Lubricating system, bearing utilizing the system, universal joint utilizing the system, and process for production thereof

A technology of universal joint and lubrication system, applied in the field of lubrication system, can solve the problems of difficulty, complicated operation, difficult assembly of parts with solid lubricant, etc., and achieve the effect of excellent running-in performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~ Embodiment 2

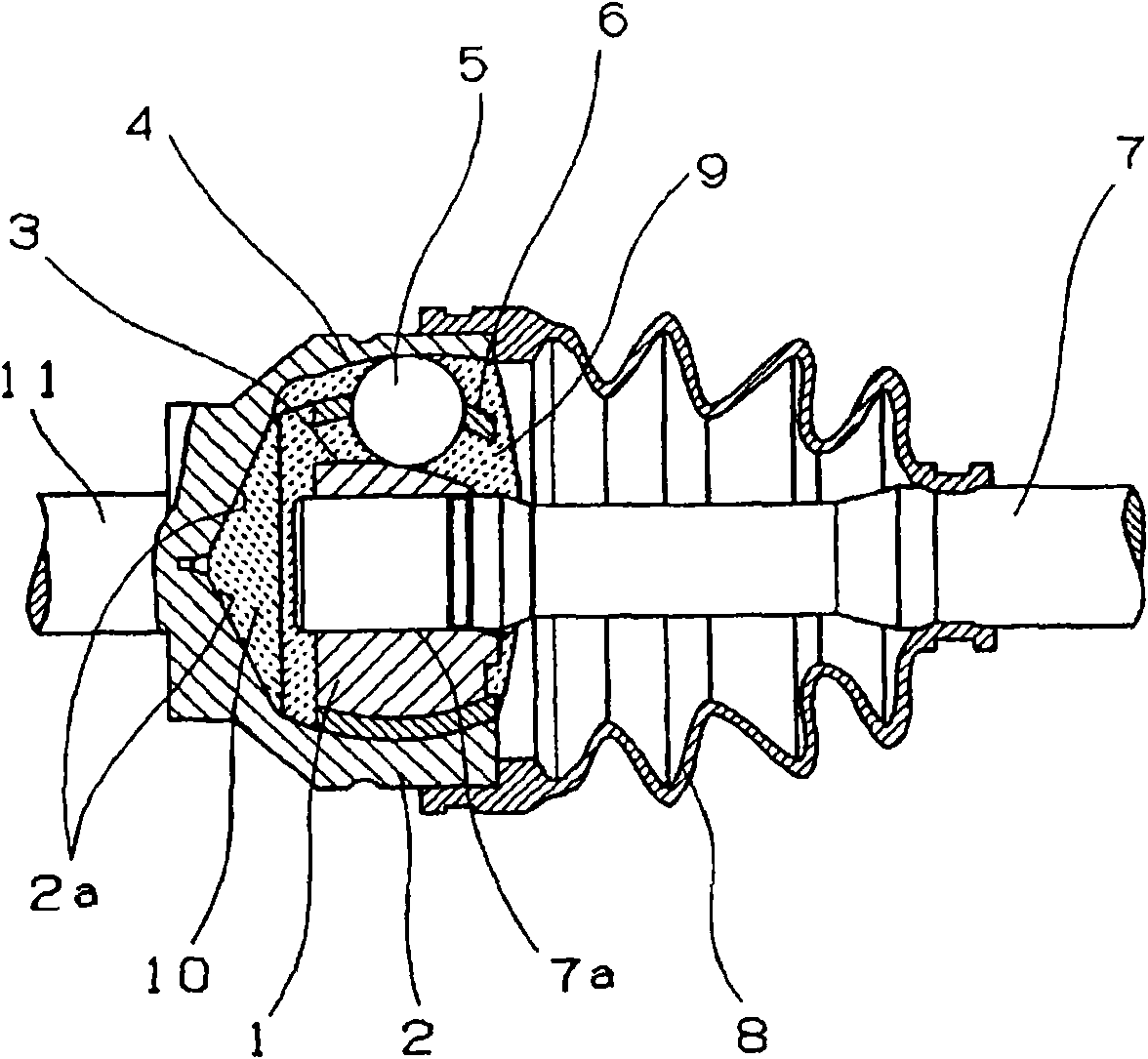

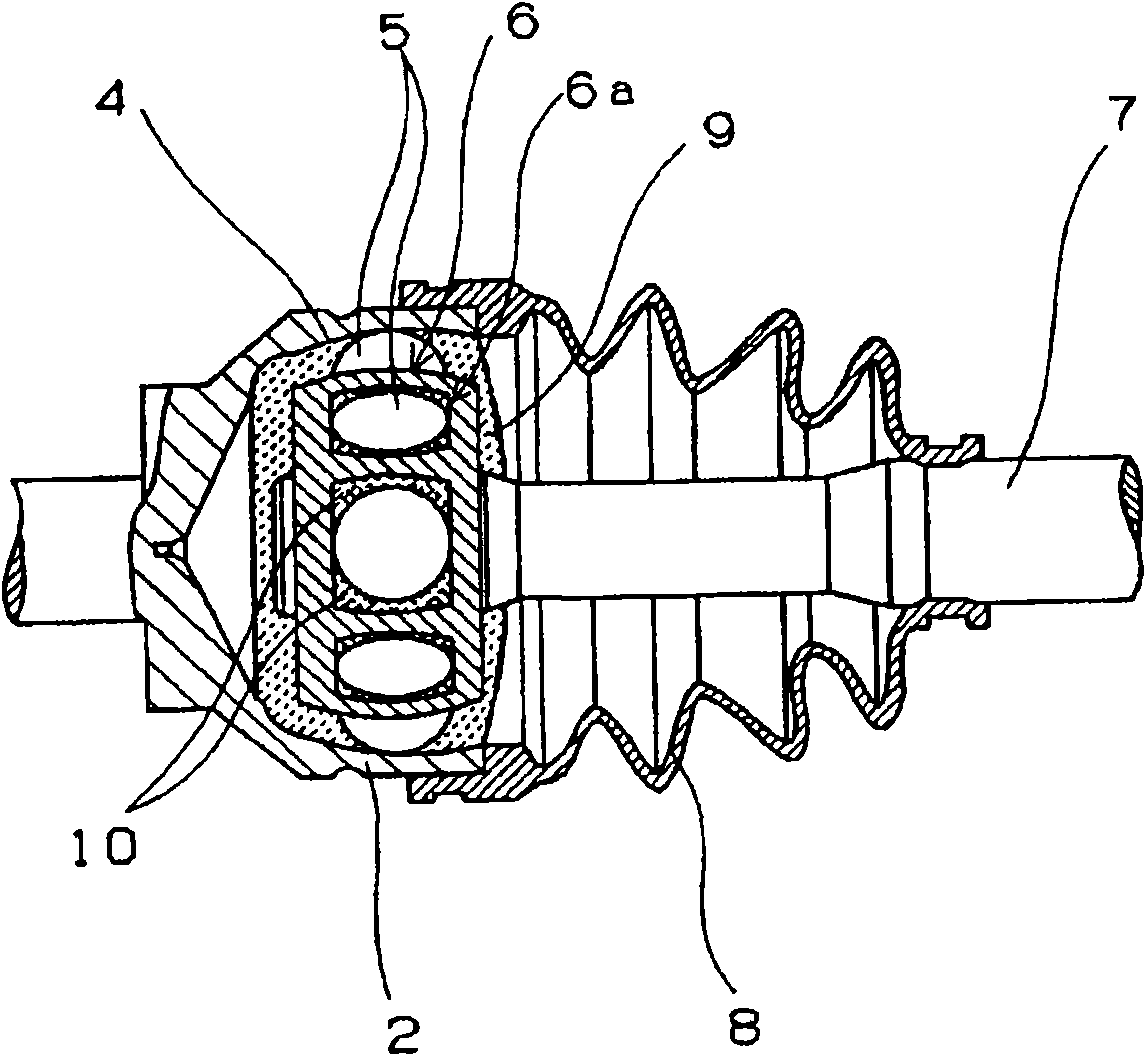

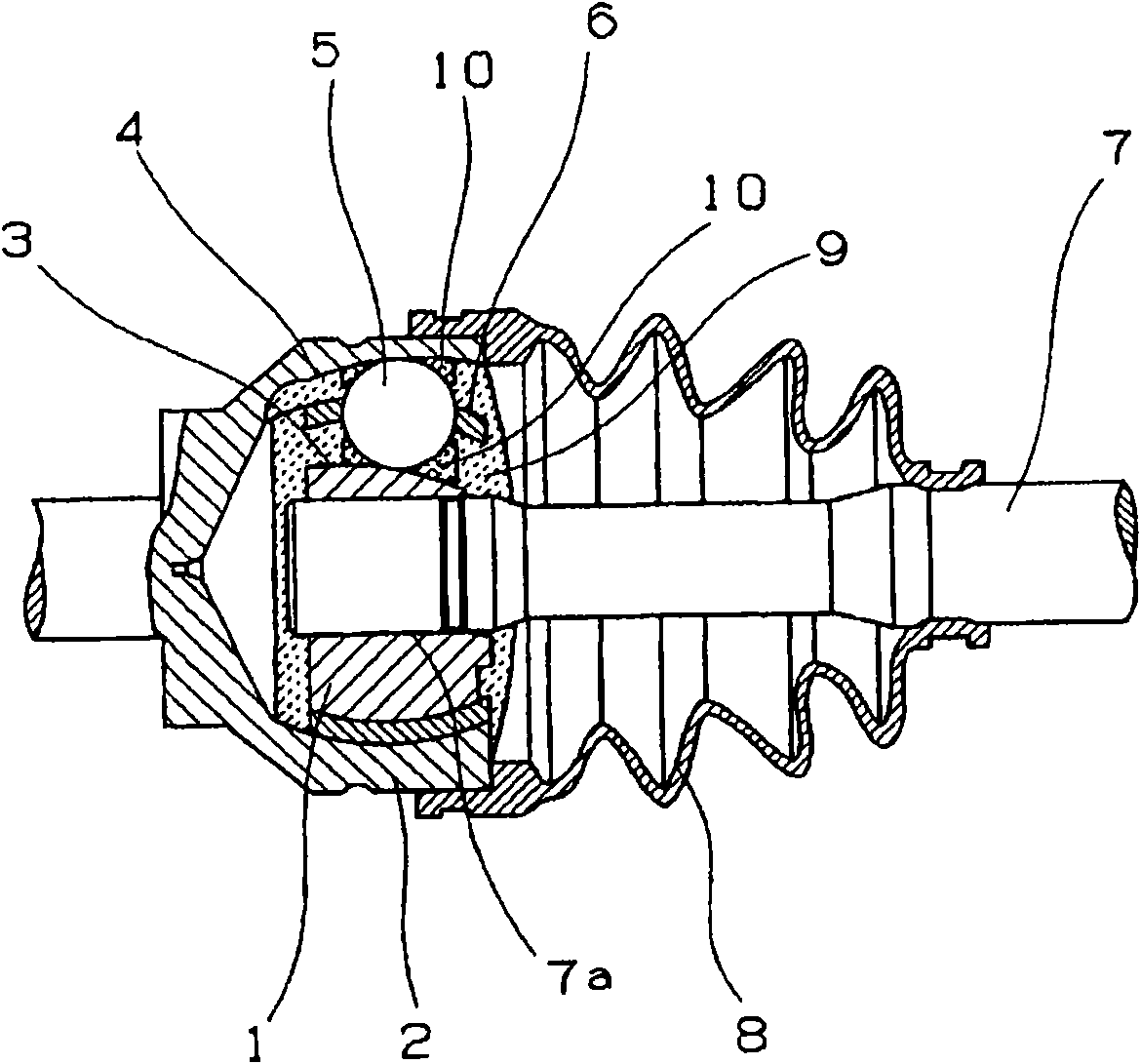

[0286] First, to figure 1 The bottom of the outer member shown, where eight fixed ball joint assemblies (EBJ82 manufactured by NTN Corporation, with an outer diameter of 72.6mm) assembled with the outer member 2, the inner member 1, the bearing cage 6 and the torque transmission member 5 , 5 g of initial lubrication grease shown in Table 1 was enclosed. Next, (a), (d), (e), and (i) in the composition shown in Table 1 were thoroughly mixed at 80°C, and (b) dissolved at 120°C was added and quickly mixed . Finally, (c) and (h) were thrown in and stirred, and then 15.0 g of the grease for initial lubrication was sealed in the joint. A few seconds later, the foaming reaction started, and it was placed in a constant temperature bath set at 100°C for 30 minutes to solidify, and other components such as a protective cover and a shaft were assembled to obtain a test piece of a constant velocity universal joint using a lubrication system. The obtained test piece was subjected to the ...

Embodiment 3~ Embodiment 4

[0300] First, in figure 1 The bottom of the outer member shown in the fixed 8-piece ball joint assembly (EBJ82 manufactured by NTN Co., Ltd. with an outer diameter of 72.6 mm) assembled with the outer member 2, the inner member 1, the bearing cage 6 and the torque transmission member 5 , 5 g of grease for initial lubrication shown in Table 1 was enclosed. A silicone-based foam stabilizer, mineral oil, an amine-based catalyst, and water as a foaming agent were added to the polyether polyol in the amount of components (composition) shown in Table 1, and heated at 90°C to fully stir. After adding isocyanate thereto and stirring well, 13.0 g of the above-mentioned joint which had already been sealed with grease for initial lubrication was sealed. After a few seconds, the foaming reaction started, and it was placed in a constant temperature bath set at 90°C for 15 minutes to solidify, and other components such as a protective cover and a shaft were assembled to obtain a test piece...

Embodiment 5~ Embodiment 6

[0312] First, in figure 1 Bottom of the outer member shown in the fixed 8-piece ball joint assembly (EBJ 82 manufactured by NTN Corporation with an outer diameter of 72.6mm) assembled with the outer member 2, the inner member 1, the bearing cage 6 and the torque transmission member 5 , 5 g of grease for initial lubrication shown in Table 2 was enclosed. Next, (a), (d), (e), and (i) in the composition shown in Table 2 were thoroughly mixed at 80°C, and then (b) dissolved at 120°C was added and quickly mixed. . Finally, (c) and (h) were thrown in and stirred, and then 15.0 g of the grease for initial lubrication was sealed in the joint. A few seconds later, the foaming reaction started, and it was placed in a constant temperature bath set at 100°C for 30 minutes to solidify, and other components such as a protective cover and a shaft were assembled to obtain a test piece of a constant velocity universal joint using a lubrication system. The same items as in Example 1 were mea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| torque | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com