A flow-disturbing dynamic separation network disk used in range hoods

A technology of range hood and flow pattern, which is applied in the direction of removing lampblack, application, household stove, etc. It can solve the problems of increasing the capture probability of lampblack particles and increasing the pressure drop, so as to reduce the cleaning burden and avoid the effect of excessive pressure drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present application will be further described in detail below through specific embodiments in conjunction with the accompanying drawings.

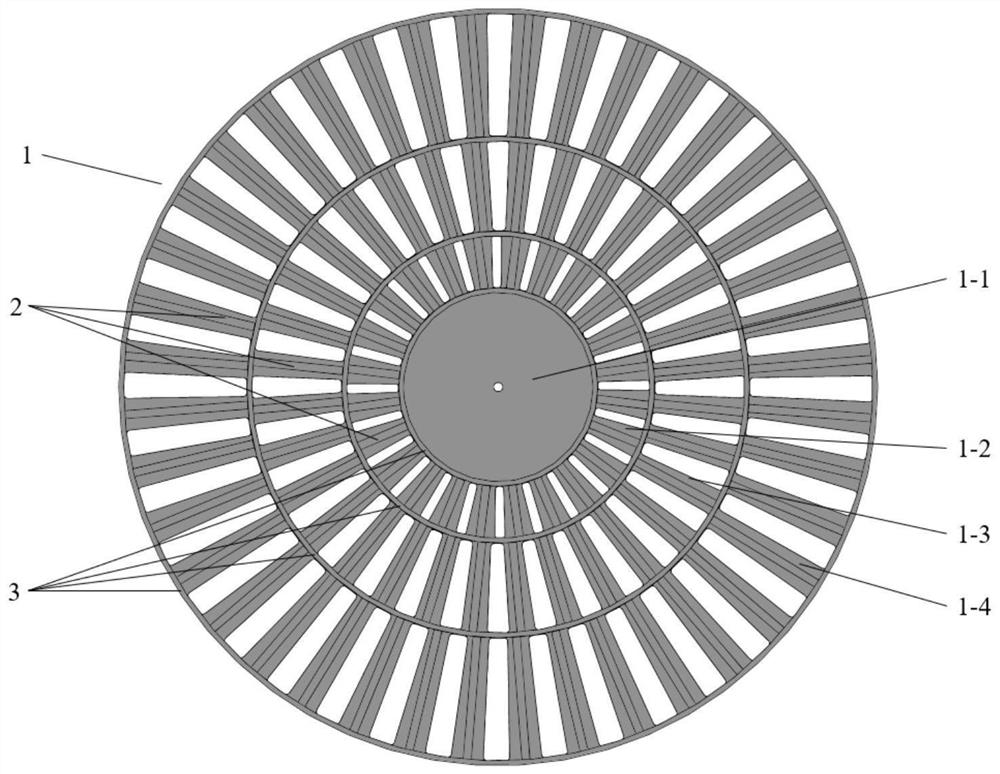

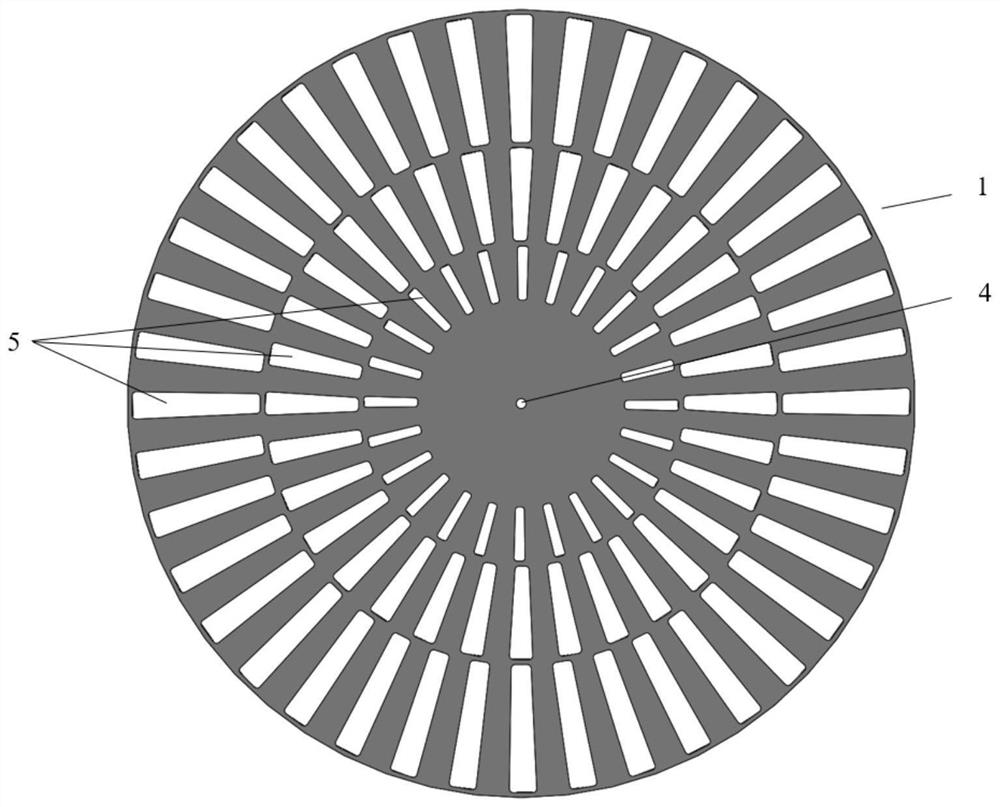

[0022] refer to figure 1 , figure 2 , a spoiler type dynamic separation screen disk for the interior of the range hood, including an integrated perforated disk 1 with a four-circle structure from the center to the surrounding, and four circles of unequal diameter baffle mounting rings are installed under the perforated disk 1 3. Distribute spoiler baffles 2 between installation rings 3 of unequal diameter baffles.

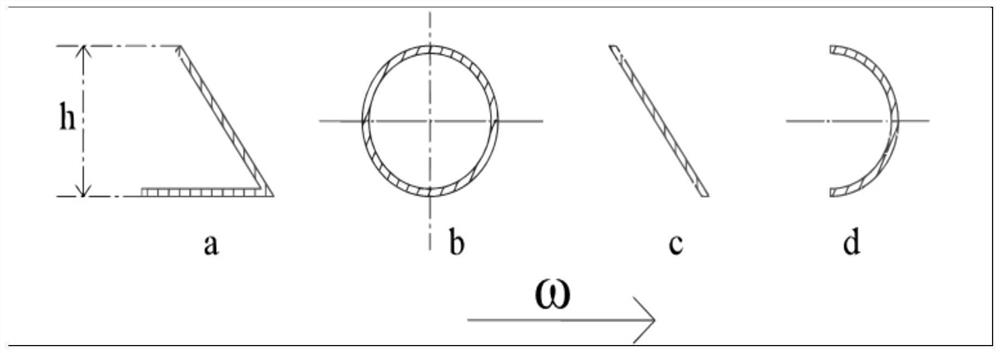

[0023] refer to image 3 , the spoiler baffles 2 are angular, spoke-shaped, oblique-shaped, "C"-shaped, or other baffle types with large changes in the pressure surface and the suction surface. Most of the soot particles directly collide with the spoiler baffle 2 or are captured by the eddy current area generated by the spoiler baffle 2, so as to prevent the soot particles from directly contacting the perforated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com