Belted layer transferring ring

A technology of transfer ring and belt layer, applied in the field of rubber machinery, can solve the problems of easy collision of forming drum, malfunction of magnetic steel, difficult synchronous movement of clamping claws, etc., to avoid dry friction, improve dynamic balance, and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

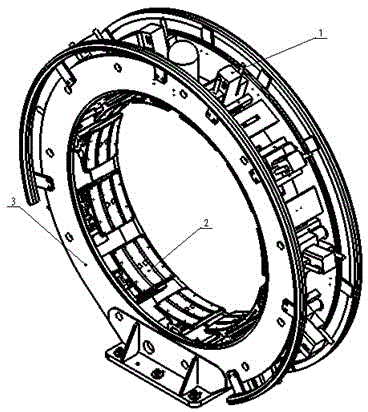

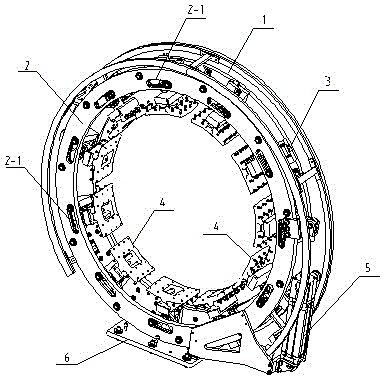

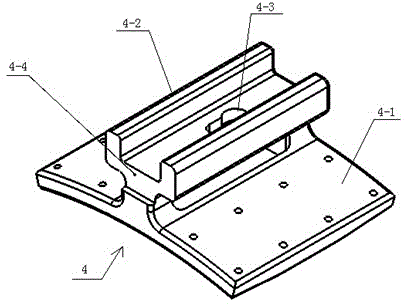

[0036] refer to figure 2 , The belt transfer ring in this embodiment includes: a fixed disc 1 , a drive disc 2 , a clamping claw bracket 3 , a clamping claw 4 and an air cylinder 5 . The fixed disk 1 is fixed on the base 6; the driving disk 2 is rotatably mounted on the fixed disk 1, and the disk surface of the driving disk 2 is provided with a plurality of elongated holes 2-1, and the elongated holes 2-1 Arranged evenly along the circumferential direction, in order to reduce the weight of the disc body and save energy consumption, the material of the drive disc in this embodiment is carbon fiber or super duralumin; the clamping claw bracket 3 is used to fix and clamp the four claws, and itself The sliding part cooperates with the fixed disk 1; the cylinder 5 is used to drive the driving disk 2 to rotate back and forth, and then dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com