Yarn processing device

A processing device and yarn technology, applied in vibration processing, equipment configuration for processing textile materials, liquid/gas/steam yarn/filament processing, etc., can solve the effect of affecting yarn sizing, reducing the firmness of sizing, weaving threads Stress concentration and other problems can be improved to achieve the effect of improving sizing quality, compact structure and improving fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

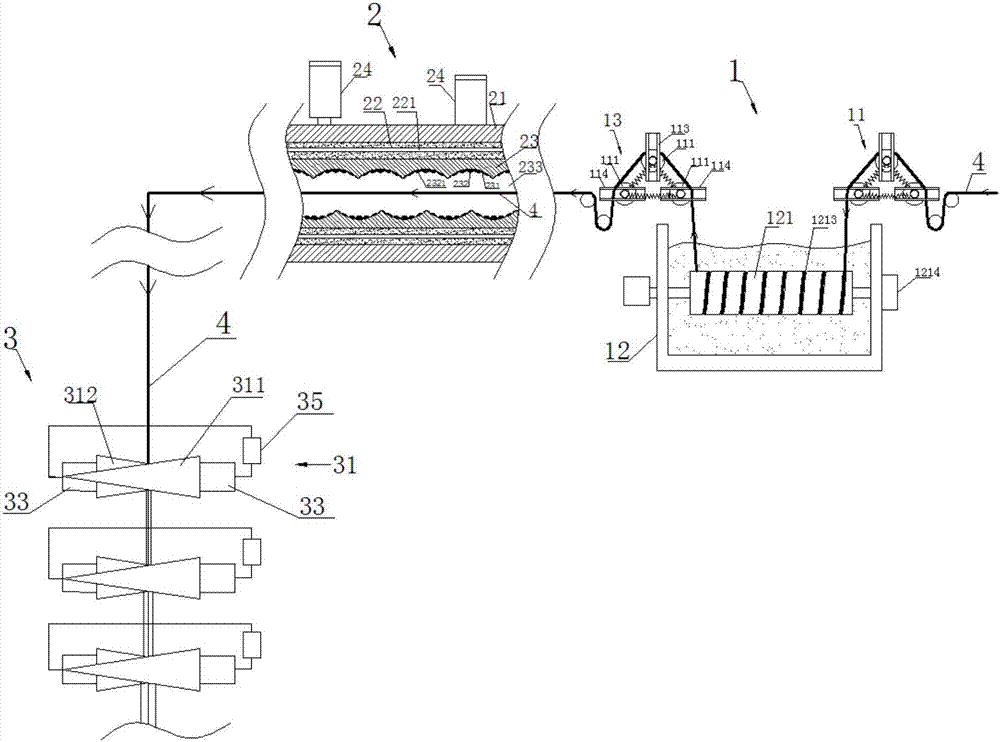

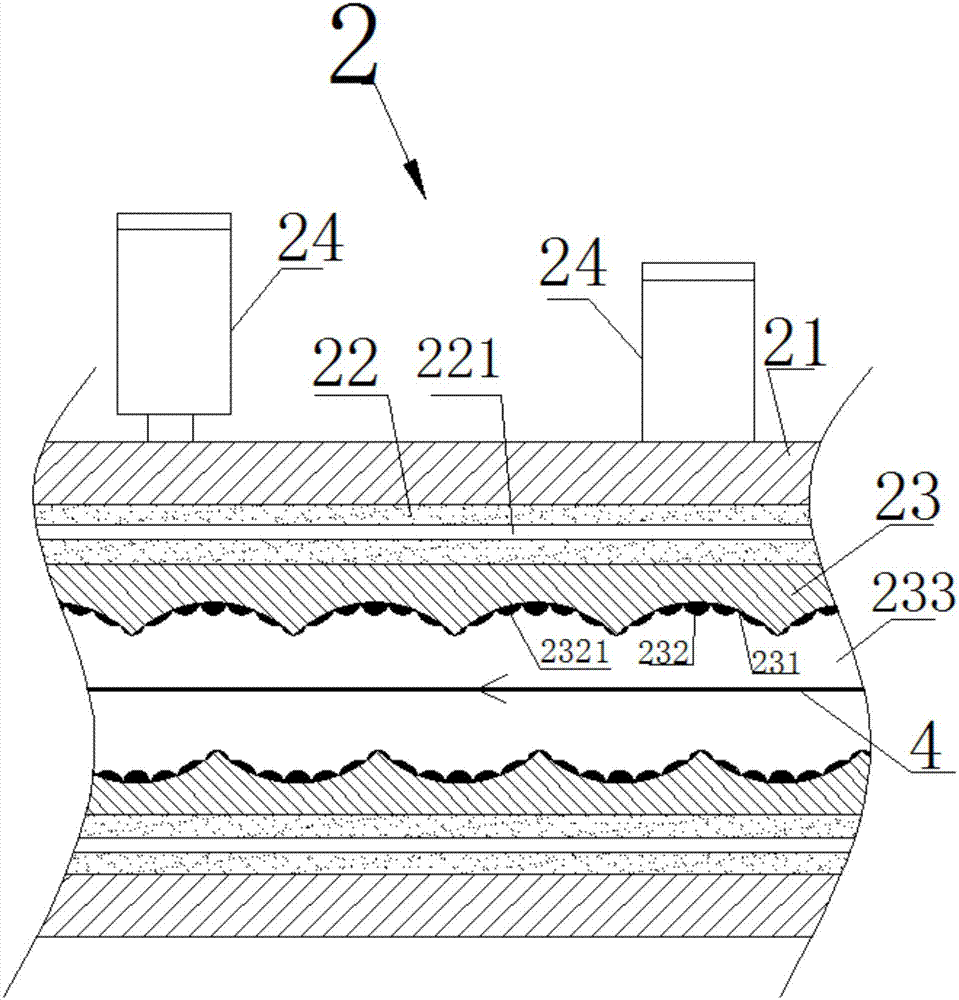

[0045] Such as figure 1 As shown, a yarn processing device includes a sizing mechanism 1 , a drying mechanism 2 and a separation mechanism 3 arranged in sequence along the moving direction of the yarn 4 .

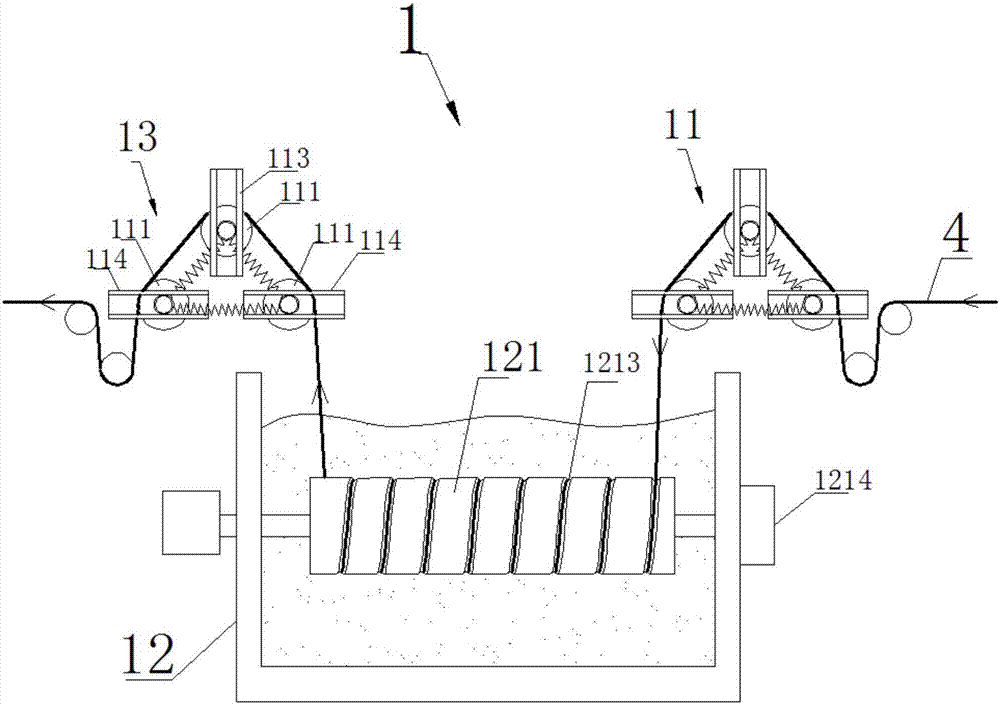

[0046] Such as figure 1 , 2 , 5, the sizing mechanism 1 includes a first micro-stress elastic roller group 11, a size tank 12 and a second micro-stress elastic roller group 13 arranged in sequence; a rotatable sizing roller is horizontally arranged in the slurry tank 12 cylinder 121; the sizing roller 121 includes a cylindrical ultrasonic transducer 1211 and a cylindrical rubber layer 1212 that is sleeved outside the ultrasonic transducer 1211 close to the ultrasonic transducer 1211; the outer peripheral surface of the rubber layer 1212 A helical track 1213 for the yarn 4 to run is provided; the ultrasonic transducer 1211 is driven by a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com