Metallurgical mechanical equipment convenient for dust transportation

A technology of mechanical equipment and dust, which is applied in the field of metallurgical machinery and equipment, can solve the problems of increasing the workload of operators, the difficulty of cleaning large operations, and affecting the working environment, so as to avoid the blockage of equipment transportation, reduce the burden of cleaning, and achieve good results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

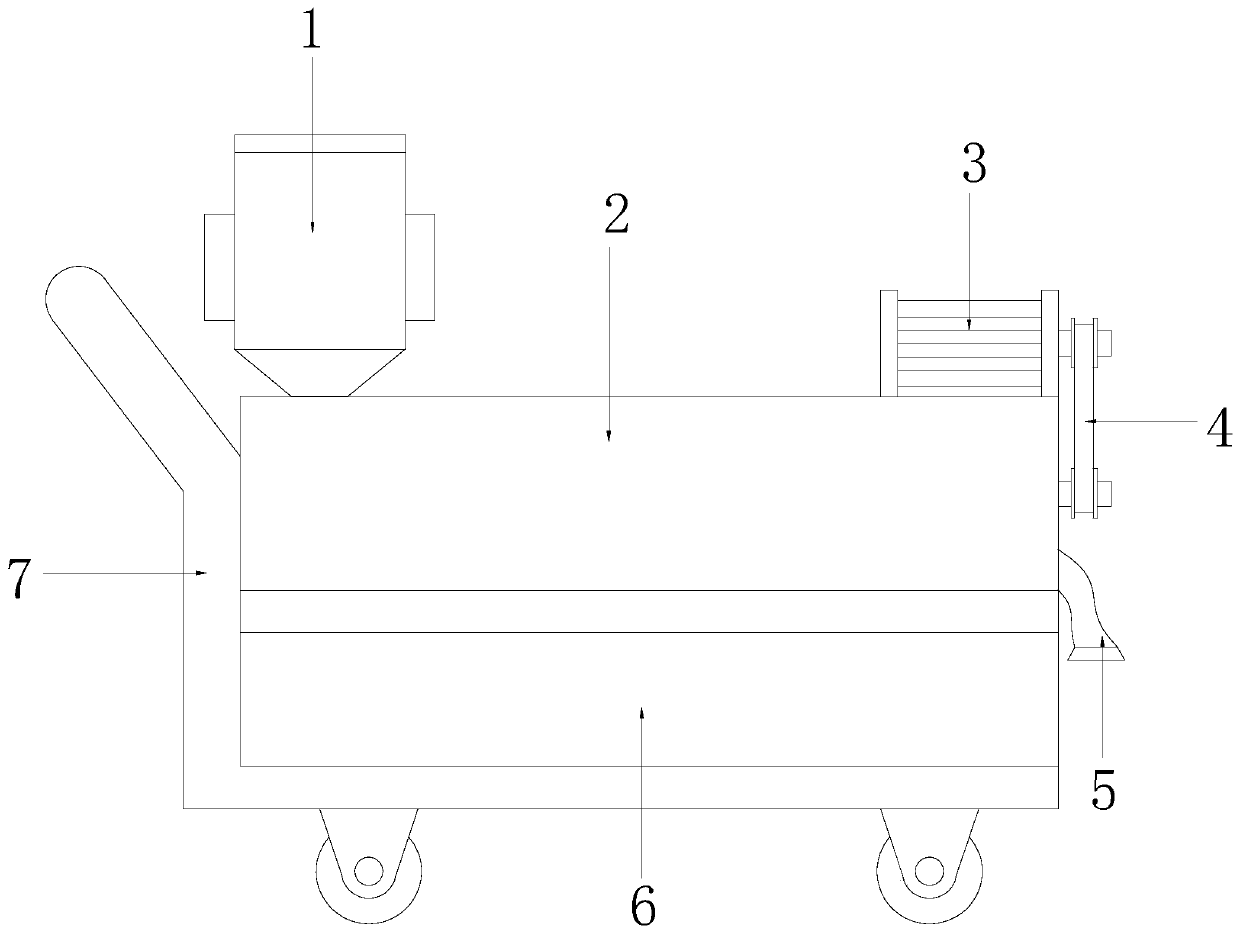

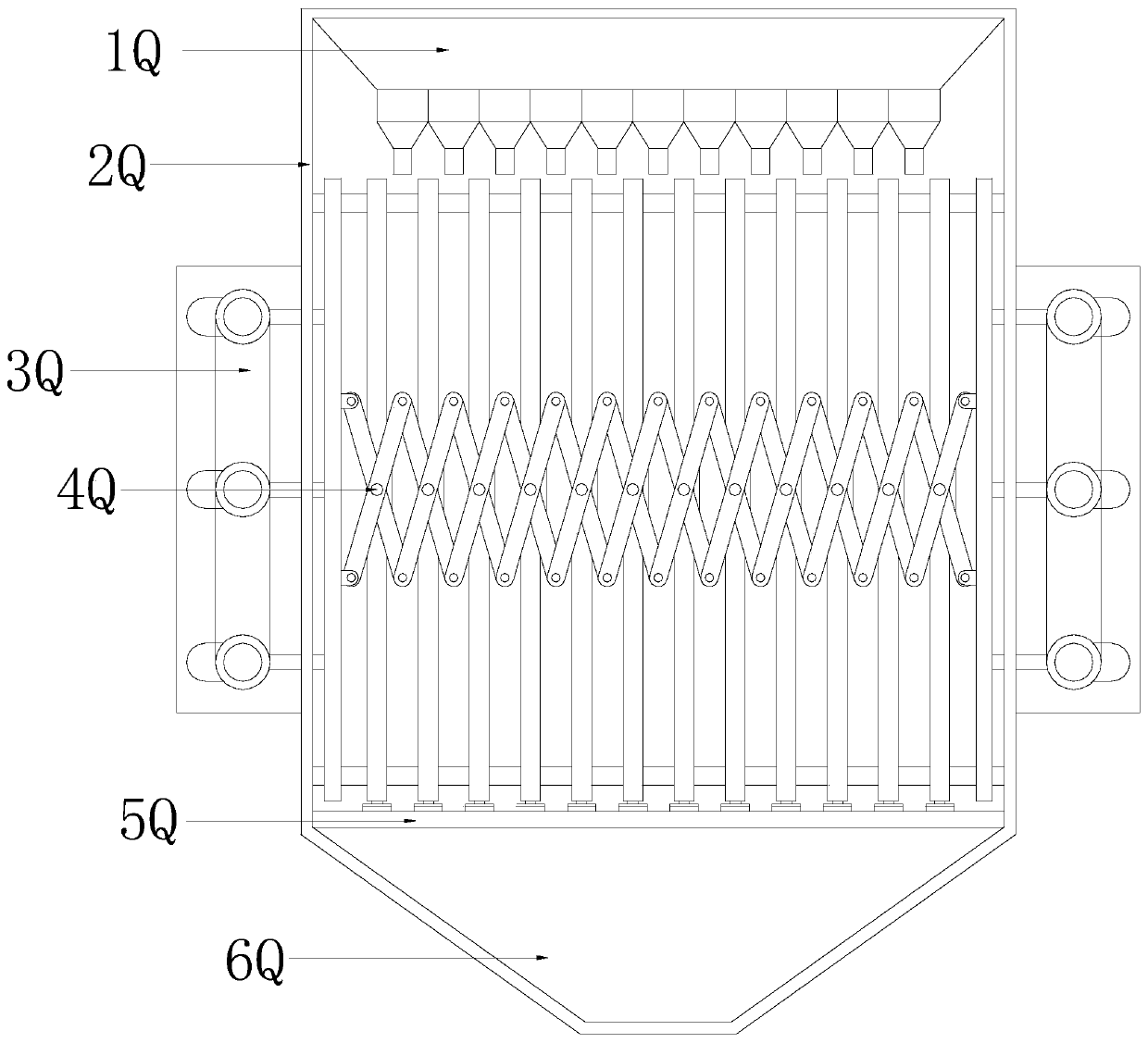

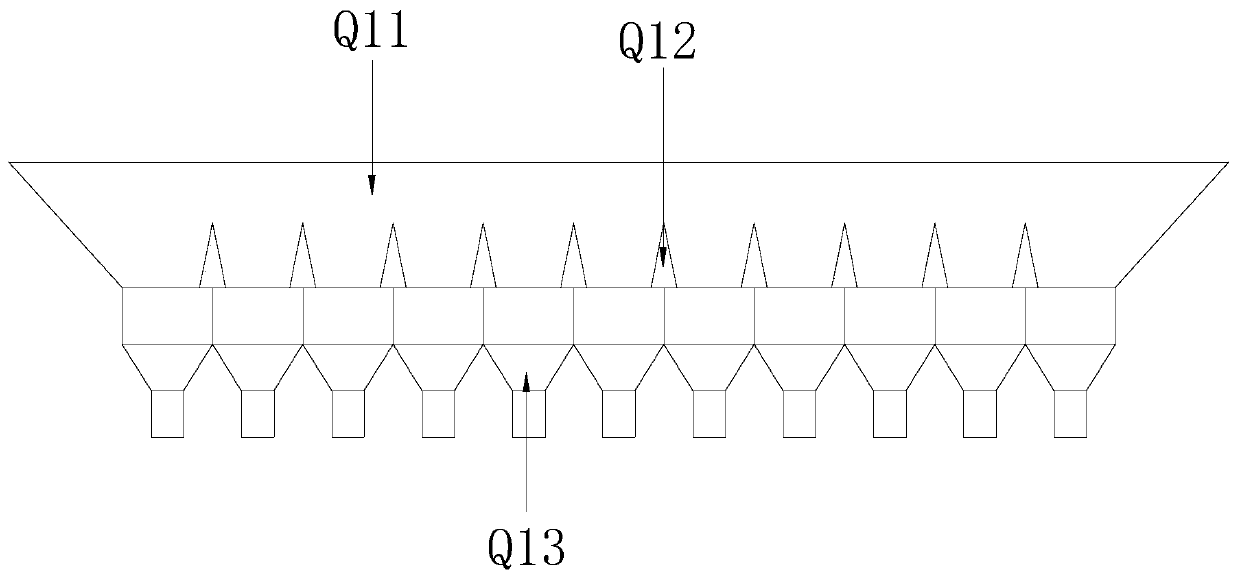

[0037] see Figure 1-5, the present invention provides a technical solution for metallurgical machinery and equipment that is convenient for dust transportation: its structure includes a dust inlet device 1, a screw dust conveyor 2, a high-efficiency energy-saving motor 3, a transmission component 4, a dust outlet pipe 5, a lifting platform 6, a hand push The mobile base 7 is mechanically connected to the lifting platform 6 on the hand-push mobile base 7, and the screw dust conveyor 2 is fixed on the lifting platform 6, and one end of the screw dust conveyor 2 is connected to the high-efficiency energy-saving motor 3 through the transmission assembly 4 The transmission connection is carried out, and the other end is connected with the dust inlet device 1. The setting of the lifting table 6 makes the screw dust conveyor 2 have a height-adjustable function, and the operator can adjust the height of the inlet and outlet materials according to the transportation situation of the ma...

Embodiment 2

[0044] see Figure 1-7 , the present invention provides a technical solution for metallurgical machinery and equipment that is convenient for dust transportation: its structure includes a dust inlet device 1, a screw dust conveyor 2, a high-efficiency energy-saving motor 3, a transmission component 4, a dust outlet pipe 5, a lifting platform 6, a hand push The mobile base 7 is mechanically connected to the lifting platform 6 on the hand-push mobile base 7, and the screw dust conveyor 2 is fixed on the lifting platform 6, and one end of the screw dust conveyor 2 is connected to the high-efficiency energy-saving motor 3 through the transmission assembly 4 The transmission connection is carried out, and the other end is connected with the dust inlet device 1. The setting of the lifting table 6 makes the screw dust conveyor 2 have a height-adjustable function, and the operator can adjust the height of the inlet and outlet materials according to the transportation situation of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com