Construction method of super high-rise building large movable arm tower crane in-situ converted from inner climbing to outer hanging

A construction method and super-high-rise technology, applied in cranes, transportation and packaging, etc., can solve the problems of large number of unloaded rods, slow unloading speed, and difficult unloading, so as to improve construction convenience, save construction period, and facilitate construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

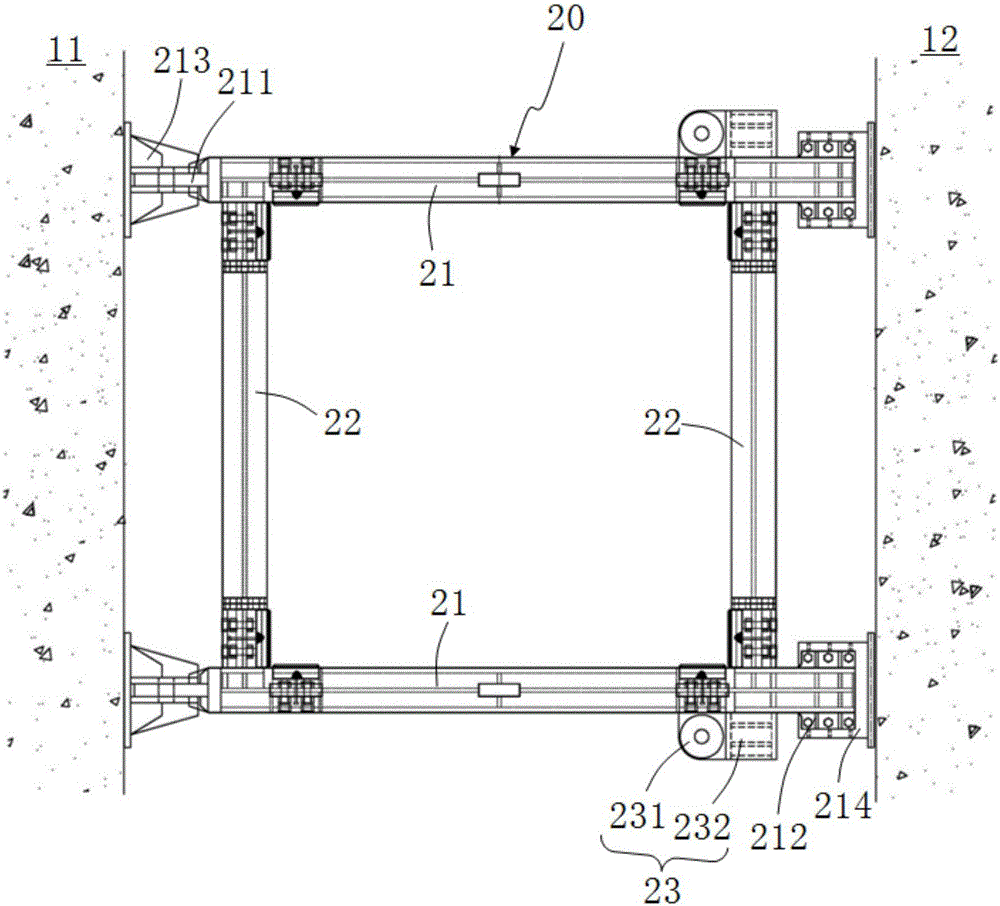

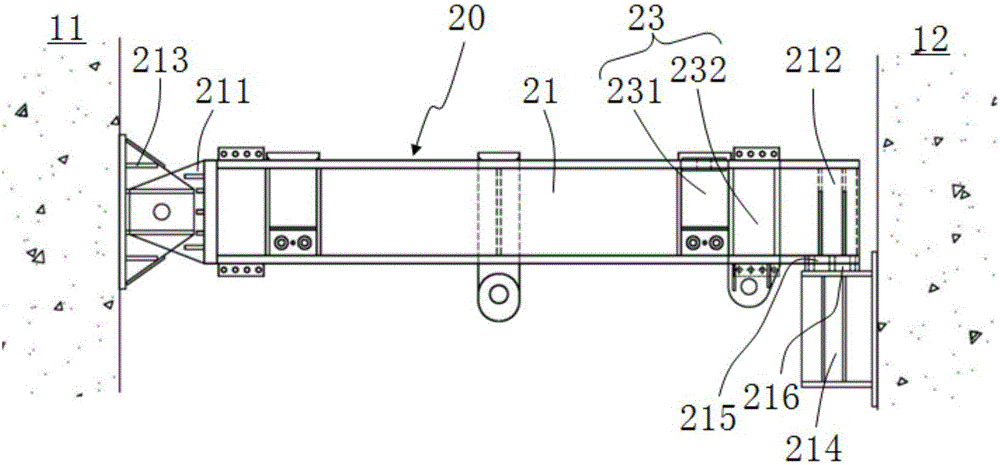

[0038] In order to facilitate the understanding of the present invention, the following will be described in conjunction with the accompanying drawings and embodiments.

[0039] see Figure 1 to Figure 11 , The present invention provides a super high-rise building large-scale boom tower crane in-situ conversion from internal climbing to external hanging construction method.

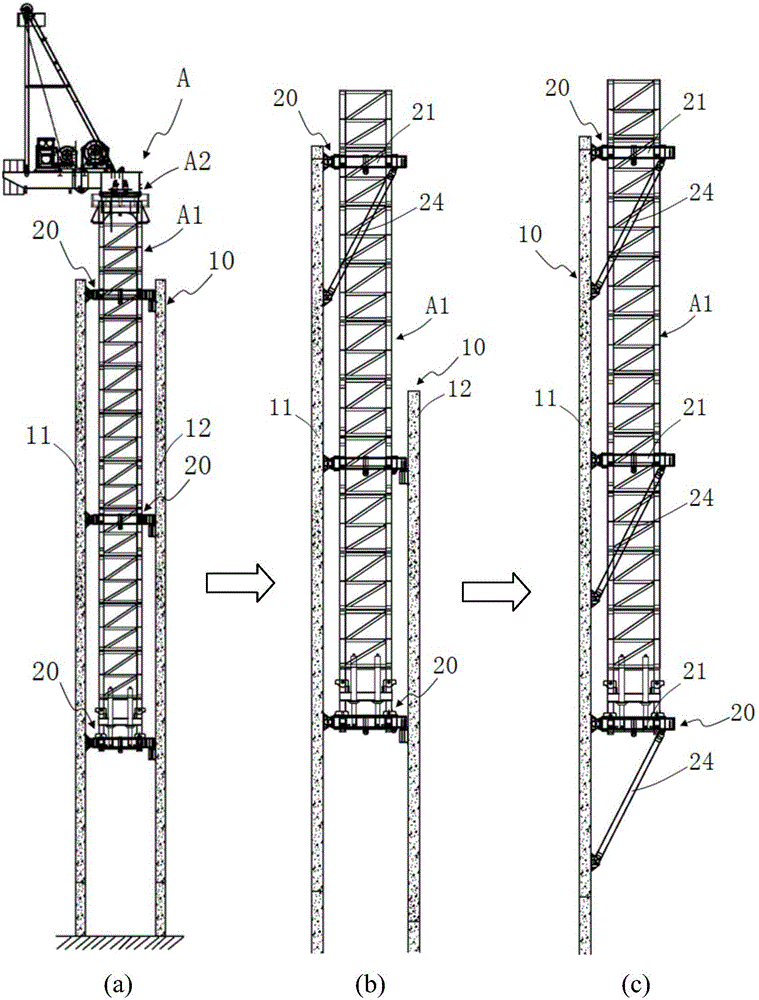

[0040] Such as figure 1 (a), (b), and (c) sequentially show the schematic diagram of the flow structure of the construction method of the present invention for converting the tower crane A from the internal climbing working condition to the external hanging working condition.

[0041] Such as figure 1 (a), the tower crane A is set between the inner wall 11 and the outer wall 12 of the core tube 10 during the internal climbing condition; the support system of the tower crane A includes multiple groups of joist mechanisms 20, and the tower crane A The tower body A1 is set between the inner wall 11 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com