Unwinding adjusting device in unwinding mechanism

A technology of adjusting device and unwinding mechanism, which is applied in the direction of winding strips, transportation and packaging, thin material processing, etc., can solve the tedious alignment operation, device adjustment without feeding, and the station or device is not completely aligned. and other problems to achieve the effect of improving accuracy, improving efficiency and saving time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

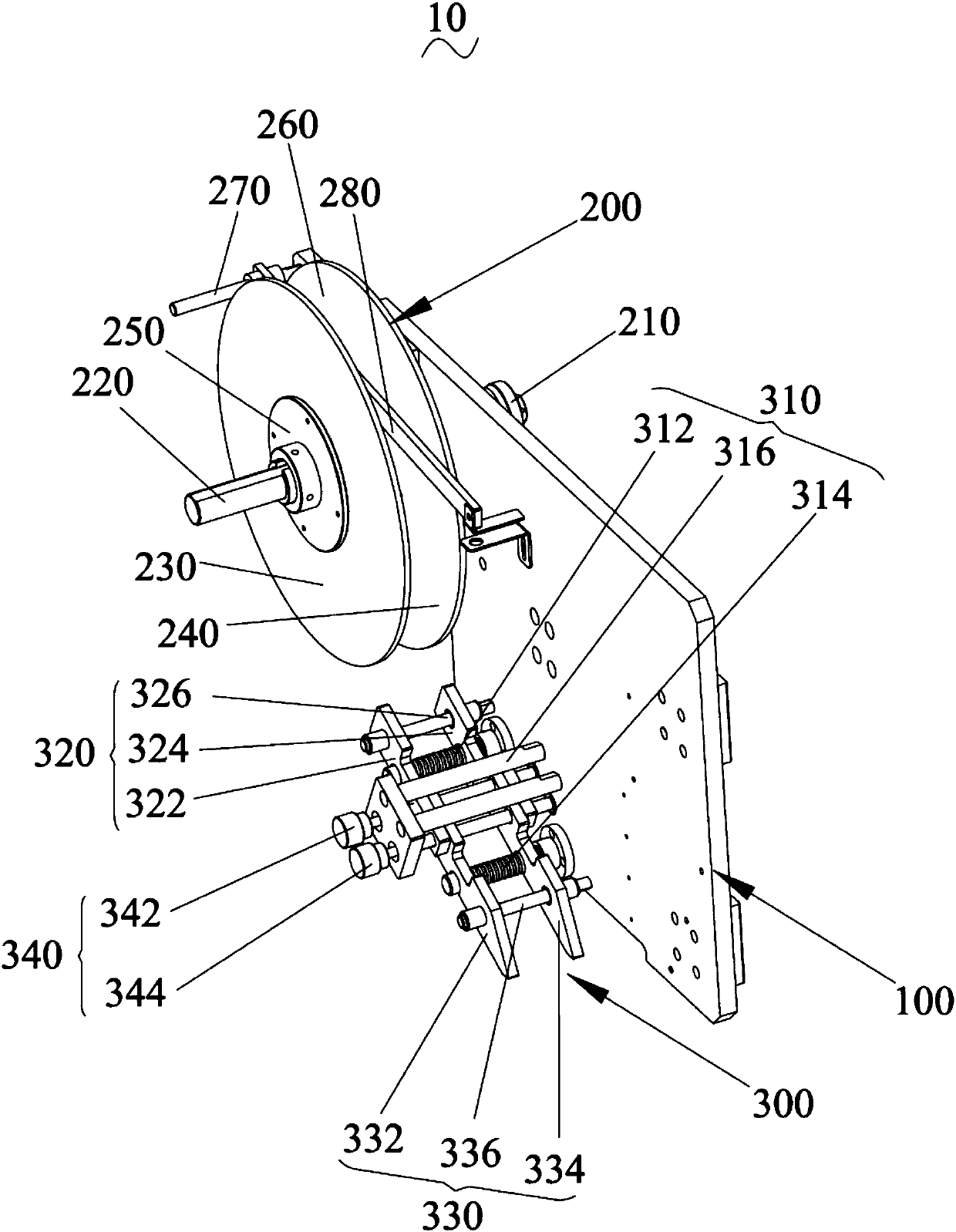

[0019] see figure 1 , the present invention provides an unwinding adjustment device 10 used in an unwinding mechanism, comprising: an unwinding adjustment bracket 100 and a material unwinding part 200 and an unwinding adjustment part 300 arranged on the unwinding adjustment bracket 100 .

[0020] The discharge part 200 includes a discharge driver 210, a discharge drive rod 220, a first discharge plate 230, a second discharge plate 240 and a discharge fixed plate 250; the discharge drive rod 220 passes through the The discharge fixed plate 250, the first discharge plate 230, the second discharge plate 240, and the pressing bracket 100 are driven and connected to the discharge driver 210; the first discharge plate 230 and The second discharge plate 240 is arranged in parallel, and the first discharge plate 230 and the second discharge plate 240 form a discharge space 260 . It should be noted that the discharging driver 210 is a driving motor.

[0021] The unwinding adjusting p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com