Patents

Literature

106 results about "Collapsible tube" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

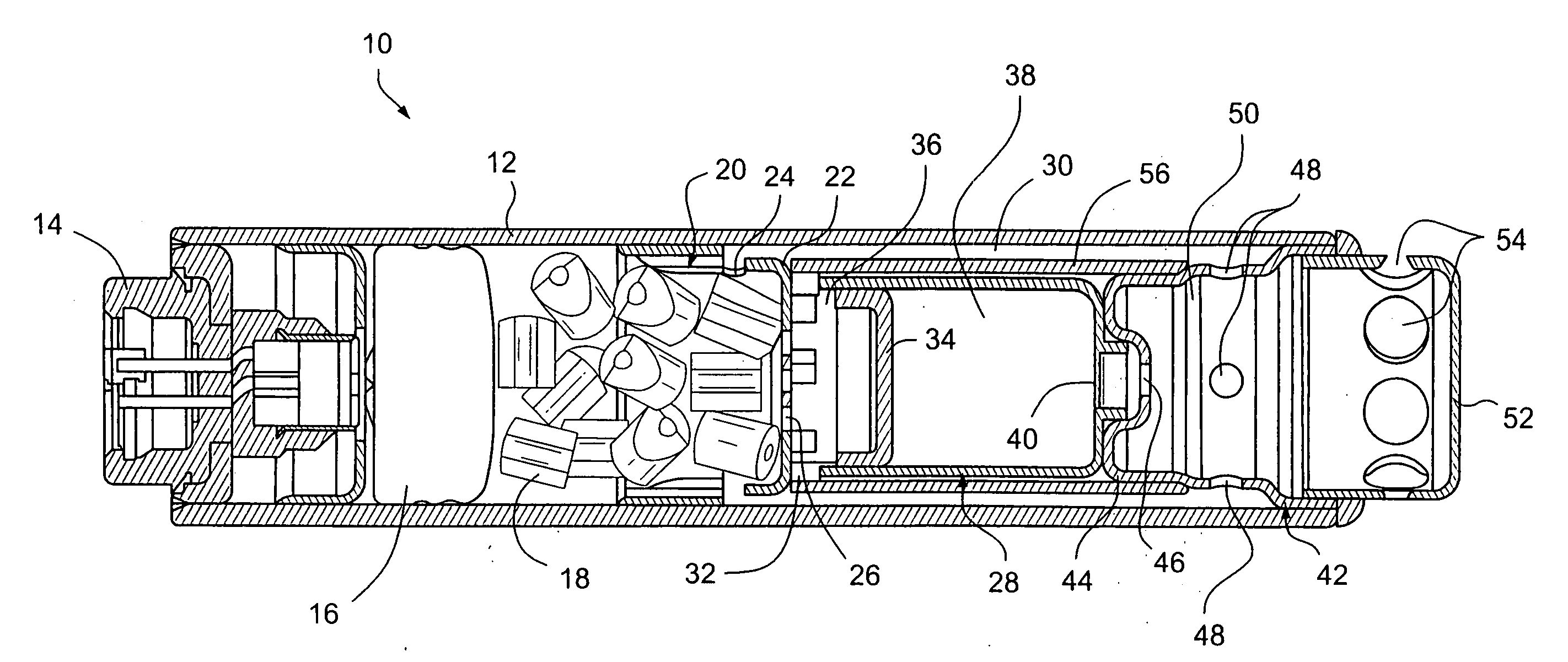

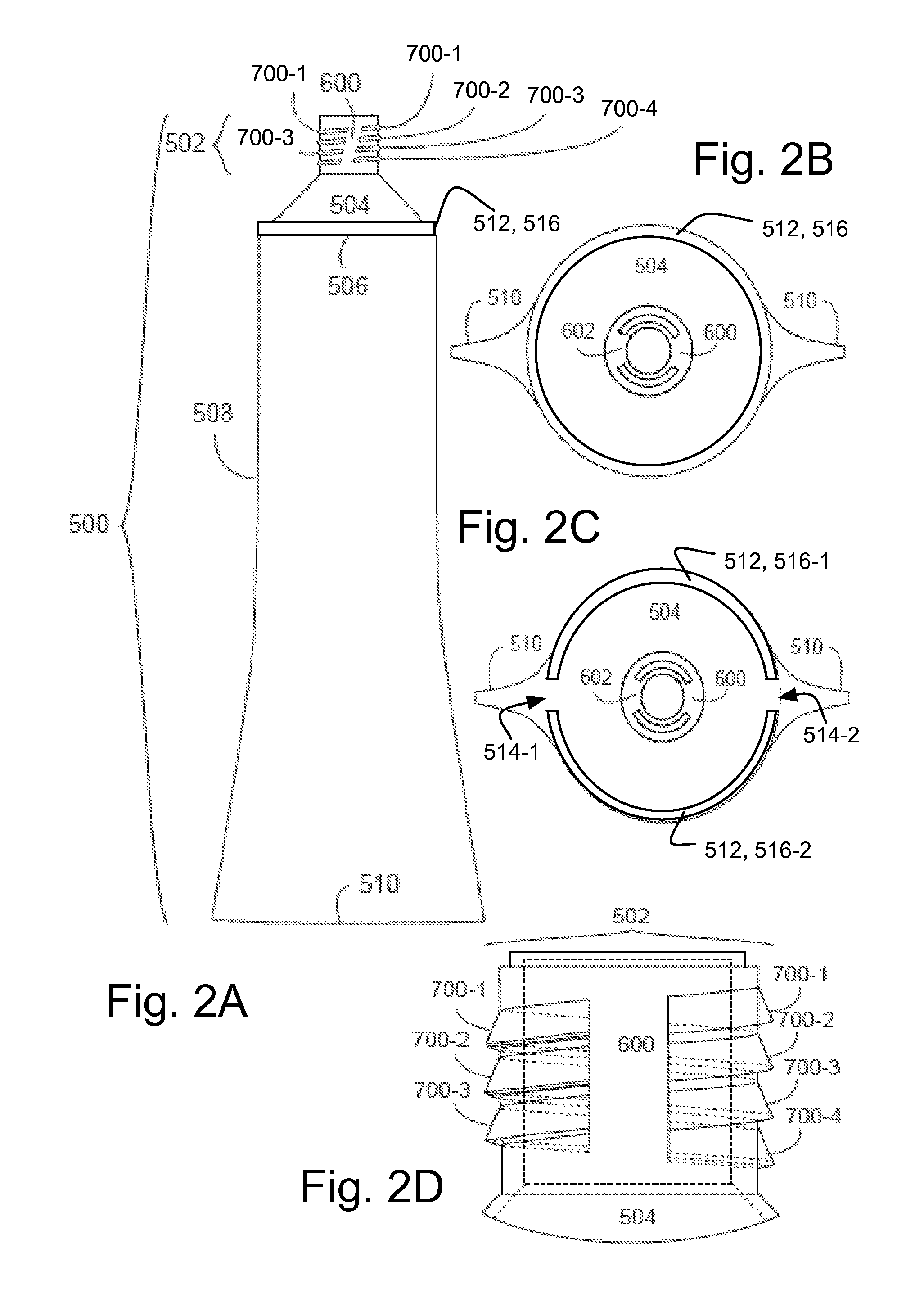

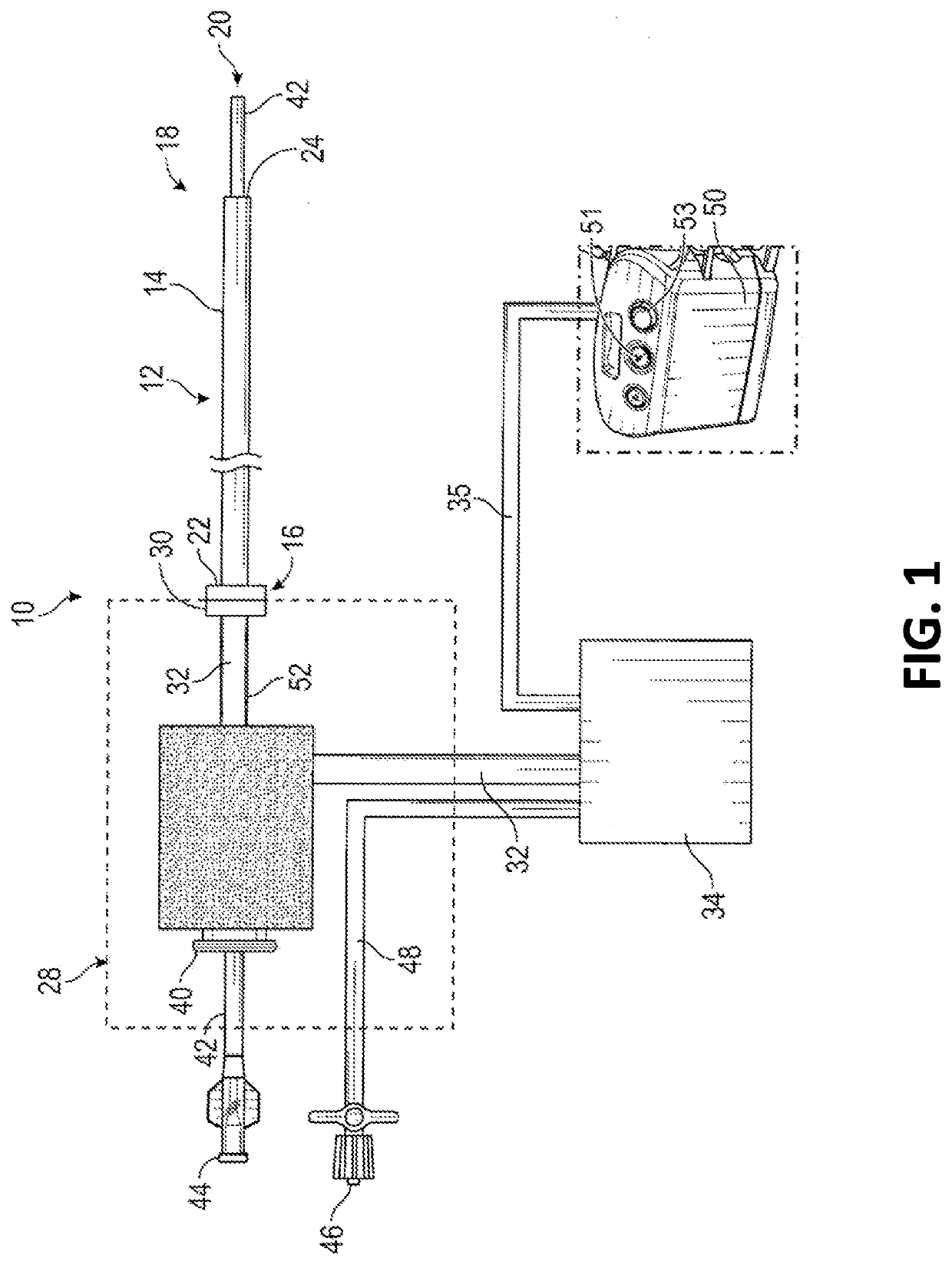

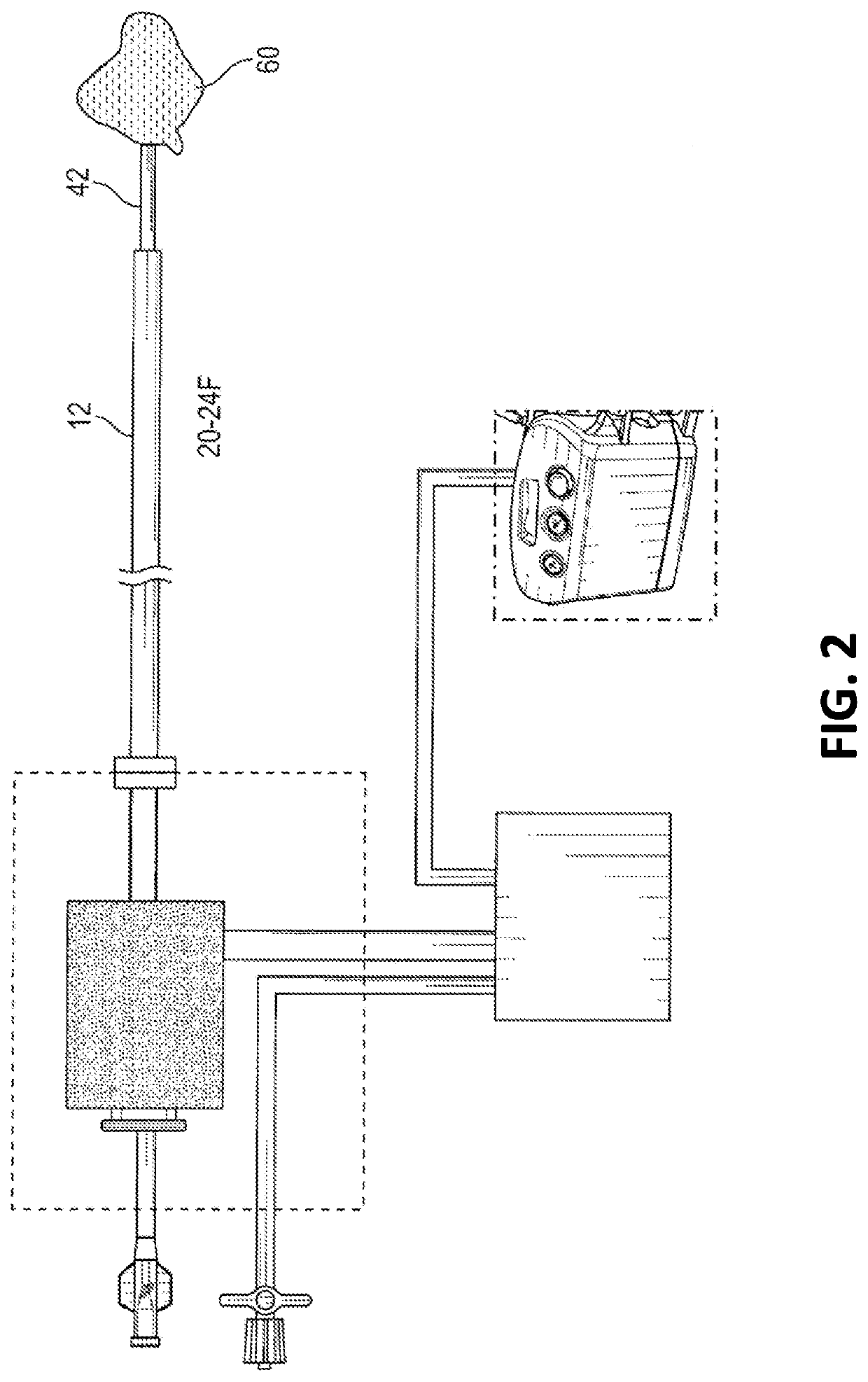

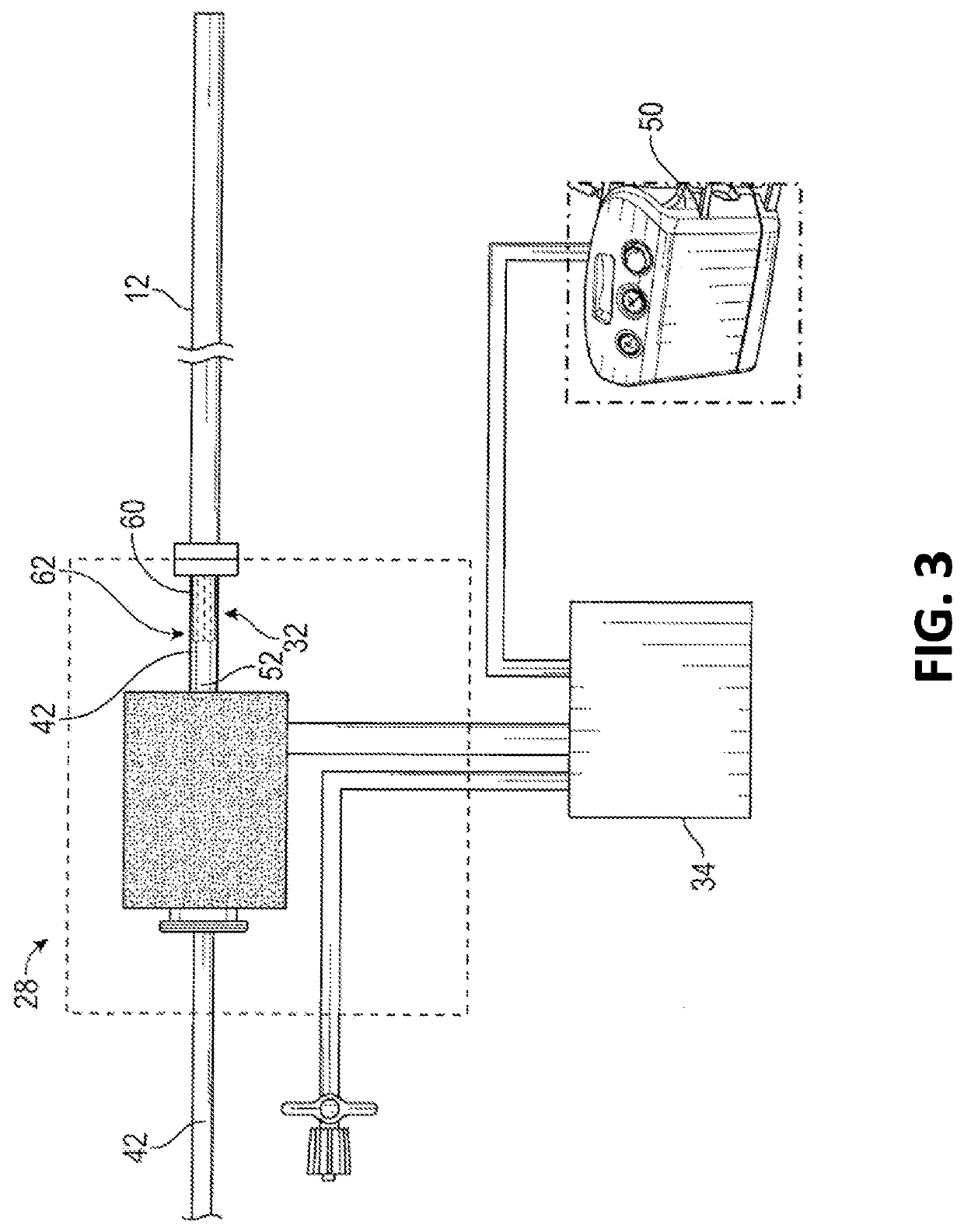

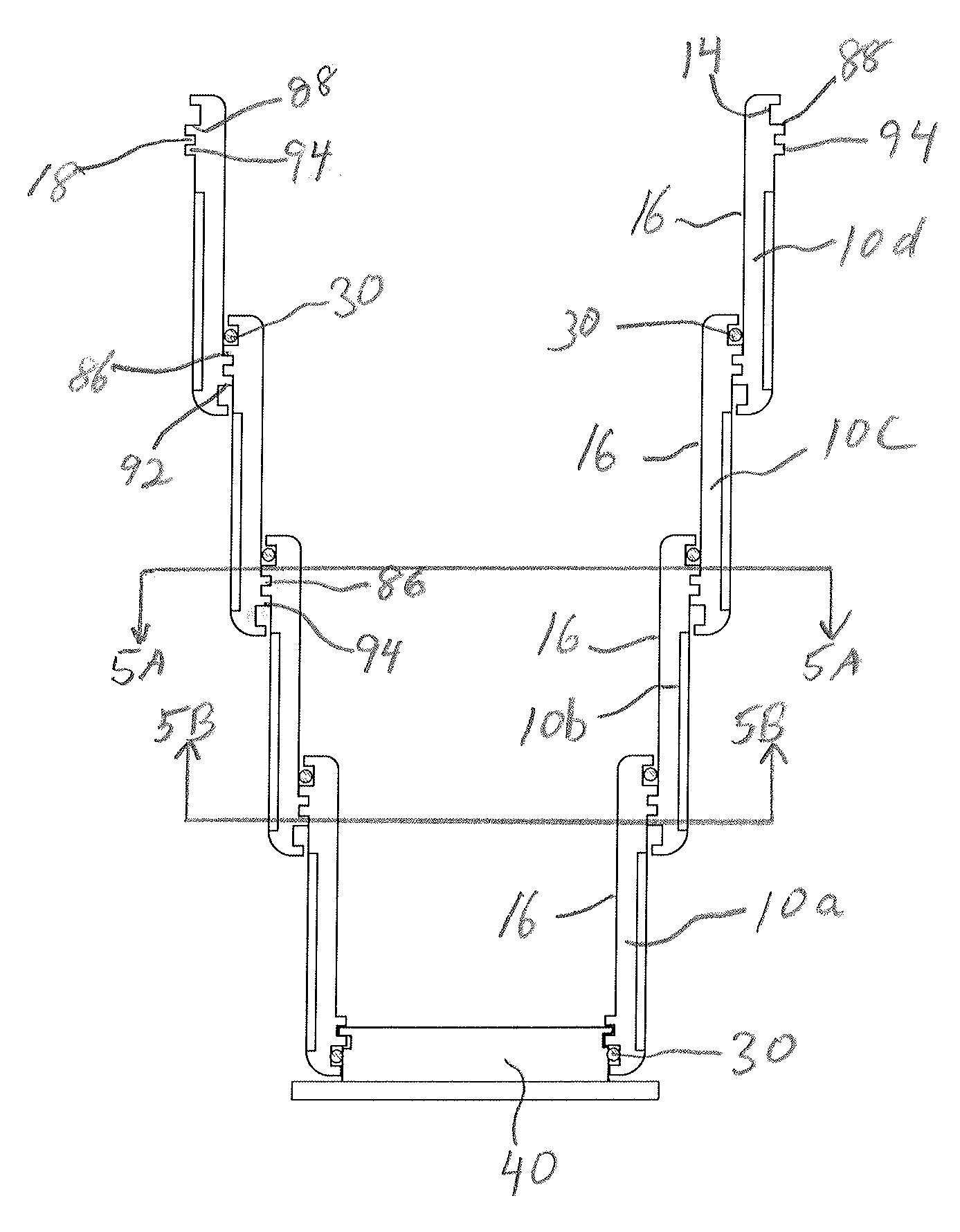

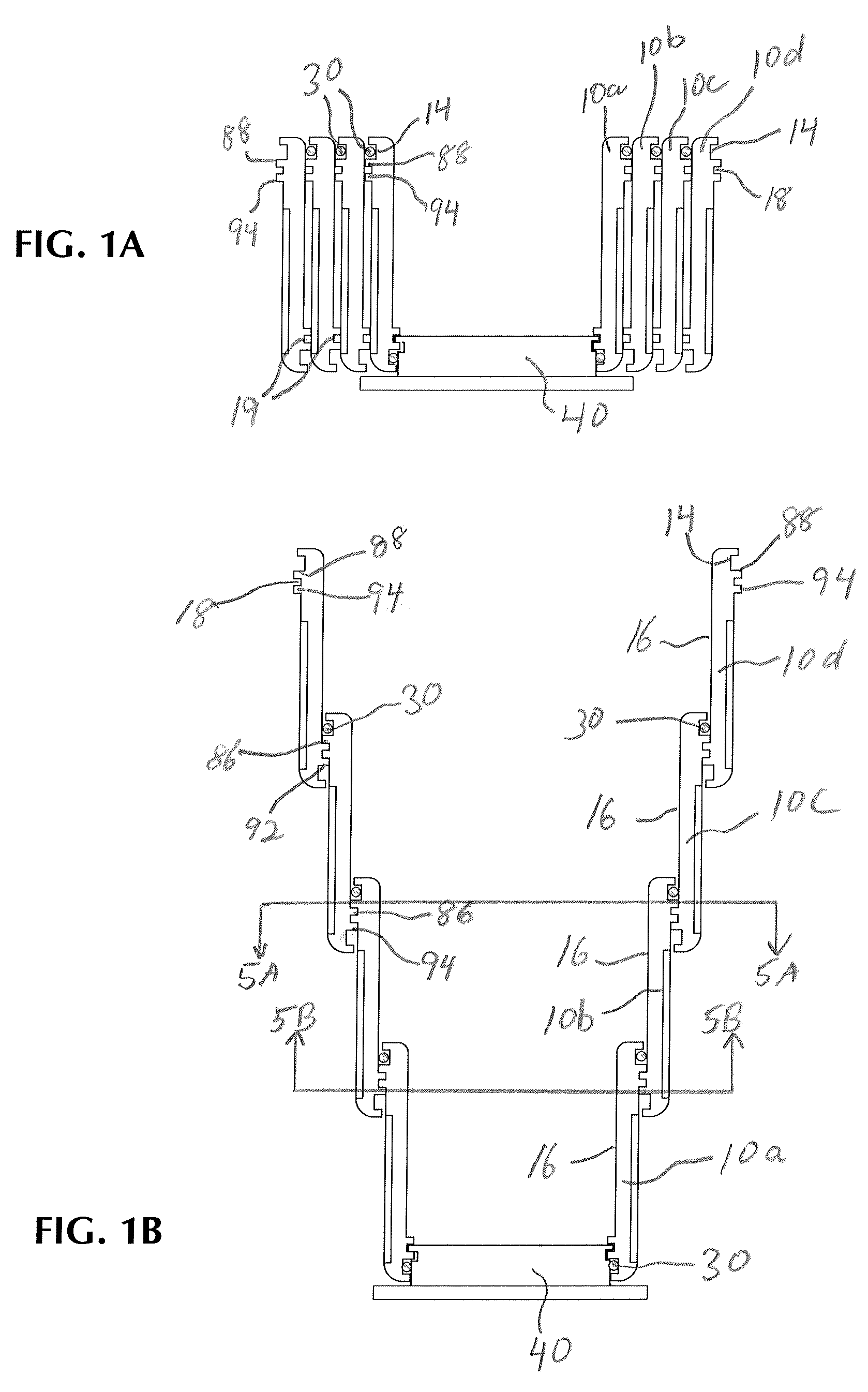

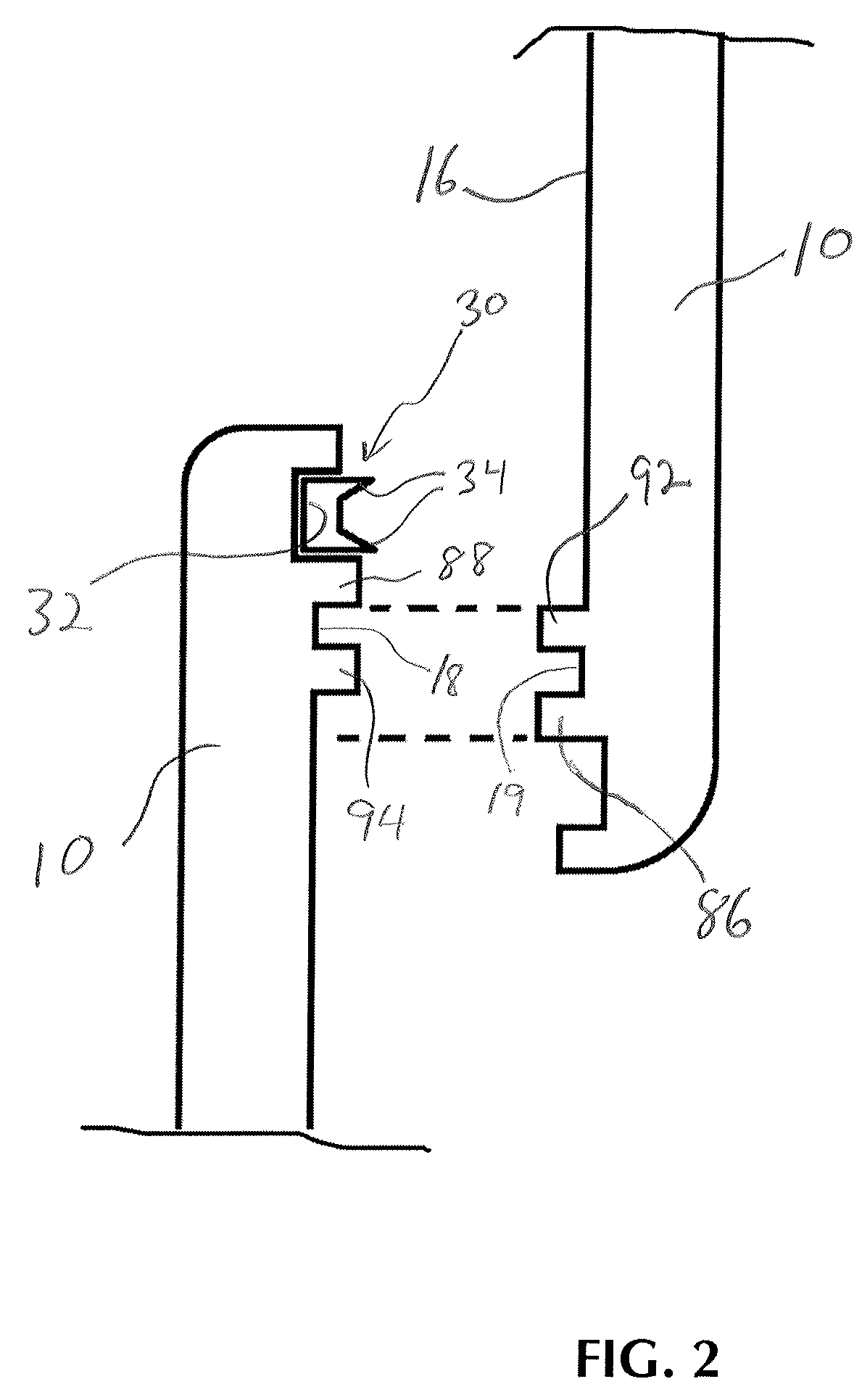

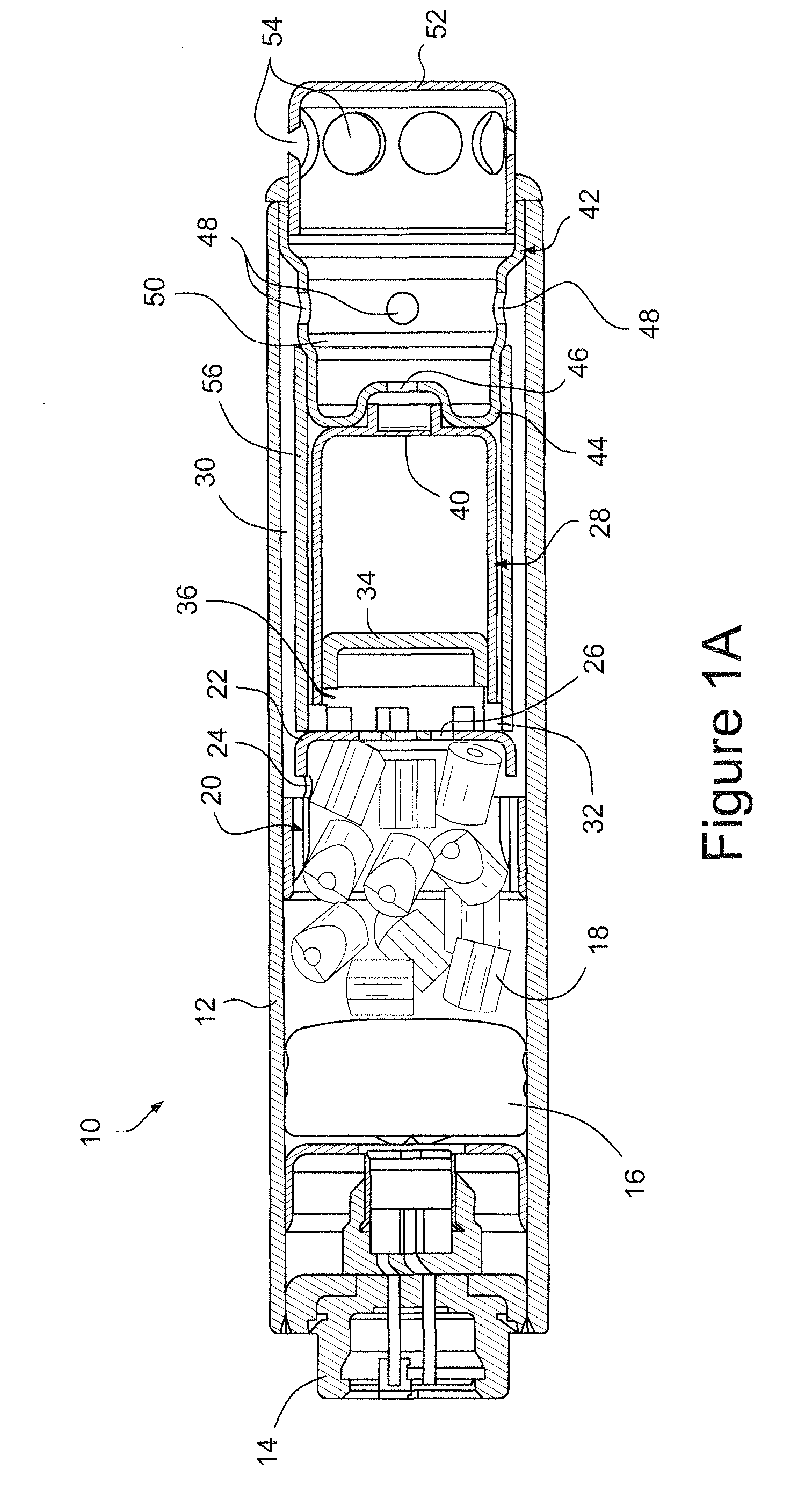

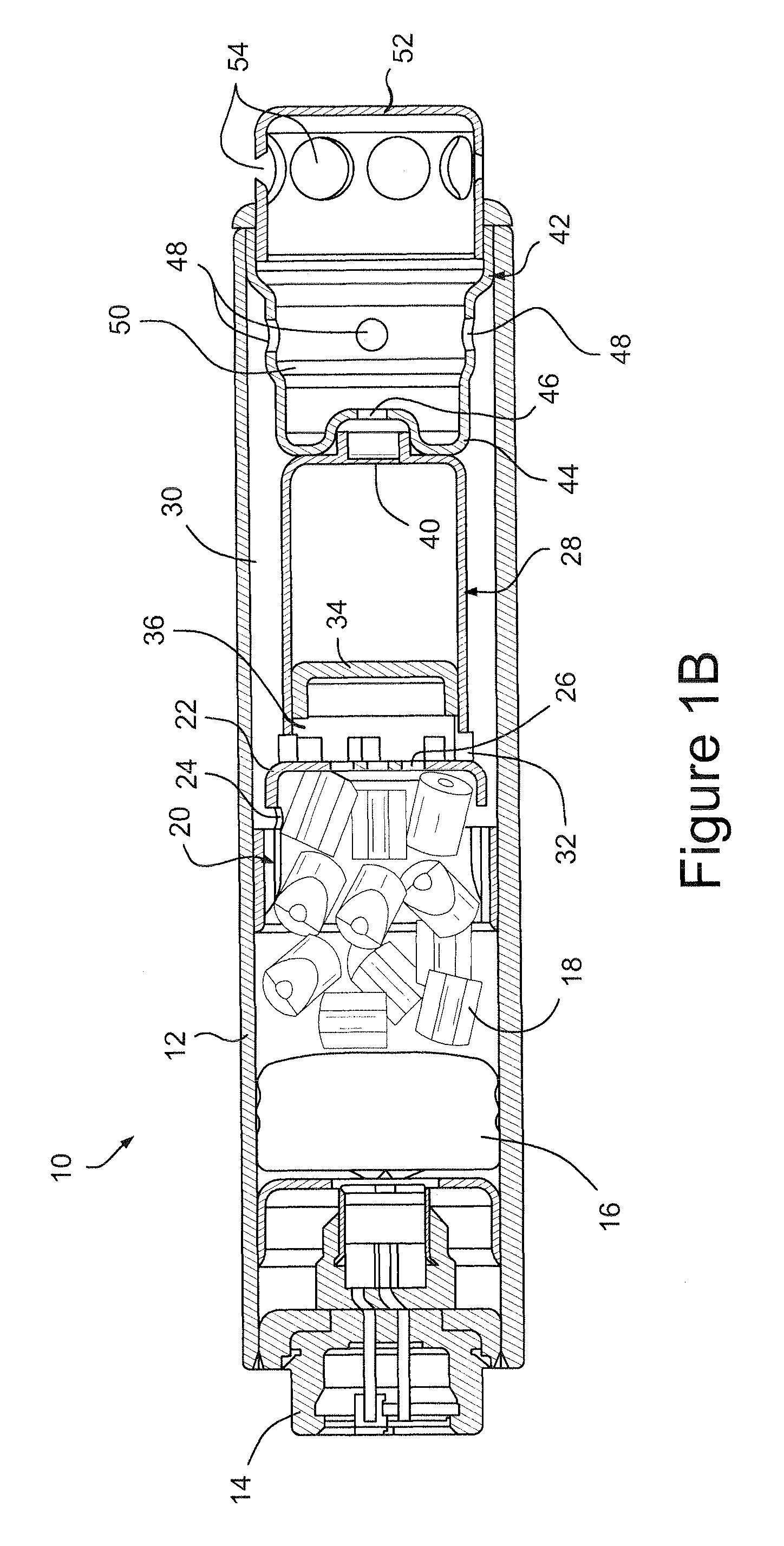

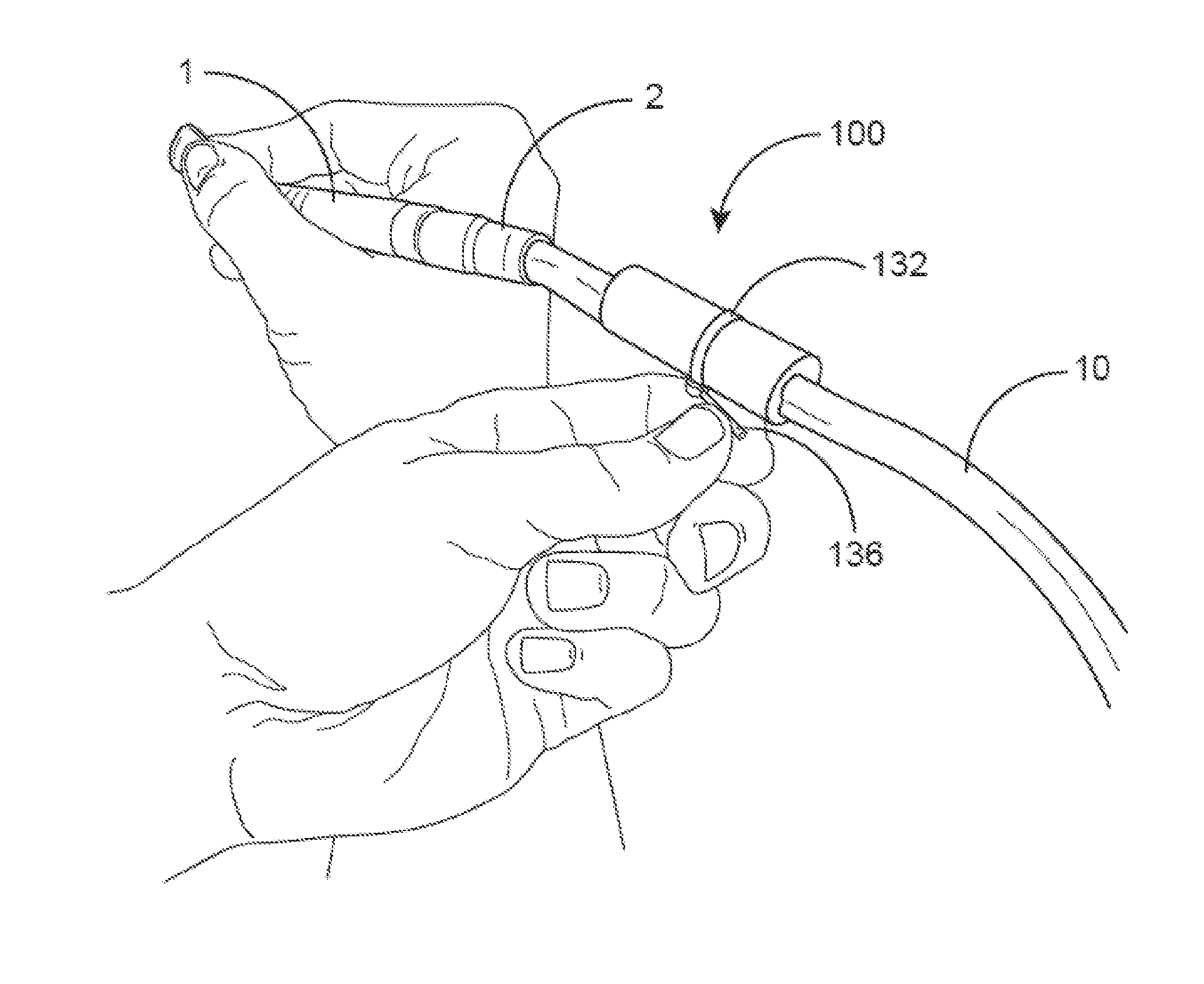

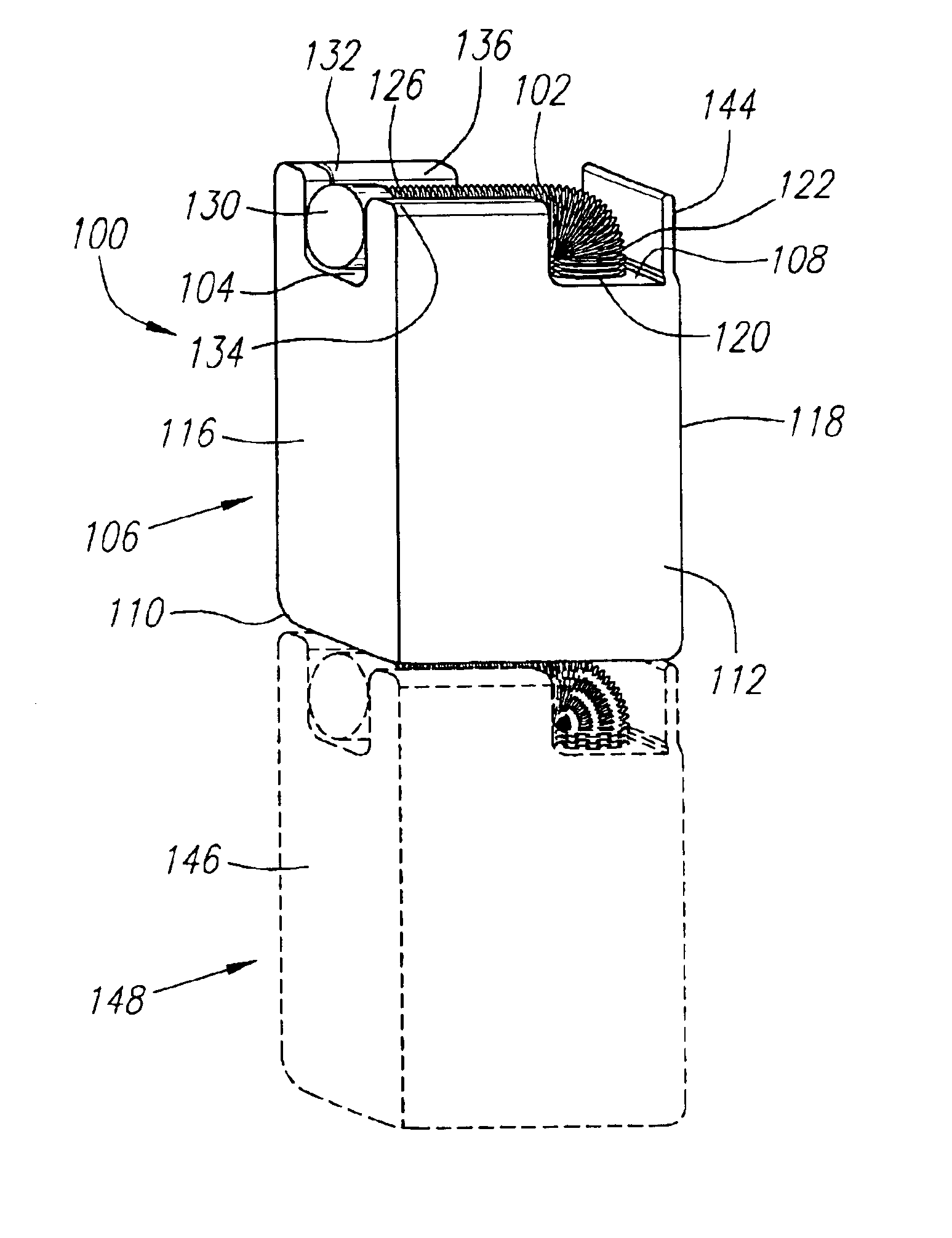

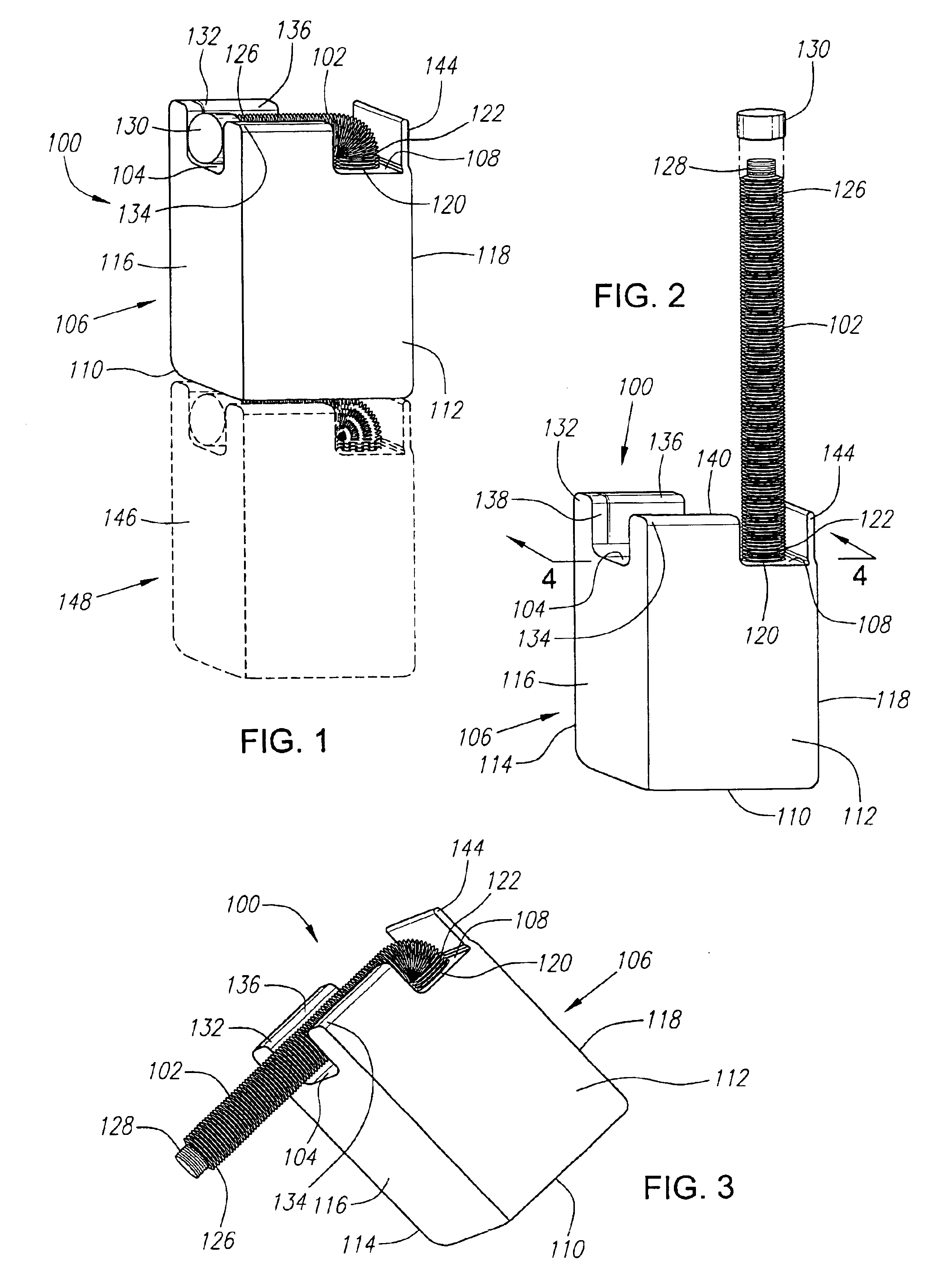

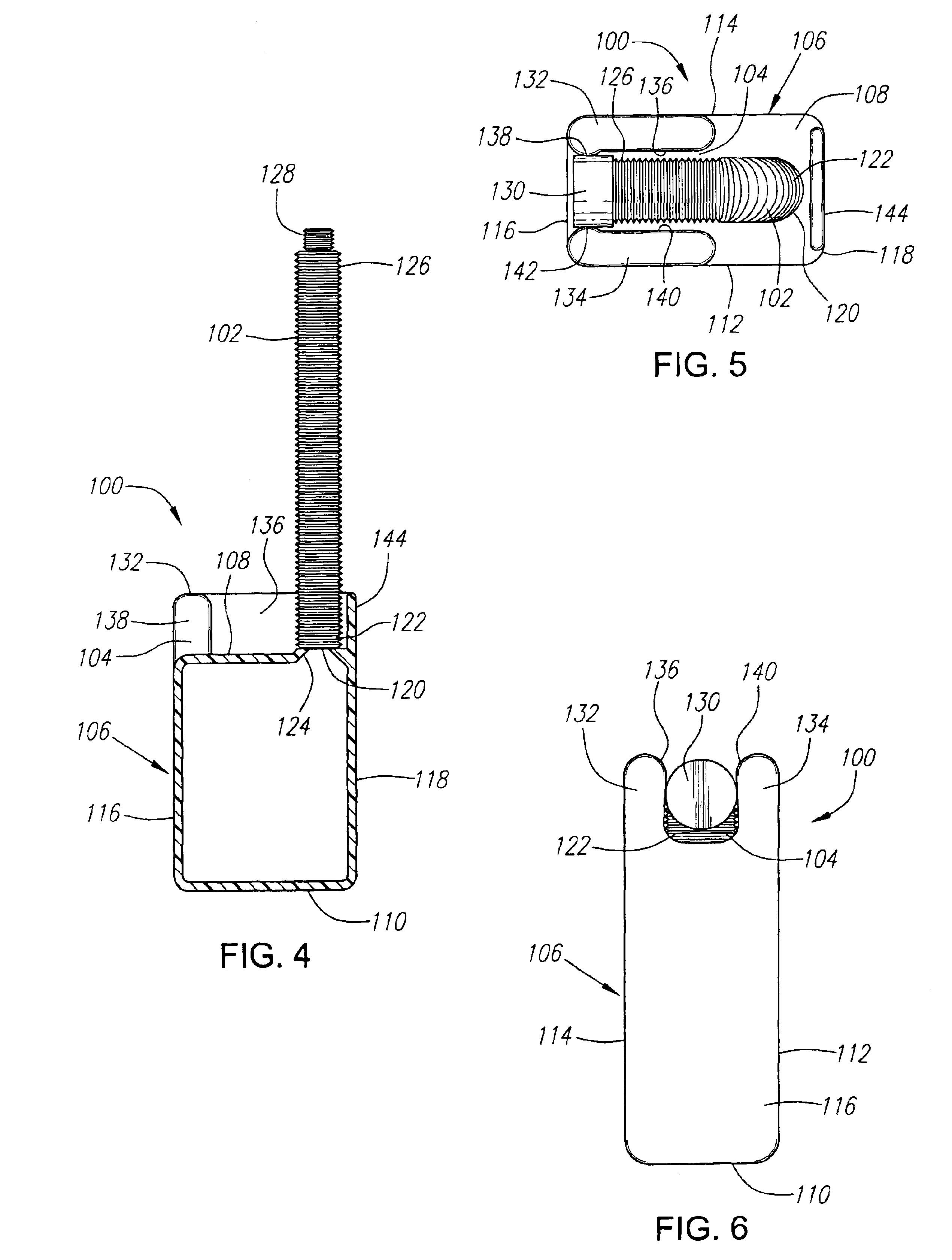

Tube occluder and method for occluding collapsible tubes

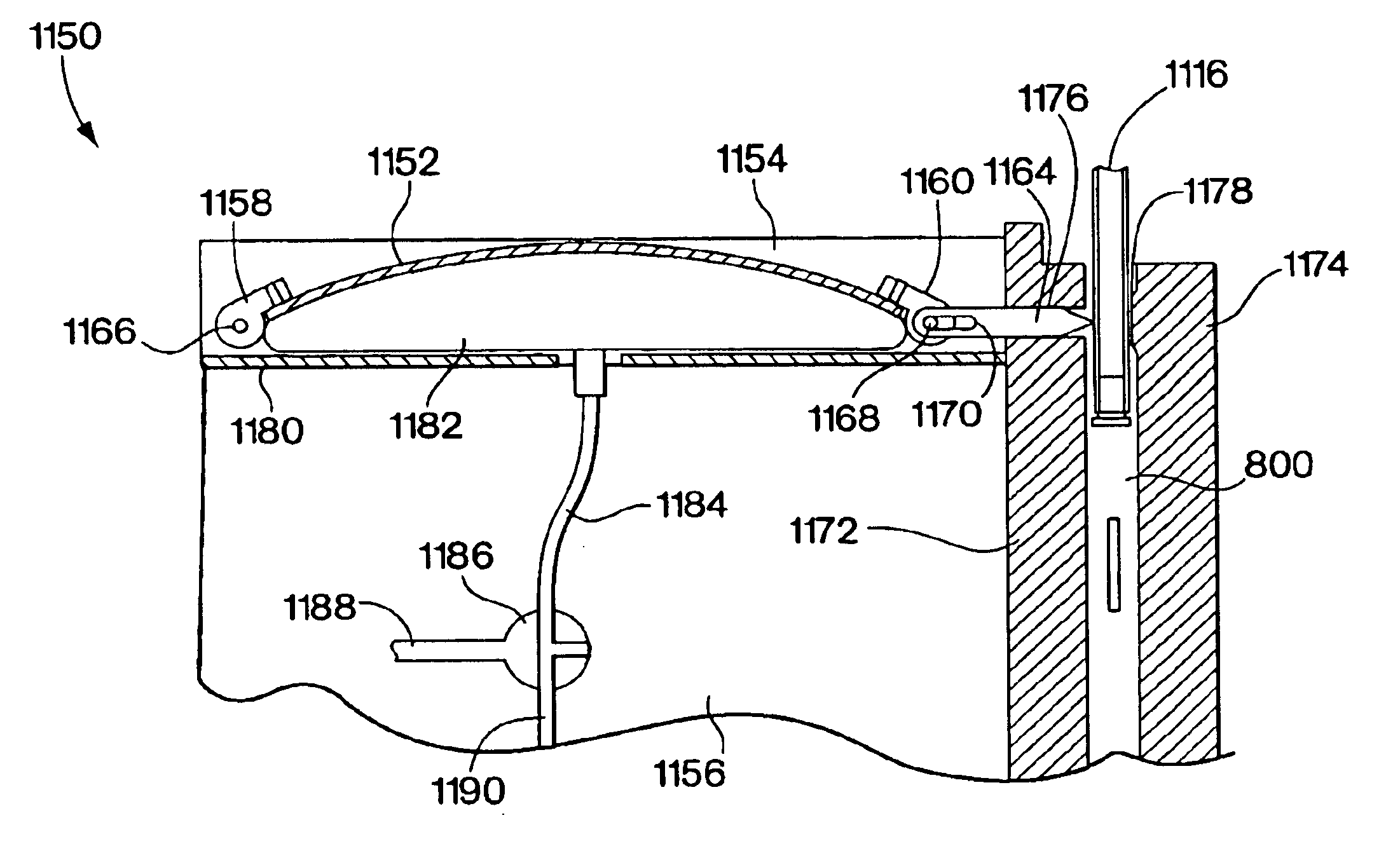

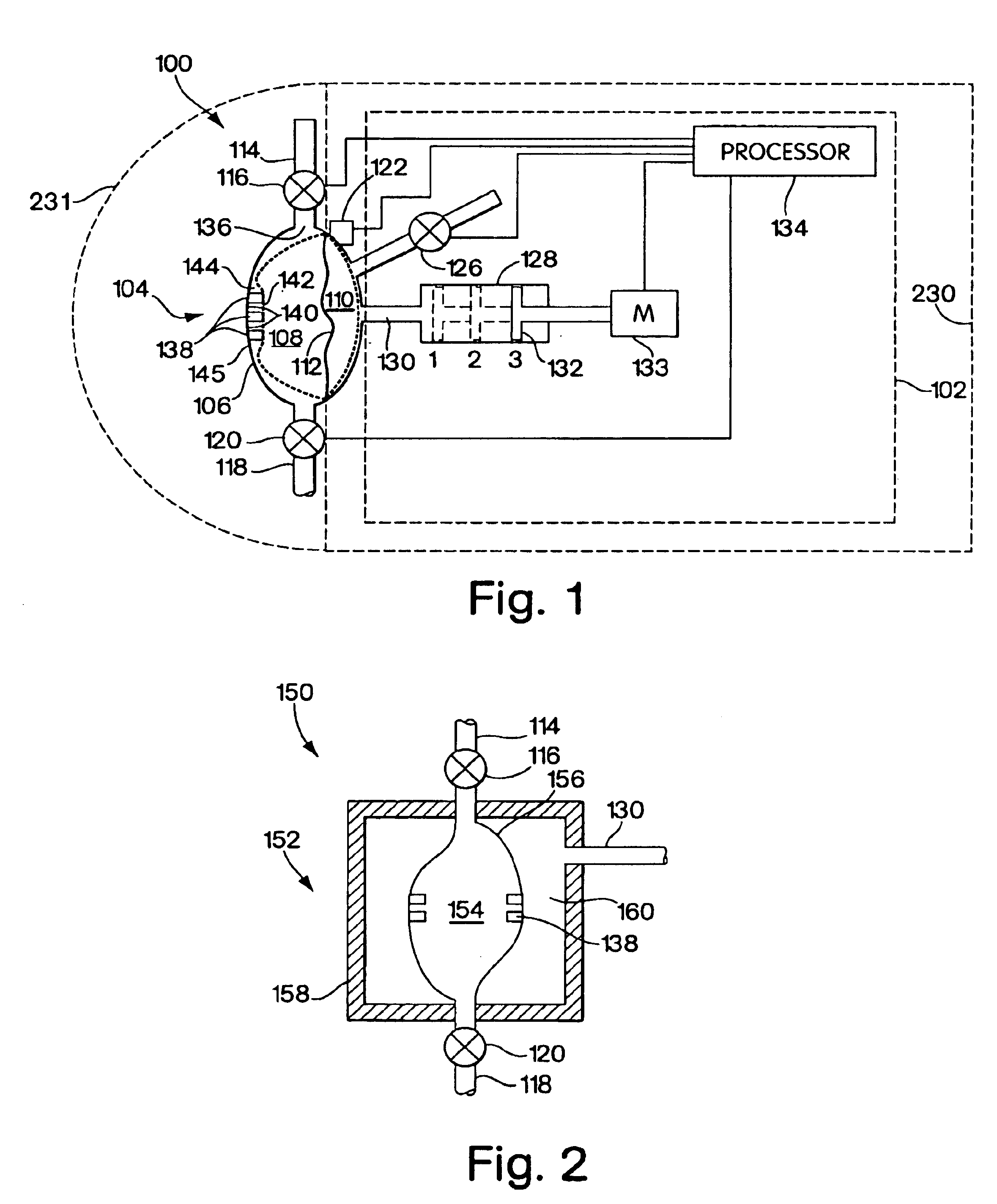

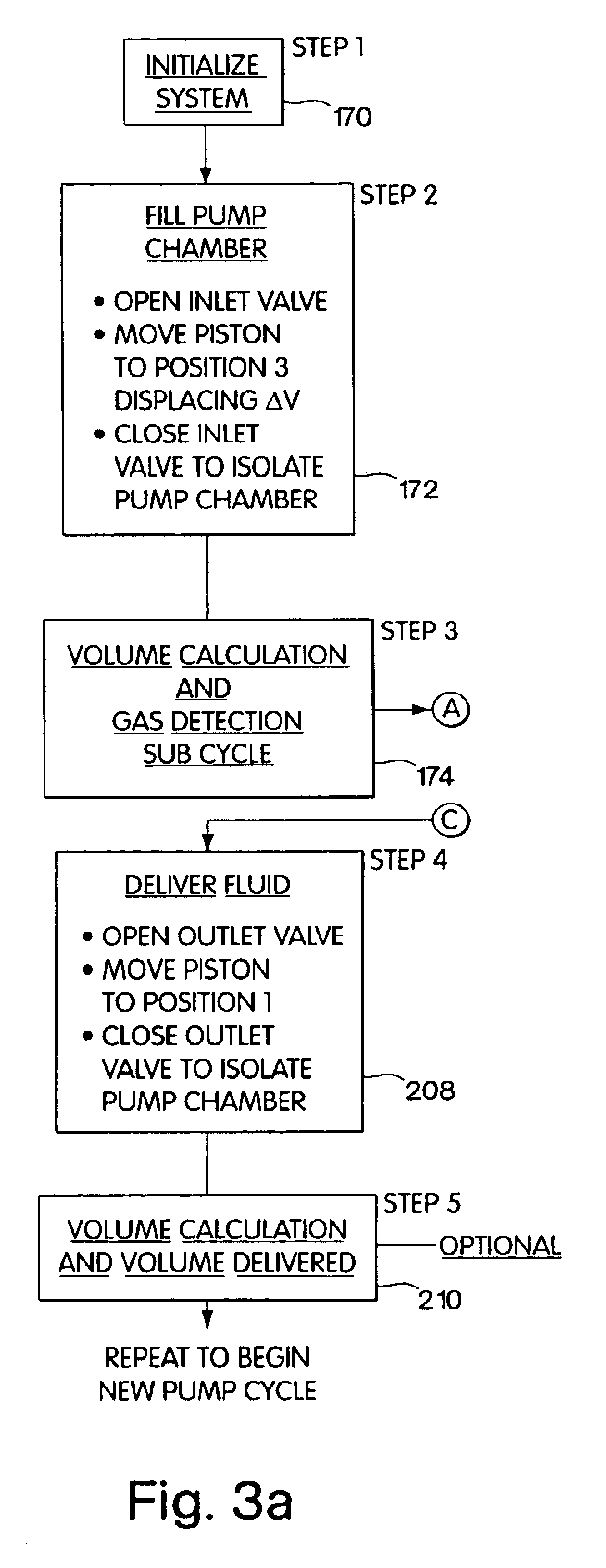

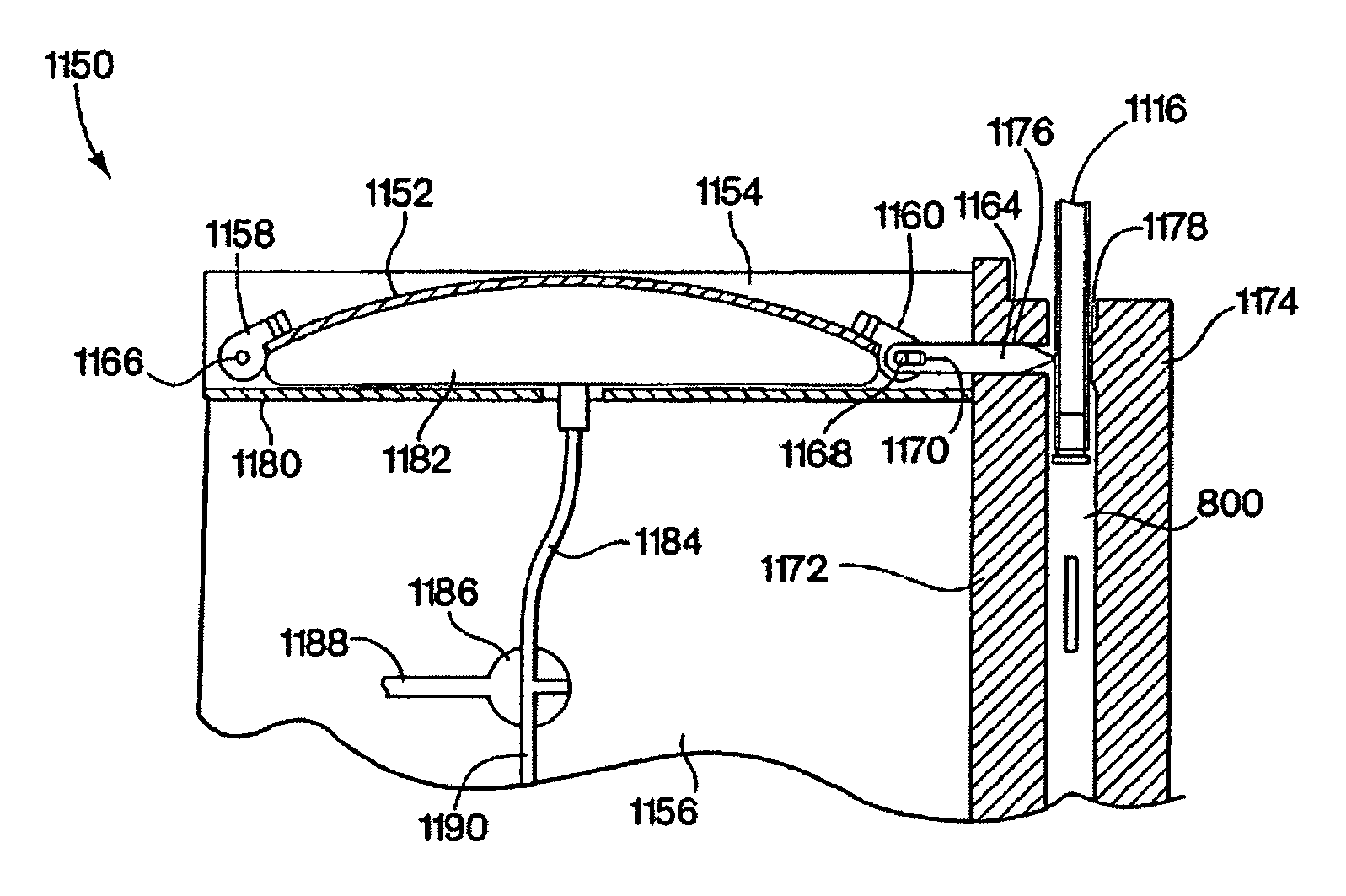

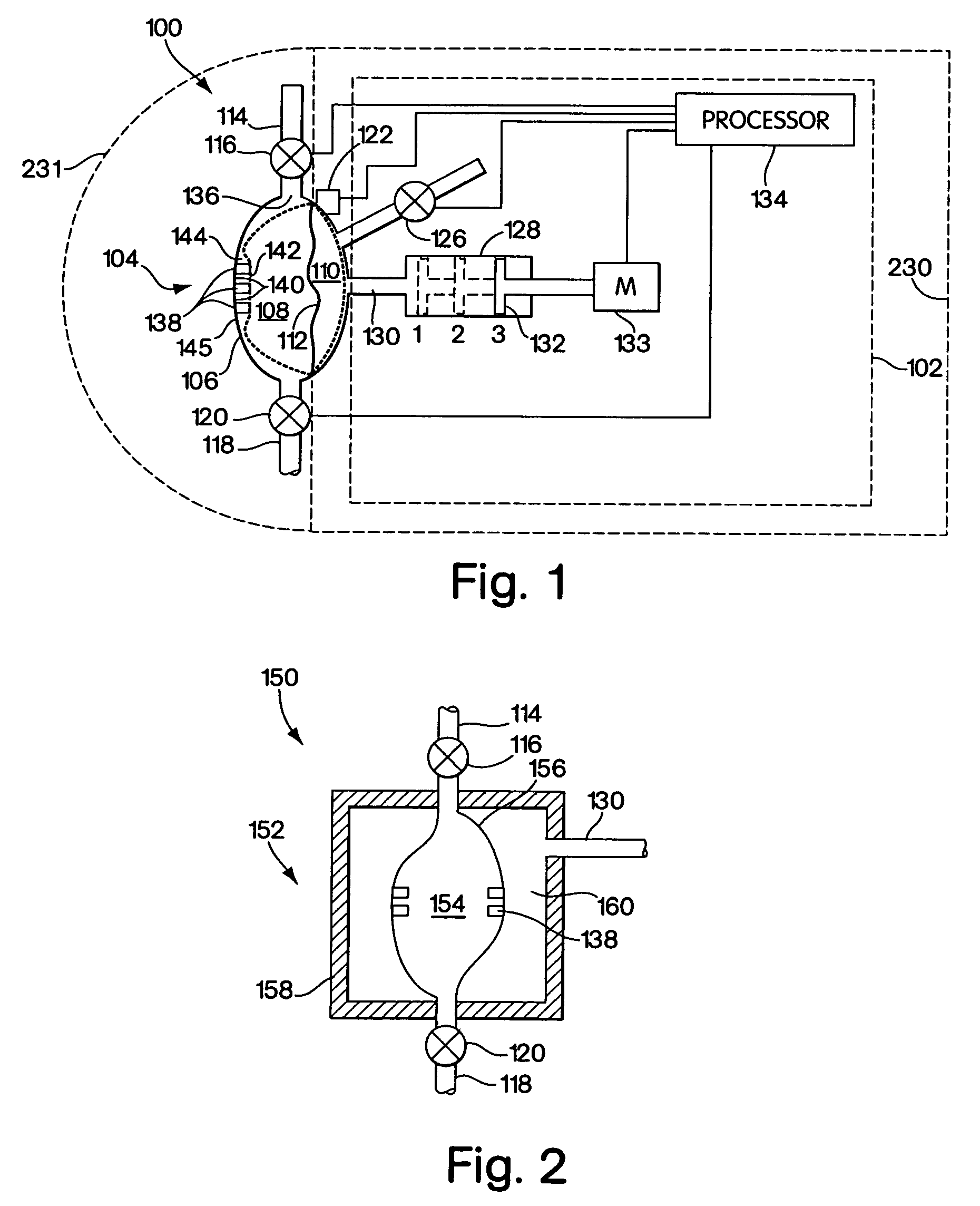

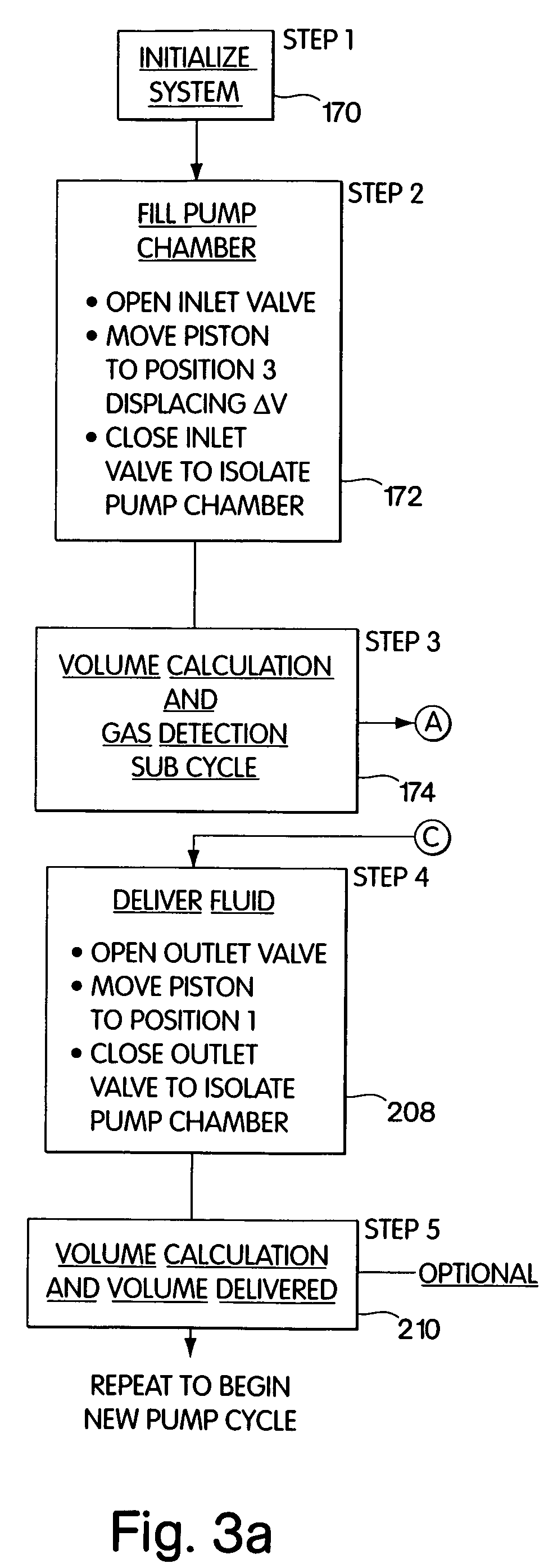

The present invention involves, in some embodiments, mechanisms and methods of occluding collapsible tubing with an occluder to prevent fluid flow therethrough. In some embodiments, a tube occluding mechanism is disclosed that includes a bendable occluding member for creating a force that can be applied to a collapsible tube to occlude the tube. In some embodiments, the collapsible tube can be an inlet / outlet tube on a removable pumping cartridge that is coupled to a reusable pump drive component when the system is in operation. In such embodiments, the occluding mechanism can be attached to the reusable component and can be used to block fluid flow to and from the pumping cartridge. In some embodiments, the occluding member can comprises a spring plate which can create a force to occlude tubing when in a relaxed, unbent configuration, and which can be bent to unocclude the tubing. In some preferred embodiments, in a default configuration of the tube occluder mechanism (when no external force is applied to the occluding member) the tubes are occluded, so that the tube occluder mechanism provides a fail-safe configuration preventing fluid flow to and from a pumping cartridge to which the tubes can be connected.

Owner:DEKA PROD LLP

Tube occluder for occluding collapsible tubes

Owner:DEKA PROD LLP

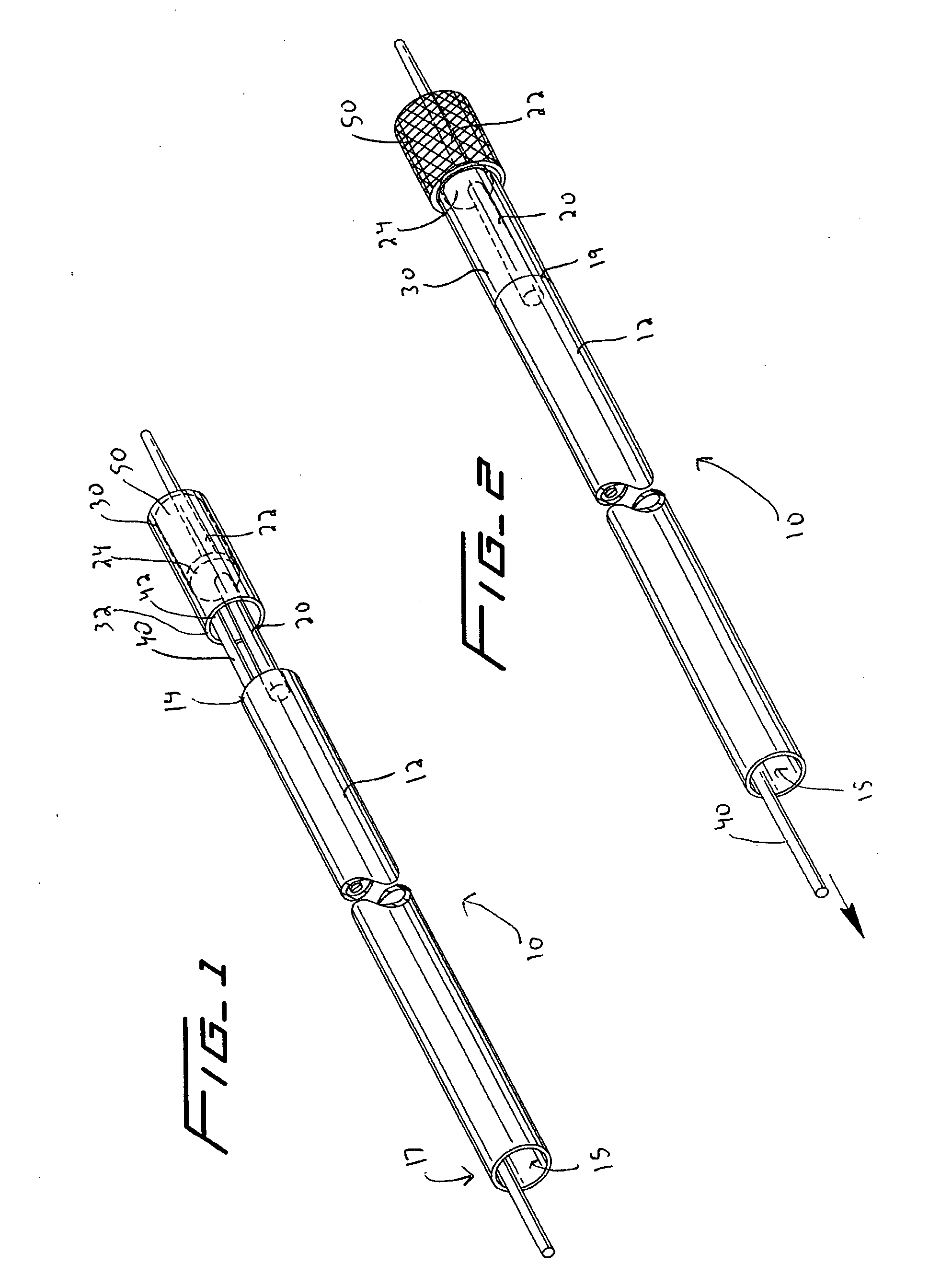

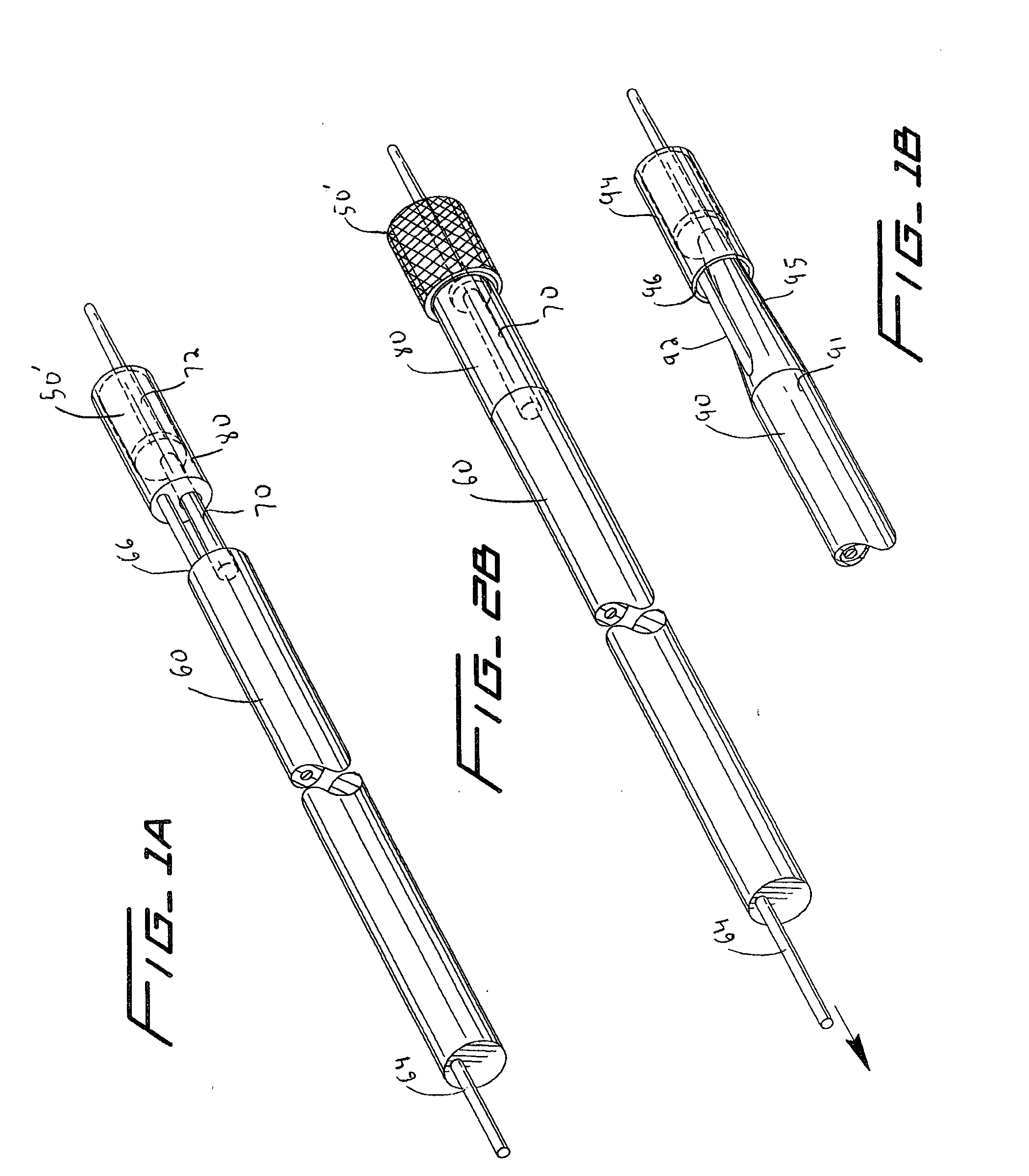

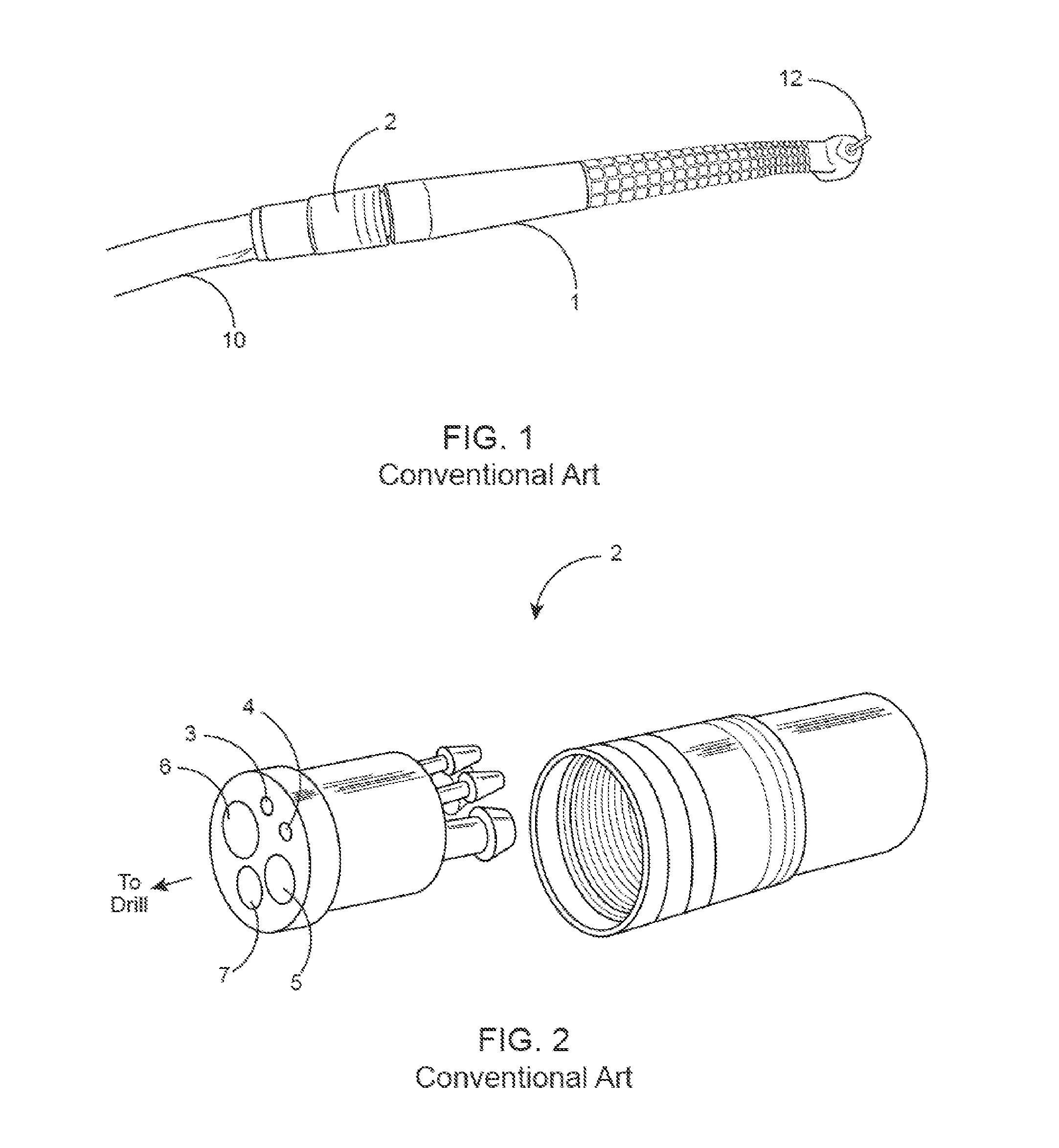

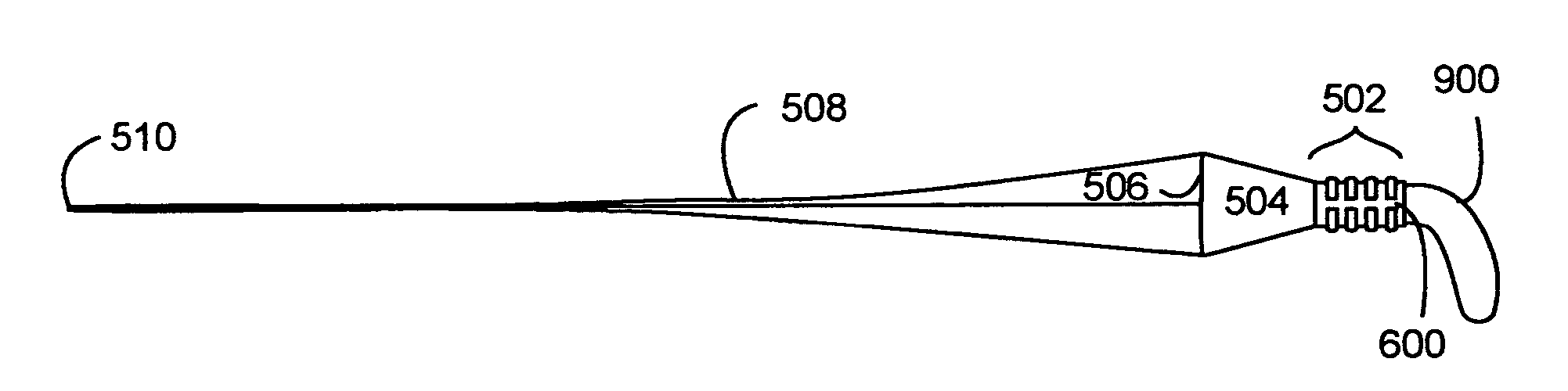

System for delivering a stent

A stent delivery system comprising a hypotube having a proximal end portion, a distal end portion and a first diameter, and a guidewire having a second diameter and a reduced diameter portion having a diameter smaller than the first diameter of the hypotube for receiving a stent. The guidewire is slidably positioned within the hypotube. Flexible material, e.g. collapsible tubing such as shrink tubing, extends from a portion of the hypotube to a portion of the guidewire. A stent is positioned on the reduced diameter portion of the guidewire,

Owner:BAY STREET MEDICAL

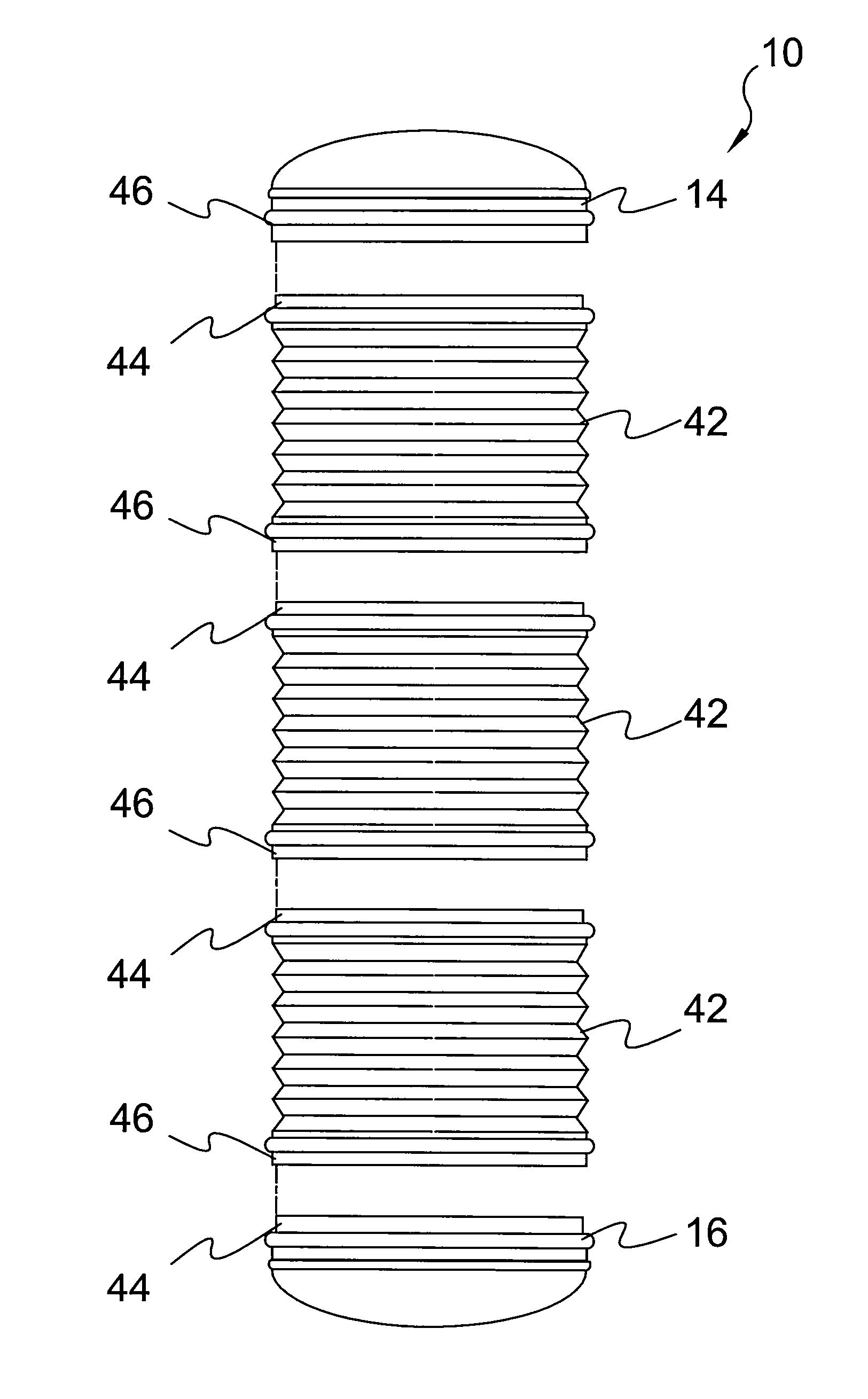

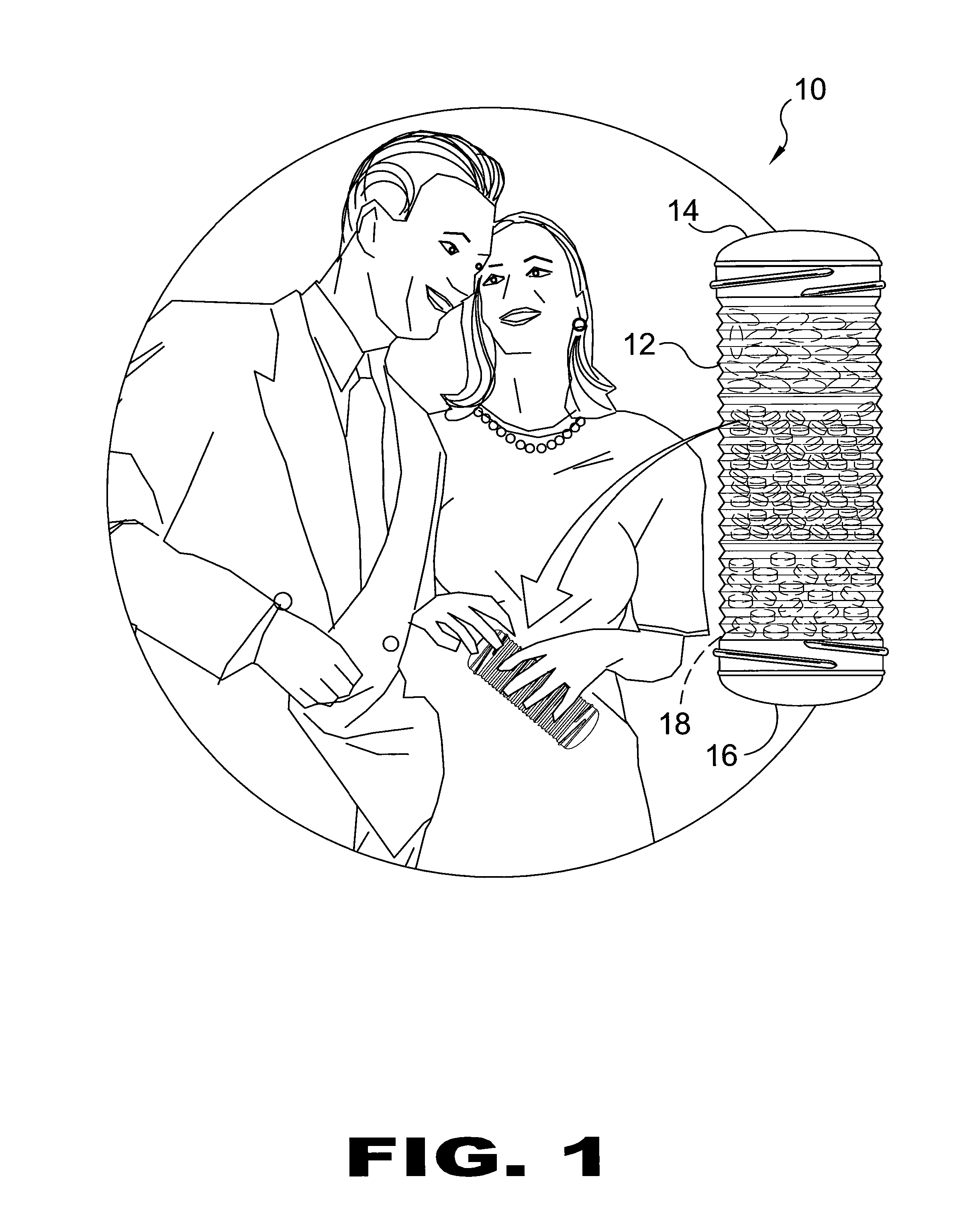

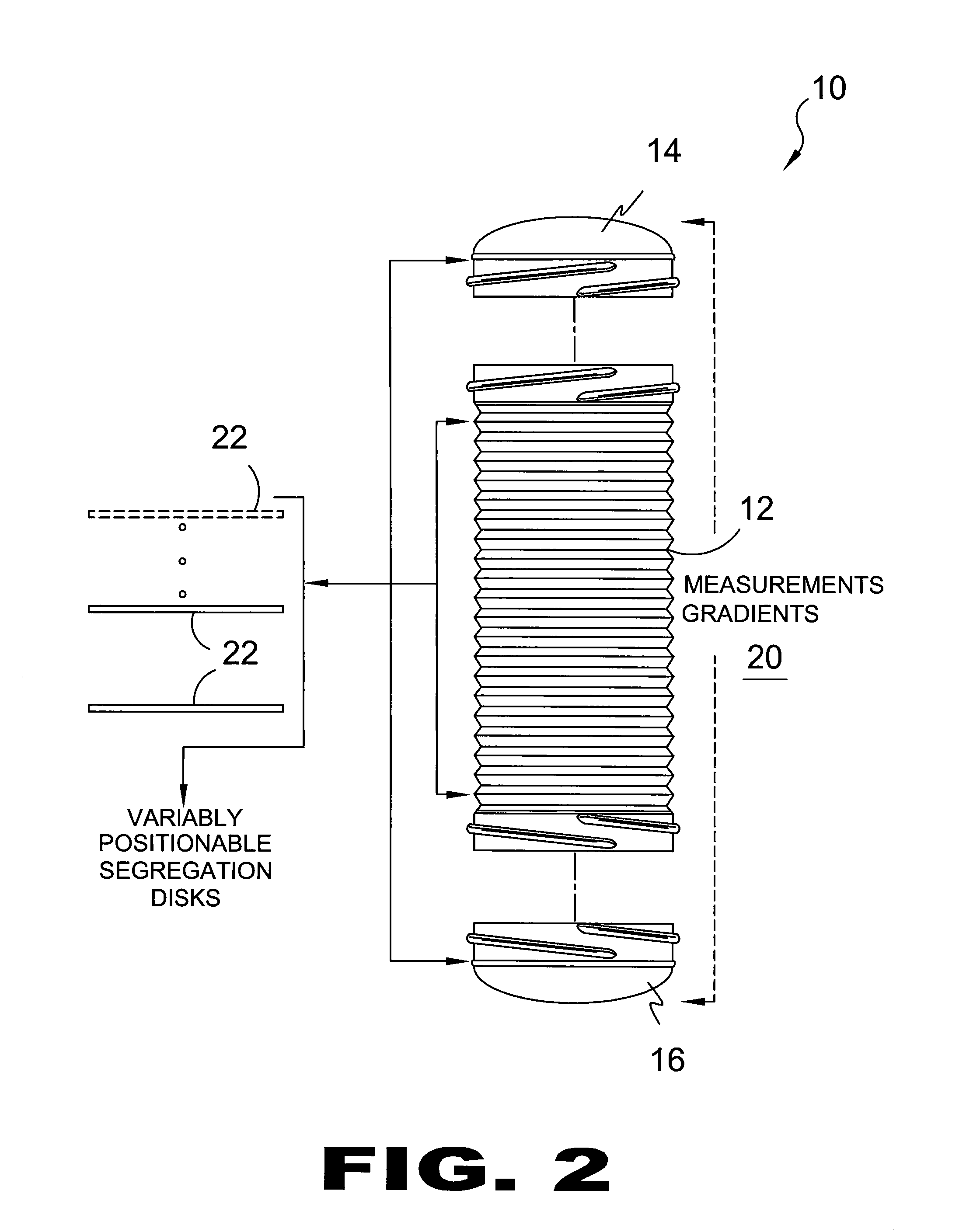

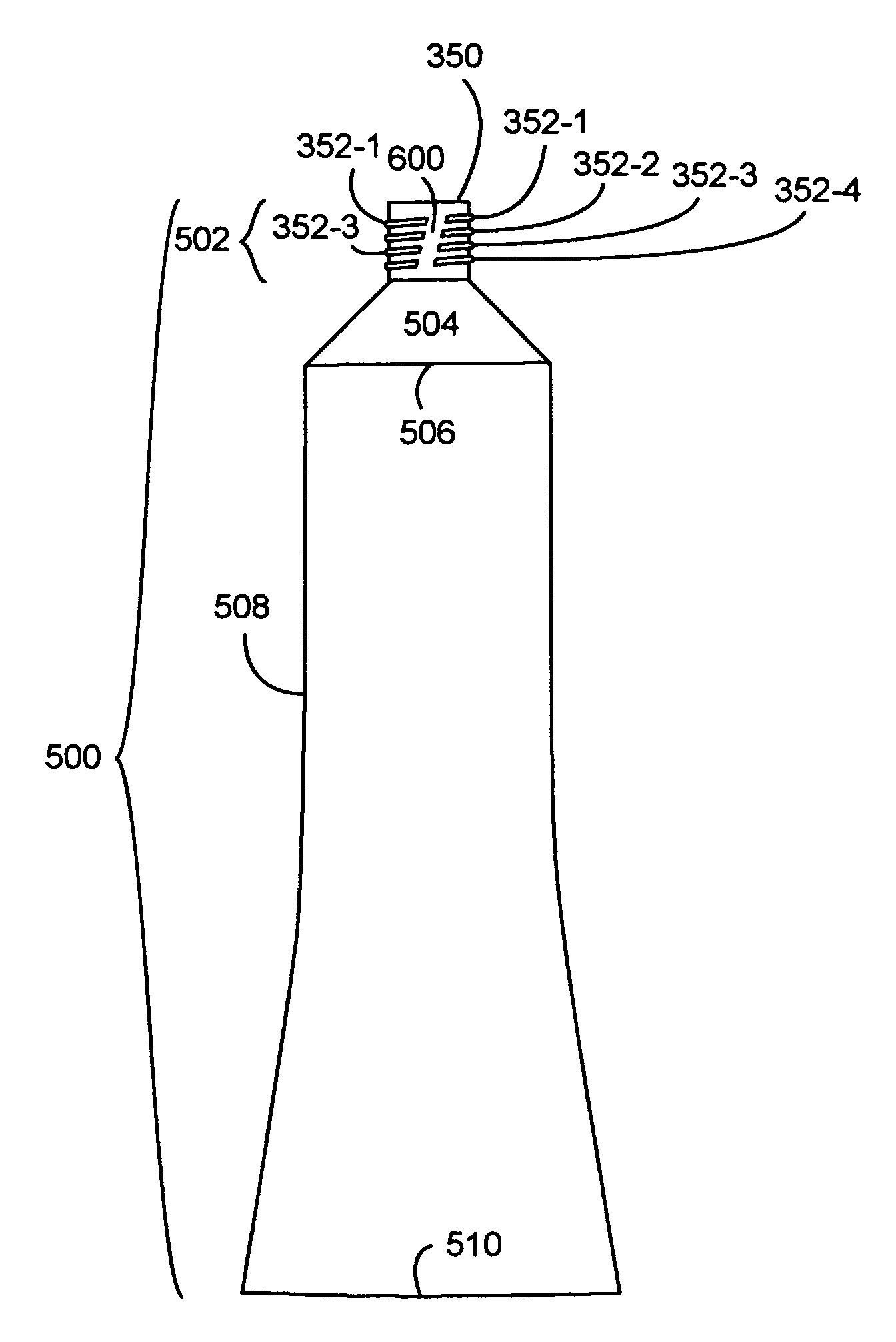

Collapsible polymeric bellows storage tube

InactiveUS7866500B1Easy to disassembleSave spaceContainer decorationsLevel indicationsStorage tubePolymer

A bellows design collapsible polymeric storage tube. The device incorporates separate flexible plastic disks as segregating spacers that are dropped inside the device creating separate spaces for a plurality of items. The spacers lock into the widest part of the bellows securing them in place. The disks are printable / markable for promotional / informative media and labeling. In a first instance of the bellows receptacle, the collapsible bellows tube consists of two threaded ends and two threaded lids. The lids pop open and have their own separate space(s) that also uses a disk to create a separate segregated compartment. When a lid is empty the top of the lid collapses in upon itself thus saving space when the lid is empty and packed away, likewise the body of the tube collapses and expands as it is filled or emptied of the contents inside in order to save space when it is packed away. In a second instance of the present invention, the bellows receptacle uses a pair of segregating discs with each positioned approximate the top and bottom of the bellows receptacle forming closure for said receptacle. Any number of additional discs can be used to create segregated compartments within said bellow receptacle.

Owner:PEGGS JOHN DAVID

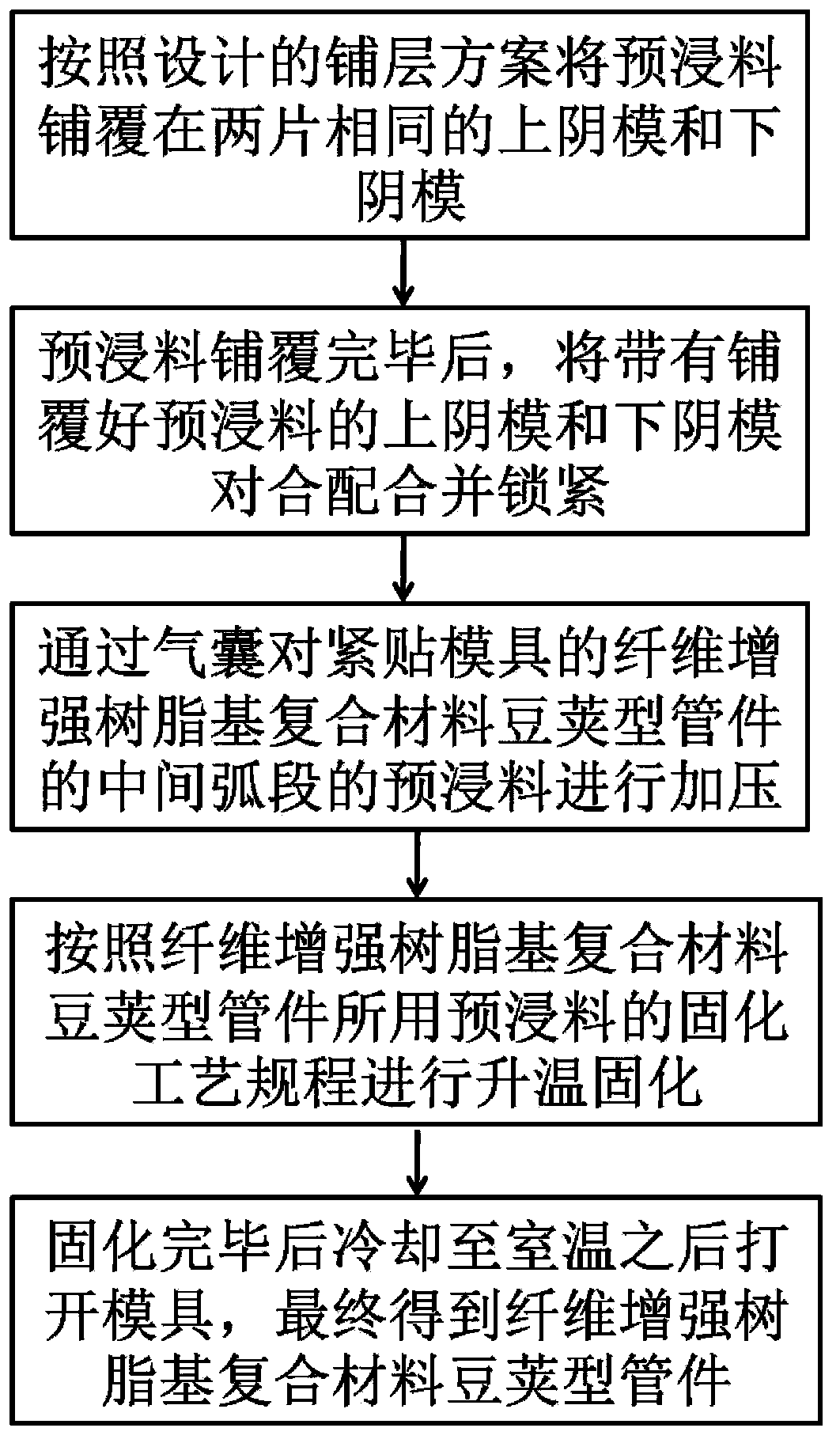

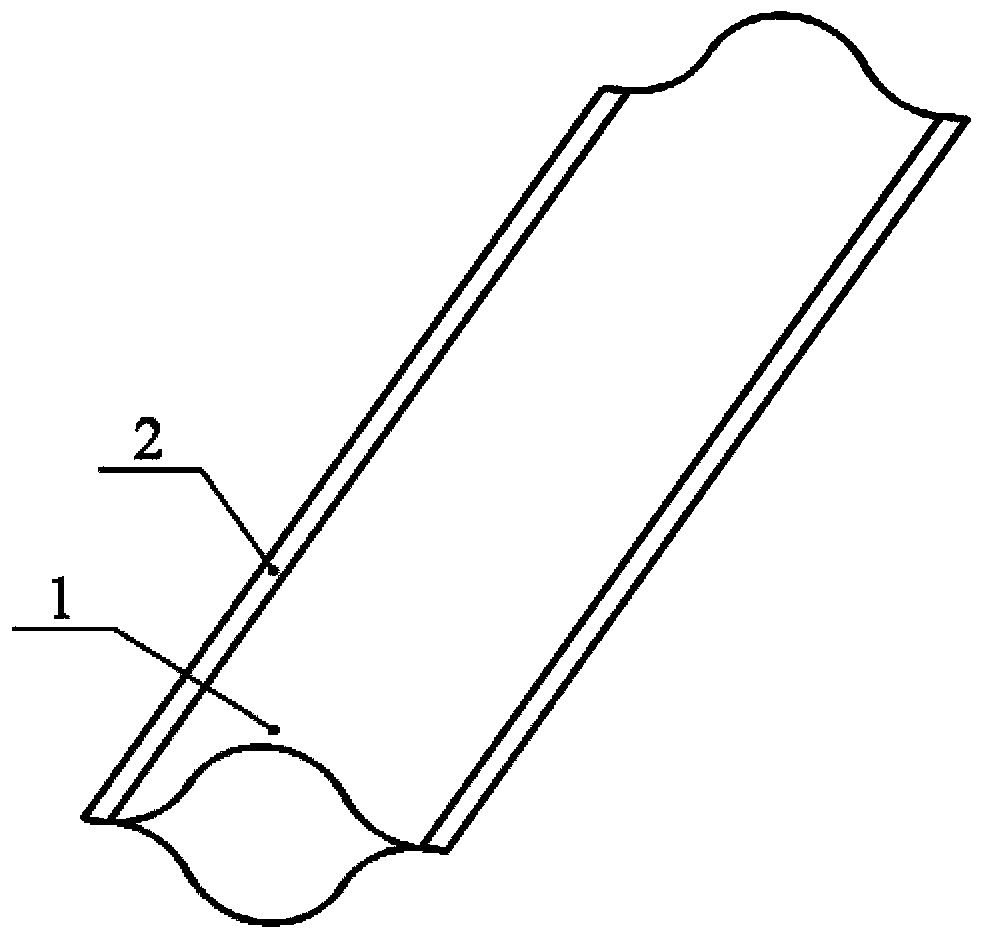

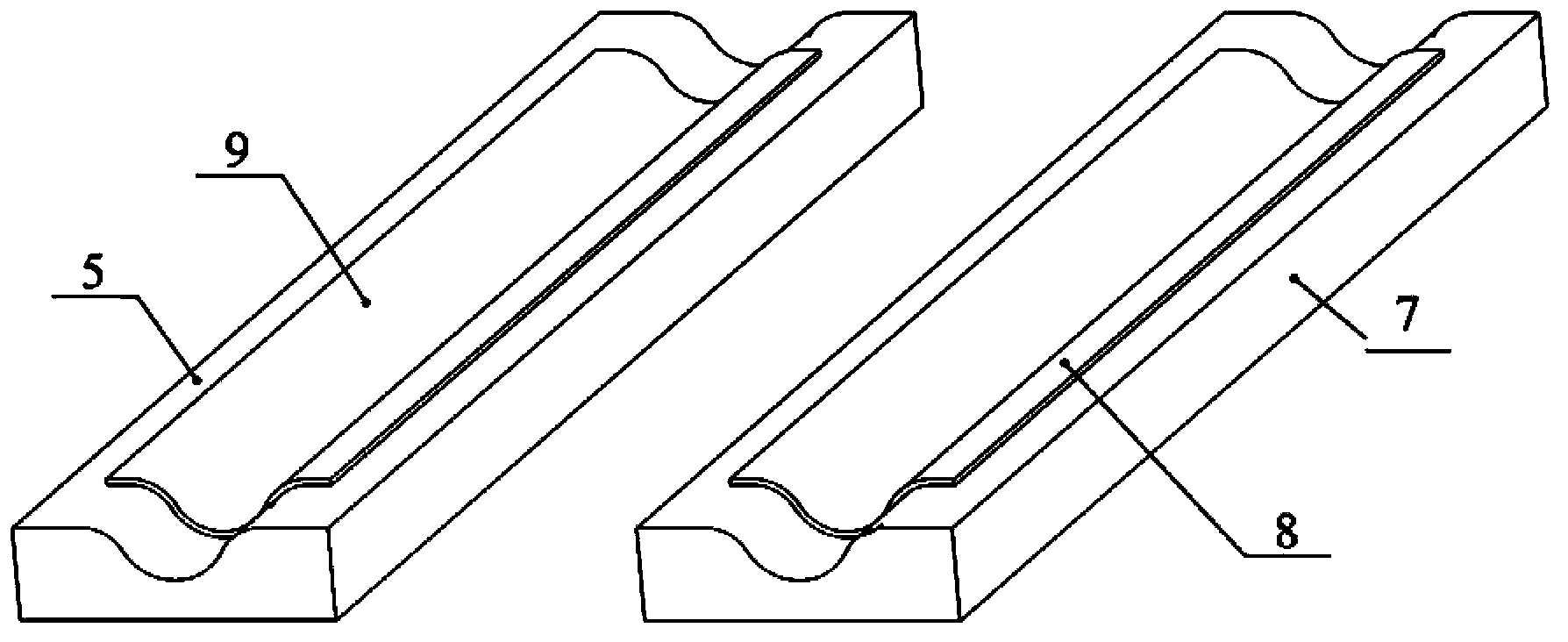

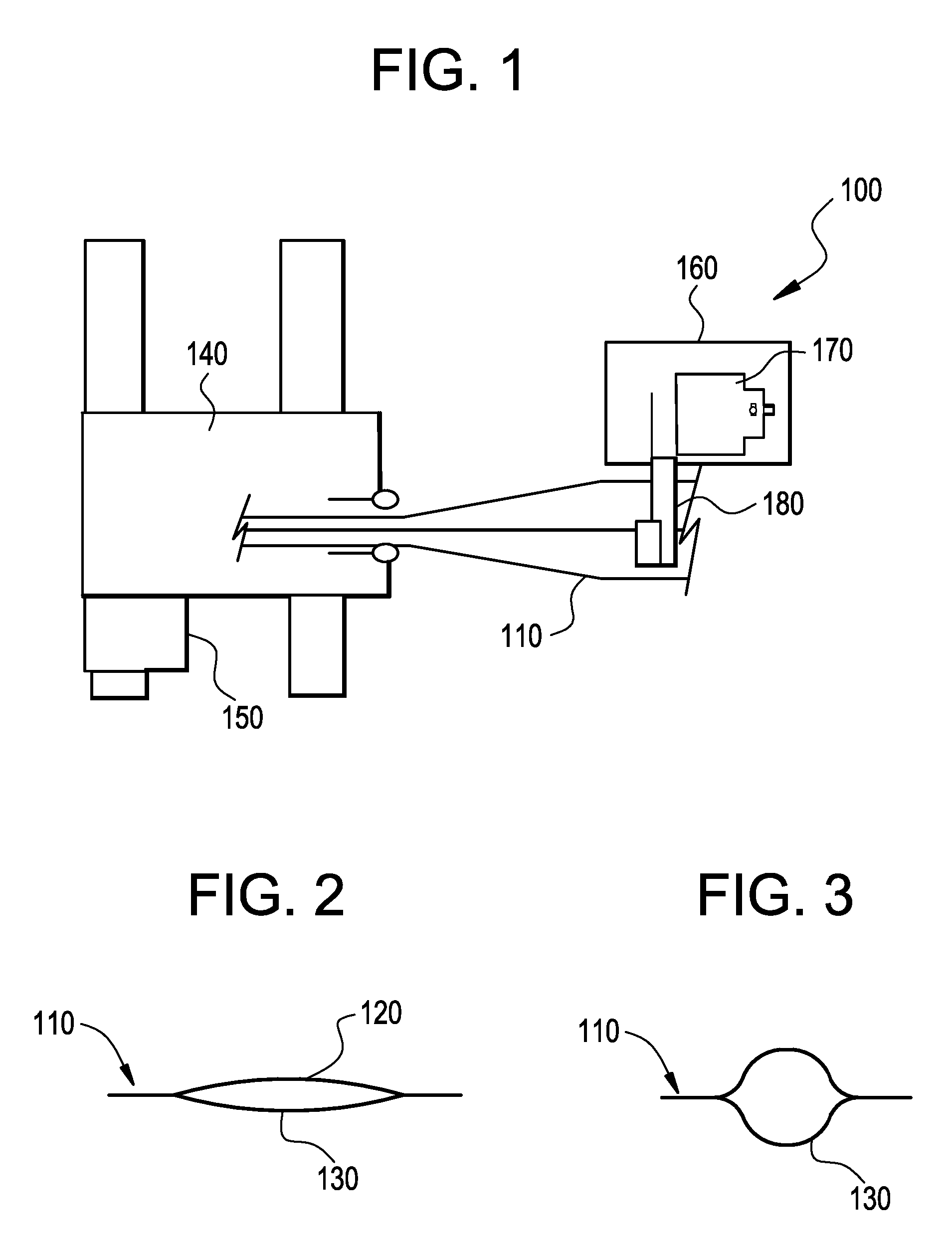

Integrally-forming method of CFRP lenticular collapsible tube

InactiveCN103407174AImprove molding qualityImprove and simplify processesRoom temperatureResin-Based Composite

The invention discloses an integrally-forming method of a CFRP lenticular collapsible tube. The integrally-forming method comprises five steps as follows: (1), laying a prepreg on an upper female mold and a lower female according to a designed laying scheme, wherein the upper female mold is the same as the lower female; (2), after the prepreg is laid, the upper female mold and the lower female covered with the prepreg are assembled oppositely and locked together; (3), pressurizing the prepreg at the arc-shaped middle section of the CFRP lenticular collapsible tube clung to the mold through an air bag; (4), performing heating and solidifying on the prepreg according to the solidification process of the prepreg for preparing the lenticular collapsible tube; (5), after the solidification completion, cooling the prepreg until the temperature of the prepreg is the room temperature, and then opening the mold. Finally, the CFRP lenticular collapsible tube is obtained. The integrally-forming method has the advantages that the inflatable air bag and the mold are used for pressurizing the prepreg together, no secondary glue joint process is needed, one-step integral forming is achieved, the forming quality is high, the technological process is greatly improved and simplified, and the cost is lowered.

Owner:BEIHANG UNIV

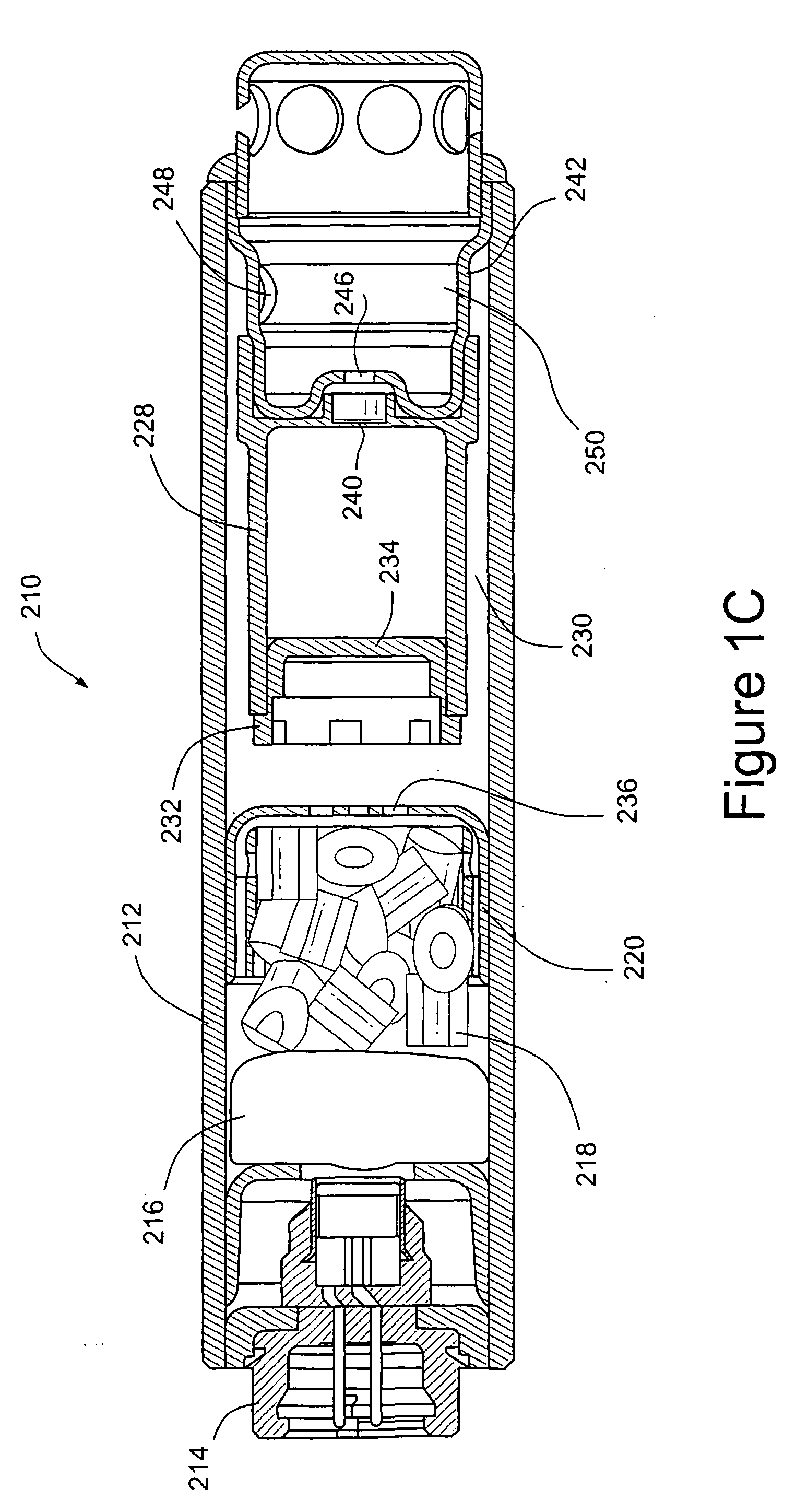

Solid propellant/liquid type hybrid gas generator

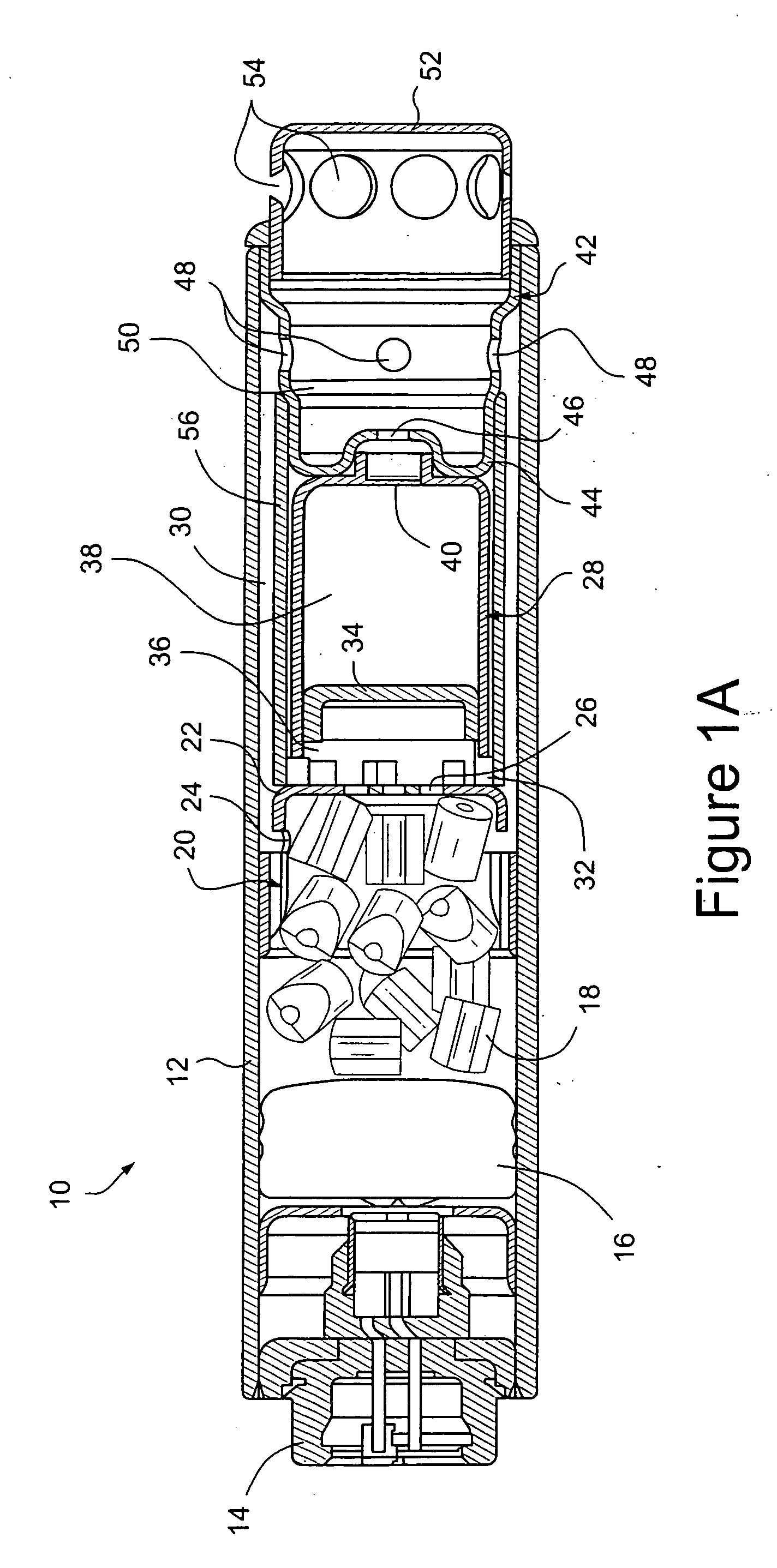

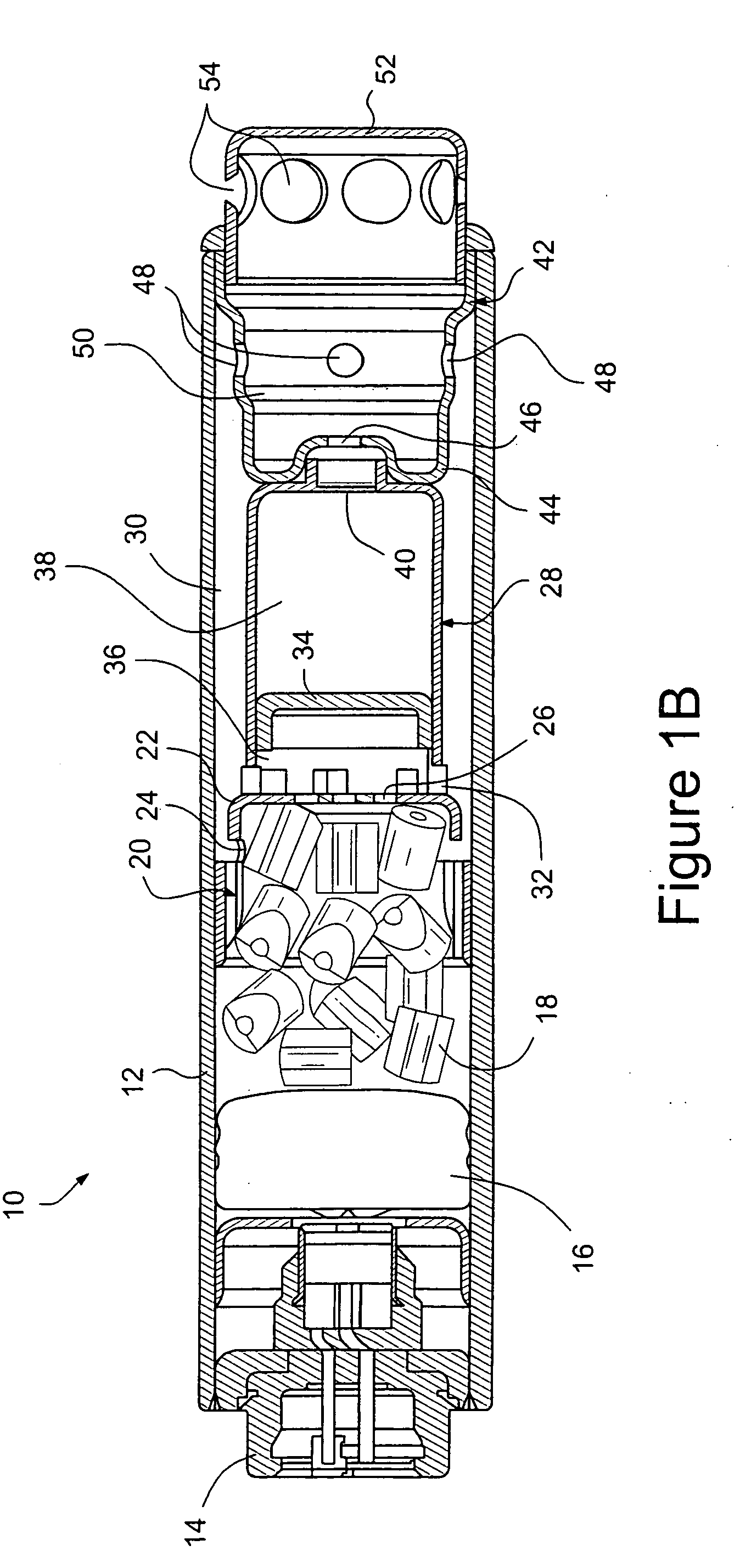

InactiveUS20100230942A1High yieldEasy to usePedestrian/occupant safety arrangementParticulatesCombustion

A gas generator comprising a housing having a mixing chamber and a pyrotechnic charge in the housing. A container having a liquid therein is disposed in the housing and has an open end and a closed end, with an end cap closing the open end and having a piston portion removably connected thereto and being movable within the liquid container to pressurize the liquid therein when the piston portion is separated from the end cap. The piston portion is positioned to be exposed to combustion gas from the pyrotechnic charge when it is ignited and is separable from the end cap when the combustion gas exceeds a predetermined pressure. In another embodiment, the liquid container may be a collapsible tube. The closed end of the liquid container has a weakened portion constructed to be opened when the pressure of the liquid in the container exceeds a predetermined pressure. The pyrotechnic charge and the weakened portion of the liquid container are in fluid communication with the mixing chamber so that combustion gases from the ignition of the pyrotechnic charge mix with and vaporize the liquid in the mixing chamber to generate a non-toxic, low temperature, low particulate inflation gas.

Owner:ARC AUTOMOTIVE

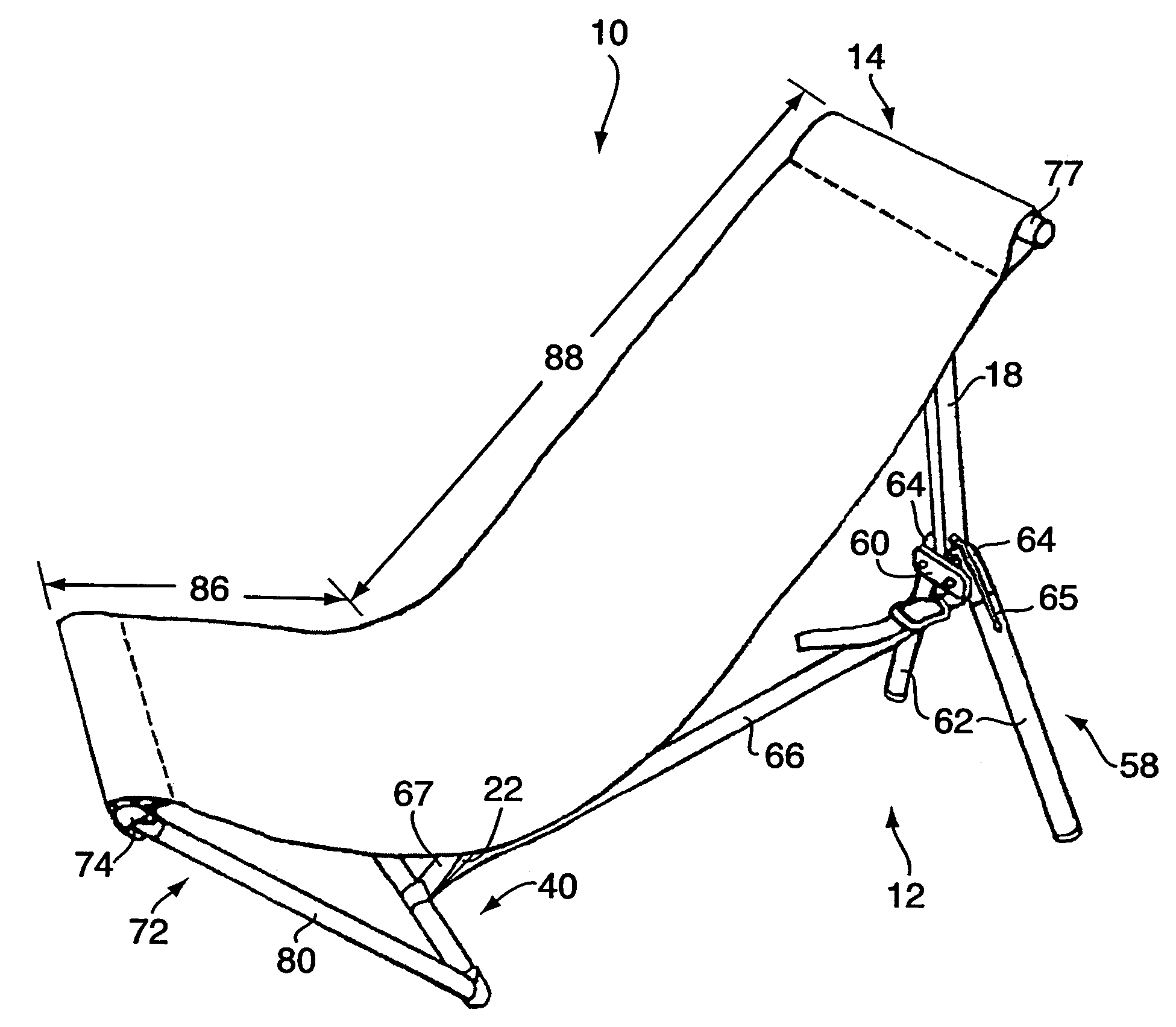

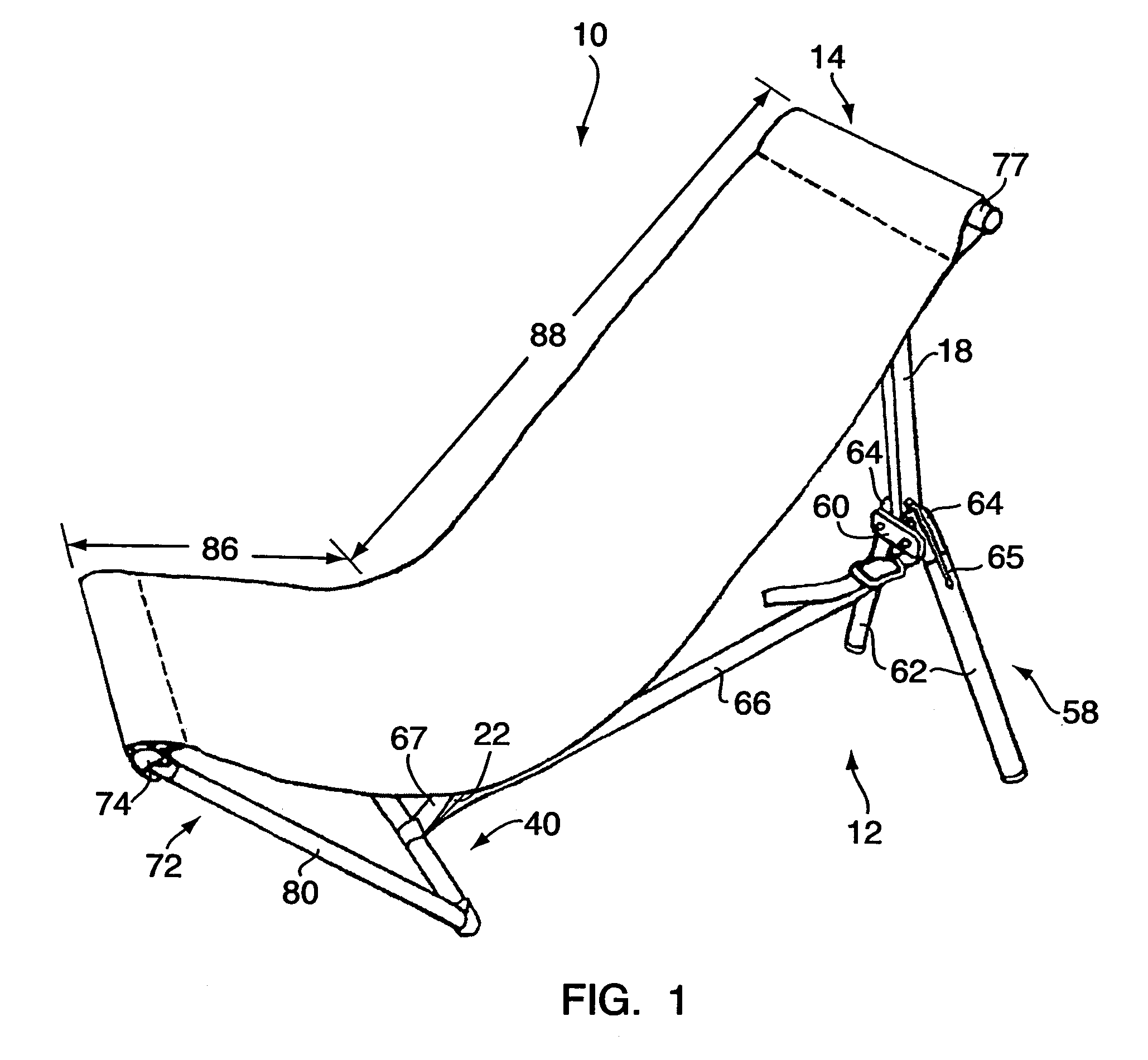

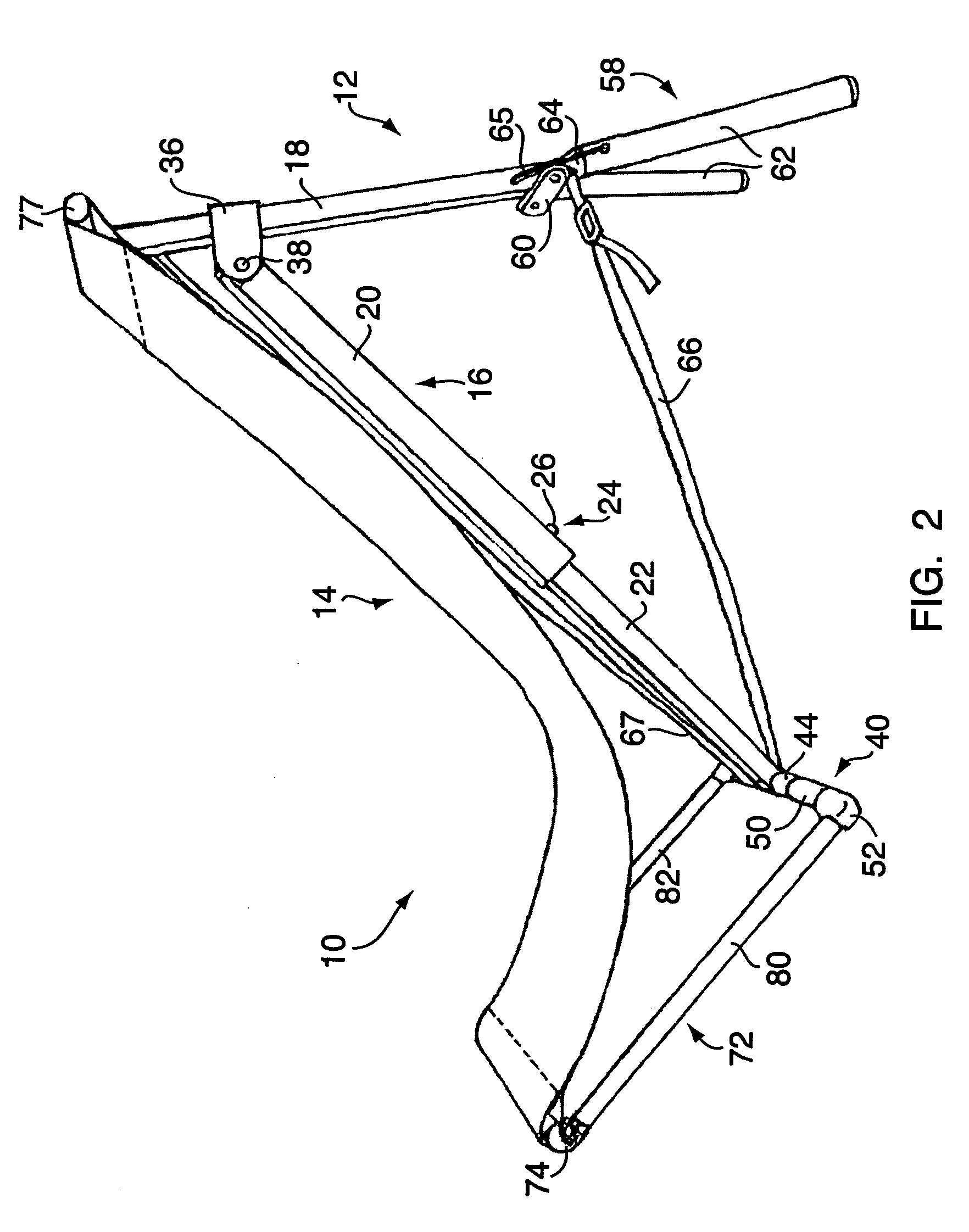

Portable sling chair

Owner:GCI OUTDOOR

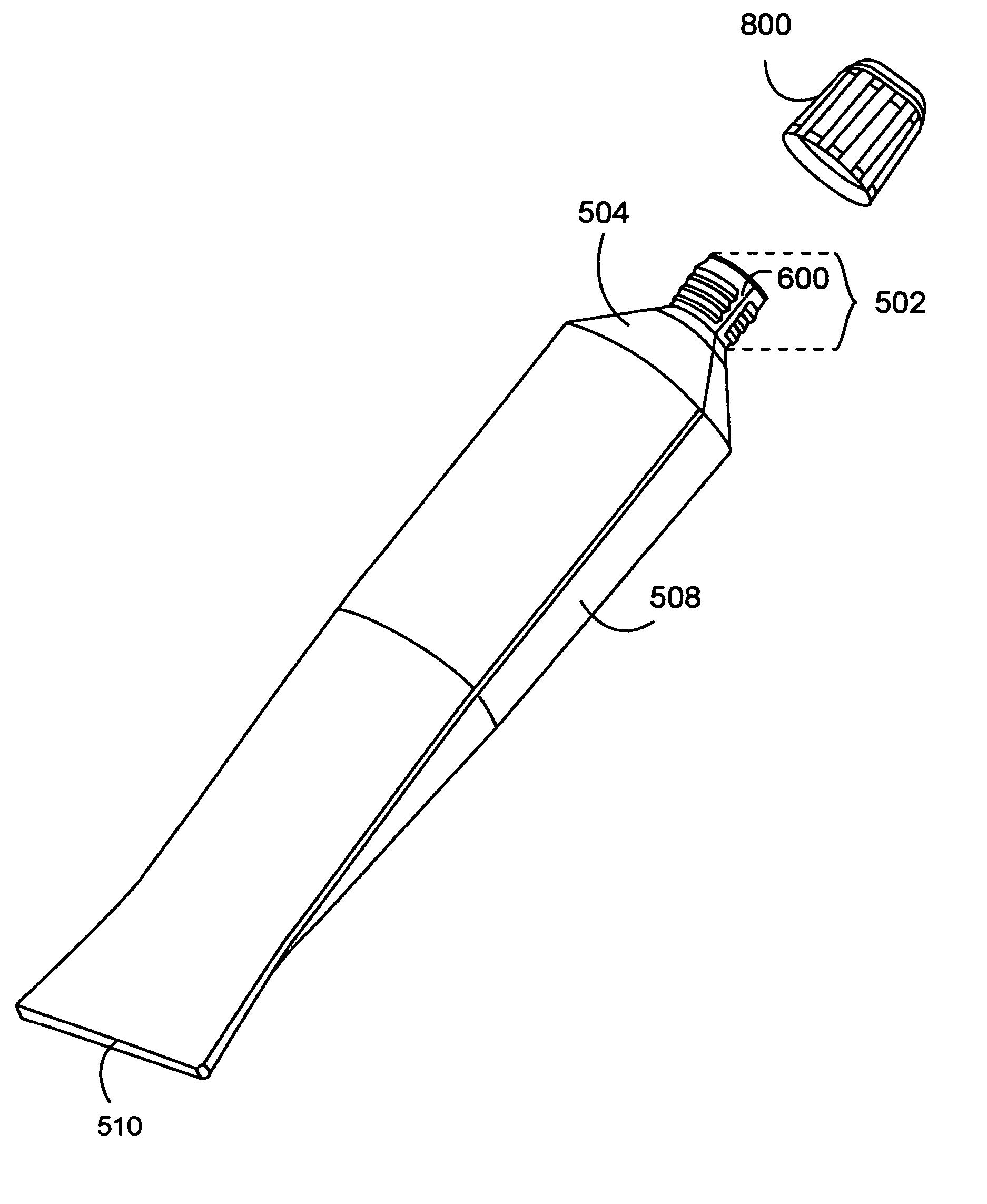

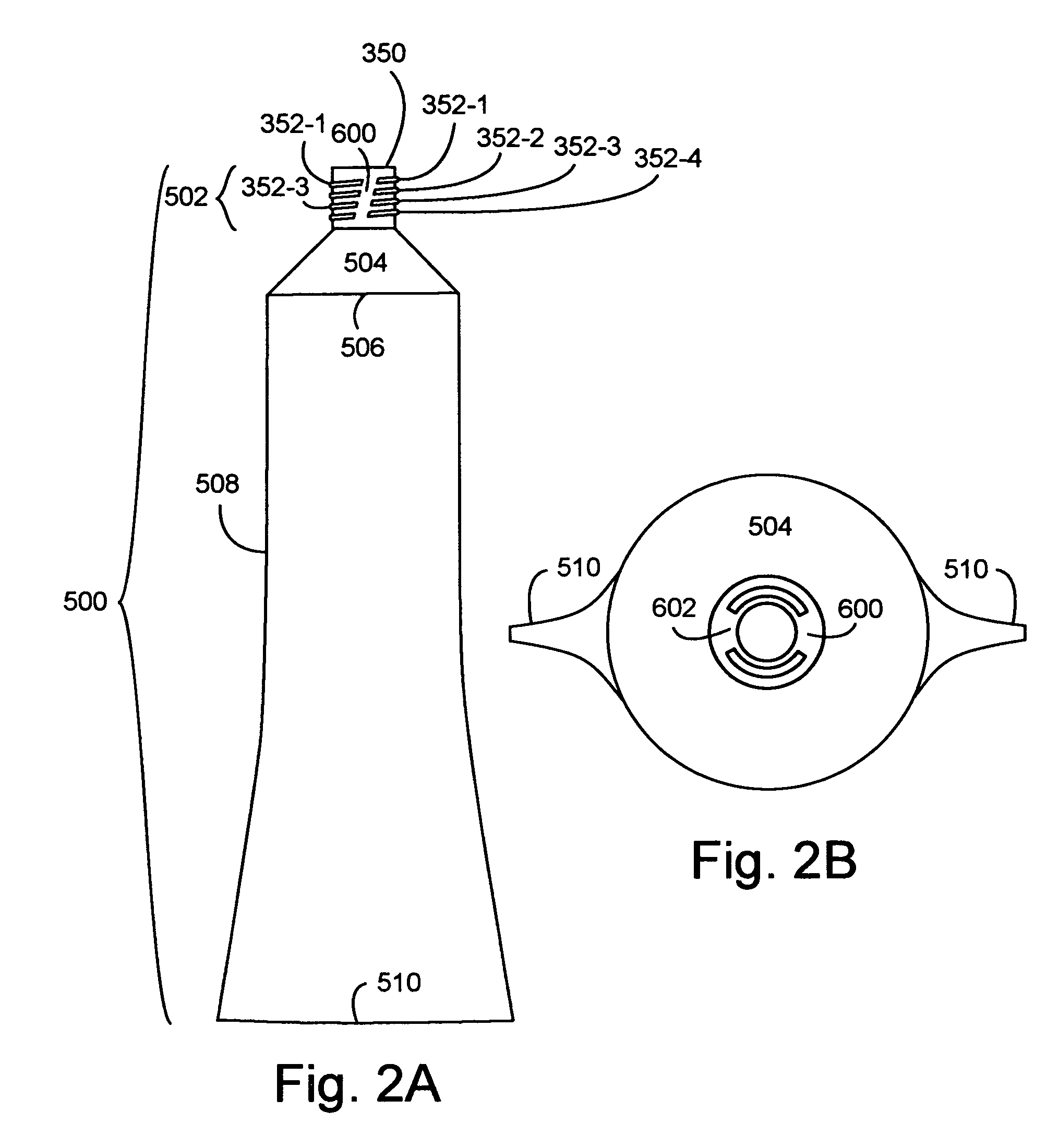

Apparatus and method for open thread, reusable, no-waste collapsible tube dispensers with control ribs and/or detent

At least one collapsible tube for containing at least one product, comprising: external flexible thread form on flexible throat coupled to flexible shoulder. The flexible throat and flexible shoulder flatten to dispense essentially all the contained product. The flexible shoulder may include a raised detent for stopping a cap and / or raised flexible ribs to control the direction of flattening the flexible shoulder. At least one cap for the collapsible tube including an interior bulge or an interior rim, both for urging an included interior thread form to engage with an external flexible thread form included in the flexible throat, and further including a lower surface to engage with the raised detent, and / or internal ribs and / or internal posts to engage with the raised flexible ribs. Manufacturing methods for the collapsible tubes and caps, and these items as products of the manufacturing processes.

Owner:ANDERSON SCOTT V +1

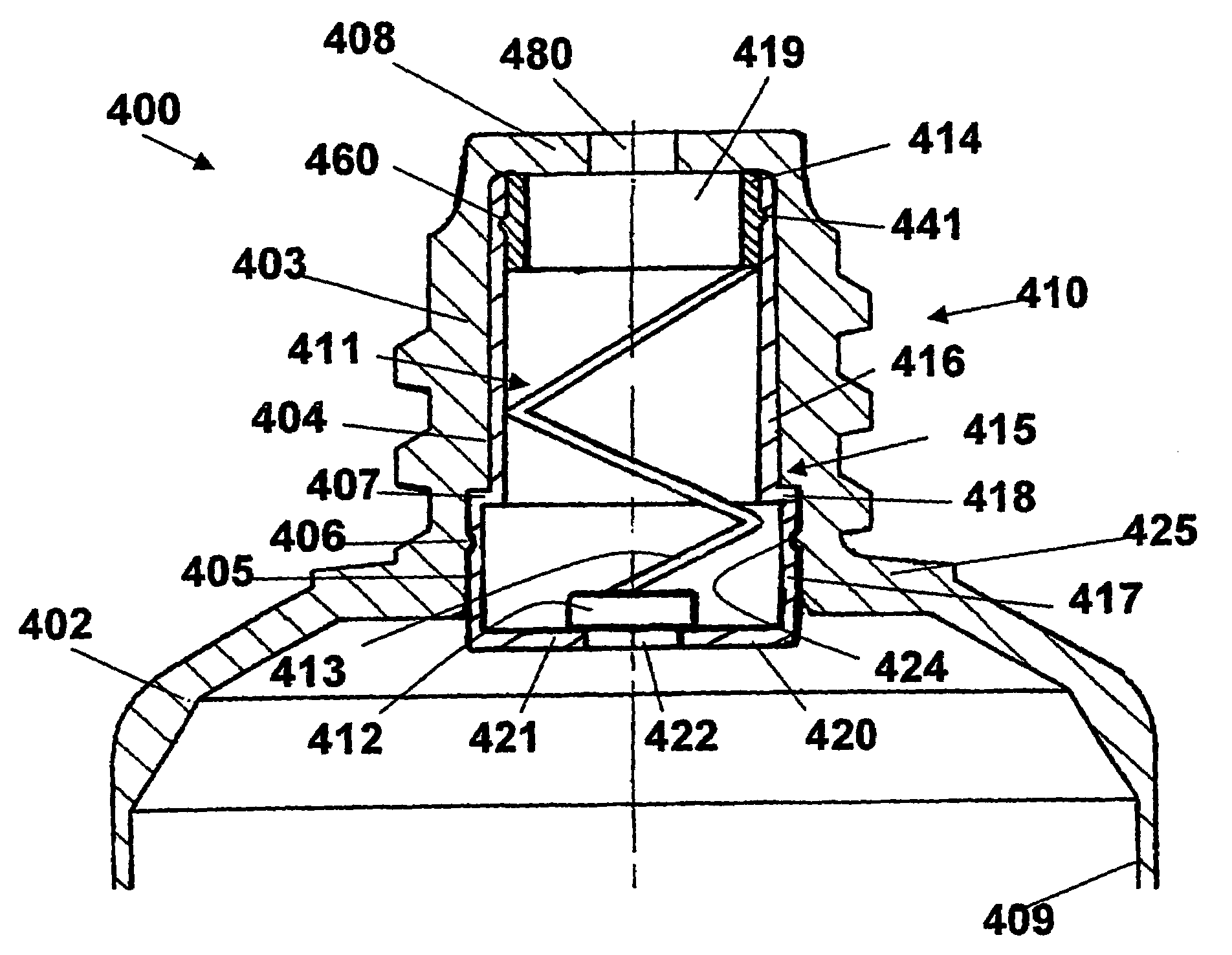

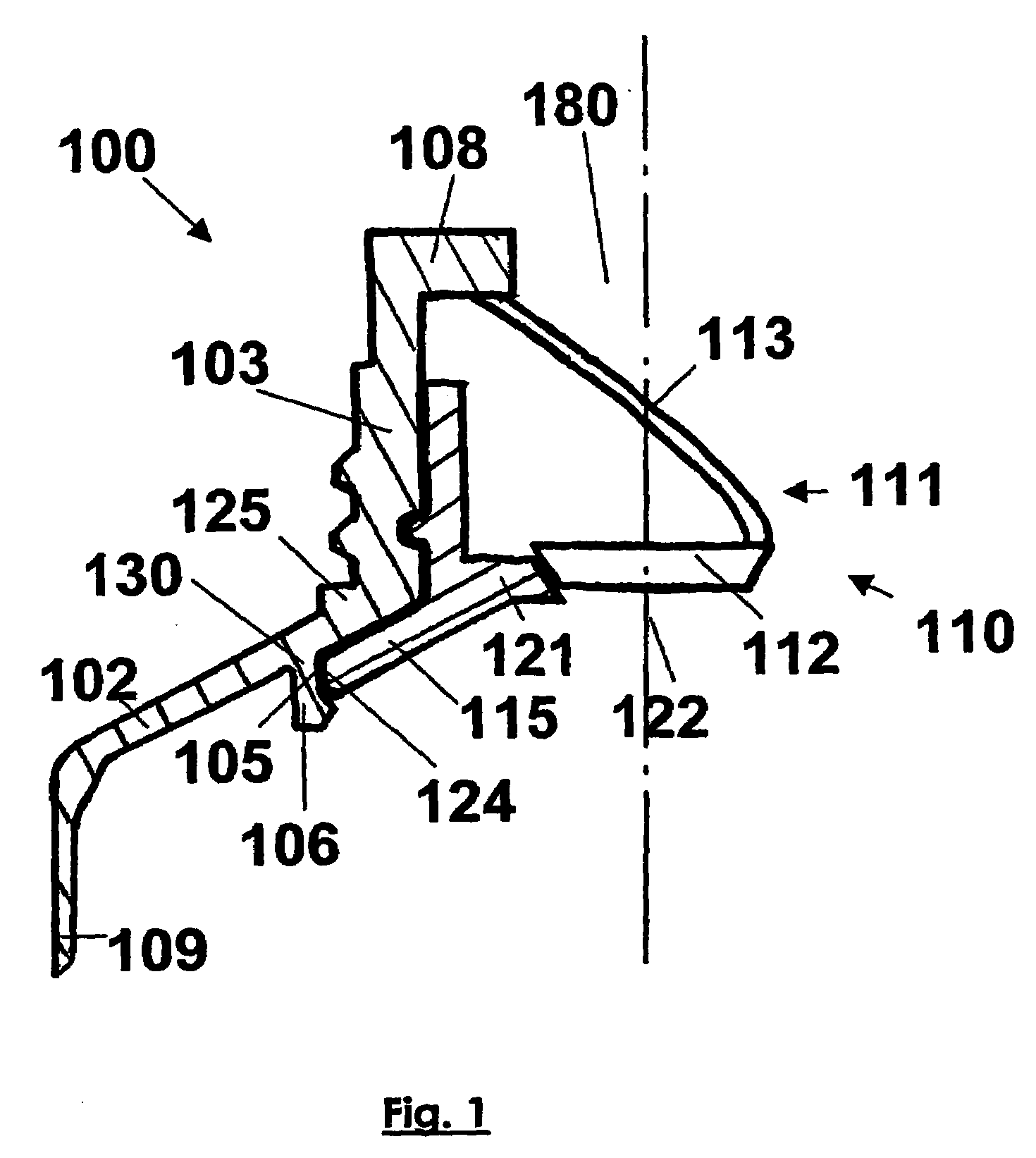

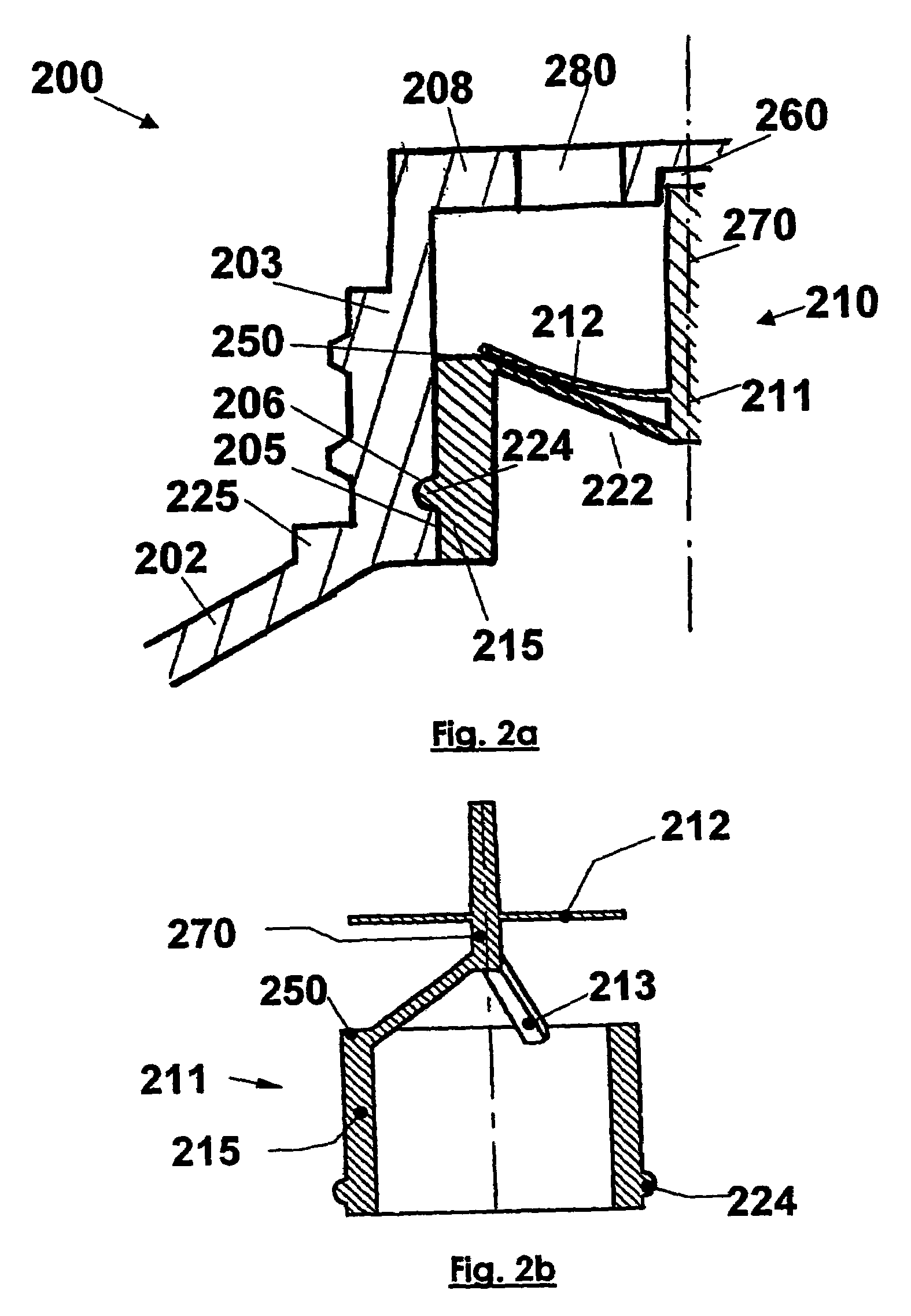

Collapsible tube with a distributor head without air return

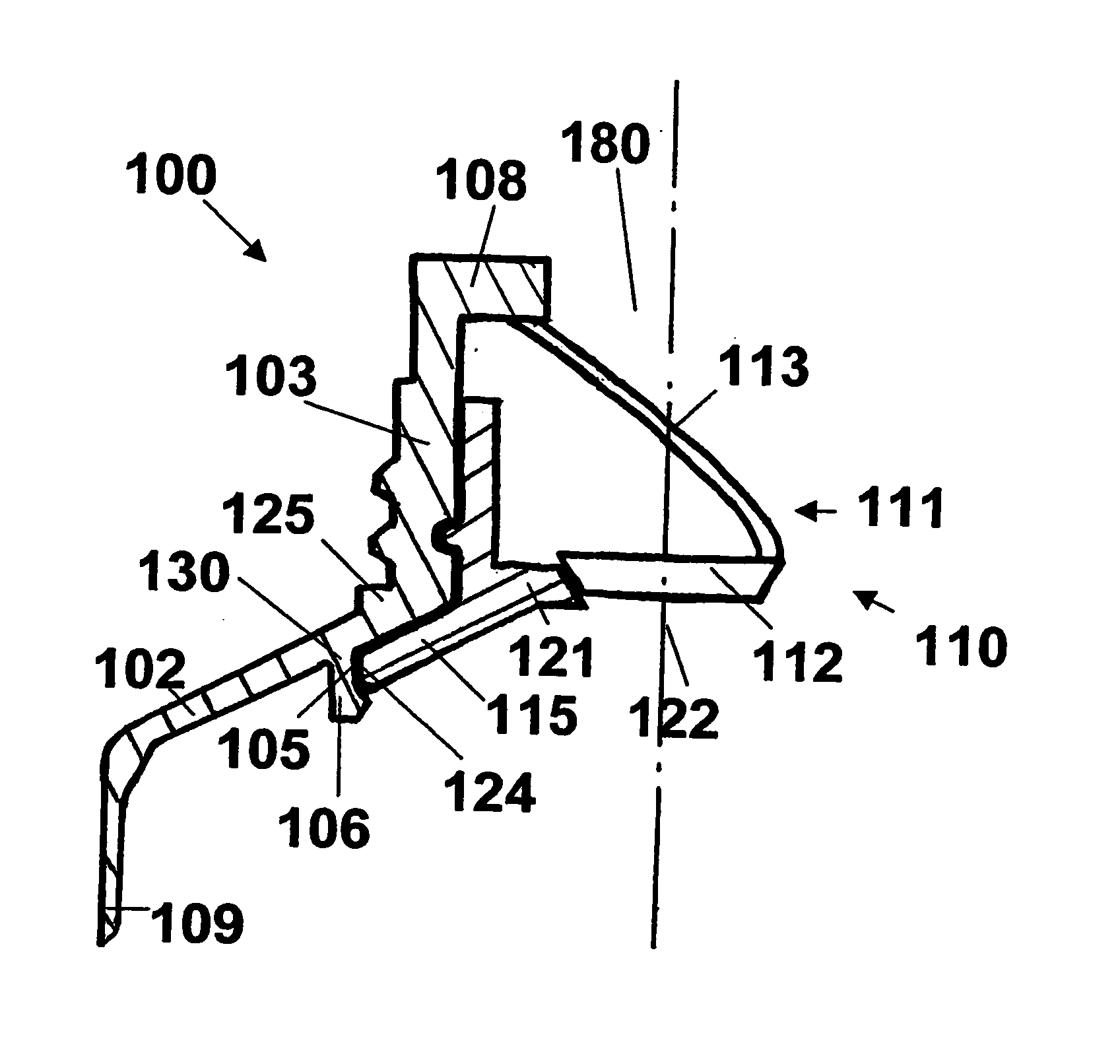

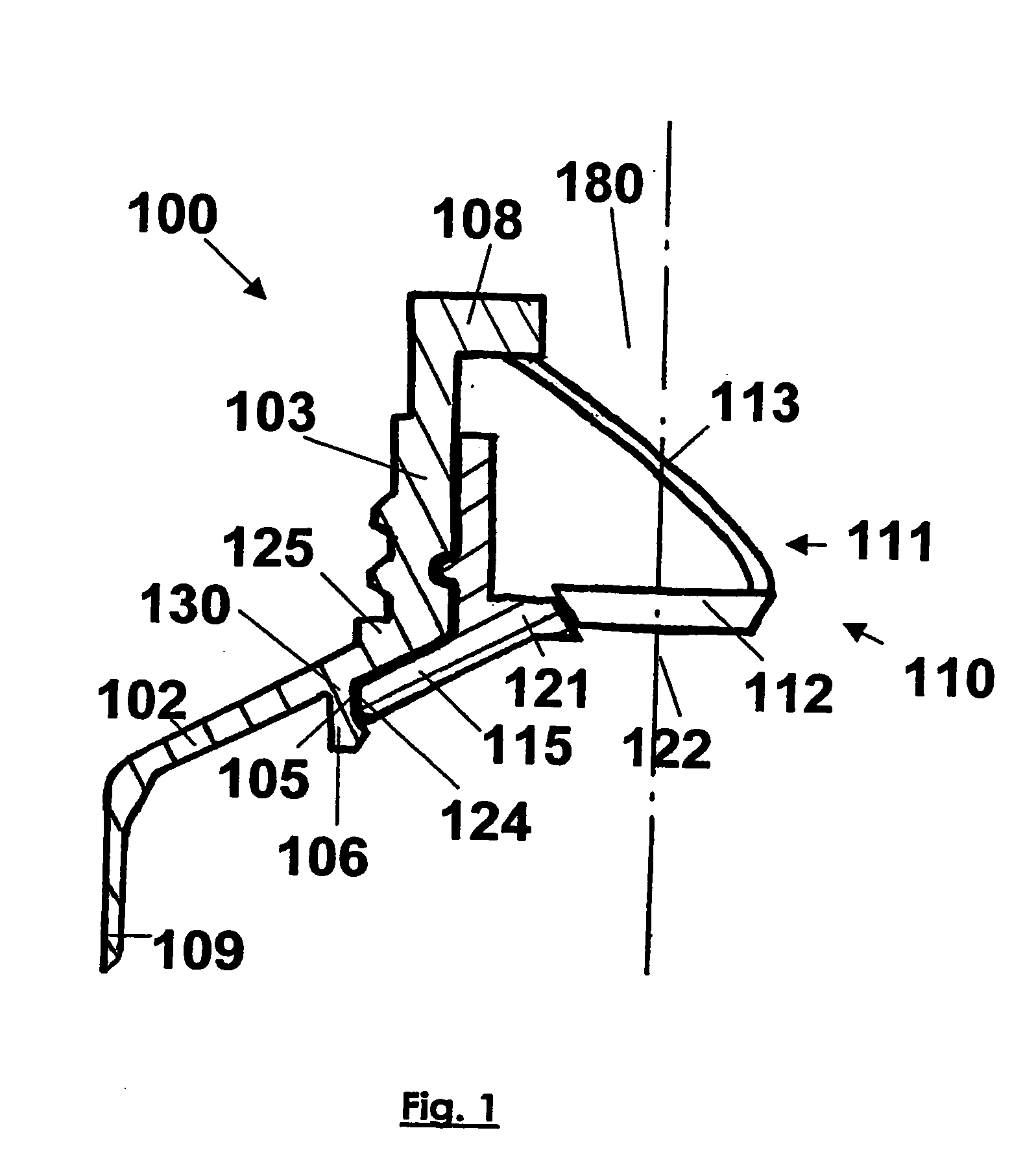

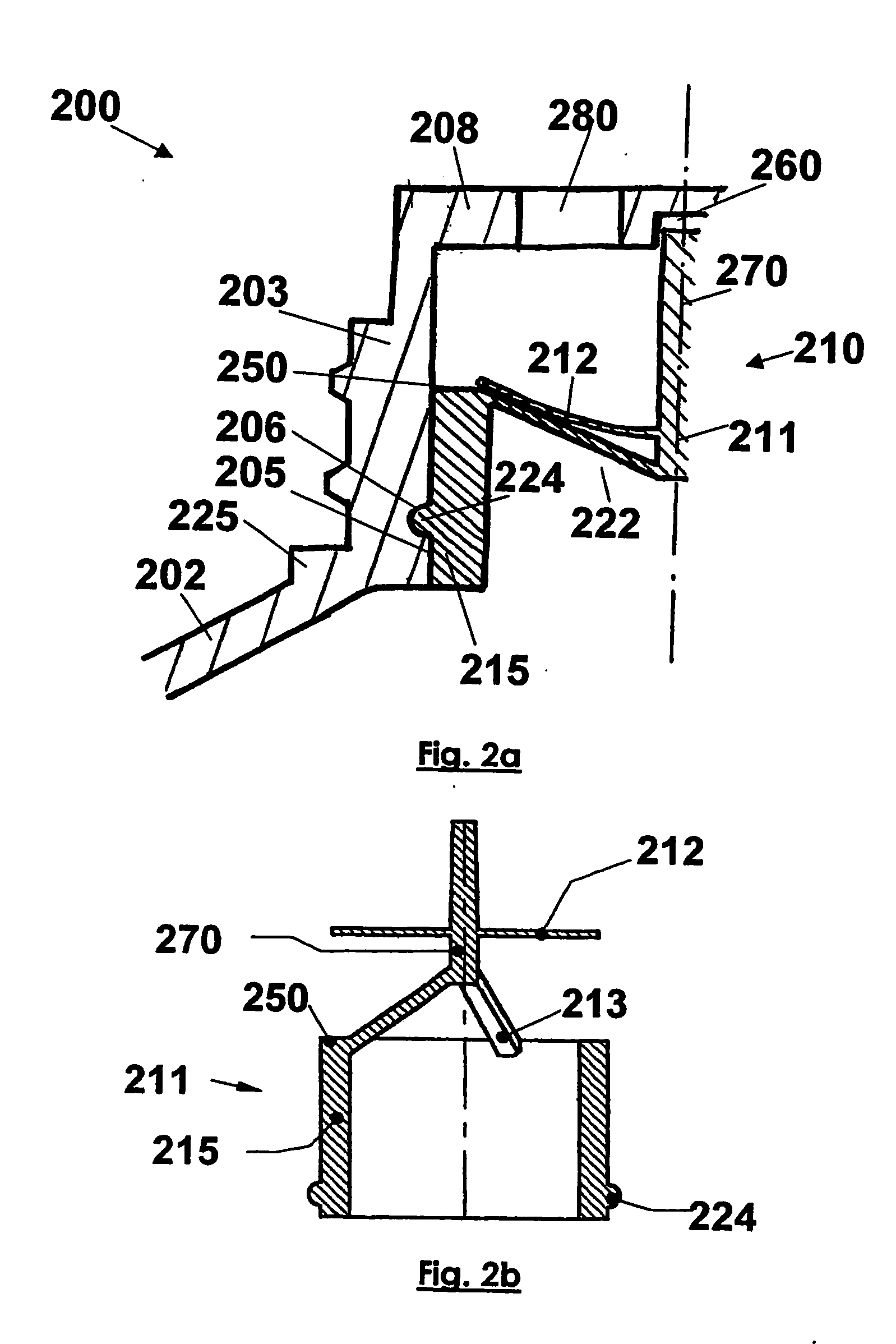

InactiveUS20040144809A1Counteracting forceLess complicatedClosuresContainers preventing decayEngineeringSoldering

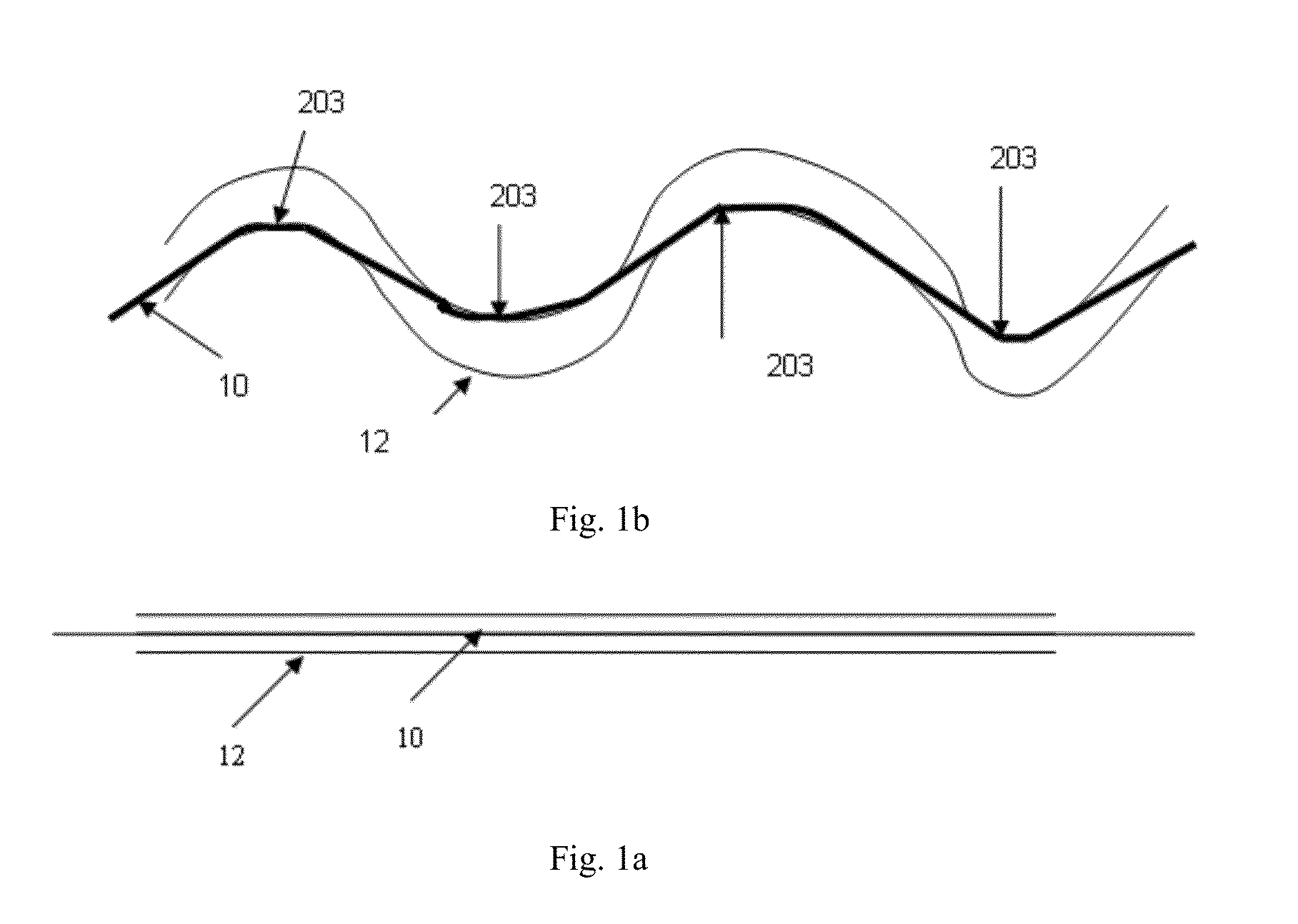

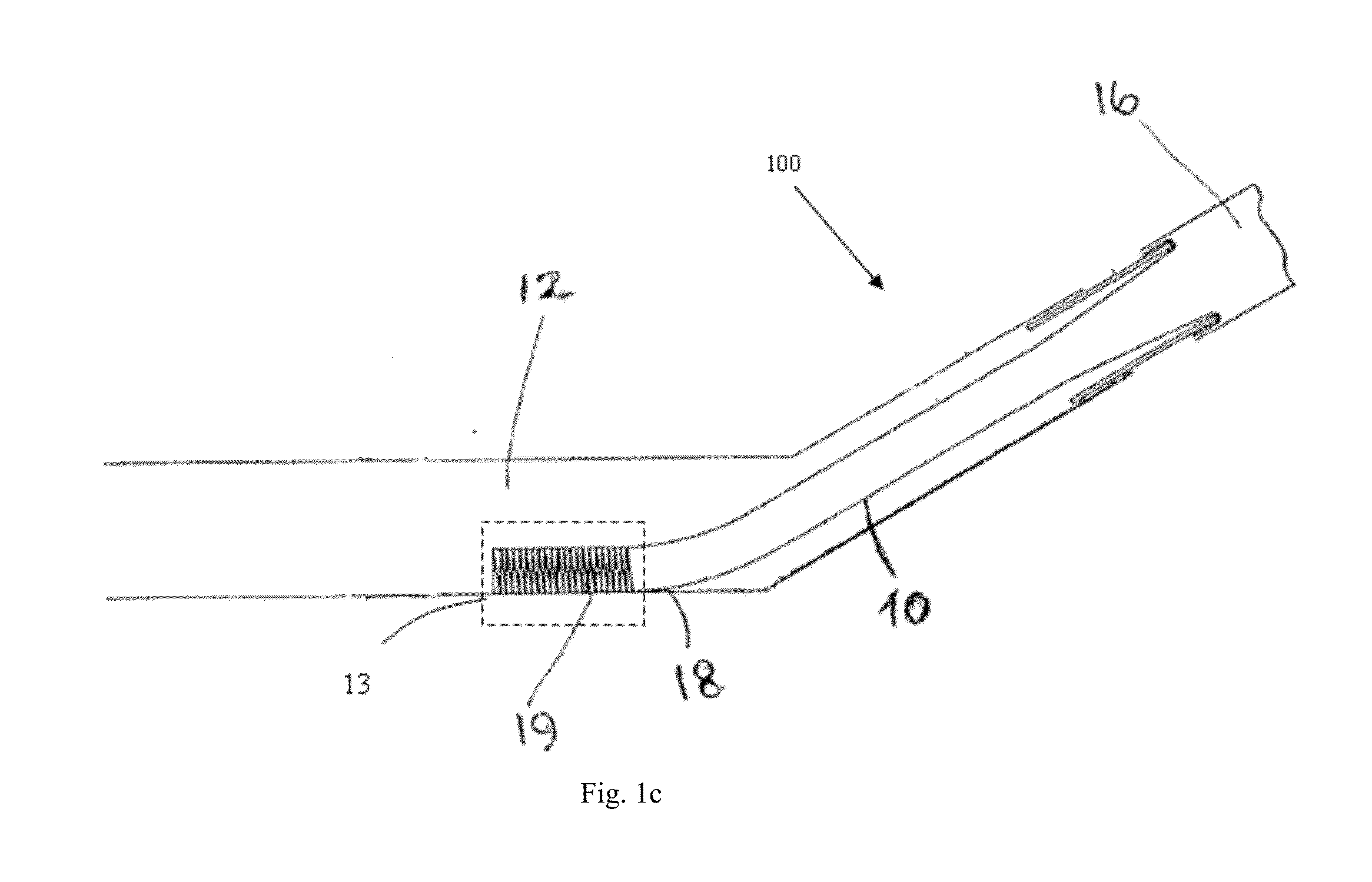

Collapsible tube head (100, 200, 300, 400) comprising a neck (103, 203, 303, 403) which is fitted, with a port (180, 280, 380, 480) and a shoulder (102, 202, 302, 402). The aforementioned head is fitted with a valve (110, 210, 310, 410) which is inserted in the neck of the said collapsible tube, the said valve comprising a sealing means (112, 212, 312, 412) which is connected to a ring support (115, 215, 315, 415) having an opening (122, 222, 322, 422), the said sealing means being maintained in the closed position of the said opening when the tube is not compressed, and being maintained in the open position when the tube is compressed. The inner surface of the tube is provided with a bore (105, 205, 305, 405) which is disposed close to the base of the said neck. The ring support is fixed to the bore by means of bonding, soldering or force fitting, and the said bore and ring support are preferably provided with complementary connection means, in particular a groove and rice grains.

Owner:CEBAL SA

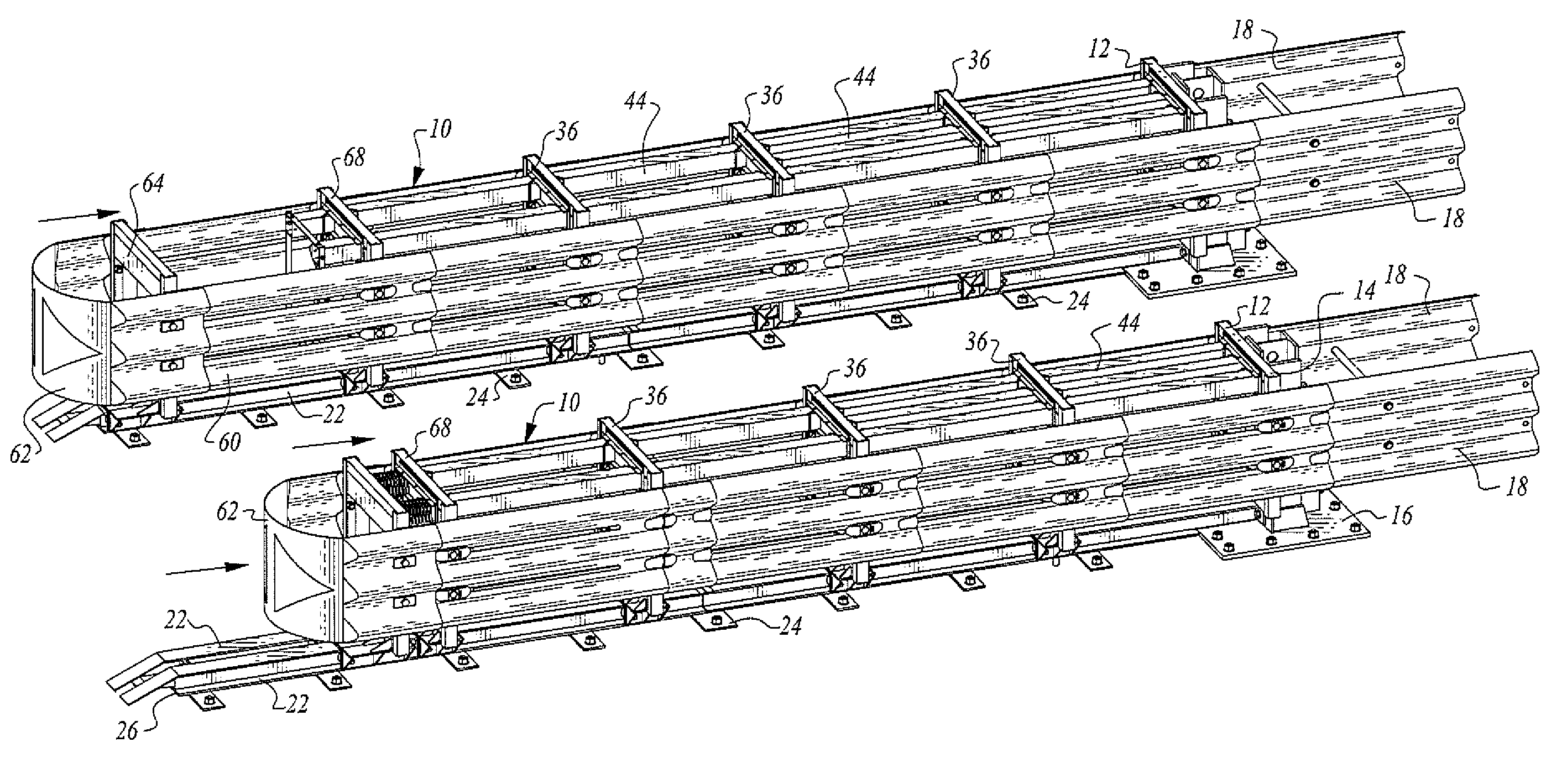

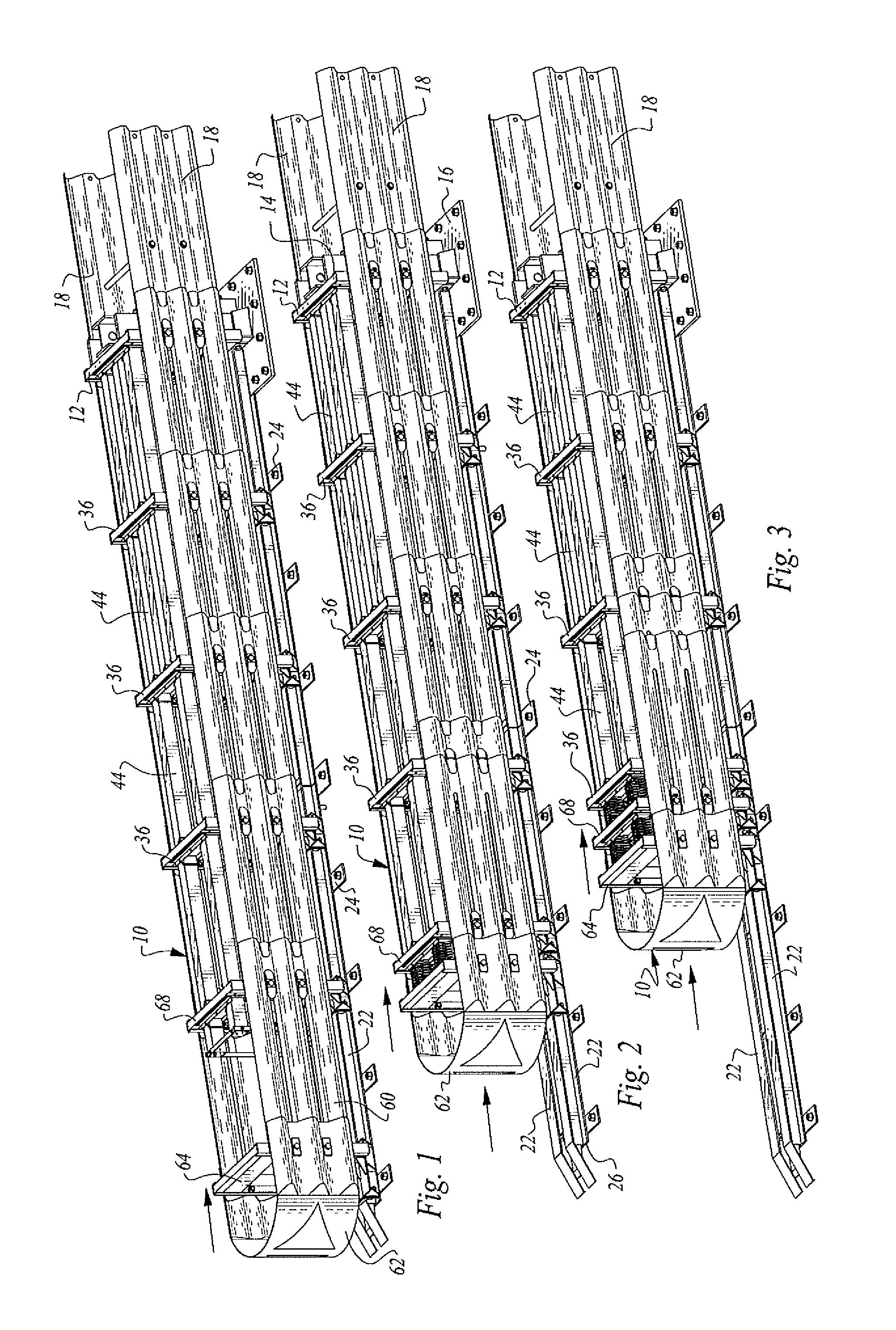

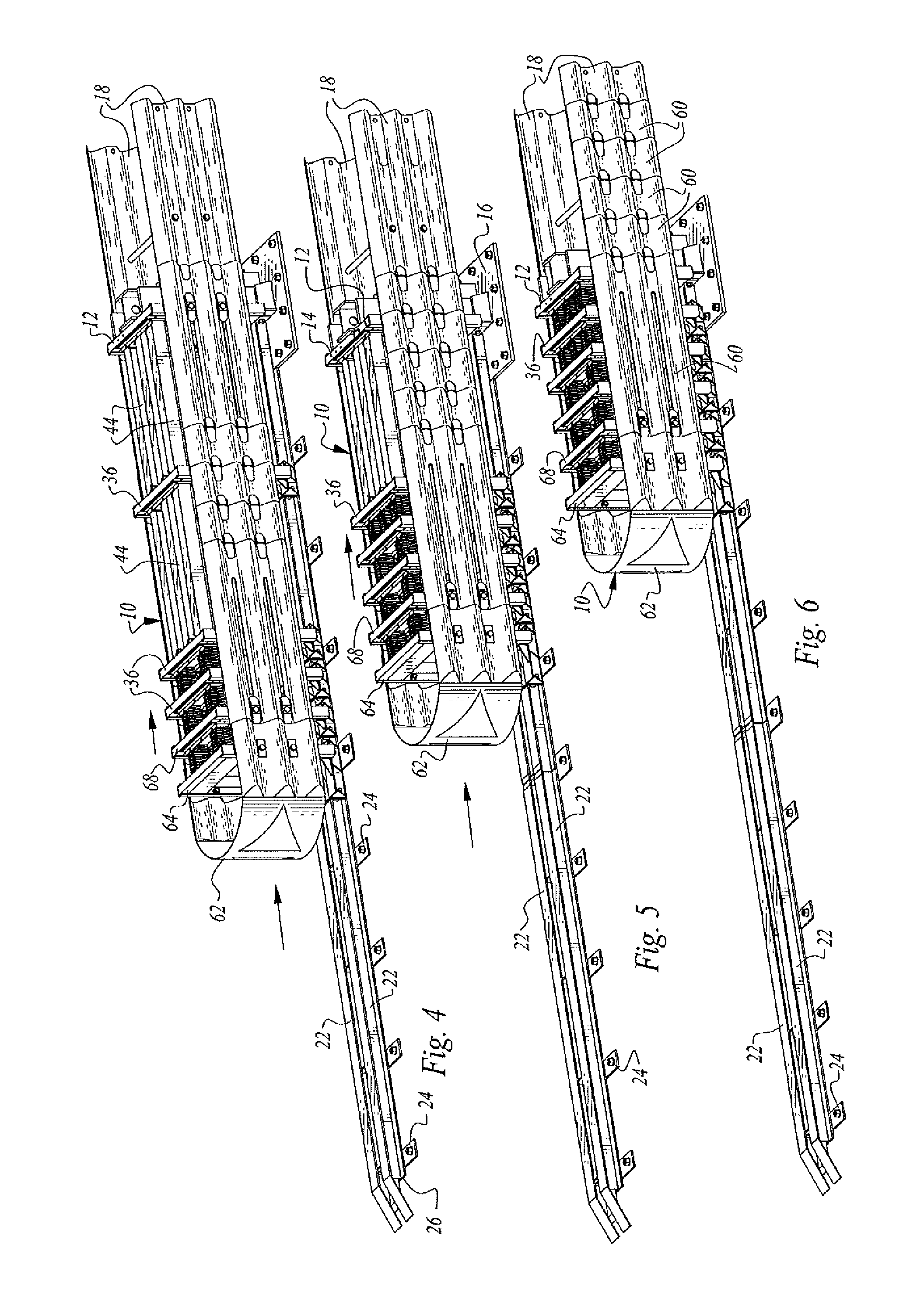

Crash attenuator apparatus

Owner:LINDSAY TRANSPORTATION SOLUTIONS LLC

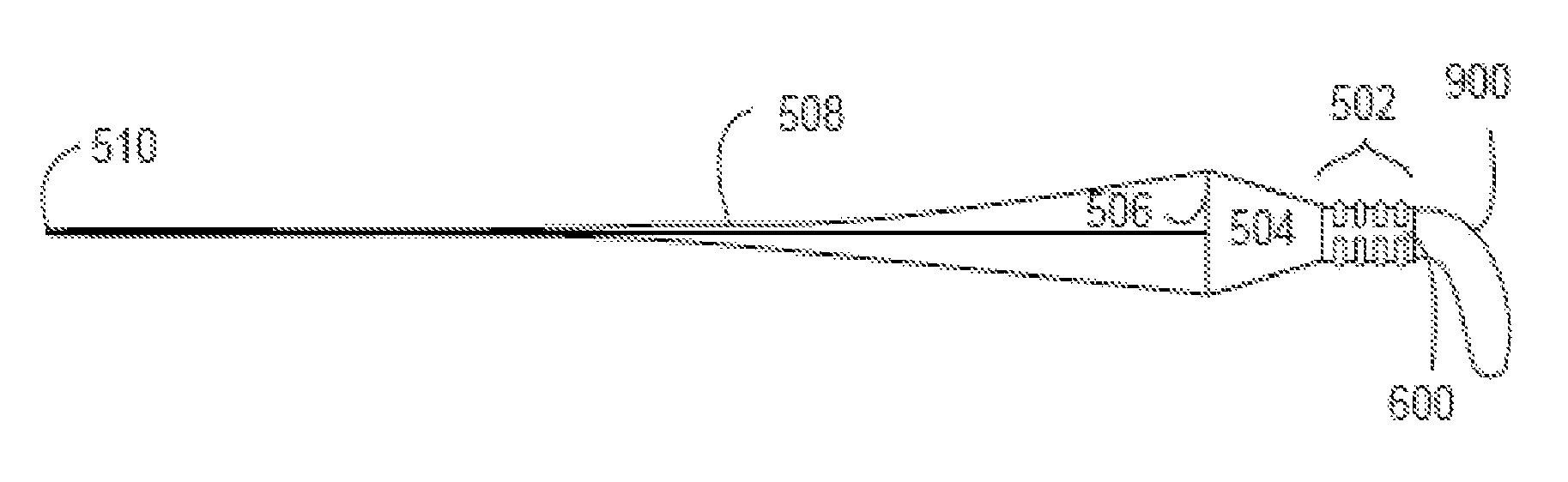

Hemostasis valve

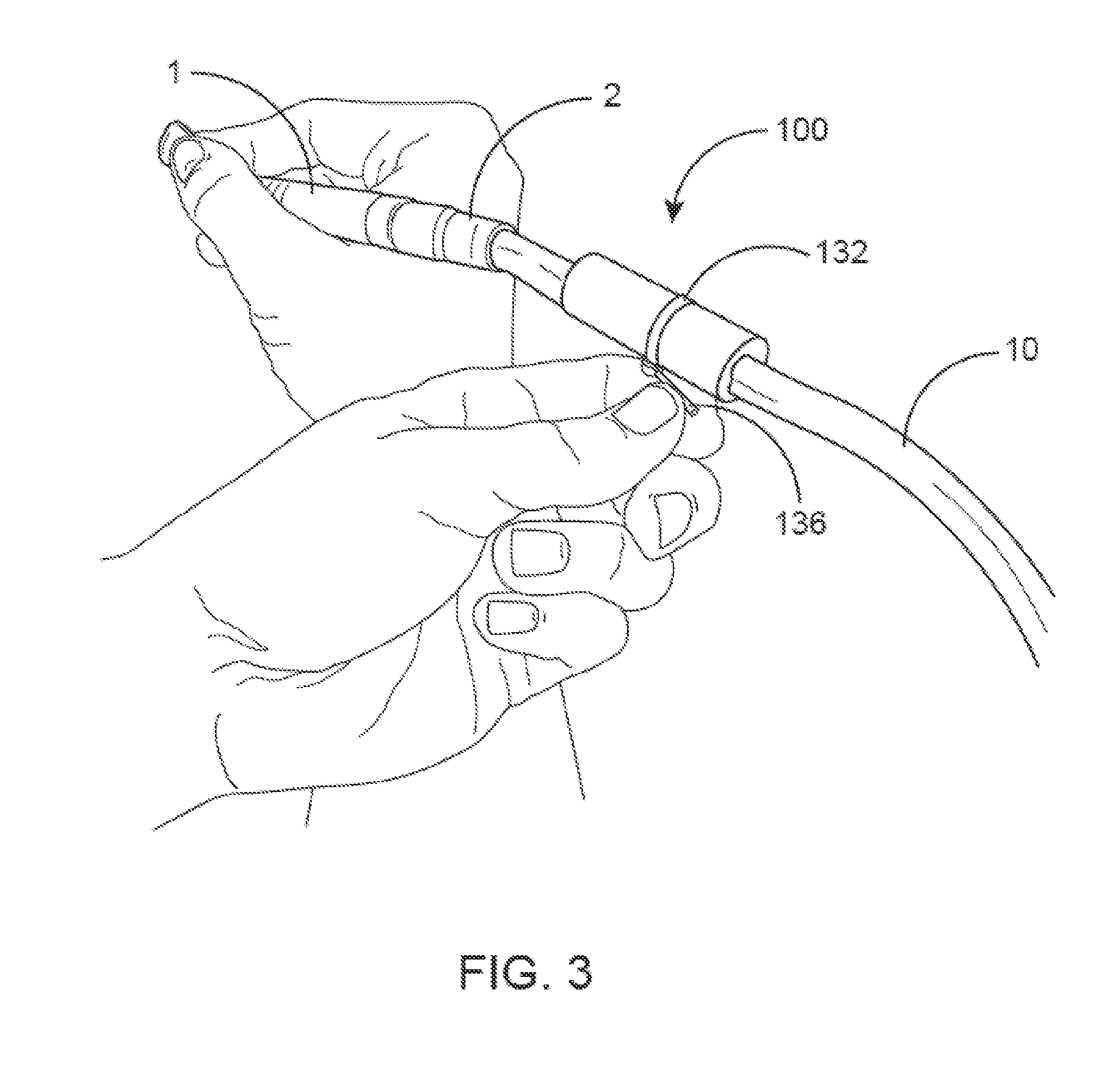

PendingUS20210316127A1Improve responseFacilitate flushing the catheter and/or dilute the contrast agentMulti-lumen catheterGuide wiresHemostasis valveBiomedical engineering

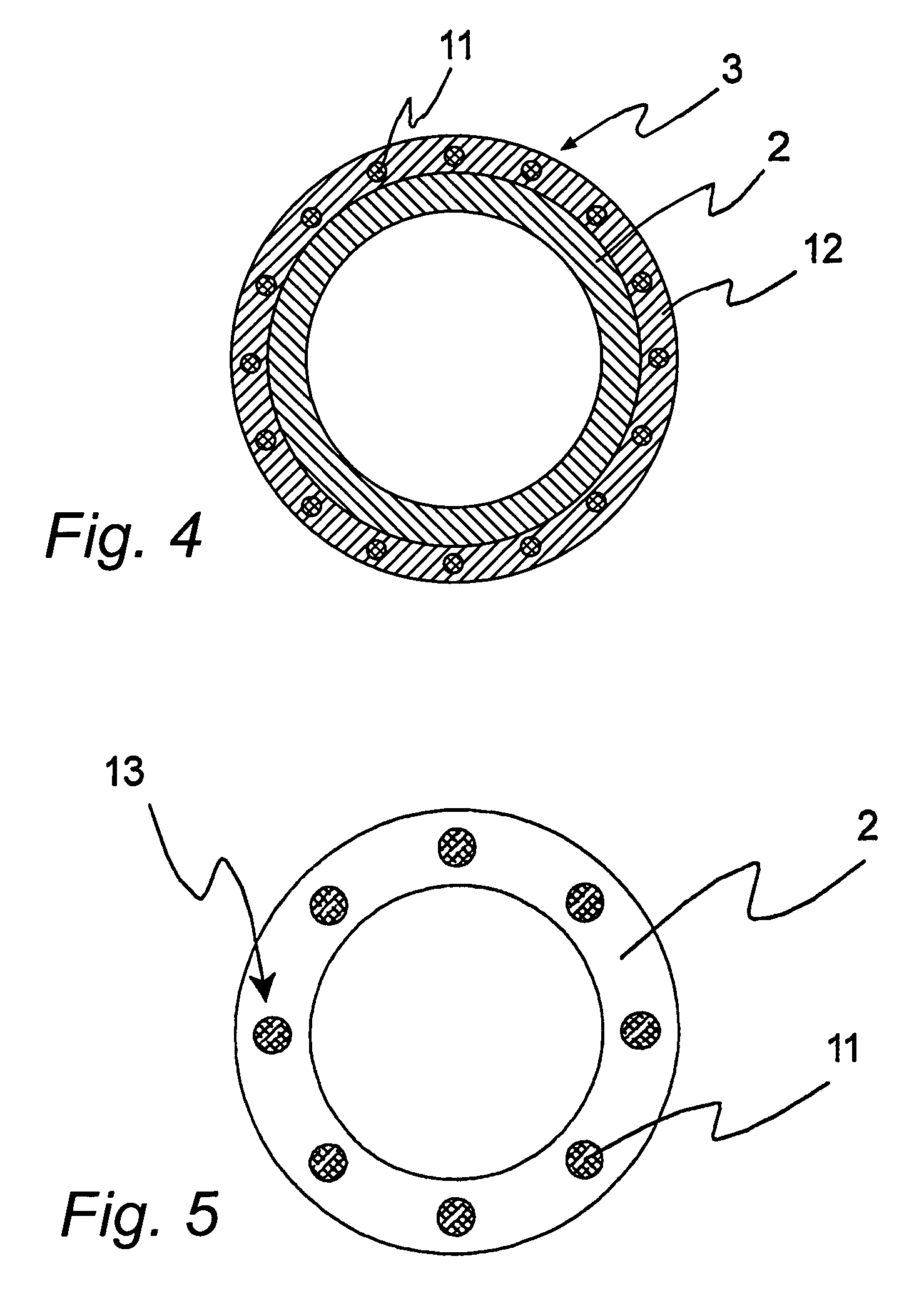

A hemostasis valve may be used with a catheter such as an aspiration catheter. The hemostasis valve comprises a support, and at least a first lever, pivotably carried with respect to the support. A collapsible tubular sidewall defining a valve lumen is carried by the support. A filament is formed into a loop around the tubular sidewall, the filament having at least a first tail portion extending away from the loop to the first lever. A first spring may be configured to move the first lever in a direction that pulls the first tail portion away from the tubular sidewall, reducing the diameter of the valve lumen in response to reducing the diameter of the loop. A second tail portion may extend away from the loop to a second lever. Each tail portion may be attached to its respective lever, or may be slidably advanceable around a fulcrum on the lever and attached with respect to the support.

Owner:IMPERATIVE CARE INC

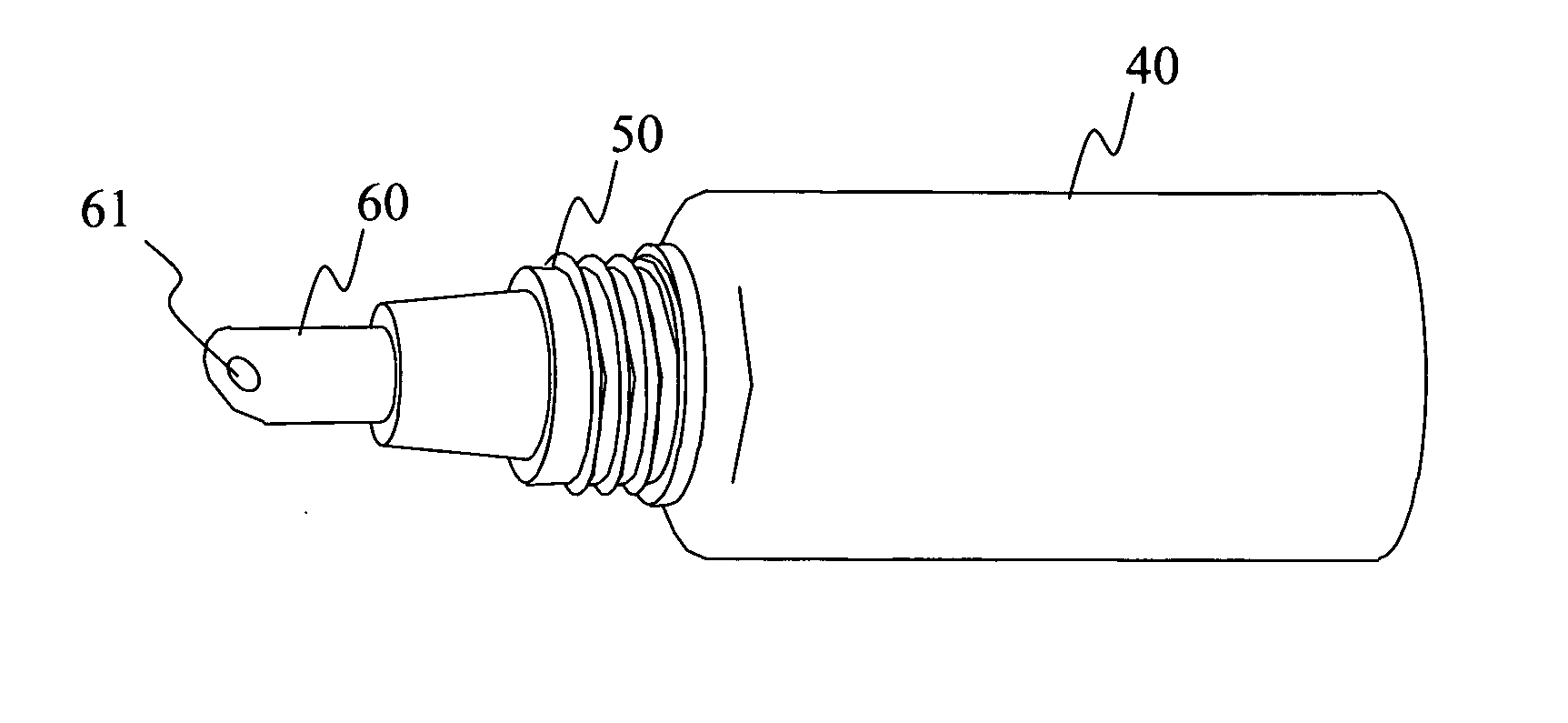

Collapsible squeeze tube

InactiveUS20070116509A1Liquid surface applicatorsPackaging toiletriesBiomedical engineeringCollapsible tube

A collapsible squeeze tube having a soft buffer member with a spout hole formed integral with and covered on the front side of the head in front of the collapsible tube body thereof for buffering flowing of the contained fluid material that is squeezed out of the collapsible tube body and the head by the user for application.

Owner:YUAN HARNG

Collapsible cup

A collapsible beverage container has a plurality of co-axially oriented, concentric cylindrical wall sections of progressively different diameters. The wall sections are extendable from a collapsed position wherein the wall sections substantially completely overlap in an axial direction to an extended position wherein the wall sections only partially overlap in an axial direction. The collapsible beverage container includes one or more elastomeric gaskets between adjacent cylindrical wall sections, each gasket providing a liquid-tight seal along the entire extension of the adjacent cylindrical wall sections between the extended and collapsed positions.

Owner:FARIS ENTERPRISES

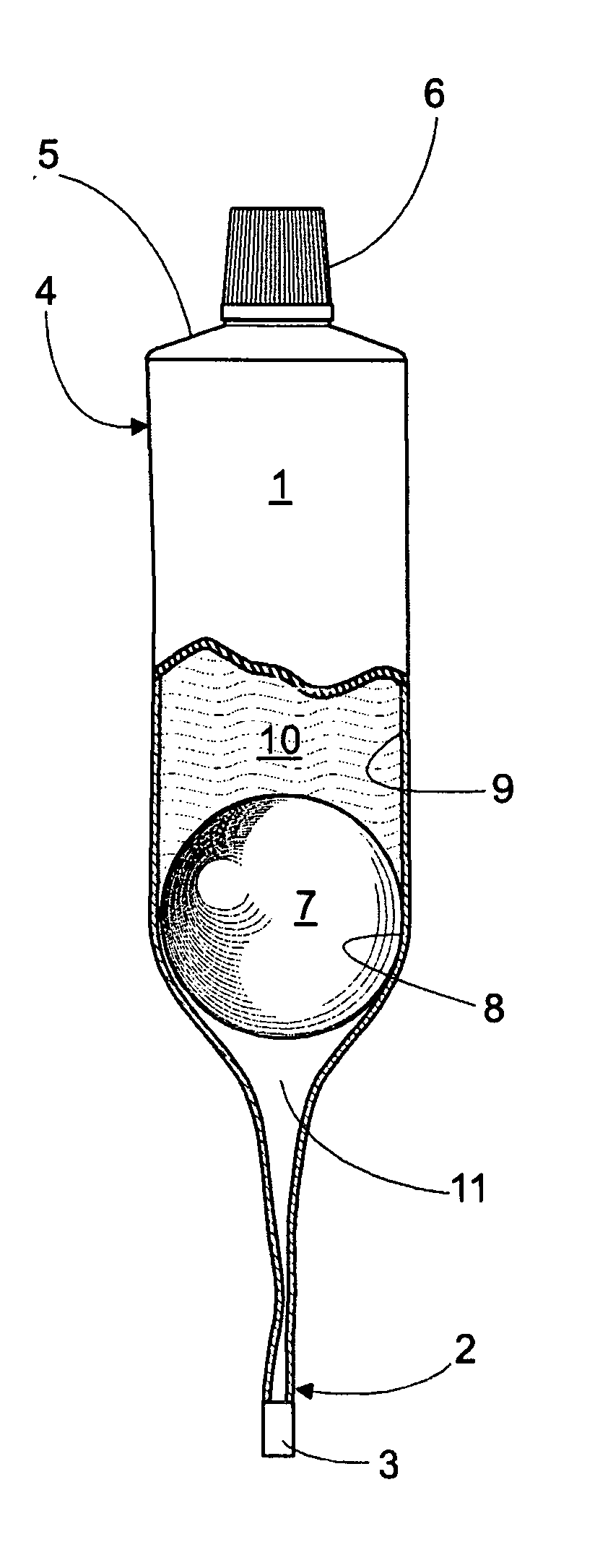

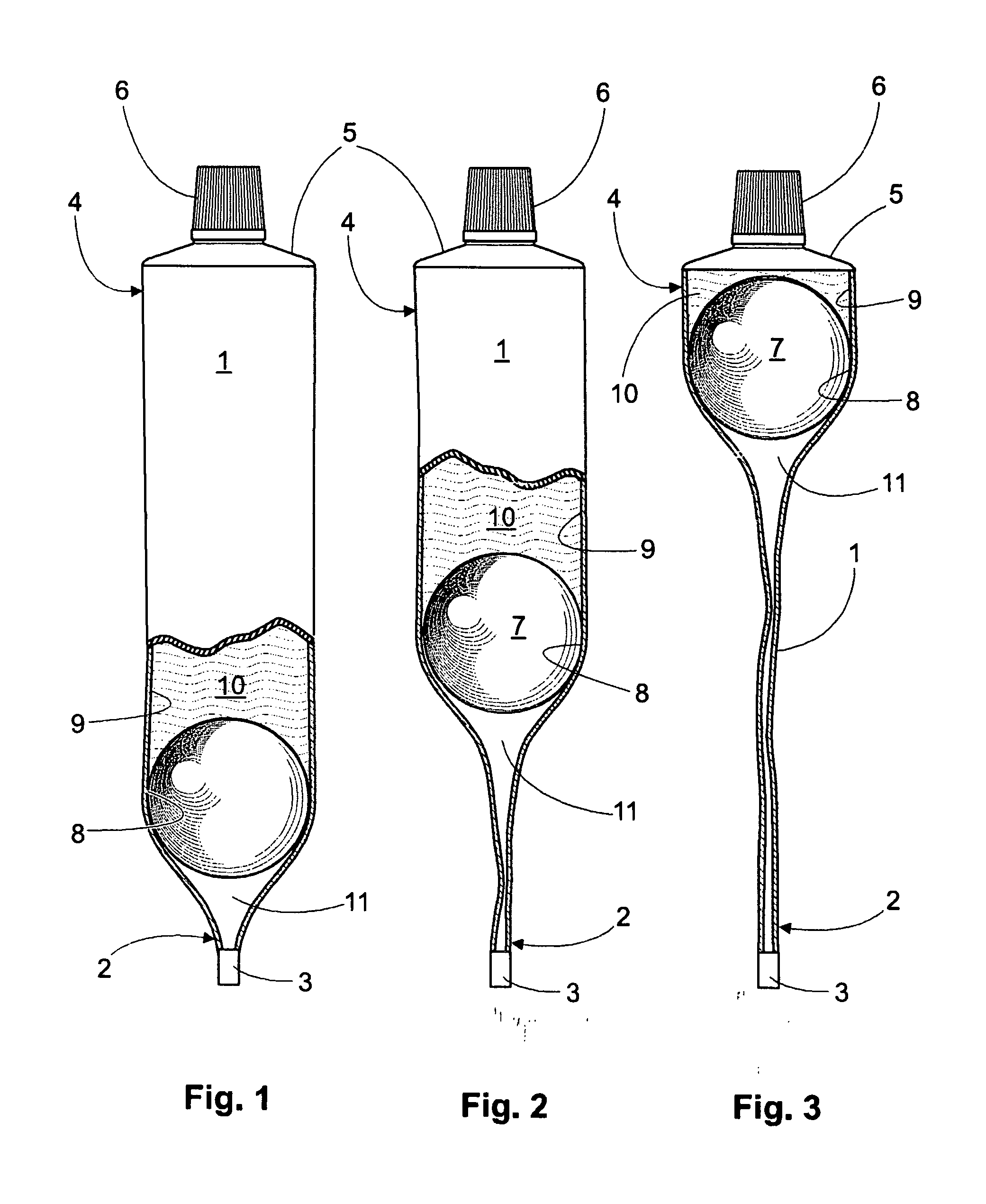

Method and apparatus for extending a tube

Apparatus and methods for extending a tube, the apparatus including a foldable tube having a folded portion inside an unfolded portion of the tube, and a source of fluid coupled to the unfolded portion for providing fluid into the unfolded portion to unfold and extend the folded portion out of the unfolded portion to become an extension of the unfolded portion. The apparatus and methods are useful, inter alia, for cleansing the colon in the normal direction, that is, from the cecum to the anus, using an apparatus that is introduced via the anus. A washing liquid is supplied deep into the colon via the soft feed tube that is inserted via the anus and is extended into the colon by inflation. The washing liquid is then drained out via the anus through a drainage channel.

Owner:TORUS MEDICAL

Solid propellant/liquid type hybrid gas generator

InactiveUS7878536B2High yieldEasy to usePedestrian/occupant safety arrangementParticulatesCombustion

A gas generator comprising a housing having a mixing chamber and a pyrotechnic charge in the housing. A container having a liquid therein is disposed in the housing and has an open end and a closed end, with an end cap closing the open end and having a piston portion removably connected thereto and being movable within the liquid container to pressurize the liquid therein when the piston portion is separated from the end cap. The piston portion is positioned to be exposed to combustion gas from the pyrotechnic charge when it is ignited and is separable from the end cap when the combustion gas exceeds a predetermined pressure. In another embodiment, the liquid container may be a collapsible tube. The closed end of the liquid container has a weakened portion constructed to be opened when the pressure of the liquid in the container exceeds a predetermined pressure. The pyrotechnic charge and the weakened portion of the liquid container are in fluid communication with the mixing chamber so that combustion gases from the ignition of the pyrotechnic charge mix with and vaporize the liquid in the mixing chamber to generate a non-toxic, low temperature, low particulate inflation gas.

Owner:ARC AUTOMOTIVE

Collapsible tube with a distributor head without air return

InactiveUS7222751B2Avoid pollutionPreventing air from enteringClosuresContainers preventing decayGynecologySoldering

Owner:CEBAL SA

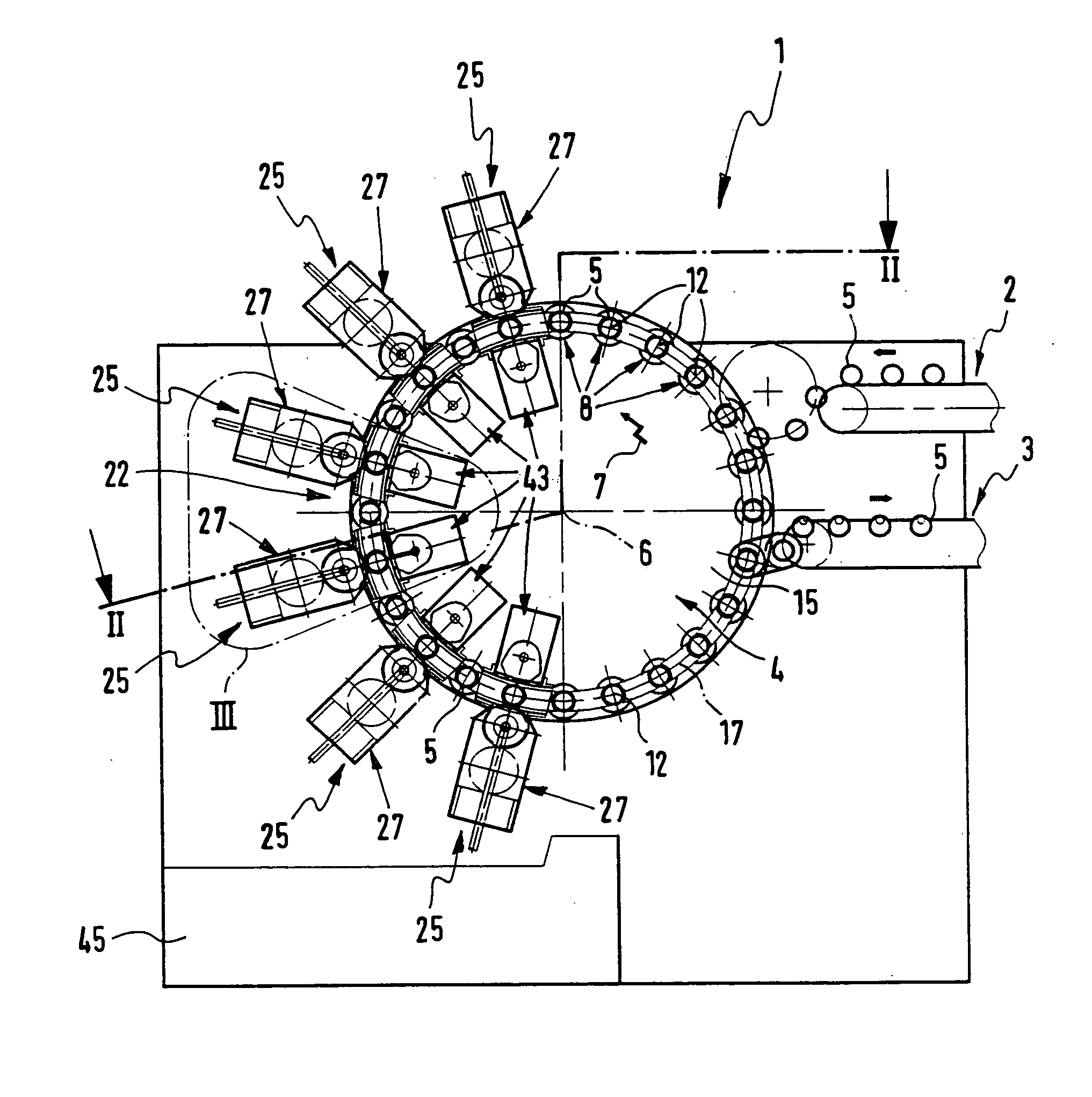

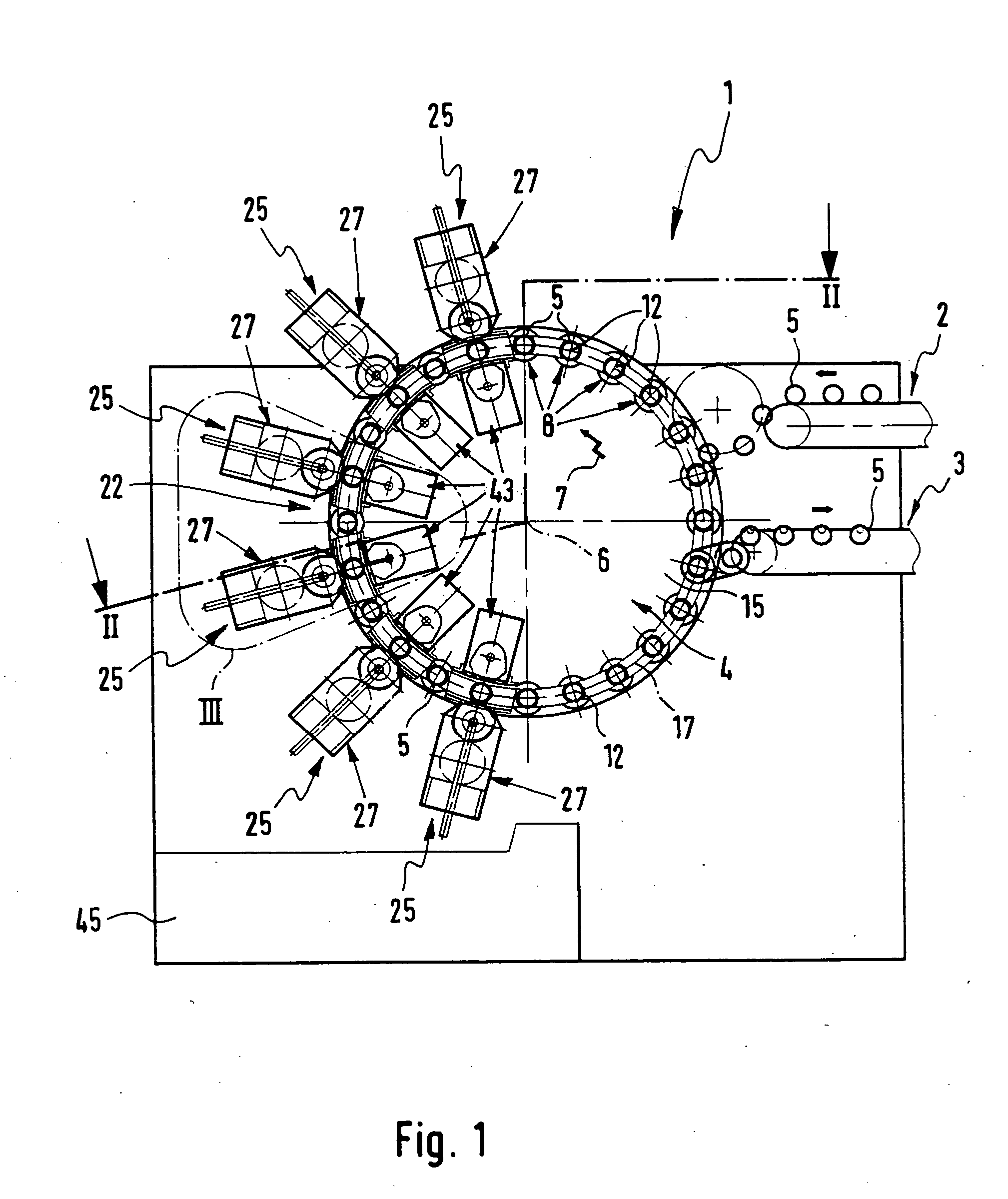

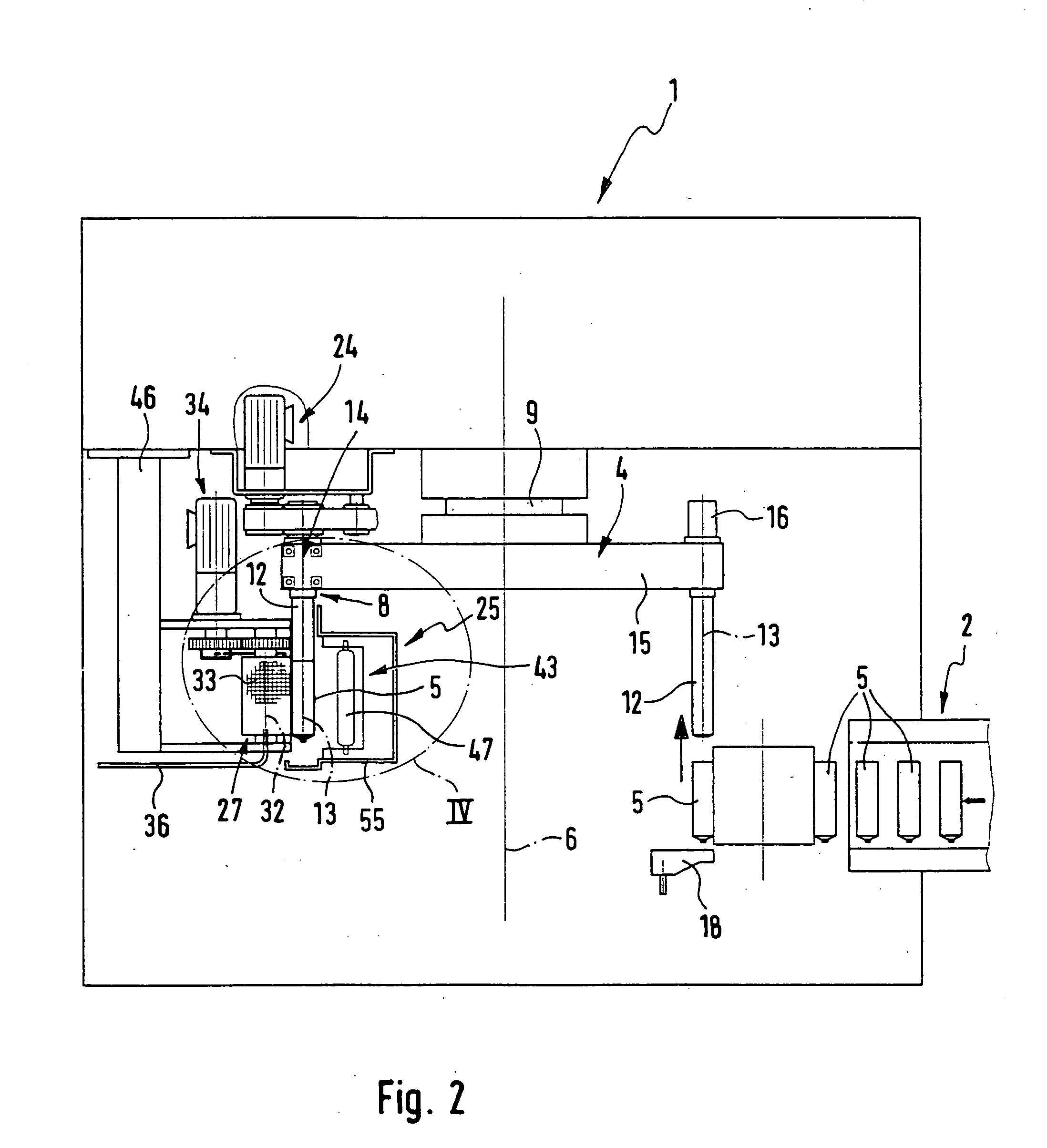

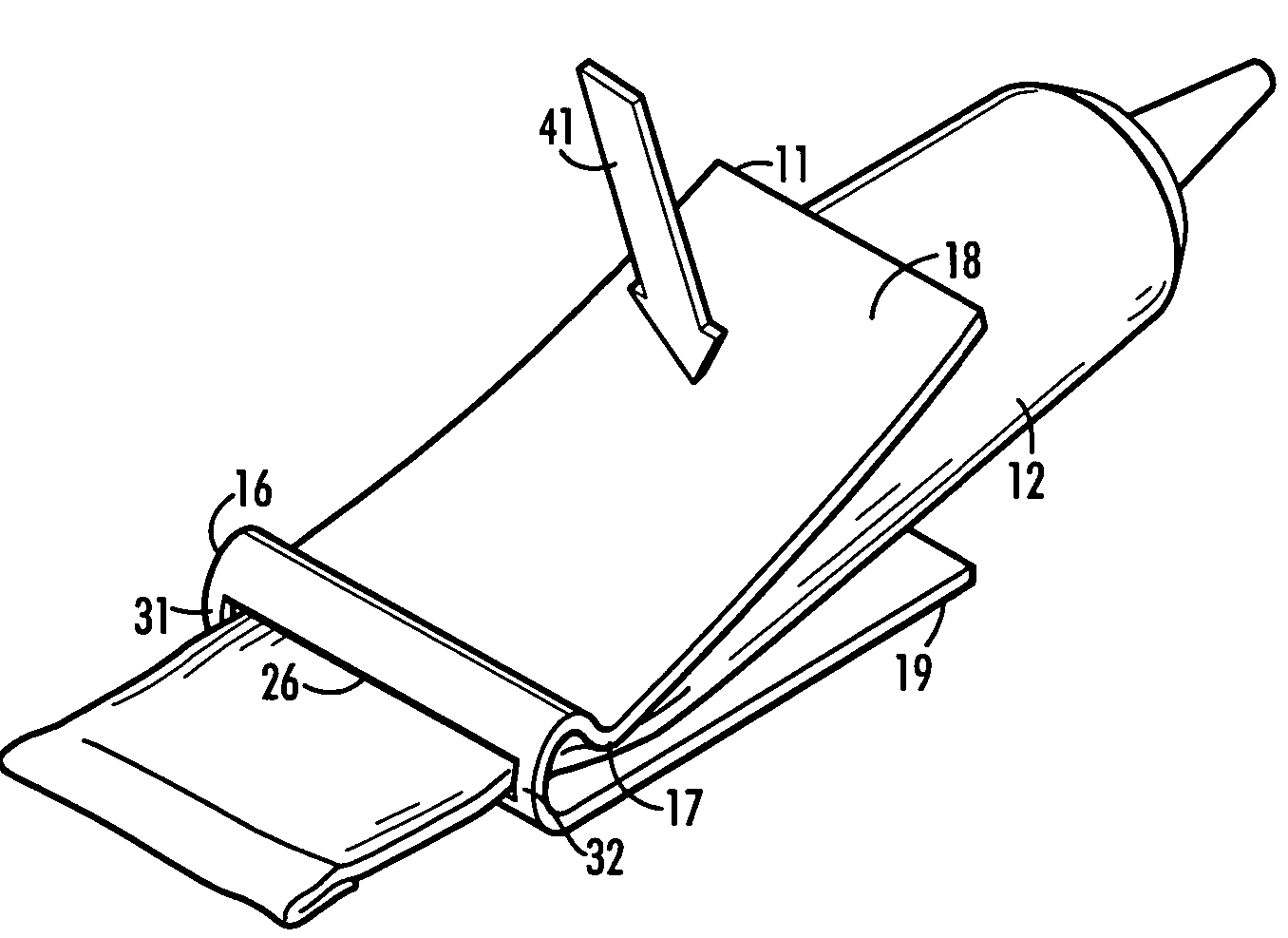

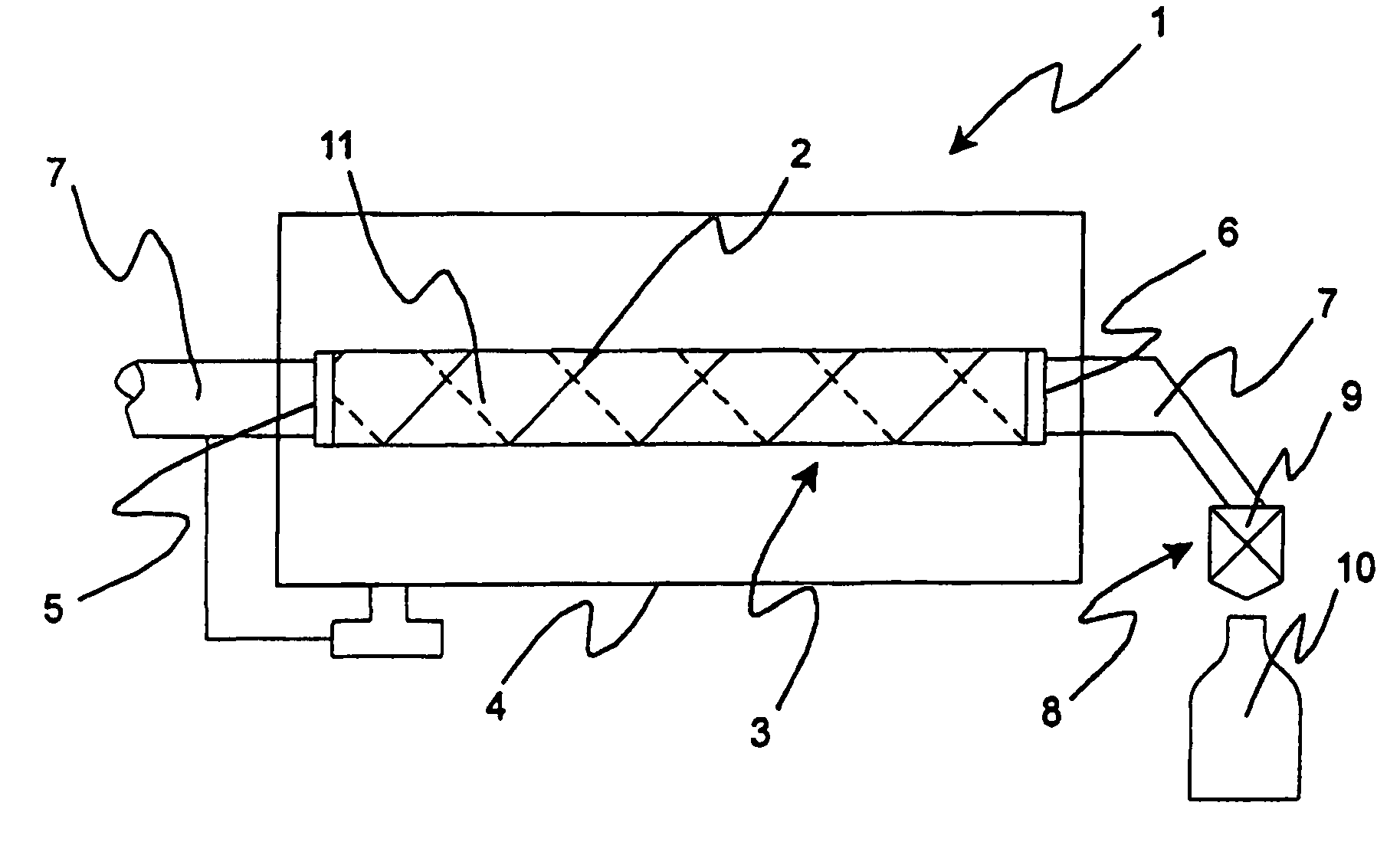

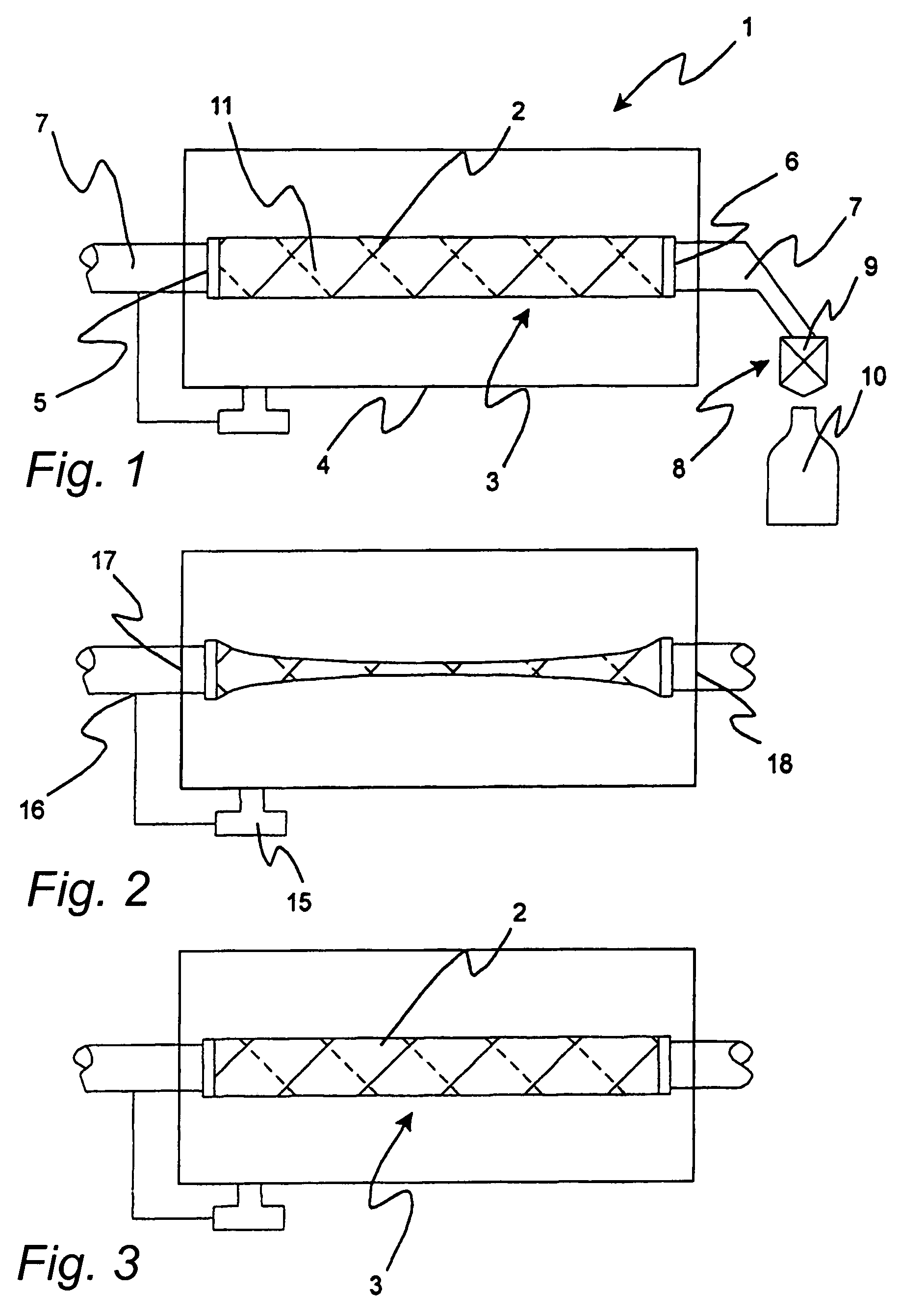

Machine for printing on hollow bodies

A machine for printing on hollow bodies such as sleeves, collapsible tubes, cans or the like, comprises receiving spindles having a horizontal axis of rotation on which receiving spindles are arranged which precede along a spindle track curve during stepped rotational movement of the spindle plate. Along this spindle track curve a plurality of combined printing and drying stations are distributed, which each possess a rotary screen printing mechanism for printing on hollow bodies mounted on the receiving spindles and a radiation dryer for drying ink applied to the hollow bodies. Within the printing and drying stations the rotary screen printing mechanism and the radiation dryer are respectively opposite one another, the latter being so designed that same may simultaneously act on the receiving spindle located at the time in the associated printing and drying station.

Owner:HINTERKOPF

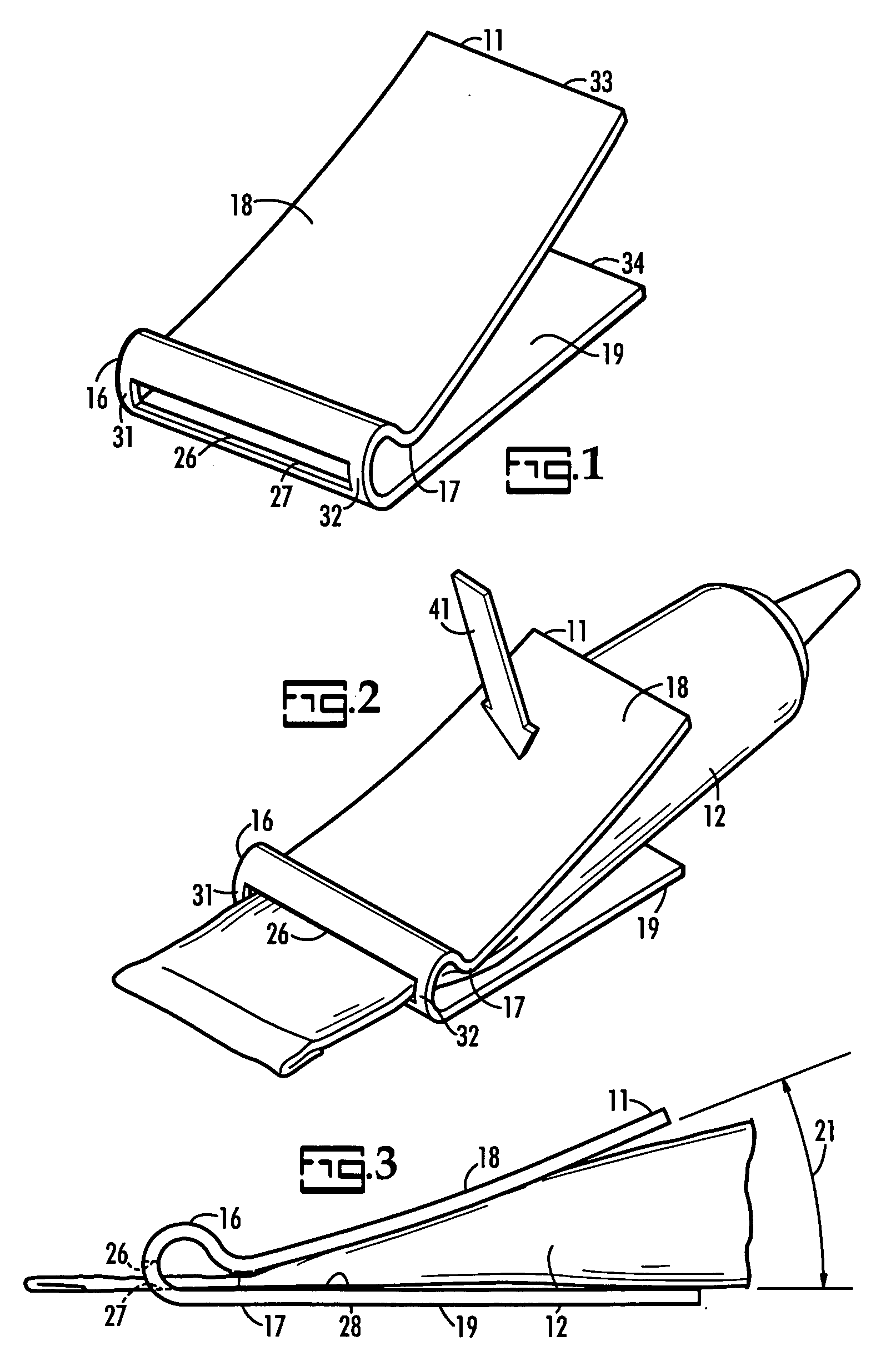

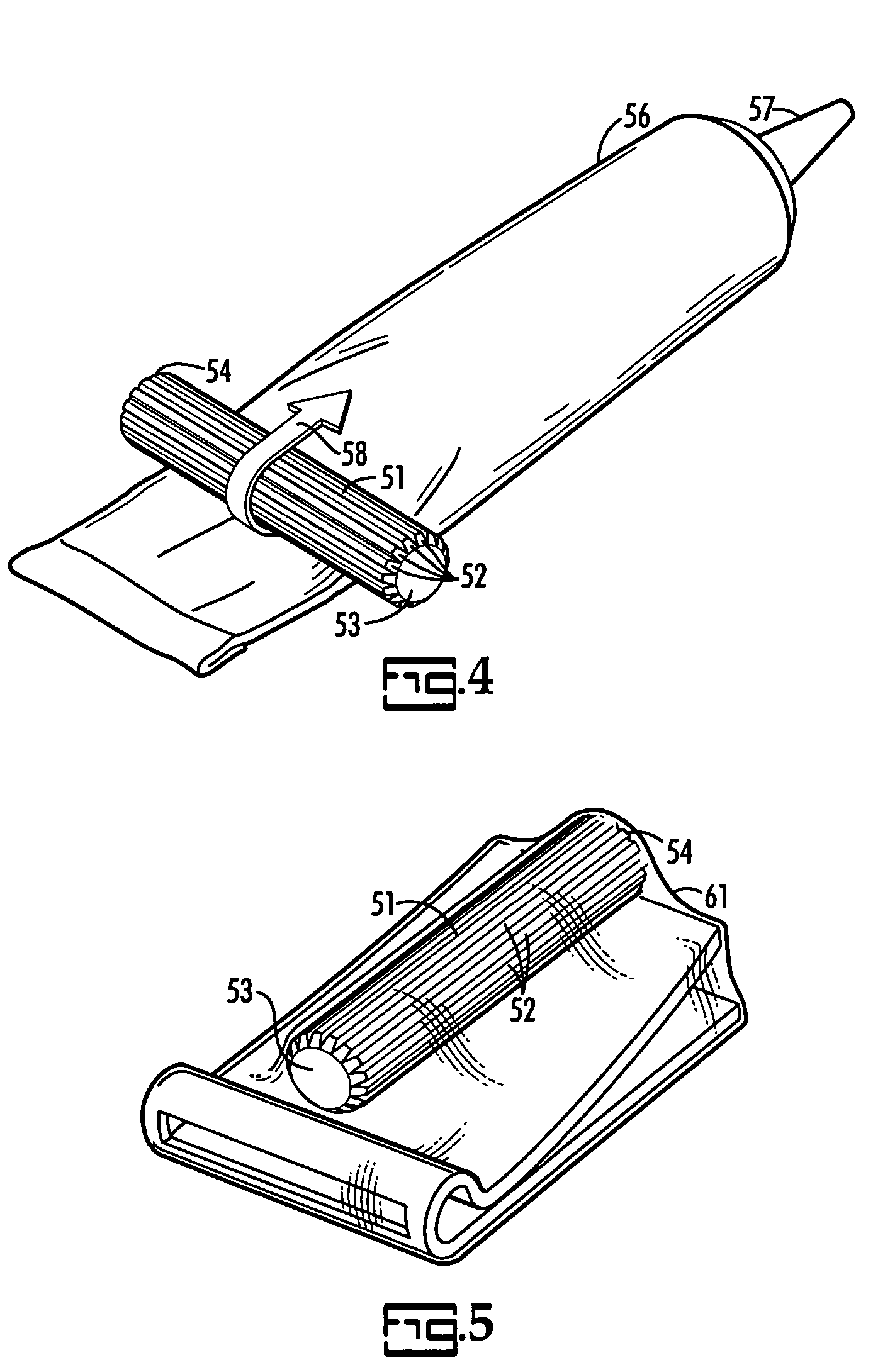

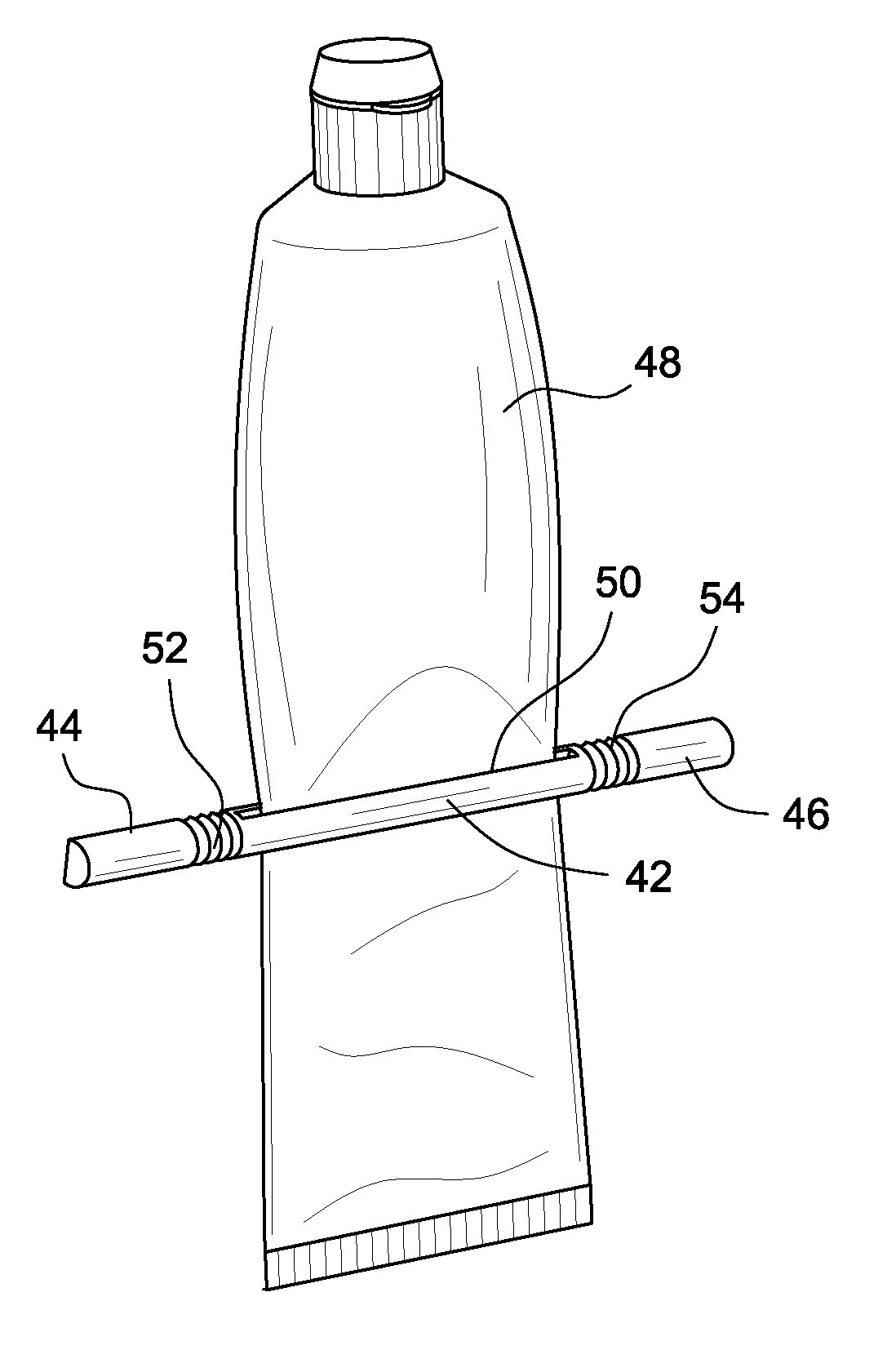

Apparatus for dispensing flowable contents of a collapsible tube

InactiveUS20060043108A1Uniform thicknessFlexible containersPliable tubular containersHand heldEngineering

A hand held tube squeezer facilitates emptying a tube of its contents. The squeezer has a gripping action on the tube to which it is applied, thus preventing rearward slipping of the squeezer. Top and bottom plates of the squeezer are connected by a loop which has a slot through which a tube extends when it is being emptied. Portions of the loop at opposite ends of the slot function as a line hinge between the top and bottom plates. The squeezer and a roller are packaged in a clear plastic wrap film.

Owner:BURRELL WILLIAM E

Ergonomically optimized, in-line water valve assembly for use with a dental handpiece

InactiveUS20150216622A1Reduce physical strainSimple designTooth rinsingBoring toolsWater flowEngineering

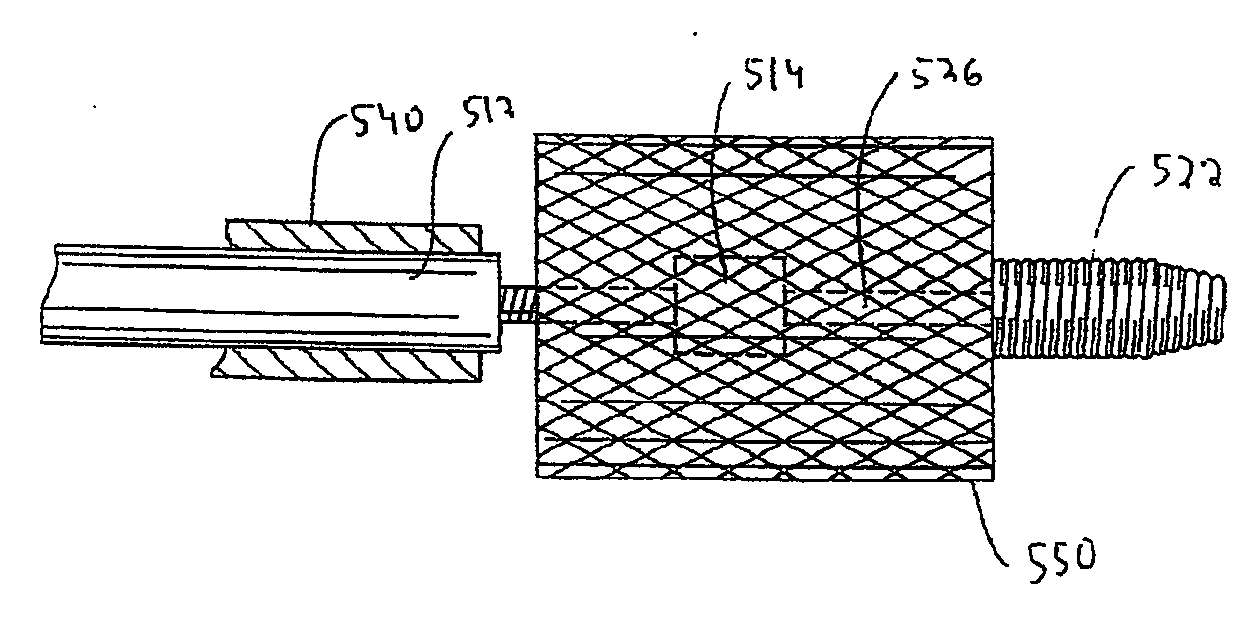

An ergonomically optimized, in-line water valve assembly for use with a dental handpiece comprises a body having a plurality of channels to accommodate the flow of water and / or air to drive and cool the dental handpiece. A portion of one such channel, the channel that supports the flow of coolant water to the dental handpiece, comprises a resilient collapsible tube. The water valve assembly further comprises an actuation screw that, when rotated in a first direction, drives down upon and collapses the resilient collapsible tube, thereby enabling an operator of the water valve assembly to disable or decrease the flow rate of coolant water to the dental handpiece. Rotating the actuation screw in the opposite direction enables the operator to enable or increase the flow rate of coolant water to the dental handpiece.

Owner:VARTANIAN ALBERT +1

Delivery-Receiving Door

A delivery-receiving door is an apparatus that is used to collect deliveries and store them for storage and subsequent access. The apparatus includes an exterior door, a collapsible tube, a controller, a first access mechanism, and a second access mechanism. The exterior door is similar to a conventional entryway door, allowing selective hinged entry into a living space. The collapsible tube is mounted to the exterior door. This allows the collapsible tube to expand for containment of items. The controller is a computer that accepts electrical input signals related to the first access mechanism and the second access mechanism, and subsequently delivers electrical output signals. The first access mechanism allows for input of delivered packages and items into the collapsible tube, while the second access mechanism allows for removal of delivered packages and items from the collapsible tube.

Owner:PATEL RUPESH JAYESH

Collapsible tube for containing and dispensing paste

A collapsible paste tube for containing and dispensing paste, the tube having a rearward closed end and a forward open end for supplying the paste, and a plunge member freely arranged within the tube, with the paste being packaged between the plunger member and the open end of the tube.

Owner:SCHANG GASTON

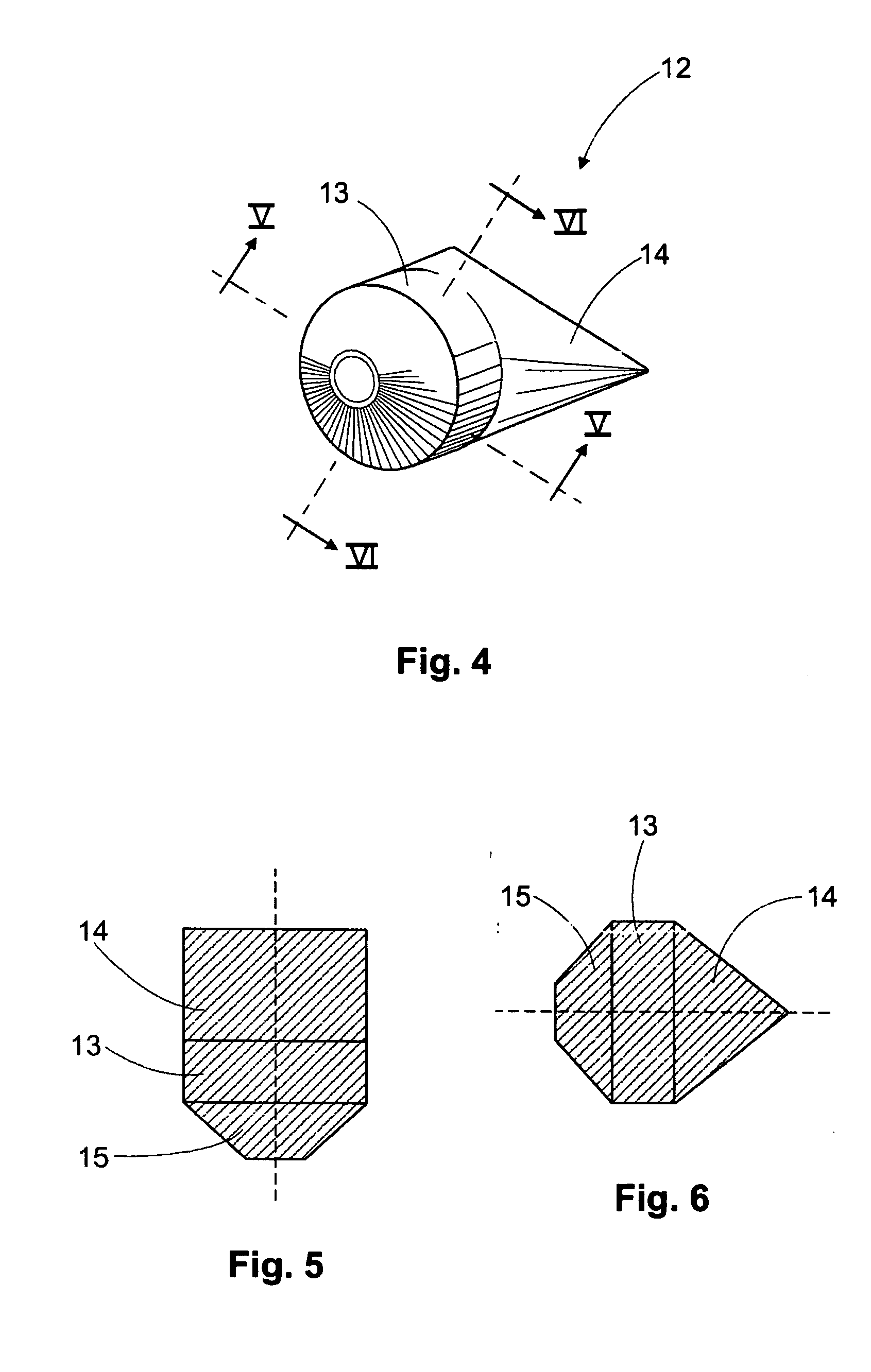

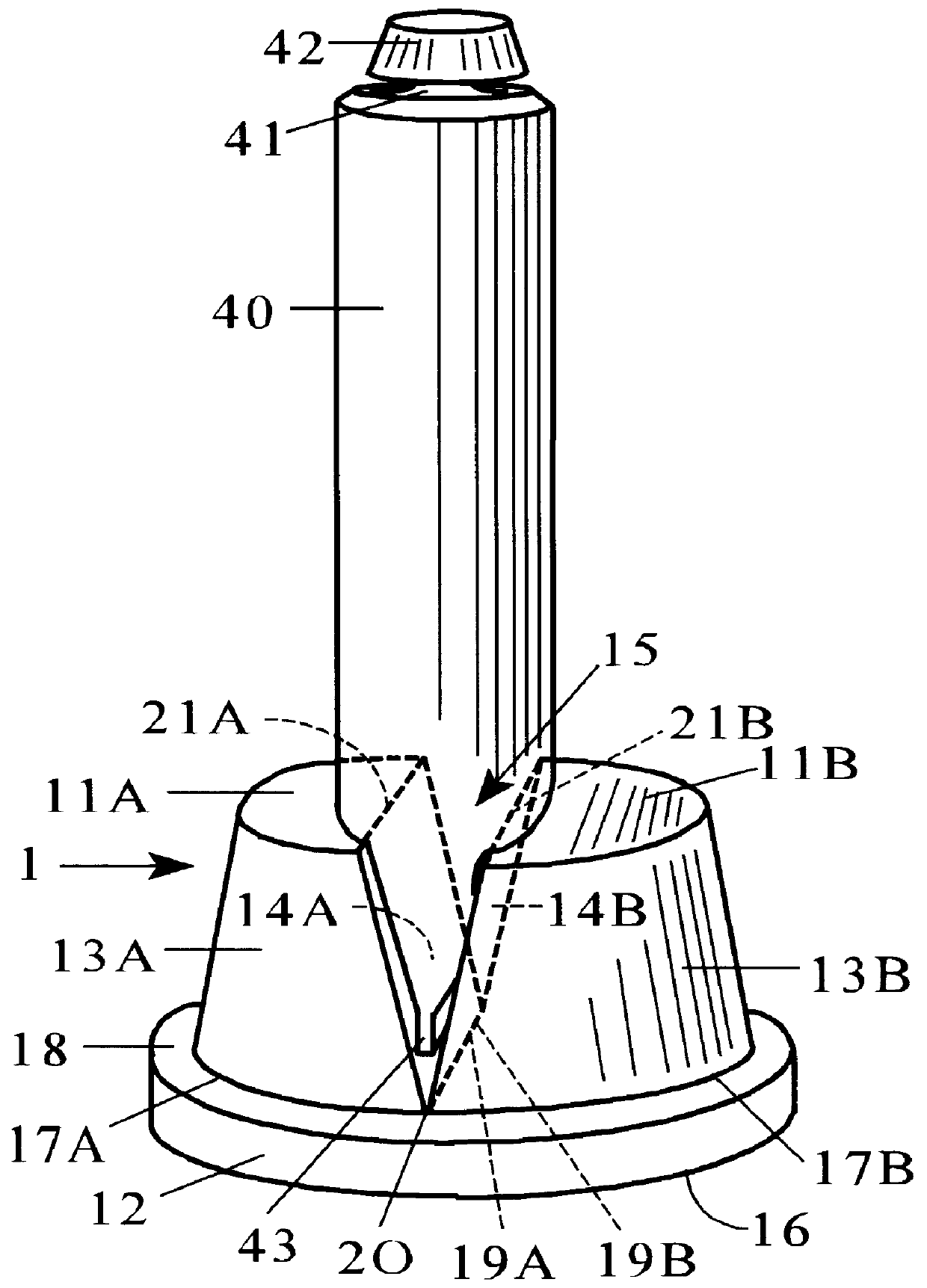

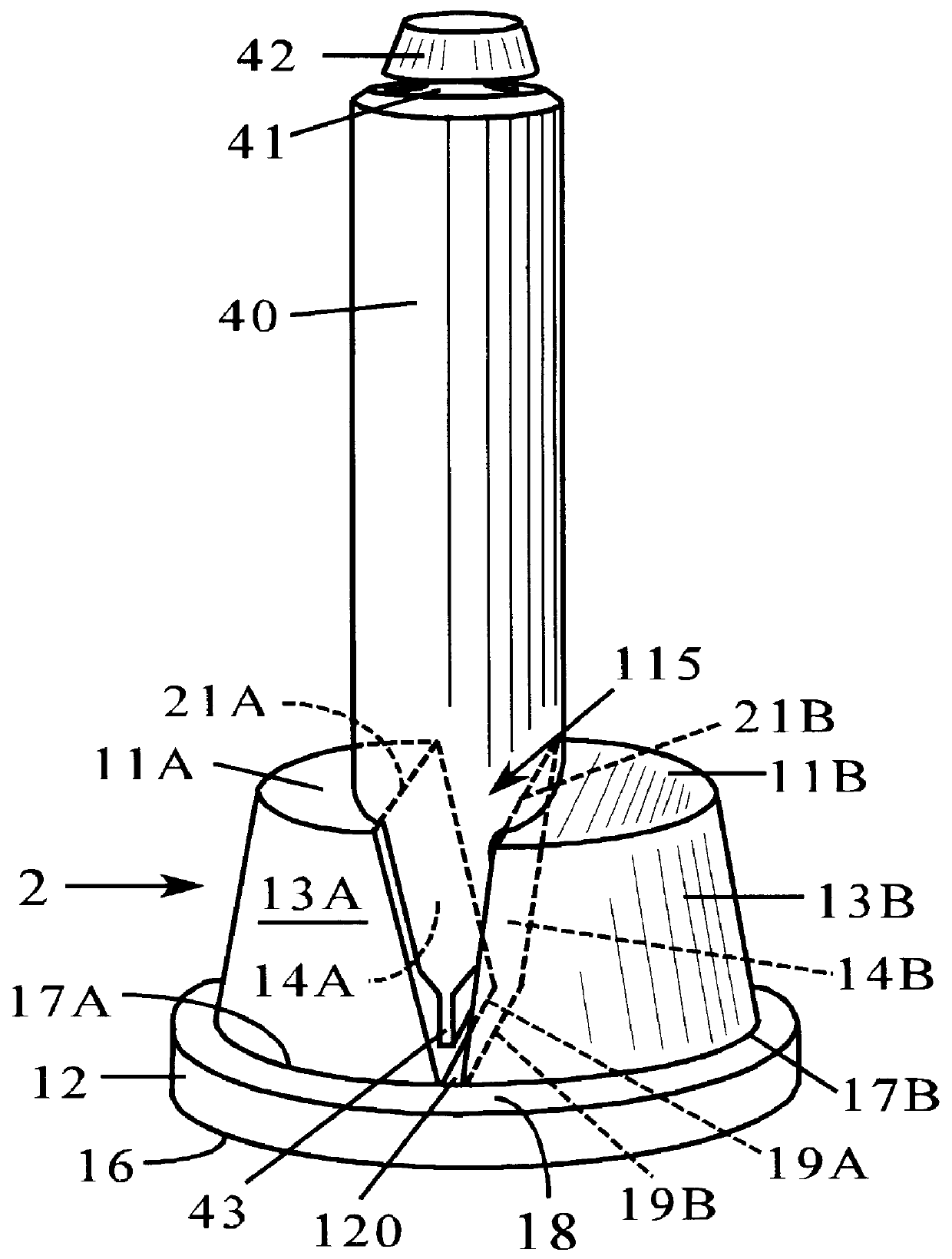

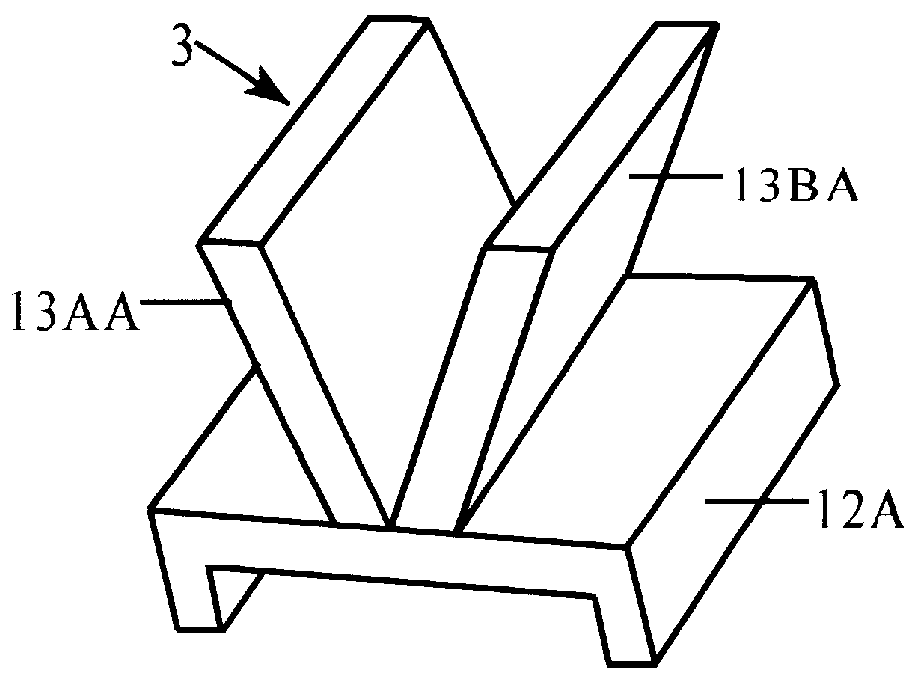

Holder for full or folded collapsible tubes

A combination of a compact, economical, decorative, rigid, one-piece holder and a squeezable collapsible dispensing tube, where the holder has a supporting base with a planar bottom standing surface to which are attached two side walls such that their substantially planar inner surface face each other and form a substantially upright V-shaped notch. The dimension of the V-shaped notch, such as its height, its top opening width, and the width of the inner surfaces of the side walls, are such that a sufficient length of the bottom section of a full collapsible dispensing tube fits into and is firmly grasped by the V-shaped notch and is securely held in an upright position. These same dimensions should also be sufficient that a partially-emptied, collapsible dispensing tube, which has been flattened and folded a plurality of time-generally about four or five times for a toothpaste tube-fits into and is securely held upright by the notch of the holder. The firm grasp of the V-notch of the holder on an inserted partially-emptied, flattened, and folded dispensing tube prevents both the tube from unfolding and the product from re-entering the folded section of the tube during use. Because of this, the use of this holder greatly simplfies the process of emptying a product from a tube.

Owner:LAYER ROBERT WESLEY

Device for compensating for pressure drop

InactiveUS7066211B2Satisfy lifeEasy to cleanAircraft componentsFilling using counterpressureCollapsible tubeEngineering

The invention relates to a device for compensating for pressure drop in a product pipe through which a liquid flows, and a system comprising such a device. The device comprises a collapsible tube portion, which is connectible to the product pipe, and is characterised by a limiting means, which is adapted to counteract stretching of the tube portion in the circumferential direction and which is adapted to allow free collapsing of the tube portion.

Owner:ECOLEAN

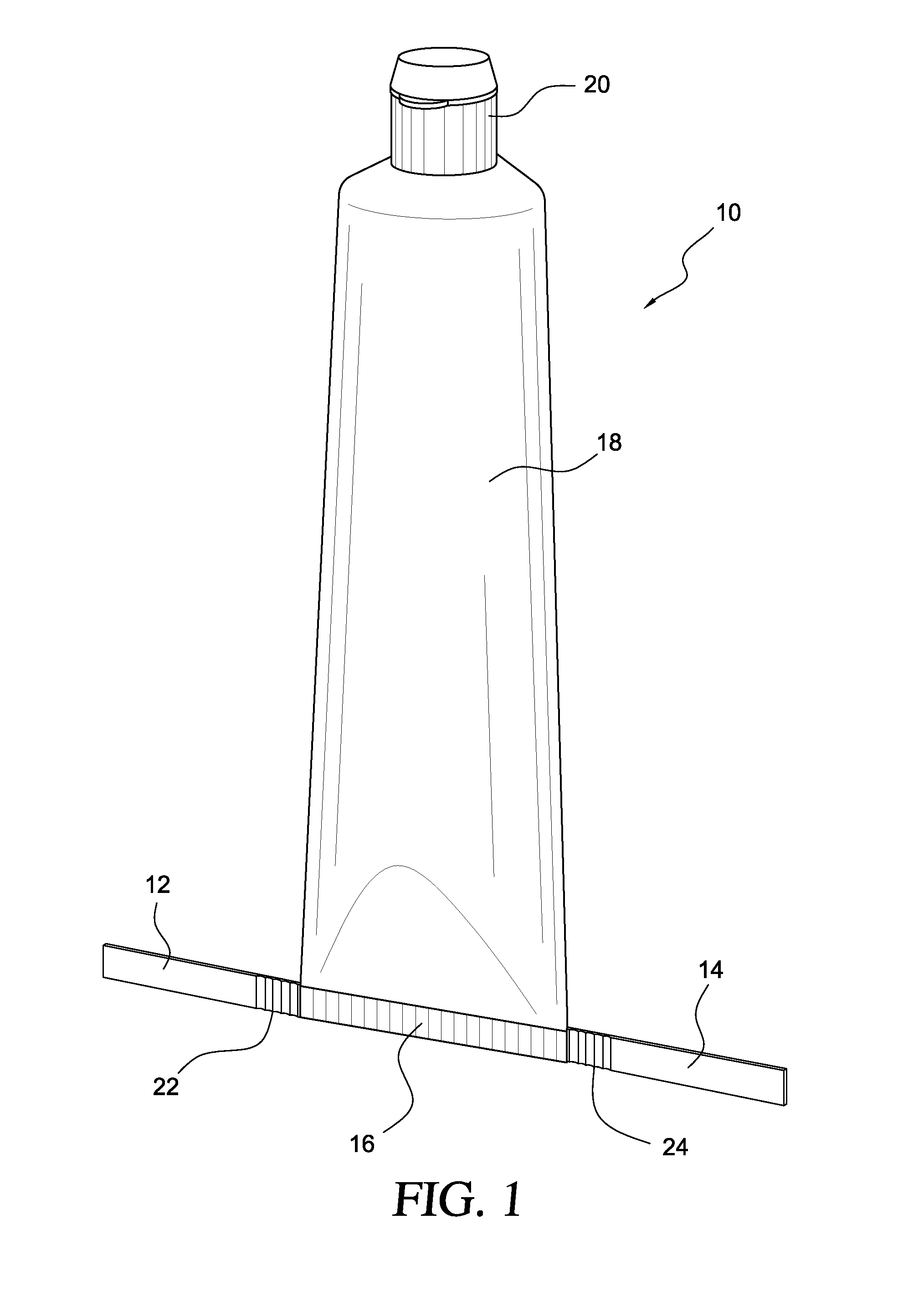

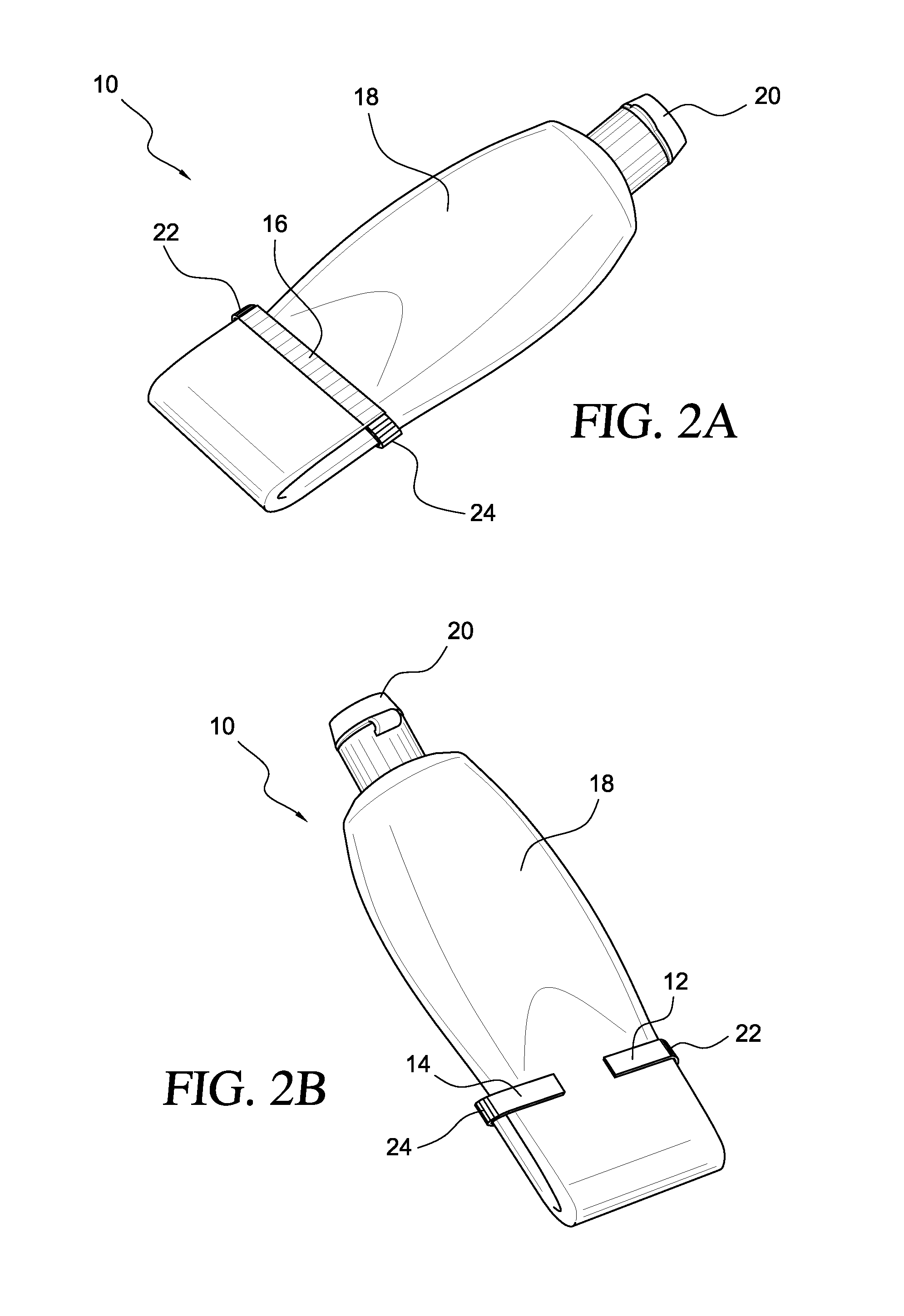

Toothpaste dispenser

An apparatus for dispensing the contents of a collapsible tube, such as a toothpaste tube. The toothpaste dispenser includes dual arms affixed to the tube that are used to reposition the contents of the tube and maintain the tube in modified configurations. The toothpaste dispenser of embodiments of the present invention allows for the product contained in the tube to be more readily compressed and dispensed from the tube relative to manual compression alone, thereby leaving less product in the tube when the tube is discarded.

Owner:LIGHTFOOT VERNON FRANCIS

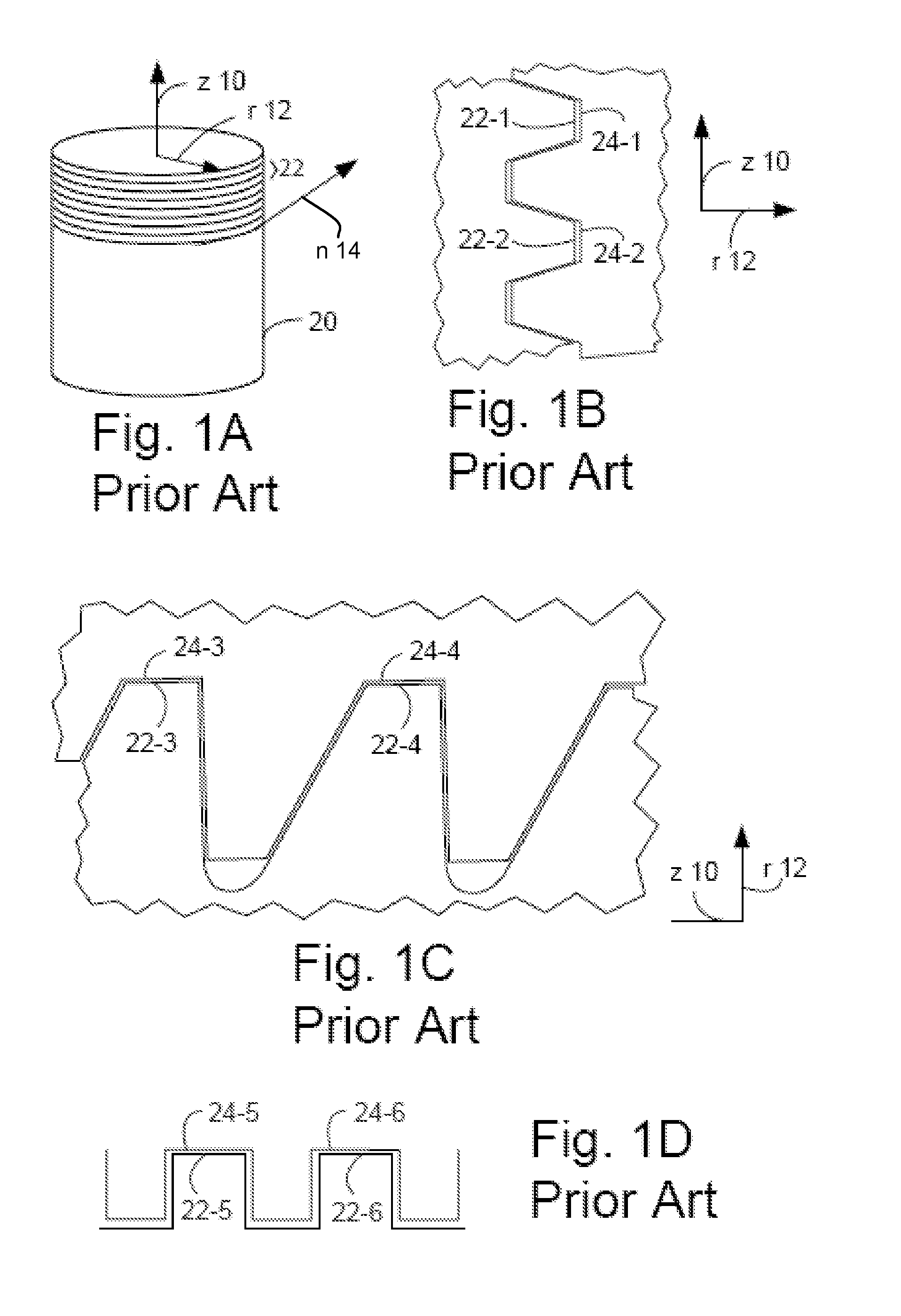

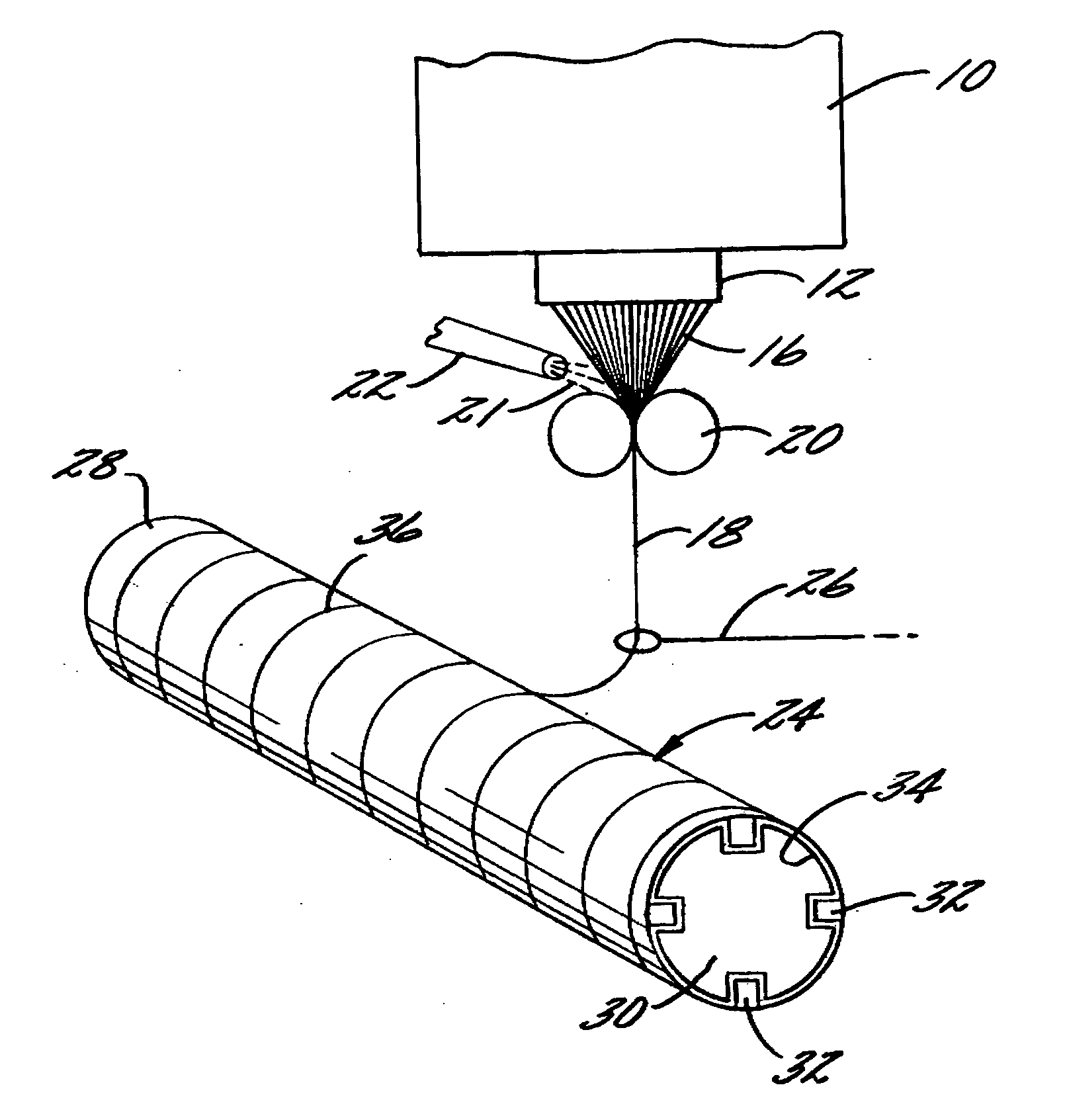

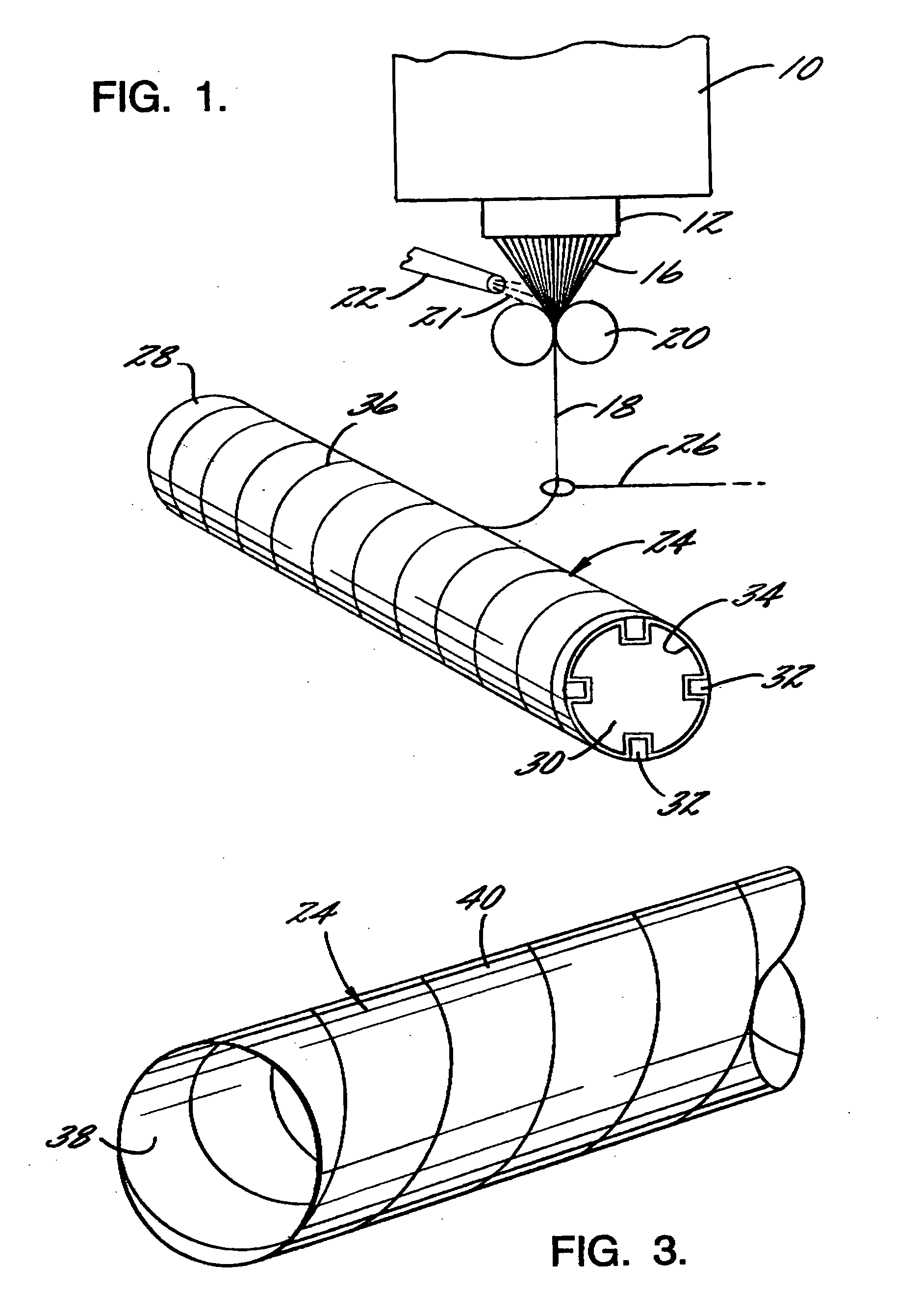

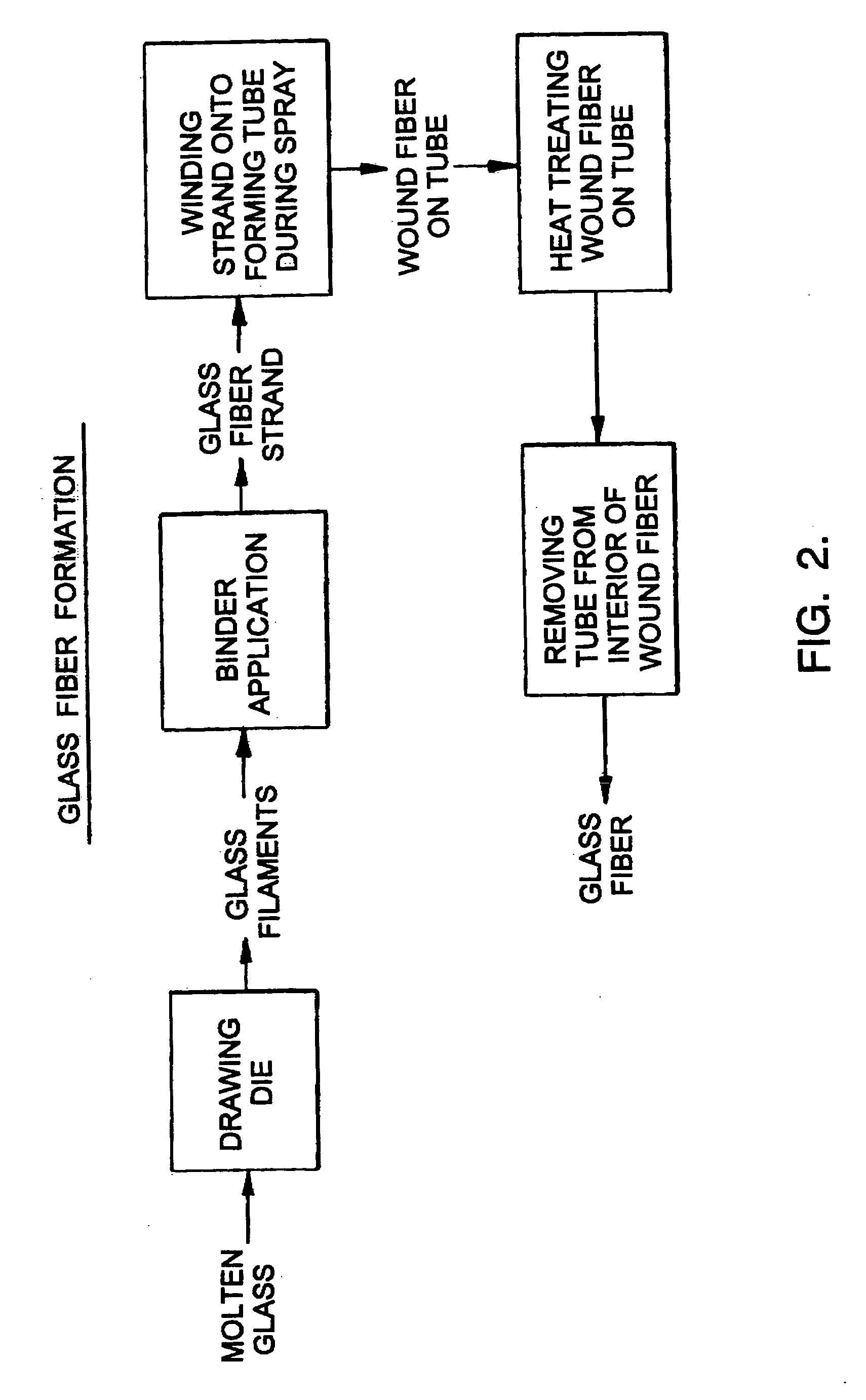

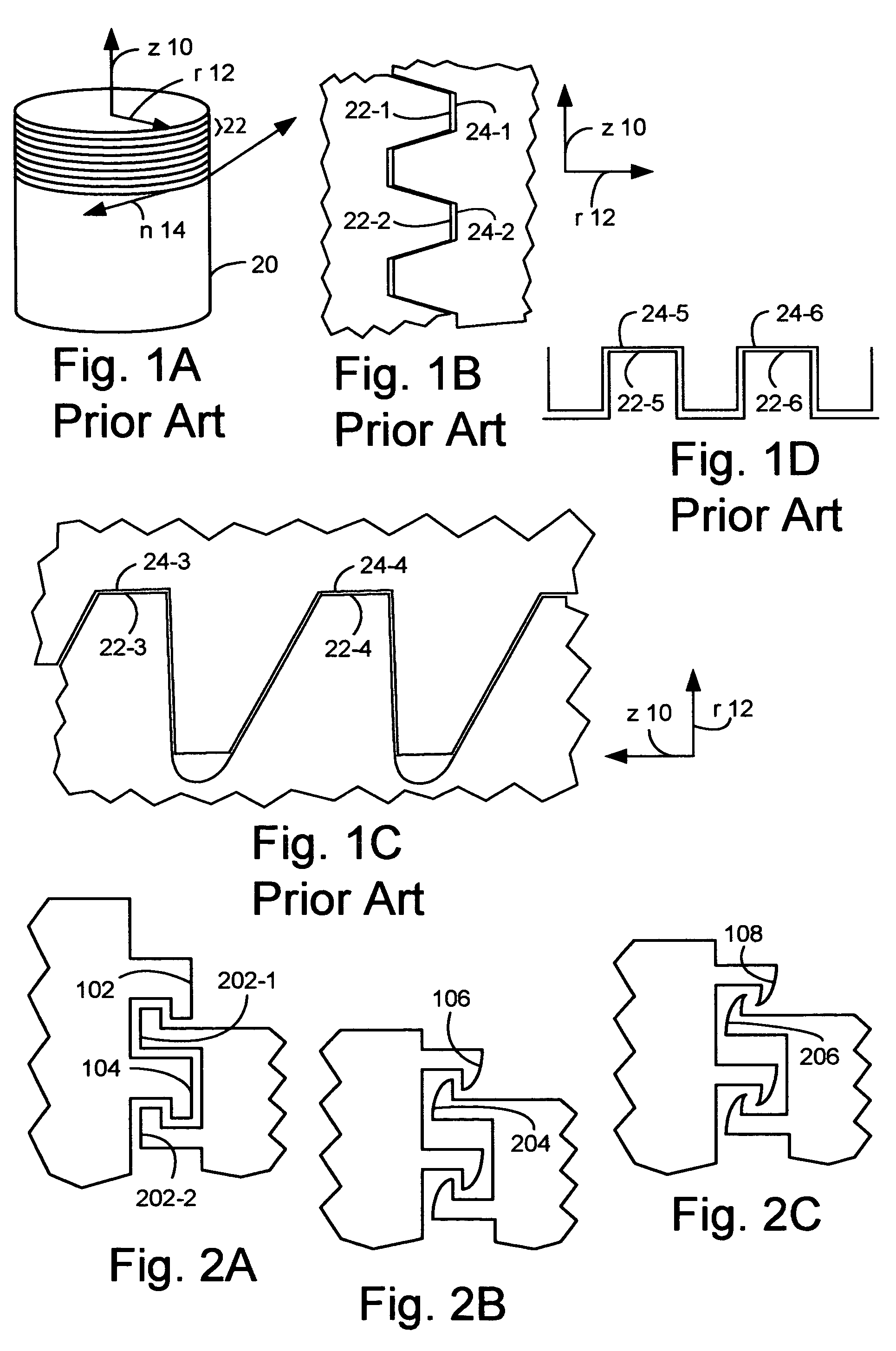

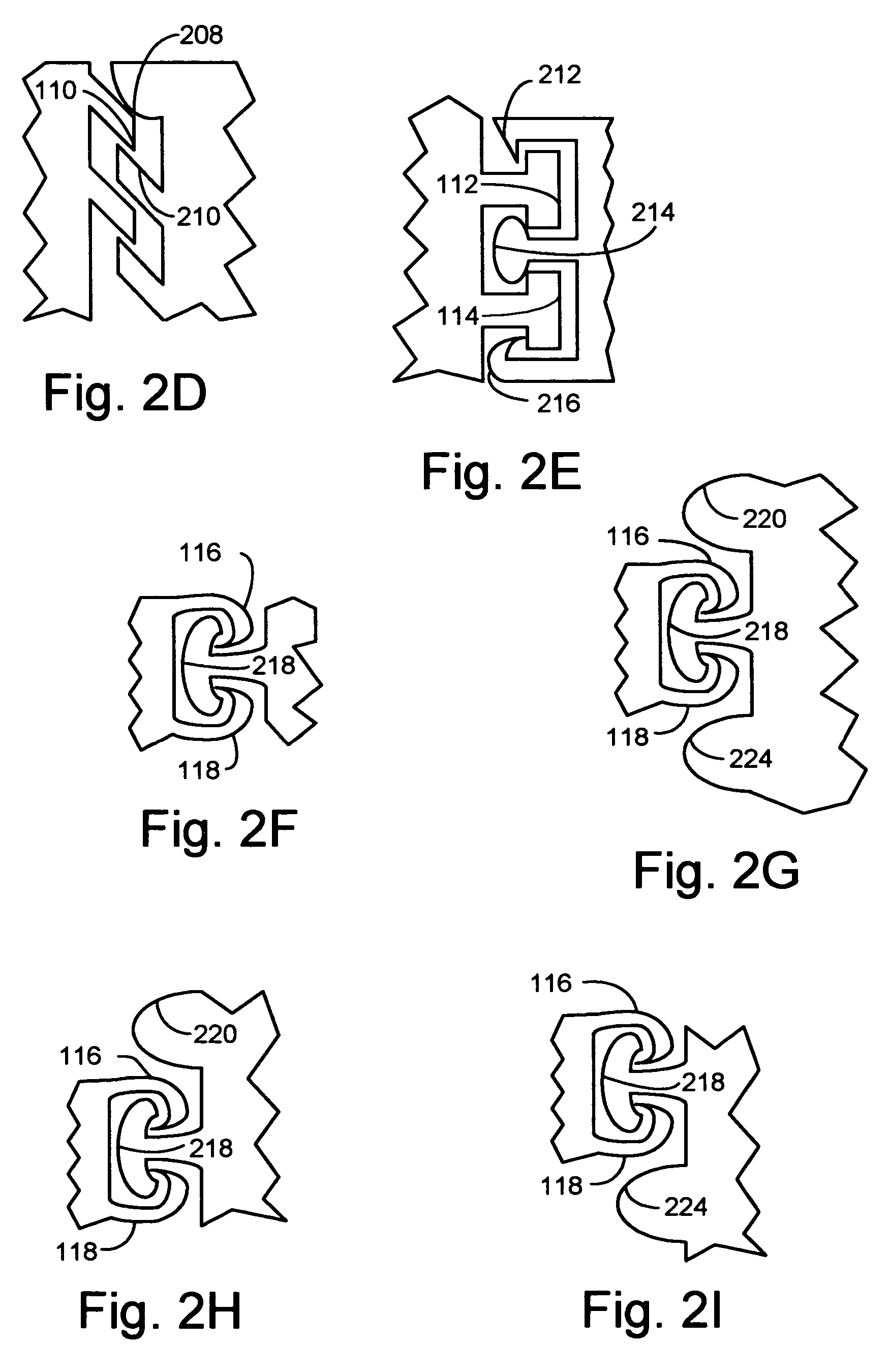

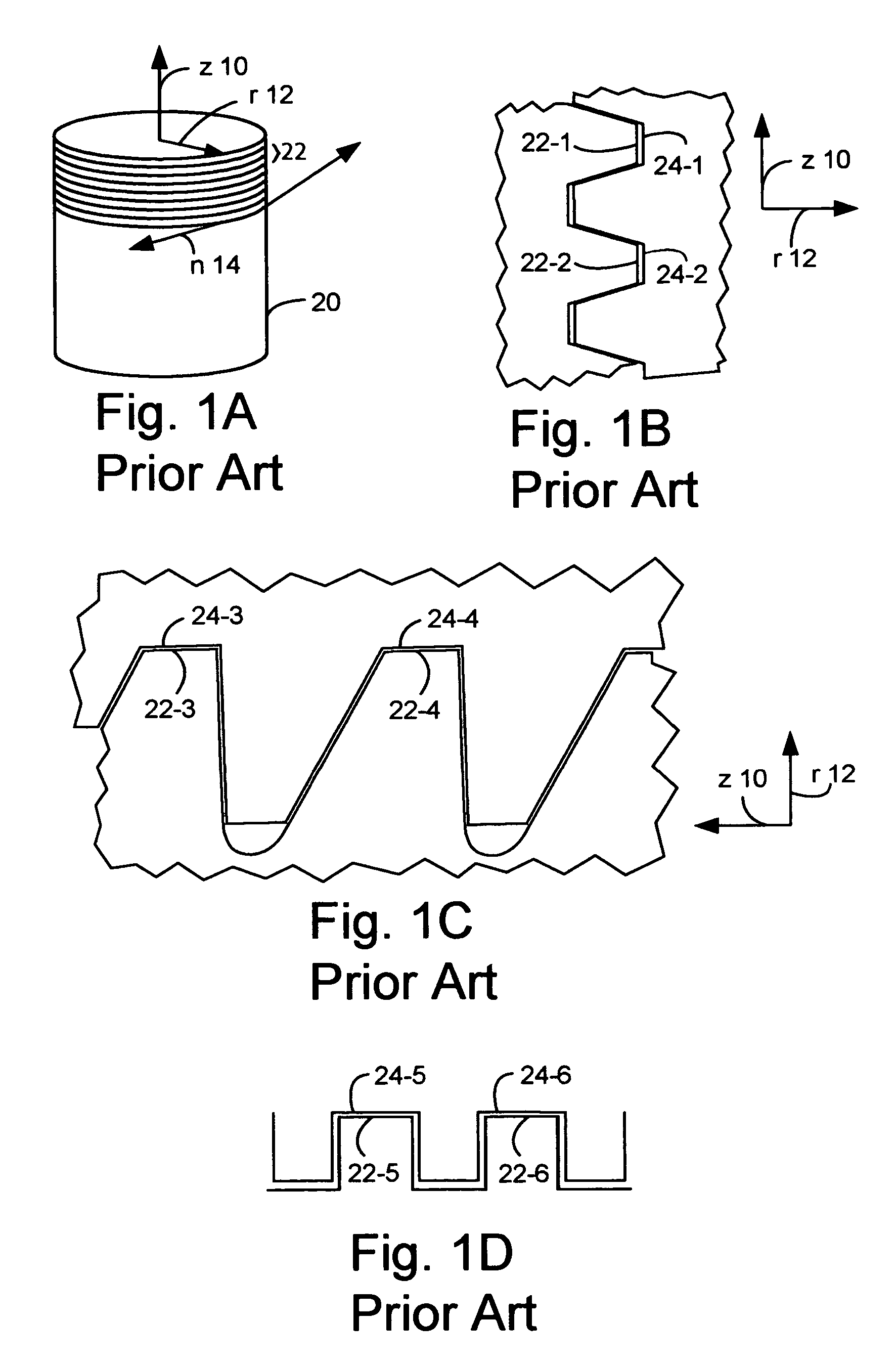

Crimped forming tubes

InactiveUS20060026997A1Cost-effectiveImprove moisture resistanceGlass making apparatusRotary drum furnacesGlass fiberMetallic materials

The invention is a collapsible tube having excellent moisture and temperature-resistance. The collapsible tube, such as a spirally wound or convolute paperboard forming tube, includes moisture-resistant and temperature-resistant layers at its inside and outside surfaces. These moisture-resistant and temperature-resistant layers may be polymeric or metallic materials, particularly metal foil layers. The collapsible tube is especially useful as a reusable forming tube in the manufacture of glass fibers.

Owner:CARAUSTAR INDS

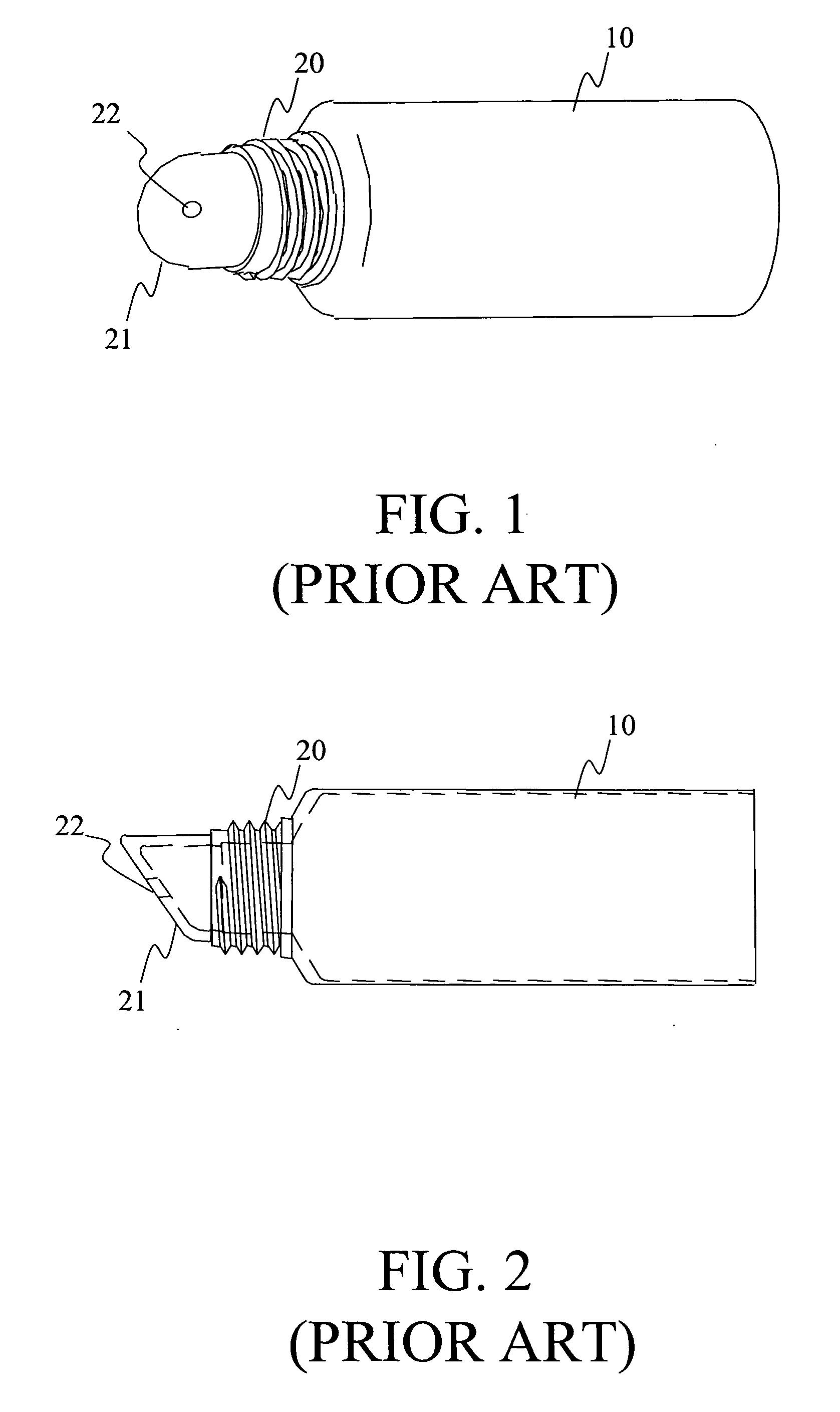

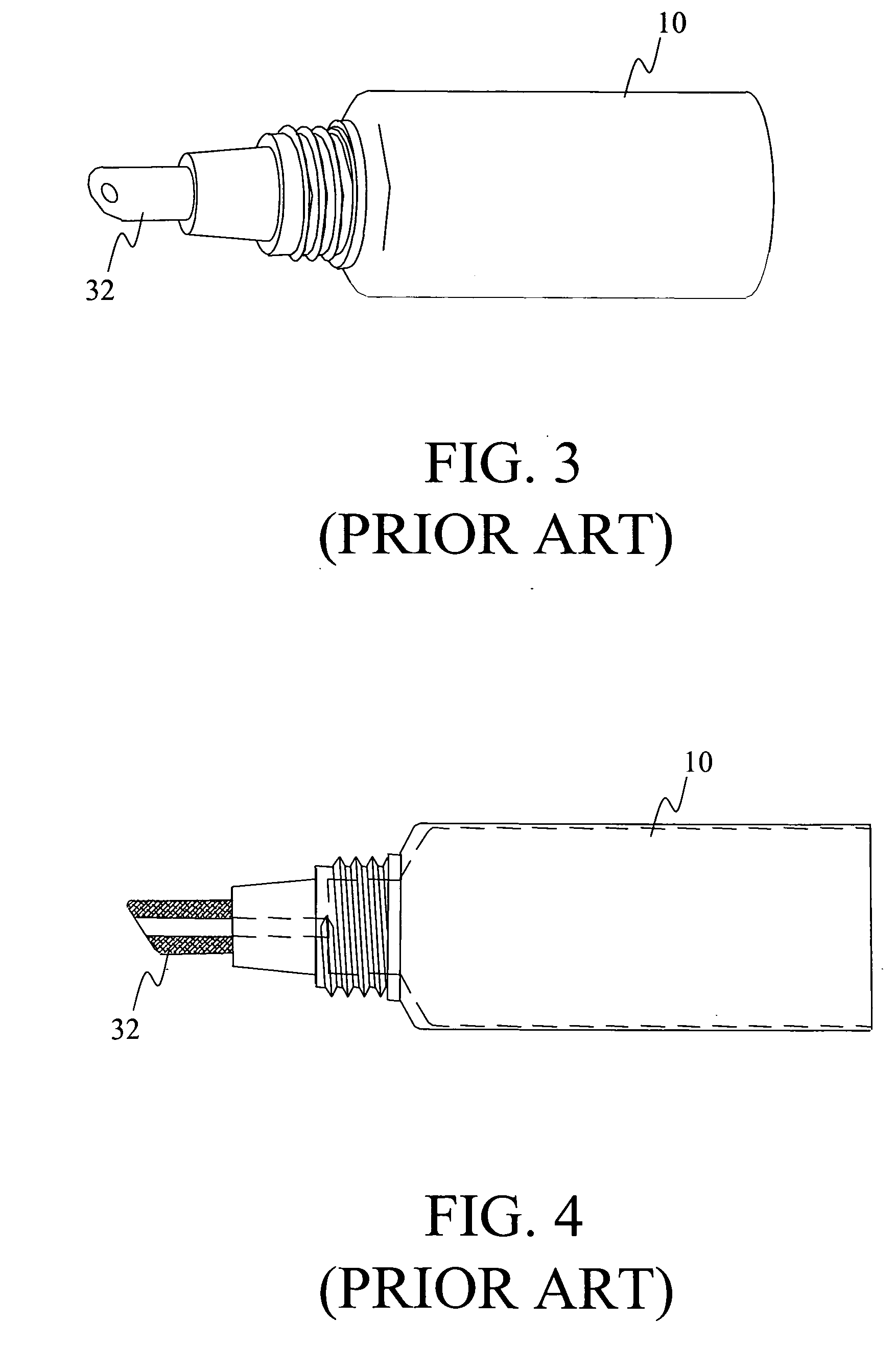

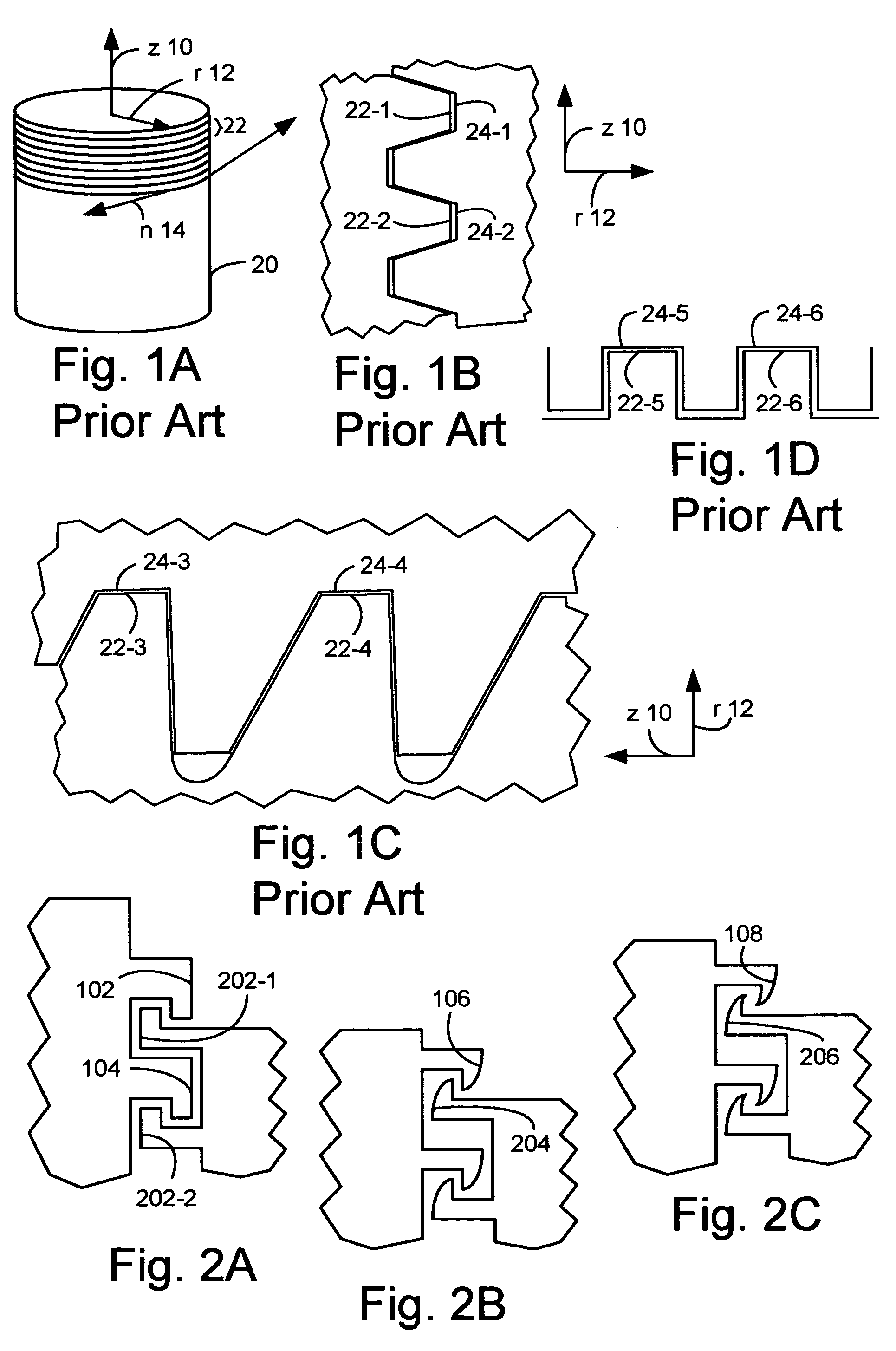

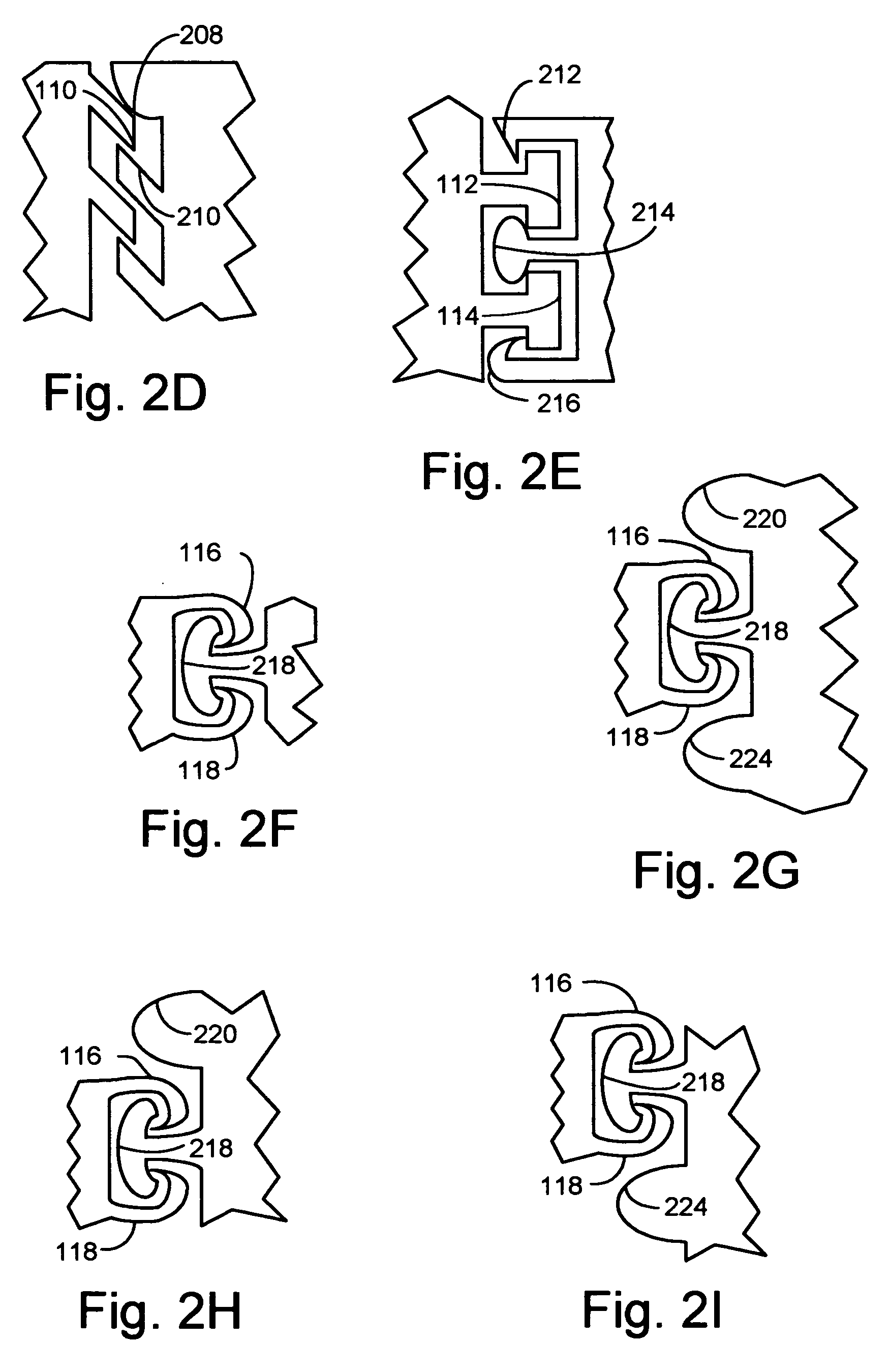

Apparatus and method for reusable, no-waste collapsible tube dispensers

The invention includes a method of using a cap containing an internal thread form matching an external thread form on a flexible throat for a collapsible tube enclosing at least one contained product. Twisting the cap engages the internal thread form and the external thread form. These collectively urge the cap and the flexible throat to seal the contained product into the collapsible tube. Deforming the flexible throat through squeezing the collapsible tube dispenses essentially all the product. The collapsible tube may preferably include an external thread form on a flexible throat coupled to a flexible shoulder. The external thread form mates to a cap with an internal thread form urging the flexible throat to seal against the cap when the cap is twisted onto the flexible throat. The flexible throat and flexible shoulder flatten to dispense essentially all of the product.

Owner:SCOTT ANDERSON & SUSAN POTTISH +2

Fluid container

InactiveUS7048150B2Facilitates vertical stackingConducive to diversificationLiquid flow controllersLiquid transferring devicesEngineeringElectrical and Electronics engineering

A fluid container for use in accessing an obstructed fill port of a machine for inserting fluids therein includes a housing for containing a fluid, the housing having a top surface with an opening formed therein. A collapsible tube is aligned with the opening and affixed to the housing for providing a fluid exit path, the tube being manually extended and retracted. A channel is formed on the top surface of the housing for receiving the collapsible tube when the tube is in a retracted lateral position. An alternative embodiment of the fluid container exhibits a molded pocket formed beneath the bottom surface of a first housing for receiving a collapsible tube of a second housing when the collapsible tube of the second housing is in a retracted lateral position. Both the channel and the molded pocket facilitate vertical stacking of the containers.

Owner:B & B

Apparatus and method for reusable, no-waste collapsible tube dispensers

The invention includes a method of using a cap containing an internal thread form matching an external thread form on a flexible throat for a collapsible tube enclosing at least one contained product. Twisting the cap engages the internal thread form and the external thread form. These collectively urge the cap and the flexible throat to seal the contained product into the collapsible tube. Deforming the flexible throat through squeezing the collapsible tube dispenses essentially all the product. The collapsible tube may preferably include an external thread form on a flexible throat coupled to a flexible shoulder. The external thread form mates to a cap with an internal thread form urging the flexible throat to seal against the cap when the cap is twisted onto the flexible throat. The flexible throat and flexible shoulder flatten to dispense essentially all of the product.

Owner:SCOTT ANDERSON & SUSAN POTTISH +2

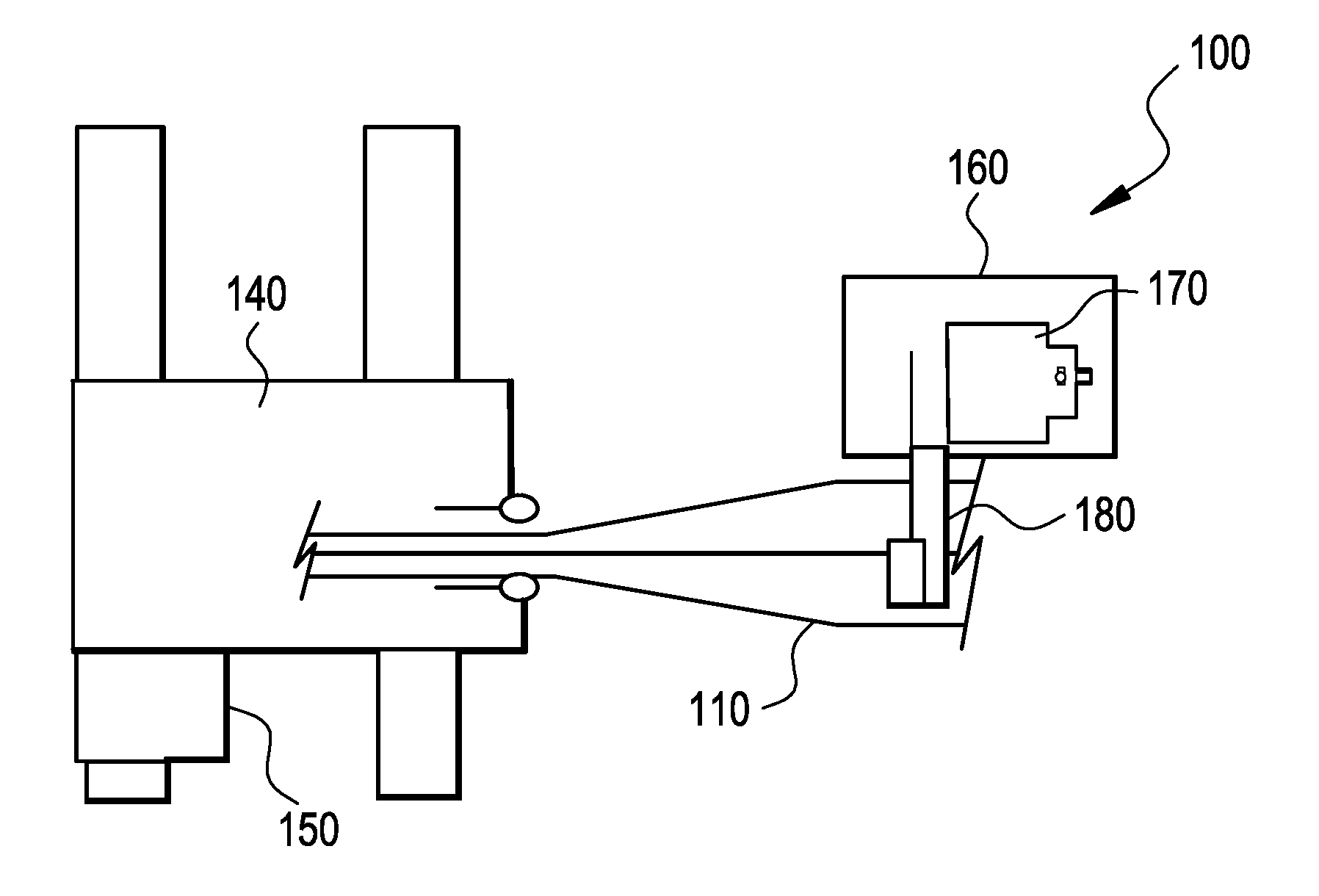

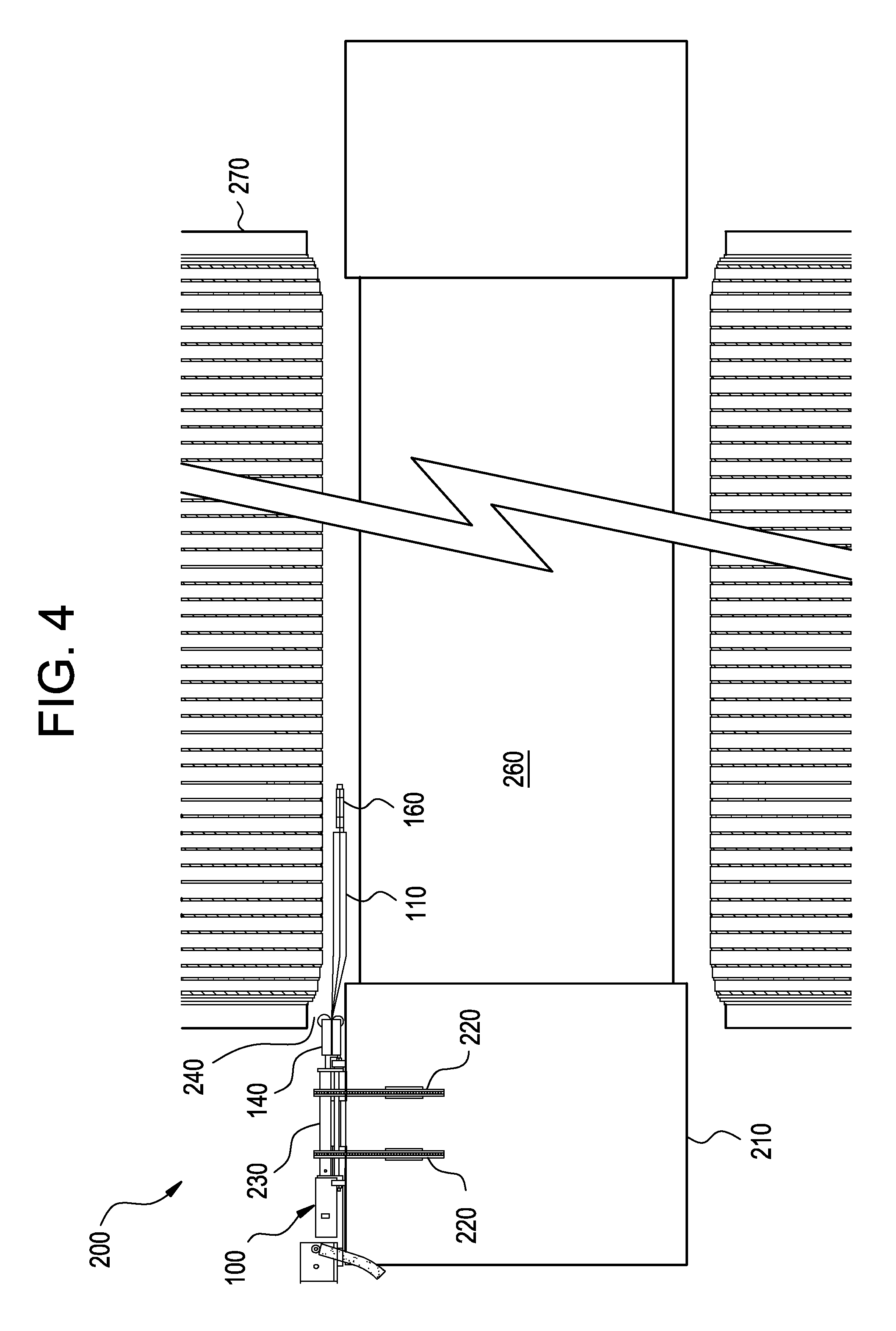

Tape fed miniature air gap inspection crawler

An air gap inspection device. The air gap inspection device may include a mast and an inspection head attached to the mast. The mast may be in the form of a collapsible tube.

Owner:GENERAL ELECTRIC CO

Apparatus and method for open thread, reusable, no-waste collapsible tube dispensers

Owner:SCOTT V ANDERSON & SUSAN POTTISH TRUSTEES UNDER THE SCOTT V ANDERSON & SUSAN POTTISH TRUST AGREEMENT DATED DECEMBER 1 2005 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com