Tube and its manufacturing method

一种制造方法、管体的技术,应用在制造工具、其他家里用具、车削设备等方向,达到实现制造成本、制造工序简化的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

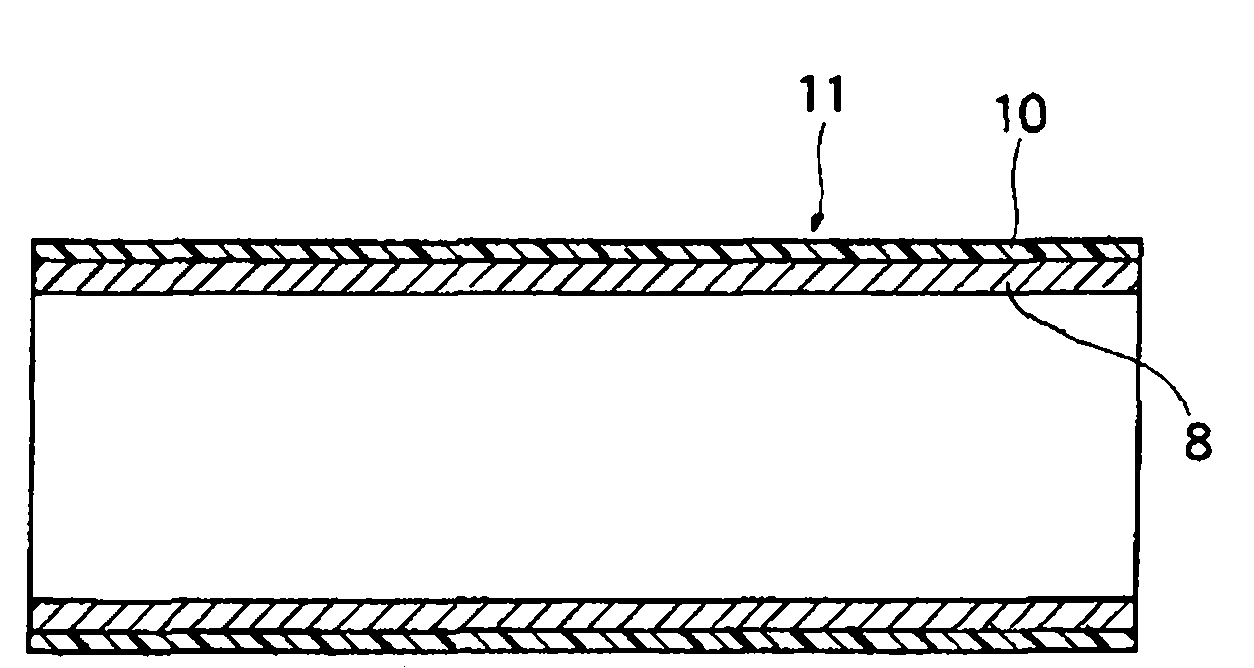

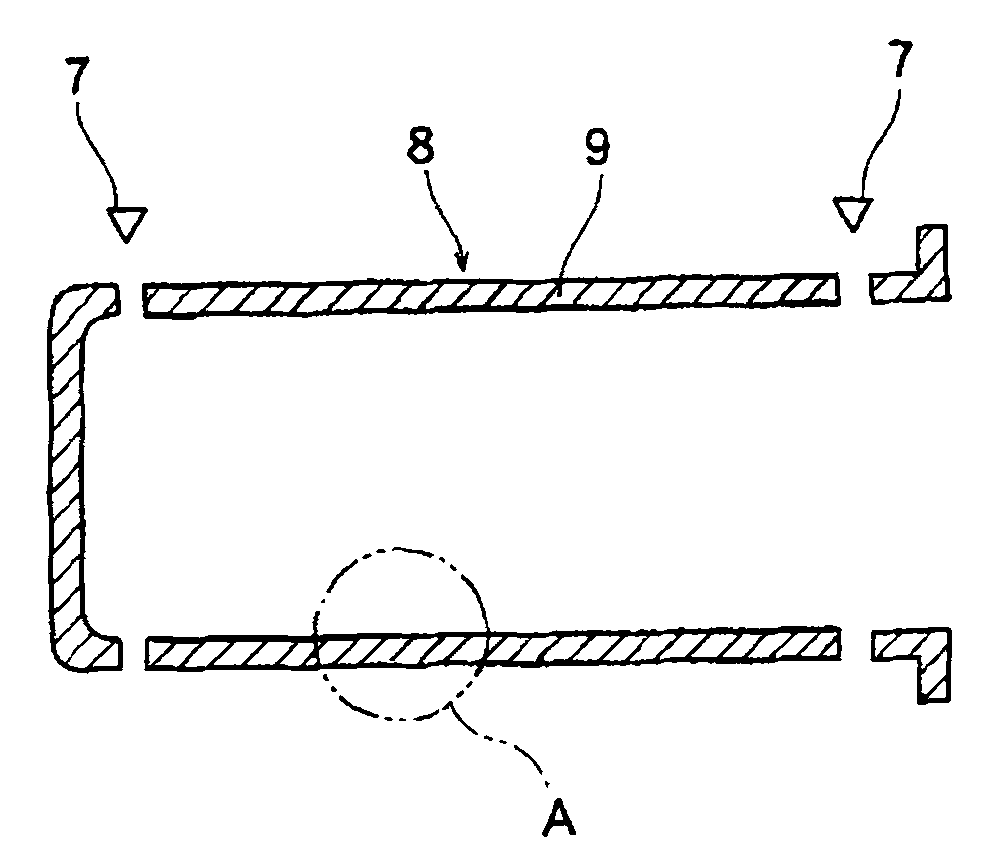

[0066] Next, it was confirmed that indentations were formed in a helical pattern on the surface of the metal tube 8 subjected to the spinning process on the bottomed blank tube 1 made of a plastically workable metal.

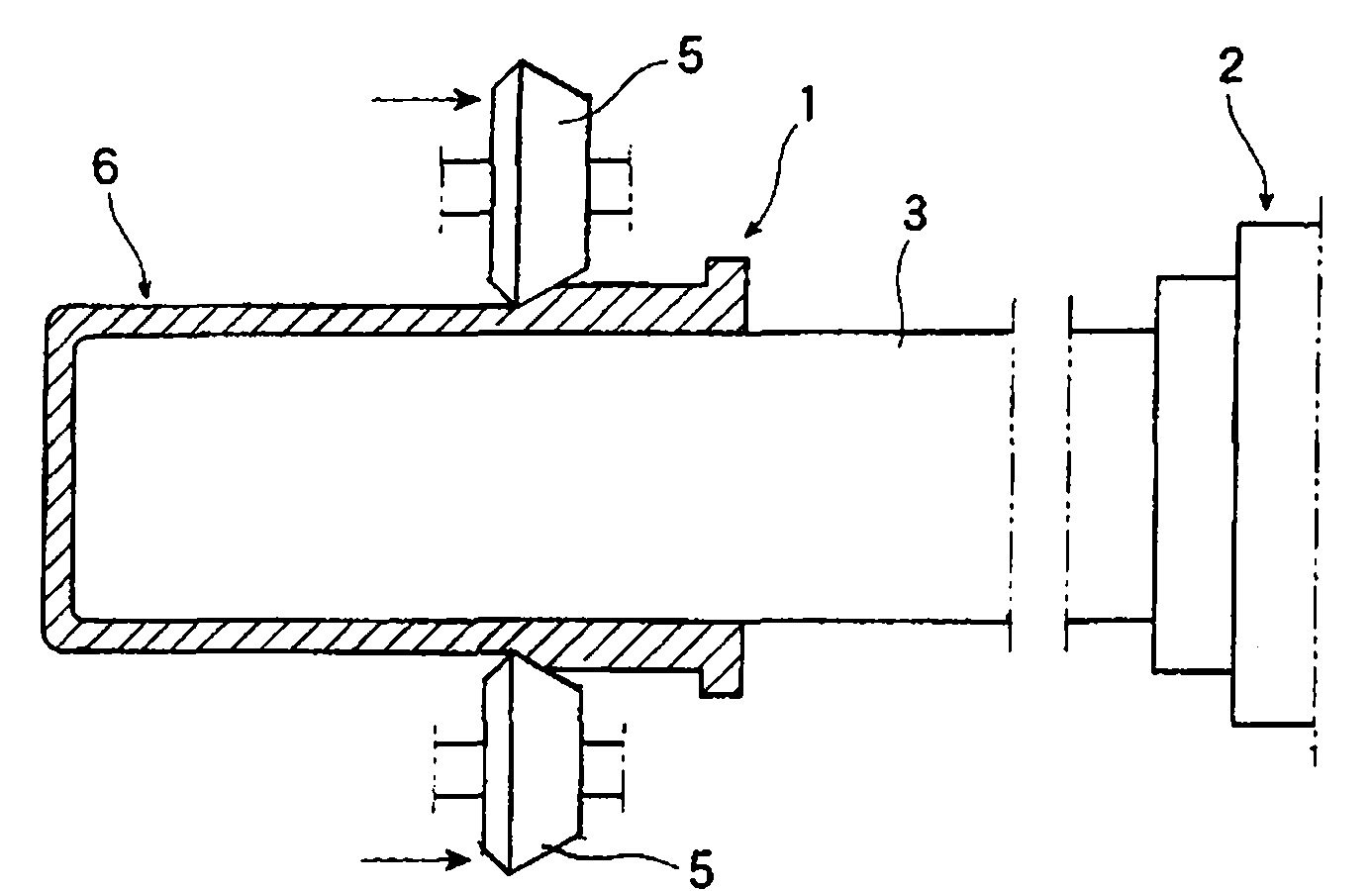

[0067] The material of the metal prototype 6 is SUS304 which is austenitic stainless steel. In addition, three stoppers 5 are arranged at equal intervals of 120 degrees on the outer periphery of the metal original body 6, and spinning is performed. The metal original body 6 is formed by rotating the bottomed blank tube 1 at a predetermined rotational speed while moving the stopper 5 at a predetermined moving speed and performing spinning.

[0068] The surface shape of the metal pipe 8 was measured with a surface roughness profile measuring device [product name: Surfcom 130A, manufactured by Tokyo Seiki Co., Ltd. (Tokyo, Japan)]. In other words, whether or not spiral-shaped indentations are formed on the surface shape of the metal pipe 8 is measured with a surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com