Electrohydraulic pressure control device for automotive brake systems

A braking system and pressure control technology, applied in the direction of brakes, braking components, electrical components, etc., can solve the problems of making sufficient optimization for mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

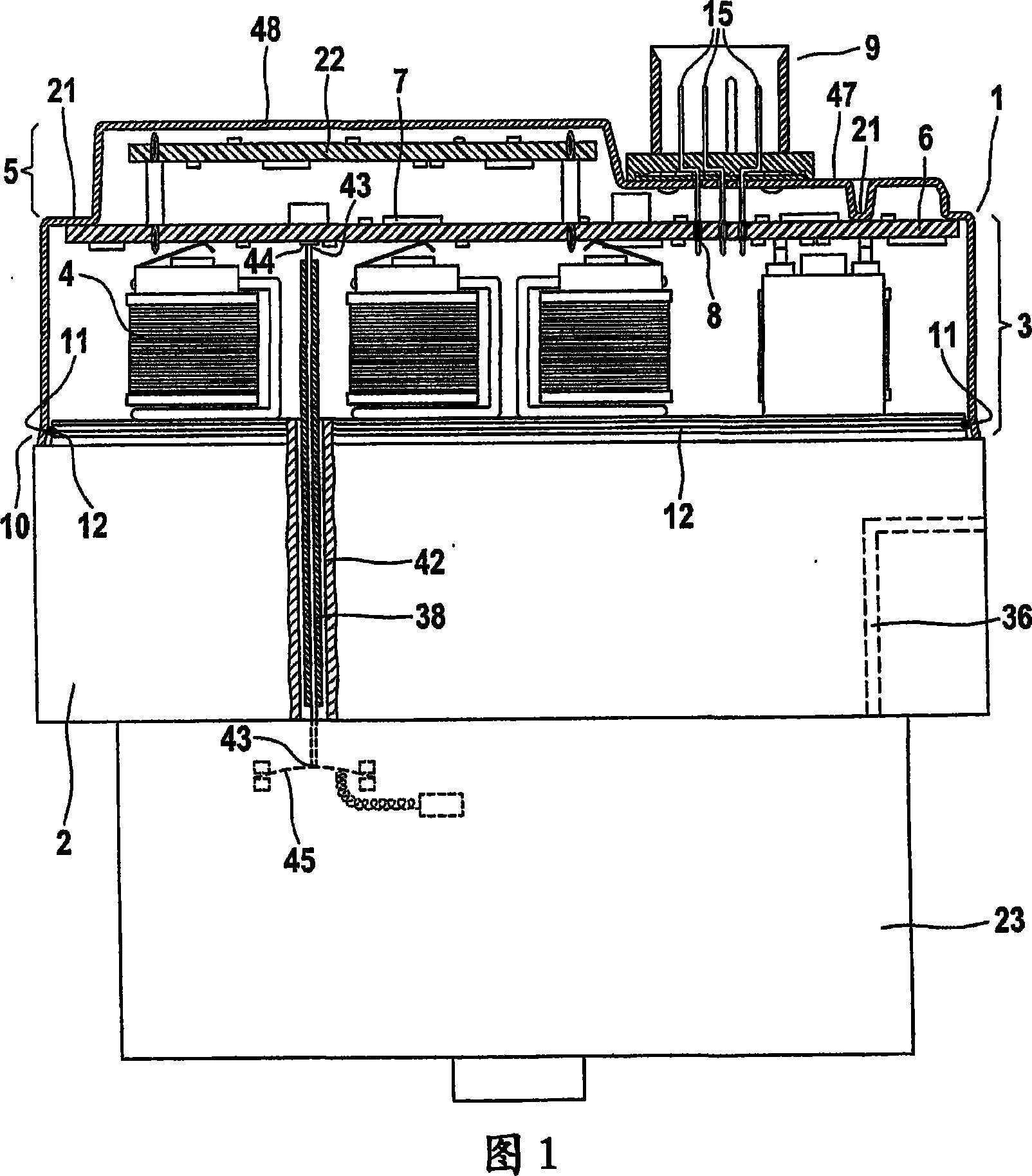

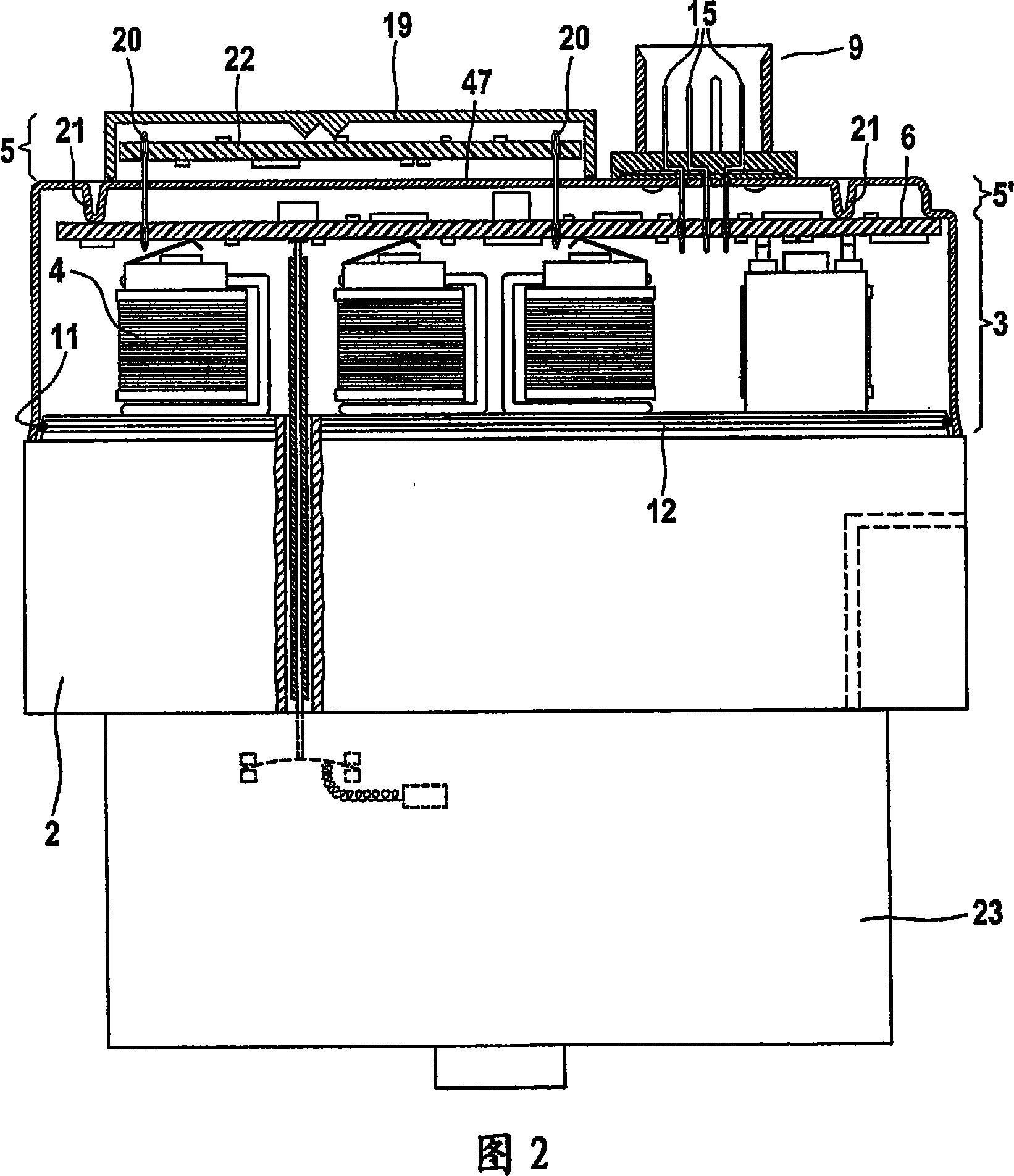

[0033] Figure 1 shows a combined ABS / ESP control. The controller 1 , the valve group 2 and the motor unit 23 represent a compact structural unit as installed in a motor vehicle for the control operation of the brakes generally. To this end, the valve block 2 is connected to a hydraulic line (not shown). The electronic control unit 7 on the printed circuit board 6 can engage the wire harness through the engaging plug 9 . Protrusions 21 on the cover push the printed circuit board 6 in the direction of the valve block 2 opposite the electrical contacts of the valve coil 4 .

[0034] The shape of the one-piece controller housing corresponds substantially to that of a thin-walled metal housing that is open at the bottom. Accordingly, the controller housing is composed of a housing volume area 3 and a housing cover area 5 .

[0035] The motor unit 23 is electrically connected through an insulated plastic adapter (motor plug) 38 with metal contained therein, which leads to the pum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com