Mixed gel polymer electrolyte and preparation method thereof, and all-solid-state zinc ion battery

A technology of mixing gel and electrolyte, applied in the direction of electrolyte immobilization/gelation, electrolyte, secondary battery, etc., can solve the problems of high and low temperature resistance, hydrogen gas flatulence, dendrite problem and other active substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

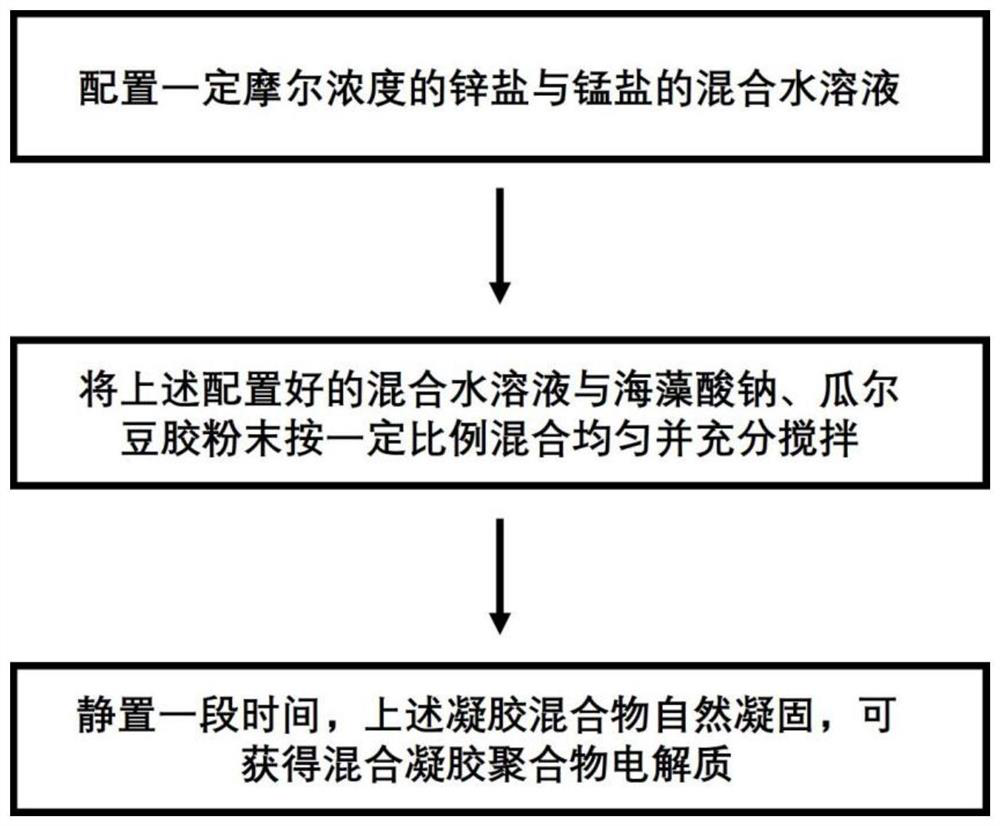

[0049] The present invention also provides a method for preparing a mixed gel polymer electrolyte, comprising the following steps:

[0050] Sodium alginate and guar gum are mixed with an aqueous electrolyte solution, and after the gel is stabilized, a mixed gel polymer electrolyte is obtained.

[0051] In the present invention, the electrolyte is preferably first dissolved in deionized water to obtain a certain concentration of electrolyte aqueous solution;

[0052] Then mix sodium alginate and guar gum with the electrolyte aqueous solution evenly, repeat stirring, and let it stand at room temperature for a period of time until the sodium alginate and guar gum polymer are solidified and stable, and the mixed coagulation can be obtained. gel polymer electrolyte.

[0053] In the present invention, zinc salt and / or manganese salt are preferably included in the aqueous electrolyte solution, and the concentration of zinc salt is preferably 1-3 mol / L, such as 1 mol / L, 1.5 mol / L, 2 ...

Embodiment 1

[0061] Example 1 Sodium Alginate Guar Gum (SAGG) Mixed Gel Polymer Electrolyte

[0062] Step 1. Configure 2MZnSO 4 and 0.1MMnSO 4 The mixed electrolyte aqueous solution;

[0063] Step 2: Take 10 mL of the above-mentioned mixed electrolyte aqueous solution, 0.4 g of sodium alginate and 0.2 g of guar gum and mix them uniformly with each other, and stir thoroughly to obtain a mixed gel.

[0064] Step 3, take the above-mentioned gel, let it stand in a petri dish at room temperature, after a certain period of time, the mixed polymer of sodium alginate and guar gum solidifies, and obtains sodium alginate guar gum (SAGG) mixed gel polymerization matter electrolyte.

[0065] see figure 1 , figure 1 The preparation method flowchart of sodium alginate guar gum (SAGG) mixed gel polymer electrolyte provided for the embodiment of the present invention;

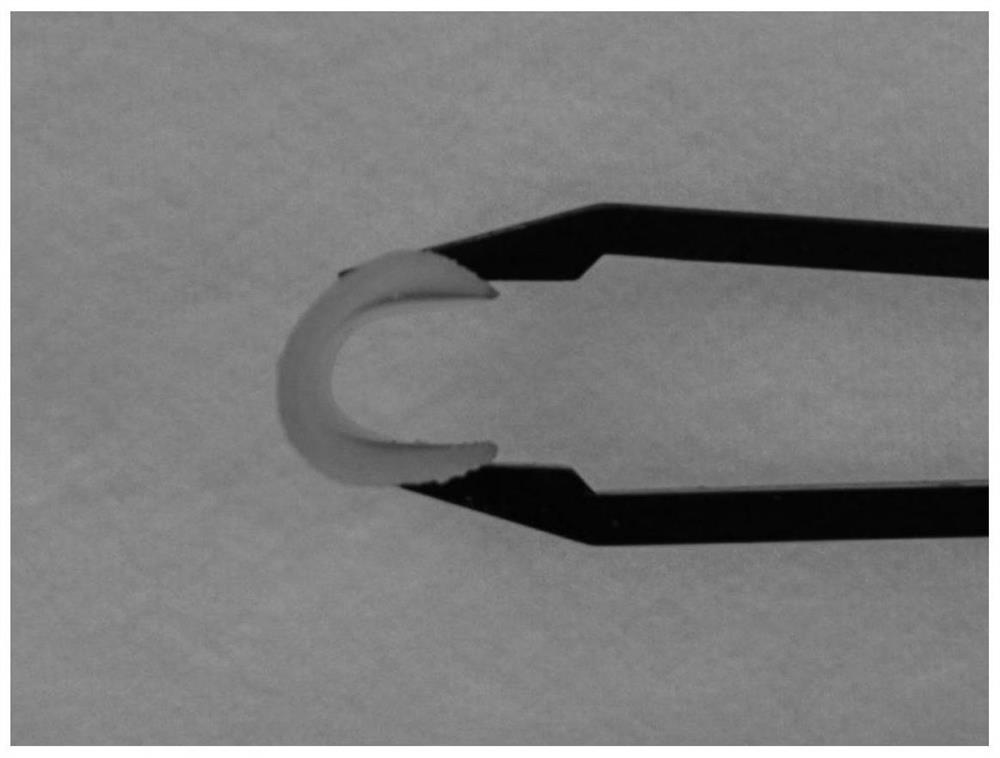

[0066] figure 2 The physical photograph of the sodium alginate guar gum (SAGG) mixed gel polymer electrolyte prepared for Example...

Embodiment 2

[0068] Example 2 Sodium Alginate Guar Gum (SAGG) Mixed Gel Polymer Electrolyte Used in All-Solid Zinc-ion Batteries

[0069] Step 1. Configure 2MZnSO 4 and 0.1MMnSO 4 The mixed electrolyte aqueous solution;

[0070] Step 2: Take 10 mL of the above-mentioned mixed electrolyte aqueous solution, 0.4 g of sodium alginate and 0.2 g of guar gum and mix them uniformly with each other, and stir thoroughly to obtain a mixed gel.

[0071] Step 3, take the above-mentioned gel, let it stand in a petri dish at room temperature, after a certain period of time, the mixed polymer of sodium alginate and guar gum solidifies, and obtains sodium alginate guar gum (SAGG) mixed gel polymerization matter electrolyte.

[0072] Step 4, put the sodium alginate guar gum (SAGG) mixed gel polymer electrolyte obtained above into the zinc ion battery system in the order of positive pole, polymer electrolyte and negative pole, Figure 4 The structural representation of the all-solid-state zinc-ion batter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ionic conductivity | aaaaa | aaaaa |

| Ionic conductivity | aaaaa | aaaaa |

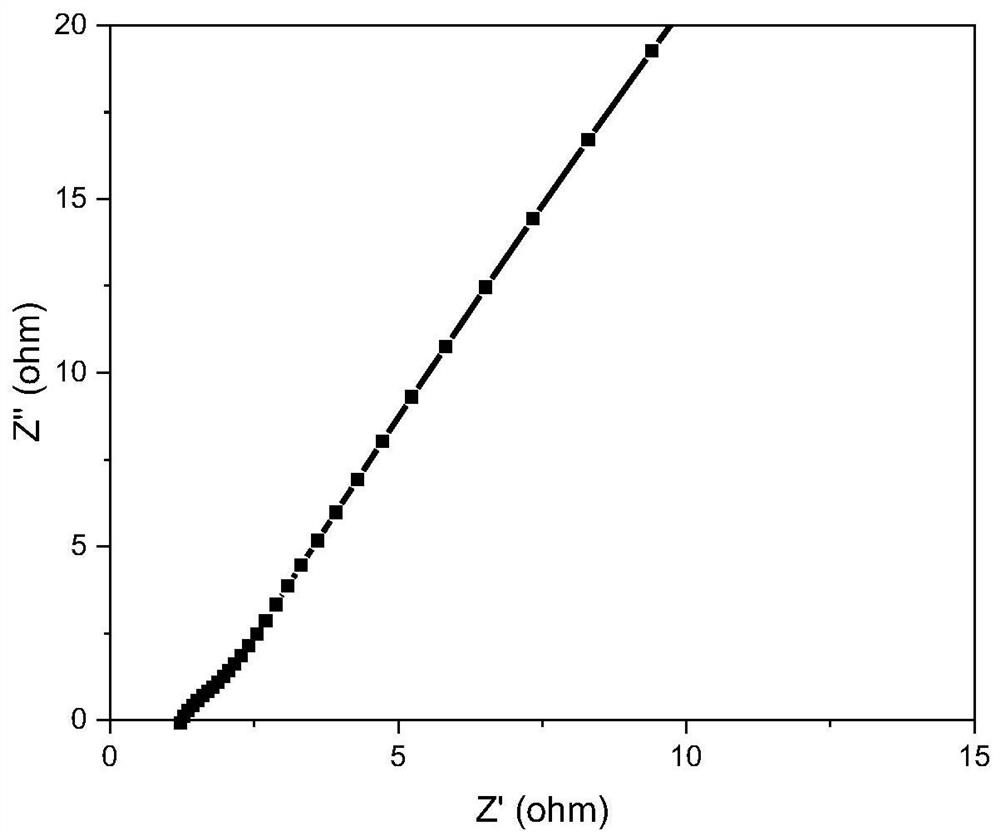

| Impedance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com