Degradable plastic film and production method thereof

A plastic film and film-level technology, applied in the field of degradable plastic film, can solve the problems of difficult to ensure fixed conditions for plastic film degradation, poor process performance, poor physical properties and appearance of plastic film products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

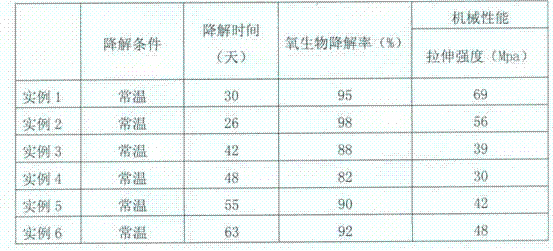

Examples

Embodiment 1

[0033] The degradable plastic film comprises the following components, and the weight and number ratios of each component are respectively

[0034] Film Grade Linear Low Density Polyethylene 70

[0035] Film Grade PLA 30

[0036] Glycerin plasticizer 2

[0037] Triphenyl phosphite heat stabilizer 1

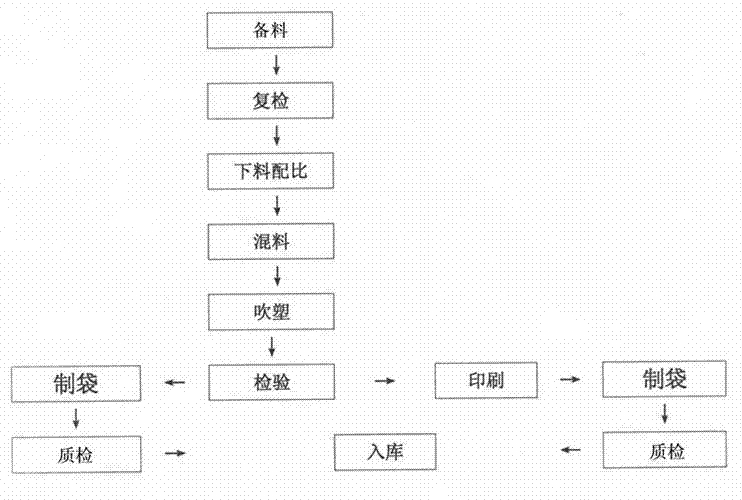

[0038] Its manufacturing method comprises the following steps:

[0039] (1) Material preparation: select film-grade linear low-density polyethylene, film-grade polylactic acid, glycerin plasticizer and triphenyl phosphite heat stabilizer as raw materials;

[0040] (2) Re-inspection: check the quality of raw materials and remove impurities;

[0041] (3) Cutting: Take the components of the degradable plastic film according to the weight ratio of the raw materials

[0042] Film Grade Linear Low Density Polyethylene 70

[0043] Film Grade PLA 30

[0044] Glycerin Plasticizer 2

[0045] Triphenyl phosphite heat stabilizer 1

[0046] (4) Mixing: Stir the raw materials of each c...

Embodiment 2

[0053] The degradable plastic film comprises the following components, and the weight and number ratios of each component are respectively

[0054] Film Grade Linear Low Density Polyethylene 60

[0055] Film Grade Polylactic Acid 40

[0056] Ethylene glycol plasticizer 4

[0057] Triphenyl phosphite heat stabilizer 1

[0058] The manufacturing method is the same as Example 1, so it is omitted.

Embodiment 3

[0060] The degradable plastic film comprises the following components, and the weight and number ratios of each component are respectively

[0061] Film Grade Linear Low Density Polyethylene 50

[0062] Film Grade Low Density Polyethylene 30

[0063] Film Grade Polylactic Acid 20

[0064] Polyethylene glycol plasticizer 3

[0065] Triphenyl phosphite heat stabilizer 1

[0066] The manufacturing method is the same as Example 1, so it is omitted.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com