Integrally-forming method of CFRP lenticular collapsible tube

A fiber-reinforced resin and composite material technology, applied in the field of composite material manufacturing, can solve the problems of complex molding process and high cost, and achieve the effect of cost reduction and high molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and implementation examples.

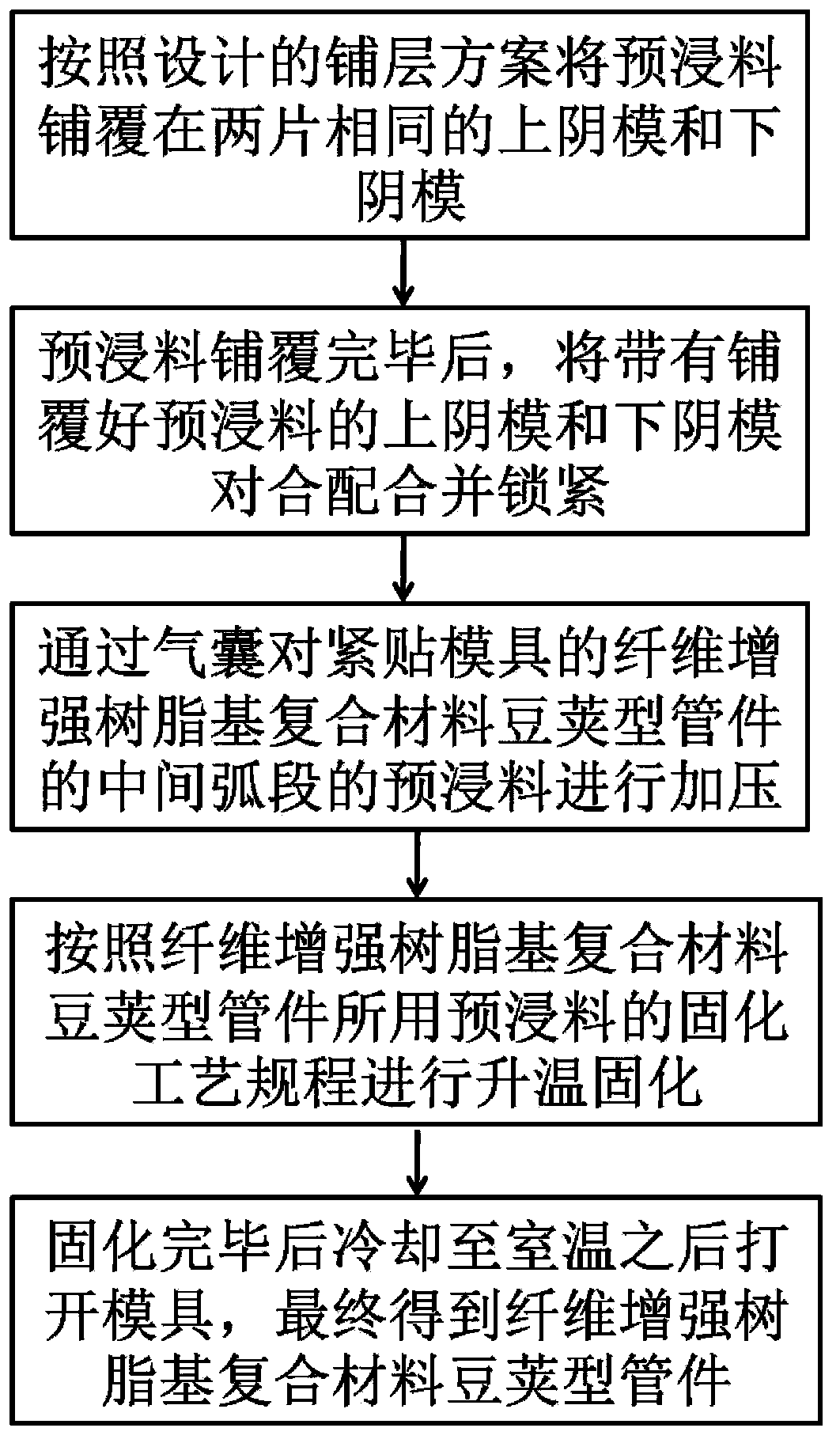

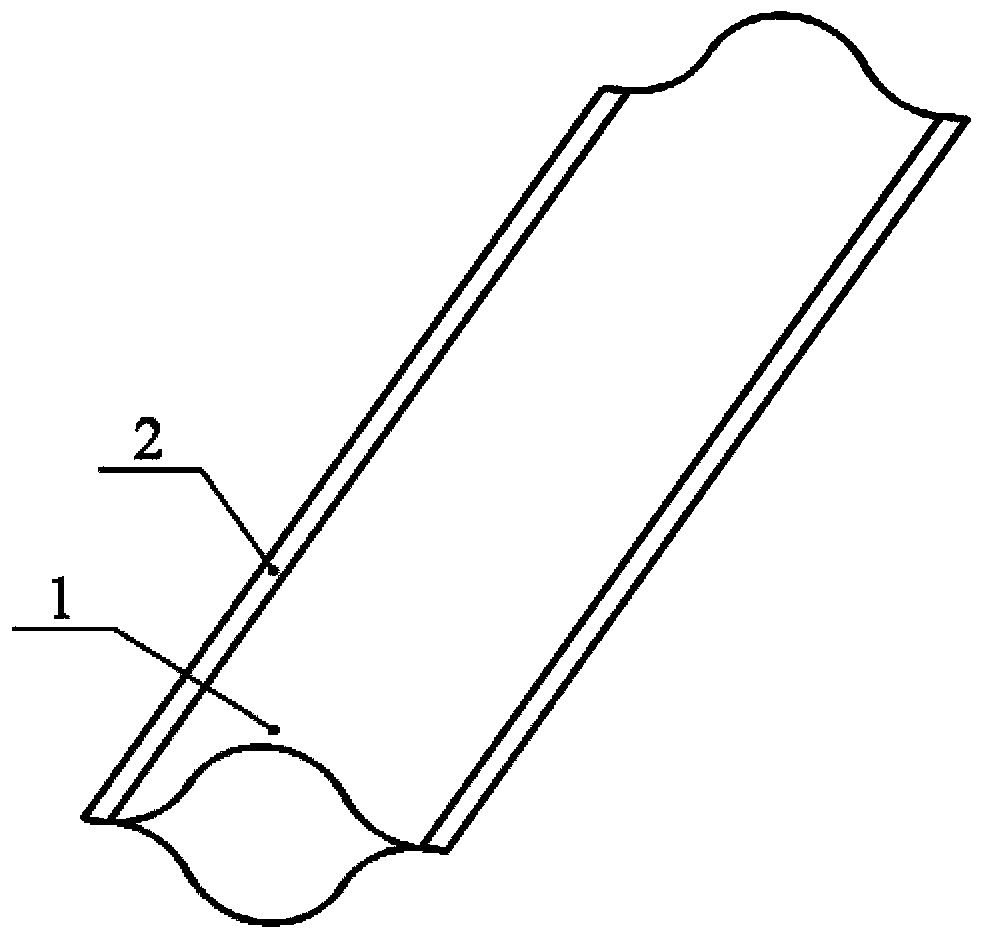

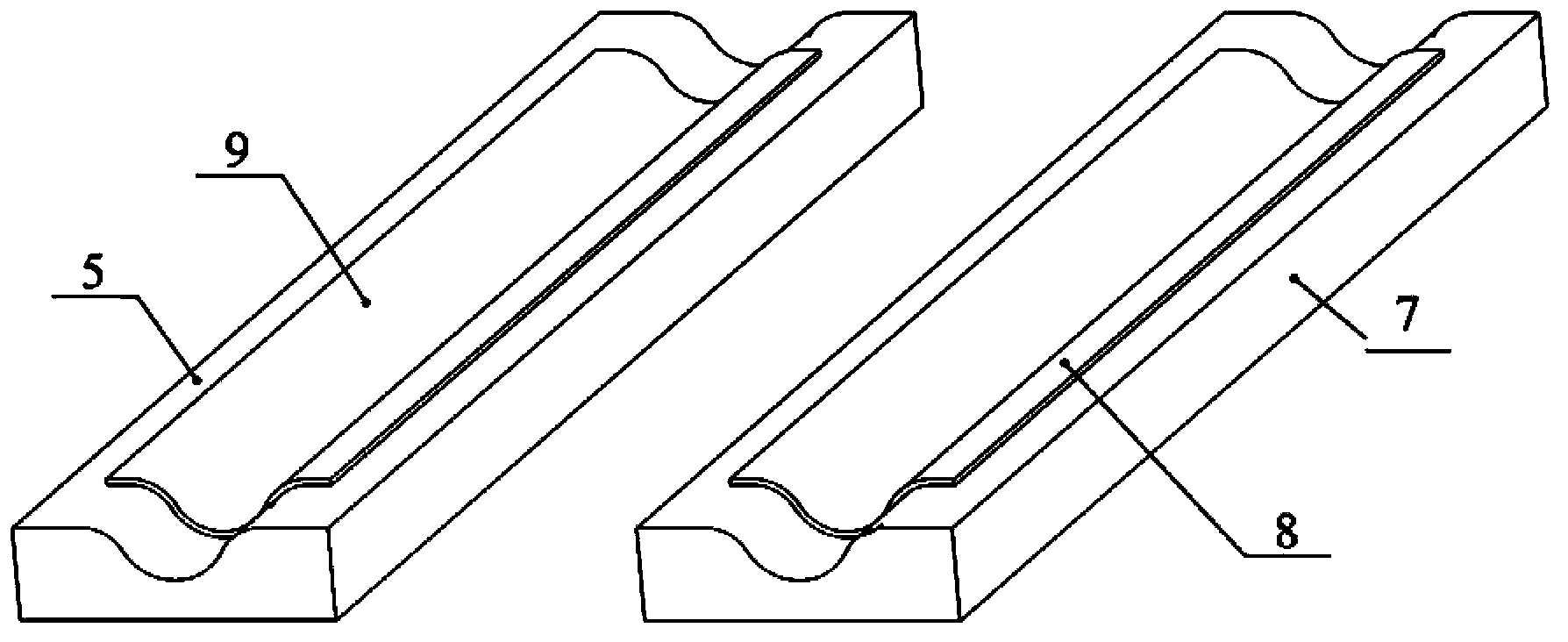

[0028] The flow chart of the present invention is as figure 1 As shown, first, the prepreg is laid on two identical upper female molds 5 and lower female molds 7 according to the designed layup scheme. After the prepreg is laid, the The upper female mold 5 and the lower female mold 7 are mated and locked, and then the impregnation material of the middle arc segment 1 of the fiber reinforced resin matrix composite material pod-shaped pipe fitting close to the mold is pressed by the air bag 4, according to the fiber reinforced resin matrix The curing process of the prepreg used in the composite pod-shaped pipe fittings is to heat up and solidify. After curing, the mold is opened after cooling to room temperature, and finally the fiber-reinforced resin-based composite material pod-shaped pipe fittings are obtained. exist figure 2 Among them,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com