Triazine derivative-based separator for vanadium battery and preparation method of separator

A technology of triazine derivatives and vanadium batteries, which can be used in fuel cells, electrochemical generators, regenerative fuel cells, etc., and can solve the problems of environmental protection, harm to human body and environment, anti-ultraviolet aging chemical stability and poor vanadium resistance. , to achieve cost saving, low price, good anti-ultraviolet aging and alkali resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

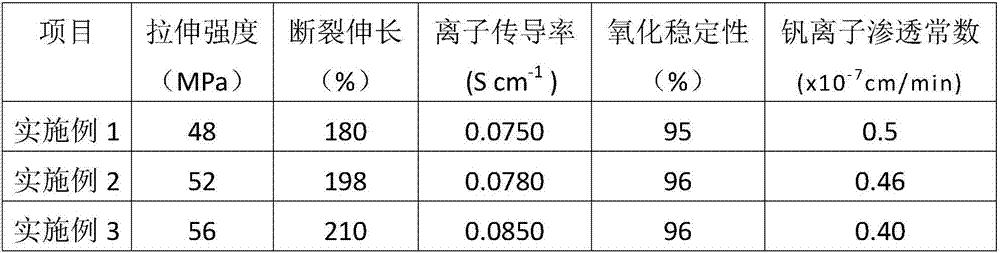

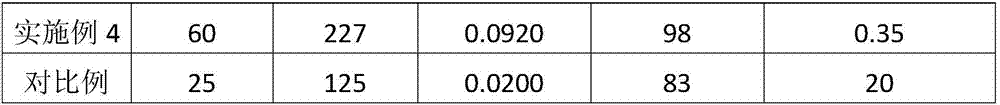

Embodiment 1

[0029] A preparation method based on a triazine derivative diaphragm for a vanadium battery, comprising the steps of:

[0030] 1) Preparation of polymeric triazine derivatives: 10 g of 2,4-diamino-6-phenyl-1,3,5-triazine and 35 g of 2-chloroethyl vinyl ether were added to 100 g of acetonitrile and mixed Evenly, stir and reflux at 30°C for 6 hours, then remove the solvent by rotary evaporation at 40°C, then wash with ether and ethyl acetate for 3 times, and finally remove the solvent by rotary evaporation at 40°C;

[0031] 2) Preparation of polymer film: 3 g of polymerized triazine derivatives prepared in step 1), 2 g of acrylonitrile, 2 g of perfluoro-n-propyl vinyl ether, 0.05 g of sodium dodecylbenzenesulfonate and benzoin Mix 0.1g of diethyl ether, drop it on a glass plate, put it under a 200nm ultraviolet lamp under a nitrogen atmosphere and illuminate it for 45 minutes, a polymerization reaction occurs, and a polymer film is obtained;

[0032] A triazine derivative-based...

Embodiment 2

[0035] A preparation method based on a triazine derivative diaphragm for a vanadium battery, comprising the steps of:

[0036] 1) Preparation of polymeric triazine derivatives: 10 g of 2,4-diamino-6-phenyl-1,3,5-triazine and 37 g of 2-chloroethyl vinyl ether were added to 110 g of diethyl ether and mixed Uniform, stirred and refluxed at 33°C for 7 hours, then removed the solvent by rotary evaporation at 43°C, washed with ether and ethyl acetate for 4 times, and finally removed the solvent by rotary evaporation at 44°C;

[0037] 2) Preparation of polymer film: 3.3 g of polymerized triazine derivatives prepared in step 1), 4 g of styrene, 3 g of perfluoro-n-propyl vinyl ether, 0.06 g of polyoxypropylene polyvinyl glyceryl ether and benzoin Mix 0.13g of dimethyl ether, drop it on a glass plate, put it under a 220nm ultraviolet lamp under an argon atmosphere and illuminate it for 48 minutes, a polymerization reaction occurs, and a polymer film is obtained;

[0038] A triazine der...

Embodiment 3

[0041] A preparation method based on a triazine derivative diaphragm for a vanadium battery, comprising the steps of:

[0042] 1) Preparation of polymeric triazine derivatives: 10 g of 2,4-diamino-6-phenyl-1,3,5-triazine and 38 g of 2-chloroethyl vinyl ether were added to 113 g of acetone and mixed Evenly, stir and reflux at 38°C for 8 hours, then remove the solvent by rotary evaporation at 48°C, then wash with ether and ethyl acetate for 5 times, and finally remove the solvent by rotary evaporation at 48°C;

[0043]2) Preparation of polymer film: 3.8 g of polymerized triazine derivatives prepared in step 1), 4.5 g of α-methylstyrene, 3.5 g of perfluoro-n-propyl vinyl ether, nonylphenol polyoxygen Mix 0.07g of vinyl ether and 0.18g of benzoin isopropyl ether, drop it on a glass plate, put it under a 240nm ultraviolet lamp under a neon gas atmosphere, and illuminate it for 55 minutes to undergo a polymerization reaction to obtain a polymer film;

[0044] A triazine derivative-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com