Equipment and method for preparing continuous carbon fiber reinforcement PEEK thermoplastic preimpregnating belt

A technology of carbon fiber and prepreg tape, applied in the direction of coating, etc., can solve the problems of unstable apparent physical properties and basic mechanical properties of prepreg tape, difficulty in meeting the requirements of composite material preparation process, and difficulty in achieving full infiltration of continuous fibers , to achieve ideal thermal insulation effect, improve impregnation effect, and release residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

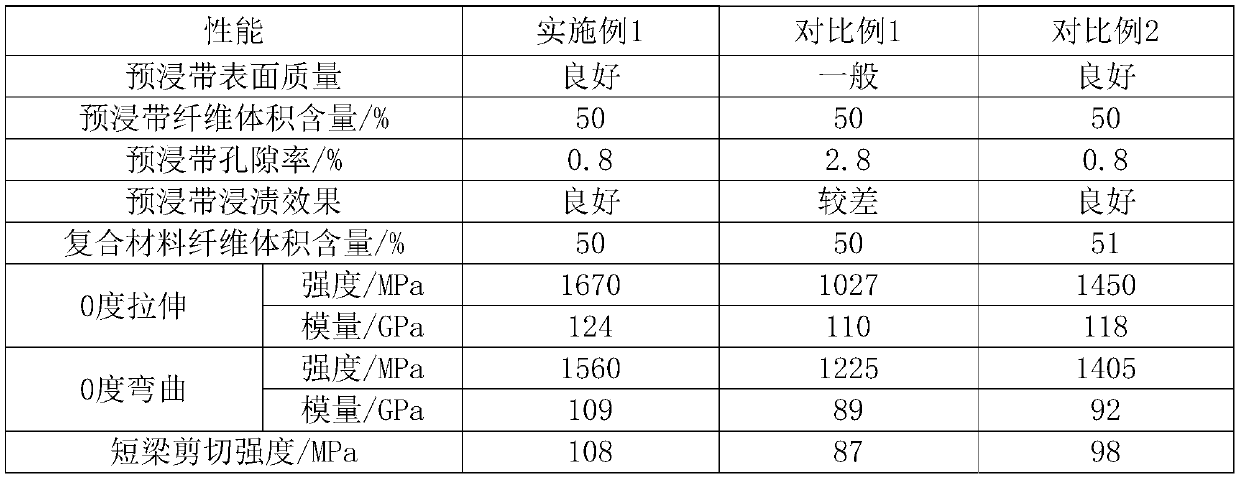

[0035] The present embodiment provides a production line preparation method of continuous carbon fiber reinforced PEEK resin prepreg tape, and the raw material charging ratio for preparing the continuous carbon fiber reinforced PEEK resin prepreg tape is composed of the following components by weight:

[0036] Continuous carbon fiber (Japan Toray T700SC, 12K continuous carbon fiber) 50wt%,

[0037] PEEK resin (viscosity is 400Pa·s at 380℃) 50wt%;

[0038] The preparation process includes the following steps:

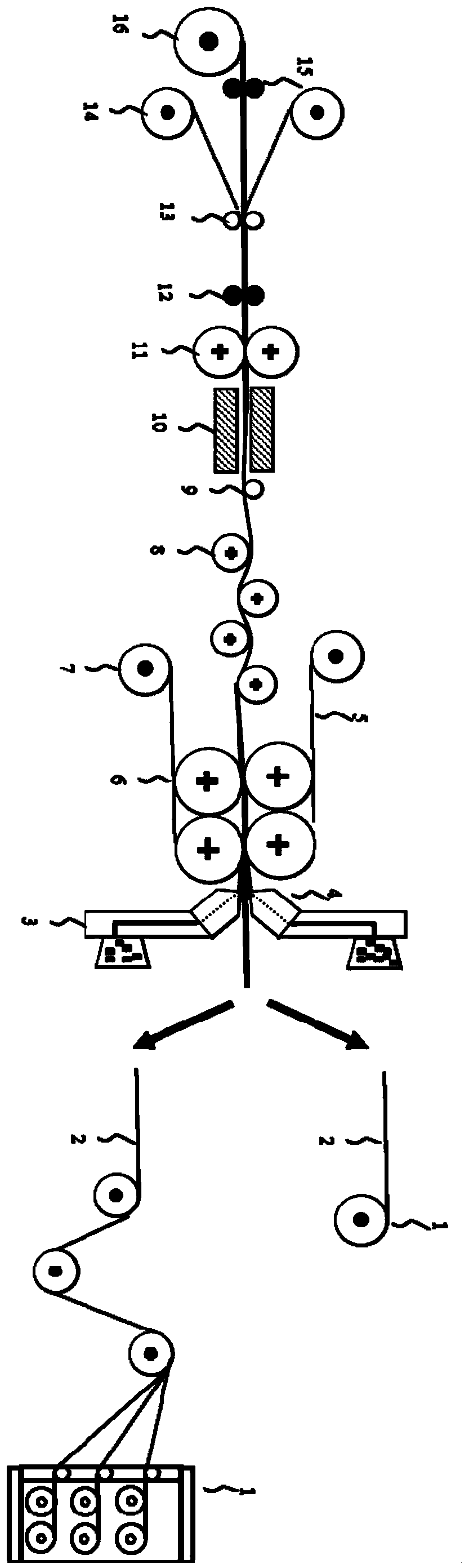

[0039] Firstly, the continuous fiber yarn 2 with a width of 250mm is placed on the carbon fiber unwinding device 1, and the continuous carbon fiber is preheated by an infrared drying tunnel to slowly heat up, and the continuous carbon fiber yarn 2 is drawn under the action of traction to the extruder. At the die head; add the used PEEK resin pellets or powder into the extruder 3, set the extruder screw speed to 15r / min, and set the extruder temperature to 400°C. The re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com