Heat-resistant alloy steel component having trans-scale multiphase in-situ enhancement effect and microstructure control process thereof

A technology with enhanced effect and cross-scale, applied in the field of deformation heat treatment of new metal materials, it can solve the problems that the comprehensive mechanical properties cannot meet the performance requirements, the process is complicated, the type and size of carbon and nitrogen compounds are single, etc., and achieve good high temperature microstructure stability. and wear resistance, simple method, excellent strength and toughness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

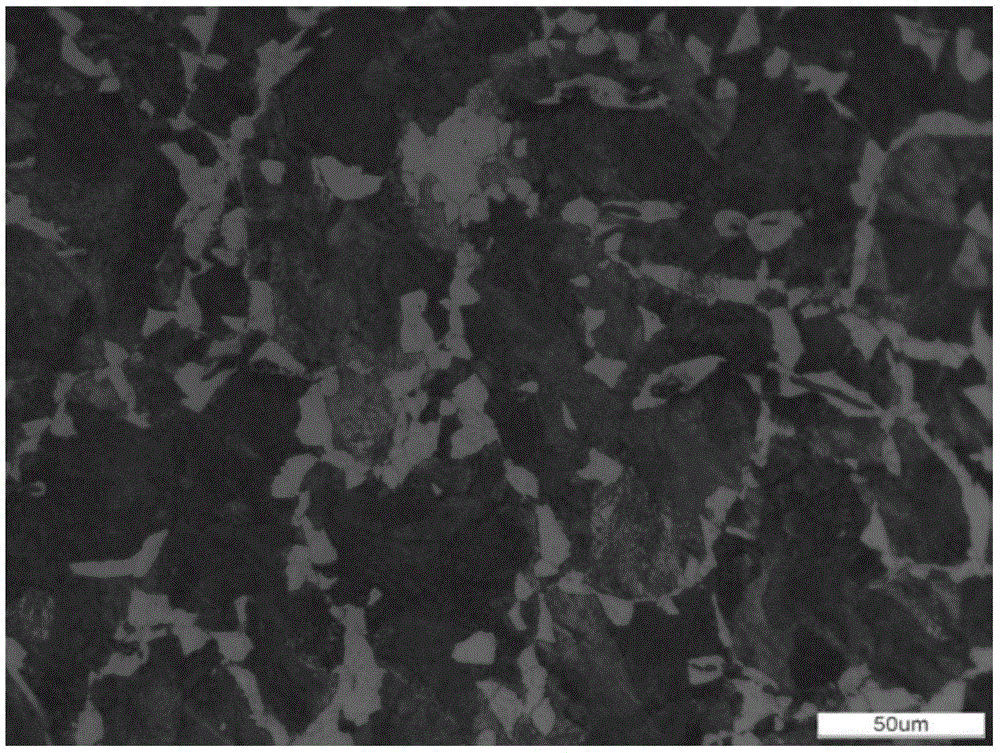

Image

Examples

Embodiment 1

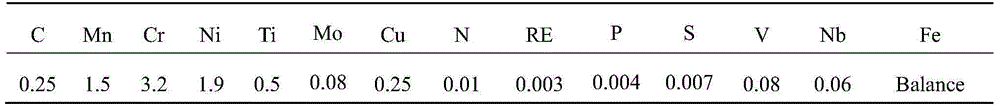

[0028] The heat-resistant alloy steel composition with cross-scale multiphase in-situ strengthening effect is characterized in that: it includes the alloying elements in the mass percentage wt% as described in Table 1:

[0029] Table 1 The chemical composition of the alloy steel used in the test:

[0030]

[0031] The microstructure control process of heat-resistant alloy steel with cross-scale multiphase in-situ strengthening effect is as follows:

[0032] (1) The above-mentioned forging blank material is heated to 1150°C by induction and kept for 0.5h, then free forging is carried out at 1000°C, the deformation amount is 20%, the deformation rate is 0.6 / s, and air cooling is controlled to 880°C;

[0033] (2) Deform the sample for 3 passes at 880°C, heat and supplement the temperature and control the interval between passes to be 120s, the total deformation amount is 35%, and control air cooling to room temperature;

[0034] (3) Heat the sample after deformation heat trea...

Embodiment 2

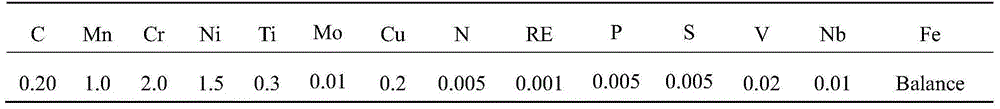

[0036] The composition of the heat-resistant alloy steel with cross-scale multiphase in-situ strengthening effect is characterized in that it includes the alloy elements in the mass percentage wt% as described in Table 1.

[0037] The microstructure control process of heat-resistant alloy steel with cross-scale multiphase in-situ strengthening effect is as follows:

[0038] (1) The above-mentioned forging blank material is heated to 1100°C by induction and kept for 1 hour, then free forging is carried out at 950°C, the deformation amount is 15%, the deformation rate is 0.2 / s, and air cooling is controlled to 850°C;

[0039] (2) Deform the sample for 2 passes at 850°C, heat and supplement the temperature and control the interval between passes to be 90s, the total deformation amount is 25%, and control air cooling to room temperature;

[0040] (3) Heat the sample after deformation heat treatment to 870°C for austenitization, holding time is 2h, and then quench, the quenching me...

Embodiment 3

[0042] The composition of the heat-resistant alloy steel with cross-scale multiphase in-situ strengthening effect is characterized in that it includes the alloy elements in the mass percentage wt% as described in Table 1.

[0043] The microstructure control process of heat-resistant alloy steel with cross-scale multiphase in-situ strengthening effect is as follows:

[0044] (1) The above-mentioned forging blank material is heated to 1200°C by induction and kept for 20 minutes, then free forging is carried out at 1050°C, the deformation amount is 35%, the deformation rate is 0.8 / s, and air cooling is controlled to 900°C;

[0045] (2) Deform the sample for 5 passes at 900°C, heat and supplement the temperature and control the interval between passes to be 300s, the total deformation amount is 60%, and control air cooling to room temperature;

[0046] (3) Heat the sample after deformation heat treatment to 880°C for austenitization, holding time is 1h, and then quench, the quench...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com