Patents

Literature

70results about How to "Reduce cleanup burden" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

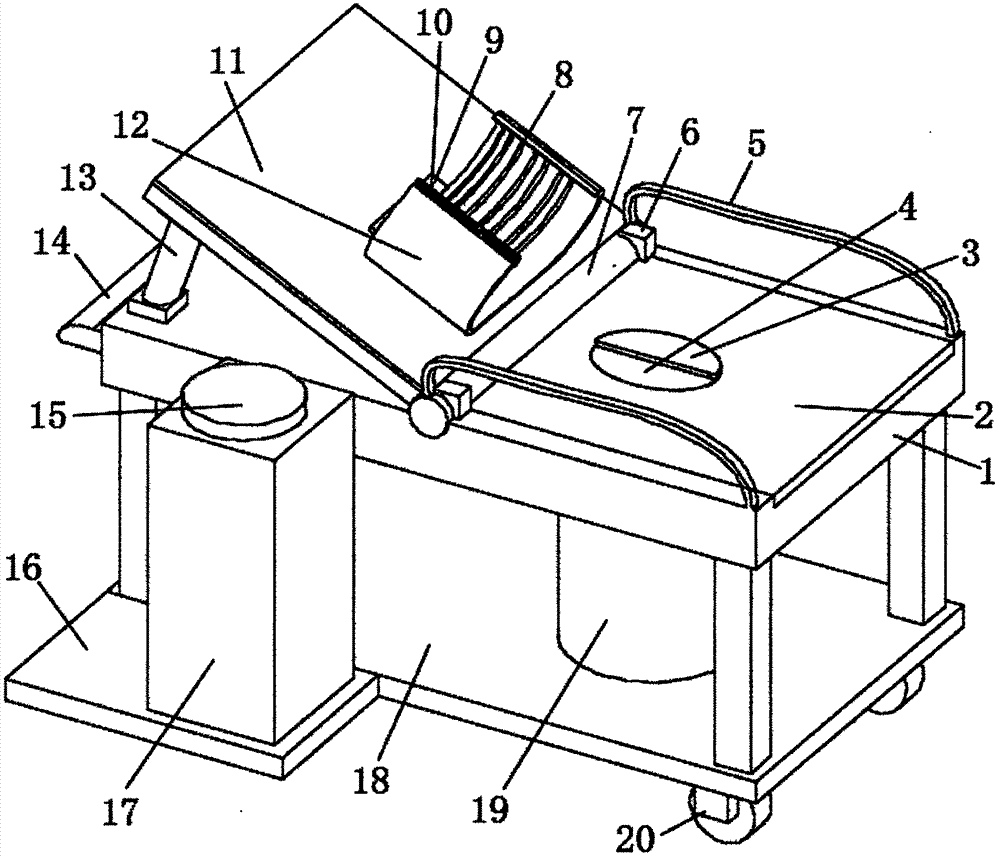

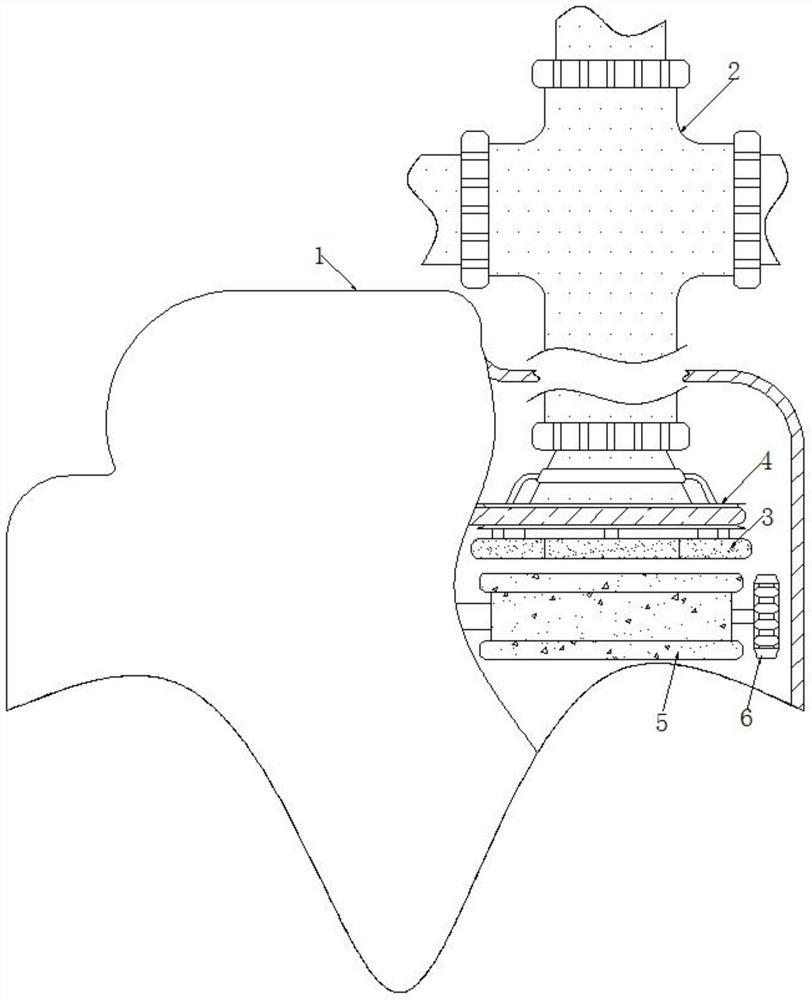

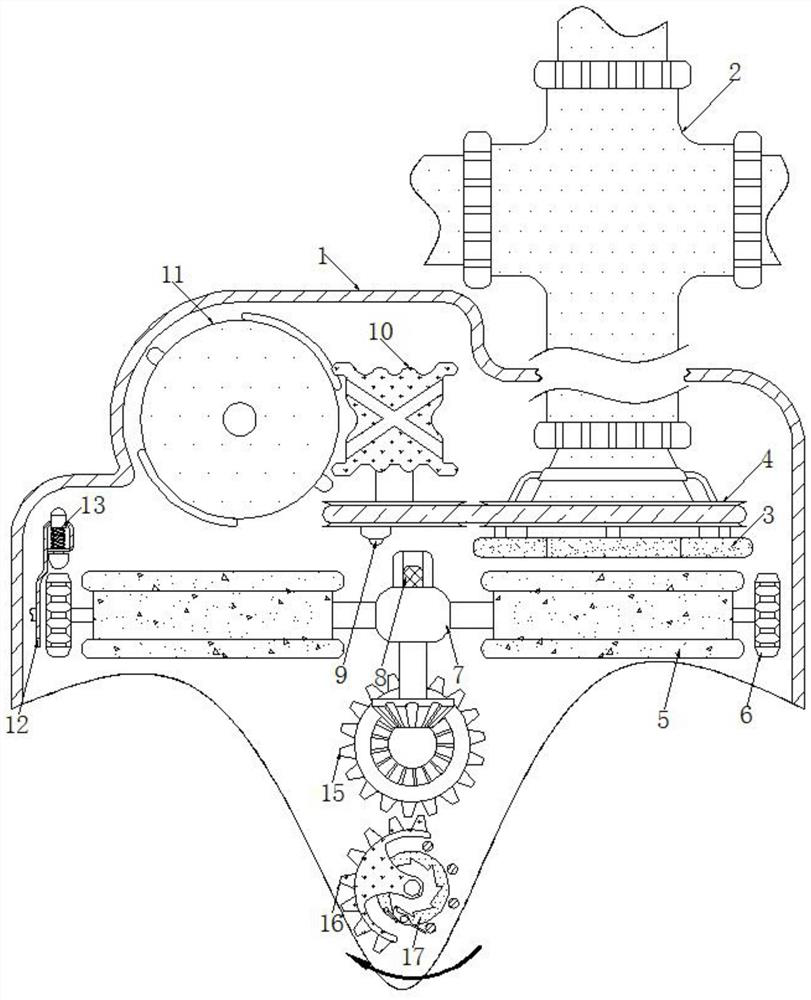

Multifunctional stomach and intestine department nursing bed

The invention discloses a multifunctional stomach and intestine department nursing bed which comprises a bed plate, wherein two bearing seats are arranged on the front edge and rear edge of the middle of the bed plate; a rotating shaft is rotationally mounted between the two bearing seats; a back plate is arranged on an arc-shaped side surface of the rotating shaft; and electronic telescopic rods are rotationally mounted at two corners of the lower bottom surface of the left side of the back plate. Due to a vomit collecting bucket which is easy to clean, the multifunctional stomach and intestine department nursing bed is capable of effectively preventing a patient from vomiting on a bed to contaminate quilts on the bed, and the cleaning burden of nursing operators is alleviated; meanwhile, due to an excrement hole in the multifunctional stomach and intestine department nursing bed, excrement for inspection of the patient can be conveniently collected by medicinal operators; the back plate of the multifunctional stomach and intestine department nursing bed can be adjusted, so that the patient can be relatively comfortable when lying down; due to stomach warming wiping cloth on the back plate, the stomach and intestine parts of the patient can be warmed; and the multifunctional stomach and intestine department nursing bed is rich in function and convenient to use, the comfort degree of the patient is increased, and the nursing burden of medicinal operators is alleviated.

Owner:毕秀叶

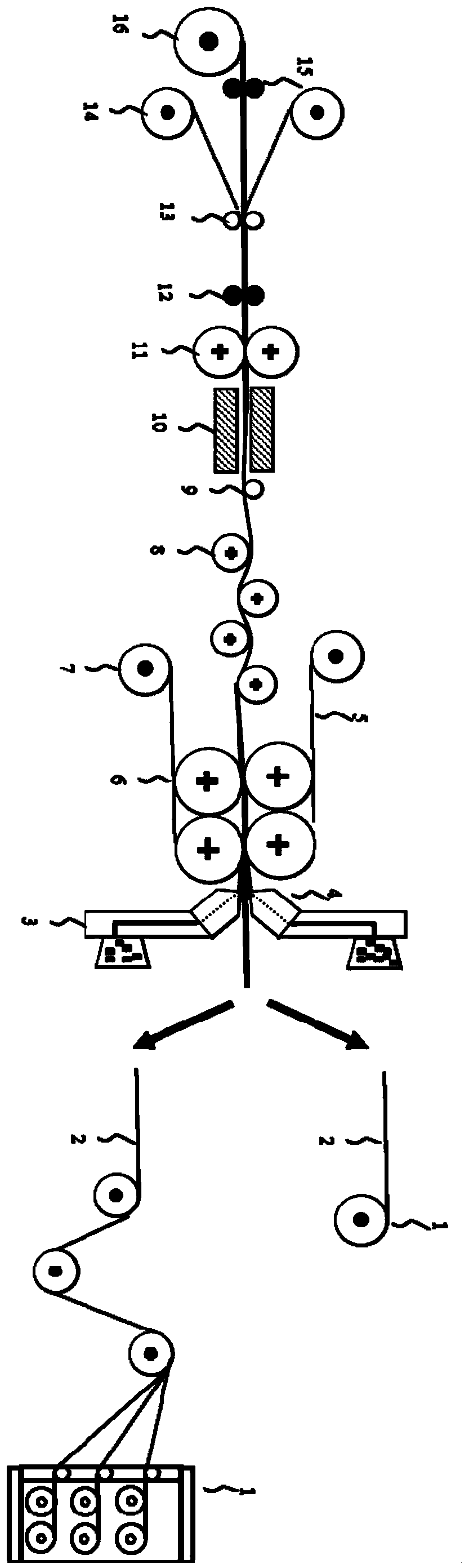

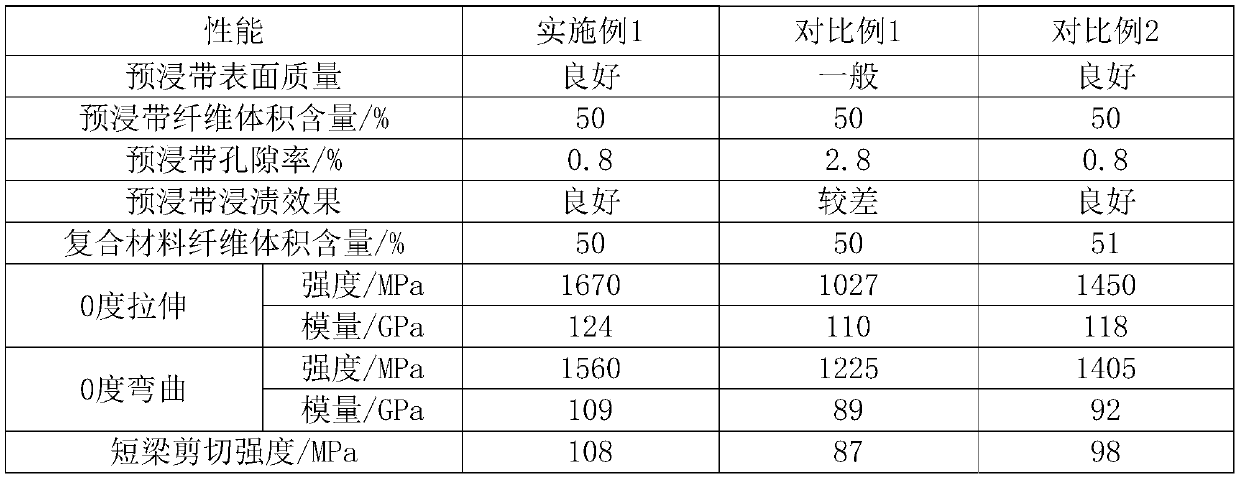

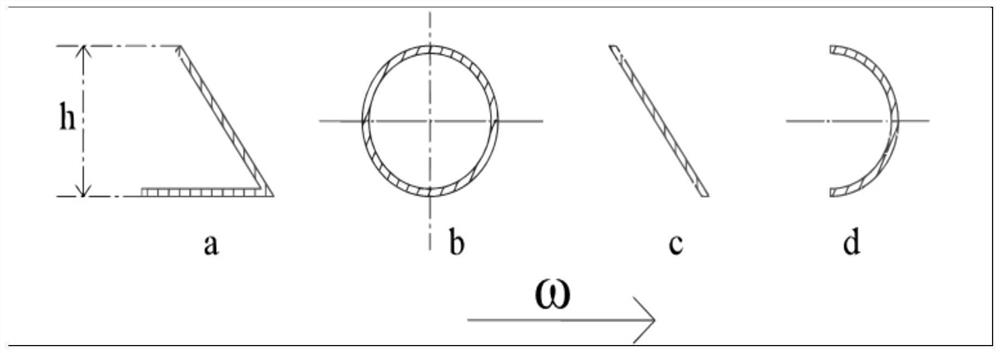

Equipment and method for preparing continuous carbon fiber reinforcement PEEK thermoplastic preimpregnating belt

The invention discloses equipment and method for preparing a continuous carbon fiber reinforcement PEEK thermoplastic preimpregnating belt. The equipment for realizing the method adopts 4 stagger heatrollers and an infrared drying tunnel which are arranged in an S shape. The method comprises the following steps that after preliminary impregnating is performed on used PEEK resin particle materialsor used PEEK resin powder and two sides of continuous carbon fiber yarn, the used PEEK resin particle materials or the used PEEK resin powder and two sides of the continuous carbon fiber yarn jointlyenter front high-temperature heating rollers for heating, and extruded impregnating; then the preimpregnating belt enters the four stagger heat rollers to perform S-shaped propelling, and in the propelling process, impregnating is realized for four times, so that resin molten mass on two sides of the preimpregnating belt and carbon fibers are sufficiently impregnated, and the situation that a resin rich layer is generated on two sides of the preimpregnating belt is avoided; after being processed by guide rollers, the propelling direction of the impregnated preimpregnating belt is parallel tothe infrared drying tunnel; the impregnated preimpregnating belt is slowly cooled in the infrared drying tunnel to eliminate residual stress, so that the resin molten mass on two sides of the carbon fiber can be repeatedly extruded and impregnated, the impregnating effect is greatly increased, and the porosity of the preimpregnating belt is reduced; and the preimpregnating belt slowly passes through the infrared drying tunnel, so that slow temperature lowering is realized, and the residual stress produced in the S-shaped propelling process is released to a great extent.

Owner:基准宇航(北京)有限公司

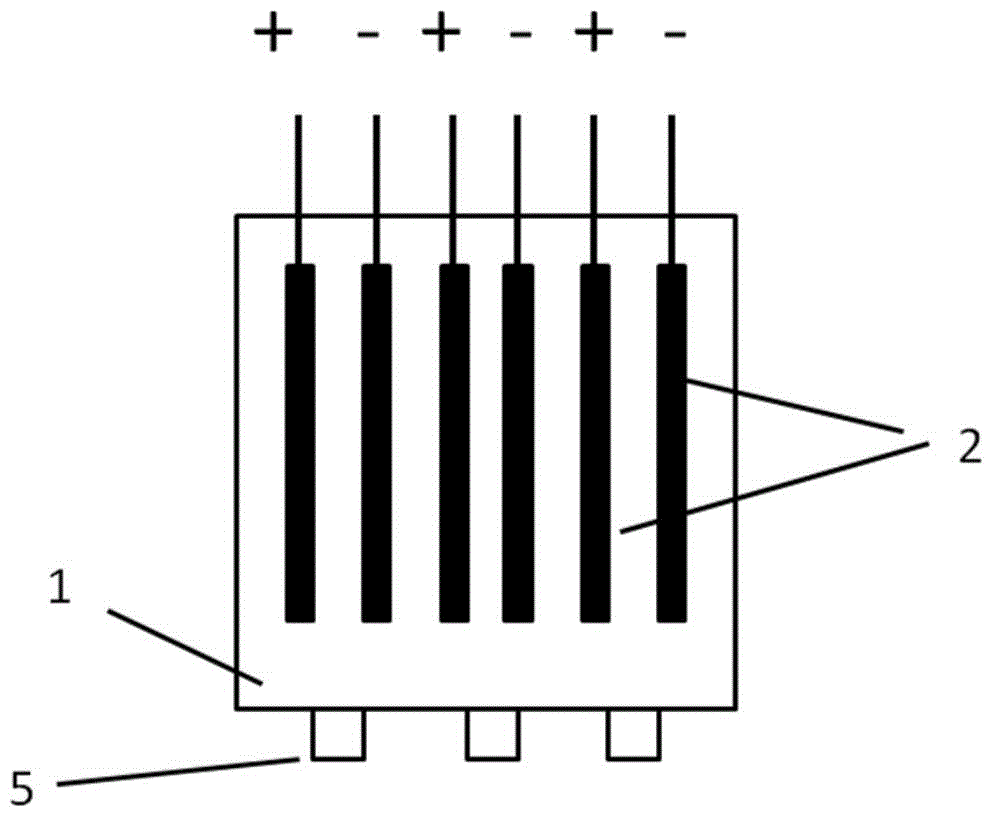

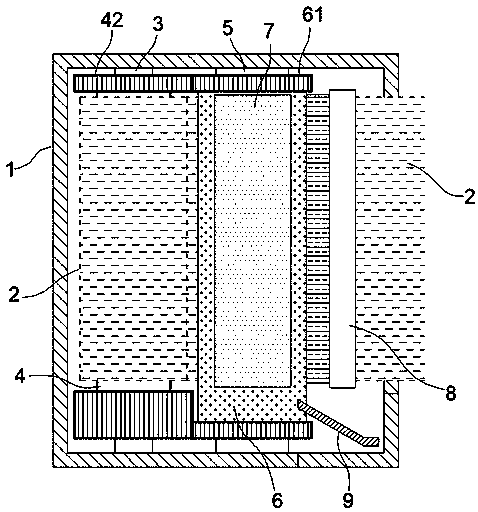

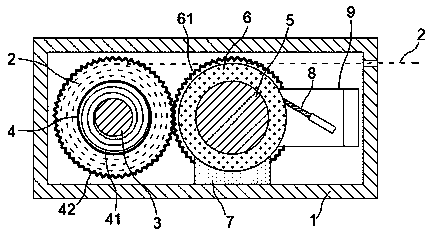

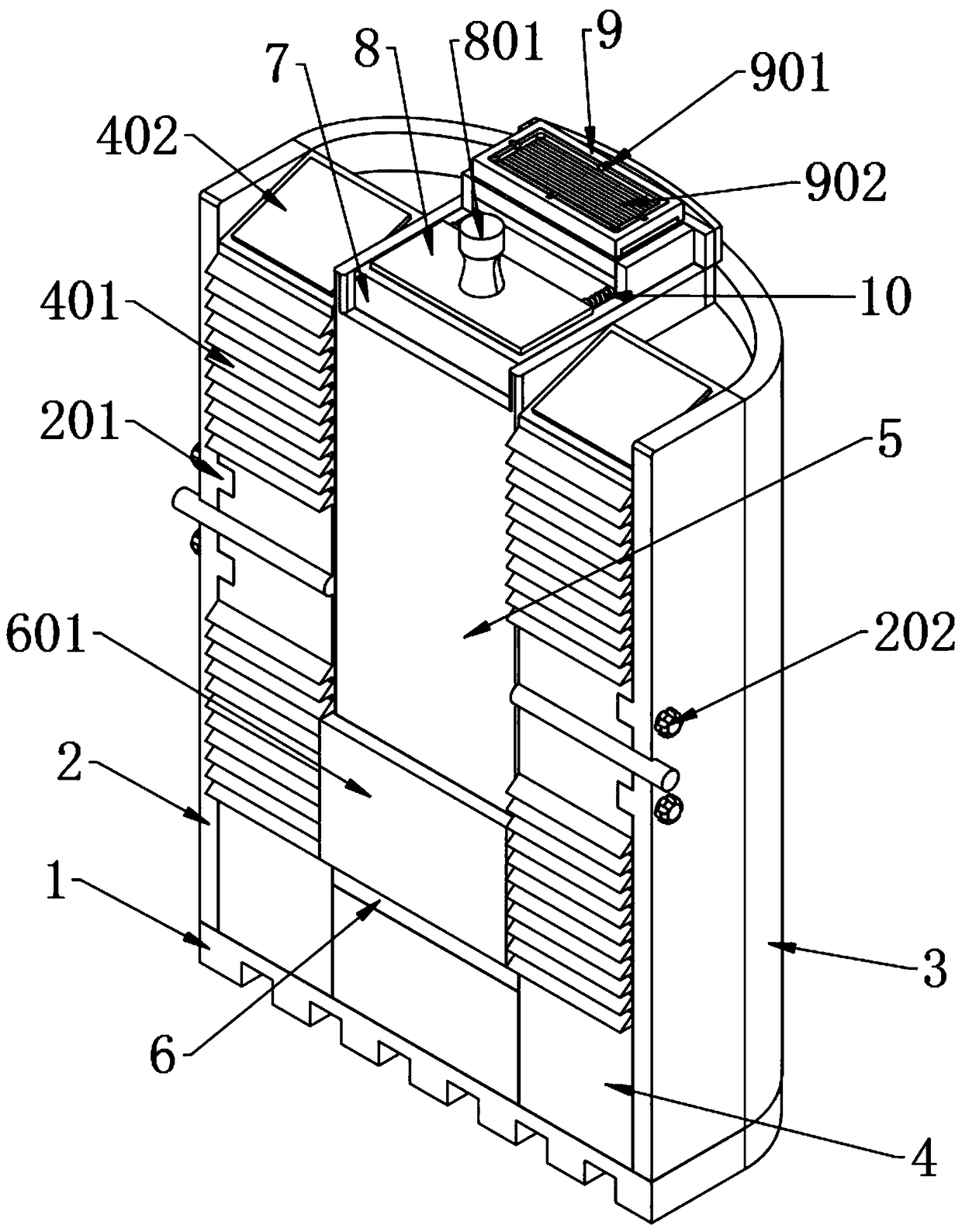

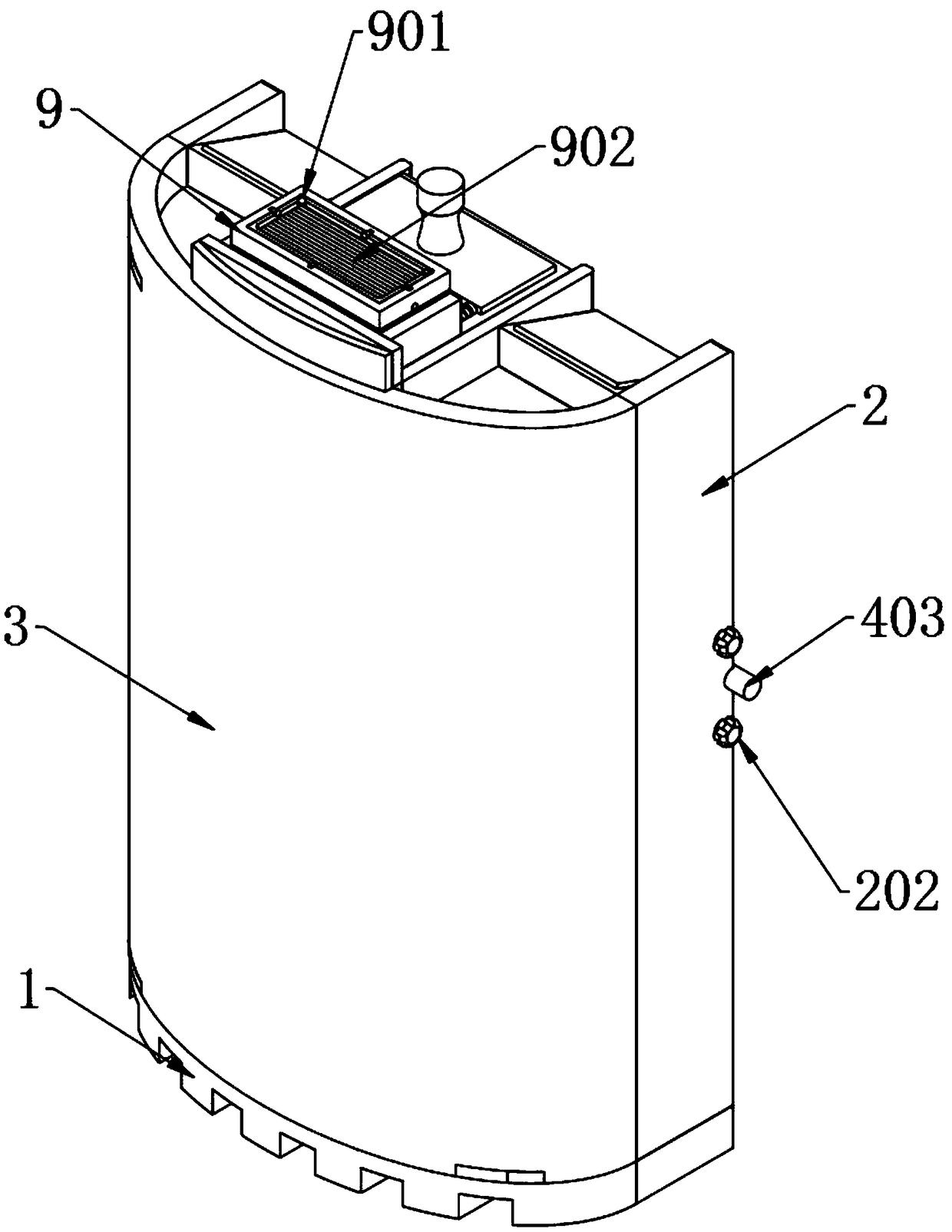

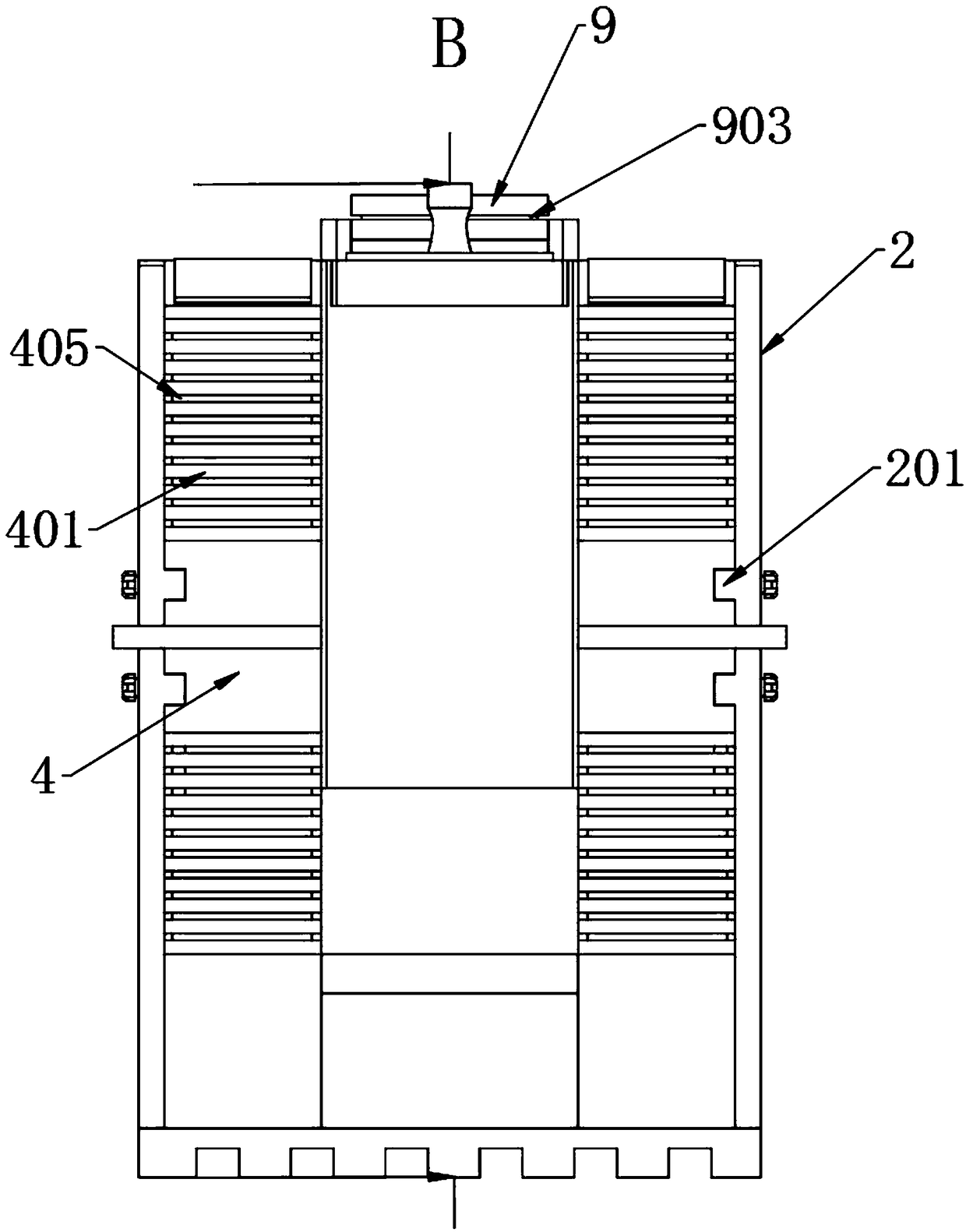

Heterotopic electro-flocculation device and method

The invention relates to a heterotopic electro-flocculation device comprising a tank body (1) and at least one pair of electrode plates (2) located inside the tank body (1), wherein the at least one pair of electrode plates (2) are respectively connected with the anode and cathode of a power source; the electrode plate at least connected with the anode of the power source is made of ferrum, aluminum or ferrum-aluminum alloy; and the heterotopic electro-flocculation device is also provided with a gas introducing pipe (5). The invention also relates to a heterotopic electro-flocculation method for realizing heterotopic electro-flocculation on wastewater by using the heterotopic electro-flocculation device, wherein acid gases are introduced to the wastewater through the gas introducing pipe (5). Preferably, the electrode plates in the device disclosed by the invention are hollow electrode plates, and the acid gases are introduced from gas inlets (3) of the hollow electrode plates. The device and method disclosed by the invention can be used for realizing heterotopic flocculation.

Owner:中大立信(北京)技术发展有限公司

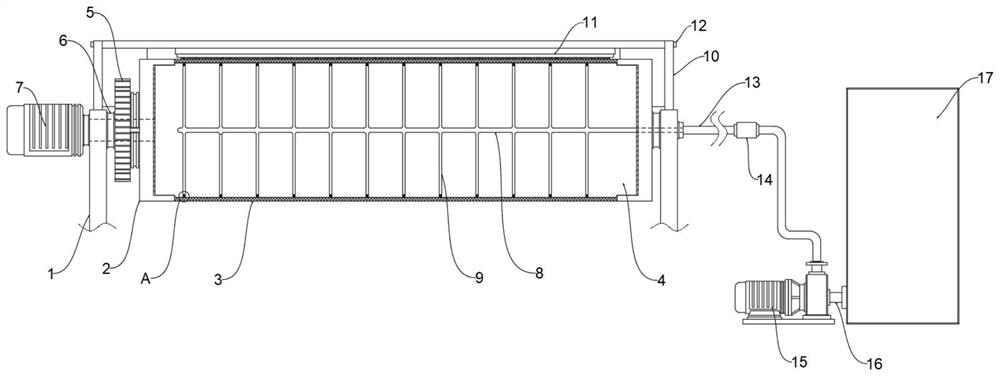

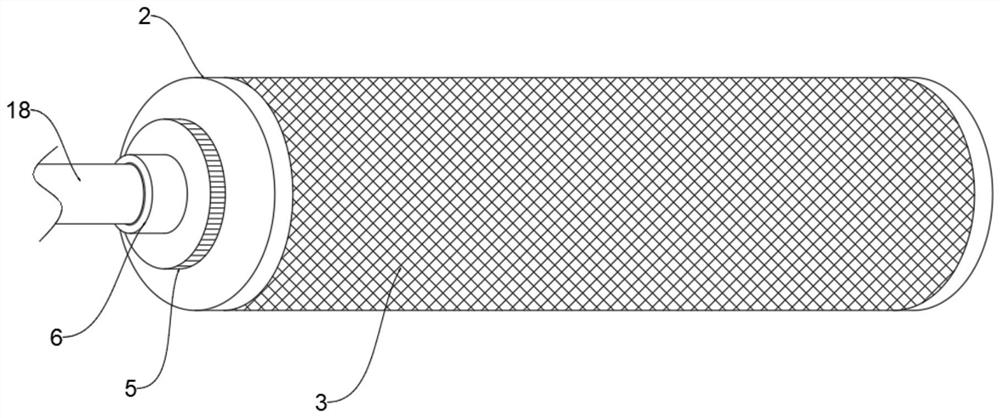

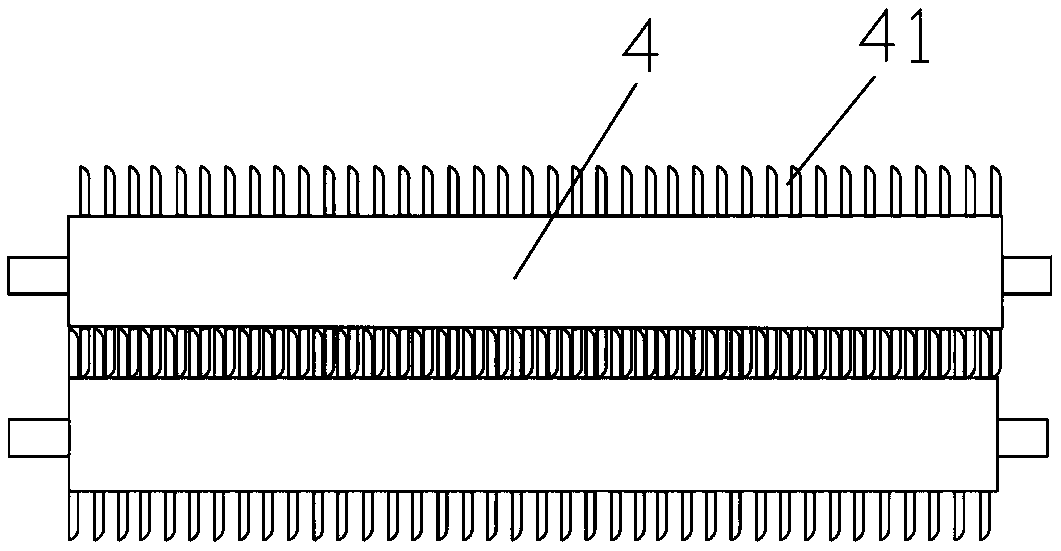

Sizing roller with self-cleaning function and using method thereof

ActiveCN112974121AAffect fit problemReduce consumptionLiquid surface applicatorsSpraying apparatusRotational axisIndustrial engineering

The invention discloses a sizing roller with a self-cleaning function and a using method thereof, and relates to the technical field of sizing rollers. The sizing roller aims to solve the problem that an existing sizing roller is inconvenient to clean after being used. Outer rollers are arranged between sizing frames, rotating shafts are fixedly arranged at the two ends of each outer roller, a sizing net cylinder is fixedly arranged between the outer rollers, an inner roller is arranged in the sizing net cylinder, the outer wall of the inner roller is attached to the inner wall of the sizing net cylinder, a liquid conveying main pipe is arranged in the middle of the interior of the inner roller, a plurality of sets of liquid conveying branch pipes are annularly and evenly arranged outside the liquid conveying main pipe, the liquid conveying branch pipes and the liquid conveying main pipe are fixed in a sealed mode, anti-blocking mechanisms are arranged at the ends, close to the sizing net cylinder, of the liquid conveying branch pipes, a mounting shaft is fixedly arranged on one side of the inner roller, the mounting shaft is rotationally connected with the rotating shafts and the sizing frames through bearings, a fan-shaped cover is fixedly arranged at the upper end of the sizing frames, and a scraping mechanism is installed in the fan-shaped cover.

Owner:南京企航橡塑有限公司

Profiling air cutting machine

ActiveCN110202620AHigh degree of automationImprove work efficiencyMetal working apparatusDrive motorEngineering

The invention relates to the technical field of metal cutting equipment, and discloses a profiling air cutting machine. The profiling air cutting machine comprises a frame, and a cutting machine mainbody arranged on the frame; the cutting machine main body comprises a mounting frame, a cutter and a sample plate; the frame comprises a worktable and a movable table; the worktable is positioned on the upper side of the movable table, and is provided with a discharge hole; the discharge hole is positioned right under the sample plate; the frame is provided with a feeding mechanism, a buffer mechanism and a pushing mechanism; the feeding mechanism comprises a fixed plate and a sliding plate relatively arranged, a conveying roller rotationally connected between the fixed plate and the sliding plate, and a driving motor for driving the conveying roller to rotate; the buffer mechanism comprises a buffer plate and a buffer spring fixedly connected; the buffer spring is fixed on the movable table; the buffer plate is positioned right under the discharge hole; and the pushing mechanism is positioned on the left side of the buffer mechanism. The profiling air cutting machine has no need to manually separate raw workpieces from a cutting plate after cutting, and achieves the effect of high working efficiency.

Owner:杭州临安荣升机械有限公司

Drainage device for agricultural water conservancy project

InactiveCN111379266AGuarantee unimpededEasy to cleanPositive displacement pump componentsFoundation engineeringEnvironmental engineeringMechanical engineering

The invention discloses a drainage device for an agricultural water conservancy project, and relates to the technical field of water conservancy project drainage. The technical scheme key point of thedrainage device is characterized by comprising a drainage pump, a water inlet of the drainage pump communicates with a square connecting pipe, a clamping groove is formed in the top of the square connecting pipe, and a first filter screen is clamped to an inner wall of the clamping groove; and the top of the square connecting pipe is fixedly connected with a servo motor located on the right sideof the first filter screen, and a bottom end of an output shaft of the servo motor is fixedly connected with a second screw. By arranging the first filter screen, impurities in water are filtered, thesituation that the draining pump sucks the impurities and is damaged is prevented, the effect of protecting the draining pump is achieved; by arranging a scraper, the impurities adsorbed to the firstfilter screen are scraped away, smoothness of the first filter screen is guaranteed, and the effect of effectively cleaning the first filter screen is achieved; and by arranging the servo motor, thescraper is driven to move up and down, and an effect of improving the cleaning efficiency of the scraper is achieved.

Owner:谢保全

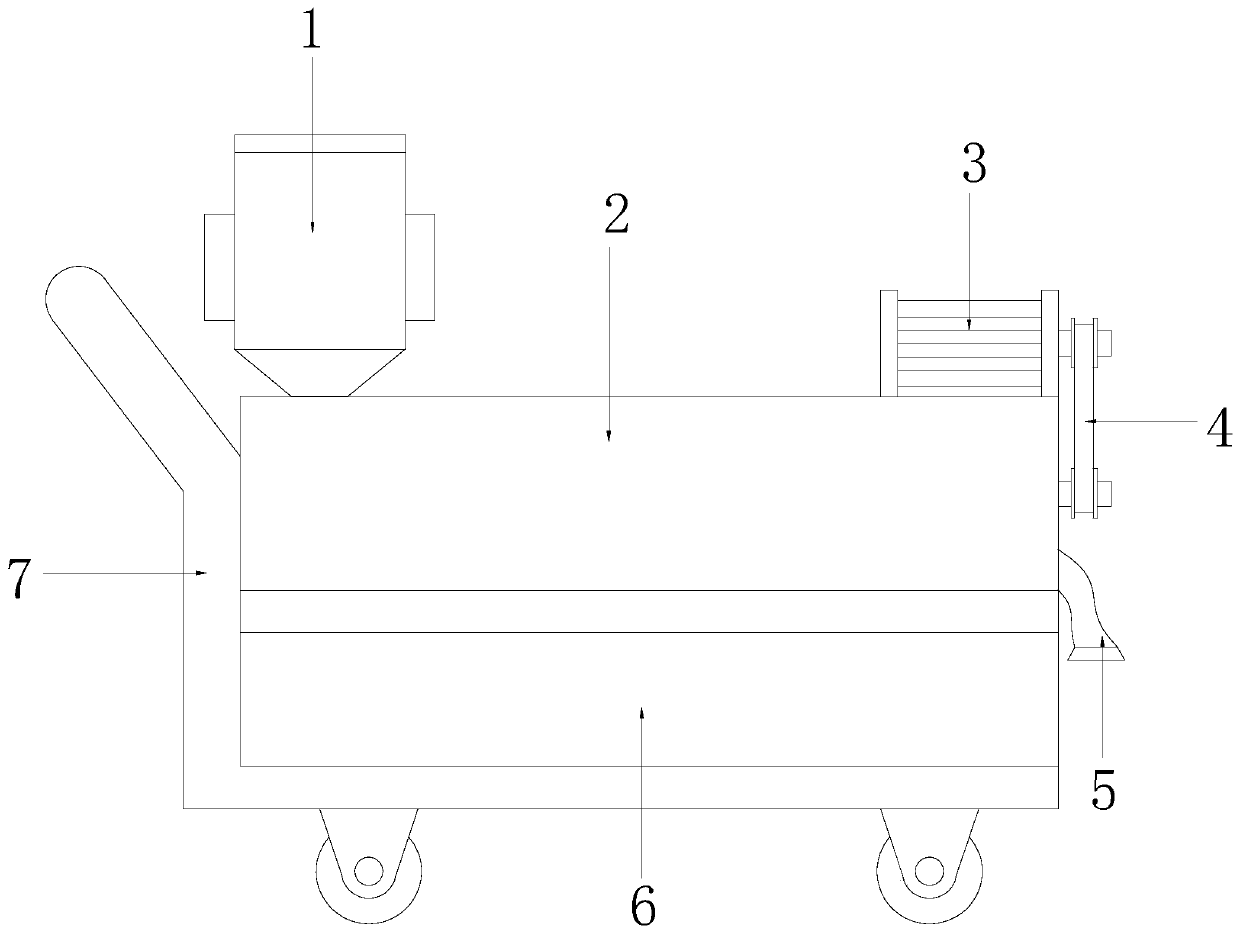

Metallurgical mechanical equipment convenient for dust transportation

ActiveCN111332818AEasy to transportImprove discharge efficiencyDirt cleaningLoading/unloadingElectric machineryEngineering

The invention discloses metallurgical mechanical equipment convenient for dust transportation. The metallurgical mechanical equipment structurally comprises a dust feeding device, a screw dust conveyer, a high-efficiency energy-saving motor, a transmission assembly, a dust discharging pipe, a lifting platform and a hand-push moving base, wherein the lifting platform is connected to the hand-push moving base in a mechanical joint mode, and the screw dust conveying machine is fixed to the lifting platform. Compared with the prior art, the metallurgical mechanical equipment convenient for the dust transportation has the beneficial effects that shear fork joint center points and shear fork joint center points increase or decrease equidistantly when a first shear fork telescopic assembly and asecond shear fork telescopic assembly are telescopic, so that a press-dispersion net shifts with the shear fork joint center points, dust can be divided into multiple parts, then the multiple parts ofdust can be pressed and dispersed, the pressing and dispersing efficiency is high, the effect is good, so that the dust is fine and evenly derived to avoid dust agglomeration and lead to device transport blockage; and through a dust splashing resistance bag, the dust is prevented from splashing everywhere due to falling flying powder, the burden of cleaning workers is reduced, and a human body isprevented from inhaling the dust and poisoning.

Owner:山东艾力德精密科技有限公司

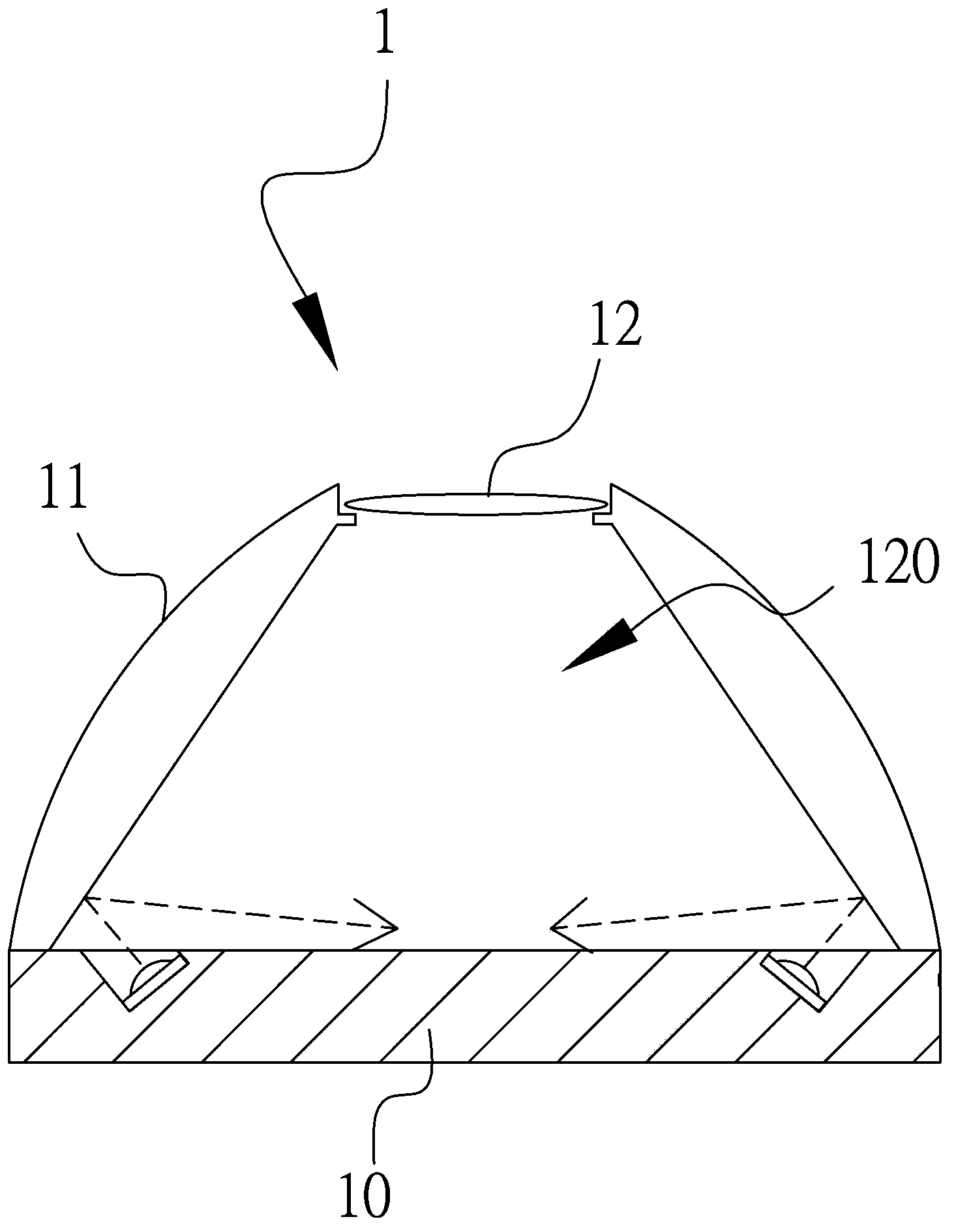

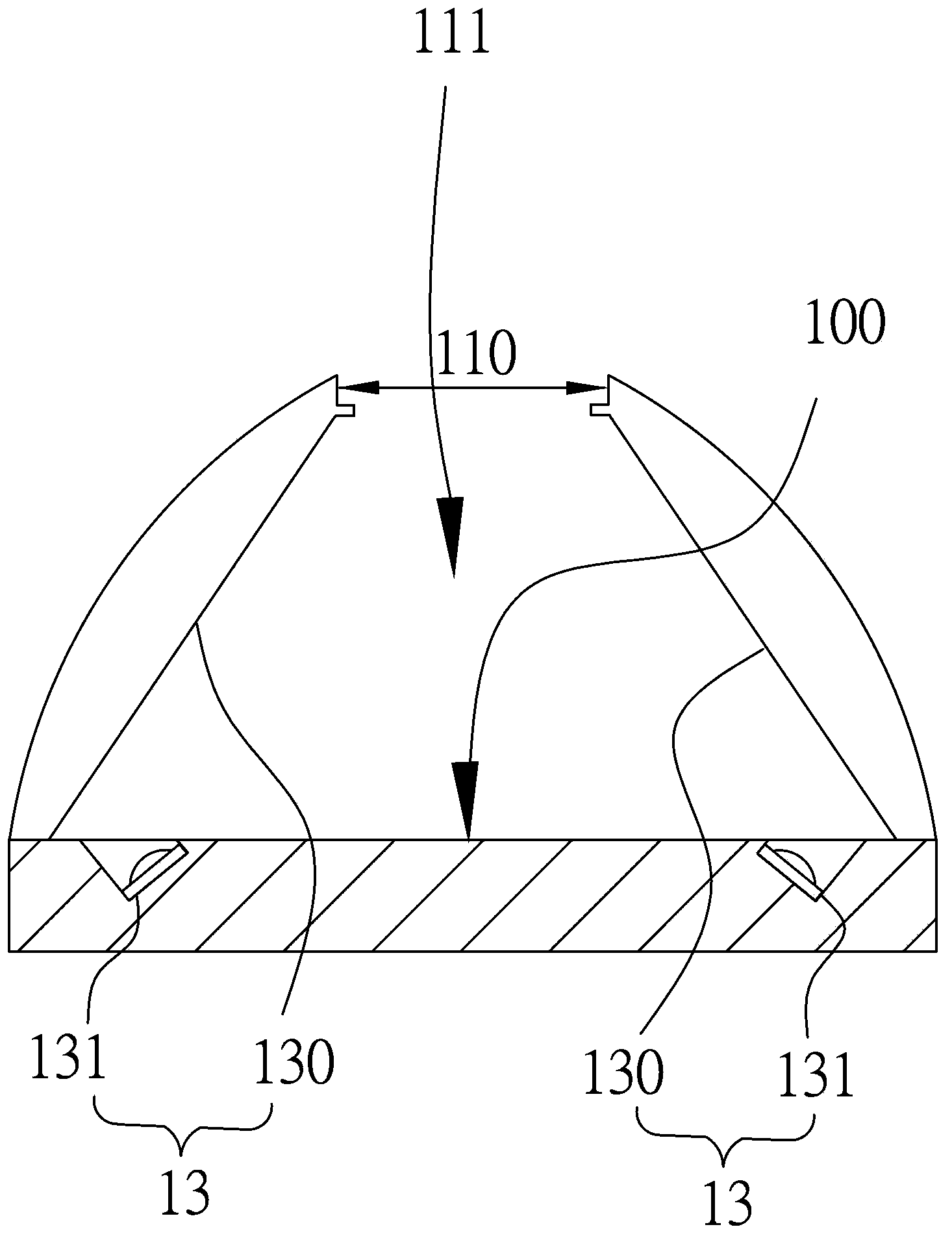

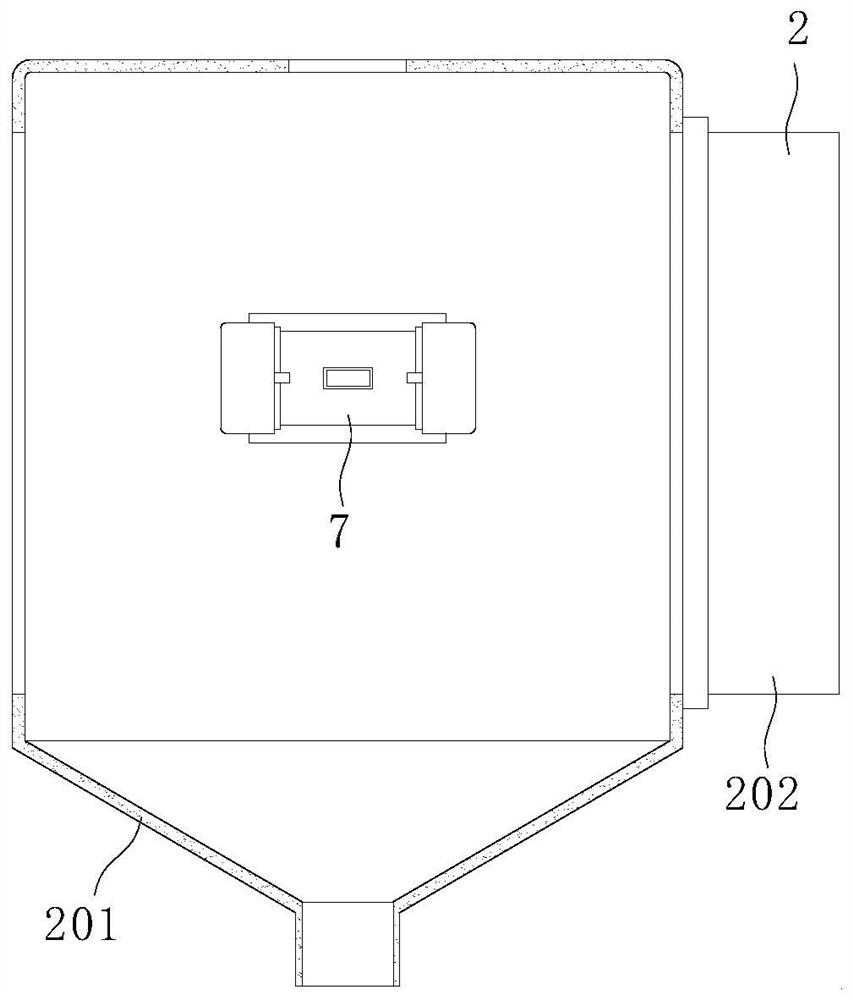

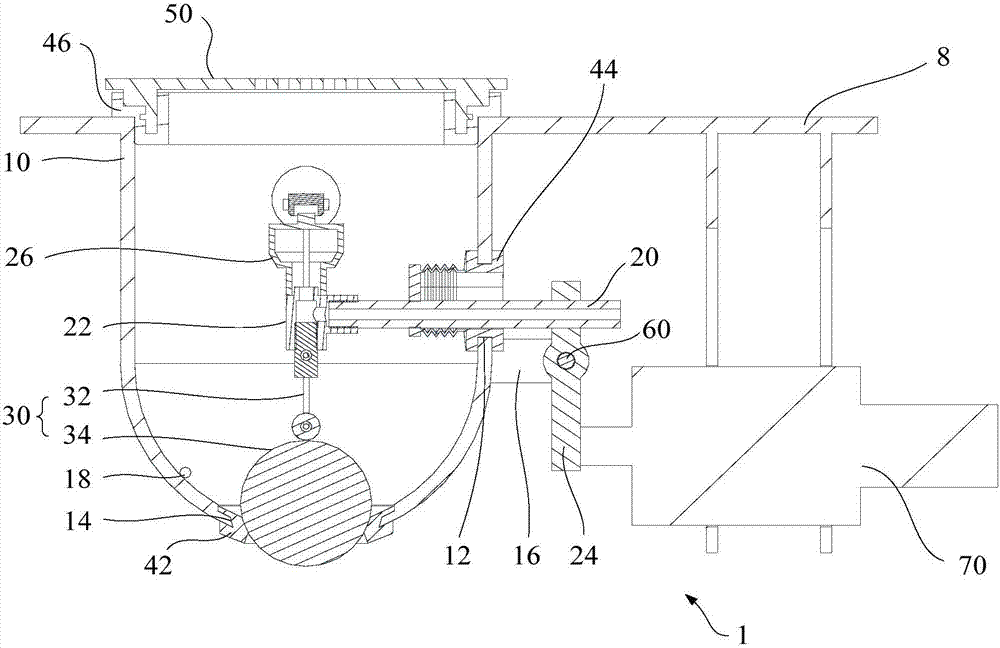

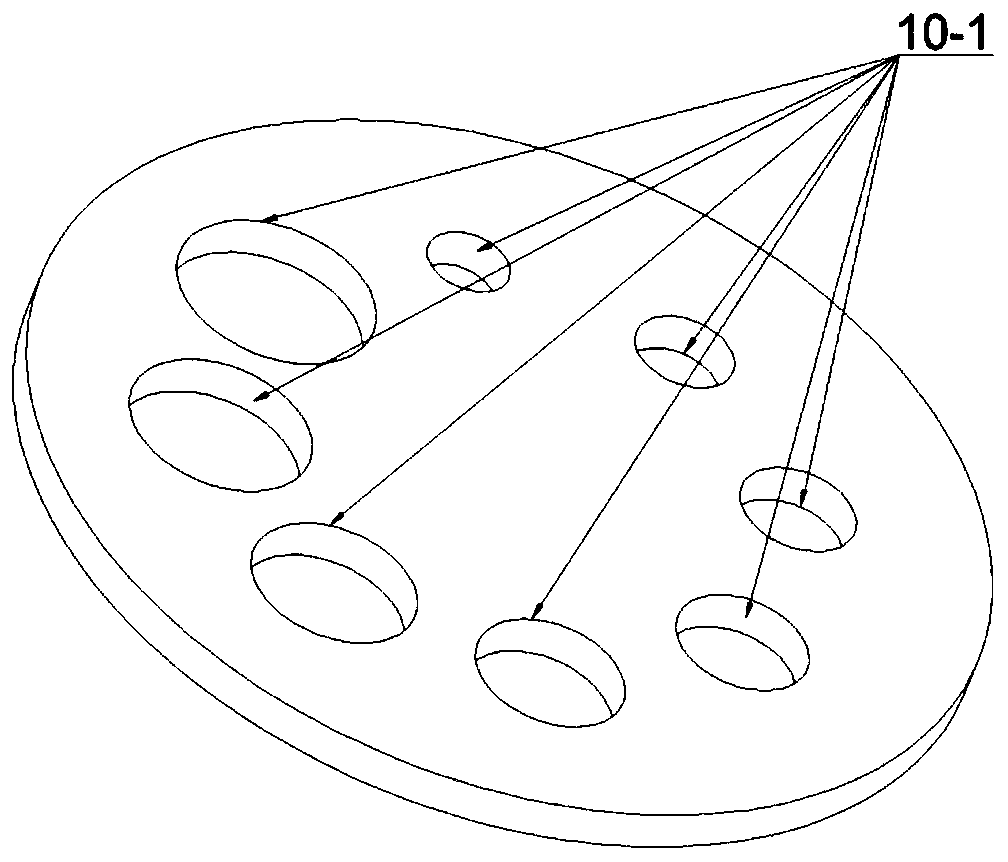

Fluorescent observation device with spaced covers, base frame and fluorescence microscope

InactiveCN104238104AReduce cleanup burdenReduce the chance of transmissionMicroscopesTelescopesOptoelectronicsFluorescence microscope

A fluorescent observation device with spaced covers can limit the movement range of a fluorescent article to be observed, so that the fluorescent article to be observed can be conveniently observed by means of the fluorescent observation device. The fluorescent observation device comprises bases with preset observation positions, the covers, light-pervious shelters and light source assemblies, wherein the covers are correspondingly connected with the bases, cover the bases correspondingly, define light shielding cavities with the bases in an enclosed mode and form light-pervious observation holes; the light-pervious shelters cover the light-pervious observation holes and define a blocking spaces with the bases and the covers in an enclosed mode; each light source assembly comprises a light source which can excite light at a low angle in the direction of the corresponding preset observation position.

Owner:LUMOS TECH

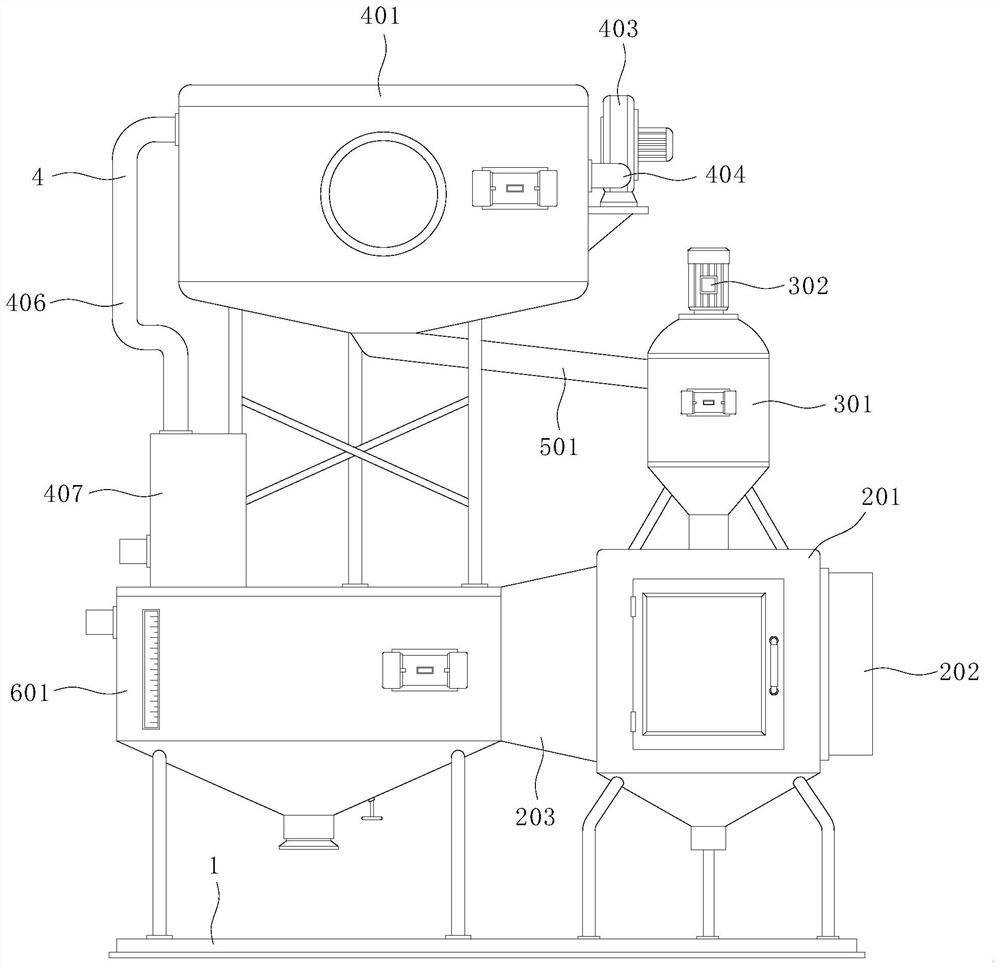

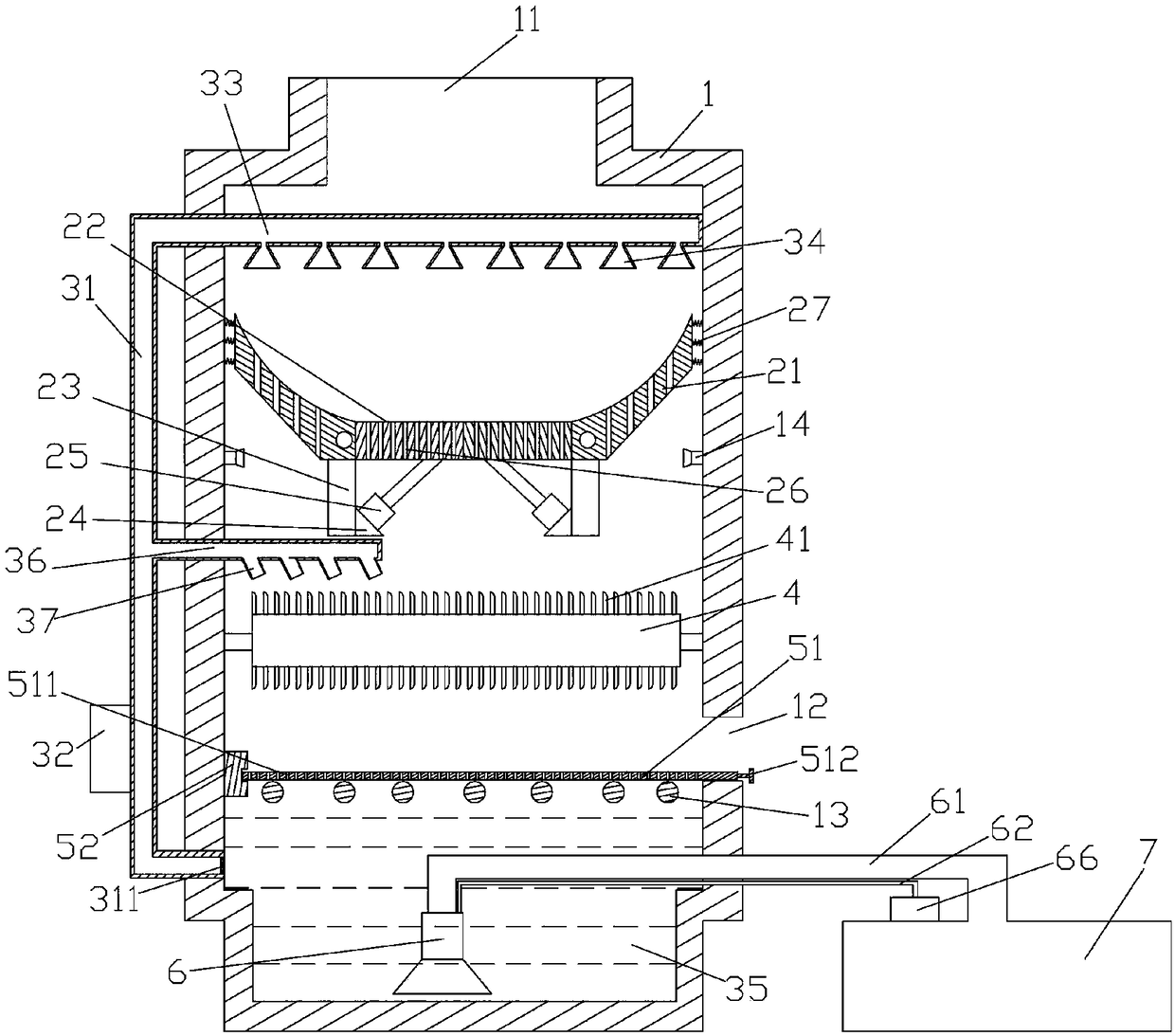

High-purity calcium hydroxide preparation process and equipment

InactiveCN113247934APrecise moisture controlQuality improvementCalcium/strontium/barium oxides/hydroxidesCalcium hydroxideInorganic chemistry

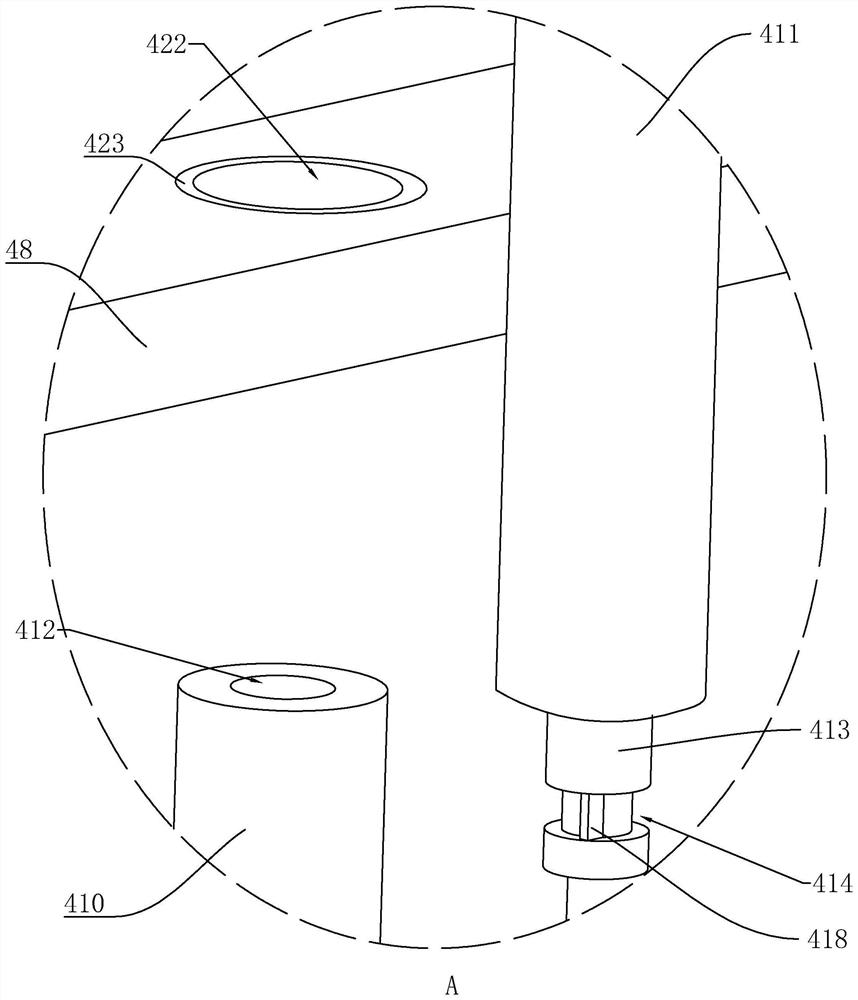

The invention discloses a high-purity calcium hydroxide preparation process and equipment, and relates to the technical field of high-purity calcium hydroxide processing. The high-purity calcium hydroxide preparation process comprises the four steps of crushing, digesting, water distribution and winnowing. The high-purity calcium hydroxide preparation equipment comprises a base; a winnowing mechanism and an output mechanism are arranged at the top of the base; a processing mechanism is arranged at the top of the winnowing mechanism; a feeding mechanism is arranged at the top of the output mechanism; and a discharging mechanism is arranged between the processing mechanism and the feeding mechanism. According to the high-purity calcium hydroxide preparation equipment, calcium hydroxide can be crushed and screened before winnowing, so that blocky calcium hydroxide is pulverized, the blocky calcium hydroxide is prevented from being cleaned as impurities due to the gravity effect in the winnowing process, and unnecessary economic losses are reduced; and calcium hydroxide to be winnowed is fed in a negative pressure mode, and compared with a manual feeding mode, the operation is easy, high efficiency and practicability are achieved, and the production and processing efficiency is improved.

Owner:江西福得利碳酸钙业有限责任公司

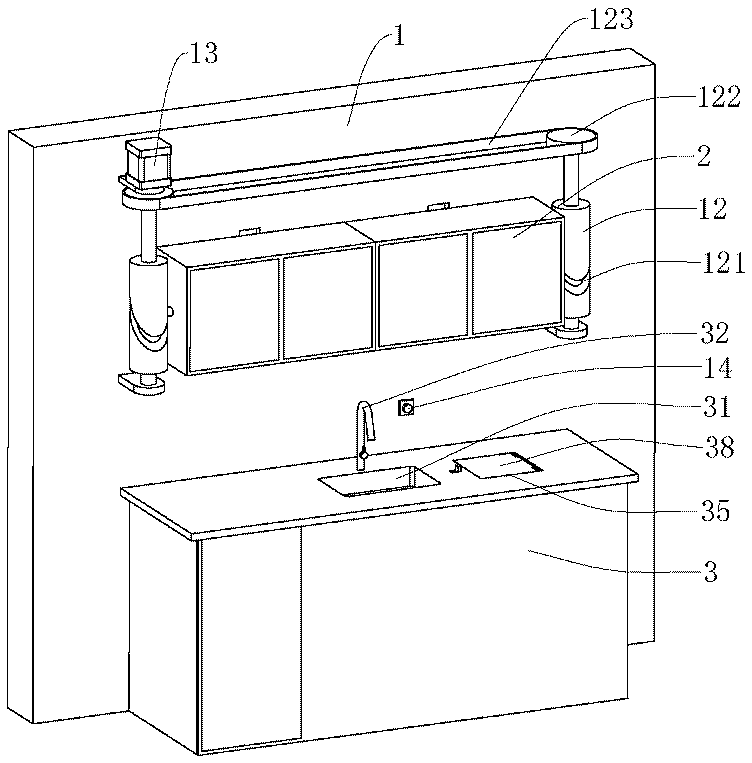

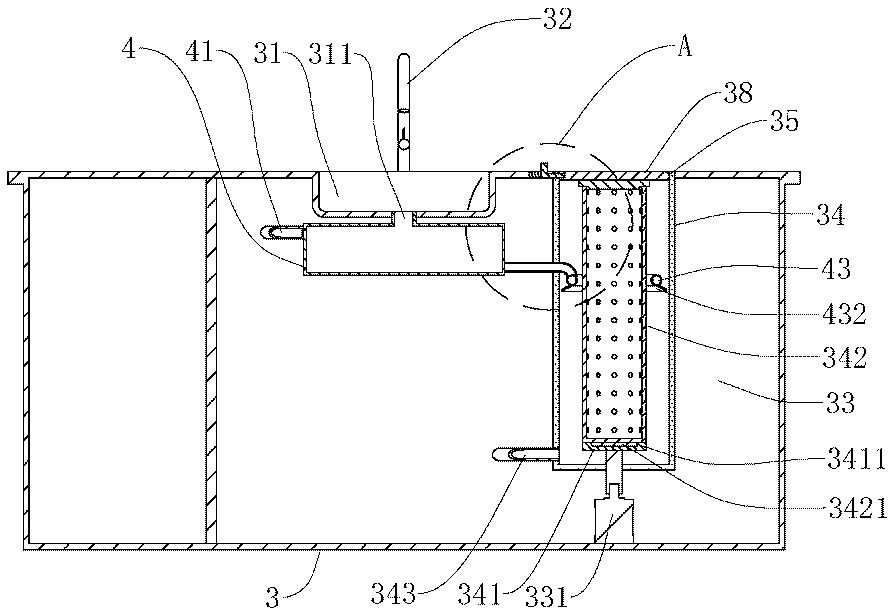

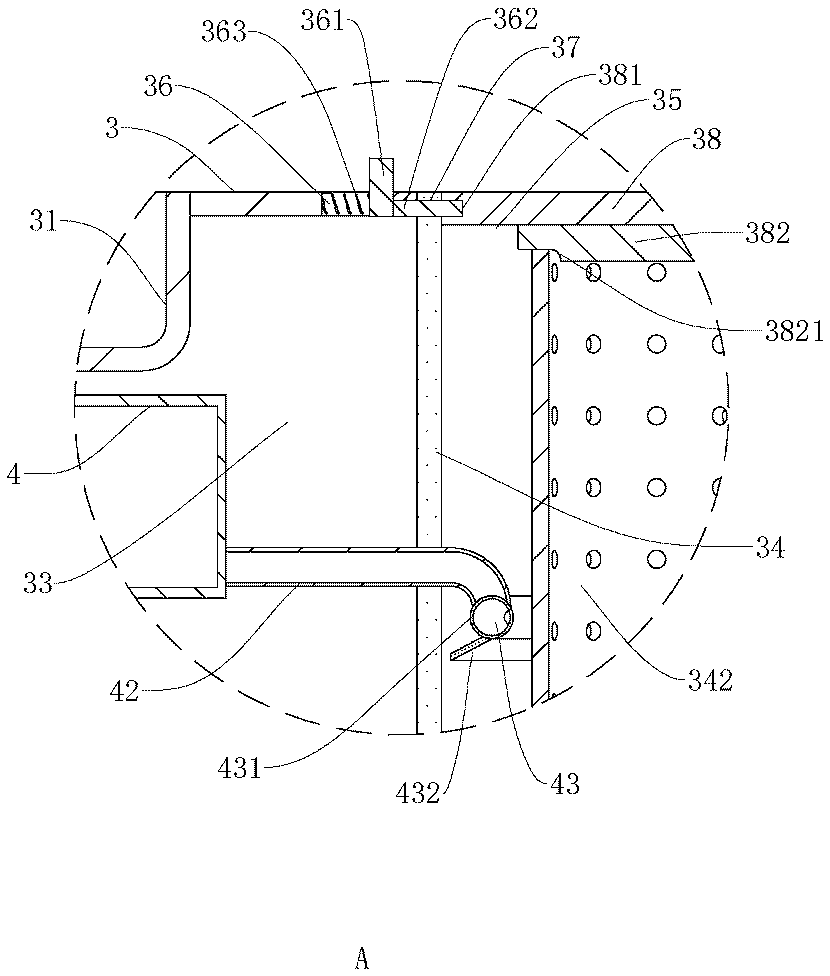

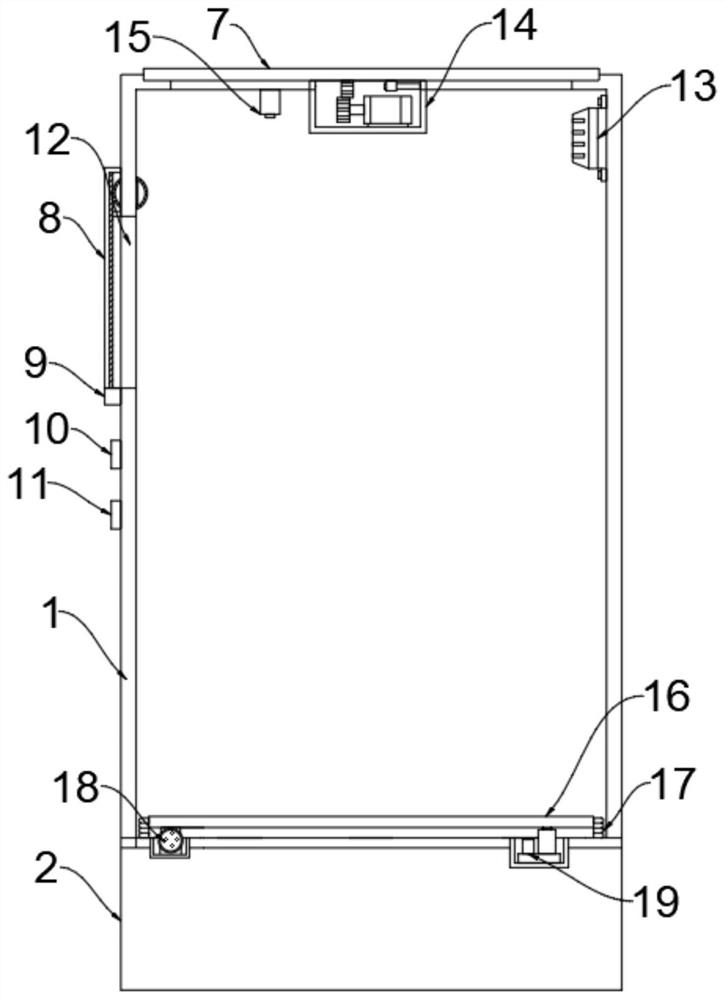

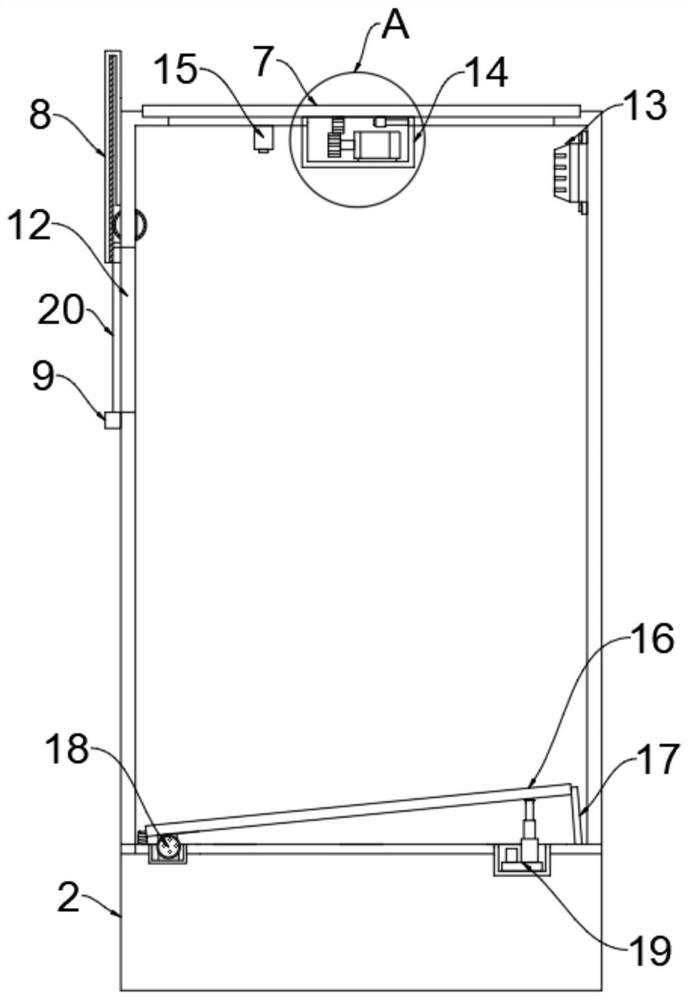

Intelligent cabinet for furniture kitchen

InactiveCN112545204ARealize wet and dry separation operationImprove cleanlinessFurniture partsKitchen cabinetsEngineeringStructural engineering

The invention relates to an intelligent cabinet for the furniture kitchen. The cabinet comprises a cabinet body, a lower cabinet body is arranged on one side of the cabinet body, a separation cylinderis arranged in the lower cabinet body, a discharging opening communicating with the separation cylinder is formed in the upper surface of the lower cabinet body, and the discharging opening is fixedly covered with a cover plate through a clamping assembly; a filter cylinder with an open top is detachably and rotationally arranged in the separation cylinder, the filter cylinder is driven by a driving assembly to rotate, and a water outlet pipe is connected to the bottom of the side wall of the separation cylinder. The driving assembly is adopted to drive the filter cylinder to rotate, dry-wetseparation is conducted on kitchen garbage in the filter cylinder through centrifugal force, water is thrown to the side wall of the separation chamber and then discharged through the water outlet pipe, breeding of mosquitoes and bacteria can be reduced, and clean and sanitary conditions of a kitchen are improved.

Owner:客来福家居(广东)有限公司

Upper cover assembly and cooking tool

ActiveCN107296511AIncrease profitSimple structureCooking-vessel lids/coversBeverage vesselsStructural engineeringSewage

The invention provides an upper cover assembly and a cooking tool. The cooking tool includes an upper cover plate, and the upper cover assembly is applied to the cooking tool. The upper cover assembly includes a washing cavity, a sewage device, a connection rod and a valve part, a mounting hole is formed in the side wall of the washing cavity, and a blanking hole and a sewage hole are formed in the bottom of the washing cavity; the sewage device is communicated with the sewage hole; the connection rod is arranged in the side wall of the washing cavity in a penetrating mode through the mounting hole, the first end of the connection rod is located in the washing cavity, the second end of the connection rod is located outside of the washing cavity, and a water inlet channel which extends from one end of the connection rod to the other end of the connection rod and is used for delivering water into the washing cavity is arranged on the connection rod; the valve part is matched with the blanking hole; the first end of the connection rod is connection with the valve part to drive the valve part to move between a first position and a second position, wherein when the valve part is at the first position, the blanking hole is plugged so that the blanking hole can be closed, and when the valve part is at the second position, the blanking hole is avoided so that the blanking hole can be open. The upper cover assembly adopts the connection rod, therefore, the integration of water inlet and valve-part driving is achieved, the whole structure is simplified, the part utilizing rate is increased, and the cost is reduced.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

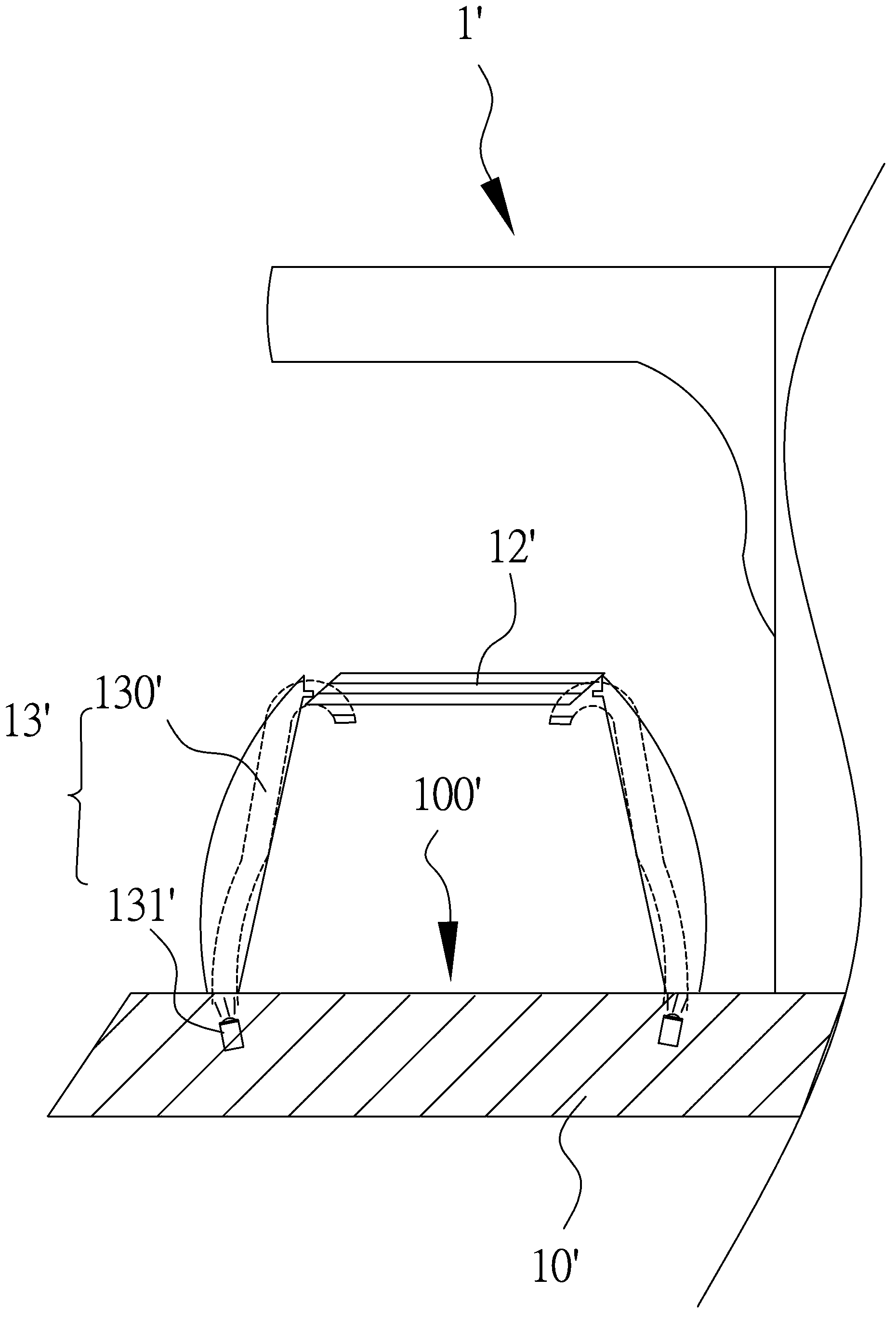

Sponge city seepage and drainage structure and water circulation system thereof

ActiveCN112681497AReduce cloggingAffect water storageFatty/oily/floating substances removal devicesSewerage structuresWater storageEnvironmental engineering

The invention discloses a sponge city seepage and drainage structure and a water circulation system thereof, relates to a city seepage and drainage system, and aims to solve the problem that a pipeline of a water collecting port is easy to block in the prior art. The technical scheme is characterized in that the sponge city seepage and drainage structure comprises a reservoir, a water collecting ditch for rainwater to flow to the reservoir and at least one drainage ditch for rainwater to flow to the water collecting ditch, wherein the water collecting ditch and the drainage ditch are laid on the ground, and filtering assemblies are detachably arranged in the water collecting ditch and the drainage ditch; rainwater enters the drainage ditch and the water collecting ditch, the rainwater entering the drainage ditch enters the water collecting ditch again, and finally is discharged into the reservoir along the water collecting ditch, and impurities in the water collecting ditch and the drainage ditch are filtered by utilizing the filtering assemblies; and when the impurities are filtered more, the filtering assemblies are detached from the water collecting ditch and the drainage ditch, and the impurities are taken out, so that the possibility that the impurities block the drainage ditch and the water collecting ditch, and consequently water cannot be drained to the reservoir can be reduced, and the possibility that water storage of the reservoir is influenced can be reduced.

Owner:江苏华亚工程设计研究院有限公司

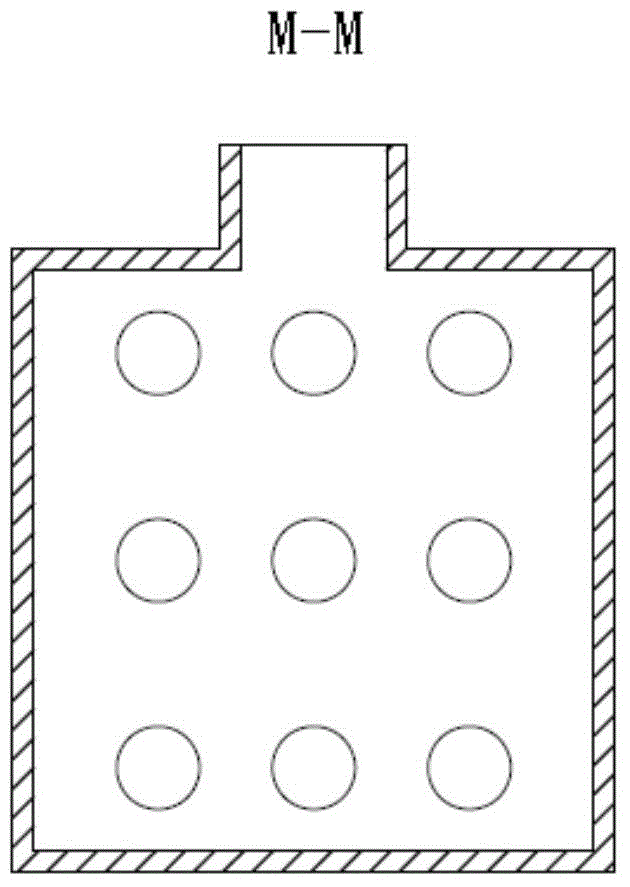

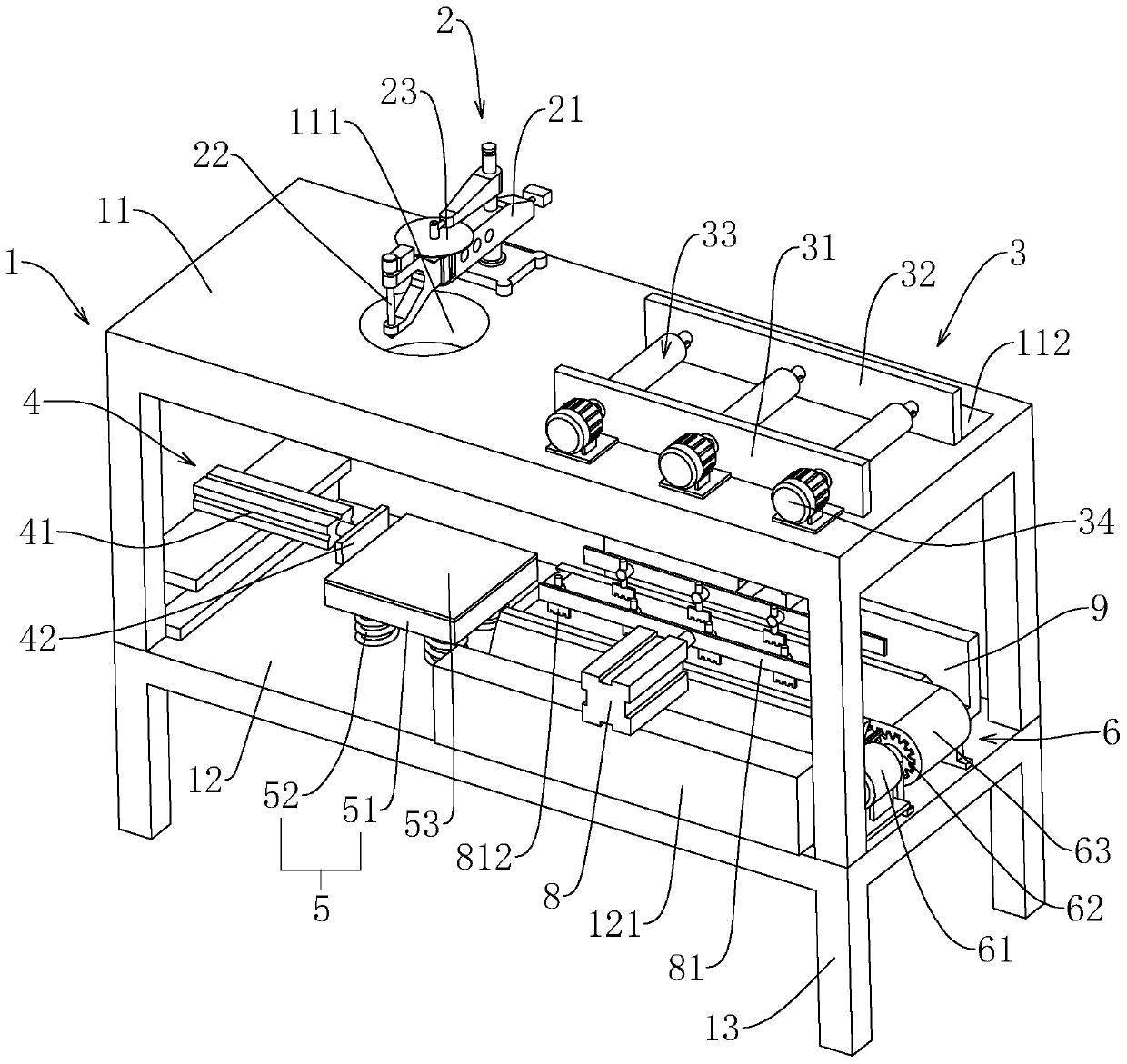

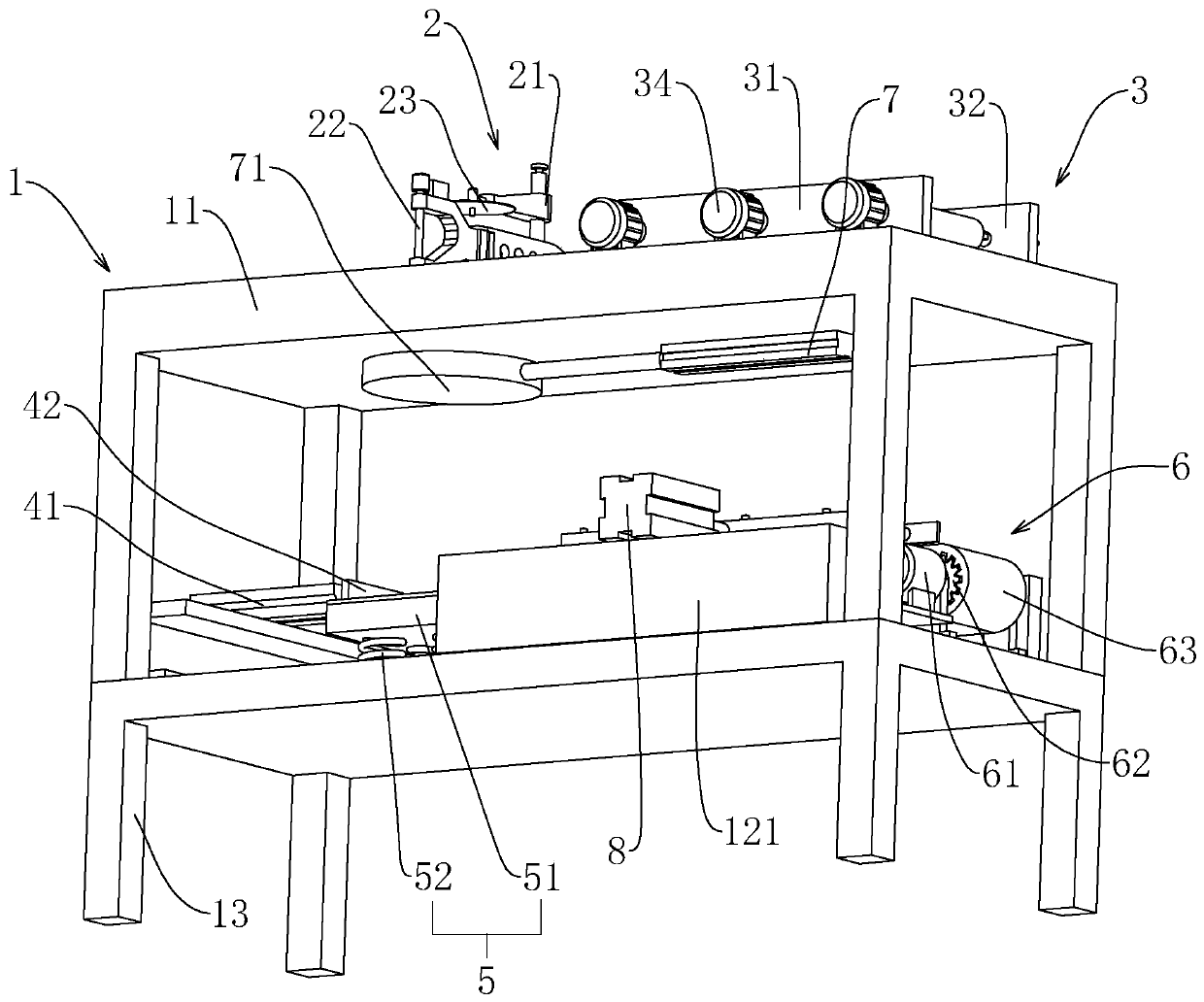

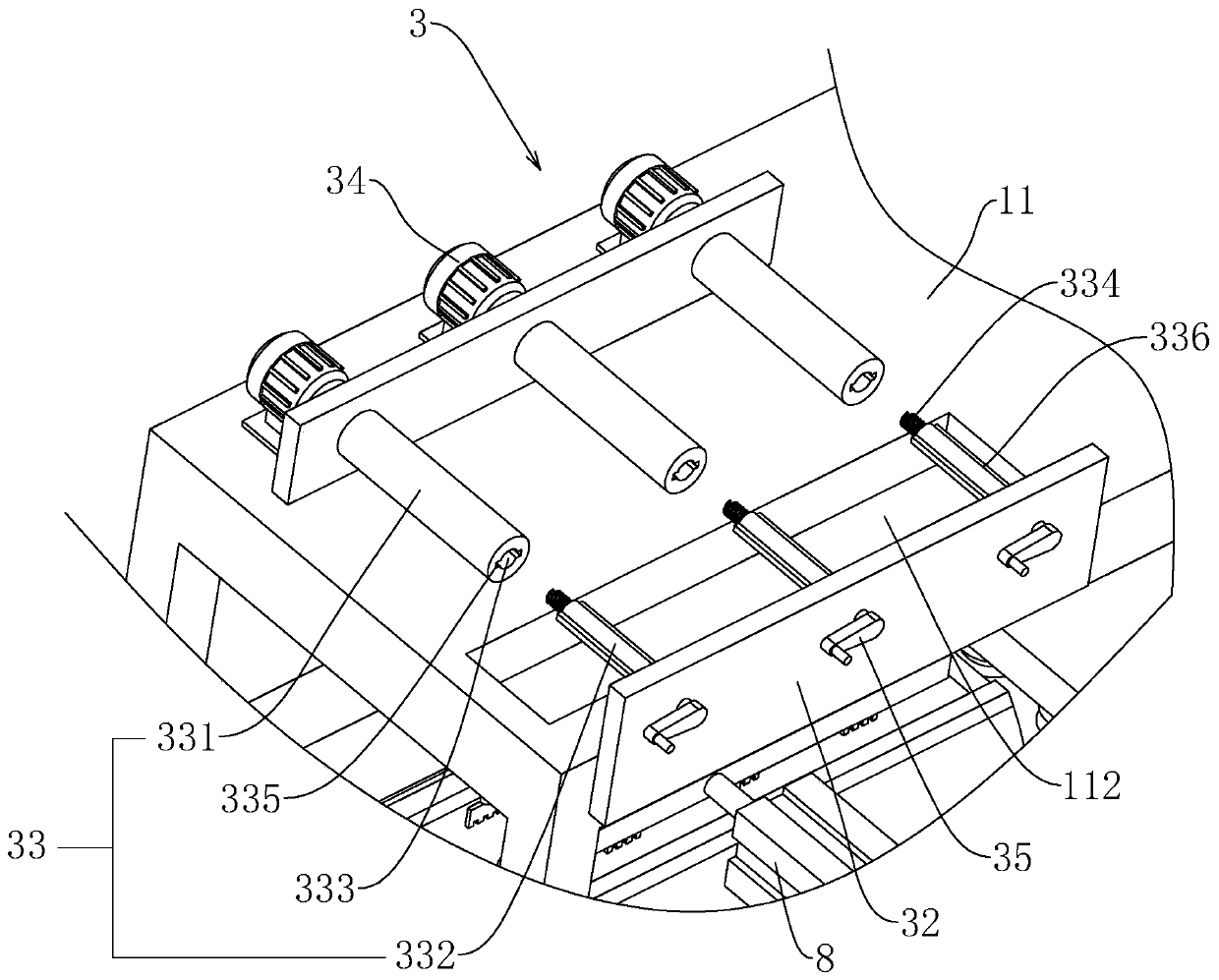

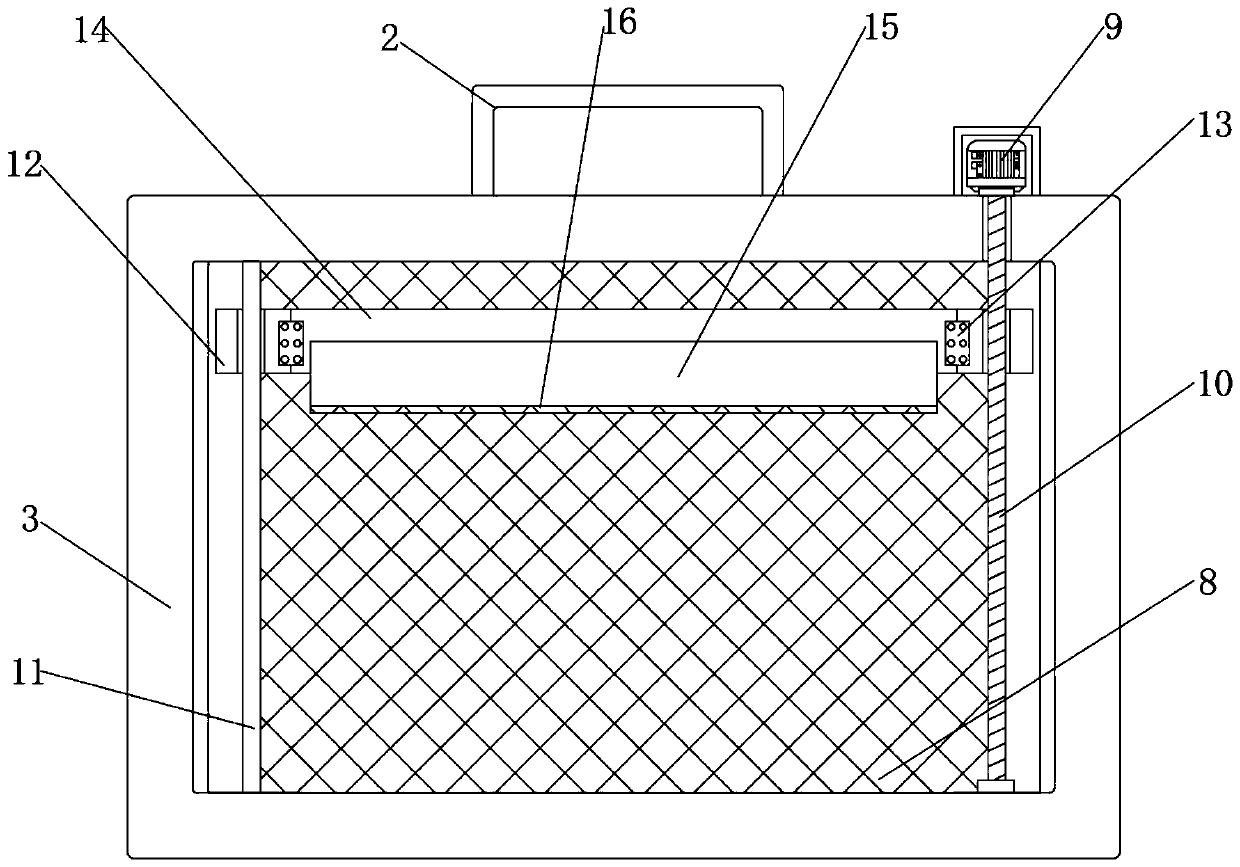

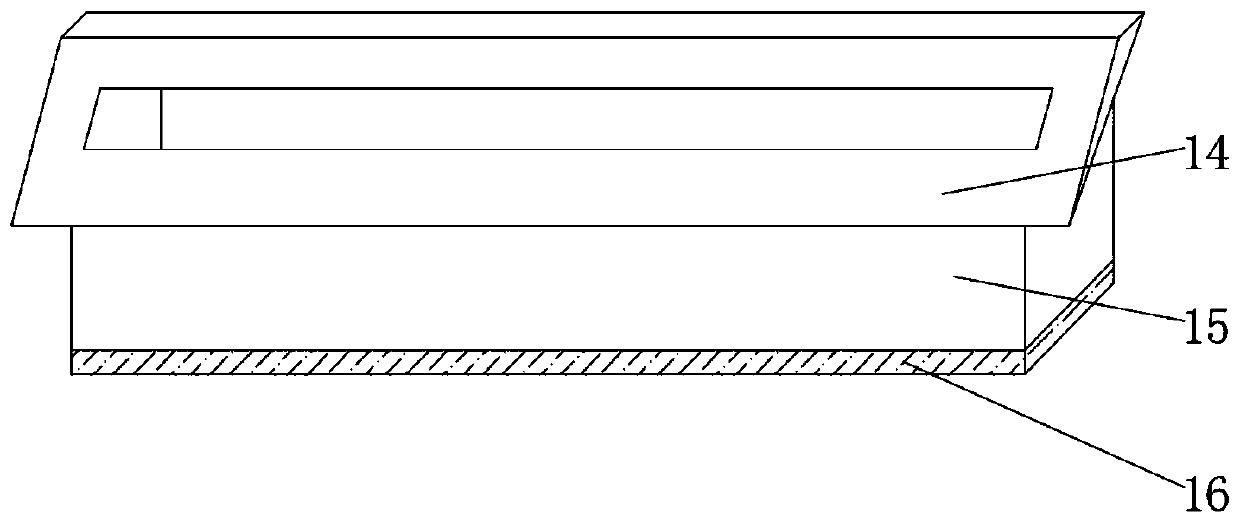

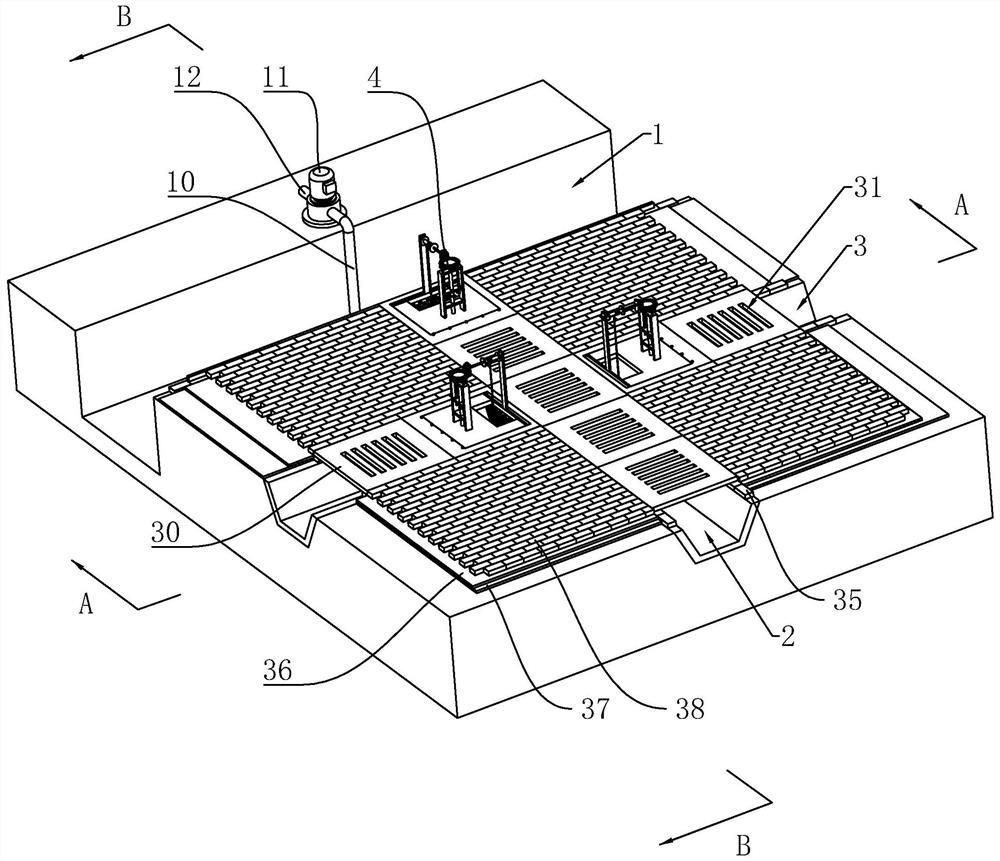

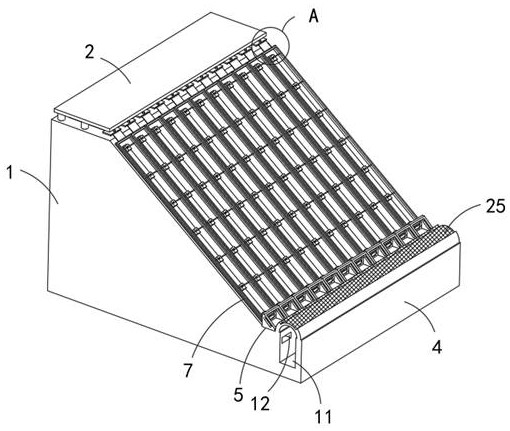

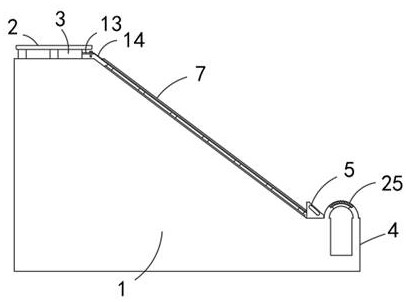

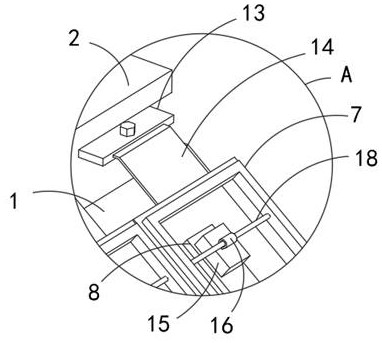

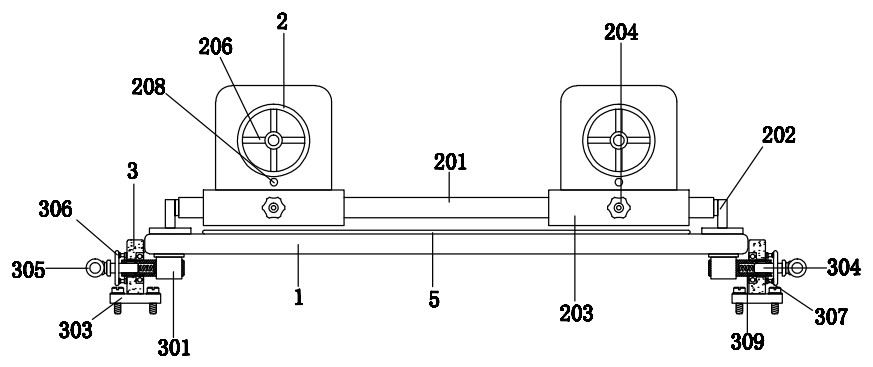

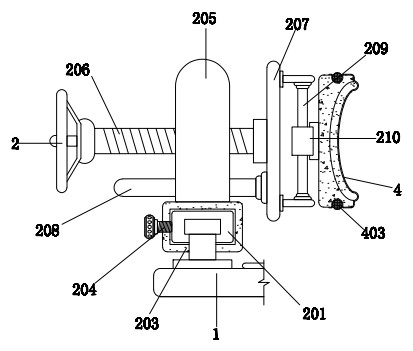

Uniform spraying based textile yarn uniform sizing and setting device

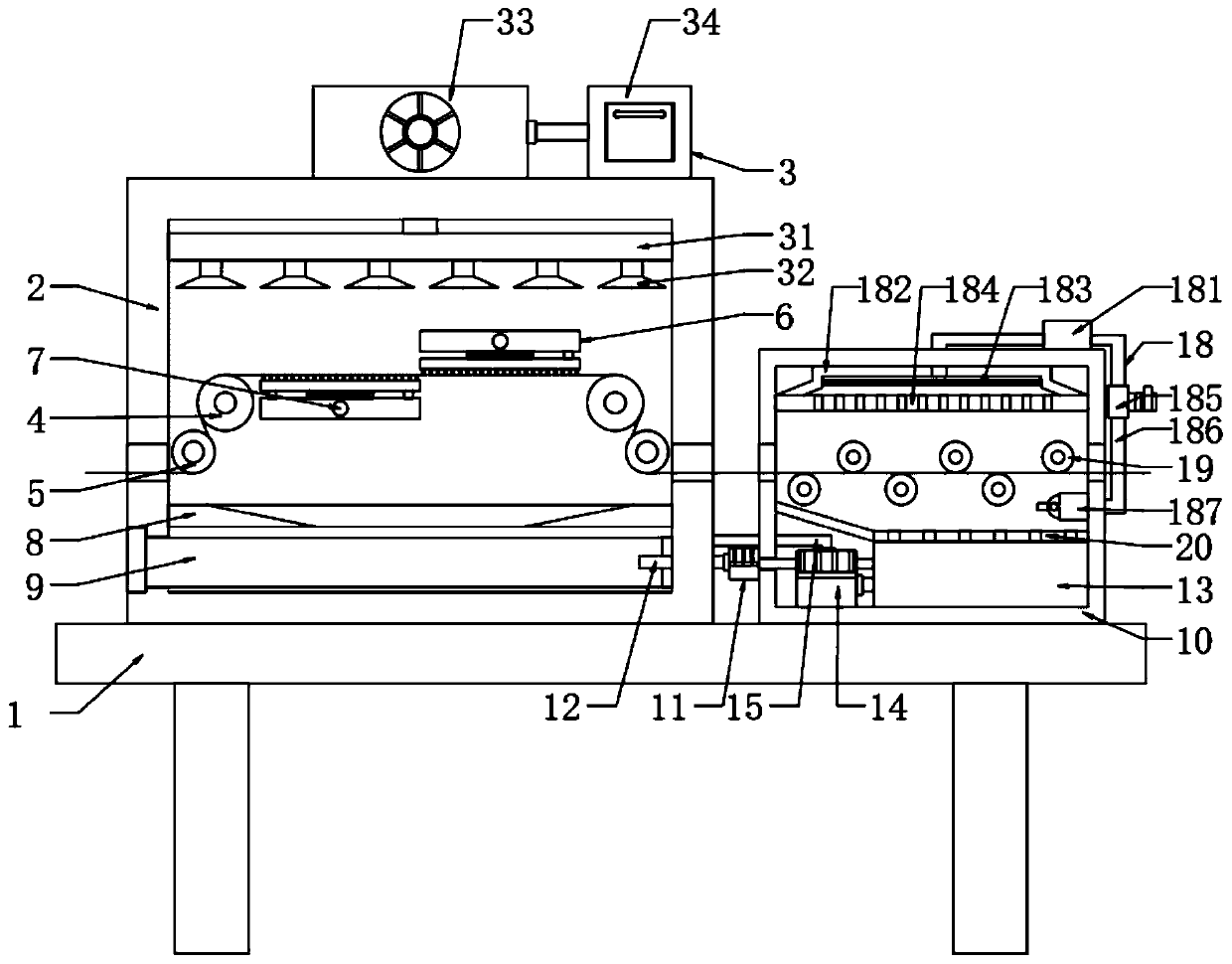

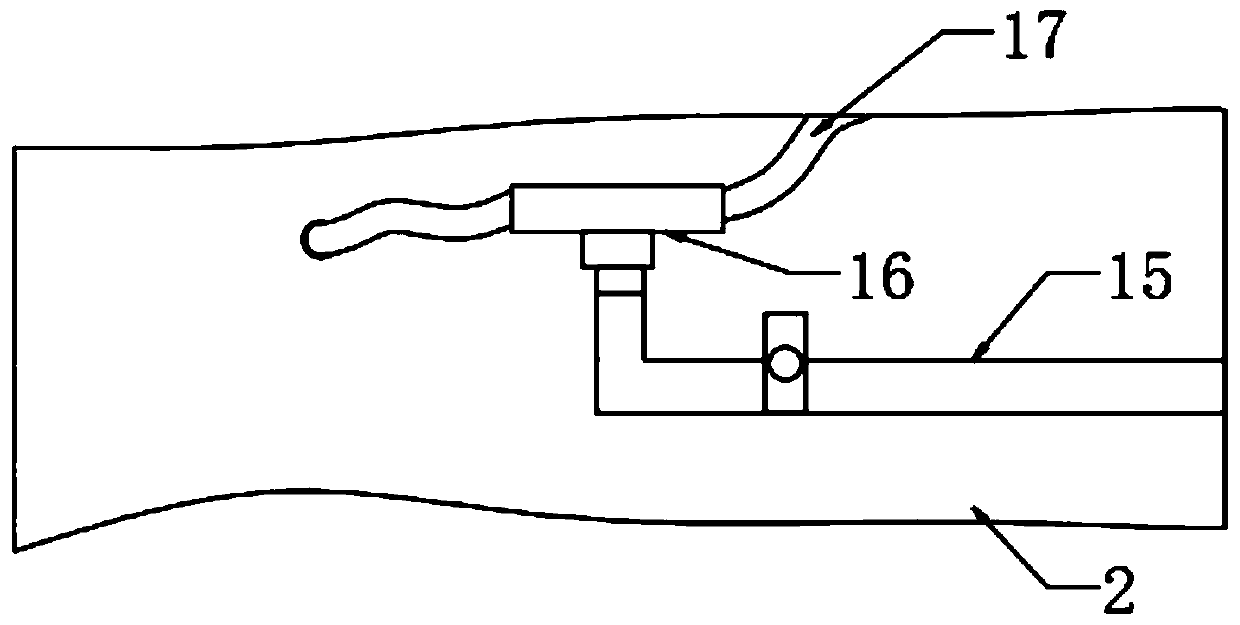

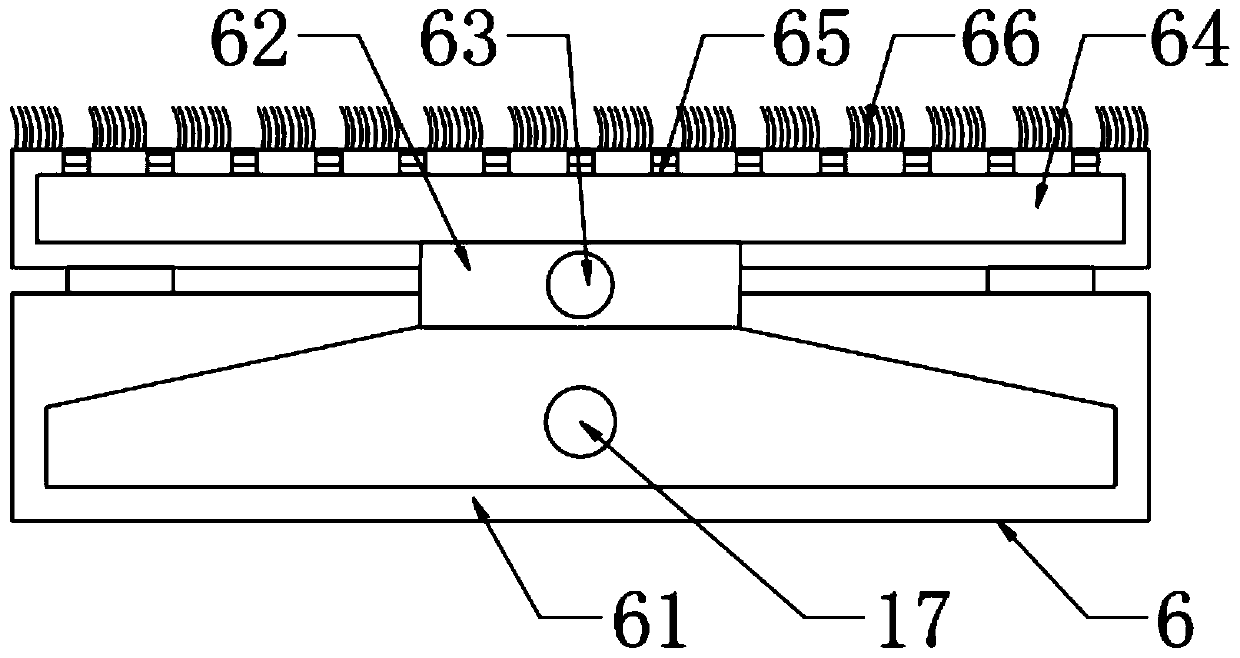

ActiveCN111334953AGuarantee the quality of sizingReduce cleanup burdenFibre cleaning/openingTextile treatment machine arrangementsTextile yarnIndustrial engineering

The invention discloses a uniform spraying based textile yarn uniform sizing and setting device in the technical field of textile yarns. The device comprises a base; the left side of the top of the base is fixedly provided with a treatment shell; the top of an inner cavity of the treatment shell is provided with a dust extraction mechanism; the middle of the inner cavity of the treatment shell issymmetrically provided with clean spraying mechanisms with the same structure in a longitudinally staggered manner; the outer wall of the back side of the treatment shell is provided with clean spraying driving mechanisms matched with the two groups of clean spraying mechanisms; the treatment shell is internally provided with a filtering part; the right side of the top of the base is provided witha setting shell; and the top of an inner cavity of the setting shell is provided with a setting drying part. The device is provided with the clean spraying mechanisms and the clean spraying driving mechanisms, so that removed burrs and impurities can be extracted, the subsequent sizing liquid cleaning burden is reduced, and the subsequent yarn sizing quality is ensured; and the two groups of clean spraying mechanisms are arranged to realize two-sided uniform sizing of the textile yarns, so that the sizing quality and the sizing efficiency are improved.

Owner:重庆华智天下科技有限公司

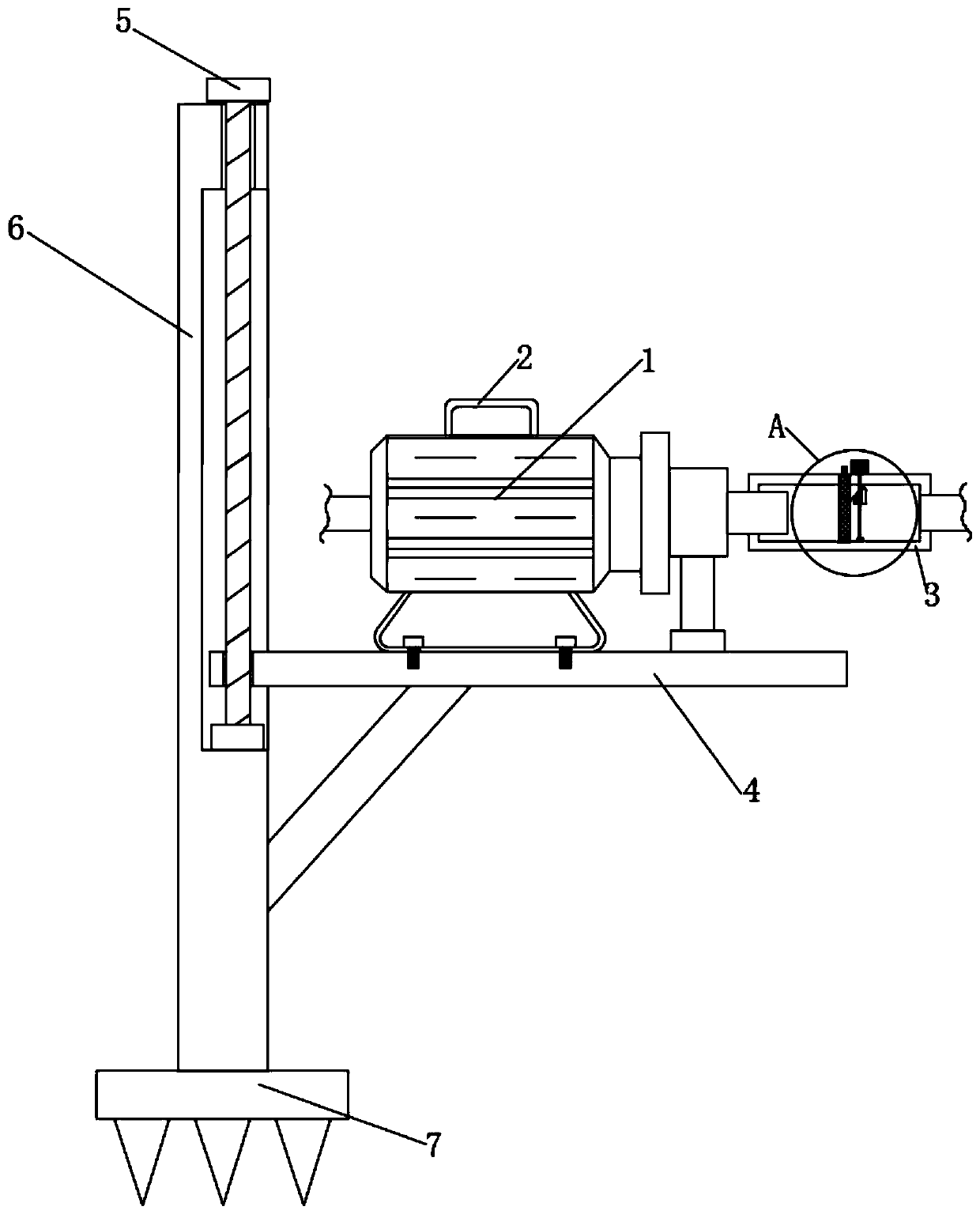

Slope protection reinforcing device for water conservancy project

InactiveCN112459008APlay the role of guideAvoid long-term accumulationCoastlines protectionExcavationsStructural engineeringHydraulic engineering

The invention belongs to the technical field of water conservancy projects, and particularly relates to a slope protection reinforcing device for a water conservancy project. The slope protection reinforcing device comprises a slope body and a protection net, wherein the upper end of the slope body is fixedly connected with a passageway, and a supporting plate is arranged between the passageway and the slope body; the lower end of the slope body is fixedly connected with a horizontal protection dike; a plurality of trapezoidal fixing blocks are evenly distributed on the side wall, adjacent tothe protection dike, of the slope body; the lower ends of the trapezoidal fixing blocks are evenly connected with a plurality of first screws fixed to the slope body; the side wall of the slope body is provided with a rectangular frame corresponding to the trapezoidal fixing blocks, and the rectangular frame and the supporting plate are connected through an installing mechanism; and the side wallof the slope body on the inner side of the rectangular frame is fixedly connected with an inclined strip-shaped plate. The slope protection reinforcing device has the beneficial effects that the material guiding function can be achieved on falling stone, that is, the falling stone is prevented from being accumulated on the lower side of the slope body for a long time, the cleaning burden of sanitation personnel on the falling stone is relieved, the accumulated stone cannot provide a springboard for subsequent falling stone, and danger is reduced.

Owner:SUZHOU ZHONGLI HEAT PRESERVATION & ENERGY SAVING MATERIAL CO LTD

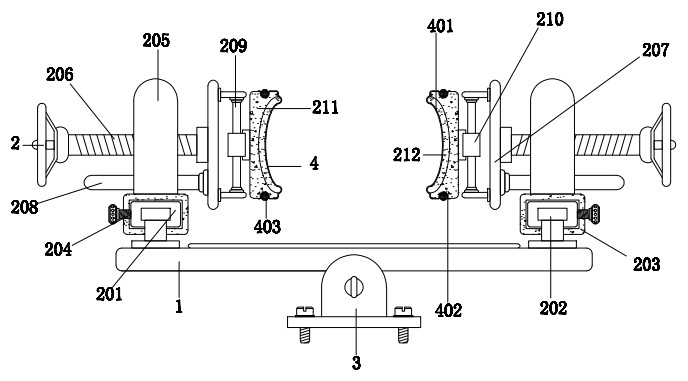

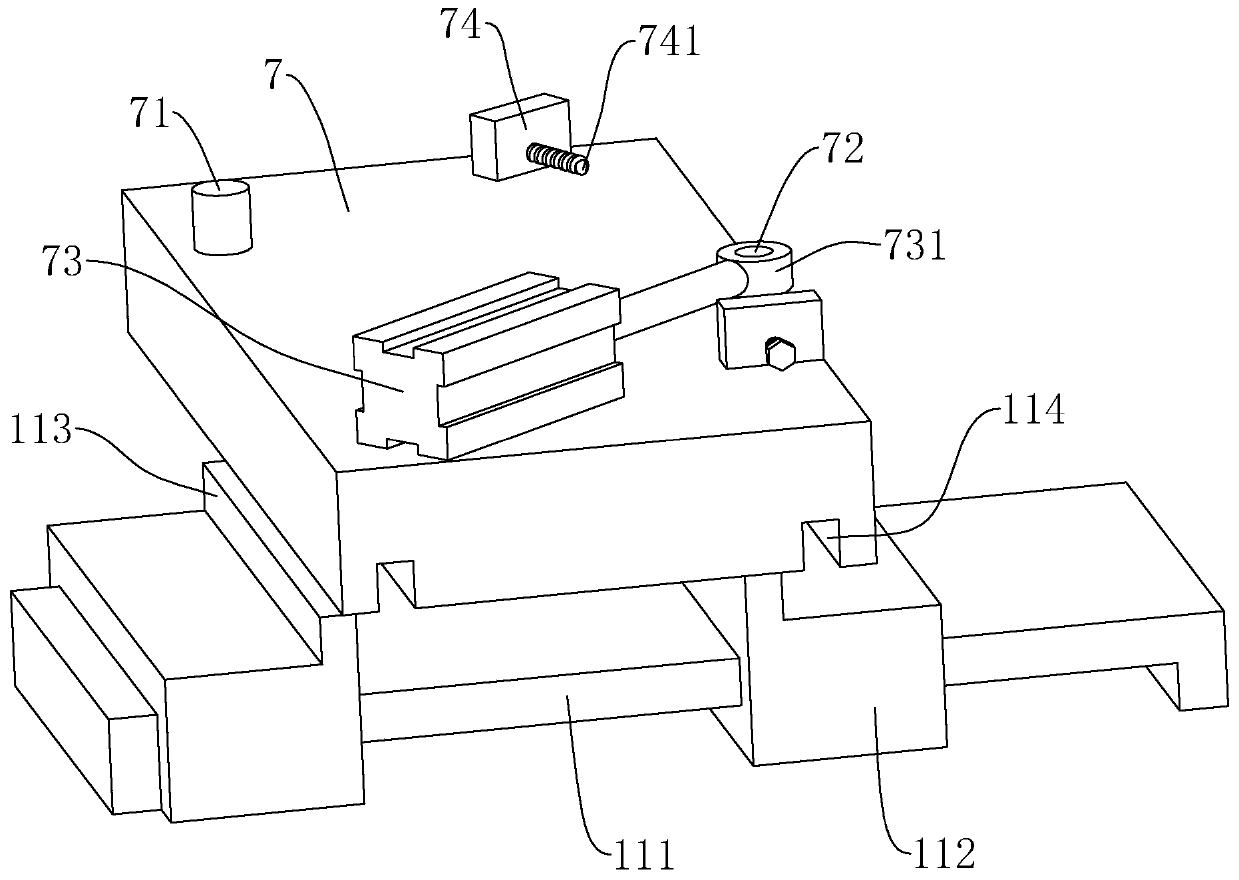

Shank operation leg positioning device for operating room

InactiveCN112022602AReduce the risk of secondary injuryNot easy to be disturbed by external forcesOperating tablesInstruments for stereotaxic surgeryPhysical medicine and rehabilitationOperating theatres

The invention discloses a shank operation leg positioning device for an operating room. The shank operation leg positioning device comprises a bottom plate, a positioning mechanism is arranged above the bottom plate, the positioning mechanism comprises square rods, supporting plates, square cylinders, screws, convex plates, bolts, flitch plates, inserting rods, sliding rods, sleeves, arc-shaped plates and soft cushions, and the two square rods are located on the front side and the rear side of the upper surface of the bottom plate correspondingly. According to the shank operation leg positioning device for the operating room, through cooperation of the bottom plate and the positioning mechanism, medical staff place a shank to be operated of a patient on the upper surface of the bottom plate, an operation focus is located in the center of the upper surface of the bottom plate, and the positions of the square cylinders are adjusted by rotating the screws anticlockwise; and after adjustment is completed, the screws are rotated clockwise to abut against the square rods, then the bolts are rotated clockwise to enable the arc-shaped plates to abut against the principle focus of the shankof the patient, the to-be-operated shank of the patient can be clamped and positioned, and the shank of the patient is not prone to being interfered by external force in the operation.

Owner:罗再萍

Vegetable cutting machine

InactiveCN108835660AEasy to handleReduce cleanup burdenMetal working apparatusFood treatmentWater storage tankAgricultural engineering

The invention discloses a vegetable cutting machine. The vegetable cutting machine comprises a box body, a cutting subassembly which is disposed in the box body, a material storage device which is disposed above the cutting subassembly, and a material receiving device and a spraying device which are disposed below the cutting subassembly, wherein a feed inlet is arranged at the top of the box body; a circulating pool is arranged at the bottom of the box body; a drainage device is disposed in the circulating pool; a water storage tank is arranged on one side of the box body; the drainage deviceis connected with the water storage tank. After vegetables are washed, waster water produced after washing of the vegetables is treated through the drainage device, the waste water containing impurities in the device can be conveniently treated, thus the cleaning burden is reduced and the practicability is high.

Owner:朱建国

Masonry pointing device

ActiveCN113389392APointing stabilityPrevent fallingBuilding material handlingCircular discEngineering

The invention discloses a masonry pointing device. The masonry pointing device comprises an operation frame, a first connecting rod and a pointing head, wherein operation frame is a main body support of the pointing device, the upper end of the operation frame is provided with a grip, the first connecting rod is welded and fixed to the side portion of the operation frame, a scraping plate is installed at one end of the first connecting rod, the pointing head is movably arranged in a second connecting rod, the interior of the upper end of the pointing head is in threaded connection with a second screw rod, and a middle bearing of the second screw rod is mounted on the second connecting rod; and the masonry pointing device further comprises a rotating shaft and a sleeve, the two ends of the rotating shaft are connected with the ends of two rolling wheels, the middle of the rotating shaft is fixedly sleeved with a disc, the sleeve is fixedly installed on the inner side of the operation frame, and the sleeve is arranged on the outer side of the rotating shaft in a sleeving mode. According to the masonry pointing device, grout after pointing can be compacted and leveled, meanwhile, grout powder generated by pointing can be cleaned, the situation that the grout powder falls into wheels due to the gravity effect during transverse pointing is prevented, and it is guaranteed that the device runs normally.

Owner:陕西建工第九建设集团有限公司

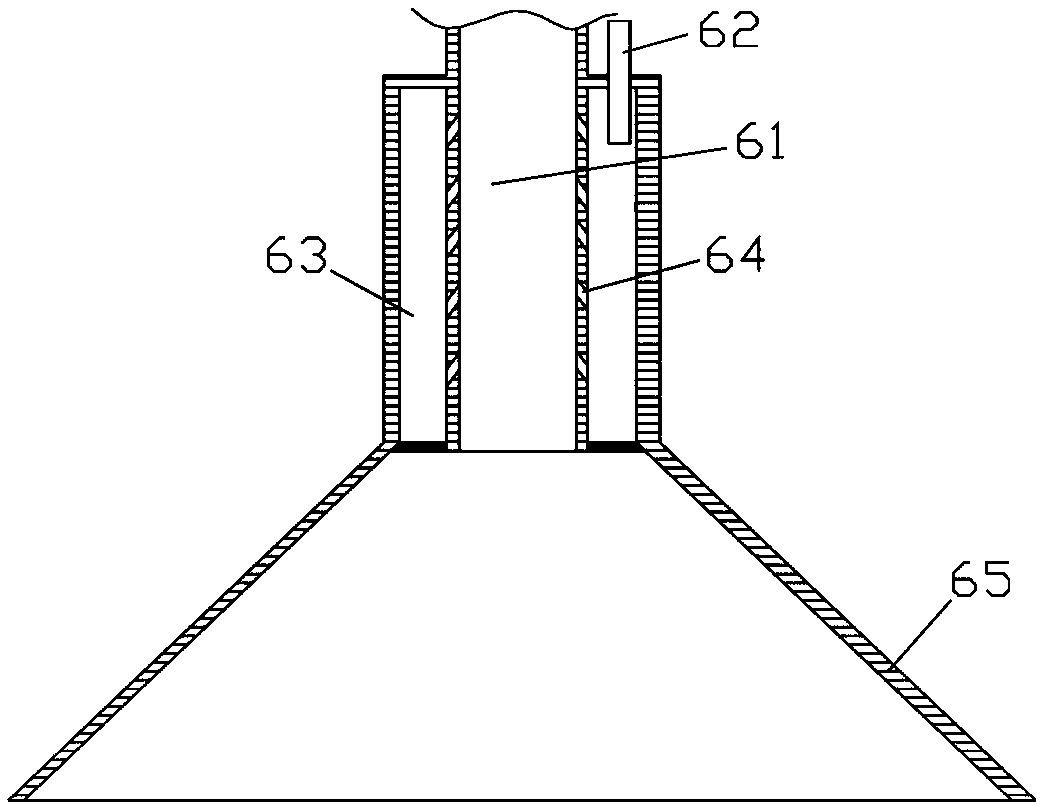

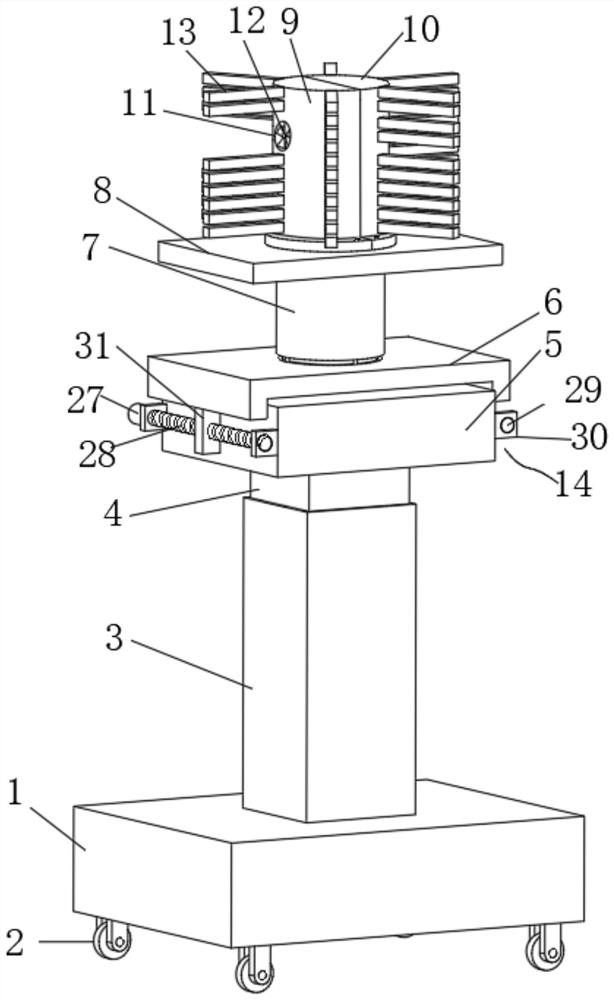

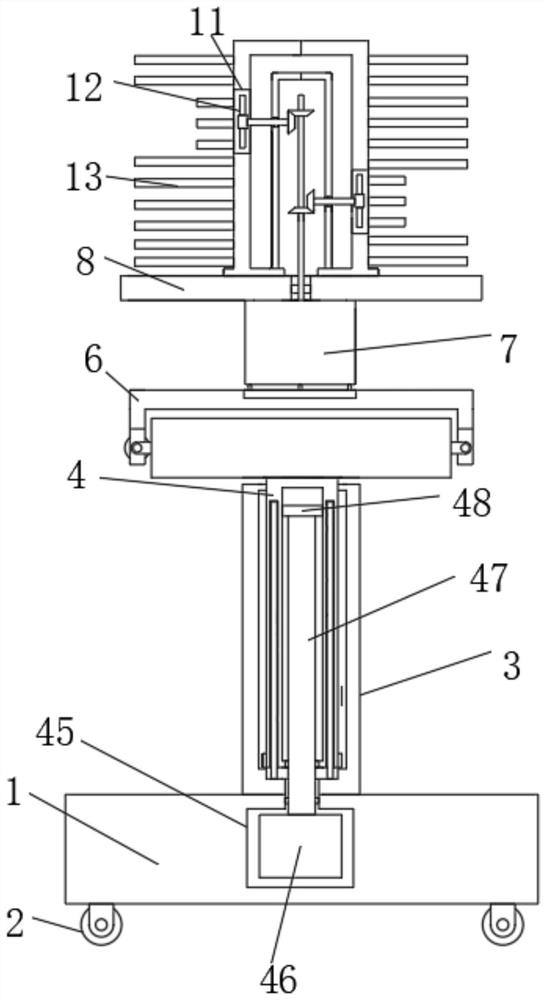

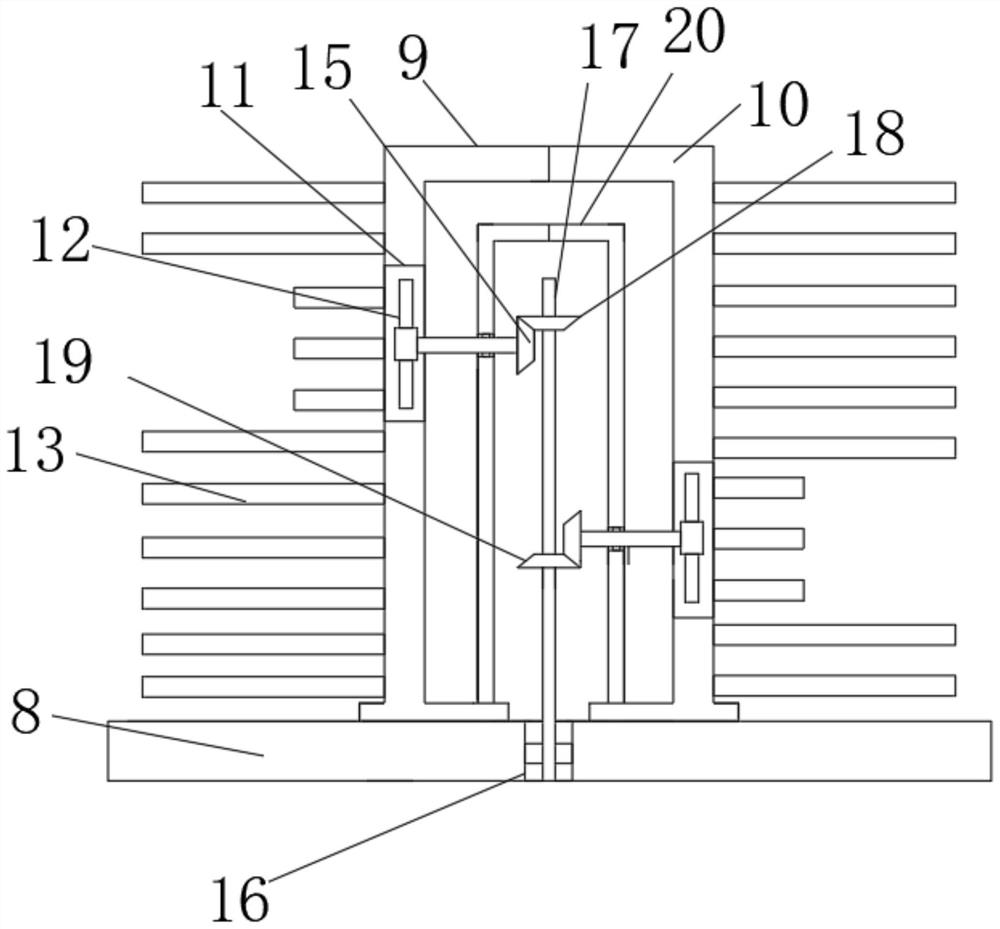

Intelligent automatic spider web cleaning equipment

InactiveCN113245268AAchieve horizontal movementEasy to achieve horizontal movementCarpet cleanersFloor cleanersSpider webSlide plate

The invention relates to the technical field of cleaning equipment, and discloses intelligent automatic spider web cleaning equipment, and solves the problems that manual spider web cleaning efficiency is low, and dust cannot be collected. The intelligent automatic spider web cleaning equipment comprises a base, moving wheels are symmetrically arranged at the bottom end of the base, and a supporting cylinder is arranged in the middle of the top end of the base; a height adjusting rod is inserted into the supporting cylinder, a height adjuster is arranged at the bottom end of the height adjusting rod, a supporting plate is arranged at the top end of the height adjusting rod, a sliding plate is connected to the top end of the supporting plate, the sliding plate is connected with a position adjuster, a stabilizing cylinder is rotationally connected to the top end of the sliding plate, and a fixing plate is arranged at the top end of the stabilizing cylinder; and a first rotating cylinder and a second rotating cylinder are arranged at the top end of the fixing plate and connected to each other. Through the design of an open groove, a suction fan and a control mechanism, dust can be conveniently collected while spider webs are cleaned, the use performance of the equipment is effectively improved, and meanwhile the dust cleaning burden is relieved for workers.

Owner:黄灵万

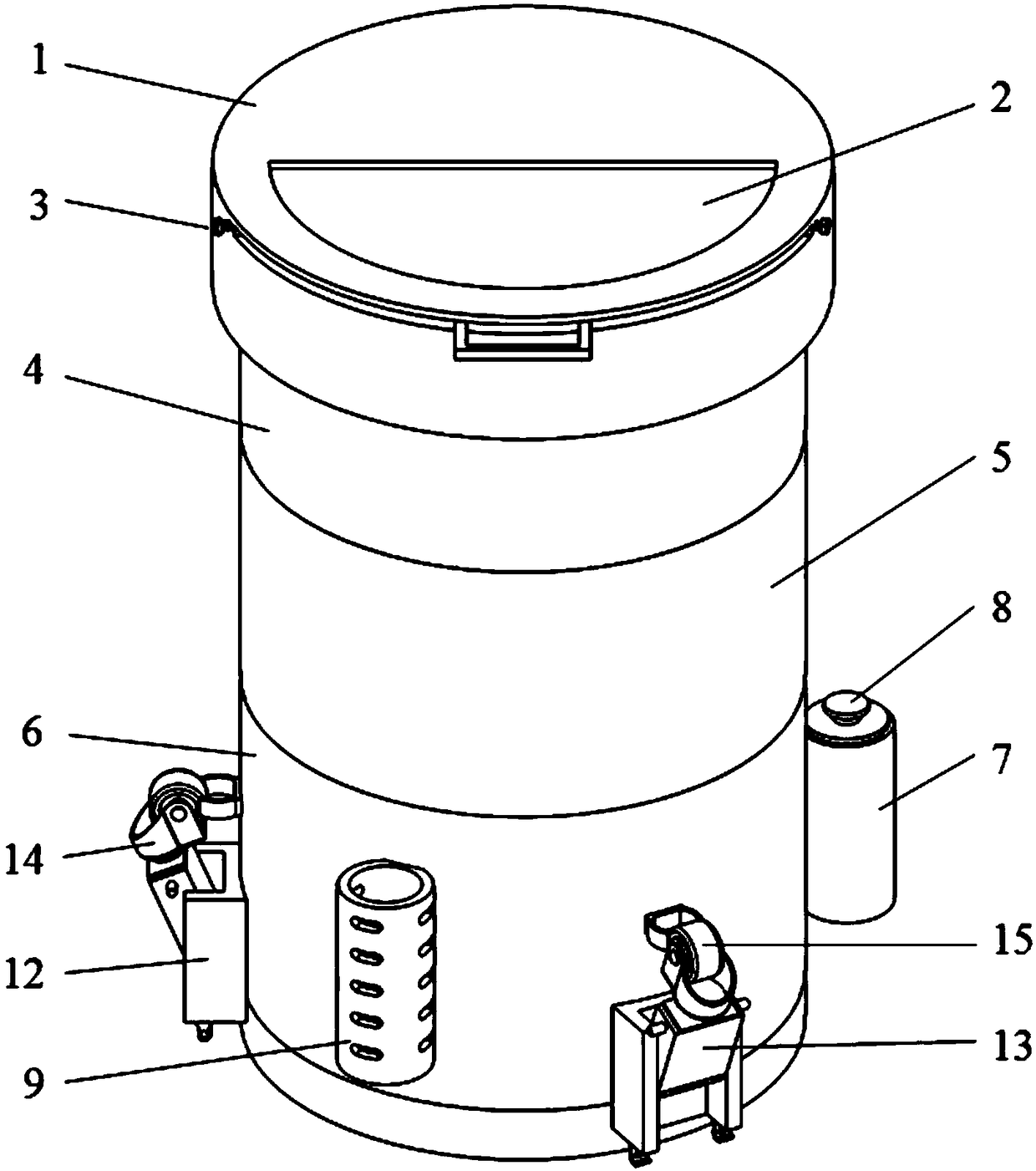

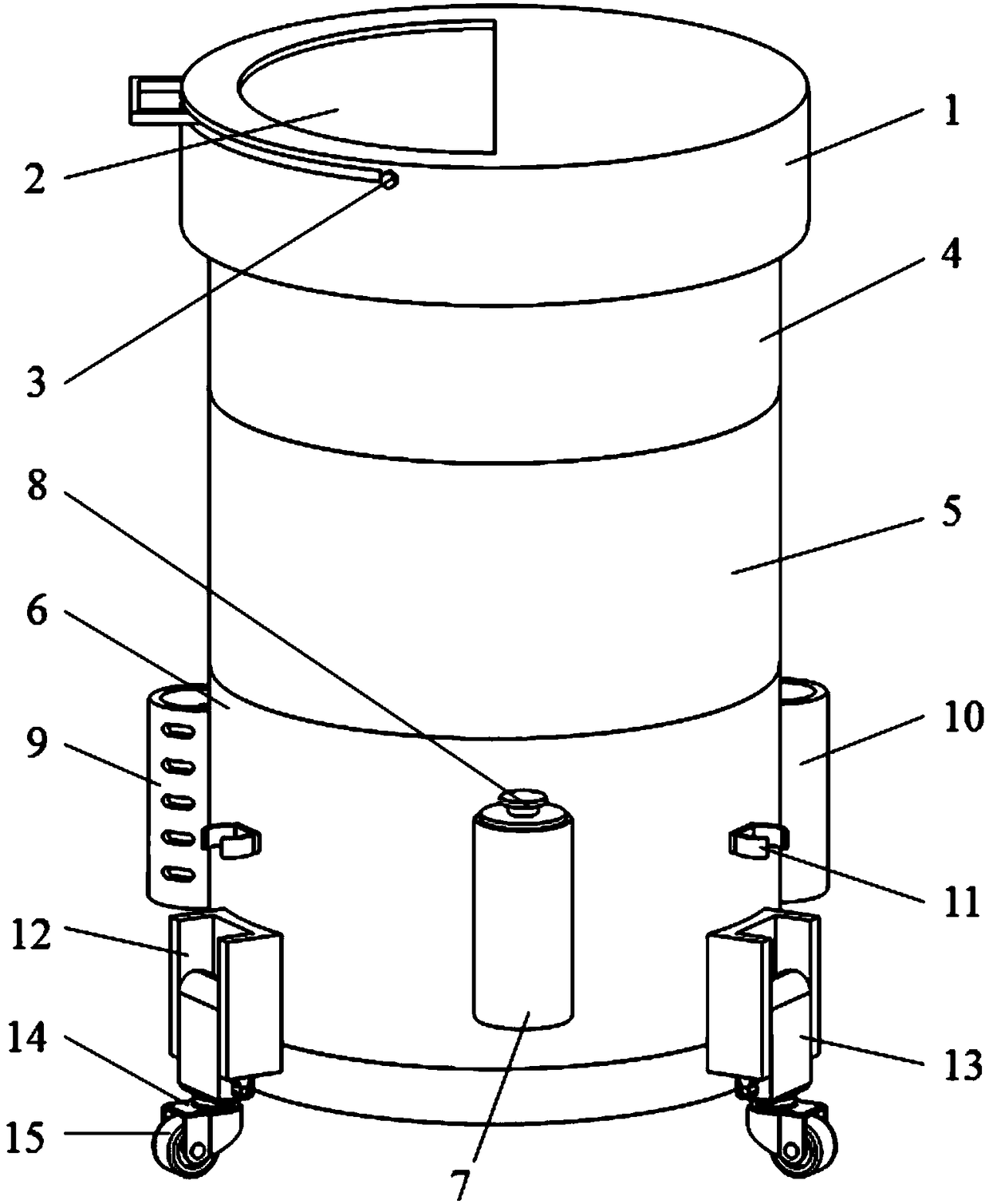

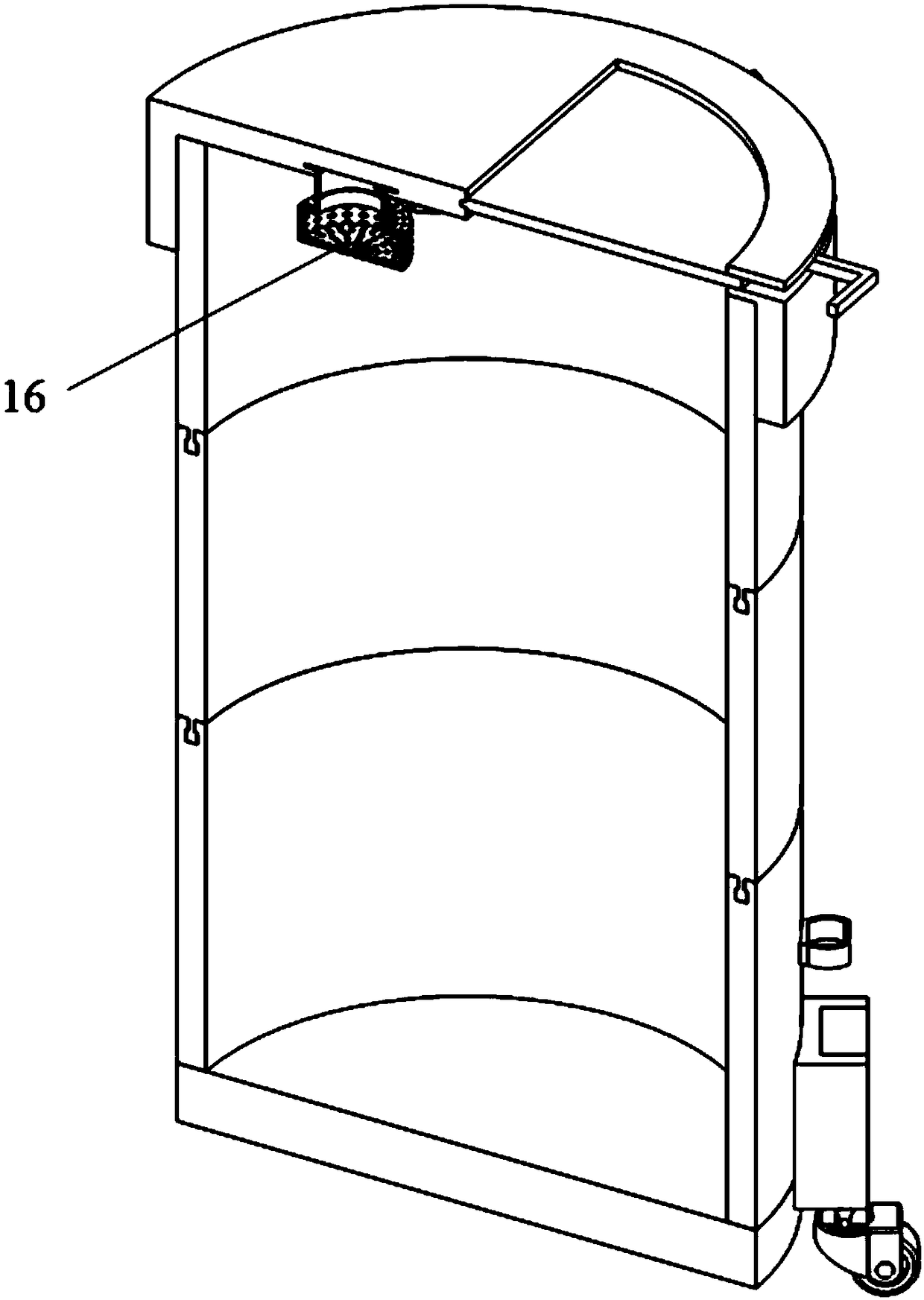

Multifunctional trash can for nursing ward

InactiveCN108408291AReduce cleaning frequencyReduce cleanup burdenWaste collection and transferRefuse receptaclesLitterEngineering

The invention relates to a trash can, in particular to a multifunctional trash can for a nursing ward and belongs to the technical field of medical instruments. The multifunctional trash can for the nursing ward comprises a can cover, an inserting plate, a screw, an upper can body, a middle adjusting can body, a lower can body, a first containing barrel, a containing barrel cover, a second containing barrel, a third containing barrel, an upper supporting frame, a lower supporting frame, a connection plate, a rolling wheel straightening frame, a rolling wheel and trays. By increasing and decreasing the middle adjusting can body, the purpose of adjusting the volume is achieved; the upper can body, the middle adjusting can body and the lower can body are all made from a transparent material,the number of trash in the can can be observed at any time, and it is facilitated that the trash in the can is compressed and cleared in time; the beneficial effects that movement is convenient and stability is good are achieved; the three trays are arranged and used for containing a peculiar smell treatment agent, a drying agent and a sterilizing and disinfecting agent, peculiar smells in the trash can can be removed, it can also be guaranteed that air in the trash can is dry, and sterilizing and disinfecting can also be performed on air in the can; and classified storing of trash can be achieved.

Owner:贾国媛

Household domestic sewage impurity separation device

InactiveCN112295293AEasy to disassemble and operateIncrease linkageStationary filtering element filtersSewageSewage treatment

The invention relates to the technical field of sewage treatment, and discloses a household domestic sewage impurity separation device which comprises a shell, and the top of the shell is fixedly connected with a pipeline. According to the invention, sewage circulation conditions are automatically and intermittently controlled, impurity cleaning operation is facilitated, filter transposition and impurity dumping operation are triggered by using a photoresistor principle, linkage between structures is increased, the degree of automation is high, the position of a filter is automatically adjusted, the filter filled with impurities is moved to the top of an impurity dumping place, thus the impurities are convenient to dump, the situations that the filter is blocked and sewage cannot smoothlycirculate due to the fact that the accumulation condition of impurities in the filter cannot be monitored in time by manpower are effectively avoided, the filter is automatically dumped, the impurities in the filter are automatically separated from the filter under the action of gravity, and cleaning of the filter and centralized collection of the impurities are achieved; and the subsequent impurity separation operation is facilitated, the cleaning burden is reduced, and the actual use condition is better met.

Owner:李月

Easy-cleaned screen window

ActiveCN110295842AImprove cleanlinessReduce cleanup burdenInsect protectionSpecial door/window arrangementsDrive wheelDrive shaft

The invention relates to an easy-cleaned screen window. The easy-cleaned screen window comprises a shell, a window gauze and a fixing bar; a fixing shaft is arranged in the shell; the fixed shaft is coaxially sleeved with a winding drum; the window gauze is coiled and stored on the winding drum; a transmission shaft is arranged in the shell; the transmission shaft is coaxially sleeved with a transmission cylinder; a transmission wheel is arranged at the cylinder end of the transmission cylinder; a driving wheel is arranged at the cylinder end of the winding drum; the transmission wheel and thedriving wheel are in fit engaged connection; the shell is provided with a friction plate; the friction plate and the cylinder surface of the transmission cylinder are in extrusion contact; a fur layer is arranged on the surface of the friction plate; a rubber layer is arranged on the cylinder surface of the transmission cylinder; and an anti-static shovel plate is arranged in the shell. The screen window is novel in structure and convenient to operate, and helps users easily clean dust attached on the window gauze to recover the cleanness of the window gauze under the condition of no need ofcomplete disassembly.

Owner:XINCHANG COUNTY WANLIAN BEARING

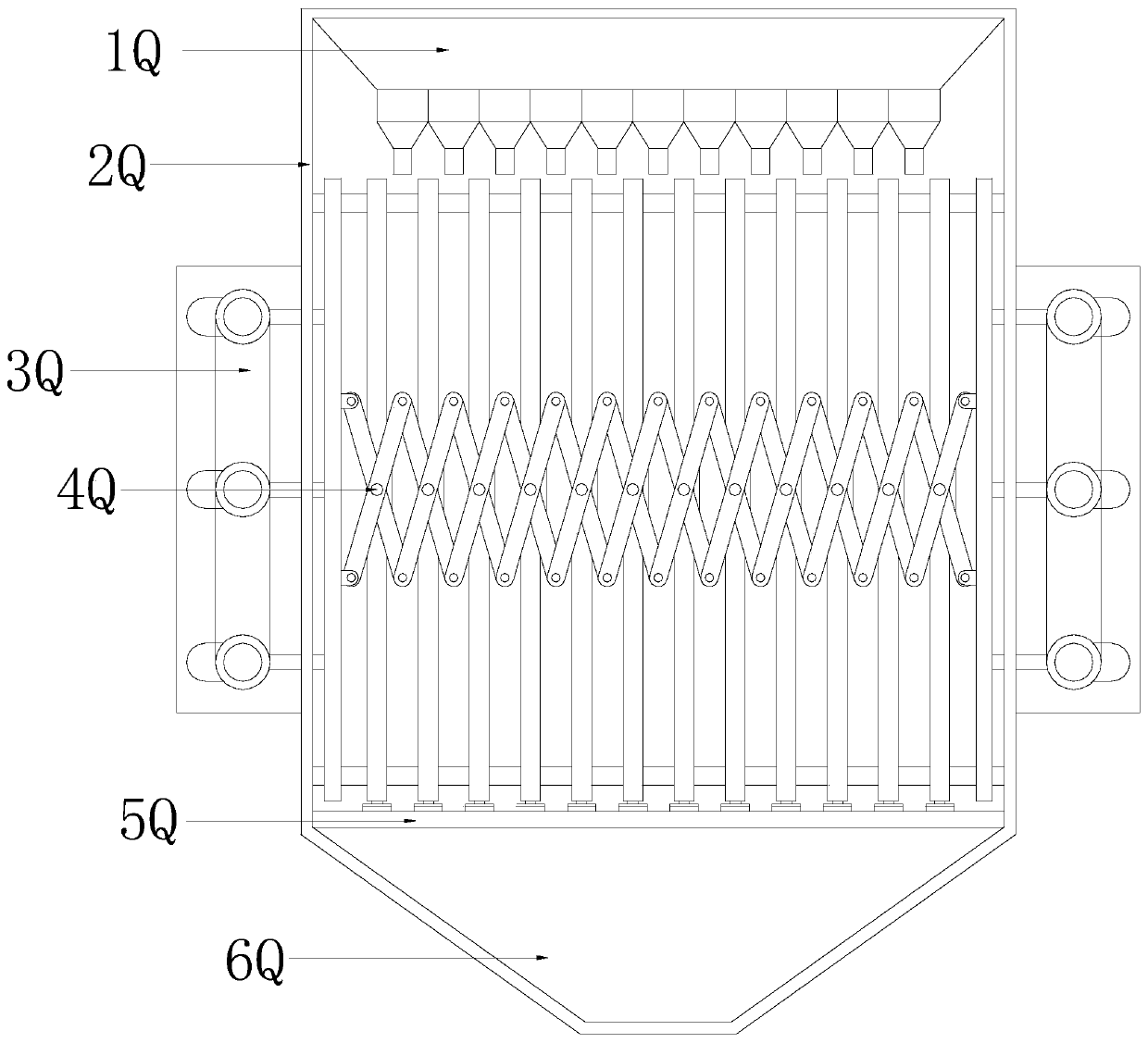

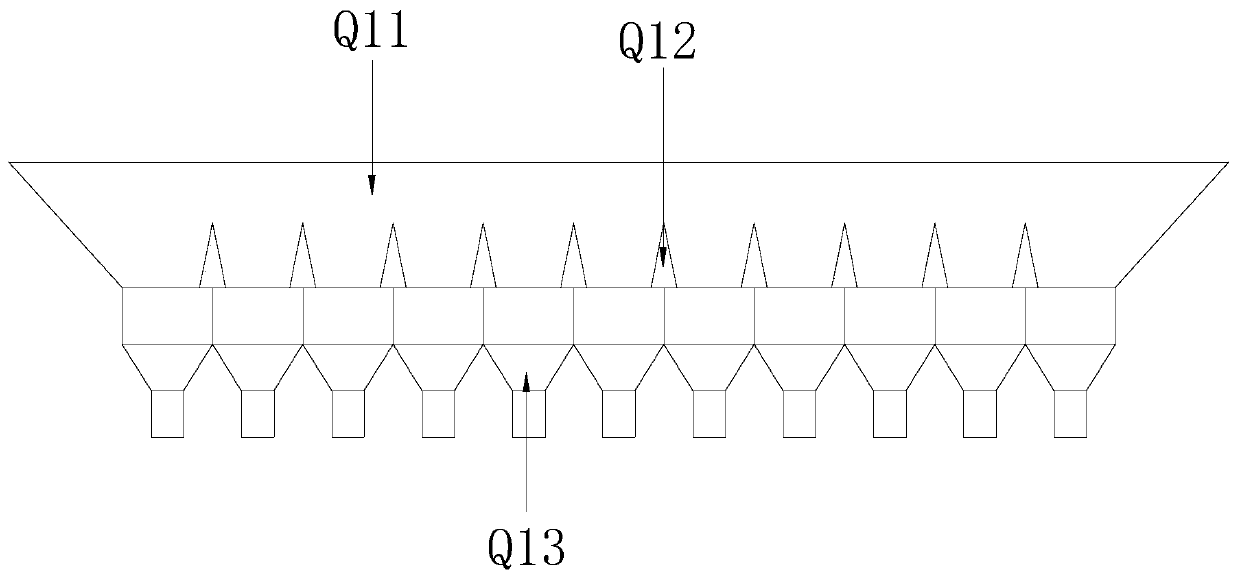

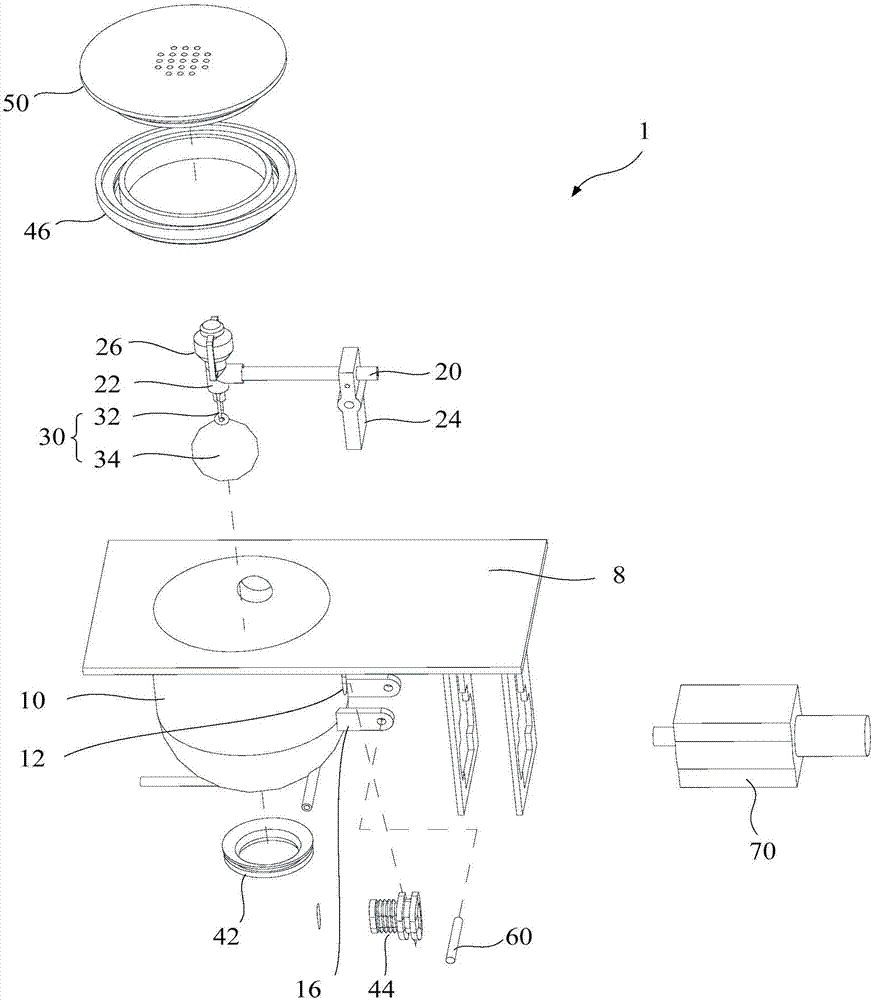

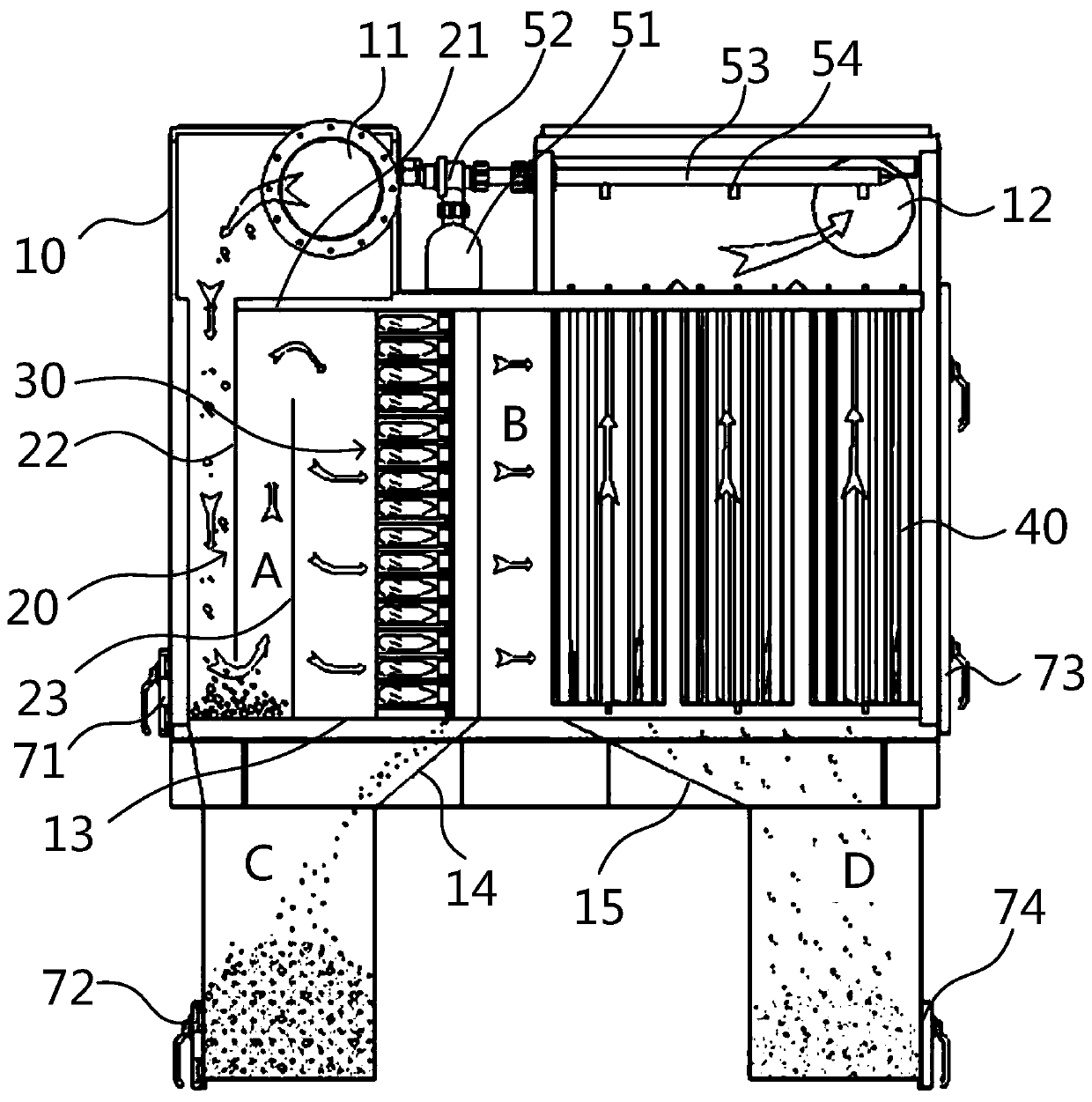

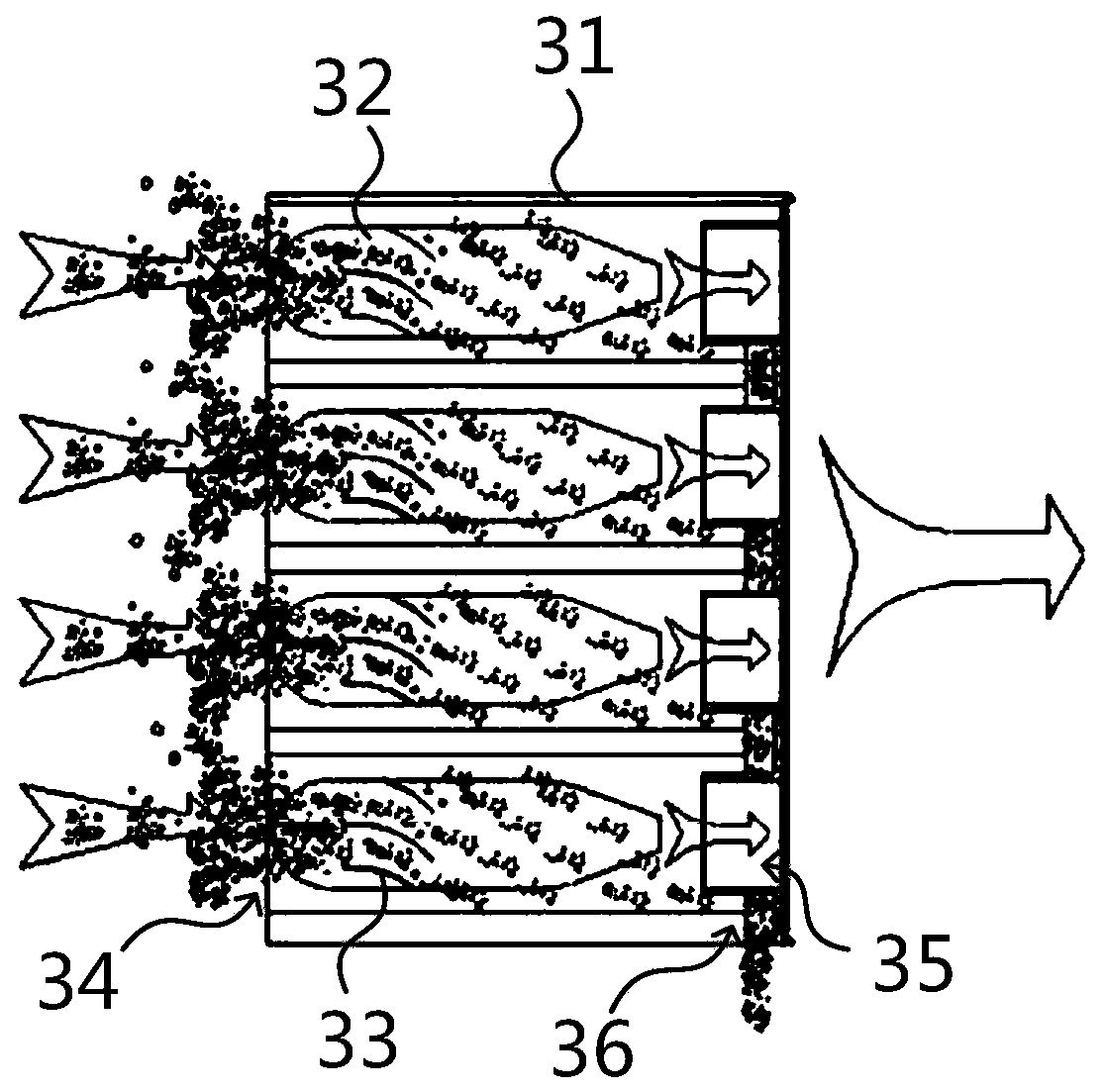

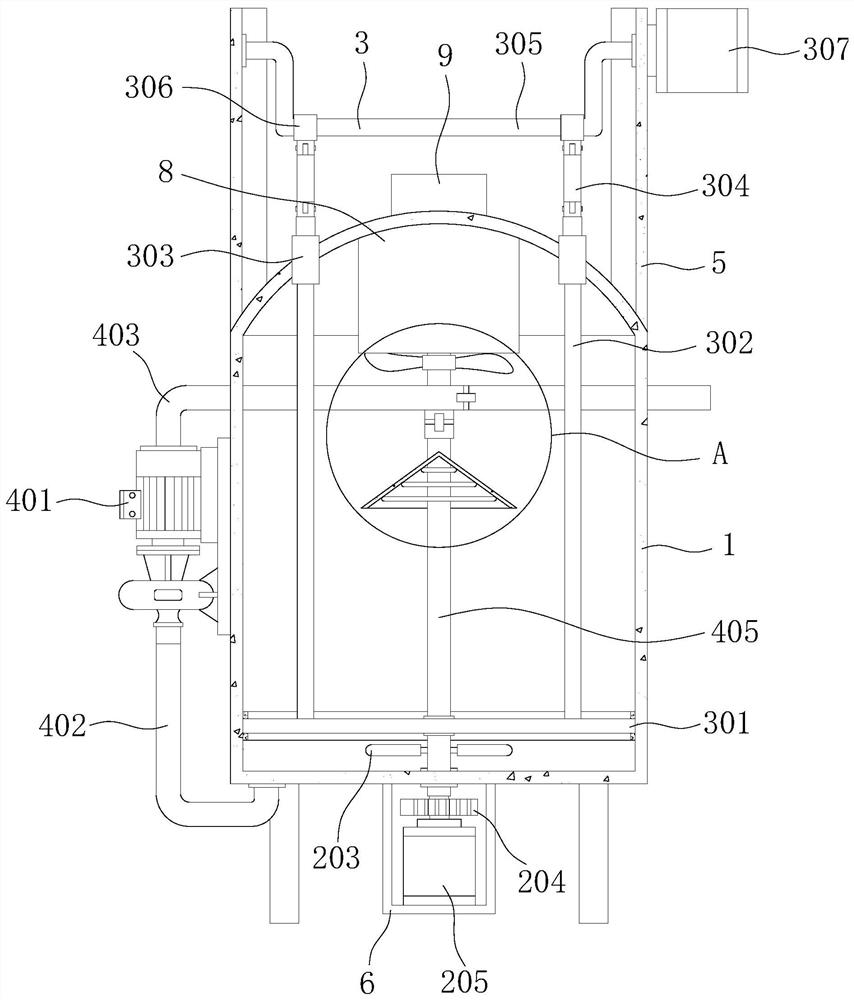

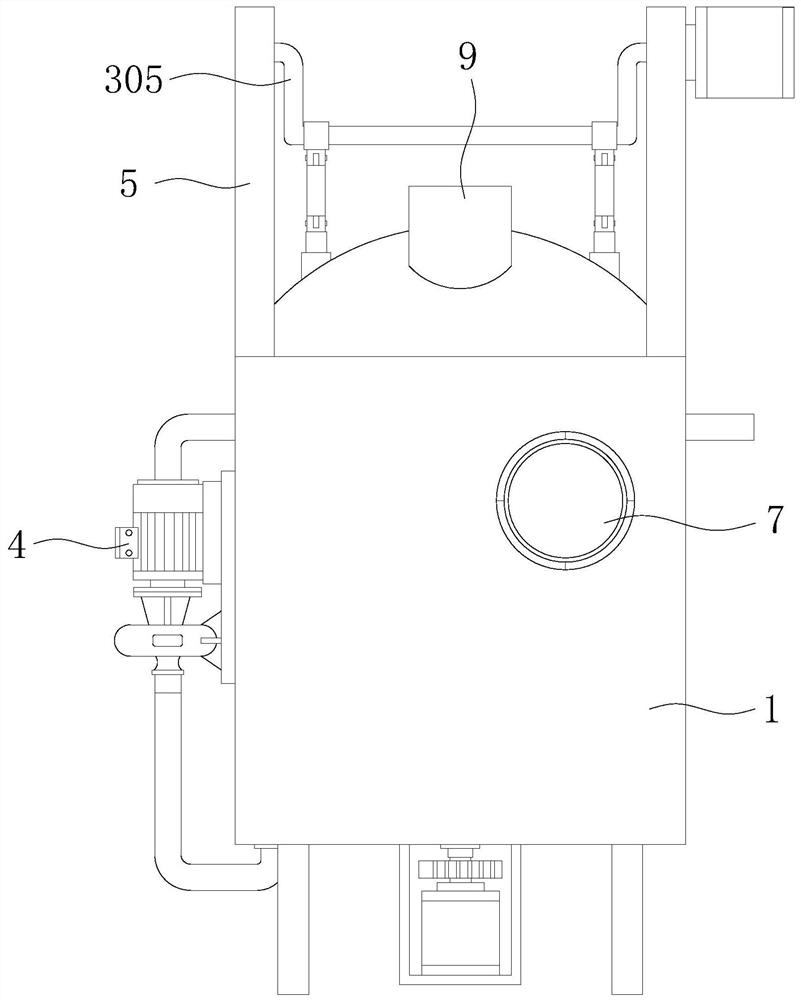

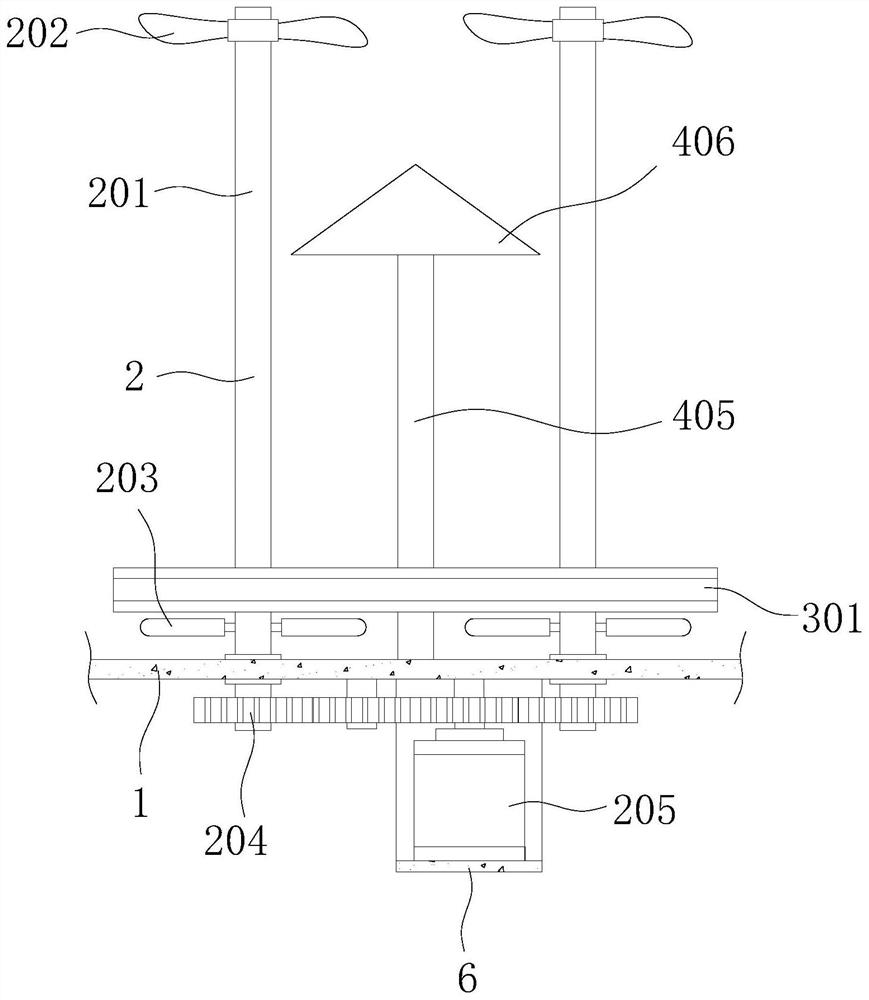

Dust removal device and vacuum operation vehicle

PendingCN110711455AStrong dust removal abilityReduce cleanup burdenCombination devicesTank vehiclesEngineeringDust control

The invention relates to a dust removal device and a vacuum operation vehicle, wherein the dust removal device comprises: a box body (10) which comprises a first filtering chamber (A) and a second filtering chamber (B) communicated with the first filtering chamber (A); a settling structure (20) that is arranged in the first filtering chamber (A); a filter cylinder body (40) which is arranged in the second filter chamber (B); a combined cyclone dust removal structure (30) that is arranged in a communication channel between the first filter chamber (A) and the second filter chamber (B). The boxbody (10) is provided with an air inlet (11) and an air outlet (12), wherein the air inlet (11) is formed in the first filtering chamber (A), and the air outlet (12) is formed in the second filteringchamber (B). According to the embodiments of the invention, the requirement of filtering precision is met through integrated arrangement of multi-stage filtering, and the cleaning burden of the dust removal device is reduced.

Owner:JIANGSU XCMG CONSTR MASCH RES INST LTD

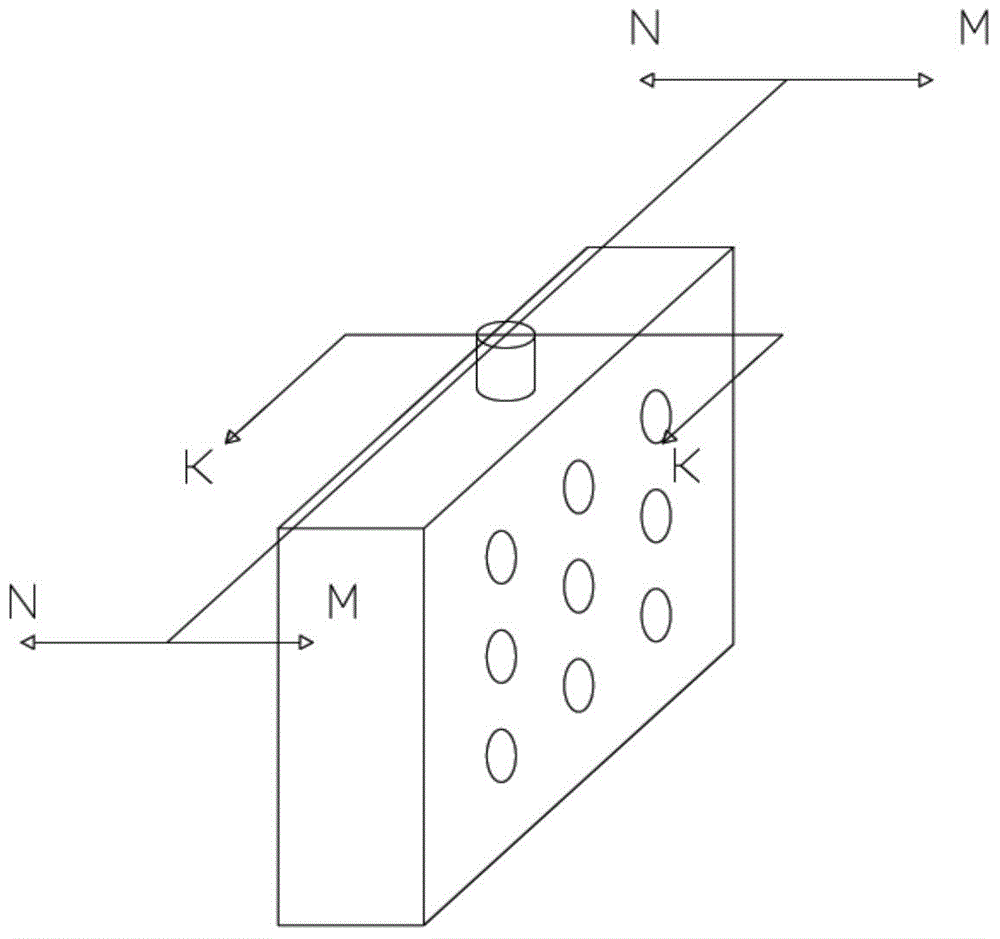

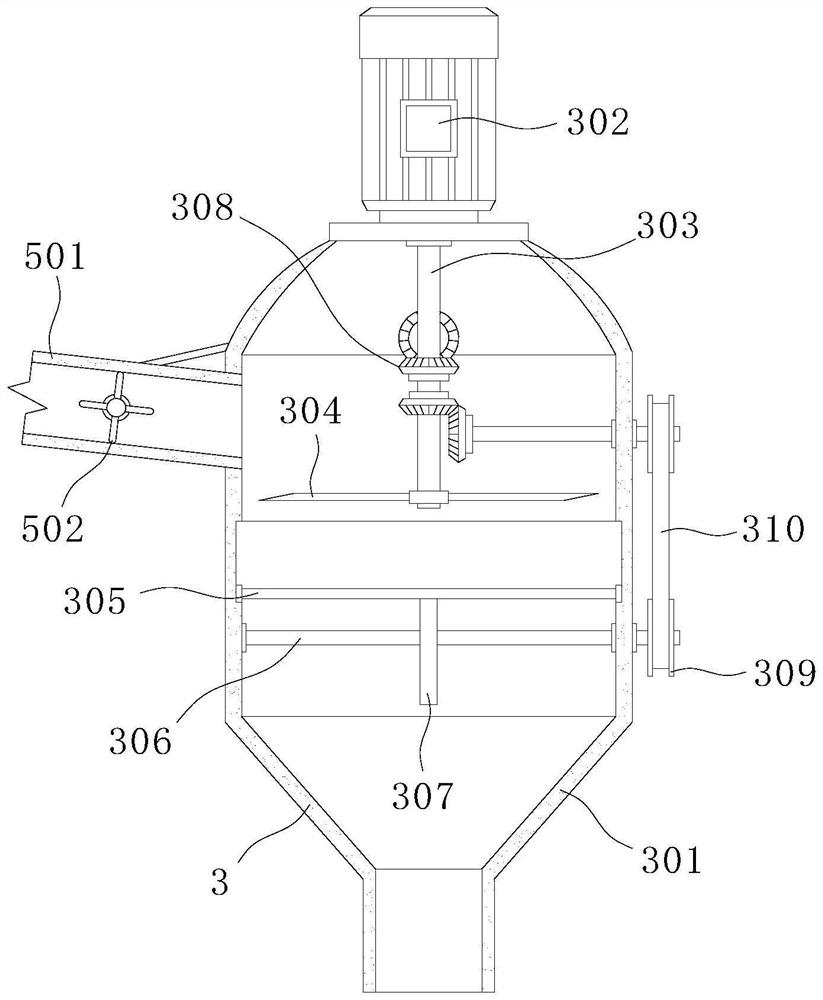

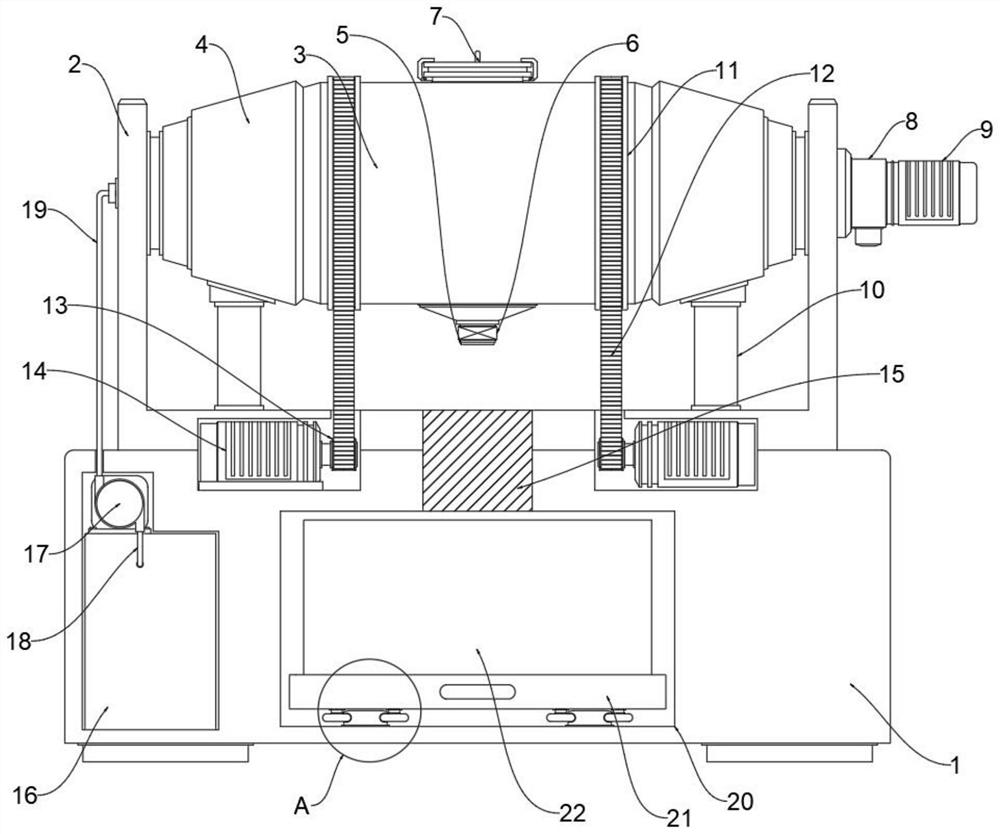

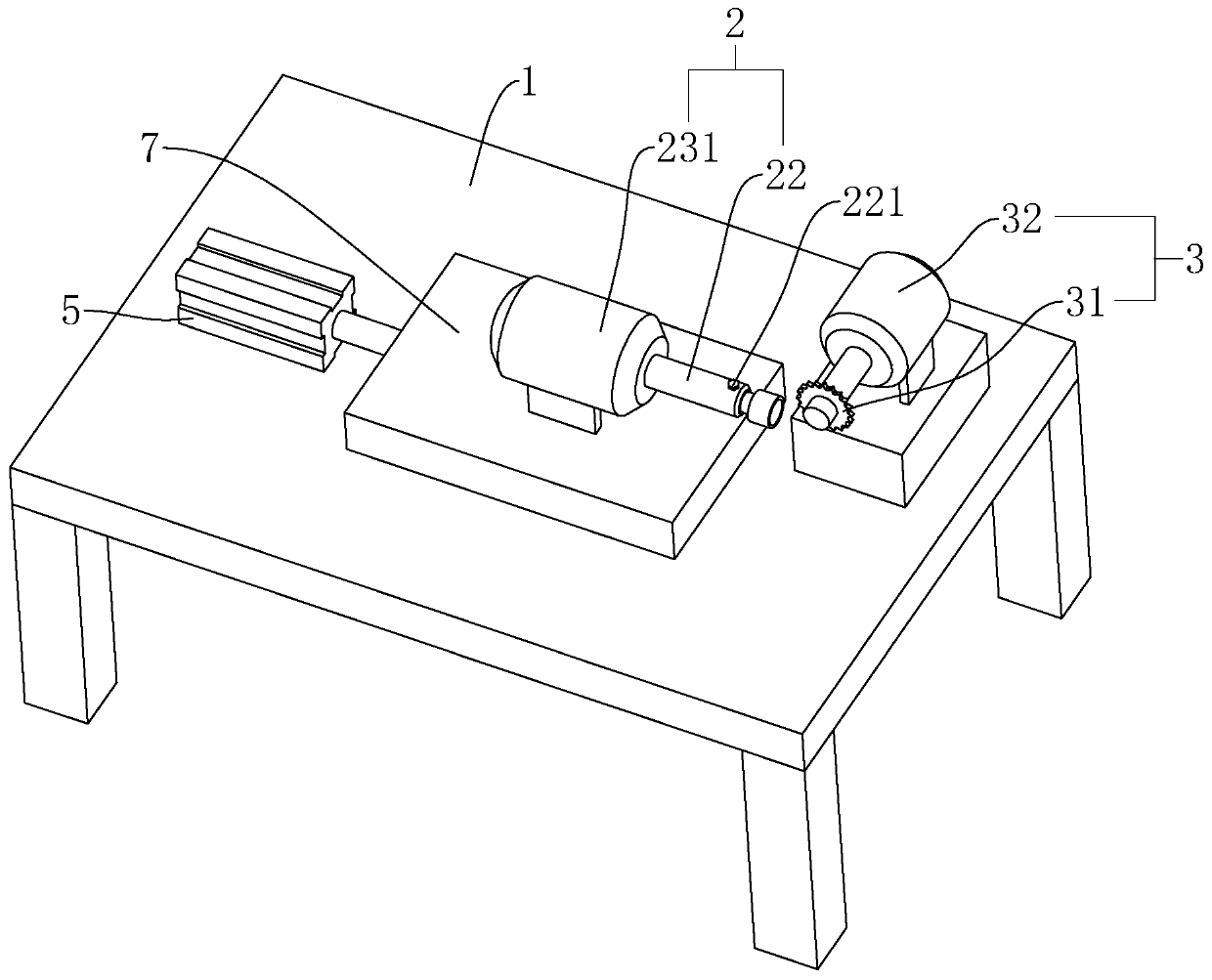

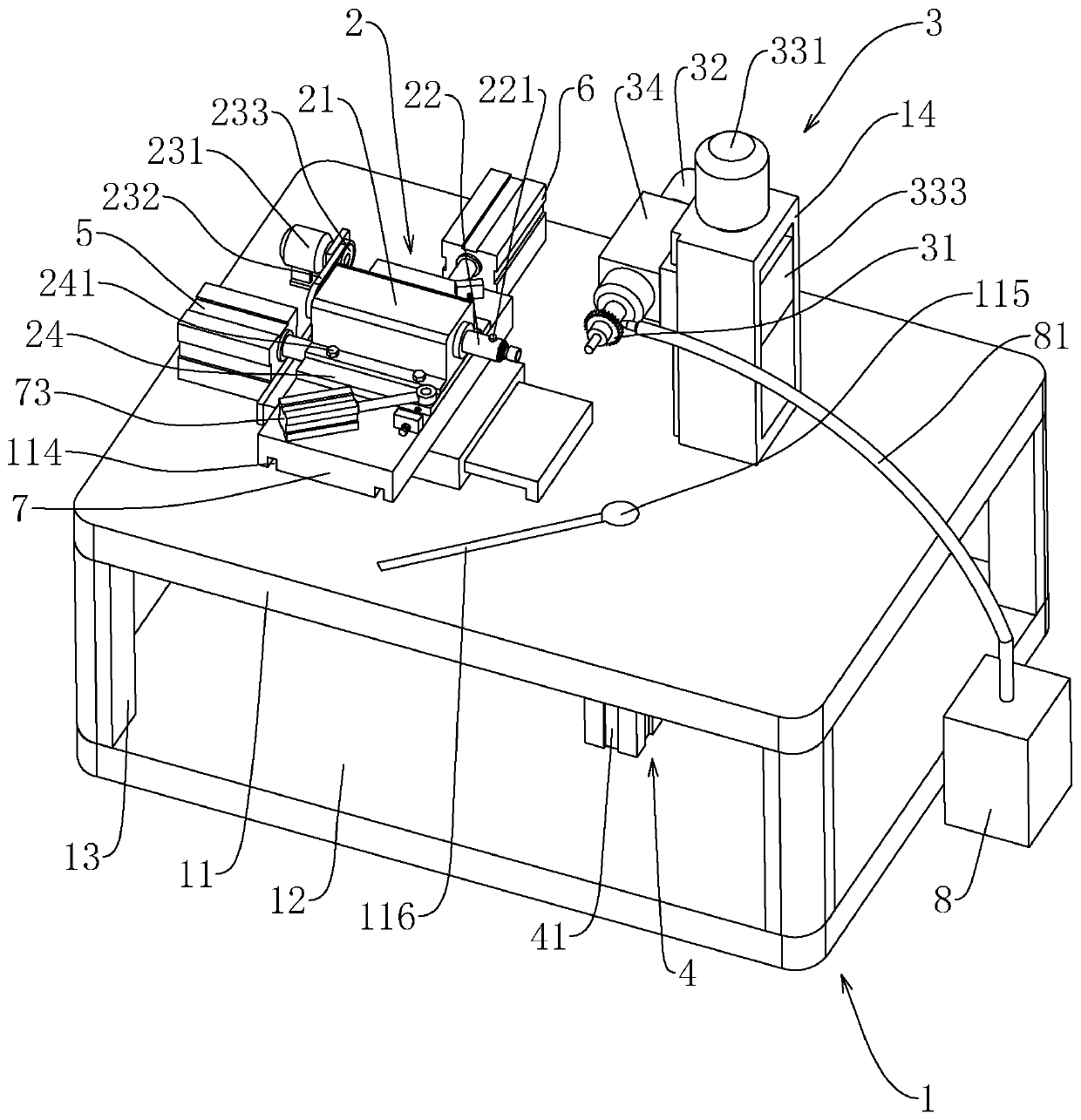

Mixer for compound fertilizer production

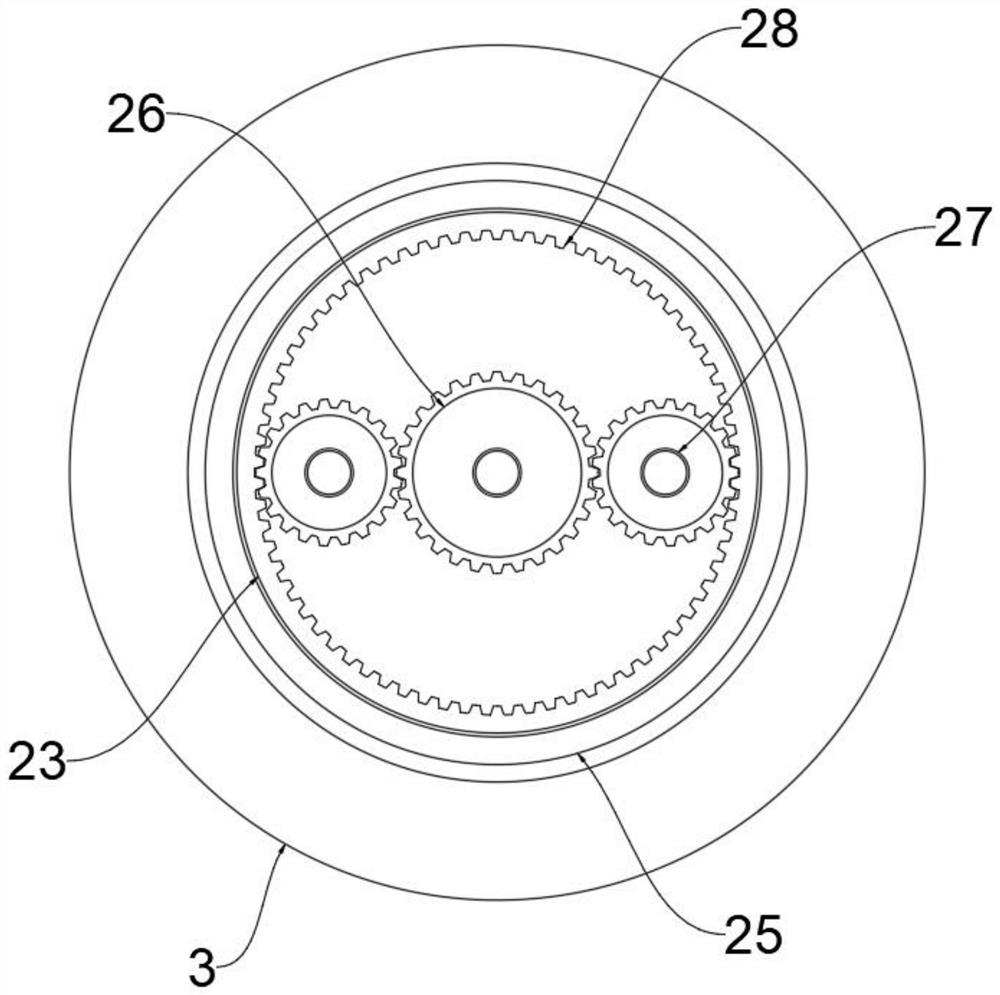

InactiveCN112108048AAchieve hybridSpeed up the mixingRotating receptacle mixersTransportation and packagingGear wheelAgricultural engineering

The invention discloses a mixer for compound fertilizer production, relates to the technical field of compound fertilizer production equipment, and aims at solving the problem that the overall mixingefficiency of an existing mixer is affected due to the fact that a stirring mechanism is simple. Supporting frames are welded and fixed to the two sides of the upper end of a base correspondingly, a rotating cylinder is rotationally installed between the supporting frames, meshing gear rings are welded and fixed to the two sides of the middle of the rotating cylinder correspondingly, belts are arranged outside the meshing gear rings correspondingly, and a transmission mechanism is arranged on one side of the interior of the rotating cylinder. The transmission mechanism is composed of a drivinggear, a planetary gear and a tooth groove, two supporting columns are arranged in the rotating cylinder, a water collecting disc is installed on the other side in the rotating cylinder, a sealing cover is arranged in the middle of the upper end of the rotating cylinder, and a discharging port is formed in the middle of the lower end of the rotating cylinder. And a storage cavity is formed in thebase.

Owner:GARSONI FERTILIZER NINGLING

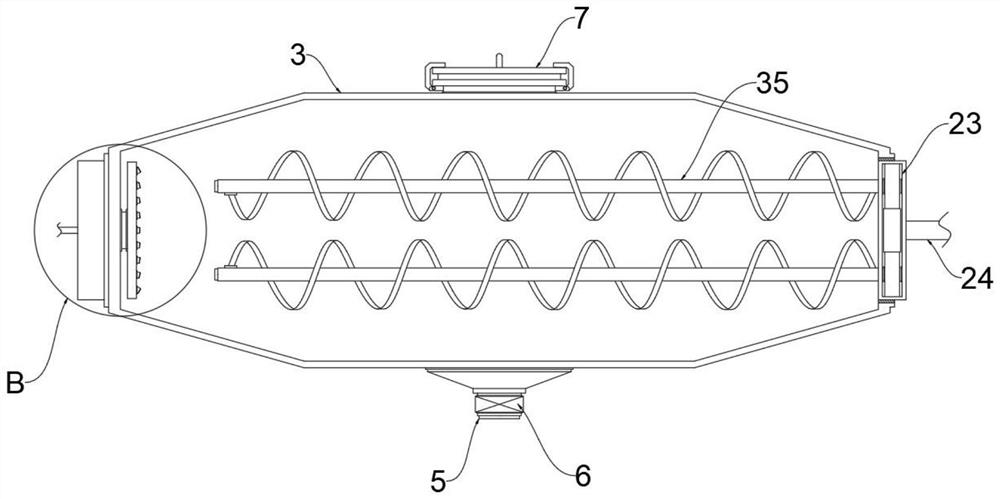

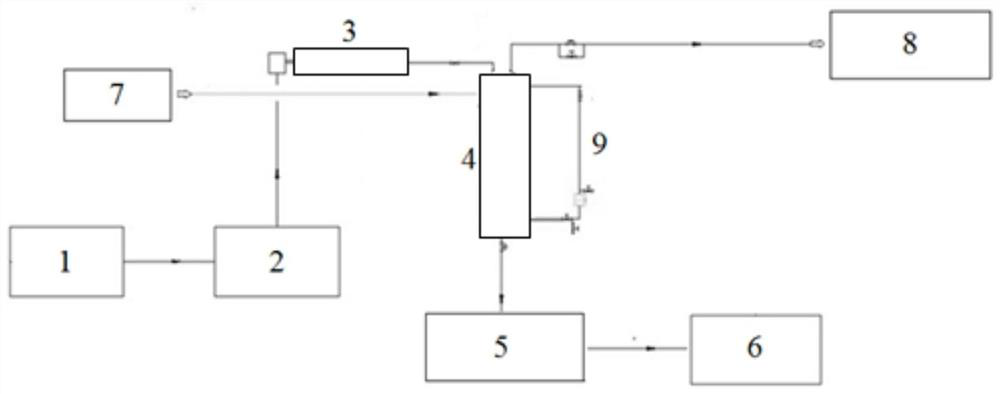

System and method for continuously producing mesophase pitch

InactiveCN111944552AImprove uniformitySimple processWorking-up pitch/asphalt/bitumen by meltingWorking-up pitch/asphalt/bitumen by solidifying/disintegratingReaction temperatureMechanical engineering

The invention relates to the field of production of mesophase pitch, in particular to a system and a method for continuously producing mesophase pitch. The system comprises a feeding device and a reaction device which are connected in sequence, wherein the feeding device is used for melting raw materials and heating the raw materials to a reaction temperature, and the reaction device is used for converting the materials from the feeding device into mesophase pitch in a free downward flowing mode under a non-stirring condition; the reaction device is a cylindrical container with a height-diameter ratio of greater than 3; the reaction device comprises a liquid material inlet located in the upper part of the reaction device, and a liquid material outlet is located in the bottom of the reaction device; and a stirring part and a filler are not arranged in the reaction device. The system and the method provided by the invention can further improve the uniformity of an obtained mesophase pitch product and the content of the mesophase pitch on the premise of ensuring good comprehensive performance of the obtained mesophase pitch product.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

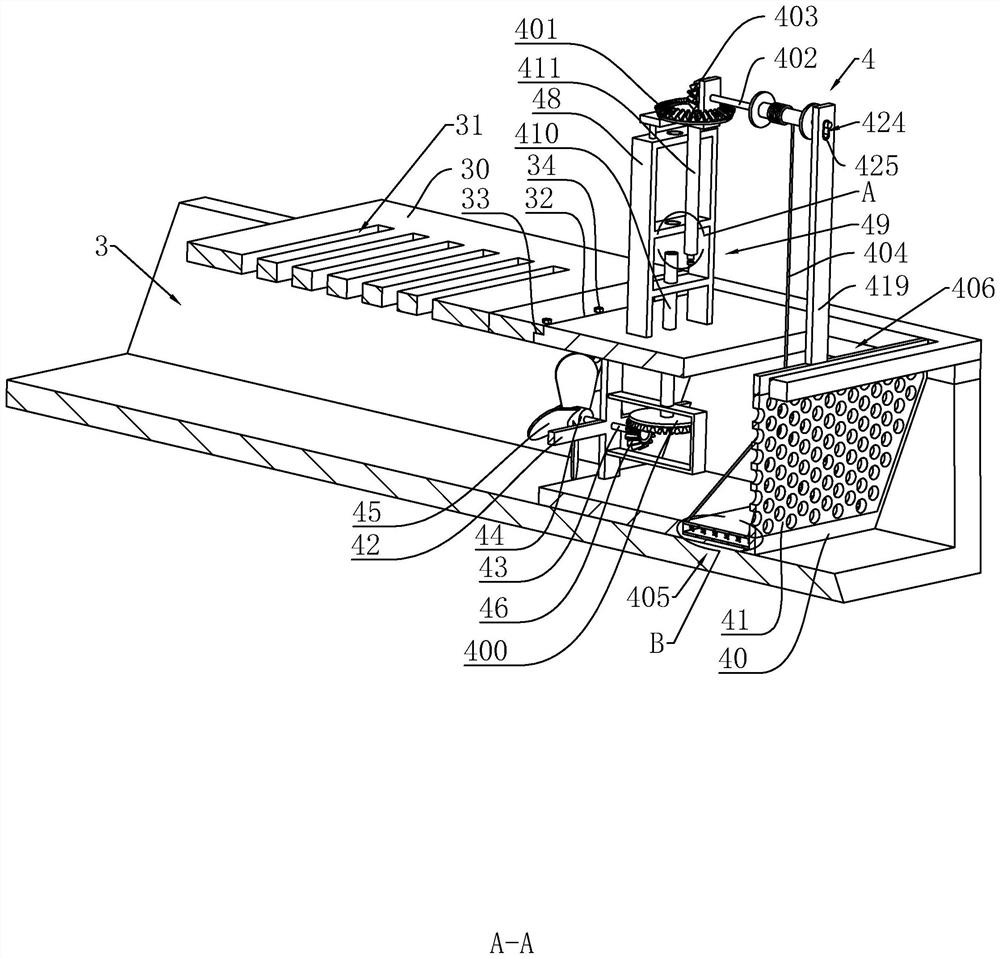

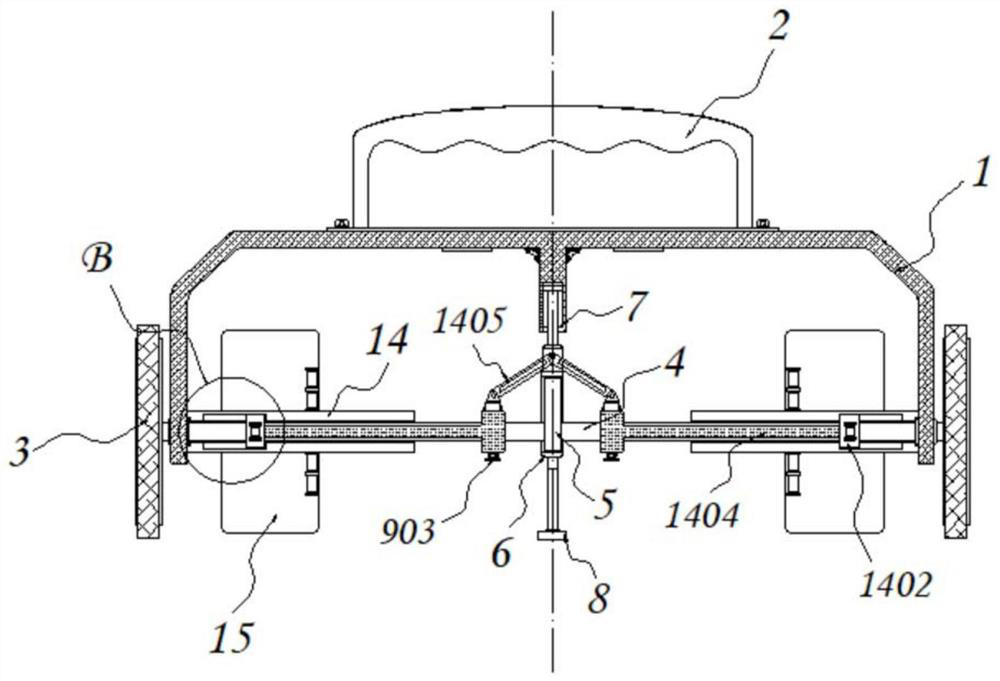

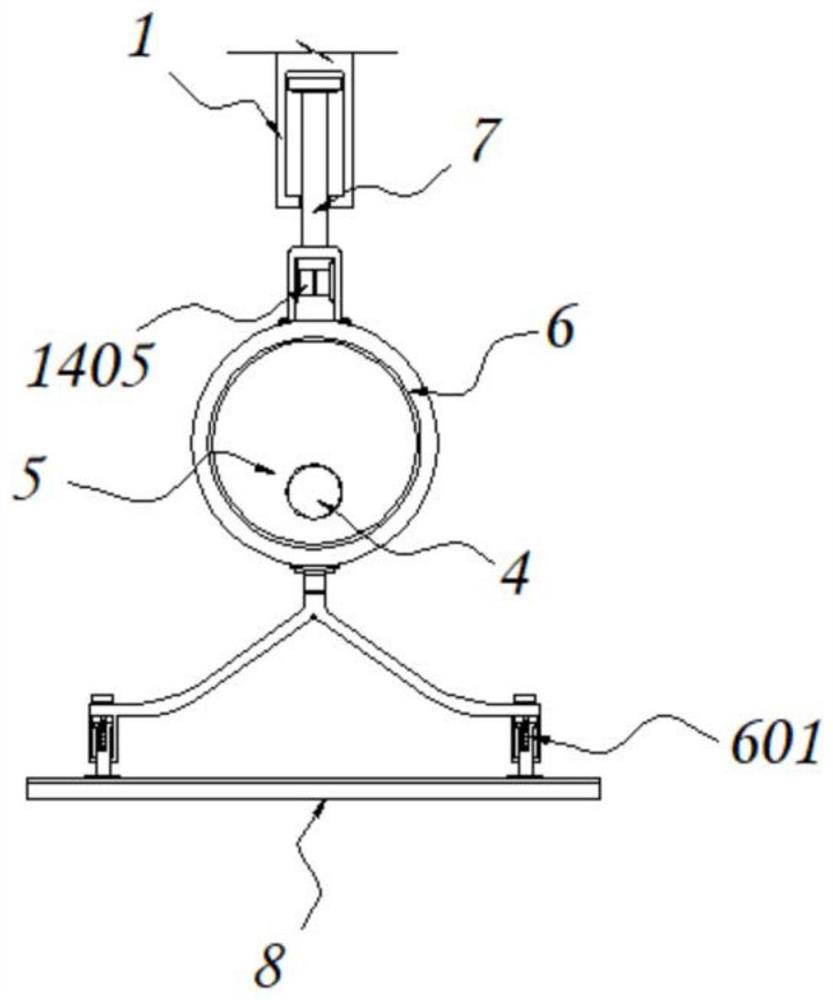

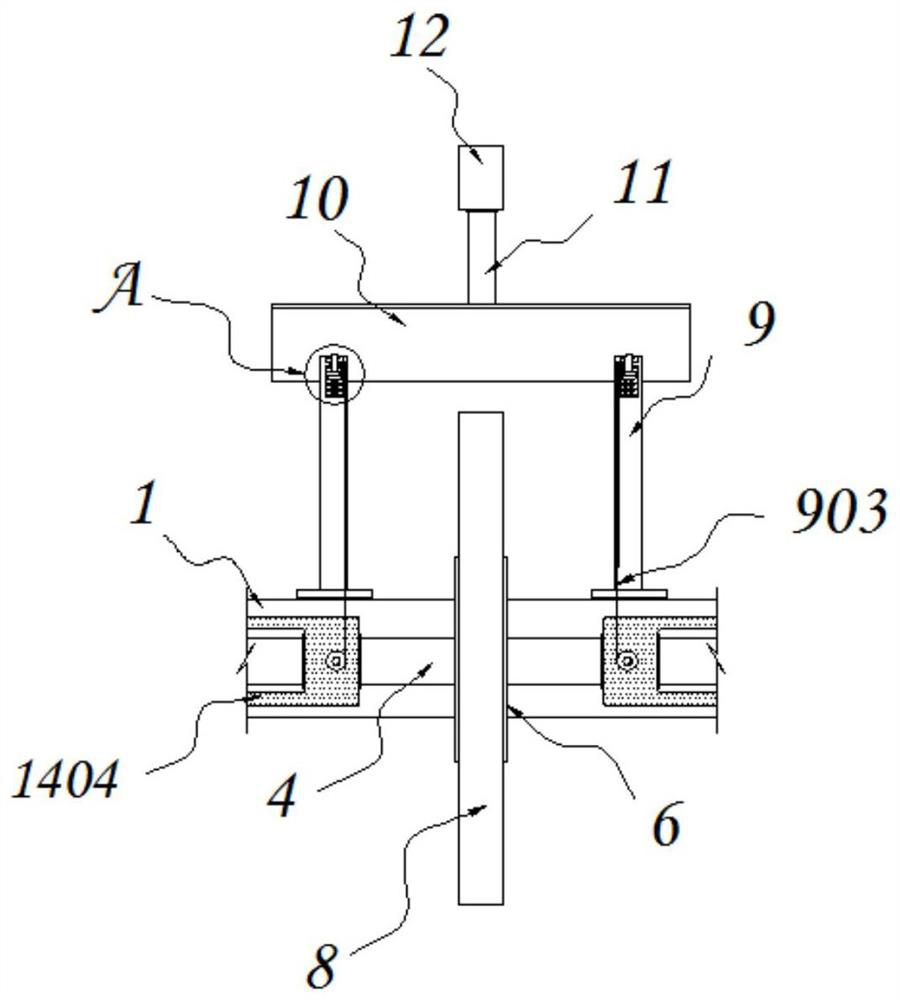

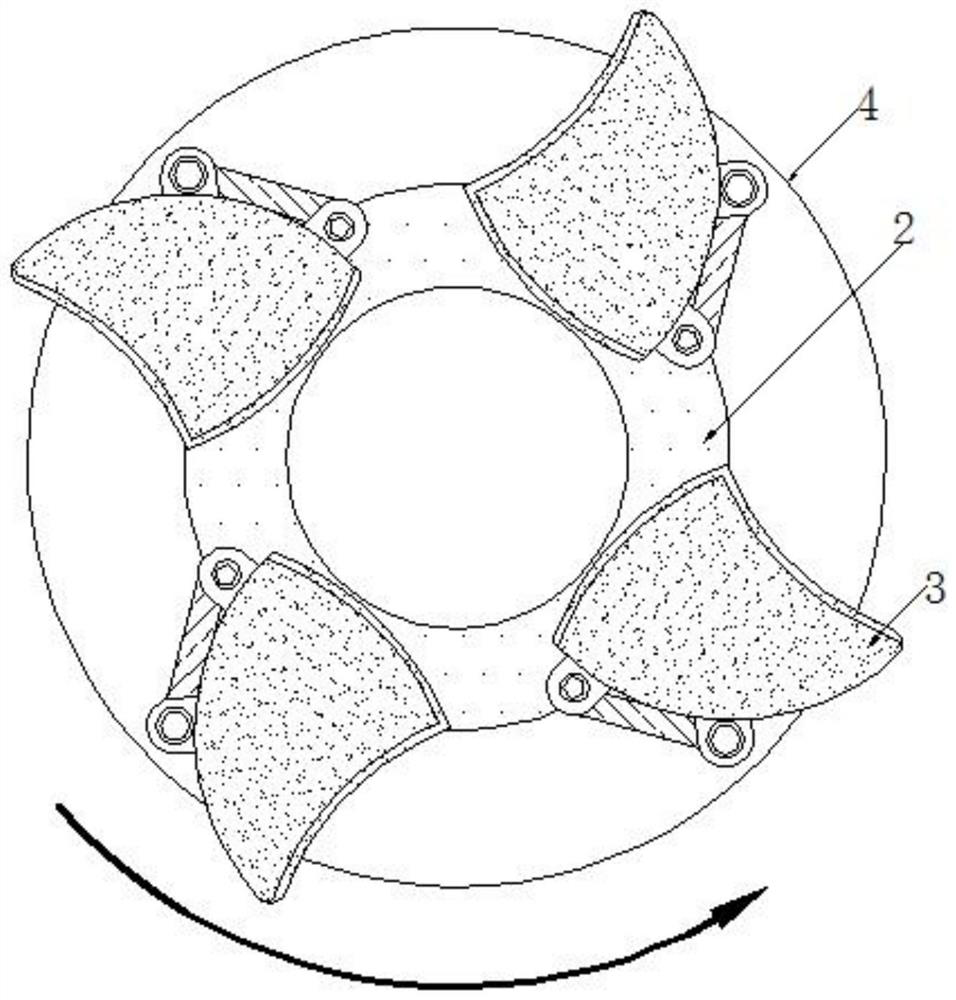

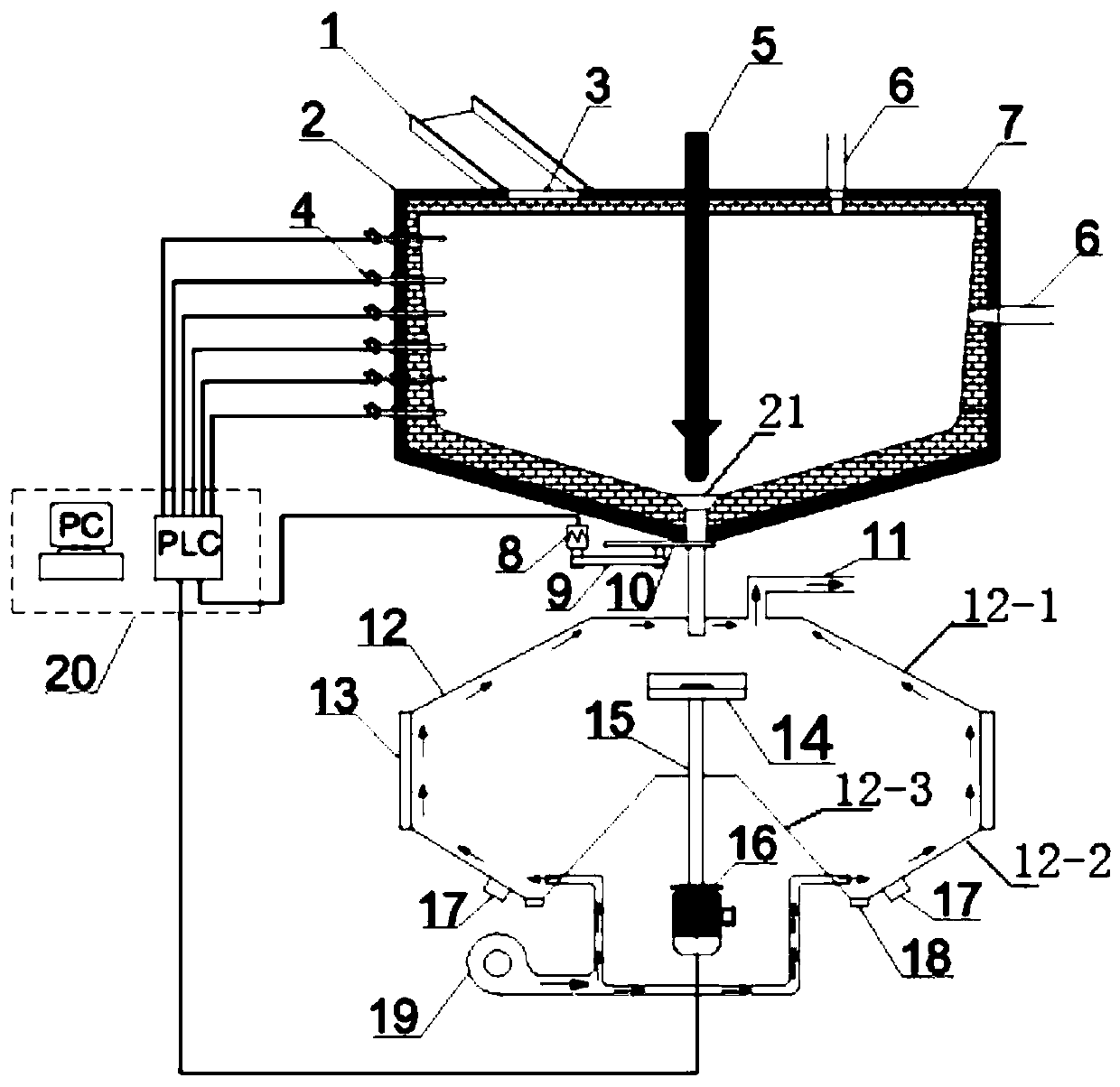

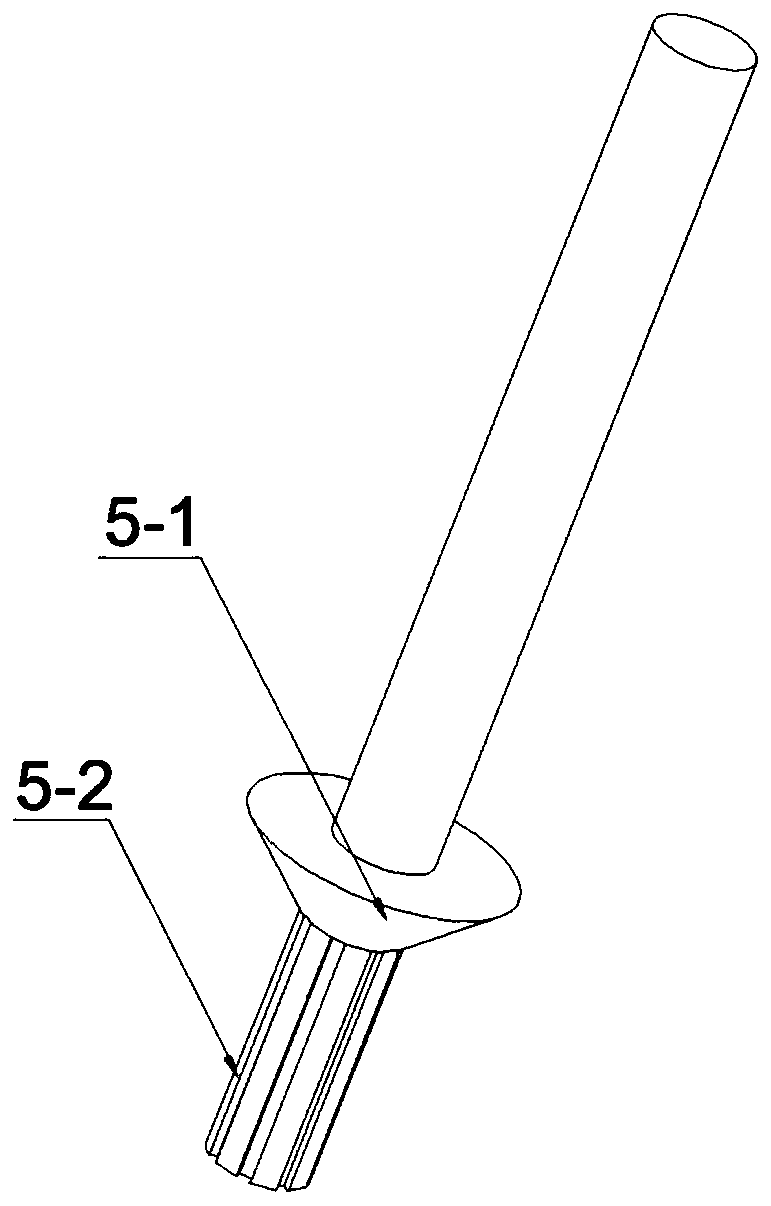

Molten slag mechanical centrifugal graining system and method

InactiveCN109880950AEasy to controlLess or avoidRecycling and recovery technologiesIntelligent controlMolten slag

The invention provides a molten slag mechanical centrifugal graining system and method. The molten slag mechanical centrifugal graining system comprises a tundish, a slag discharging adjusting deviceand a graining unit; liquid level detection devices are sequentially arranged on the side wall of the tundish from top to bottom; the slag discharging adjusting device is used for adjusting the size of a slag outlet, and the graining unit is arranged right below the slag outlet and is used for graining the molten slag; the molten slag mechanical centrifugal graining system further comprises an intelligent control unit, and the intelligent control unit is connected with the liquid level detection devices, the slag discharging adjusting device and the graining unit. Through the arrangement of the liquid level detection devices, the size of caliber is controlled according to detected liquid level signals, the control of the slag discharge flow of the slag outlet of the tundish can be realized, the granulating speed is set according to the flow, better matching of the slag flow and the graining rotation speed can be achieved, granulation can be uniform, slag wool or larger massive solids generated by granulated particles can be less or avoided, and better granulation effect can be achieved.

Owner:QINGDAO UNIV +1

Mesh belt type composite foaming device for plastic floor production

ActiveCN112248349APlay the role of forced cutting and mixingQuality improvementDispersed particle filtrationFoaming agentMechanical engineering

The invention discloses a mesh belt type composite foaming device for plastic floor production, and relates to the technical field of plastic floor production. The mesh belt type composite foaming device for plastic floor production comprises a barrel, a stirring ventilation mechanism, an extrusion mechanism and a circulation mechanism are arranged on the barrel, two sets of arc-shaped frames arewelded to the top of the barrel and are symmetrically distributed, an installation frame is welded to the outer surface of the bottom of the barrel, and a sealing cover is installed at an opening at the front side of the barrel in a threaded manner. According to the mesh belt type composite foaming device for plastic floor production, a stainless steel mesh belt extrudes a plastic raw material anda foaming agent which are reacting in the barrel in a reciprocating manner, the plastic raw material and the foaming agent continuously penetrate through gaps in the stainless steel mesh belt to achieve forced cutting and mixing, and therefore the plastic foaming quality of the device is improved; and the reaction efficiency rate is increased, the reaction time is shortened, the practicability and production efficiency of the device are improved, and application and popularization are facilitated.

Cigarette ash and butt collector of hospital public washroom

The invention provides a cigarette ash and butt collector of a hospital public washroom. The cigarette ash and butt collector comprises a base, a fixing tray and a spring, wherein rectangular side guard plates are vertically and fixedly arranged on the side edges of the left end and right end of the top of the base, the rear end of the base is a semicircular structure, and a semi-arc-shaped rear back plate is fixedly arranged on the upward portion of the semi-arc edge of the top of the rear end of the base; the middles of the inner side walls between the two side guard plates are slidably connected with smoke smell absorption boxes respectively through two side sliding blocks, and the top of the base between the two smoke smell absorption boxes is fixedly provided with a cuboid-shaped cigarette ash collection body. The cigarette ash and butt collector of the hospital public washroom has the advantages that through the mutual cooperation of the above structures, the cigarette ash and butt collector of the hospital public washroom is achieved, after a smoker smokes, the cigarette ash and butt collector can eliminate smoke within the shortest time to avoid affecting other entering persons, the use is safe, spatial isolation can be rapidly carried out through a sealing block to avoid the occurrence of fire disasters, and the cigarette ashes generated during smoking can be centrallytreated.

Owner:WUHU HUIYU TRADING CO LTD

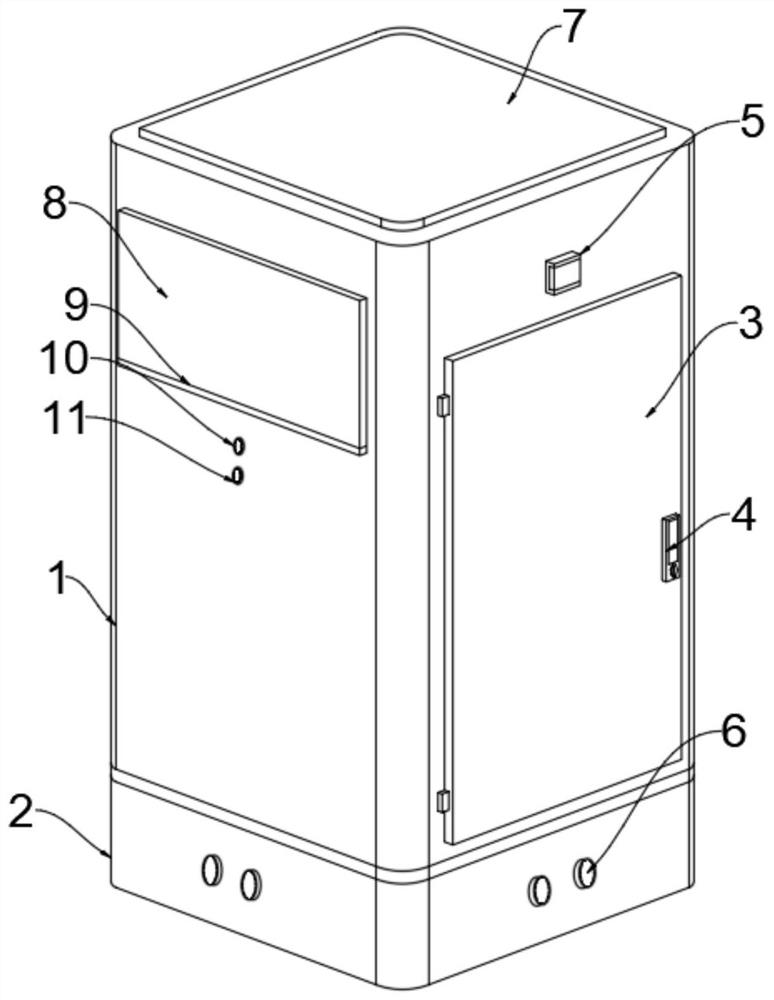

High-precision environment-friendly medical human body induction flip intercommunication garbage cabinet

PendingCN114684511AAchieve normal operationAvoid collisionRefuse receptaclesWaste collection and transferComputer hardwareLaser transmitter

The invention discloses a high-precision environment-friendly medical human body induction flip intercommunication garbage cabinet, relates to the technical field of medical garbage cabinets, and aims to solve the problems that an existing medical intercommunication garbage cabinet can only remind people to clean garbage when the garbage in the garbage cabinet is too much, cannot be adjusted autonomously and is high in manpower consumption. A base is installed at the lower end of the garbage cabinet body, a cabinet door is installed at the front end of the garbage cabinet body, an infrared sensor is arranged above the cabinet door, the rear end of the infrared sensor is fixedly connected with the garbage cabinet body, a material uniformizing opening is formed in one side of the garbage cabinet body, and a transmission frame is installed on the outer wall of the material uniformizing opening. A sliding cover is arranged outside the transmission frame, and a laser transmitter is arranged below the transmission frame.

Owner:安徽诚远医疗科技有限公司

Milling machine

ActiveCN110315114AReduce the temperatureAvoid it happening againMilling machinesMaintainance and safety accessoriesMilling cutterEngineering

The invention relates to the technical field of machine tools, and discloses a milling machine. According to the technical scheme, the milling machine comprises a machine frame, a clamping assembly and a milling assembly, wherein a pushing air cylinder is arranged on the machine frame, the machine frame is connected with a moving plate in a sliding mode, a piston rod of the pushing air cylinder isfixedly connected with the moving plate and drives the moving plate to move towards one side close to the milling assembly, and the moving plate is rotationally connected with a mounting plate through a rotating shaft; the clamping assembly comprises a mounting box arranged on the mounting plate, a mounting shaft rotationally connected with the mounting box and a rotating assembly which drives the mounting shaft to rotate, a workpiece is mounted on the mounting shaft, a driving cylinder is mounted on the moving plate, a driving ring is connected to a piston rod of the driving cylinder, and afixing shaft rotationally connected with the driving ring is fixed on the mounting plate; and the milling assembly comprises a milling cutter, a driving motor used for driving the milling cutter to rotate, and a lifting assembly used for driving the milling cutter to ascend and descend. The milling machine has the advantages that grooves with different angles can be machined on the workpiece, andthe application range is wide.

Owner:浙江成洲合金工具有限公司

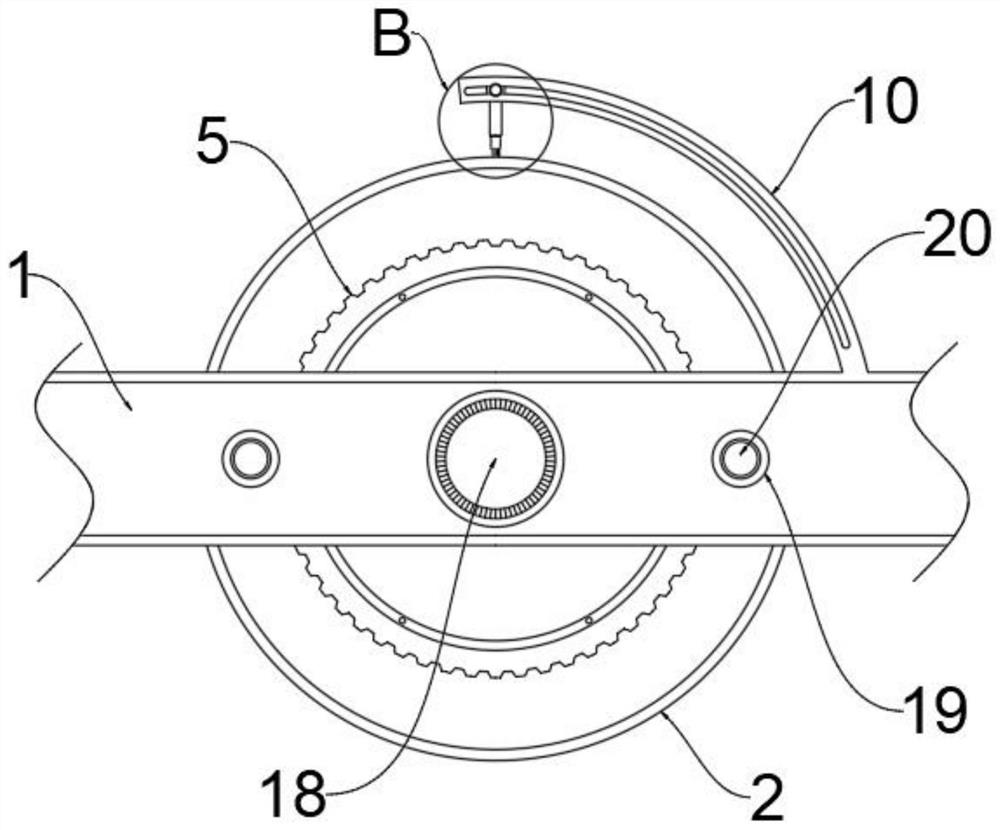

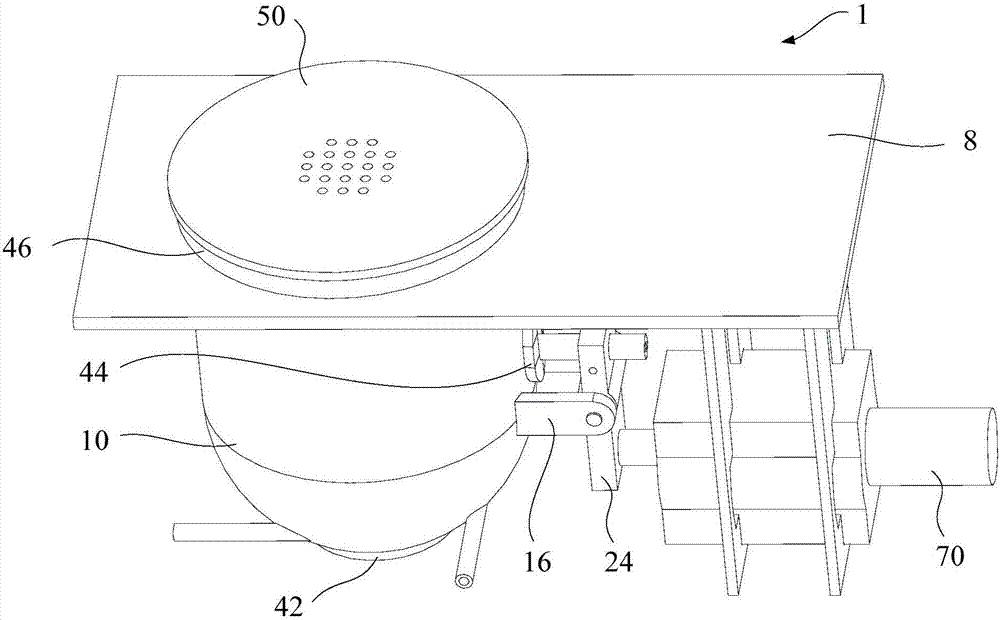

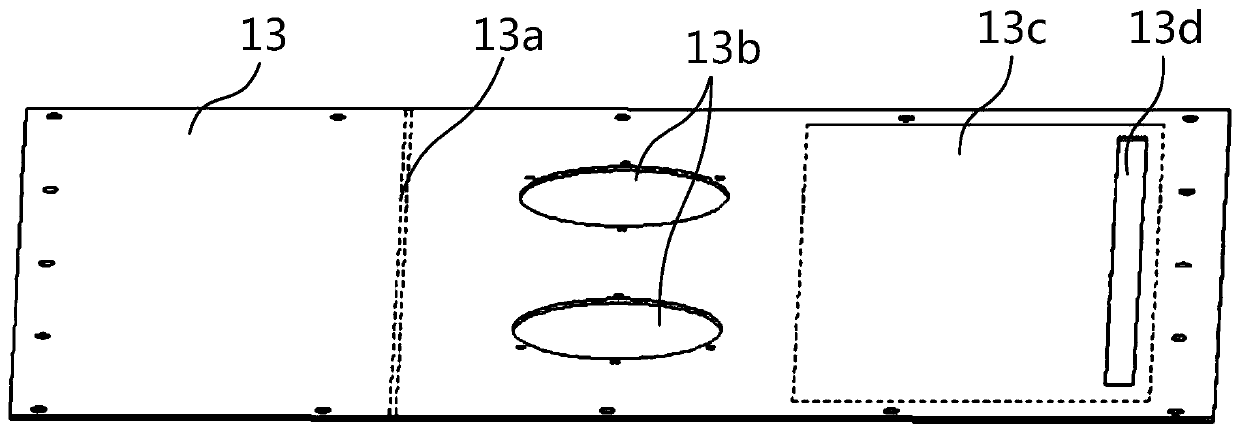

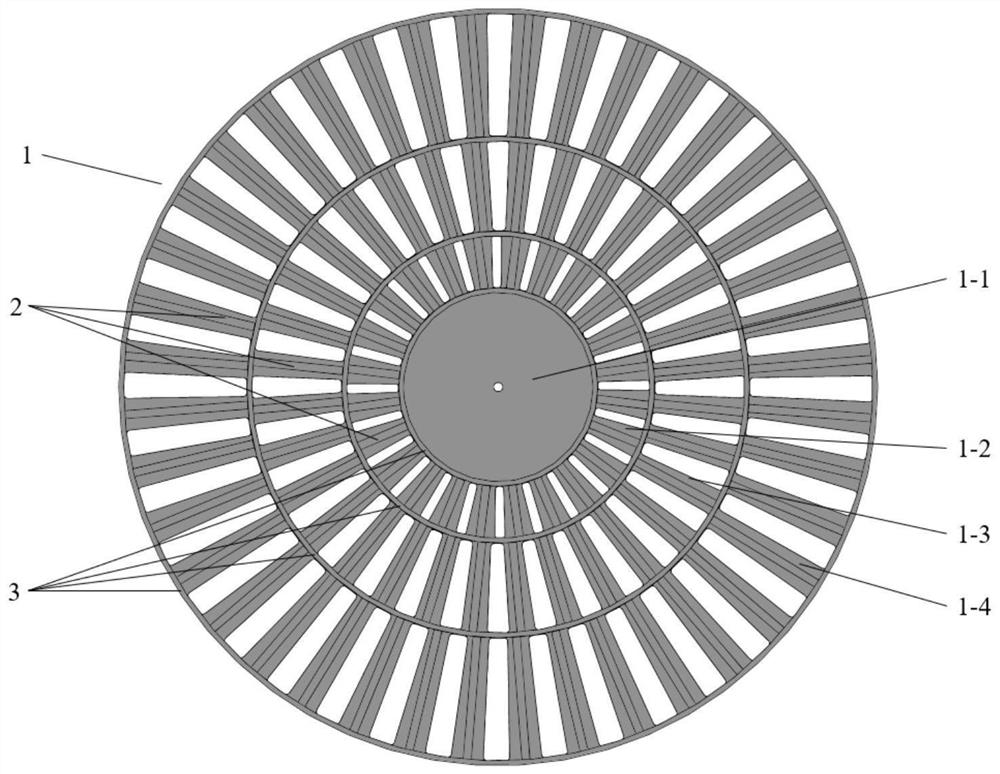

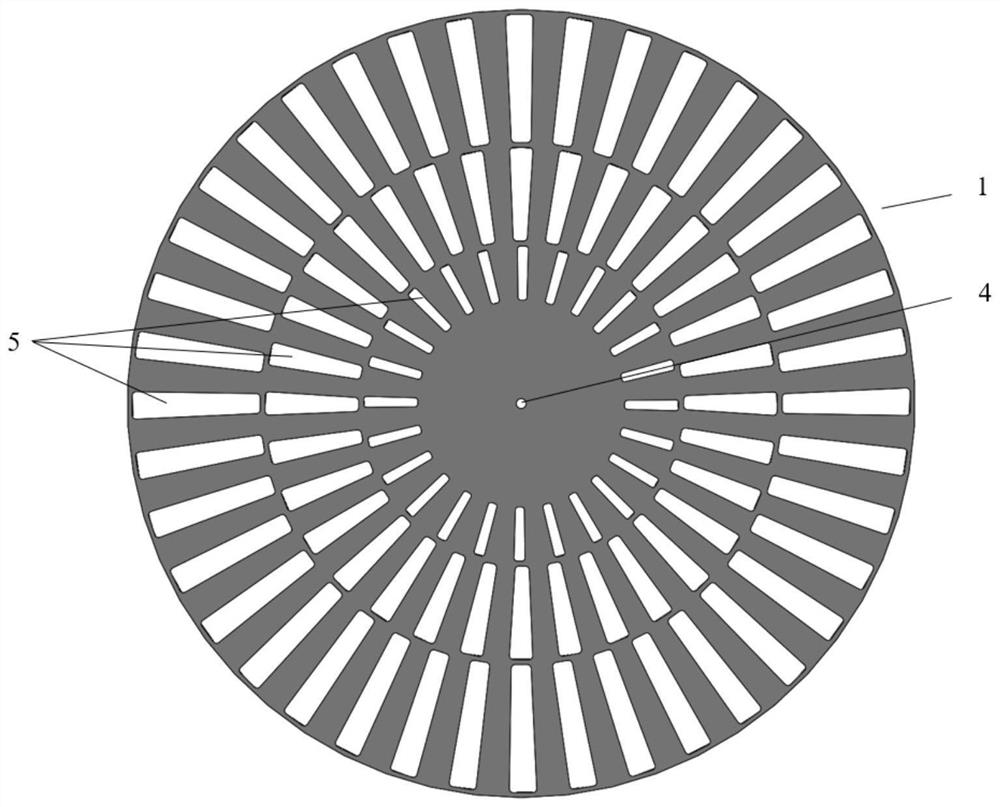

A flow-disturbing dynamic separation network disk used in range hoods

ActiveCN112664988BAvoid excessive pressure dropReduce cleanup burdenDomestic stoves or rangesLighting and heating apparatusSuction forceFuel tank

A flow-disturbing dynamic separation network disk used inside the range hood, including an integrated perforated disk with four rings from the center to the surroundings. The second ring of hole ring and the third ring of hole ring; four rings of unequal diameter baffle mounting rings are installed under the hole plate, and spoiler baffles are distributed between the unequal diameter baffle mounting rings; the invention rotates at high speed, A vortex zone is formed on the suction side of the spoiler. Except for the soot particles that directly collide with the pressure side of the spoiler, most of the remaining soot particles enter the vortex zone and continue to maintain the original motion state to be captured, and the other part enters the opening. The opening channels of the orifice plate are captured, and all the captured particles are finally collected into the oil tank to achieve separation; the invention creates a vortex area through the spoiler, increases the capture rate of oil fume particles, and greatly improves the removal rate of oil fume particles on the order of 10 μm .

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com