Cerium fluoride porous nanosheet regulated mixed matrix membrane, preparation method and application thereof

A technology of mixed matrix membrane and cerium fluoride, applied in the preparation/treatment of rare earth metal compounds, chemical instruments and methods, nanotechnology, etc., can solve processing difficulties, poor chemical corrosion resistance of polymer materials, gas permeability and selectivity and other problems, to achieve the effects of improving solubility, improving water vapor permeability coefficient and water vapor/nitrogen selectivity, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] An embodiment of the present invention provides a method for preparing a mixed matrix membrane regulated by porous nanosheets of cerium fluoride as described above, which specifically includes the following steps:

[0040] (1) dissolving the polymer matrix in a solvent to prepare a polymer matrix solution;

[0041] Among them, the polymer matrix is polyether block polyamide (PEBAX1074 or PEBAX2533), perfluorosulfonic acid resin, sulfonated polyetheretherketone, sulfonated polysulfone, sulfonated polyethersulfone, sulfonated polyphenylene ethersulfone Any one or a mixture of the two; the mass concentration of the polymer matrix solution is 5% to 20%, and the solvent is one of n-butanol, N-methylpyrrolidone, dimethylacetamide, dimethylformamide or various mixes;

[0042] (2) Add porous cerium fluoride nanosheets to the polymer matrix solution, heat and stir, defoam, form a membrane, remove residual solvent in the membrane, and obtain a mixed matrix membrane regulated b...

Embodiment 1

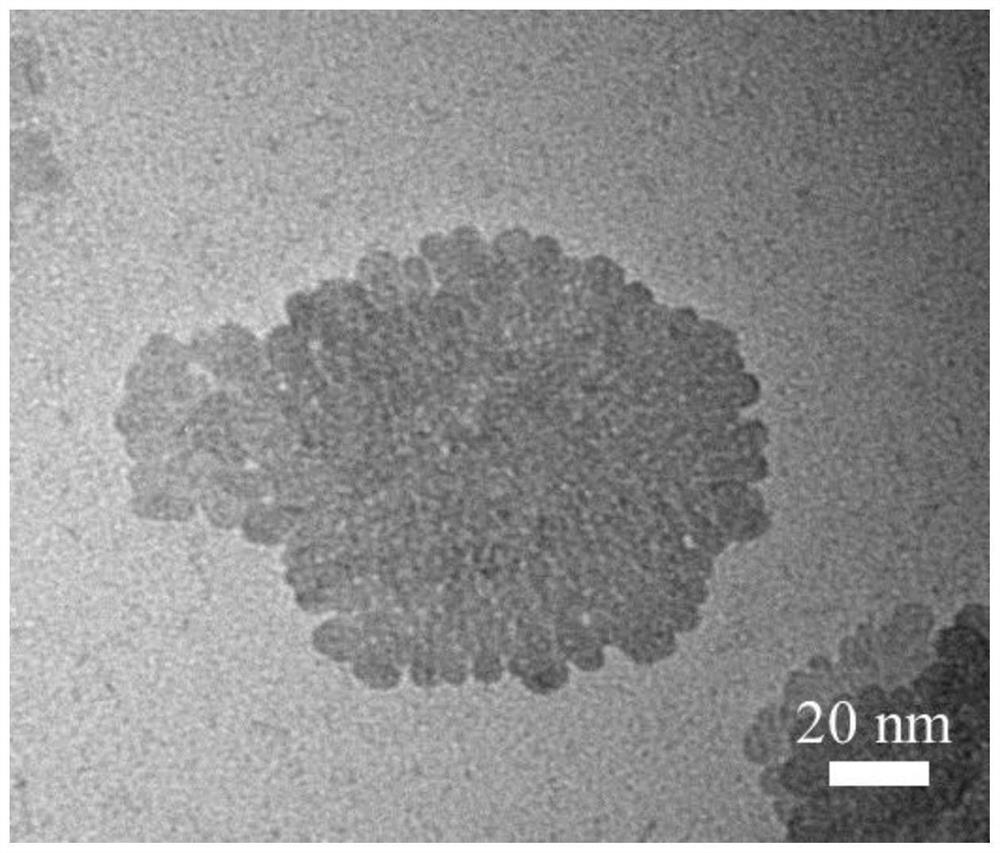

[0044] Embodiment 1 of the present invention discloses a preparation method of porous cerium fluoride nanosheets, the specific steps are:

[0045] (1) Rinse the instrument with ultrapure water several times until the surface of the instrument is clean; use a three-neck flask to take 360mL of ultrapure water, and inject nitrogen gas with a purity of 99.99% for 1 hour, and keep the nitrogen flow rate at 5mL / min during this period, and pass it into the water for neutralization The airtightness of three-necked flask obtains nitrogen gas ultrapure water;

[0046] (2) Take 100mL of the above nitrogen-gassed ultrapure water in a graduated cylinder, and add 4mL of it to the concentration of 30mg·mL -1 Then add 1.1484g of cerium acetate to the remaining ultrapure water in the three-necked flask to mix, and carry out precipitation reaction at a temperature of 25°C and a speed of 260rpm for 12h to obtain uniform cerium fluoride nanosheets.

Embodiment 2

[0048] Embodiment 2 of the present invention provides a method for preparing a mixed matrix membrane regulated by cerium fluoride porous nanosheets, which specifically includes the following steps:

[0049] (1) Dissolve 1 g of polyether block polyamide (PEBAX1074) polymer in 14 g of n-butanol at 90°C under reflux for 4 hours until a uniform polyether block polyamide (PEBAX1074) solution is obtained;

[0050] (2) Add 0.025 g of the cerium fluoride nanosheets prepared in Example 1 into 5 g of n-butanol, stir at room temperature for 2 h, then put it into a 250 W ultrasonic cleaning machine, and ultrasonically react for 2 h until sufficient dispersion is achieved.

[0051] (3) The nanosheet dispersion was added to the polyether block polyamide (PEBAX1074) solution, and the resulting solution mixture was continuously stirred for 4 hours, and then ultrasonically degassed for 2 hours. Prepare the membrane casting solution,

[0052] (4) Finally, the mixed solution was poured on a gla...

PUM

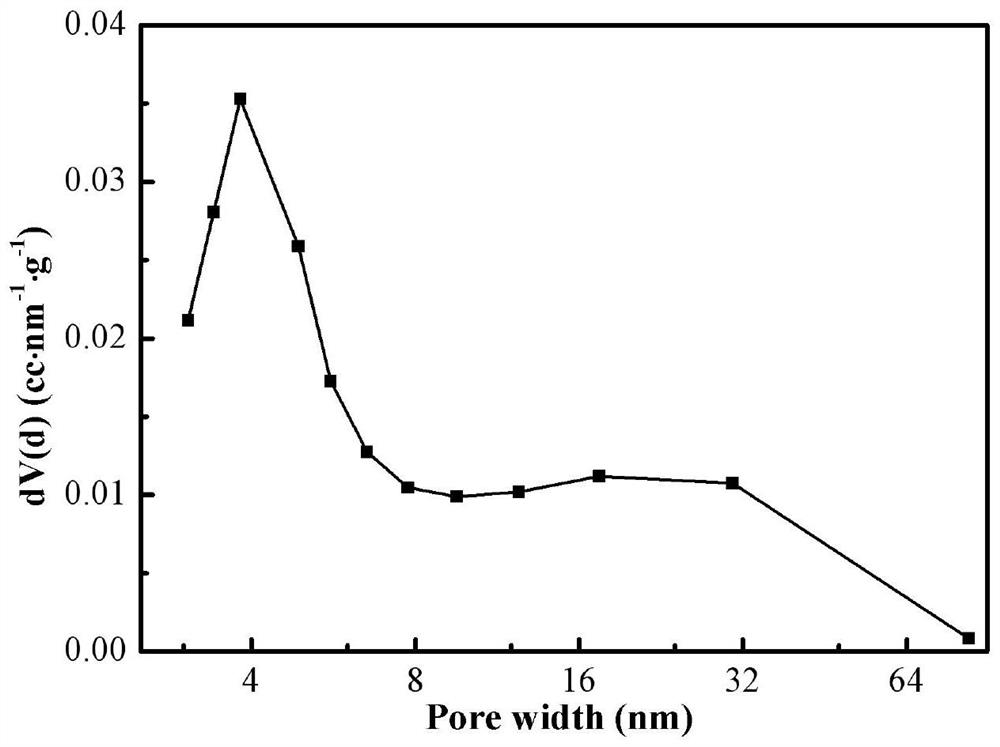

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com