Production system for low-cost and high-quality unidirectional warp knitted fabric

A unidirectional fabric and production system technology, applied in warp knitting, knitting, textiles and papermaking, etc., can solve problems such as low production efficiency and increased spinning cost, and achieve the effects of easy production, improved fabric quality, and simple and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

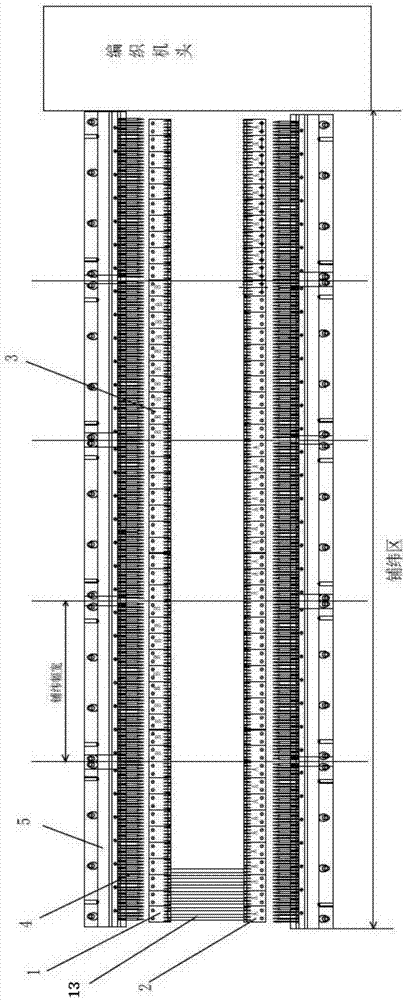

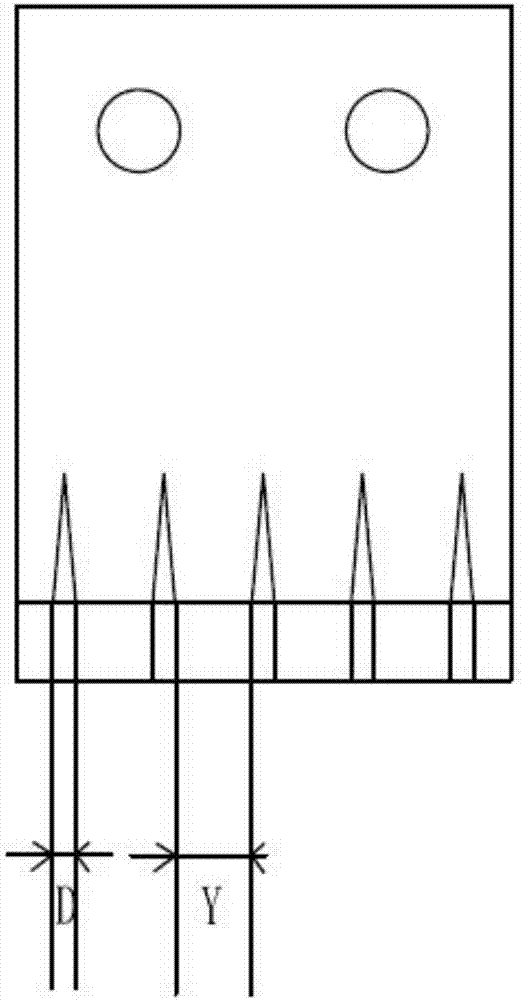

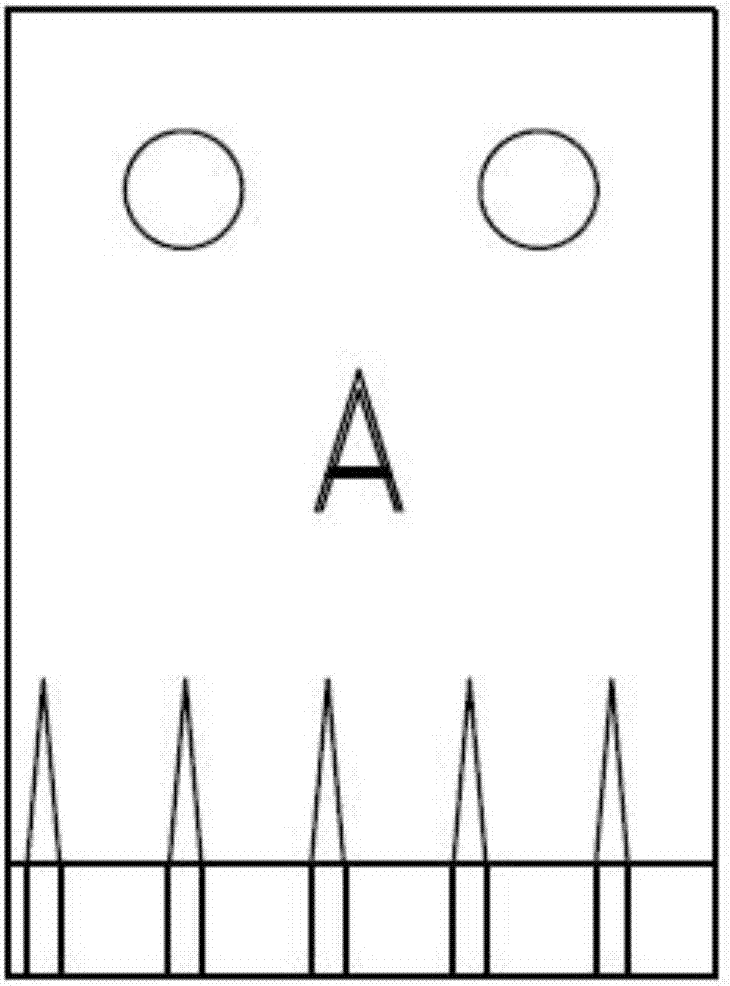

[0032] See Figure 1 to Figure 5, the production system of the low-cost high-quality warp-knitted unidirectional fabric of the present embodiment adopts a multiaxial warp knitting machine, and the multiaxial warp knitting machine includes a weft yarn needle block group, a weft laying trolley, a conveying device 4, and a yarn guide needle block 5, knitting head, constant tension yarn supply device 6 and auxiliary device 7; yarn guide needle block 5 corresponds to the weft yarn needle block group, and the pitch of yarn guide needle block 5 is the same as that of the weft yarn needle block group needle block; The needle block group includes standard needle block 1, A-type needle block 2 and B-type needle block 3 with the same width. X needles are set on each of the three needle blocks; Arrange X needles with a diameter of Dmm at equal distances; the setting position of the X needles on the A-type needle block 2 is based on the standard needle block 1, and each needle moves in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com