Apparatus for dispensing flowable contents of a collapsible tube

a technology of flowable contents and collapsible tubes, which is applied in the direction of flexible containers, pliable tubular containers, packaging, etc., can solve the problems of difficulty, if not impossible, in emptying the contents of some tubes, and not being completely satisfactory in ease of handling, operation, durability, maintenance and/or cost, etc., and achieve uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

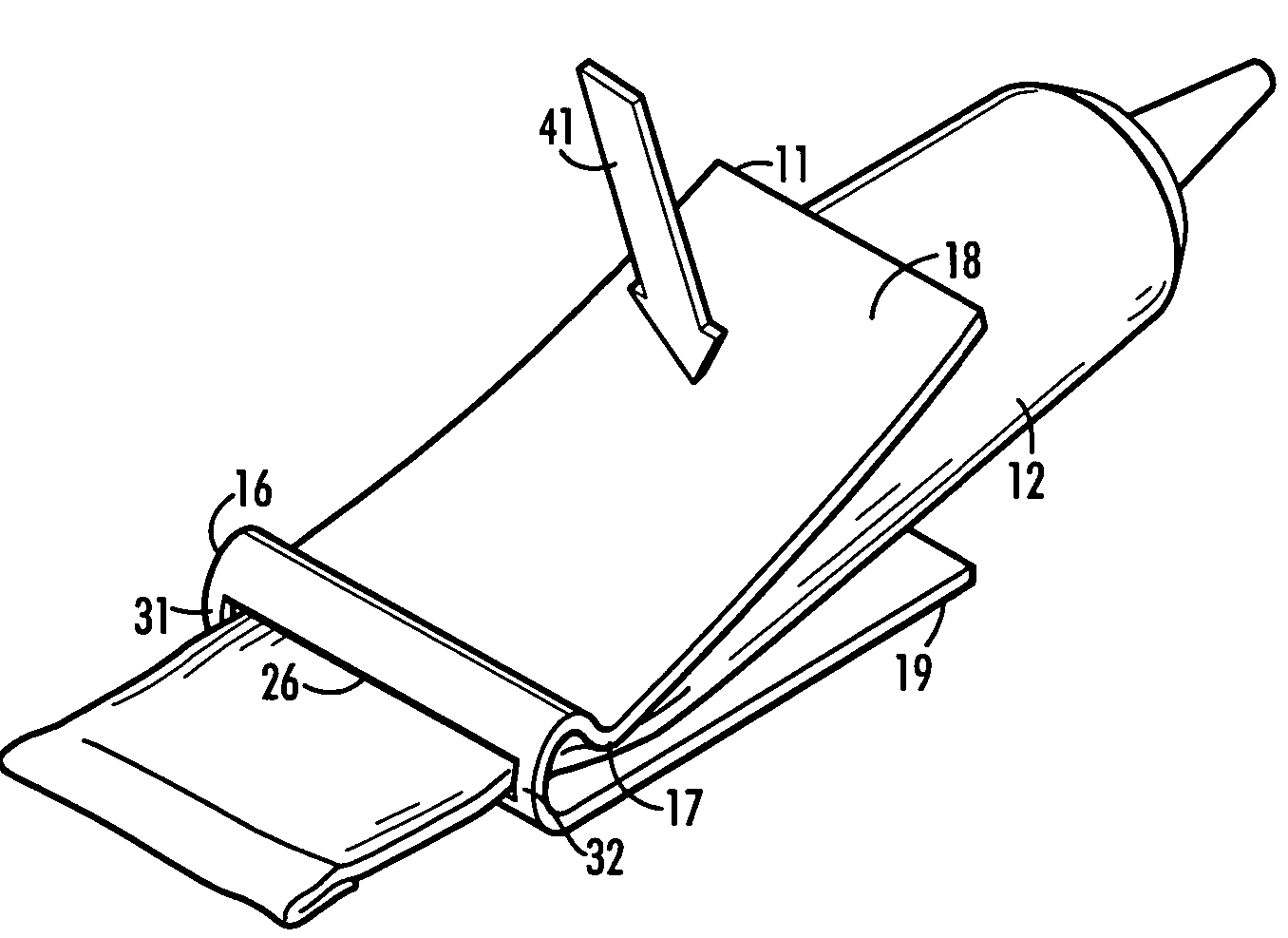

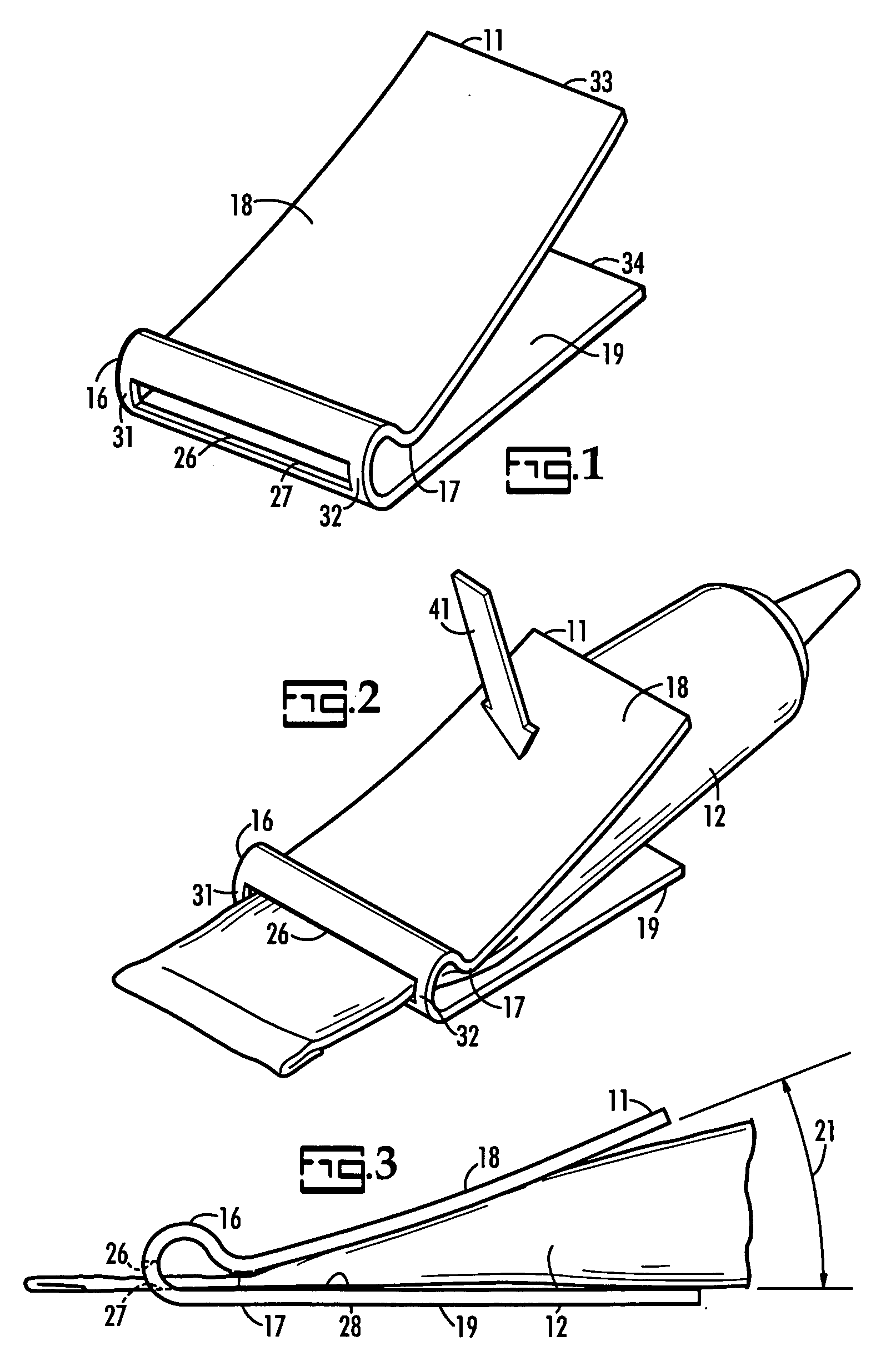

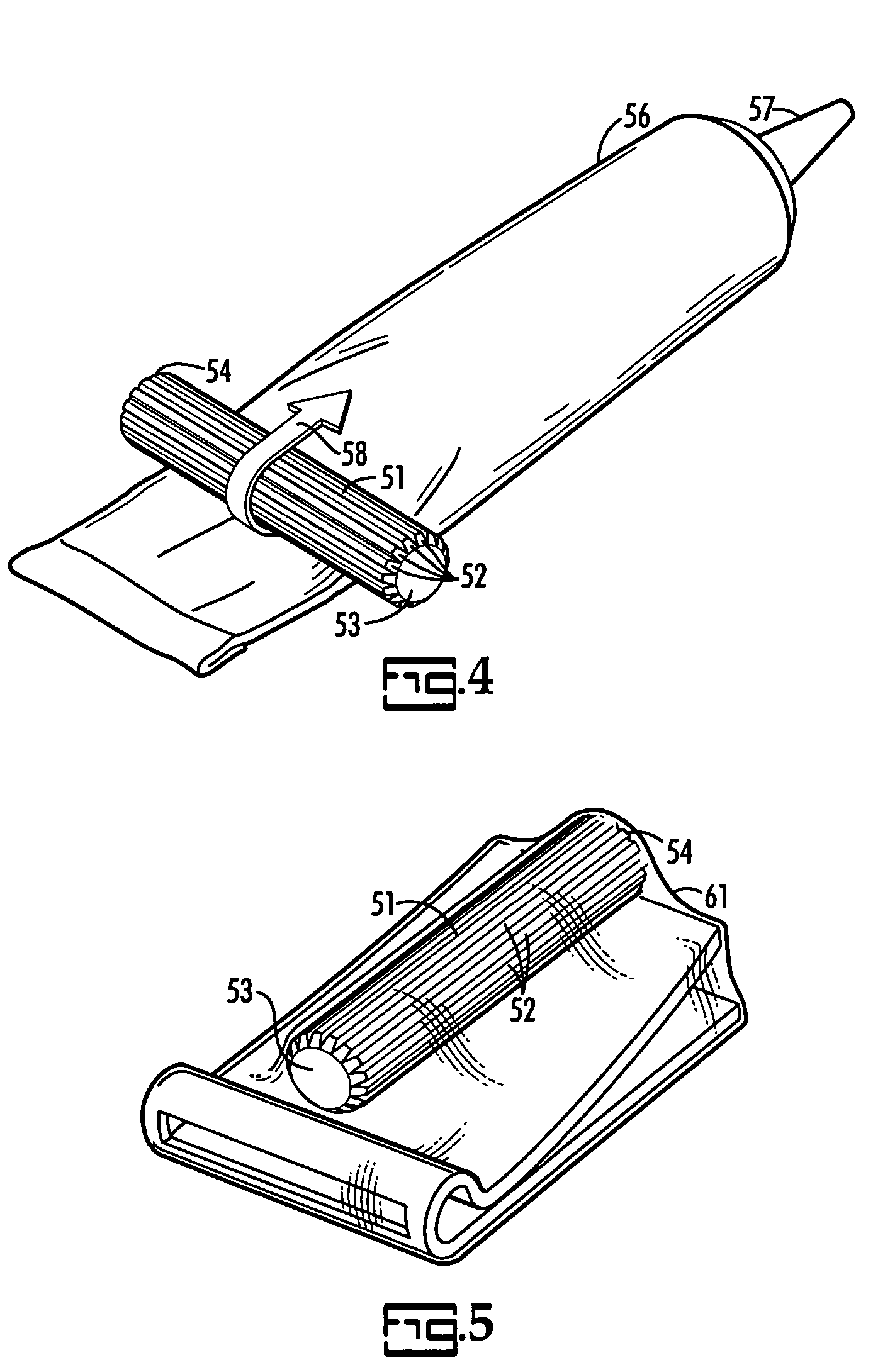

[0009]FIGS. 1 through 3 show the hand held device or tube squeezer 11 for emptying the contents of a collapsible tube 12 which may contain any one of a wide variety of industrial products such as caulking, grouting, sealants or household products such as toothpaste. The tube squeezer is made of an elongated segment of thin flat resilient material of uniform thickness, preferably thermo plastic, which is bent over on itself about 165 degrees at near the midpoint of its length to form a loop 16. The segment is next bent upwardly from the loop to form a downwardly extending dimple 17 and then is bent upwardly a slight amount to present a slightly rounded or concave top plate 18 extending above a flat bottom plate 19 at an acute angle 21 between 10 and 25 degrees preferably about 17 degrees. The downward extending dimple 17 provides a rounded laterally extending tube gripping ridge which grips the tube when the top plate is pivoted downwardly about a live hinge. The width of the tube sq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com