Heat exchange tube, heat exchanger and air conditioner

A technology of heat exchange tubes and heat exchangers, which is applied in the fields of heat exchange tubes, heat exchangers and air conditioners, can solve the problems of large pressure drop, achieve the effects of reducing heat transfer resistance, strengthening fluid disturbance, and prolonging time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

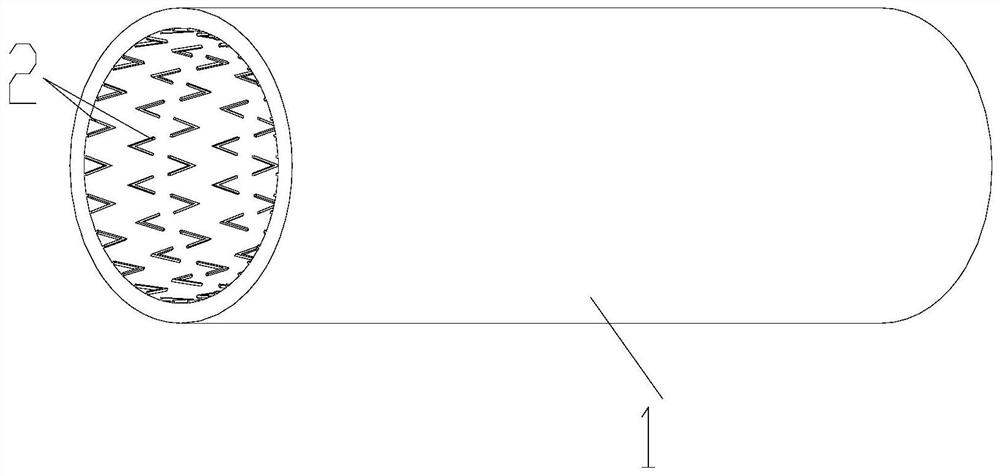

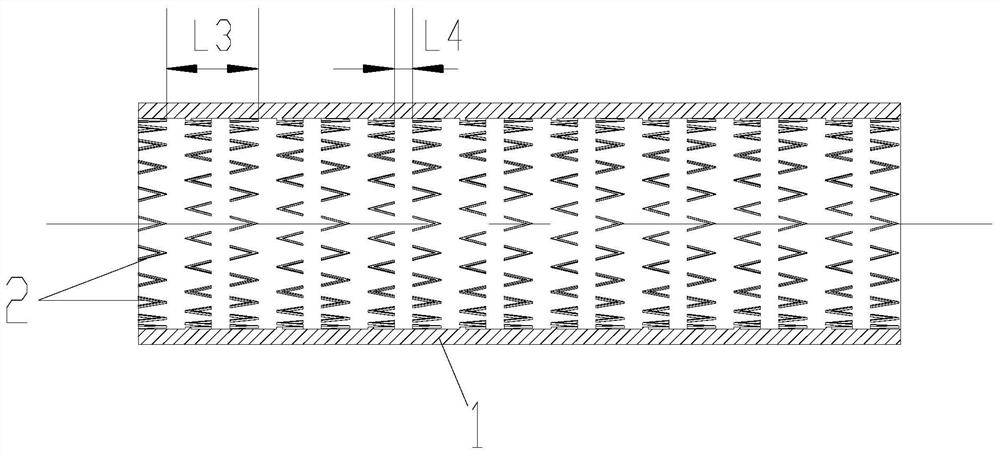

[0043] Such as Figure 1-4 As shown, the present invention provides a heat exchange tube, which includes:

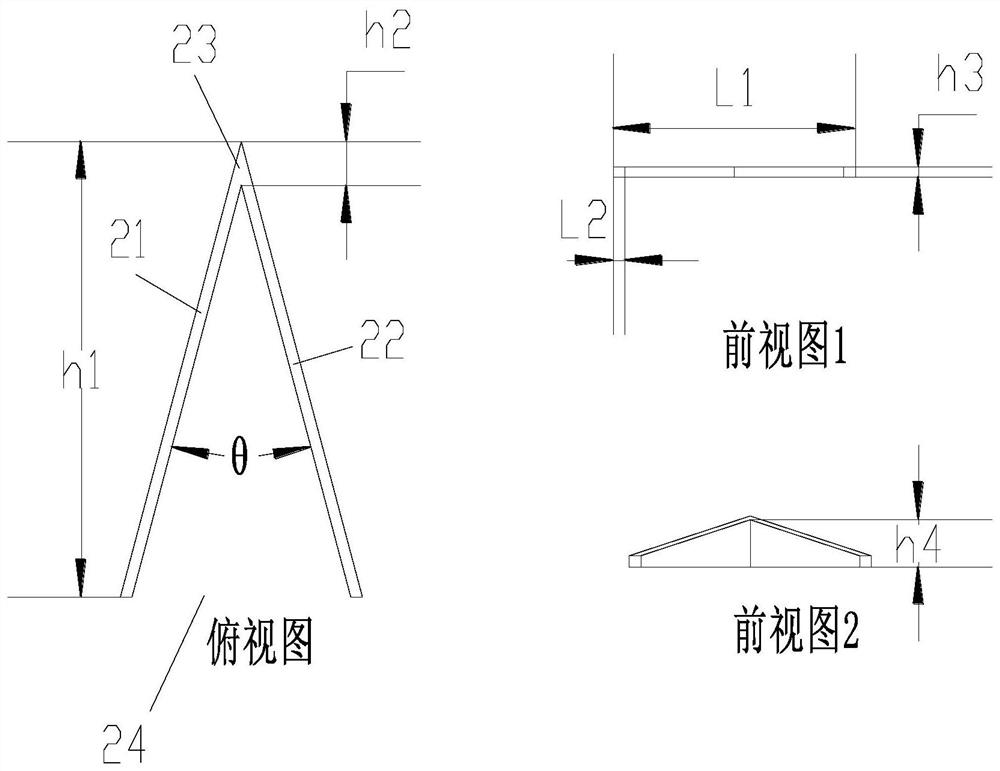

[0044] The tube base 1 and the V-shaped tooth 2 arranged on the inner wall of the tube base 1, the V-shaped tooth 2 is a tooth structure protruding inward from the inner wall of the tube base 1, and perpendicular to the In the section of the extending direction of the V-shaped tooth 2, the shape of the V-shaped tooth 2 is V-shaped.

[0045] In the present invention, a V-shaped tooth structure protruding toward the inside is provided on the inner wall of the tube base of the heat exchange tube. The inner wall becomes larger, and the fluid boundary layer near the wall of the heat exchange tube is stretched thinner, which reduces the heat transfer resistance, so the thickness of the fluid boundary layer in the heat exchange tube can be effectively reduced, thereby increasing the degree of fluid turbulence. The heat exchange in the tube is effectively enhanced, and there i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com