Rotor and stator unsheathing device

A technology of rotor stator and sleeve removal, applied in electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problems of difficult separation and sleeve removal, low sleeve removal efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

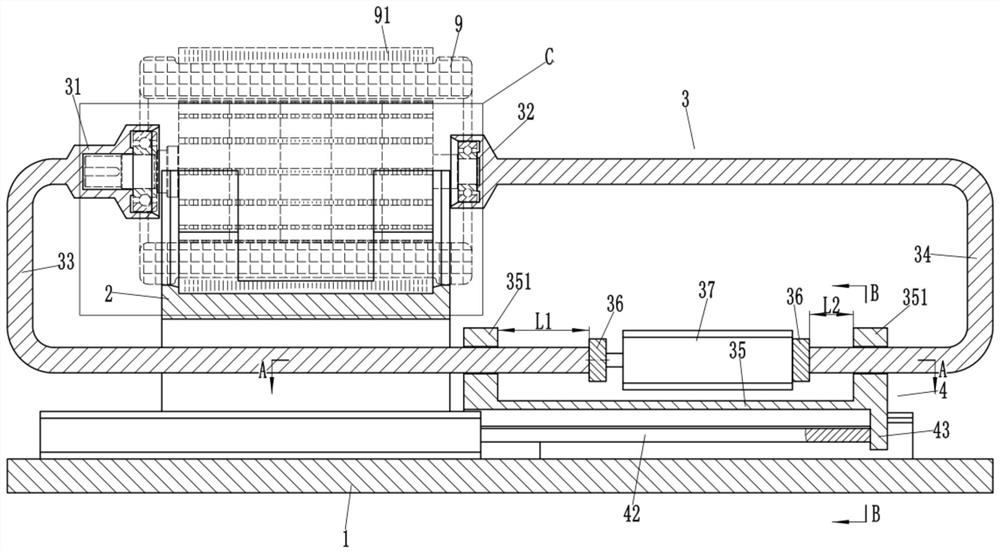

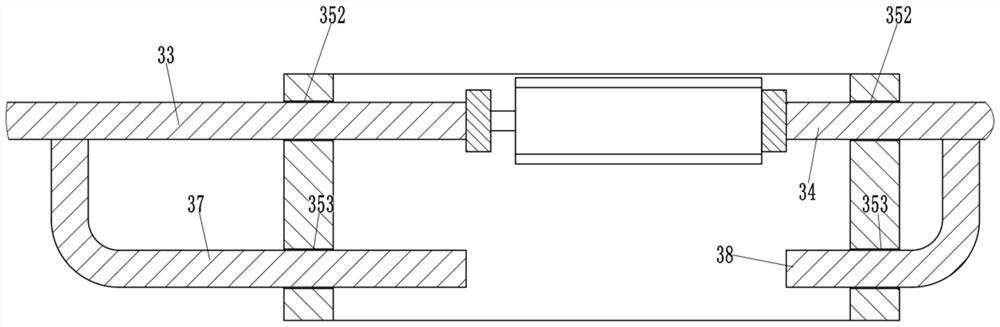

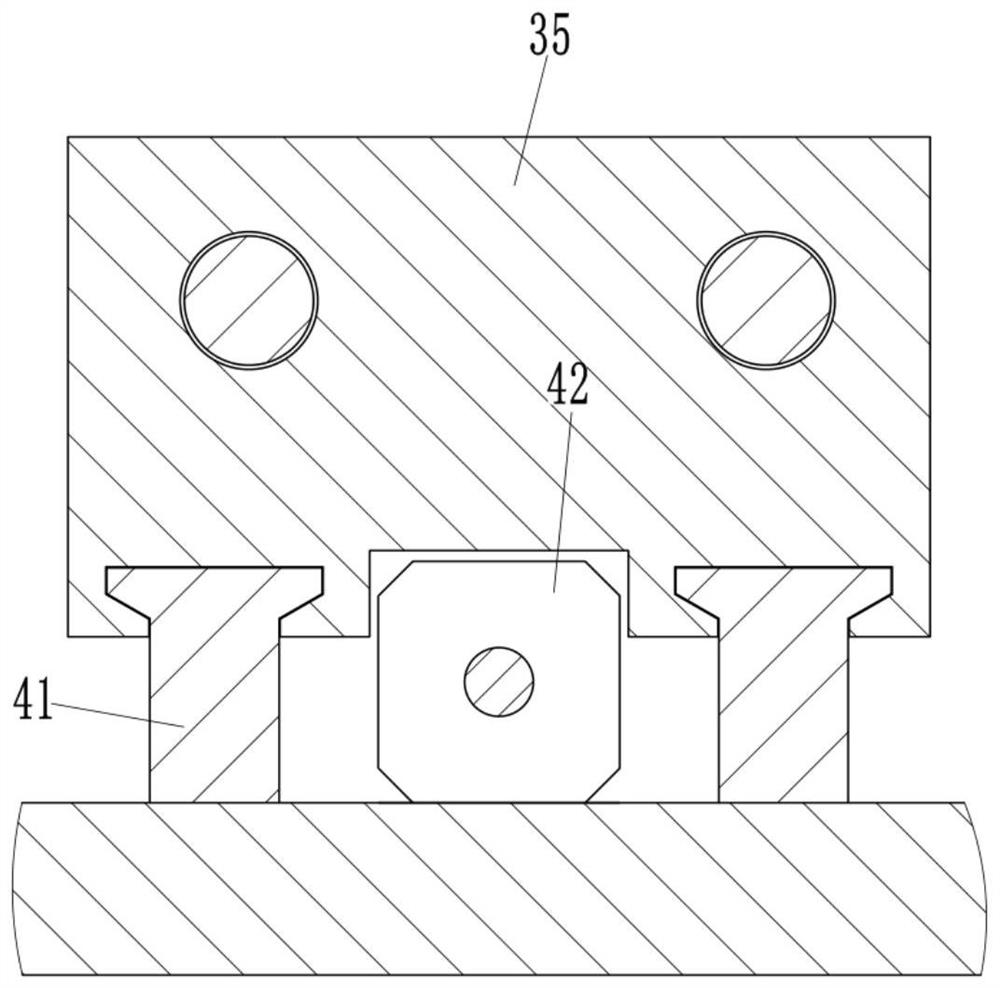

[0020] Examples, see e.g. Figure 1 to Figure 5 As shown, a rotor stator unsleeving device includes a base plate 1, on which a stator positioning seat 2 is fixed, and the left end and the right end of the stator positioning seat 2 are respectively provided with a rotor clamping mechanism 3, and the rotor clamping mechanism 3 includes The left indenter 31 and the right indenter 32 that are arranged on the same axis, the left indenter 31 is fixed on one end of the first U-shaped bar 33, the right indenter 32 is fixed on one end of the second U-shaped bar 34, and the first U-shaped bar The other end of 33 and the other end of the second U-shaped bar 34 pass through the extended end of the corresponding guide hole 352 on the two side plates 351 of the U-shaped guide seat 35 to be fixed with a stopper 36, and the two stoppers 36 are respectively It is fixed on the piston rod and the cylinder body of the first oil cylinder 37; the guide seat 35 is provided with a translation mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com