Preparation method and application of aqueous polyurethane latex as vacuum plastic-absorption adhesive

A water-based polyurethane and emulsion technology, applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve the problems of PVC decorative leather peeling off, unfavorable wide practical application, and increase production costs. Water resistance, cost saving, good blending performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

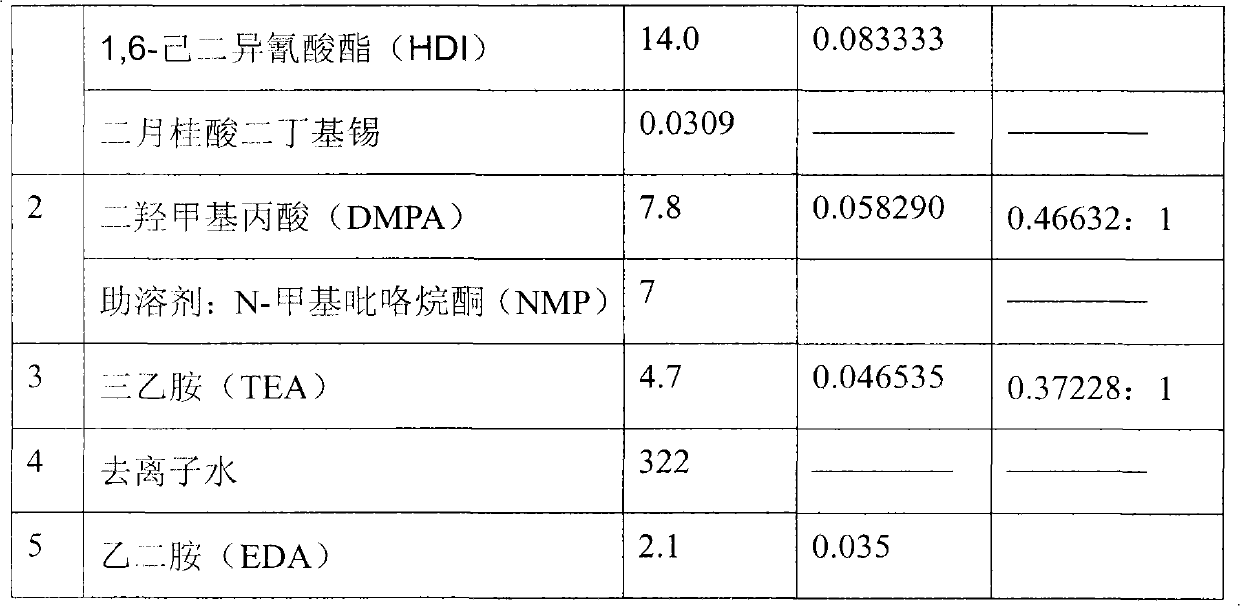

[0036] Additives and amounts added in the preparation process:

[0037]

[0038]

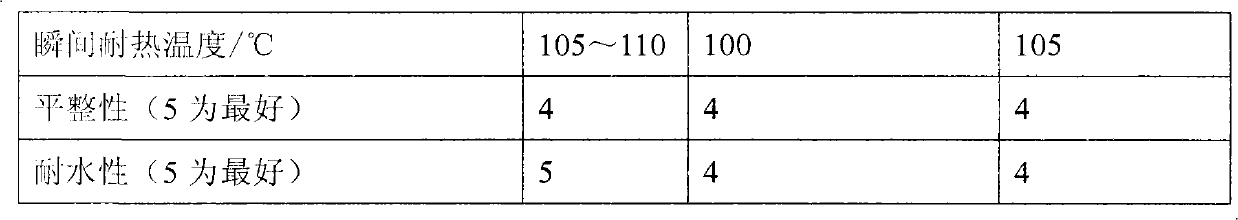

[0039] The raw material polyester polyol in this example is prepared from adipic acid and 1,4-butanediol, its molecular weight is 2000, its hydroxyl value is 56±1 mgKOH / g, and its OH functionality is 2. Fill the above-mentioned polyester polyol, IPDI, HDI and catalyst dibutyltin dilaurate into a 1000ml flask equipped with a thermometer and a stirrer, and react at 80° C. for 2.5 hours to obtain a prepolymer. Then add DMPA and co-solvent NMP, and react at 65°C for 4 hours. Then add TEA for neutralization, add the neutralized prepolymer into deionized water to disperse, and maintain emulsification for 2 minutes after adding, then add EDA for chain extension, the adding time is 8 minutes, and disperse for 45 minutes after adding, to obtain A kind of water-based polyurethane emulsion, its solid content is 46.5%, Ph=7.1, viscosity (27 ℃)=150mPa.s, bond strength (PVC / PVC)=3.9N / mm, bond strength (P...

Embodiment 2

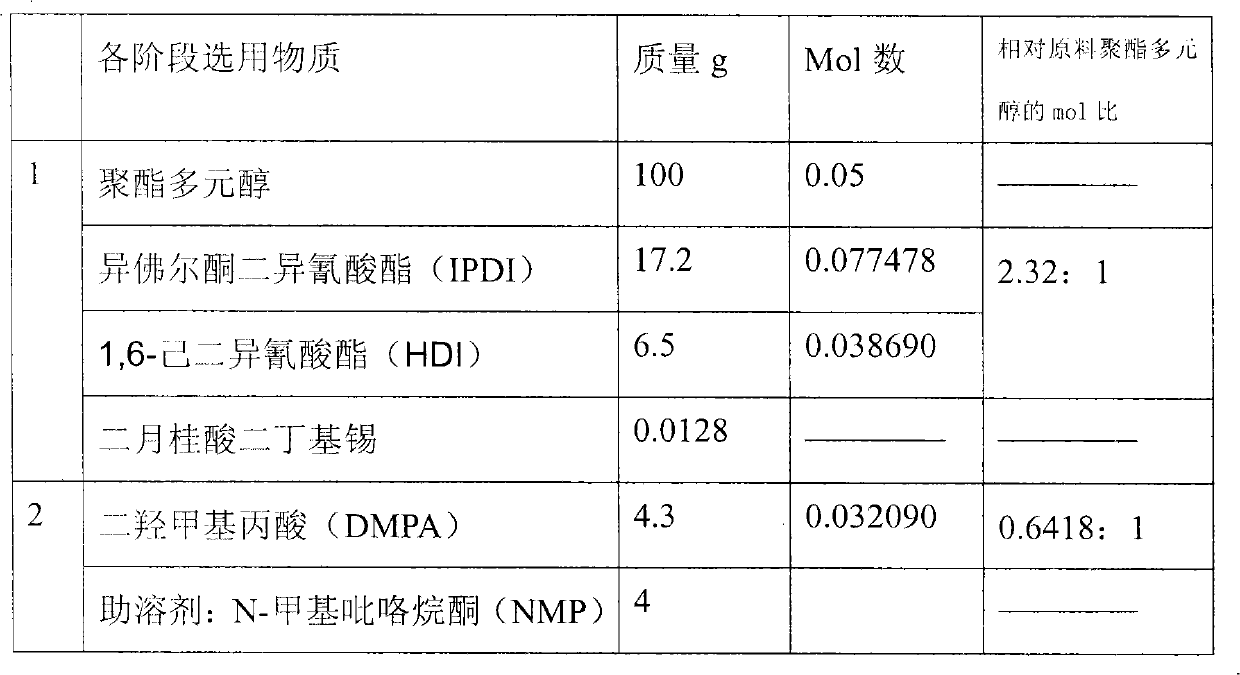

[0041] Additives and amounts added in the preparation process:

[0042]

[0043]

[0044] The raw material polyester polyol in this example is prepared from adipic acid and 1,4-butanediol, its molecular weight is 2000, its hydroxyl value is 56±1 mgKOH / g, and its OH functionality is 2. Put polyester polyol, IPDI, HDI and catalyst dibutyltin dilaurate in the 1000ml flask that is equipped with thermometer, stirrer, react at 80 ℃ for 2.5 hours to obtain prepolymer. Then add DMPA and co-solvent NMP, react at 65°C for 4.5 hours. Then add TEA for neutralization, add the neutralized prepolymer into deionized water to disperse, keep it for 2 minutes after the addition, then add EDA for chain extension, the addition time is 10 minutes, and disperse for 45 minutes after the addition, to obtain a A kind of aqueous polyurethane emulsion, its solid content is 48.5%, Ph=7.1, viscosity (27 ℃)=235mPa.s, bonding strength (PVC / PVC)=3.6N / mm, bonding strength (PVC / MDF) =2.0N / mm, the activa...

Embodiment 3

[0046] Additives and amounts added in the preparation process:

[0047]

[0048]

[0049] The raw material polyester polyol in this example is prepared from adipic acid and 1,4-butanediol, its molecular weight is 2000, its hydroxyl value is 56±1 mgKOH / g, and its OH functionality is 2. Put polyester polyol, IPDI and catalyst tin octoate into the 1000ml flask equipped with thermometer and stirrer, and react at 85°C for 3 hours to obtain prepolymer. Then add DMPA and co-solvent NMP, react at 60°C for 5 hours. Then add TEA for neutralization, add the neutralized prepolymer into deionized water to disperse, keep it for 2 minutes after the addition, then add EDA for chain extension, the addition time is 5 minutes, and disperse for 45 minutes after the addition, to obtain a A kind of aqueous polyurethane emulsion, its solid content is 49.5%, Ph=7.3, viscosity (27 ℃)=175mPa.s, bonding strength (PVC / PVC)=4.1N / mm, bonding strength (PVC / MDF) =2.3N / mm, the activation temperature i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Bond strength | aaaaa | aaaaa |

| Bond strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com