P91 steel welding method

A welding method and welding layer technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of brittle cold cracks in welded joints, high technical level of welders, and decreased impact toughness of welds, etc., to achieve tempering Increased temperature, increased welding labor productivity, and improved welding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

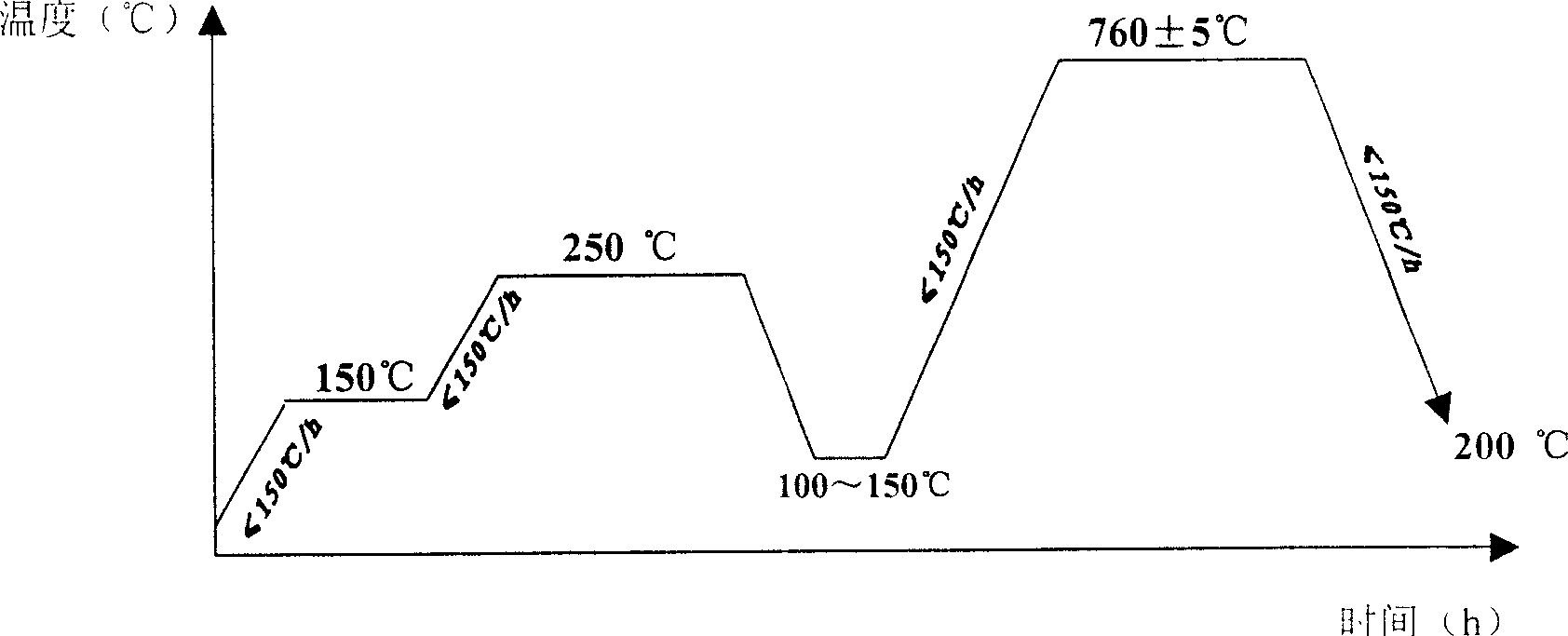

[0020] The T91 steel welding operation method of the present invention is as follows:

[0021] 1. Machine tools and welding materials

[0022] ①Welding equipment should choose inverter welding machine with good characteristics;

[0023] ②Welding wire: TGS-9Cbφ2.4, electrode: C9MVφ2.5, C9MVφ3.2

[0024] 2. Groove preparation

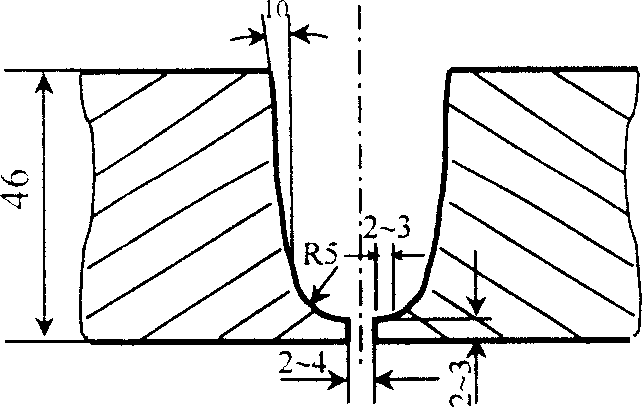

[0025] ①Bevel shape and size (mm) see figure 1 ;

[0026] ②The groove is processed mechanically during preparation;

[0027] ③The groove and the rust, oil, scale and other dirt within 20mm on both sides of the inner and outer walls are cleaned to reveal the metallic luster.

[0028] 3. Welding method

[0029] ①The welding of the test piece is fixed in a horizontal position, and the welding is performed symmetrically by two welders to maintain a balanced heating;

[0030] ② Bottoming: use manual tungsten argon arc welding TGS-9Cbφ2.4 wire for bottoming;

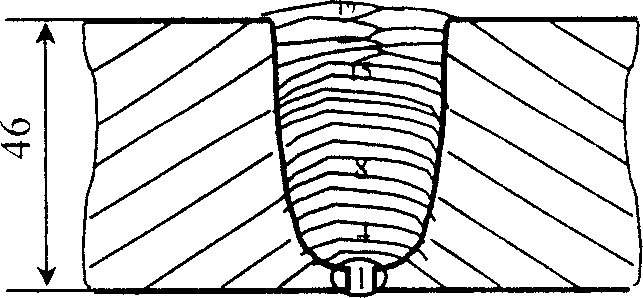

[0031] ③ Filling adopts manual welding rod C9MVφ2.5, C9MVφ3.2 arc welding filling and combined...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com