Wire winding and arrangement machine

The technology of a wire arranging machine and a wire winding machine is applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc., which can solve the problems of affecting the stability of the pay-off, the degree of automation is not high, and the winding is not neat enough. Achieve the effect of realizing automatic loading and unloading, improving the degree of automation, and preventing wire deflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

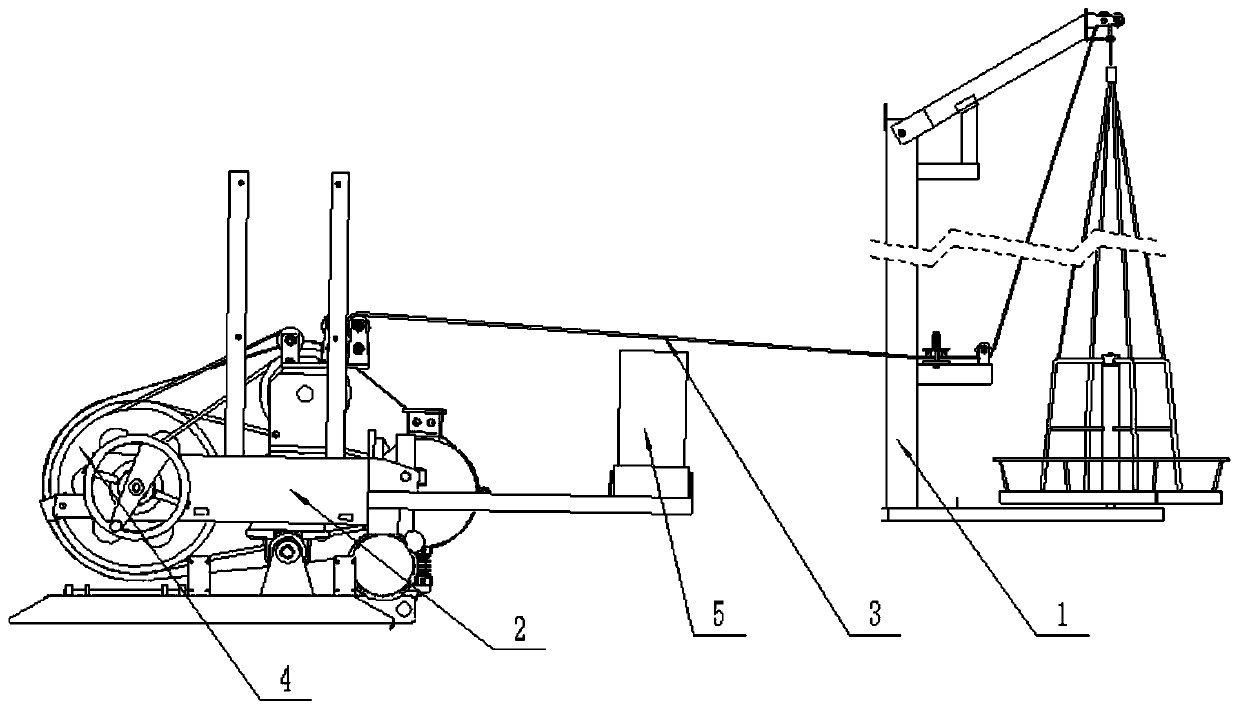

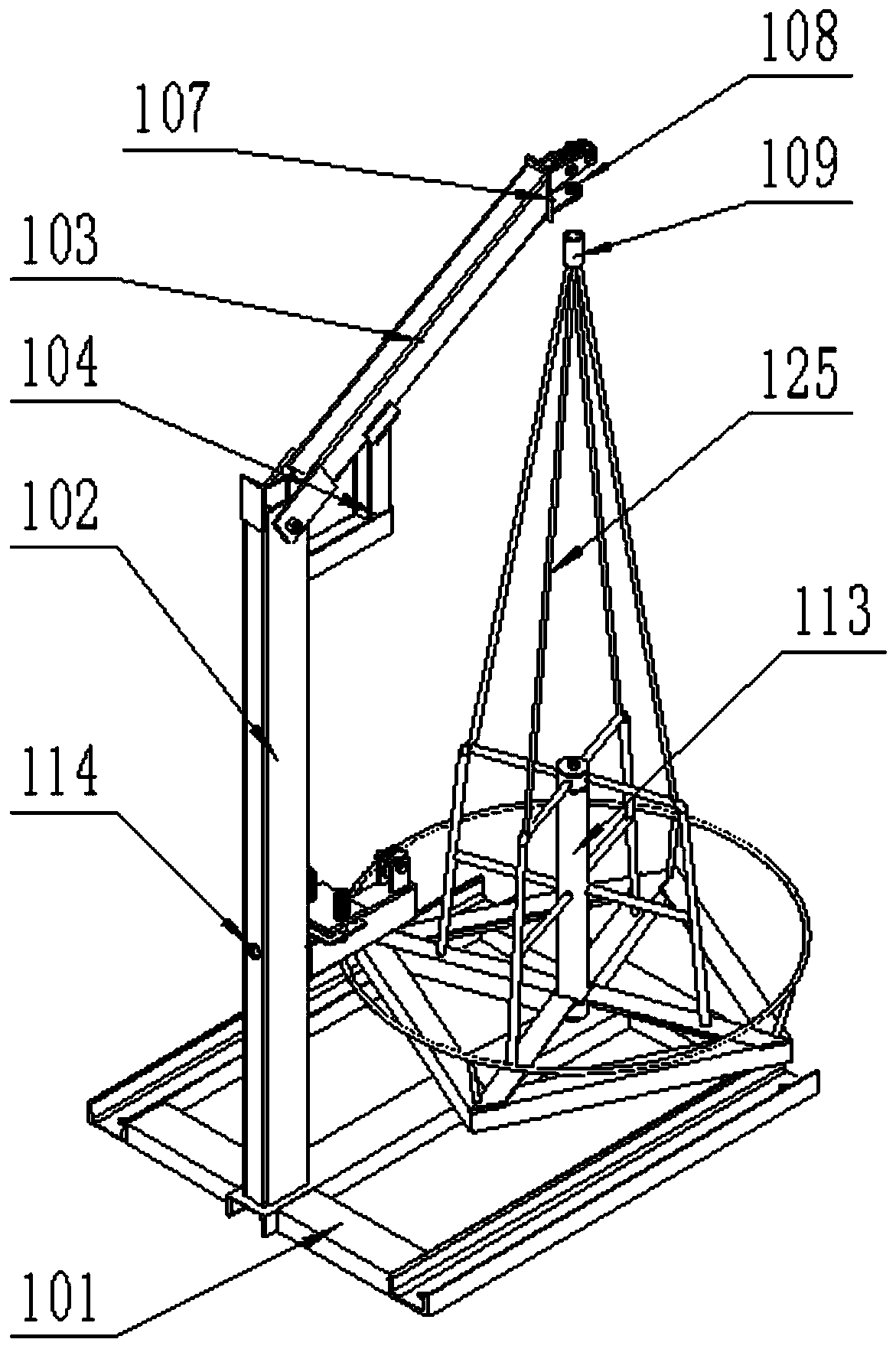

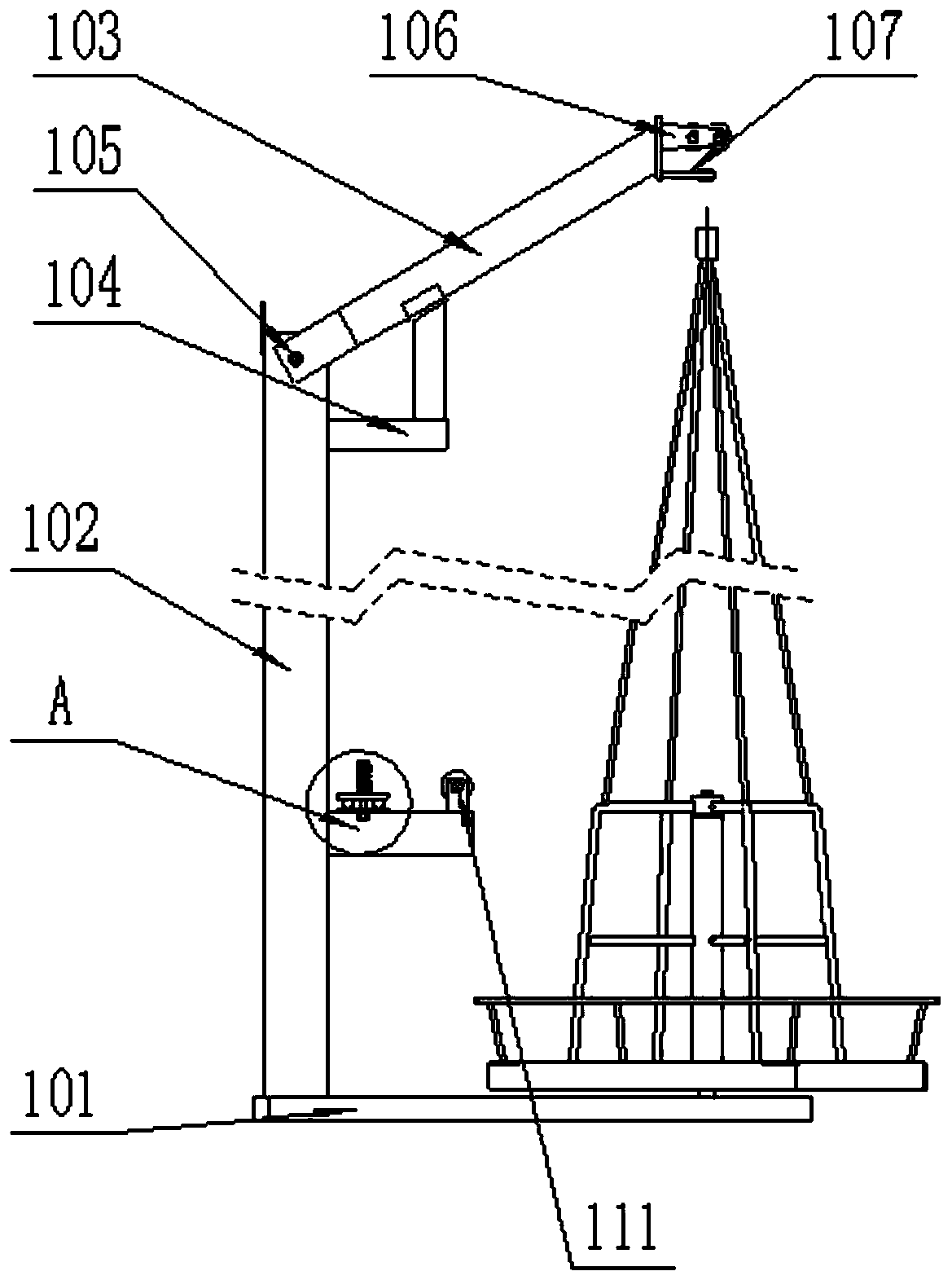

[0040] like Figure 1-13 as shown,

[0041] A wire winding and arranging machine, including a wire guide mechanism 1 and a wire arranging mechanism 2 arranged along the conveying direction of the steel wire 3, and an AC for welding steel wire joints is installed between the corresponding guide wire mechanism 1 and the wire arranging mechanism 2 on the frame. The butt welding machine 5 is used to weld the steel wire connection through the AC butt welding machine to realize the function of continuous cable arrangement.

[0042]The wire guide mechanism 1 includes a base 101, on which a supporting mechanism for supporting the steel wire coil is installed. The supporting mechanism includes a supporting shaft and a cone-shaped support frame. Above, the tapered support frame includes a support sleeve 121, a support plate 122, and a support ring 123. The support sleeve 113 is coaxially installed on the support shaft. A rotating bearing 126 is installed between the support sleeve and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com