Intelligent flexible thermal-insulation single tube unreeling mechanism and unreeling method

An unwinding mechanism, intelligent and flexible technology, applied in the direction of conveying filamentous materials, thin material handling, transportation and packaging, etc., can solve the problems of low efficiency and long time consumption, reduce the number of personnel, reduce labor consumption, and reduce the size of traction. suitable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

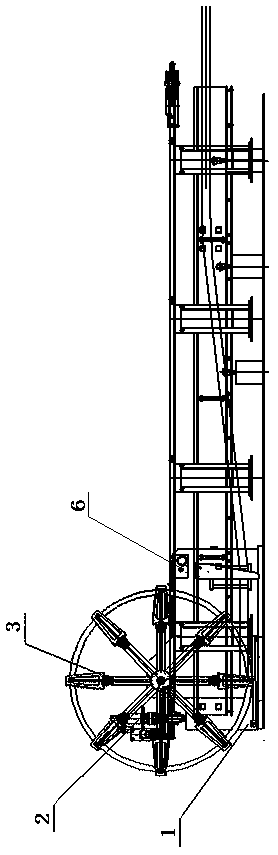

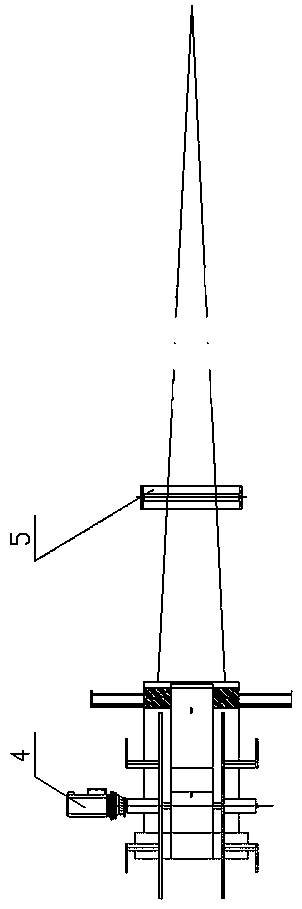

[0023] An intelligent flexible thermal insulation single-tube unwinding mechanism, which consists of: an unwinding platform 1 and a guiding mechanism 5. The unwinding platform is a frame structure, and an unwinding actuator 3 is installed inside the frame structure. The unwinding actuator has 8 slider devices, and the 8 slider devices are arranged at an equal angle at the center position. The cylinder 2 is fixed on the right side bracket of the unwinding actuator, and the unwinding platform One side of the frame is fixed with a motor 4 by bolts, the motor is connected to the unwinding actuator through a connecting shaft, and a control panel 6 is installed on the upper right frame of the unwinding platform.

Embodiment 2

[0025] According to the intelligent flexible thermal insulation single-tube unwinding mechanism described in embodiment 1, the guide mechanism includes a fixing device, the middle part of the fixing device has a groove, and two guide wheels are respectively installed on both sides of the groove , the working pipe passes between the two guide wheels and enters the unwinding actuator.

Embodiment 3

[0027] According to the intelligent flexible thermal insulation single-tube unwinding mechanism described in Example 1, the unwinding platform is welded into a frame by eight pieces of 400×200 square steel, and the unwinding platform is formed by welding a 4mm thick baffle plate at the left end of the frame.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com