System and method for continuously producing mesophase pitch

A mesophase pitch and asphalt technology, which is applied in the field of mesophase pitch production, can solve the problems of insufficient product uniformity and insufficient content of mesophase pitch, and achieve the effects of ensuring mass production, reducing the degree of coking, and good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

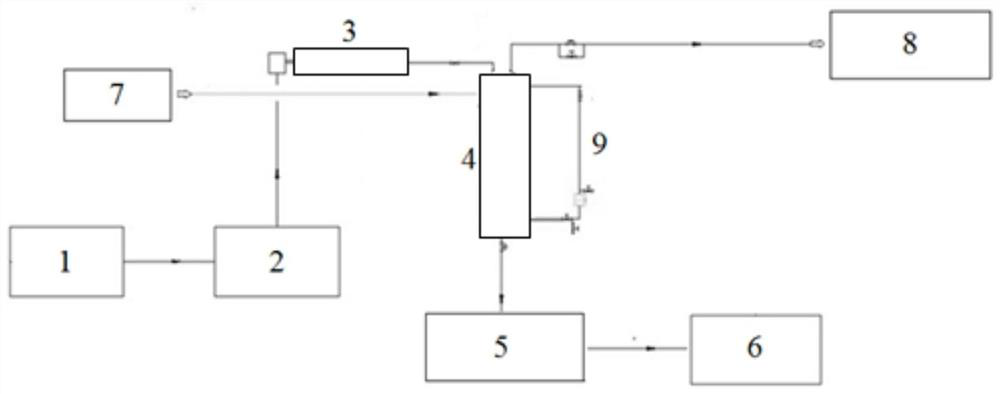

[0052] Pass the raw material medium temperature coal tar pitch into the figure 1 In the system shown, pass through the following devices in sequence and set the following parameters:

[0053] (1) Drying and crushing device 1: firstly, it is dried to a water content of 0.8% by weight through a drying device, and then crushed to a particle size of 3 mm or less using a crushing device;

[0054] (2) lifting metering device 2: the material is lifted to the top of the extruding feeding device 3 at the same level as the liquid material inlet of the reaction device 4, and the weight entering is controlled by a weight loss scale;

[0055] (3) Extrusion feeding device 3 (specifically a twin-screw extruder): the material is melted in the extrusion feeding device 3 and heated to 420°C, and enters the reaction device 4 through the liquid material inlet of the reaction device 4;

[0056] (4) Reaction device 4: The molten material at 420°C reacts spontaneously in the reaction device 4 while...

Embodiment 2

[0065] The same system and operation mode as in Example 1 were used, except that in the reaction device 4, the height was 7, the cross-sectional diameter was 0.5, and the aspect ratio was 14. The residence time of the material in the reaction device 4 is 9 hours by controlling the liquid level.

[0066] Obtain the solid product at the outlet of the output packaging device 6, denoted as A2.

Embodiment 3

[0068] The same system and operation mode as in Example 1 were adopted, except that in the reaction device 4, the height was 10, the cross-sectional diameter was 1.5, and the aspect ratio was 6.7. The residence time of the material in the reaction device 4 is 12 hours by controlling the liquid level.

[0069] Obtain the solid product at the outlet of the output packaging device 6, denoted as A3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com