A kind of anti-icing coating with low ice adhesion and its preparation method and application

An anti-icing and adhesion technology, applied in coatings, polyurea/polyurethane coatings, etc., can solve problems such as loss of lubricating layer, high cost of antifreeze protein preparation, and difficulty in secondary deicing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

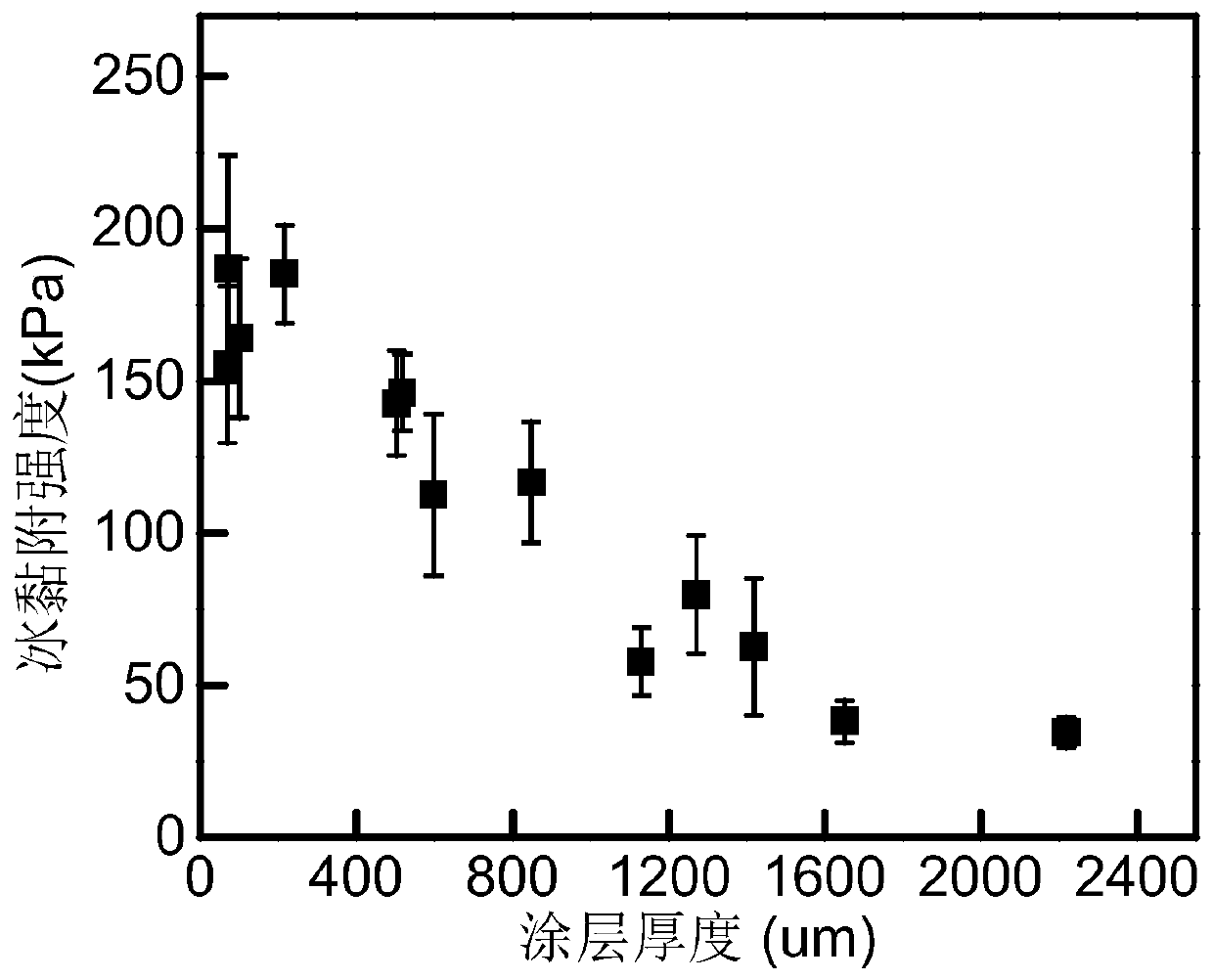

[0056] As mentioned above, the present invention provides a kind of preparation method of the anti-icing coating of low ice adhesion, in a preferred embodiment of the present invention, the specific preparation method of described anti-icing coating comprises:

[0057] (1) Dissolve a certain ratio (stoichiometric or excess) of prepolymers and cross-linking agents with free chain components (may not be added), or a certain mass of long-chain polymers, mix evenly, and centrifuge at 6000r / min for 10min , evacuating in a vacuum drying oven for 0.5h to remove air bubbles to obtain the anti-icing coating;

[0058] (2) coating the coating in step (1) after removing air bubbles on the surface of the cleaned substrate, leveling it into a film layer with a uniform thickness of 0.01 to 2.5 mm, and curing it by heat (or UV curing) to obtain the described Anti-icing coating.

[0059] In the present invention, the curing temperature is controlled at 25-70°C and the curing time is controlle...

Embodiment 1

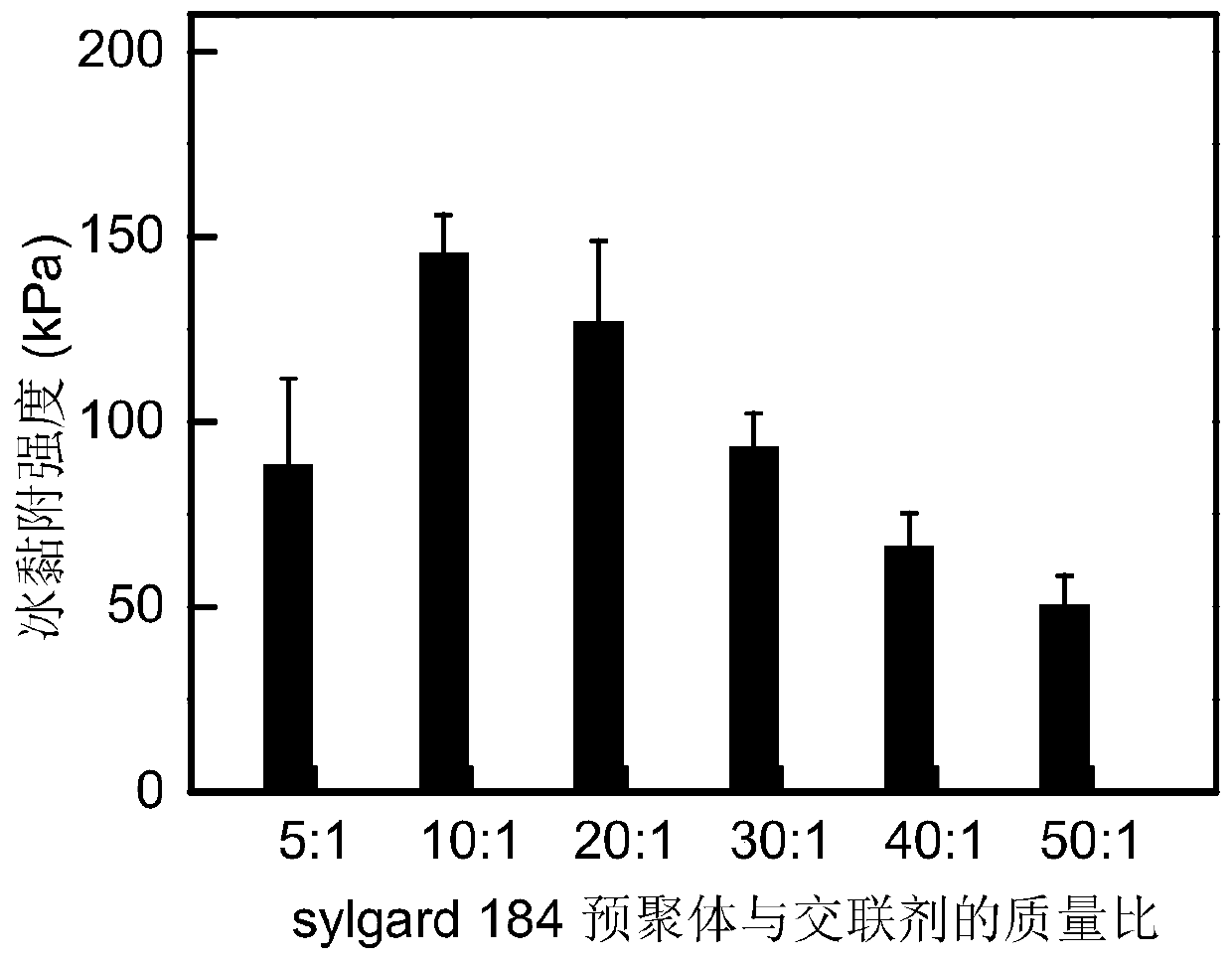

[0069] Change the mass ratio of prepolymer and crosslinking agent in Sylgard 184 to reduce the modulus of polymer elastic network and realize low ice adhesion of anti-icing coating. The free chain is an excess of siloxane prepolymer or crosslinking agent.

[0070] Mix the prepolymer and crosslinking agent in Sylgard 184 according to the mass ratio of 5:1, 10:1, 20:1, 30:1, 40:1, 50:1, centrifuge at 6000r / min for 10min, and dry in vacuum Vacuum the box for 30 min to remove air bubbles.

[0071] Use a clean silicon wafer as the substrate, spread it on a petri dish, level it into a coating of about 1.6mm, and cure it at 70°C for 12.5 hours to obtain an anti-icing coating with low ice adhesion.

[0072] When the ambient temperature is -30°C and the ambient humidity is 50%, freeze for 5 hours to test its anti-icing performance.

[0073] The results show that: by figure 1 It can be seen that when the ratio of siloxane prepolymer to crosslinking agent is 10:1, the anti-icing abili...

Embodiment 2

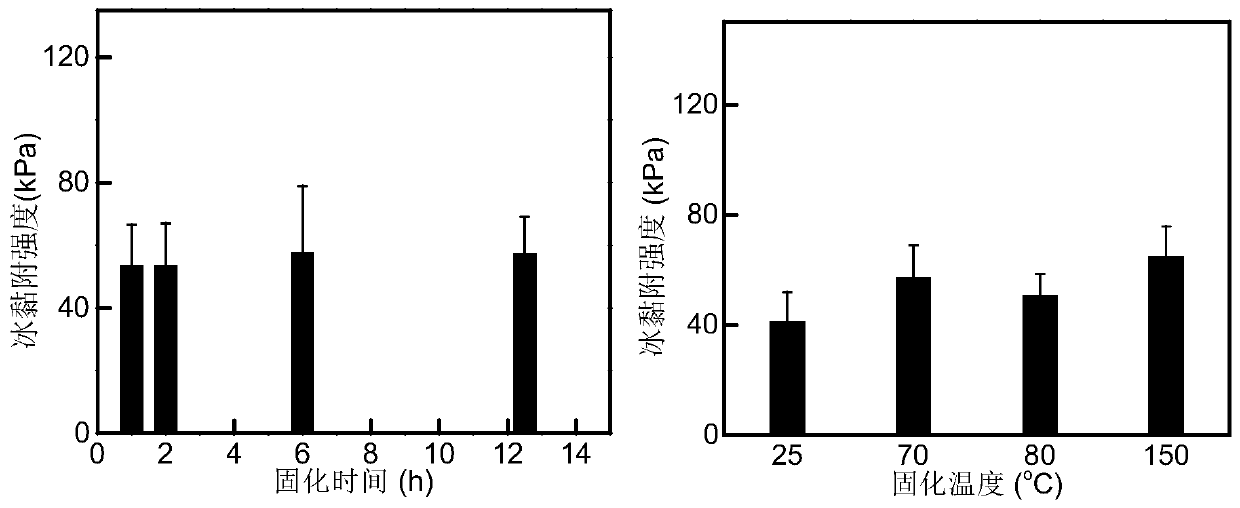

[0075] The temperature and time of crosslinking reaction between siloxane prepolymer and crosslinking agent in Sylgard 184 were changed to adjust the modulus of polymer elastic network, and the effect on low ice adhesion of anti-icing coating was studied. The free chain is an excess of siloxane prepolymer.

[0076] Mix the siloxane prepolymer and cross-linking agent in Sylgard 184 evenly at a mass ratio of 50:1, centrifuge at 6000r / min for 10min, and vacuum in a vacuum oven for 30min to remove air bubbles.

[0077] (1) Use a clean silicon wafer as the base material, spread it in a petri dish, level it into a coating of about 1.6mm, and cure it at 70°C for 1h to 12.5h to obtain an anti-icing coating.

[0078] (2) Use a clean silicon wafer as the substrate, spread it in a petri dish, level it into a coating of about 1.6mm, and cure it at 25°C, 70°C, 80°C, and 150°C for 12.5 hours to obtain an anti-icing coating Floor.

[0079] When the ambient temperature is -30°C and the ambi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com