Automatic sizing machine

A sizing machine and automatic technology, applied in the field of spinning yarn processing device and automatic sizing machine, can solve the problems of changing the sizing method, increasing the labor intensity of operators, reducing production efficiency, etc. The effect of maintaining the practicality of the mechanism and improving the production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

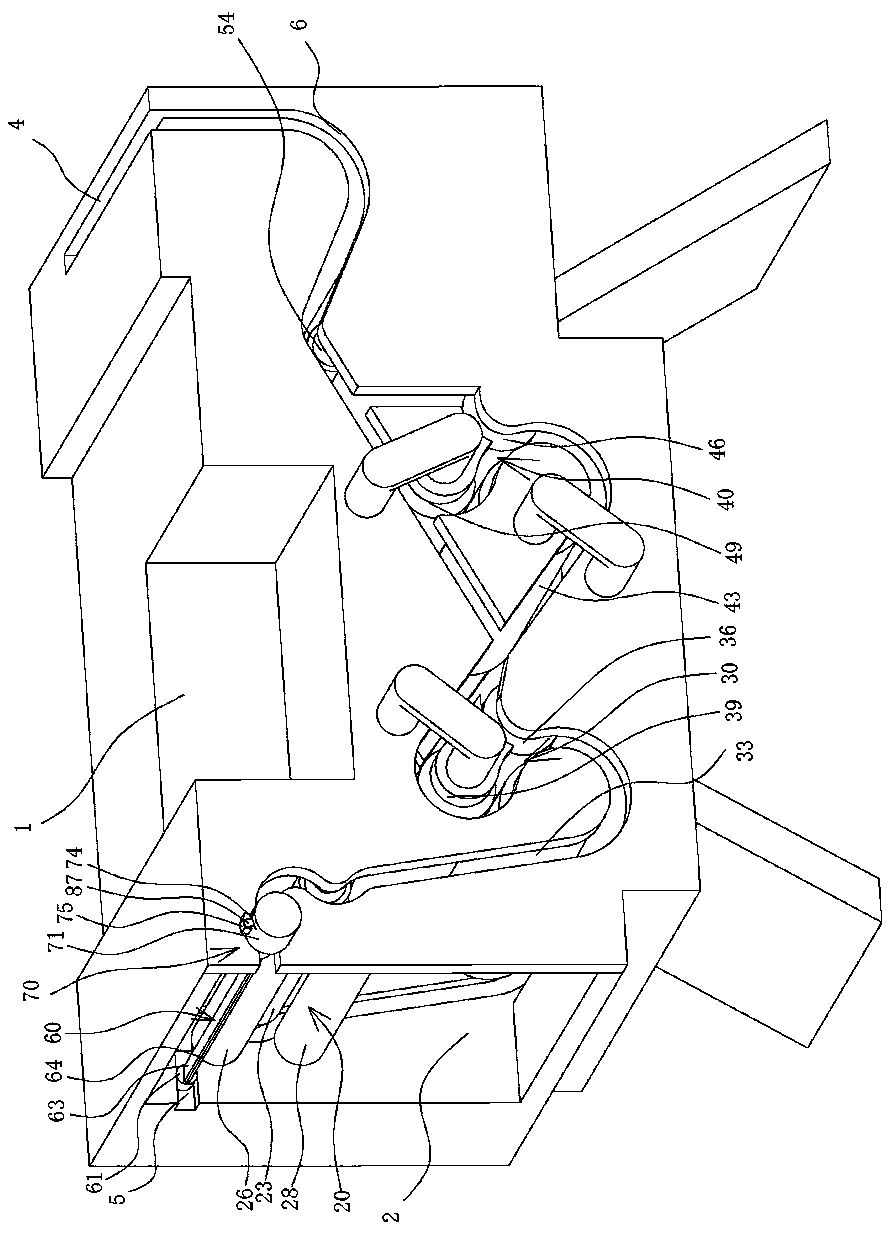

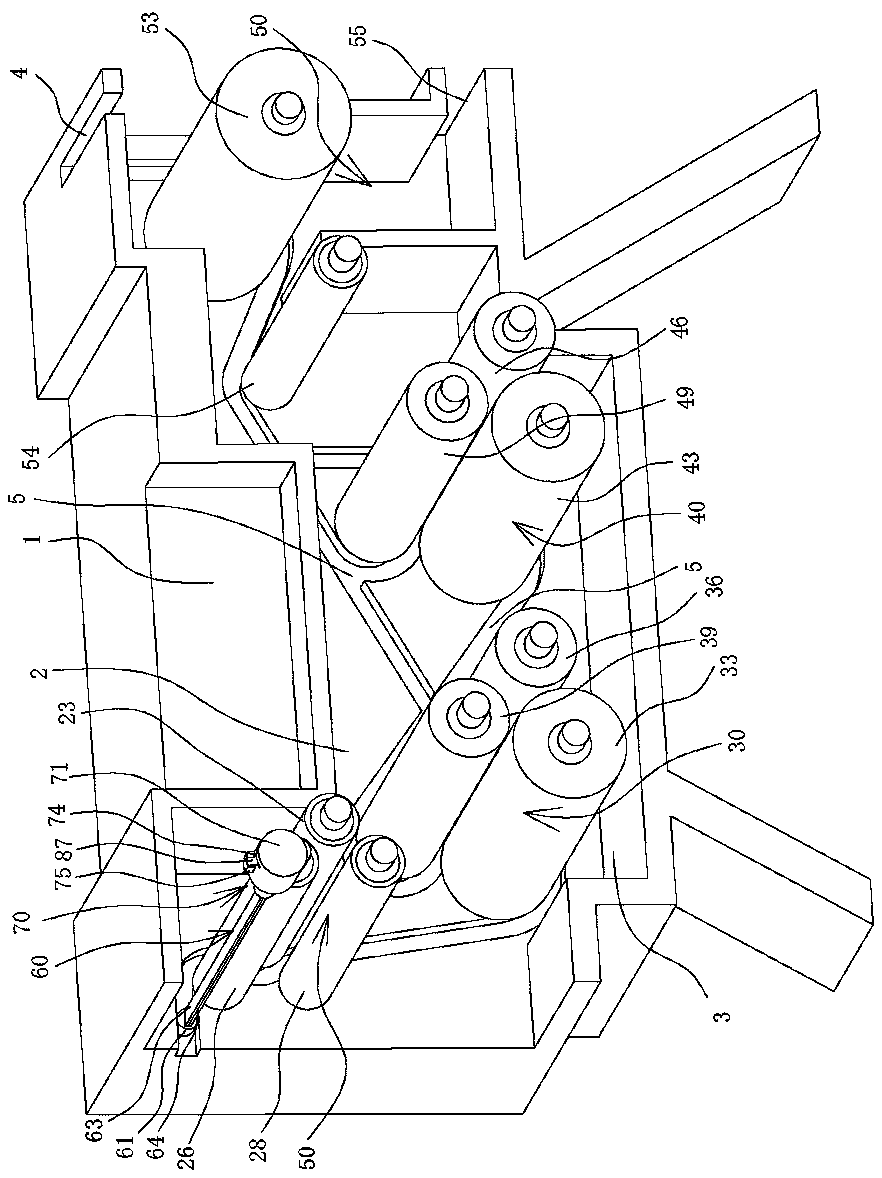

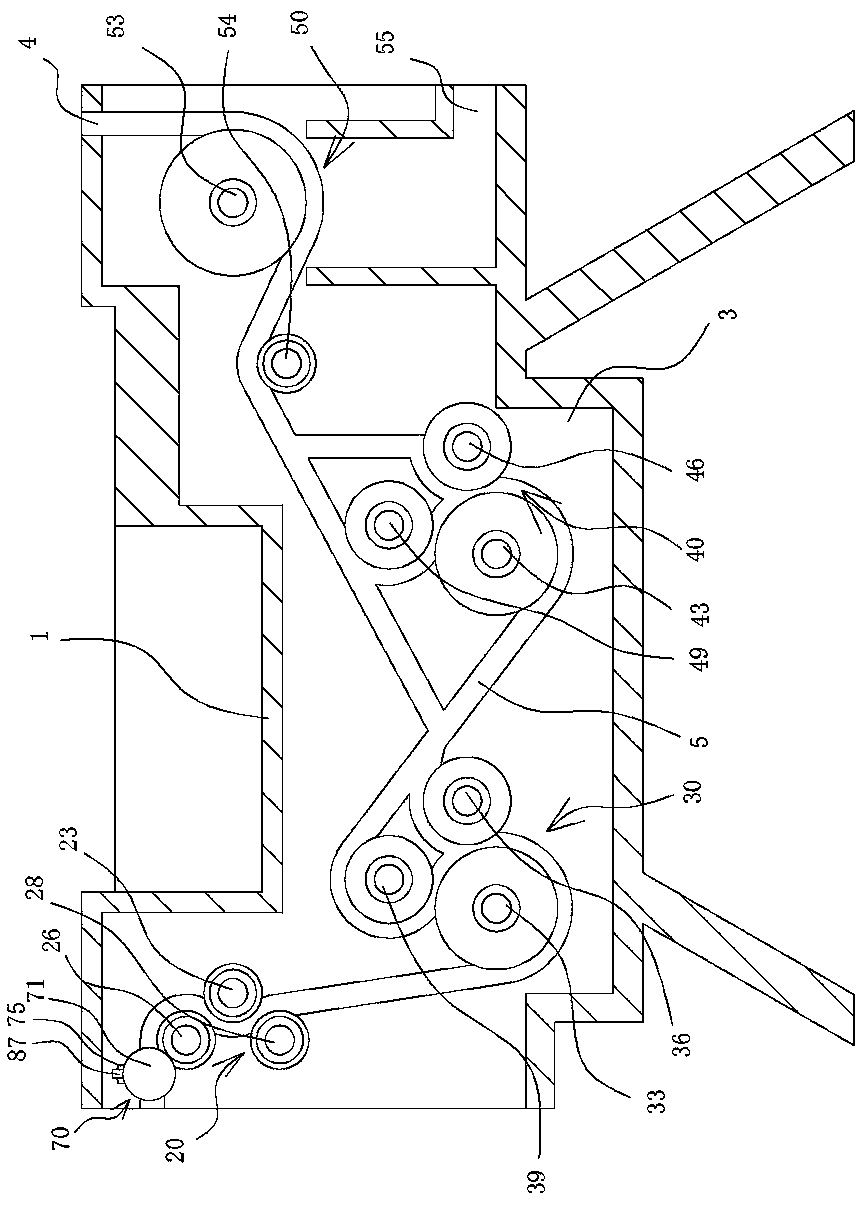

[0030] Such as figure 1 , figure 2 and Figure 4 As shown, the automatic sizing machine of the present invention includes a cabinet 1, the cabinet 1 is provided with an inner chamber 2, the right side of the cabinet 1 is provided with a discharge port 4, and the middle of the inner chamber 2 is provided with a power mechanism 10, and the left side of the power mechanism 10 is connected with a carding mechanism 20. A first sizing mechanism 30 is connected under the carding mechanism 20, a second sizing mechanism 40 is connected under the power mechanism 10, a sizing tank 3 is arranged under the first sizing mechanism 30 and the second sizing mechanism 40, and the right side of the power mechanism 10 is connected to There is a drying mechanism 50, the front side of the inner wall of the cabinet 1 is provided with a first chute 5, the rear end of the cabinet 1 is provided with a second chute 6 corresponding to the first chute 5, and the first chute 5 is provided with a clamping...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com