Dynamic sealing device suitable for low-temperature and high-speed repeated use

A dynamic sealing, high-speed technology, applied to the components of pumping devices for elastic fluids, machines/engines, liquid fuel engines, etc. Seal wear, increase seal life, avoid dry friction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

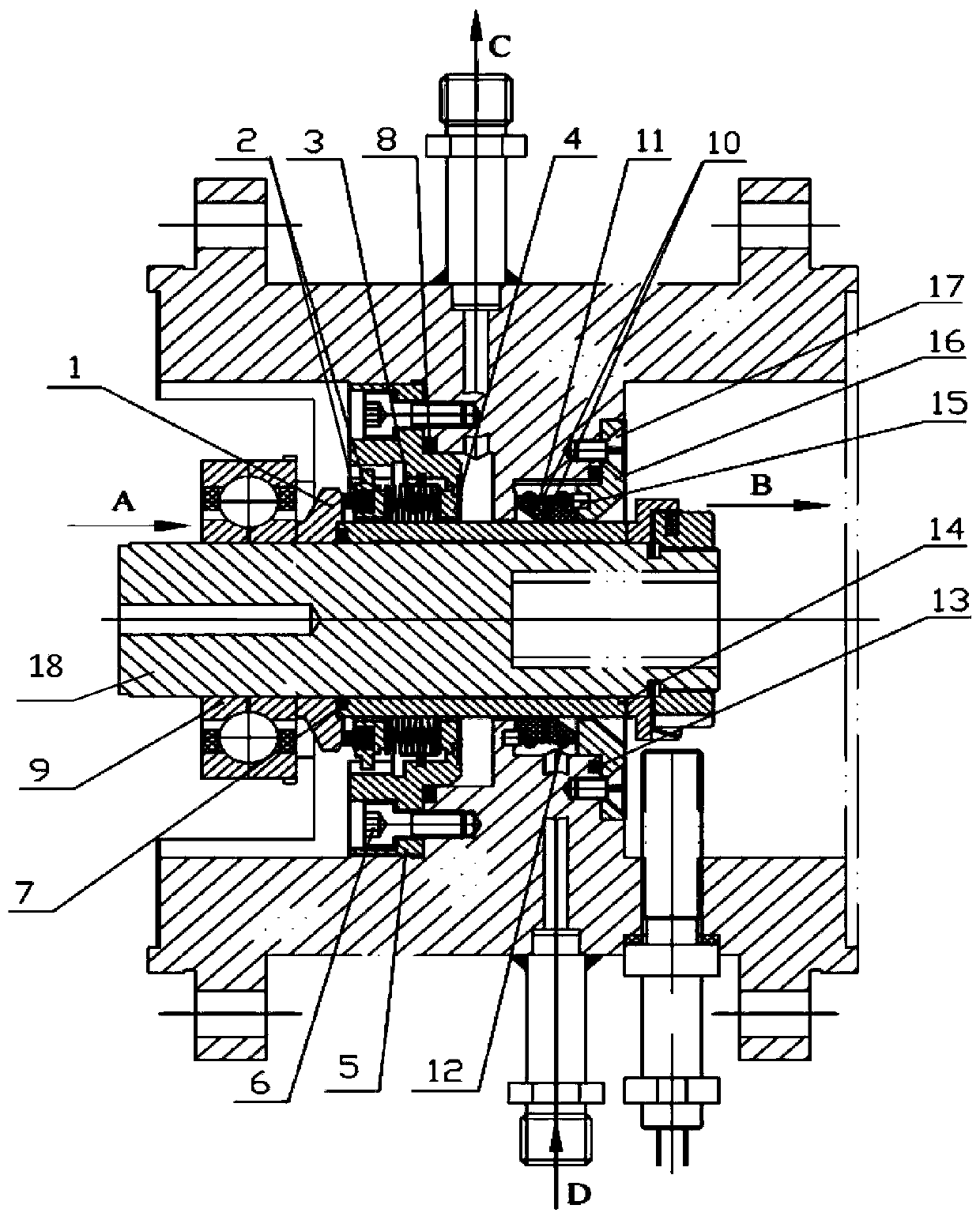

[0035] See figure 1 , figure 1 It is a schematic structural diagram of a dynamic sealing device suitable for low-temperature high-speed repeated use provided by an embodiment of the present invention. This embodiment provides a dynamic sealing device suitable for low-temperature and high-speed reuse. The dynamic sealing device is mainly used between the liquid oxygen pump and the methane pump of the liquid rocket engine to isolate liquid oxygen and methane. The two media belong to the sealing device for the turbopump of the liquid rocket engine. Of course, the dynamic sealing device can also be applied to the turbopump of other liquid rocket engines. The present invention can also be used in the rotating devices in the fields of aviation and weapons. No specific requirements are made here, the turbopump of the liquid rocket engine mainly includes a shaft 18 and a bearing 9 sleeved on the shaft 18, the dynamic sealing device includes a main sealing structure, and the main seal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com