Epoxy resin adhesive for impregnation with high heat resistance and preparation method thereof

A technology of epoxy resin glue and epoxy resin, applied in the direction of epoxy resin glue, adhesive, non-polymer adhesive additives, etc., can solve harsh reaction conditions, reduce toughness, and it is difficult to obtain bisphenol fluorene-based epoxy resin and other problems, to achieve the effect of high bond strength, high fullness, enhanced mechanical strength and electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

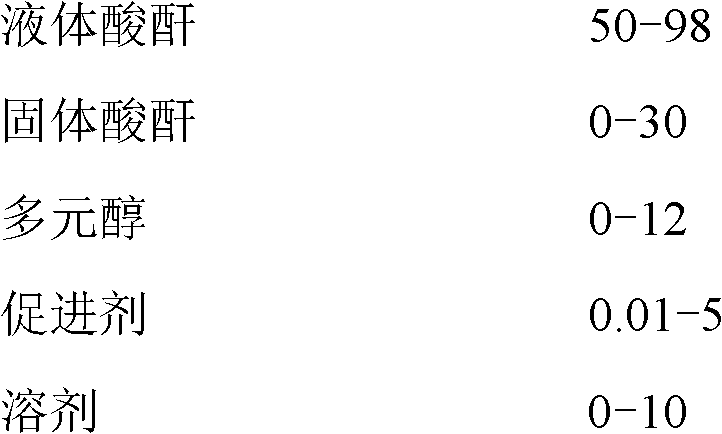

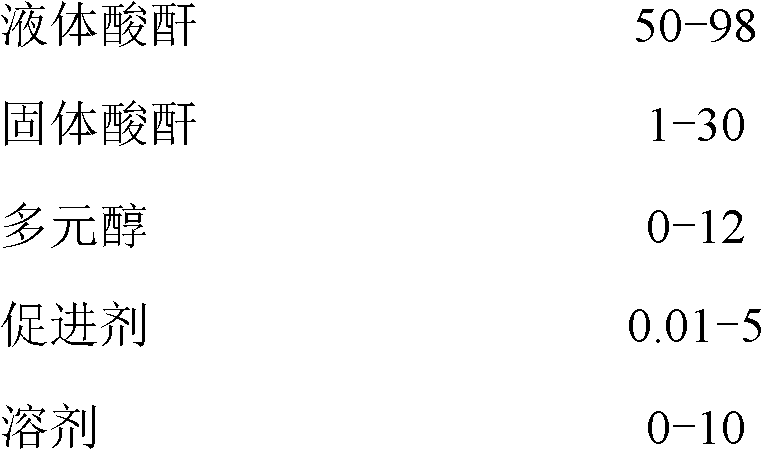

Method used

Image

Examples

Embodiment 1

[0029] The preparation of modified epoxy resin: the EPN (DOW company D.E.N.431) of weight part 30, the TGIC (CIBA company PT-801) of weight part 8, the TDE (Swiss CIBA company TDE-85) of weight part 55, join in In the reaction vessel, stir and heat up to 100°C, mix for 1.5 hours, cool to 70°C and vacuumize for 40 minutes at a vacuum degree of not less than 0.095MPa, cool down to 60°C, and add 7 parts by weight of co-solvent (ethanol and acetone according to mass ratio of 30:50, the same below), after mixing for 1 hour, the material was filtered to obtain a viscous liquid with a viscosity of 17000mPa.s at 25°C.

[0030]Preparation of curing agent: After heating HMNA (Puyang Huicheng Chemical Co., Ltd.) of 35 parts by weight, MHHPA (Hitachi Chemical NH-5500) of 45 parts by weight, and MCTC of 12 parts by weight to 150 ° C to dissolve evenly, add 3 parts by weight The trimethylolpropane was reacted at 150°C for 1 hour, cooled to 70°C and vacuumed for 30 minutes under a vacuum of ...

Embodiment 2

[0034] The preparation of modified epoxy resin: the EPN (DOW company D.E.N.431) of weight part 28, the TGIC (CIBA company PT-801) of weight part 15, the TDE (Swiss CIBA company TDE-85) of weight part 48, weight part Add the 1,4-butanediol diglycidyl ether of 5 into the reaction vessel, stir and heat up to 100°C, mix for 1.5 hours, cool to 70°C and vacuumize for 40 minutes under a vacuum of not less than 0.095MPa, and cool down After reaching 60°C, add 4 parts by weight of solvent, mix for 1 hour, and filter out the material to obtain a viscous liquid with a viscosity of 18700 mPa.s at 25°C.

[0035] Heat-resistant epoxy resin glue preparation: the resin component and the curing agent component of Example 1 were heated and mixed at 30° C. at a weight ratio of 10:9, and the viscosity of the mixture was 4250 mPa.s.

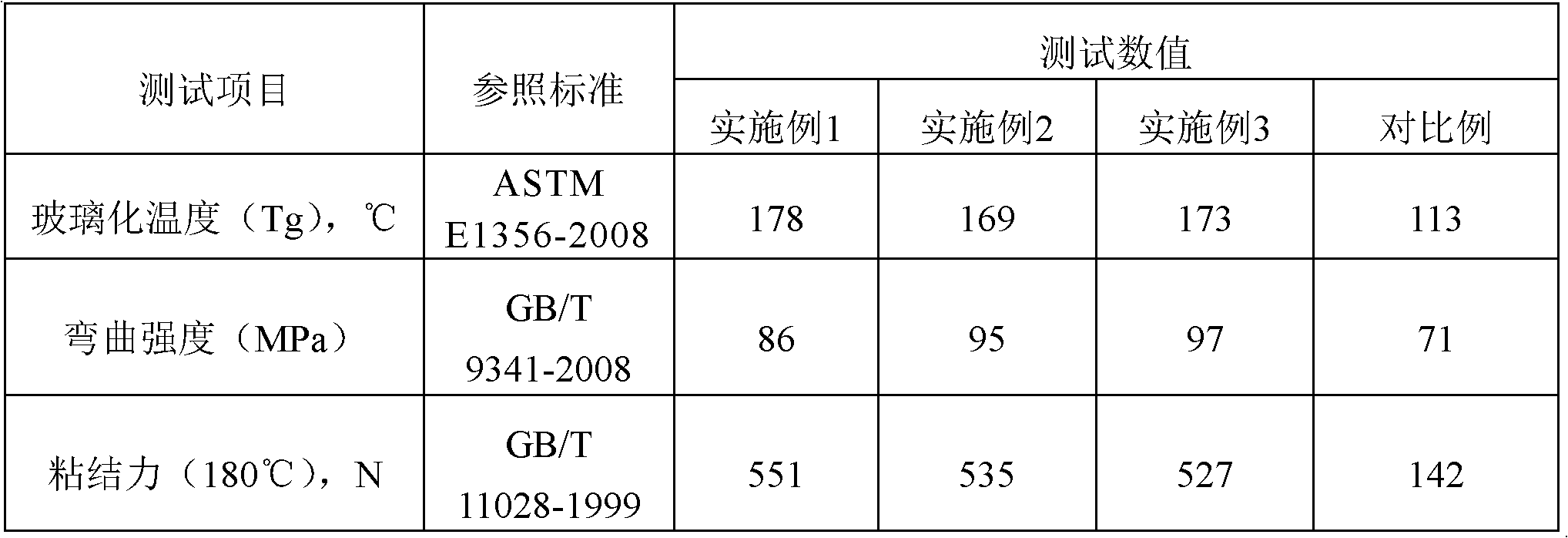

[0036] The glass transition temperature and cohesiveness of the obtained epoxy resin glue were tested, and the curing conditions for sample preparation were 120°C / 40...

Embodiment 3

[0038] Modified epoxy resin preparation: the EPN (DOW company D.E.N.431) of weight part 28, the TGIC (CIBA company PT-801) of weight part 10, the TDE (Swiss CIBA company TDE-85) of weight part 60, weight part 2 Add 1,4-butanediol diglycidyl ether into the reaction vessel, stir and heat up to 100°C, mix for 1.5 hours, cool to 70°C and vacuumize for 40 minutes under a vacuum of not less than 0.095MPa, cool to 60°C, a viscous liquid with a viscosity of 29000mPa.s at 25°C was obtained.

[0039] Preparation of curing agent: After heating HMNA of 45 parts by weight, MHHPA (Hitachi Chemical NH-5500) of 40 parts by weight, and MCTC of 12 parts by weight to 150 ° C to dissolve evenly, add trimethylolpropane of 3 parts by weight at 150 Reaction at ℃ for 1 hour, cooling to 70 ℃ and vacuuming for 30 minutes at a vacuum degree of not less than 0.095 MPa, adding 1.5 parts by weight of a mixing accelerator, mixing for 1 hour to obtain a homogeneous liquid with a viscosity of 1200 mPa.s.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com