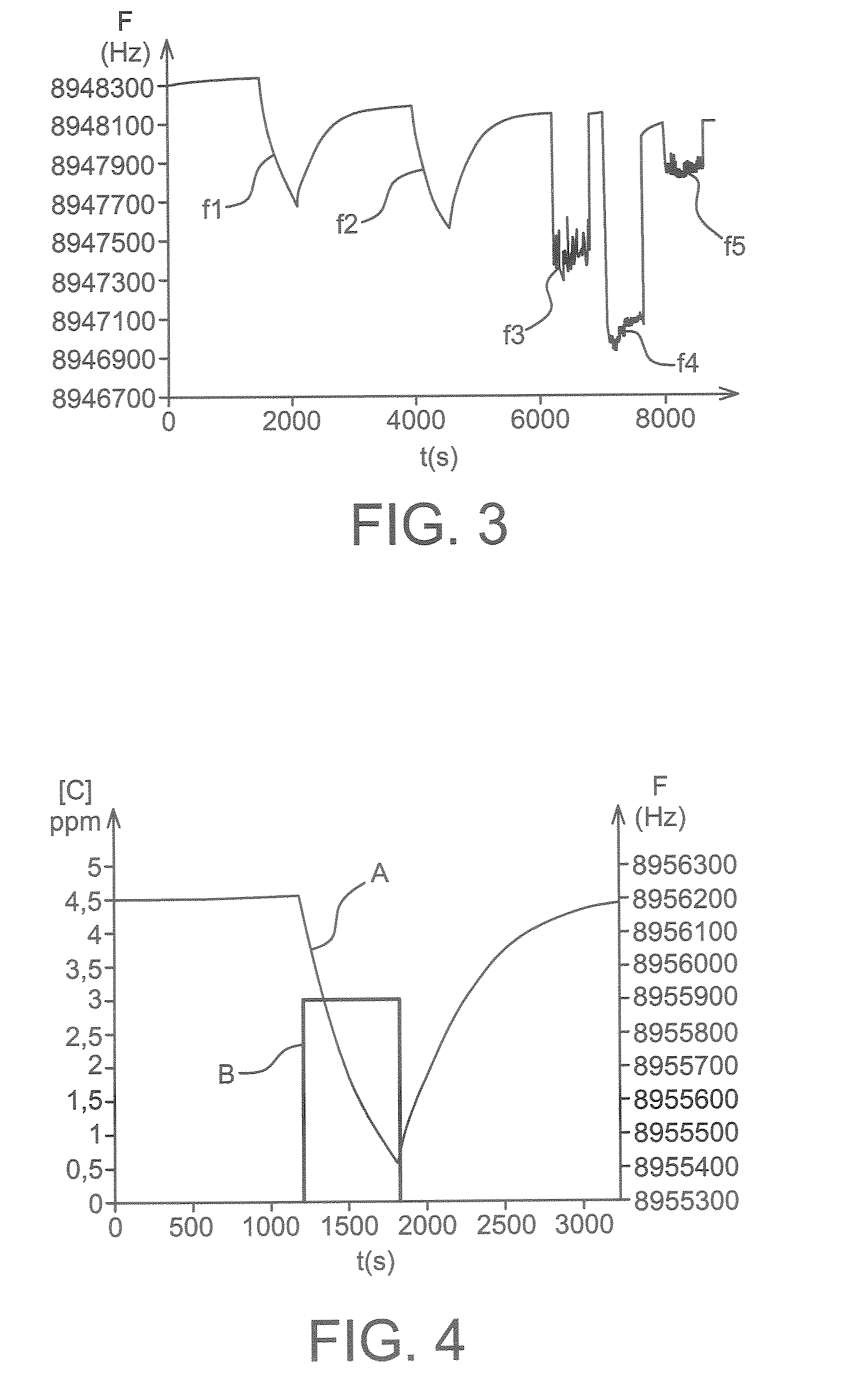

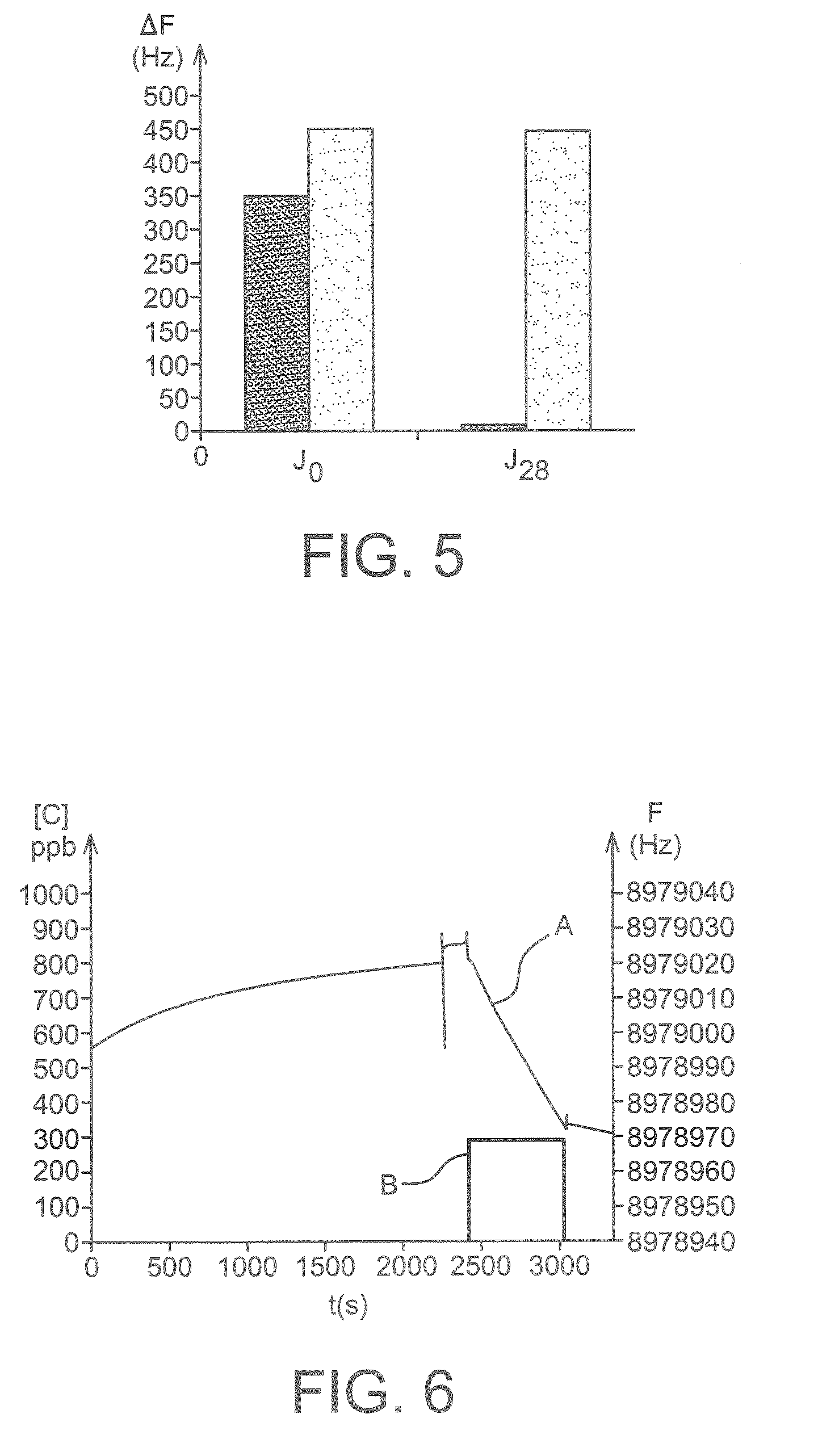

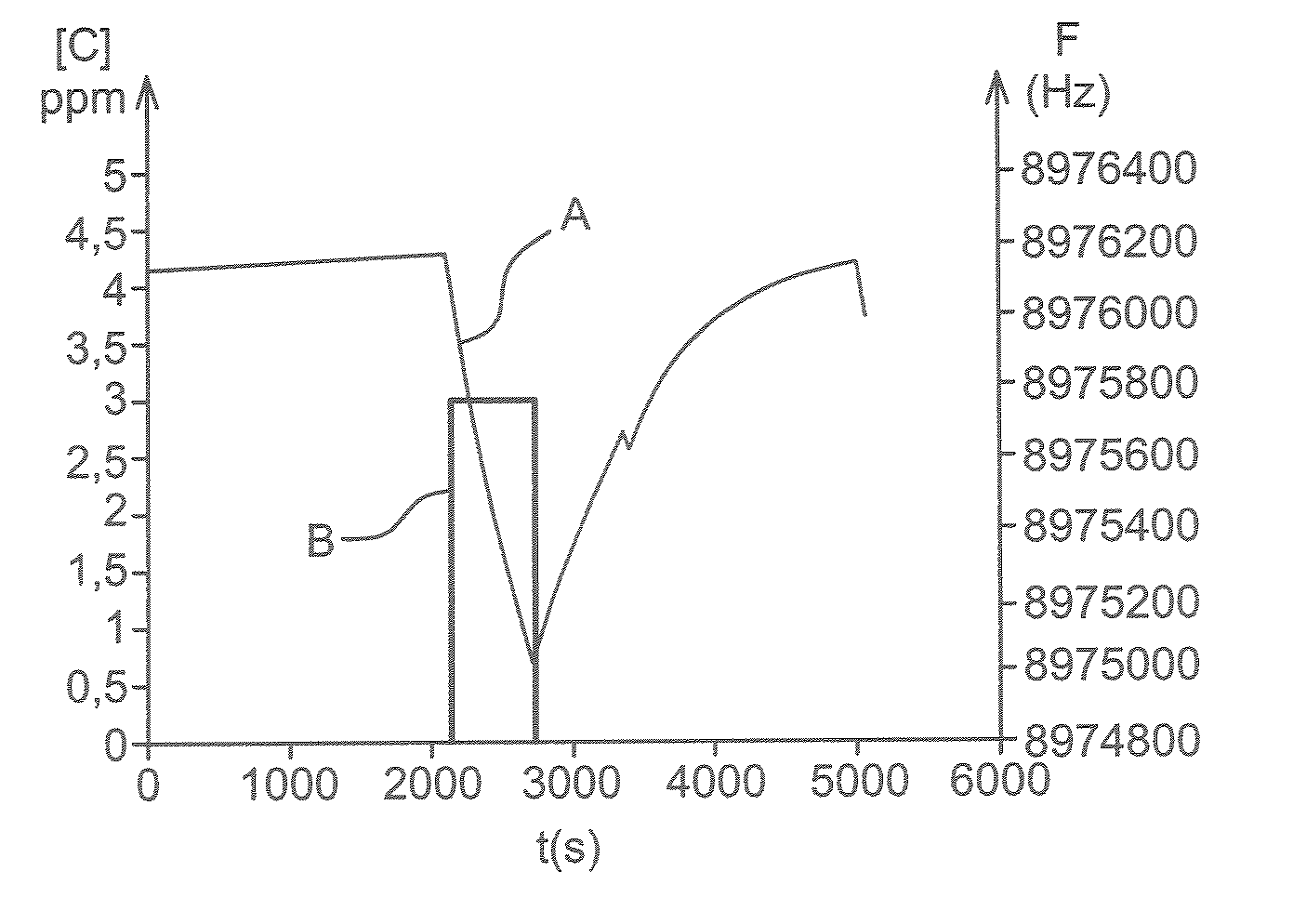

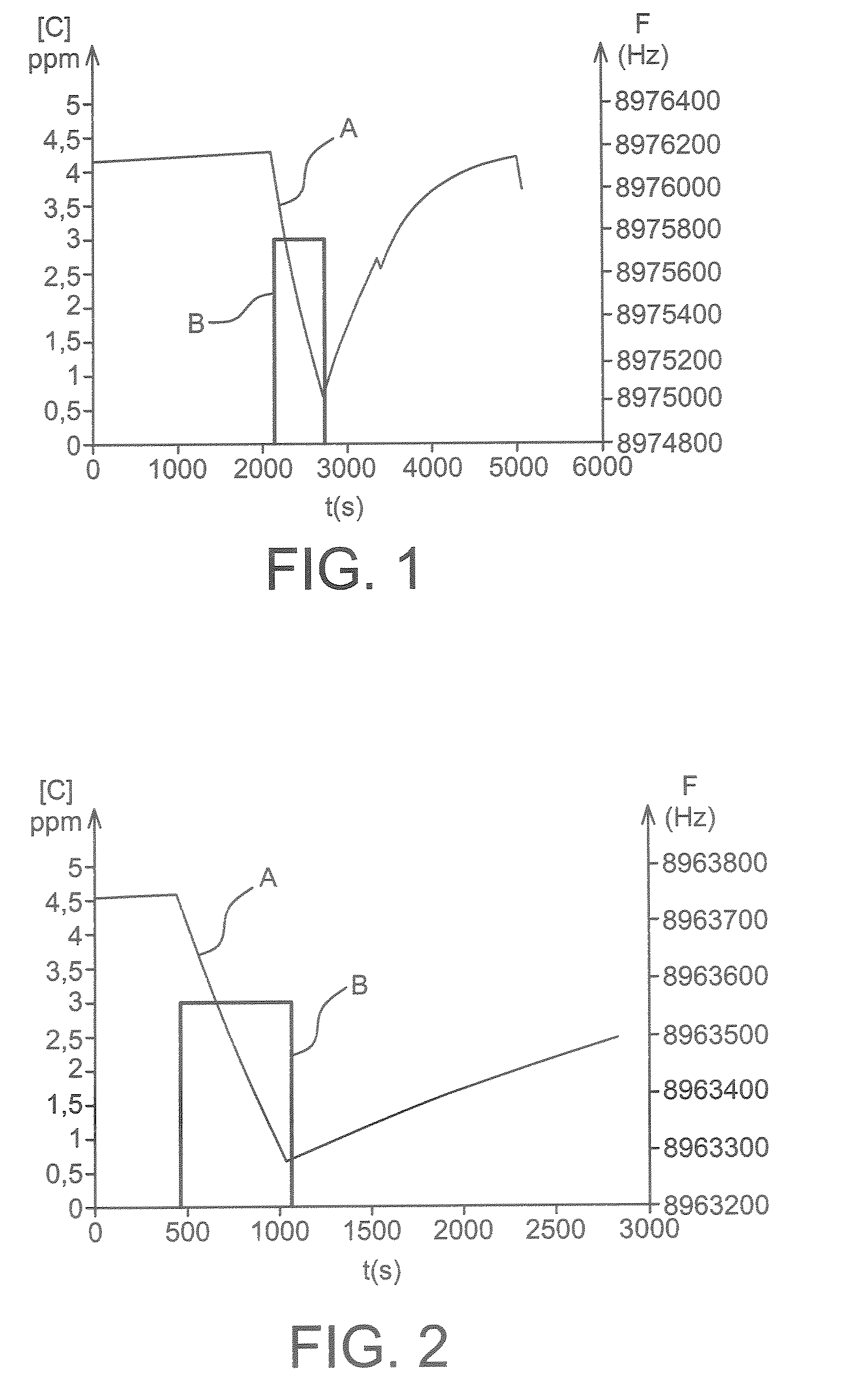

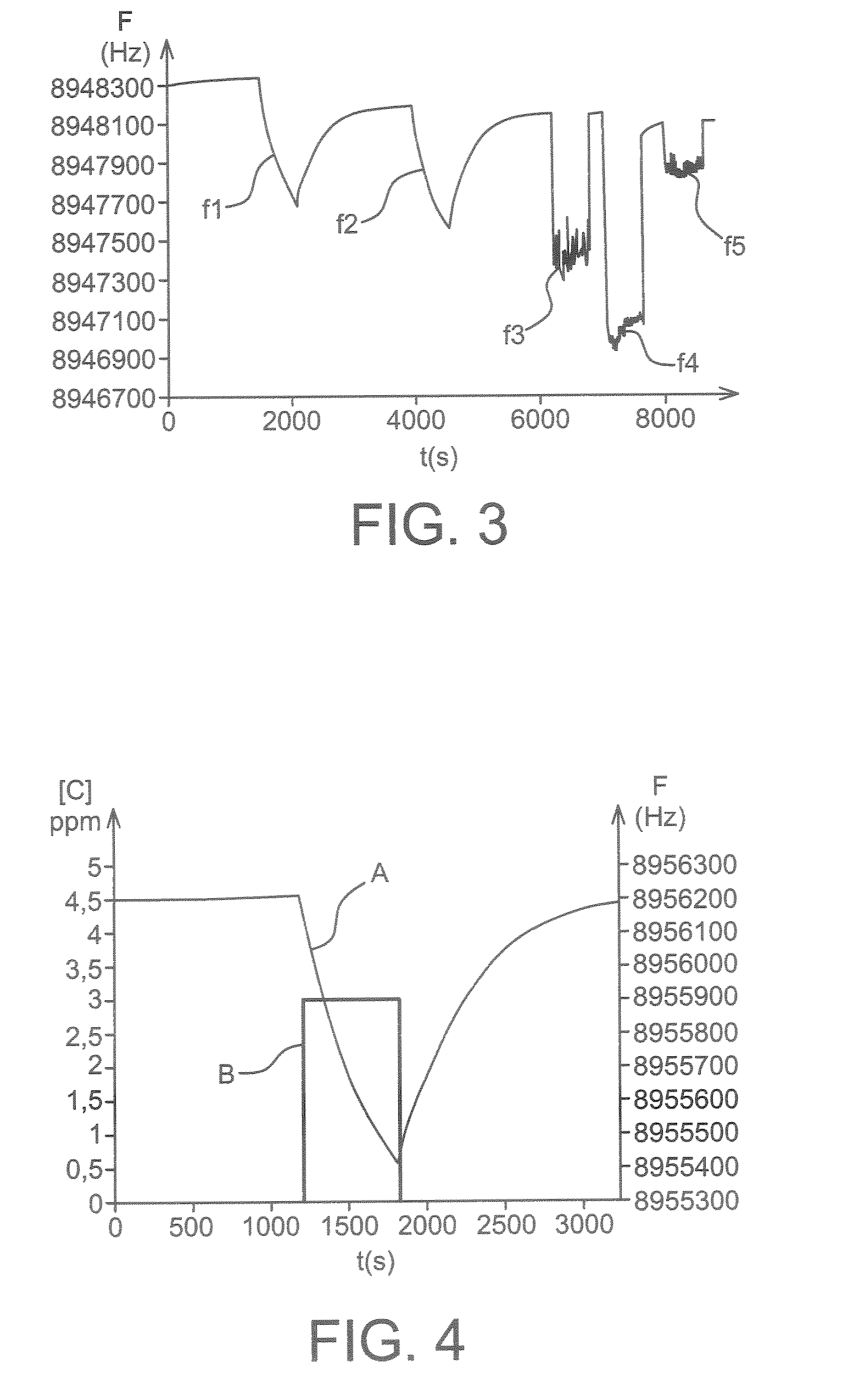

Chemical Sensors Comprising Aniline Polysiloxanes as Sensitive Materials and Use Thereof for Detecting of Assaying Nitro Compounds

InactiveUS20080070316A1Improve mechanical propertiesImprove performanceMaterial analysis using sonic/ultrasonic/infrasonic wavesMicrobiological testing/measurementNitro compoundChemical compound

The invention relates to chemical sensors comprising aniline-grafted polysiloxanes as sensitive materials, and to the use thereof for detecting or assaying nitro compounds, in particular nitroaromatic compounds. Fields of application detecting explosives, checking and monitoring atmospheric pollution and the quality of the ambient air in relatively confined spaces, monitoring of industrial sites.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

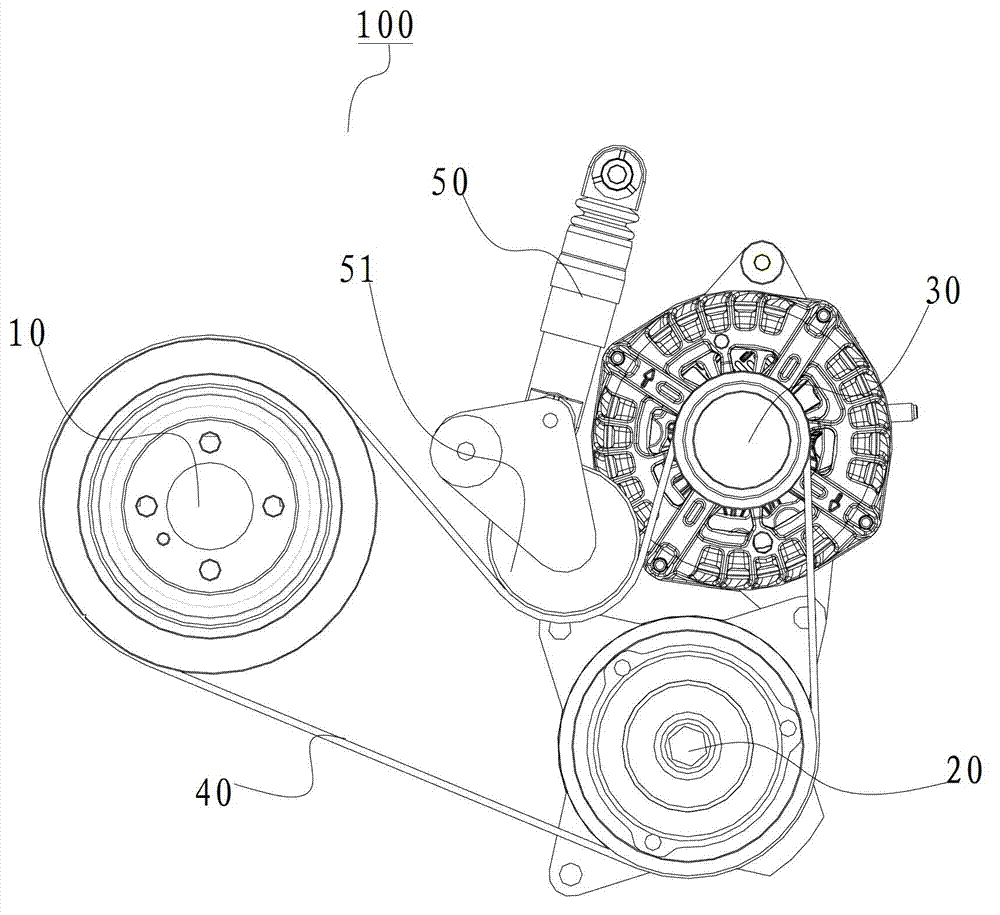

Accessory wheel system for automobile engine and automobile engine with accessory wheel system

InactiveCN103114907ACompact layoutSmall form factorGearingMachines/enginesMiniaturizationEngineering

The invention discloses an accessory wheel system for an automobile engine and an automobile engine with the accessory wheel system. The accessory wheel system comprises a crankshaft damping belt wheel, an air conditioning compressor belt wheel, a power generator belt wheel, a belt and a hydraulic automatic tensioner, the crankshaft damping belt wheel is connected with a crankshaft of the automobile engine to rotate along with the engine crankshaft, the air conditioning compressor belt wheel, the power generator belt wheel and the crankshaft damping belt wheel are positioned in a same plane, the belt is sleeved on the crankshaft damping belt wheel, the air conditioning compressor belt wheel and the power generator belt wheel to enable the air conditioning compressor belt wheel and the power generator belt wheel to rotate along with the crankshaft damping belt wheel, a belt wheel of the hydraulic automatic tensioner abuts against the belt to apply a preset tensioning force to the belt, and the crankshaft damping belt wheel, the air conditioning compressor belt wheel, the power generator belt wheel and the hydraulic automatic tensioner are positioned in a same plane. According to the accessory wheel system for the automobile engine, overall compactness and miniaturization of the engine are realized to adapt to a narrow arrangement space of an engine room of a whole automobile.

Owner:GREAT WALL MOTOR CO LTD

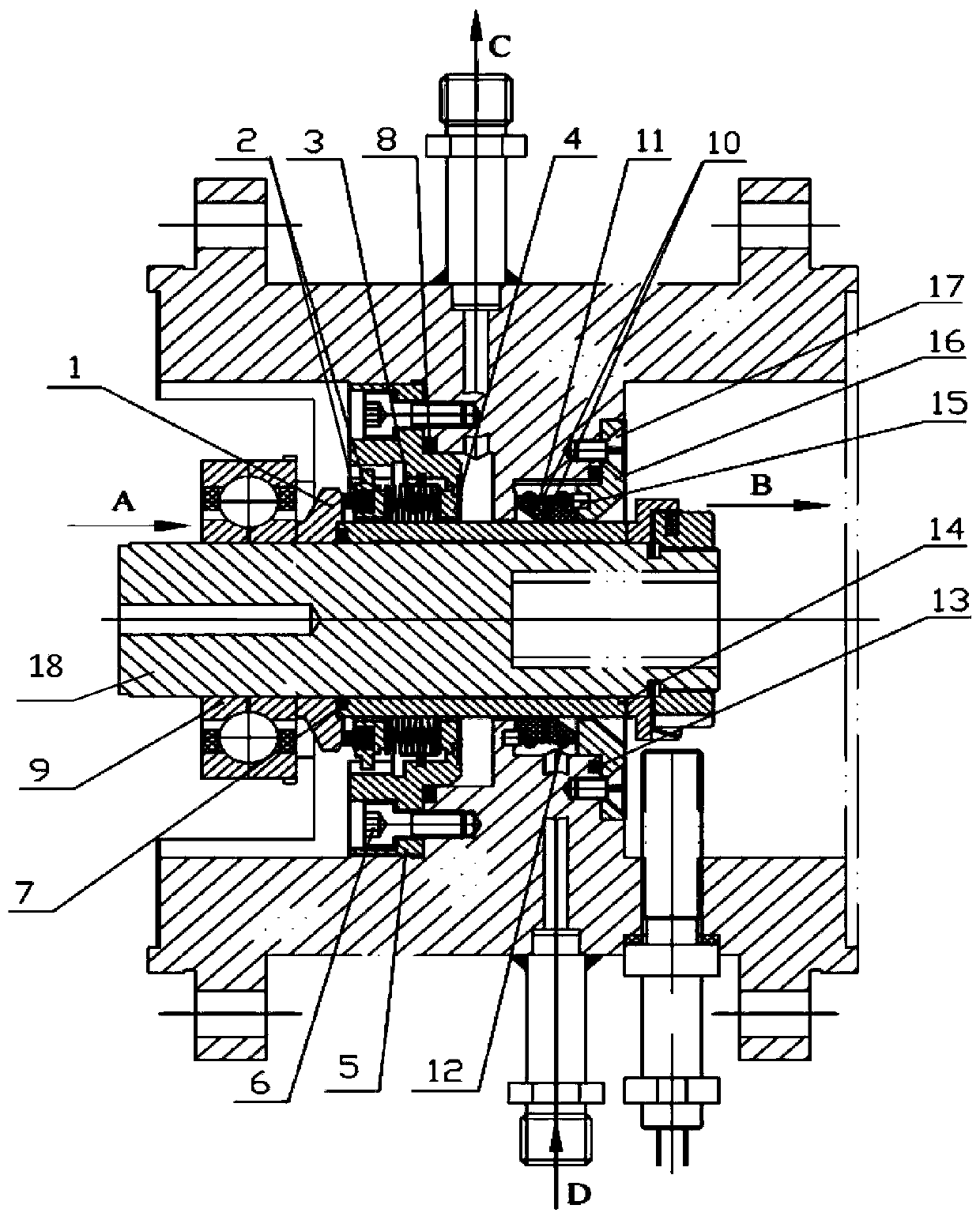

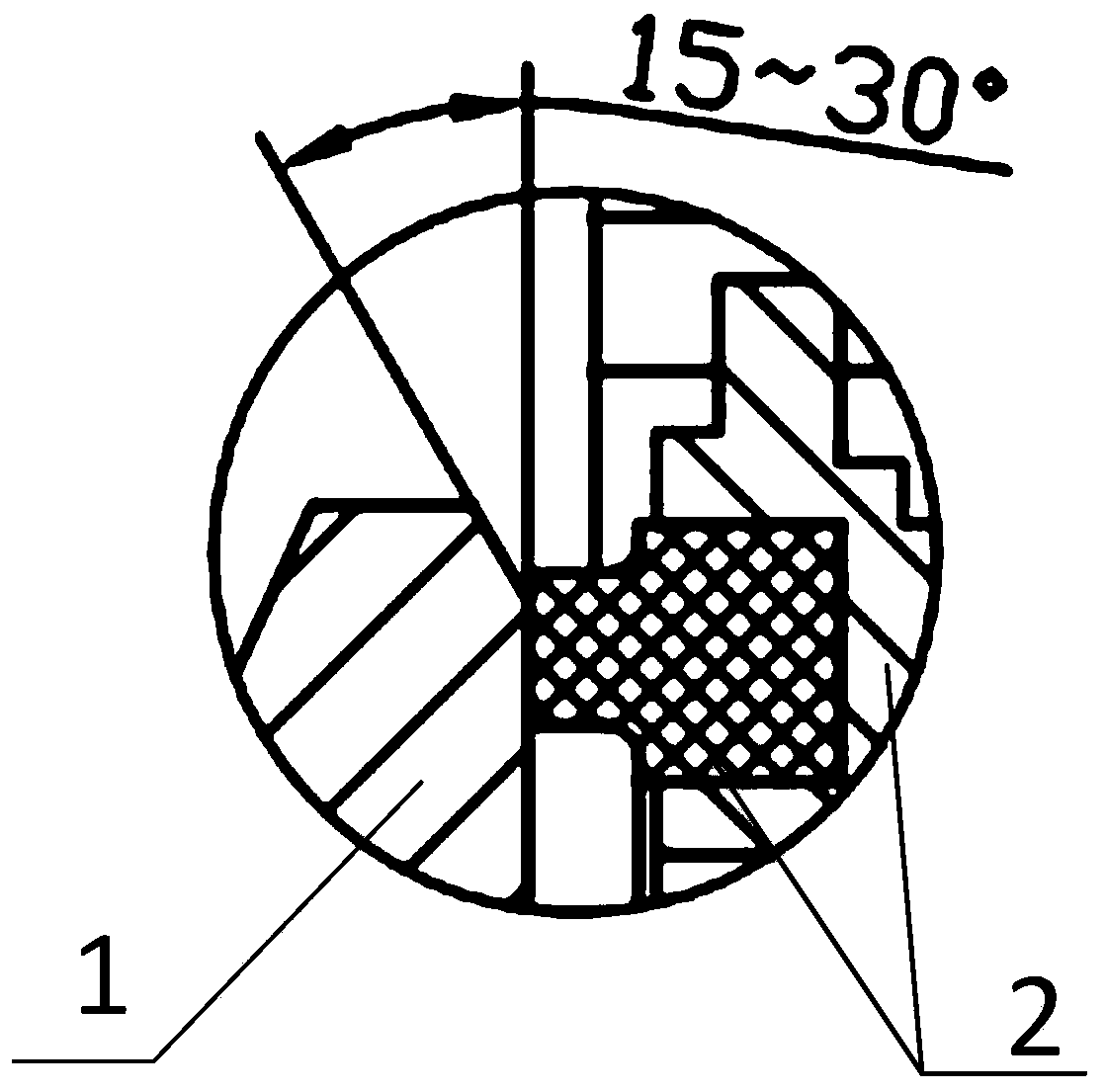

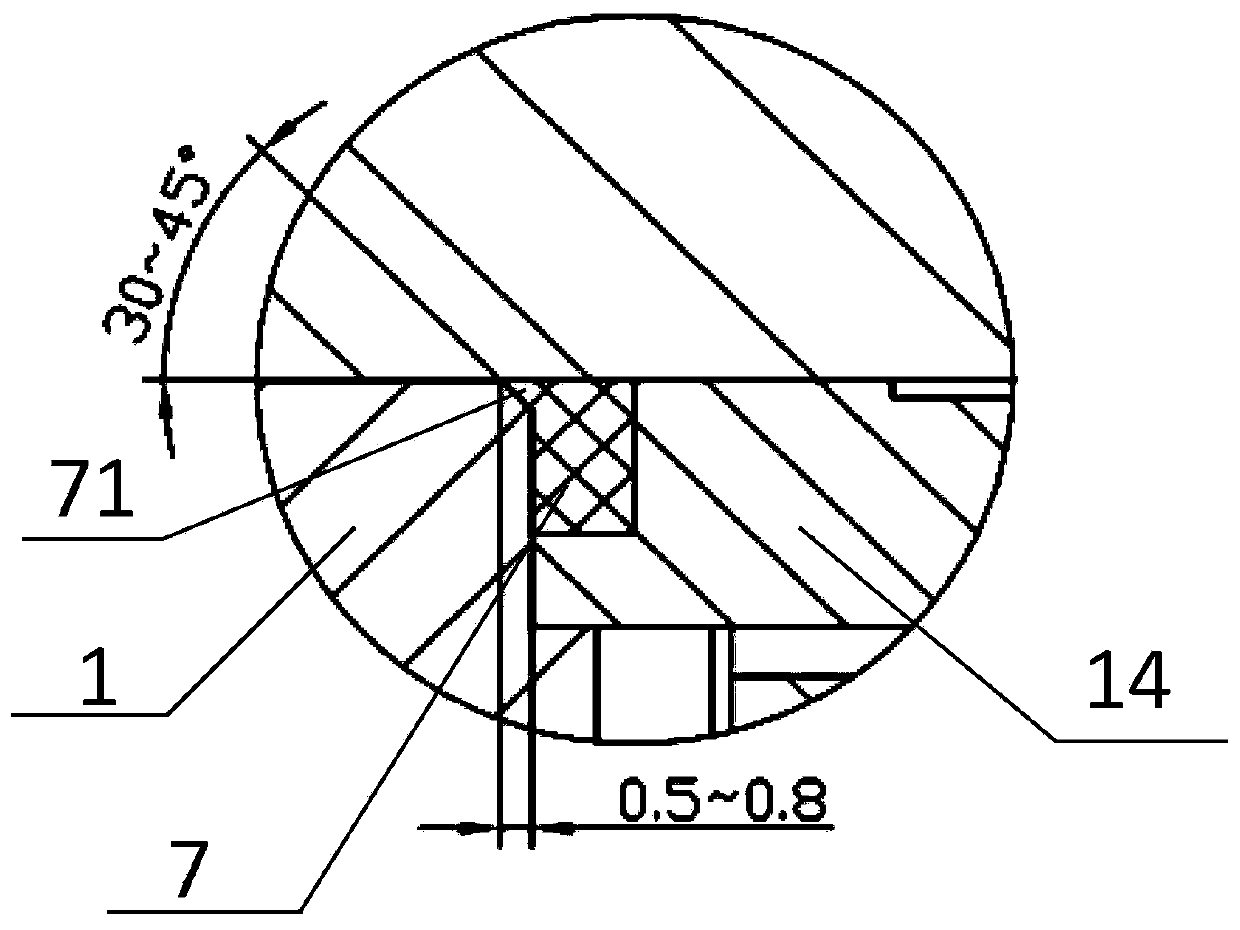

Dynamic sealing device suitable for low-temperature and high-speed repeated use

The invention relates to a dynamic sealing device suitable for low-temperature and high-speed repeated use. The dynamic sealing device is applied to a liquid rocket engine turbopump. The liquid rocketengine turbopump comprises a shaft (18) and a bearing (9) sleeving the shaft (18). The dynamic sealing device comprises a main sealing structure. The main sealing structure comprises a dynamic ring (1), a static ring assembly (2), a corrugated pipe (3), a rear ring (4), a sealing shell (5) and a shaft sleeve (14). The dynamic sealing device comprises the main sealing structure, so that low-temperature media can easily enter a dynamic ring and static ring assembly joint surface, dry friction on the sealing surface is avoided, sealing wear is reduced, the sealing service life is prolonged, andrequirements for long service life and repeated use under severe working conditions such as high rotating speed, high pressure and large radial runout of the turbopump are met.

Owner:BEIJING XINGJI RONGYAO SPACE TECH CO LTD

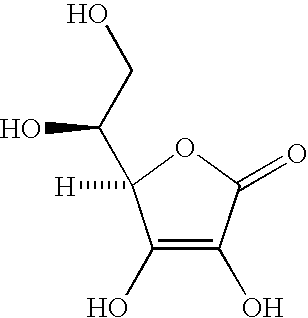

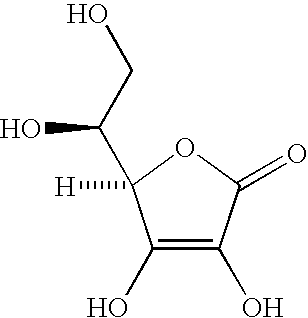

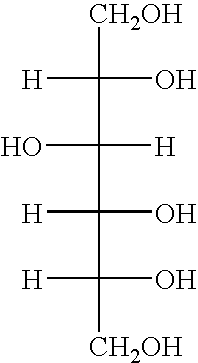

Methods of using stable ascorbic acid compositions

InactiveUS20070178058A1Improve stabilityPromote absorptionBiocideCosmetic preparationsPercutaneous absorptionPre treatment

Excellent percutaneous absorption of vitamin C is achieved by pre-treating skin with a cationic constituent such as cationic salt or solution thereof prior to application of a vitamin C composition.

Owner:JR CHEM LLC

Chemical mechanical polishing pad, production method thereof, and chemical mechanical polishing process

InactiveUS20050222336A1High polishing rateSatisfactory useful lifeFlexible-parts wheelsGrinding devicesCompound (substance)Polymer chemistry

A chemical mechanical polishing pad comprising a water-insoluble matrix which comprises (A) a styrene polymer and (B) a diene polymer. A method for producing the above chemical mechanical polishing pad, the method comprising the steps of preparing a composition comprising (A) a styrene polymer, (B) a diene polymer and (C) a crosslinking agent, shaping the above composition into a predetermined shape, and heating the composition during or after shaping to cure it. A chemical mechanical polishing process which comprises polishing a surface to be polished of an object to be polished by use of the chemical mechanical polishing pad. According to the present invention, it is possible to provide a chemical mechanical polishing pad which can be suitably applied to polishing of metal film and insulation film, particularly to an STI technique, provides a flat polished surface, can provide a high polishing rate and has a satisfactory useful life.

Owner:JSR CORPORATIOON

Chemical sensors comprising aniline polysiloxanes as sensitive materials and use thereof for detecting of assaying nitro compounds

InactiveUS7968343B2Improve mechanical propertiesImprove performanceMaterial analysis using sonic/ultrasonic/infrasonic wavesMaterial analysis by electric/magnetic meansNitro compoundChemical compound

A chemical sensor including a substrate having at least two faces, at least one of the faces being covered by a thin film that includes a sensitive material, and a means for measuring a change in a physical property of the sensitive material; and, methods of detecting the presence of a nitro compound with the chemical sensor.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

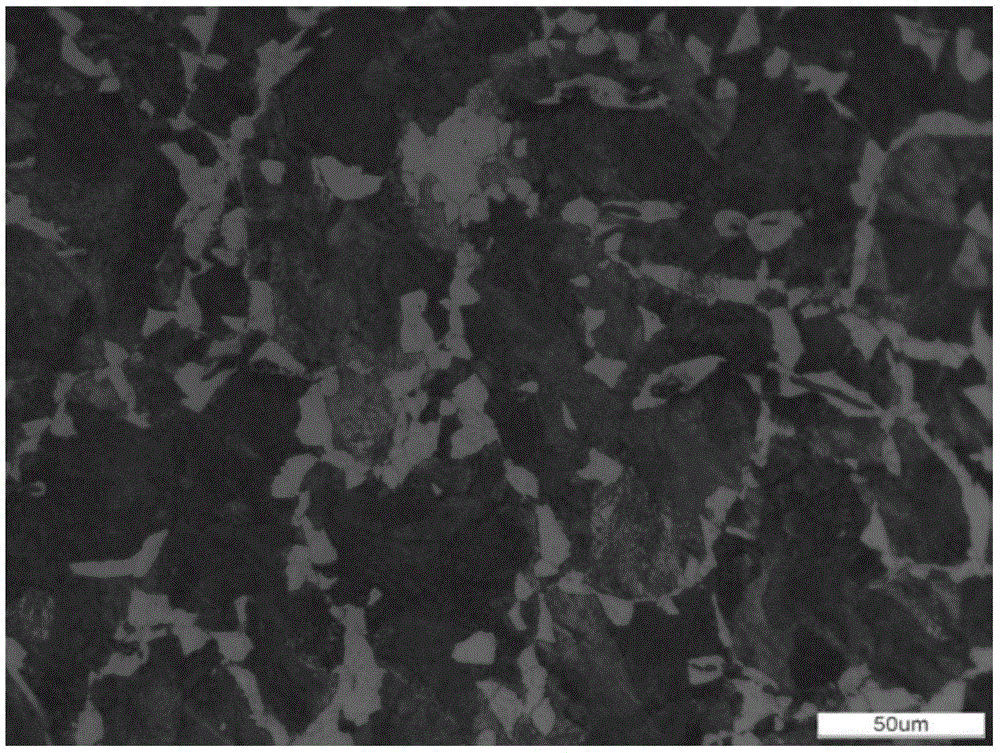

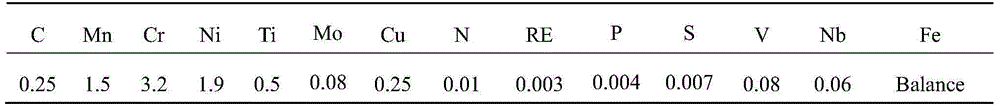

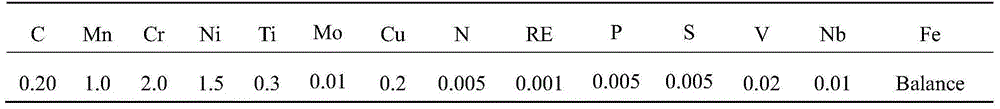

Heat-resistant alloy steel component having trans-scale multiphase in-situ enhancement effect and microstructure control process thereof

The invention discloses a heat-resistant alloy steel component having trans-scale multiphase in-situ enhancement effect and a microstructure control process thereof. The component is characterized by comprising the following alloy elements in percentage by mass: 0.20-0.45% of C, 1.0-2.0% of Mn, 2.0-4.0% of Cr, 1.5-3.0% of Ni, 0.3-0.8% of Ti, 0.01-0.1% of Mo, 0.2-0.8% of Cu, 0.005-0.015% of N, 0.001-0.008% of RE, P not more than 0.005%, 0.005-0.01% of S, and one or two of V and Nb. The heat-resistant alloy steel component having trans-scale multiphase in-situ enhancement effect and the microstructure control process thereof, provided by the invention, can prominently improve the toughness, the wear resistance, the high-temperature structure stability and the mechanical performance of alloy steel; and the method is simple, and is easy to be realized.

Owner:NANJING INST OF TECH

Device for compensating for pressure drop

InactiveUS20060054232A1Satisfy lifeEasy to cleanAircraft componentsFilling using counterpressureEngineeringPhysics

The invention relates to a device for compensating for pressure drop in a product pipe through which a liquid flows, and a system comprising such a device. The device comprises a collapsible tube portion, which is connectible to the product pipe, and is characterised by a limiting means, which is adapted to counteract stretching of the tube portion in the circumferential direction and which is adapted to allow free collapsing of the tube portion.

Owner:ECOLEAN

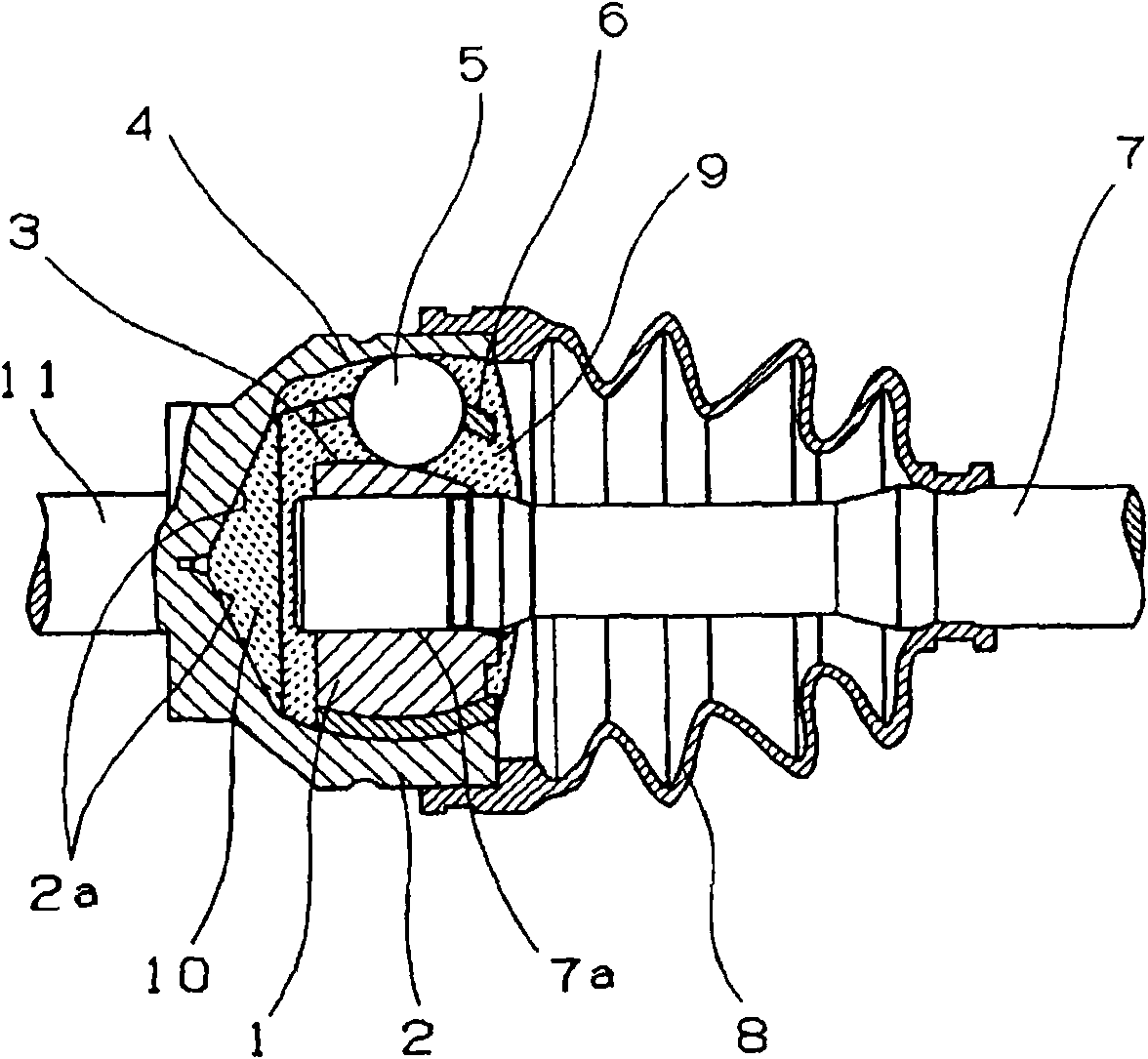

Lubricating system, bearing utilizing the system, universal joint utilizing the system, and process for production thereof

InactiveCN101558142ALubrication helpsMaintain lubrication functionYielding couplingBearing componentsProduction rateUniversal joint

It is an object of the present invention to provide a lubricating system that improves the force of retaining a lubricating component of a foam lubricant, minimizes an exudation amount of the lubricating component caused by deformation of the foam lubricant, is excellent in initial lubrication, has a long life, has a low cost, and is excellent in the productivity thereof; a bearing utilizing the lubricating system; a universal joint utilizing the lubricating system; and a process for the production thereof. A lubricating system includes a foam lubricant (9) containing a lubricating component in a resin thereof which foams, hardens, and becomes porous and a lubricant (10) for initial lubrication which is present together with the foam lubricant (9) in a portion to be lubricated. The lubricant (10) for initial lubrication consists of grease having a worked penetration not less than 300 or having a degree of oil separation not less than 0.7 wt% when the grease is left 24 hours at 70 DEG C. or consists of lubricating oil having a kinematic viscosity not less than 50mm 2 / second at 40 DEG C.. In initial lubrication of the lubricating system, the lubricant (10) for initial lubrication is essentially present at a sliding portion of the portion to be lubricated.

Owner:NTN CORP

Organic electric field light emitting element and production therefor

InactiveUS20110215312A1Improve luminous efficiencySatisfy lifeElectroluminescent light sourcesSolid-state devicesSimple Organic CompoundsOrganic electroluminescence

Owner:MITSUBISHI CHEM CORP

Si-based-alloy anode material

ActiveUS9508990B2Improve charge and discharge performanceLarge capacityNegative electrodesNon-aqueous electrolyte accumulator electrodesLithiumMetallurgy

Disclosed is a Si-based alloy anode material for lithium ion secondary batteries, including an alloy phase with a Si principal phase including Si and a compound phase including two or more elements, which includes a first additional element A selected from Ti, V, Cr, Mn, Fe, Co, Ni, Cu, Zr, Nb and Mg and a low-melting second additional element B selected from S, Se, Te, Sn, In, Ga, Pb, Bi, Zn, Al. This compound phase includes (i) a first compound phase including Si and the first additional element A; a second compound phase including the first additional element A and the second additional element B; and one or both of a third compound phase including two or more of the second additional elements B and a single phase of the second additional element B.

Owner:SANYO SPECIAL STEEL COMPANY

Carbon-dioxide-gas absorber, method for separating carbon-dioxide-gas using carbon-dioxide-gas absorber, and apparatus for separating carbon-dioxide-gas including carbon-dioxide-gas absorber

ActiveUS7670410B2Reduce bloatSatisfy lifeAlkaline earth titanatesIsotope separationStrontium carbonateComposite oxide

A carbon-dioxide-gas absorber includes a main component of composite oxide, the composite oxide including Ti and X that is at least one of Sr and Ba, and the composite oxide having a molar ratio (X / Ti) of about 1.8 to about 2.2. A substance having a perovskite structure and an (X / Ti) of about 0.9 to about 1.1 or at least one selected from green sheets, green sheet wastes, green-sheet-laminate wastes, and precursors of green sheets including the substance is fired with at least one of strontium carbonate and barium carbonate. An apparatus includes a carbon-dioxide-gas-absorbing mechanical unit that allows a carbon-dioxide-gas absorber to absorb a carbon dioxide gas at about 1.0×104 to about 1.0×106 Pa and at about 500° C. to about 900° C.; and a carbon-dioxide-gas-evolving mechanical unit that evolves the absorbed carbon dioxide gas at about 1000 Pa or less and at at least about 750° C.

Owner:MURATA MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com