Uncoiler uncoiling operation method

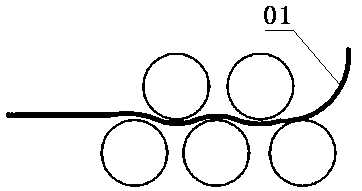

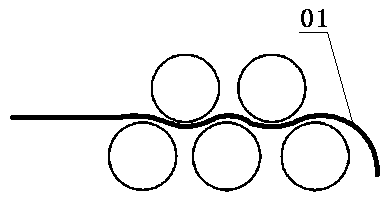

An operation method and uncoiler technology, which is applied in the field of lap joints between steel coils and steel coils, can solve the problems that the steel coils cannot enter the lap joint smoothly, and achieve the goal of improving the effective operation rate and uncoiling efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

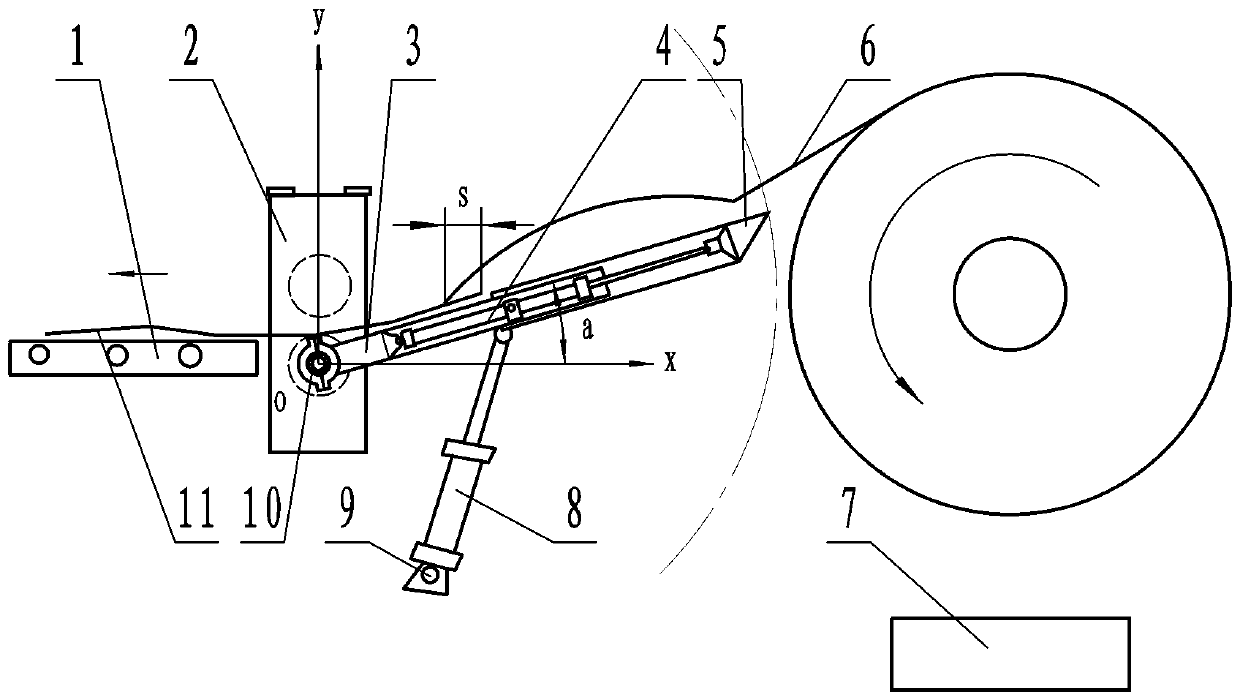

[0022] An uncoiler uncoiling operation method, such as image 3 and Figure 4 The shown uncoiler has a frame body 2 provided with a steel plate conveying channel, the frame body 2 is adjacent to the conveyor belt 1, a guide plate device is used, and the guide plate device includes a hinge shaft 10, the hinge shaft 10 of this embodiment is installed On the frame body 2 below the steel plate conveying channel; on the hinge shaft 10, a fixed cover plate 3 protruding from the frame body 2 is hinged, and the rear end of the fixed cover plate 3 protrudes from the rear of the frame body 2; the fixed cover plate 3 Connected with the lifting power cylinder, the lifting power cylinder of the embodiment is the lifting hydraulic cylinder 8, the fixed end of the lifting hydraulic cylinder 8 is installed on the support 9, and the support 9 is fixed on the ground; the movable end of the lifting hydraulic cylinder 8 is connected On the bottom surface of the fixed sleeve plate 3; the fixed sl...

Embodiment 2

[0029] An uncoiler uncoiling operation method, such as image 3 and Figure 4 The shown uncoiler has a frame body 2 provided with a steel plate conveying channel, the frame body 2 is adjacent to the conveyor belt 1, a guide plate device is used, and the guide plate device includes a hinge shaft 10, the hinge shaft 10 of this embodiment is installed On the frame body 2 below the steel plate conveying channel; on the hinge shaft 10, a fixed cover plate 3 protruding from the frame body 2 is hinged, and the rear end of the fixed cover plate 3 protrudes from the rear of the frame body 2; the fixed cover plate 3 Connected with the lifting power cylinder, the lifting power cylinder of the embodiment is the lifting hydraulic cylinder 8, the fixed end of the lifting hydraulic cylinder 8 is installed on the support 9, and the support 9 is fixed on the ground; the movable end of the lifting hydraulic cylinder 8 is connected On the bottom surface of the fixed sleeve plate 3; the fixed sl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com