Key structure for large load motor iron core and rotating shaft transmitting torque, and installation method thereof

A technology for transmitting torque and large load, applied in the direction of magnetic circuit shape/style/structure, key connection, connecting member, etc., can solve the increase of equipment process requirements, the sliding of rotor core and shaft, and the inability of rotor punching and shaft to synchronize. Problems such as production, to achieve the effect of easy mass production and convenient assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

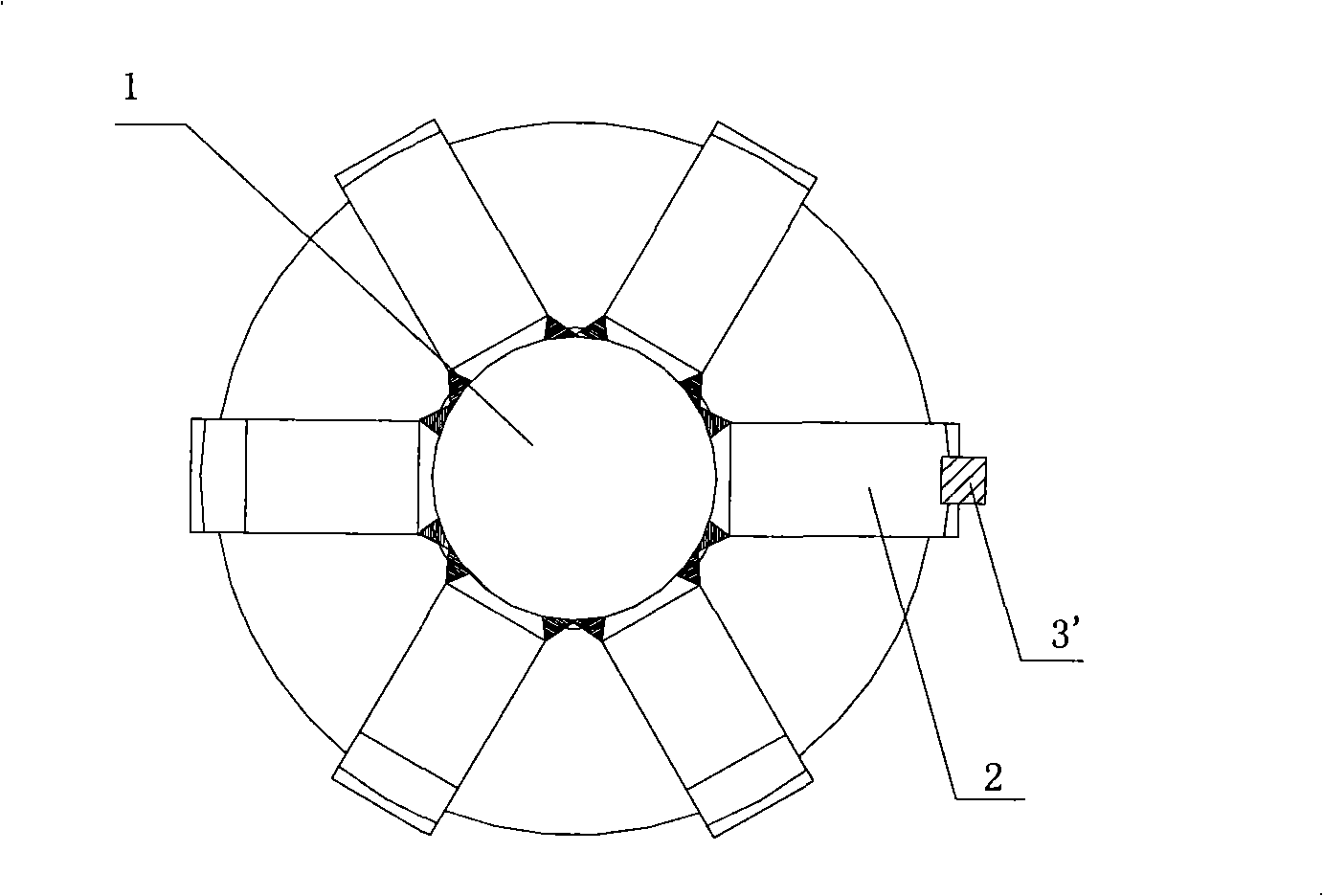

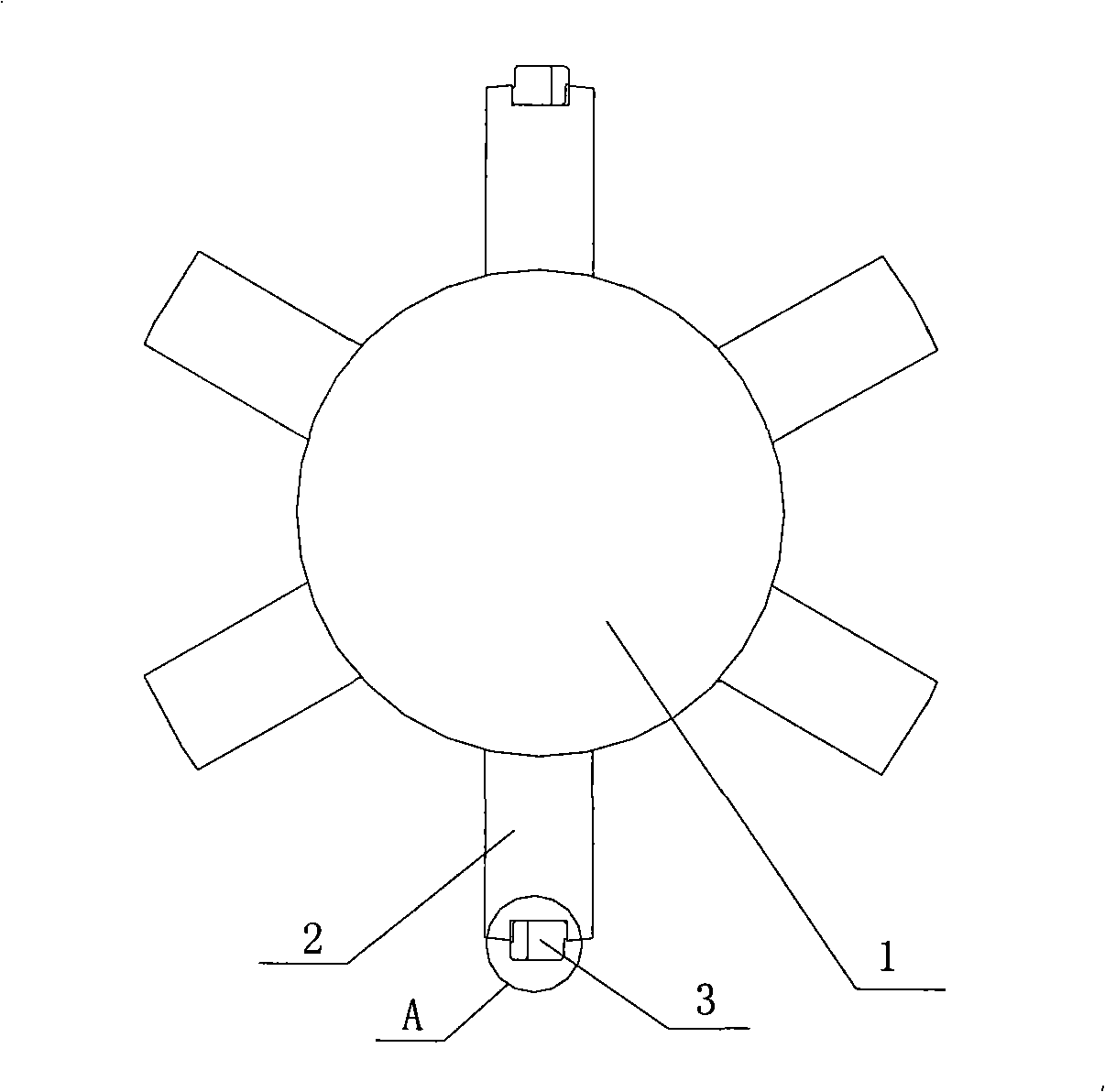

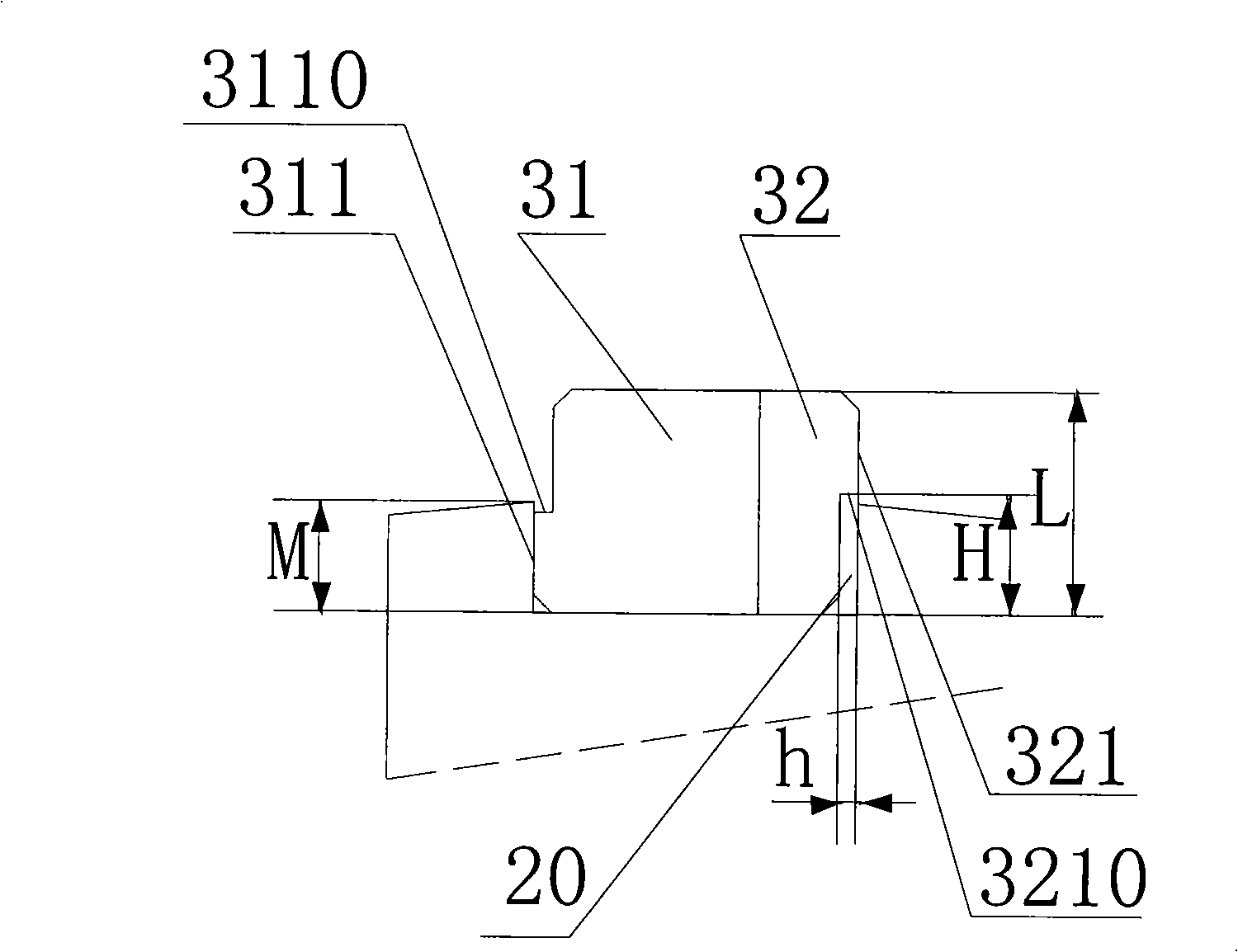

[0016] see figure 2 , a structure of a key for the torque transmission between the iron core of a large-load motor and the rotating shaft of the present invention, including at least one pair of key grooves (not shown in the figure) relative to 180° on the inner circle of the iron core, and evenly arranged on the outer peripheral surface of the motor rotating shaft 1. Several welding bars 2, key slots 20 corresponding to the key slots of the iron core provided on the outer circumference of the welding bars 2, and keys 3 embedded in the key slots of the two.

[0017] If the motor is single steering, a pair of key grooves 20 with a relative position of 180° are arranged on the outer circle of the welding rib 2 of the rotating shaft 1, and a pair of key grooves corresponding to the welding rib 2 are also arranged on the inner circle of the iron core. If the motor is required to have forward and reverse rotation, two pairs of key grooves 20 are arranged on the outer circle of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com