Patents

Literature

58results about How to "Improve unwinding efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

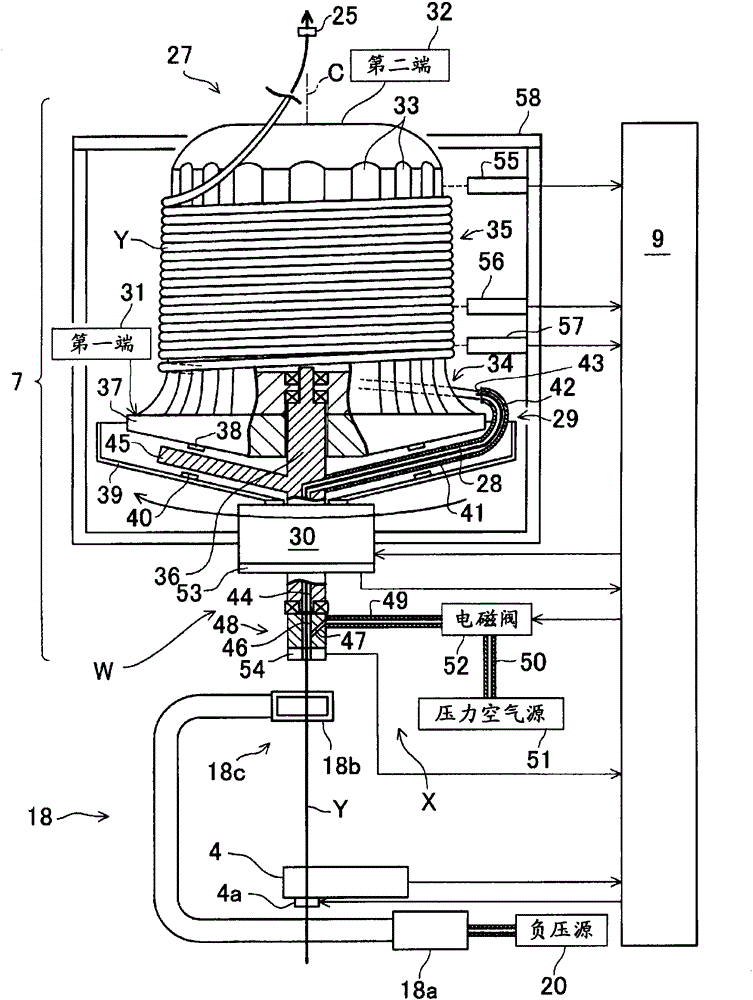

Yarn winder

ActiveCN102548884AExcellent power consumption reductionIncrease power consumptionFilament handlingYarnBobbin

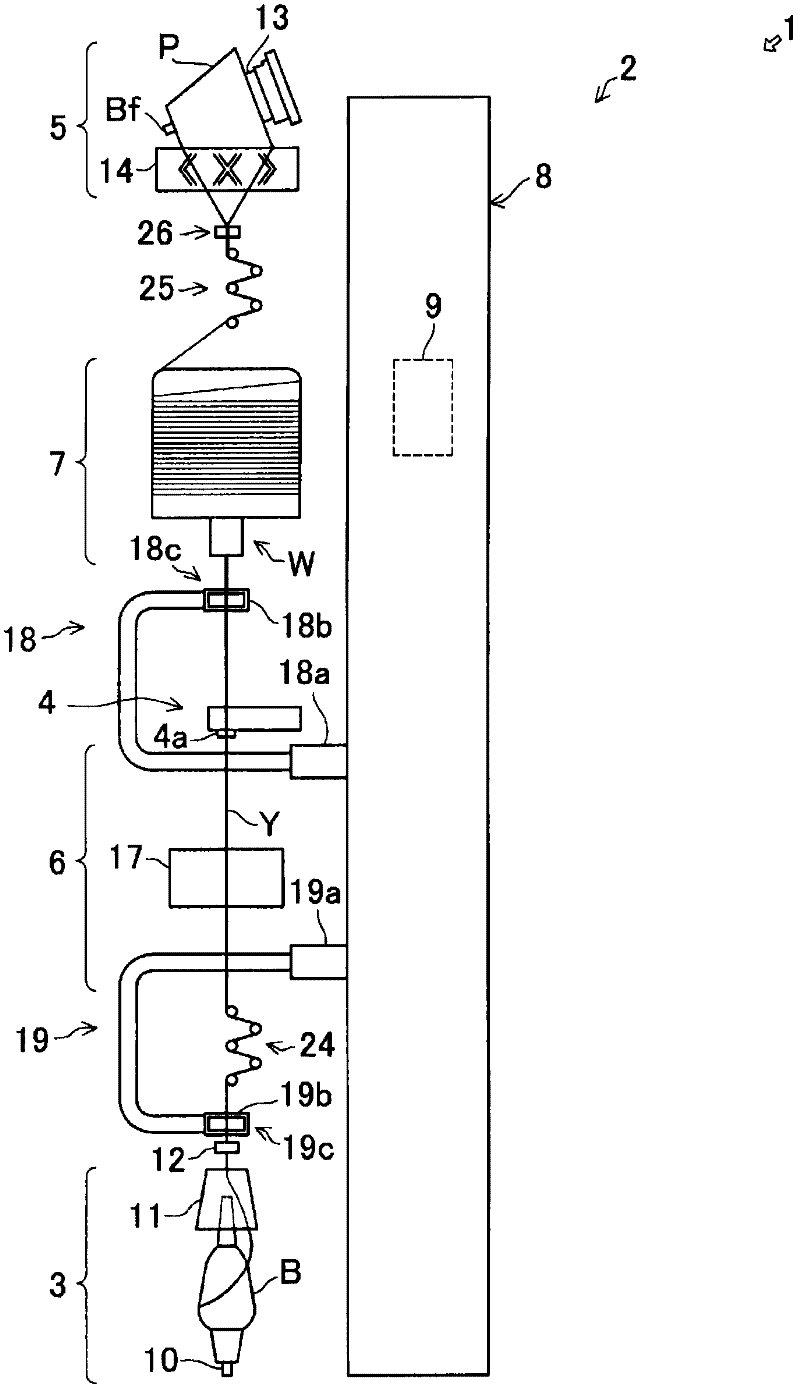

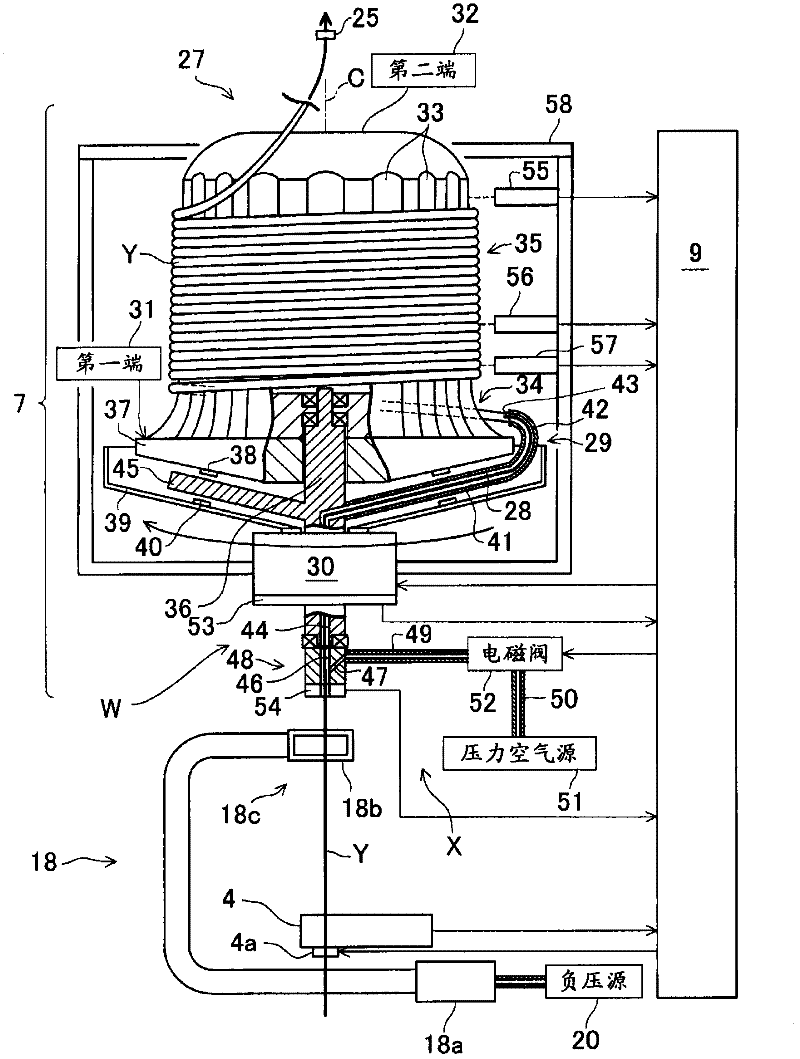

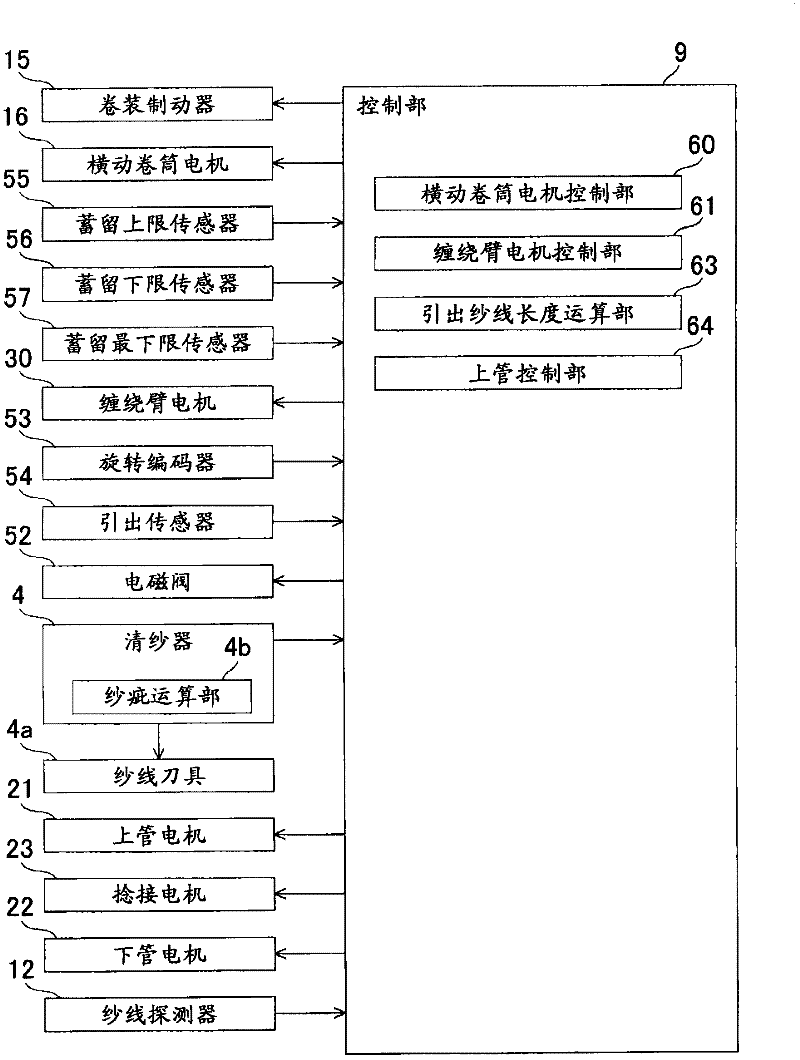

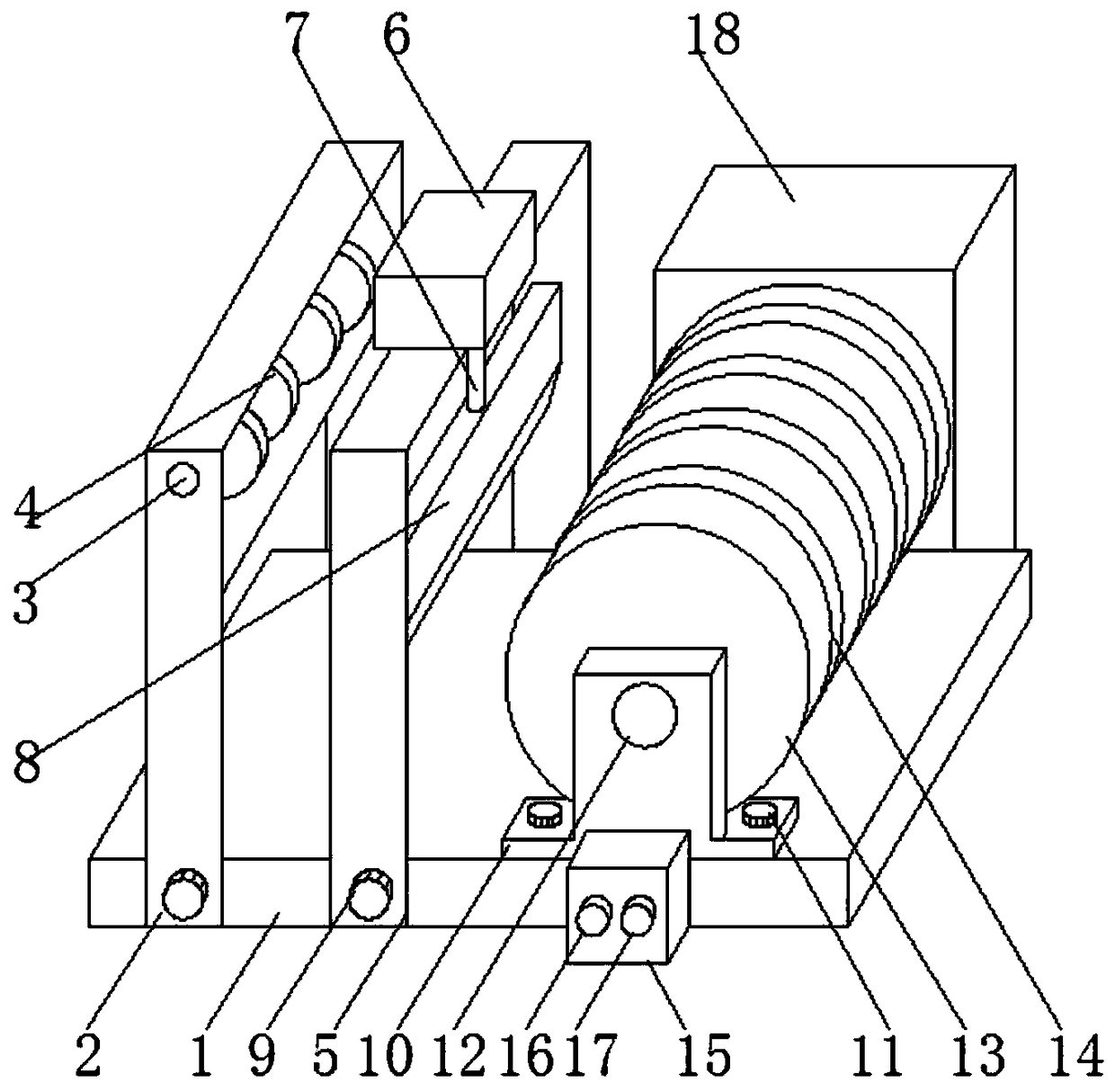

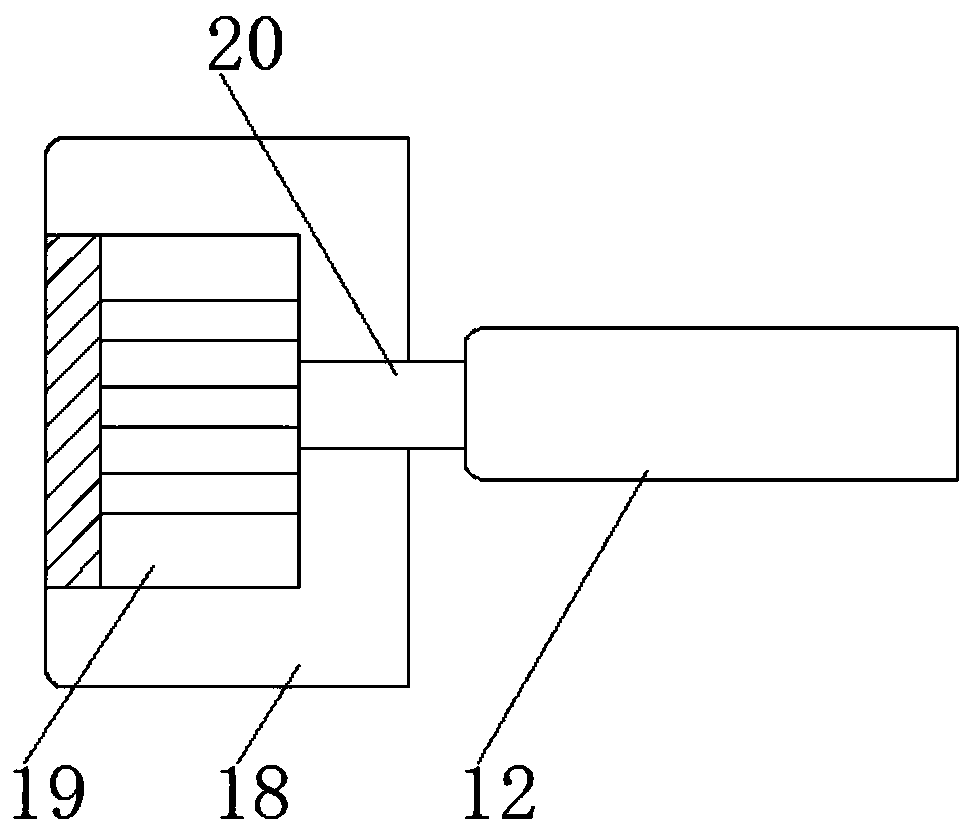

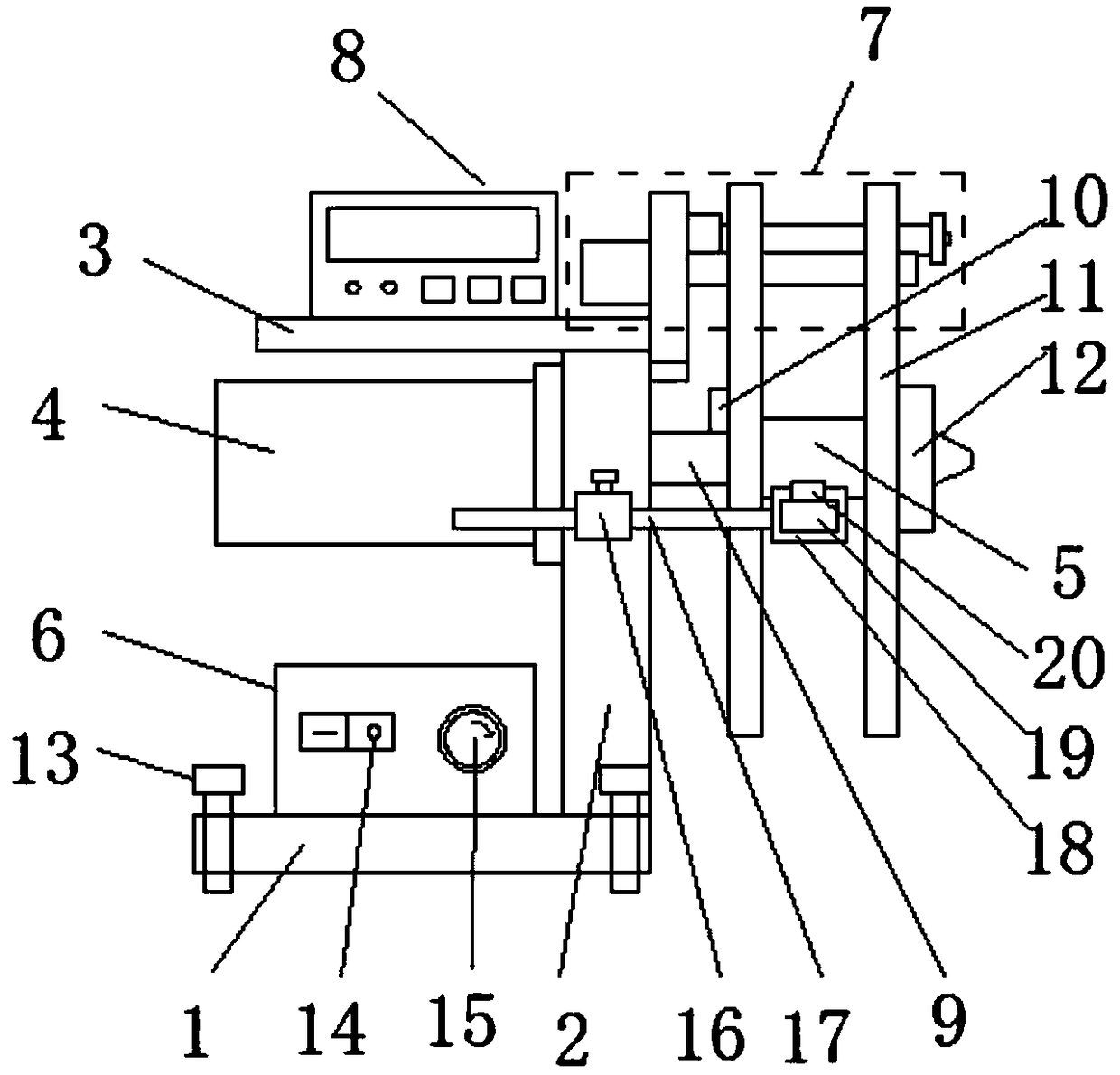

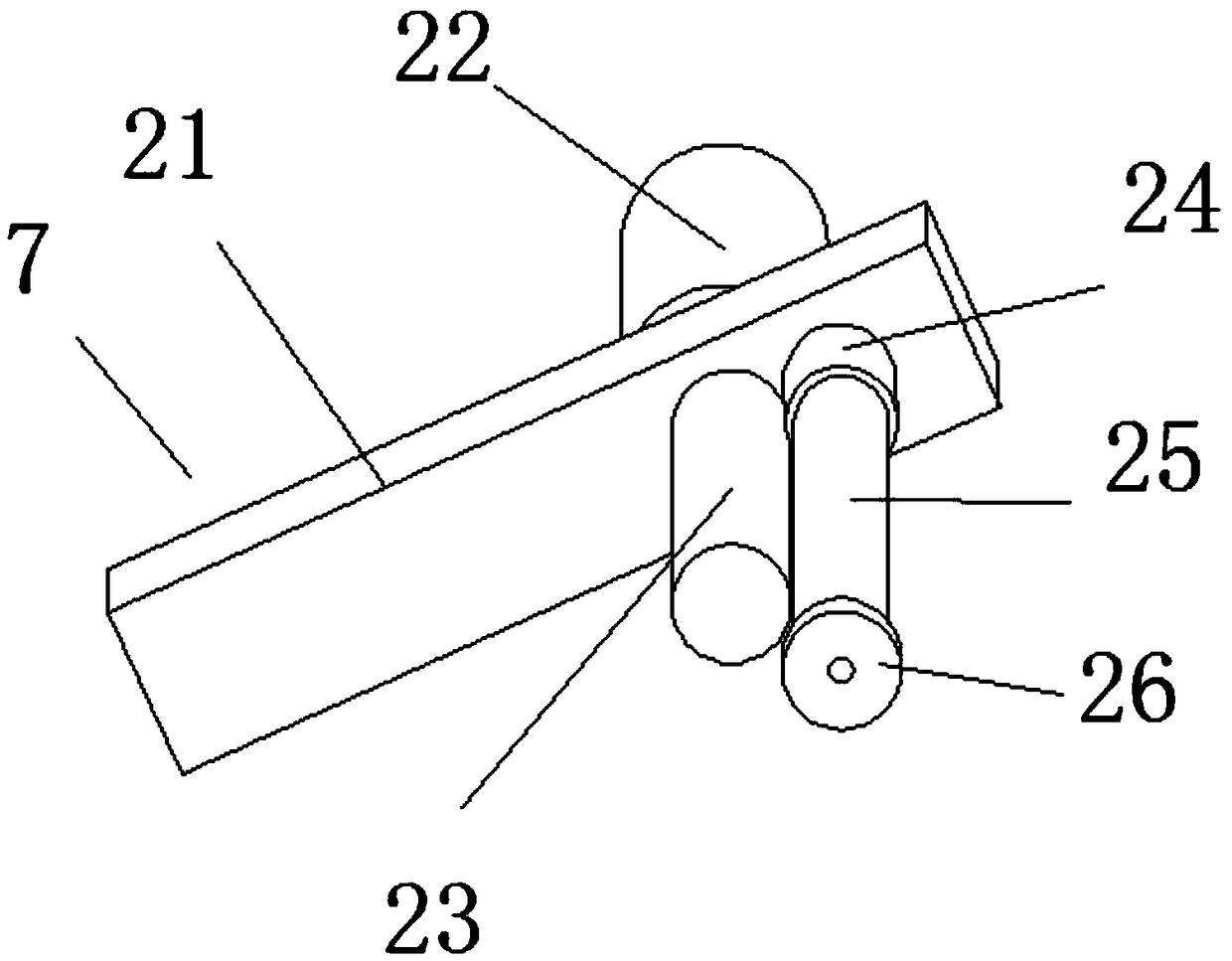

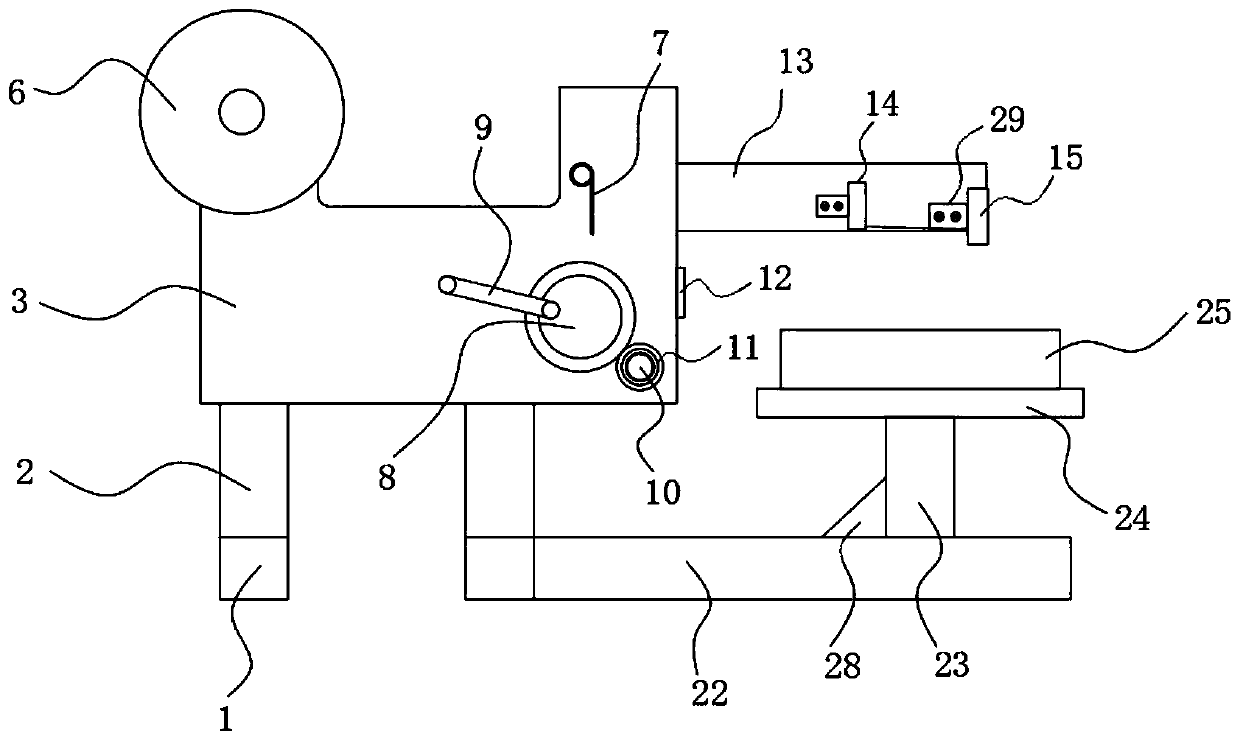

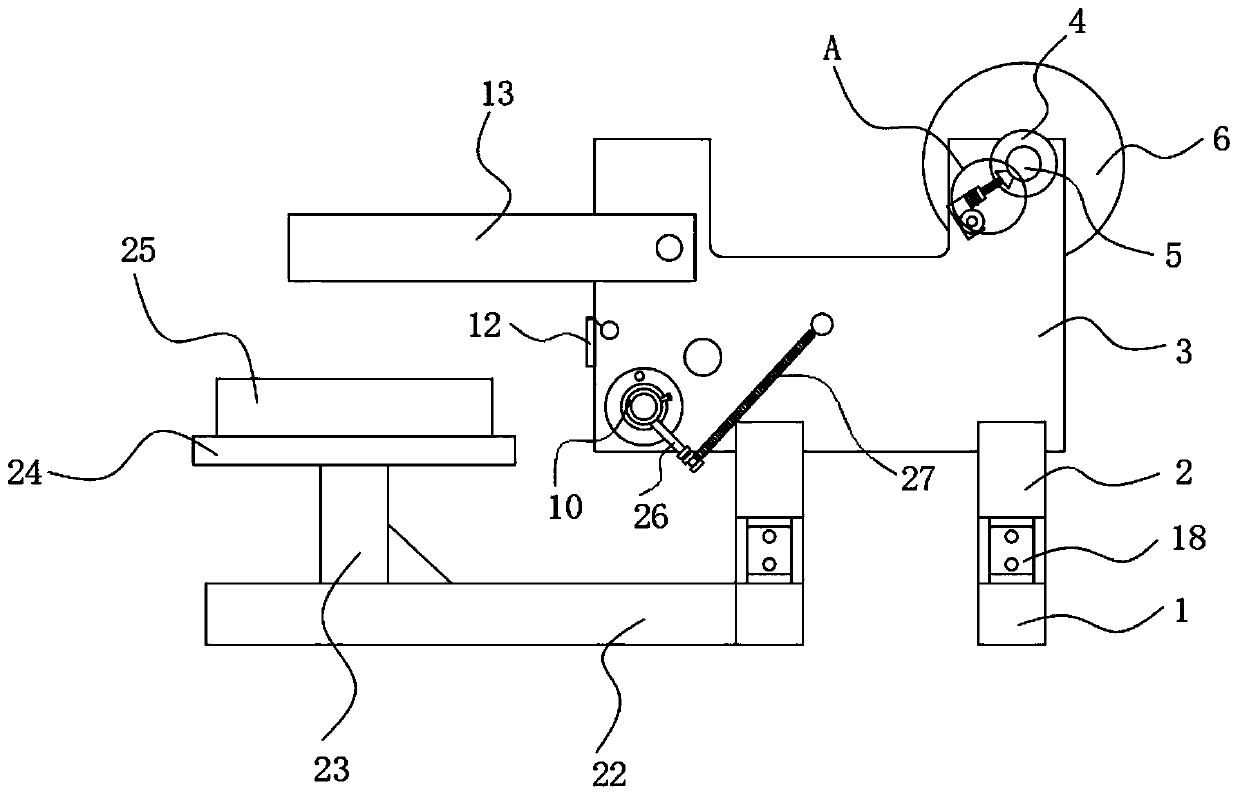

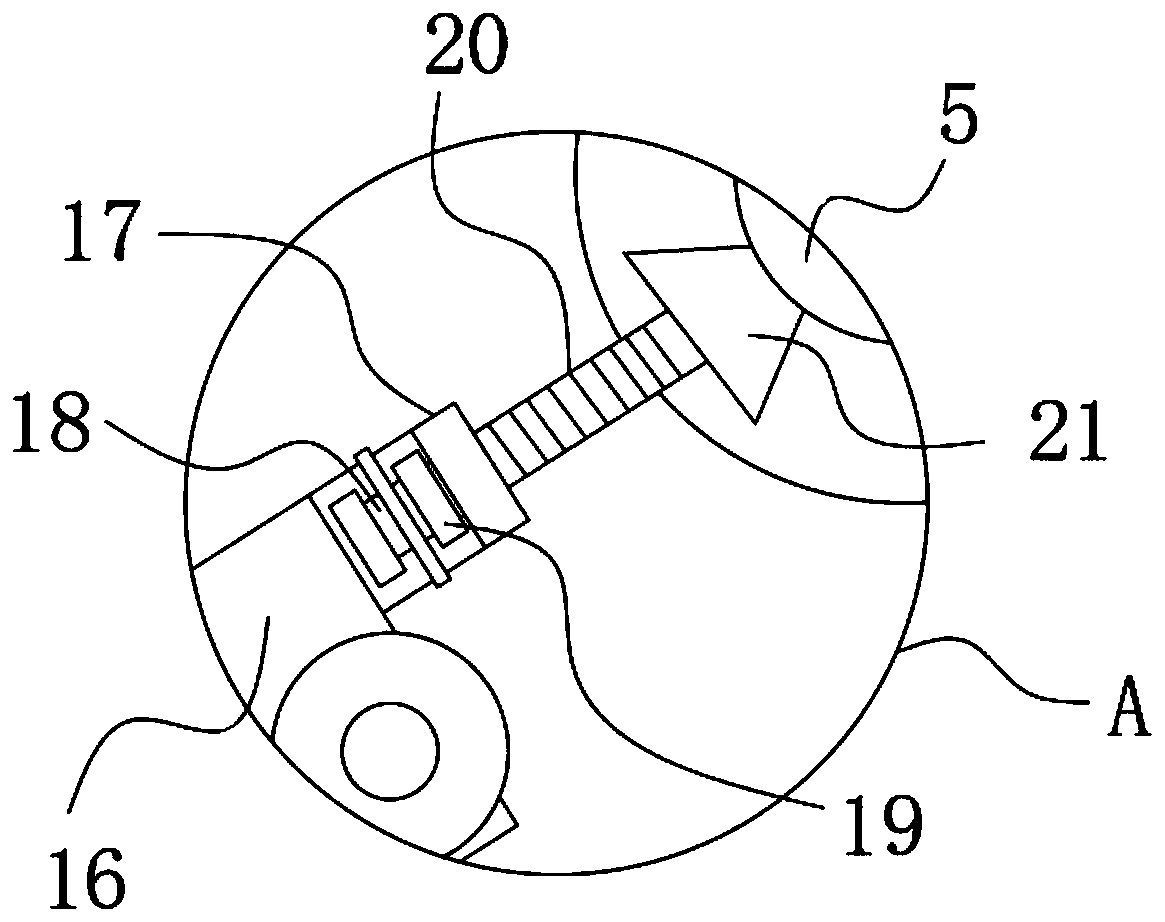

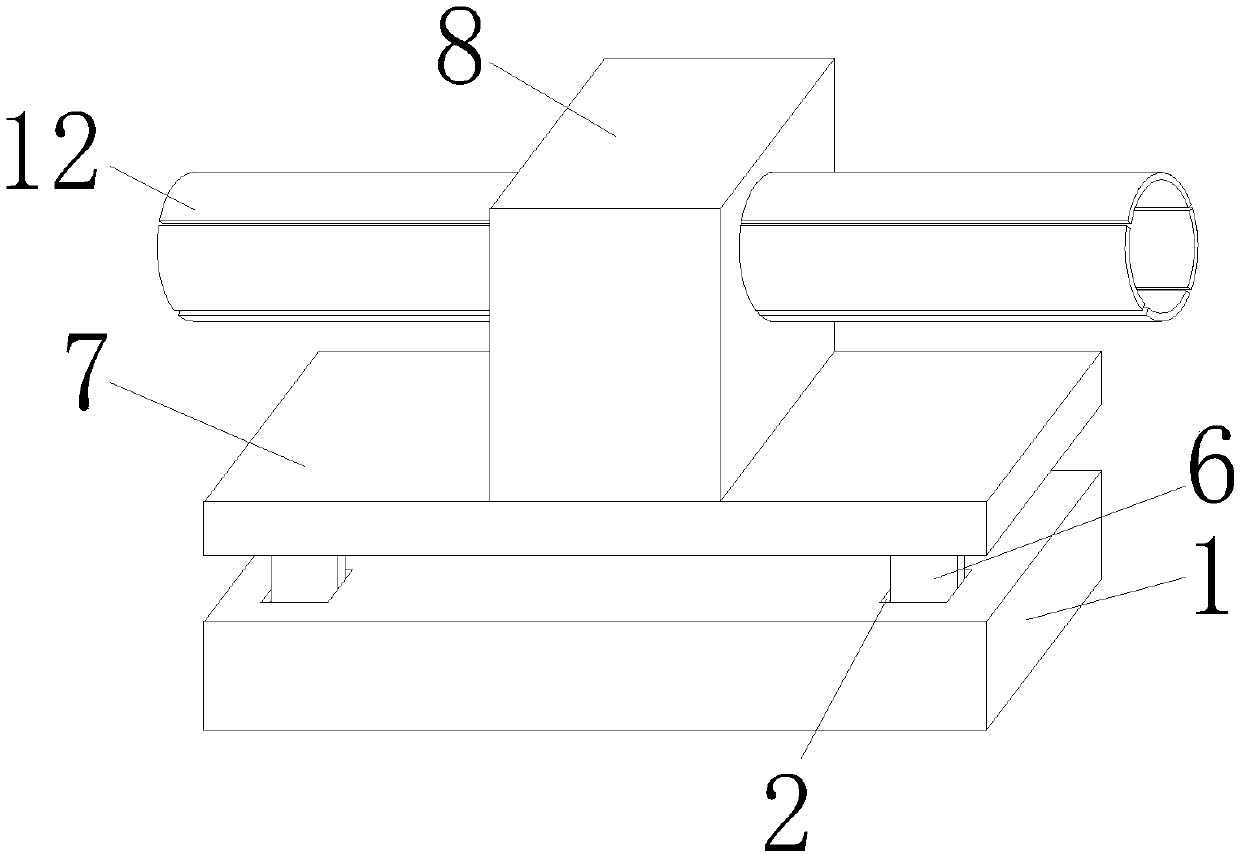

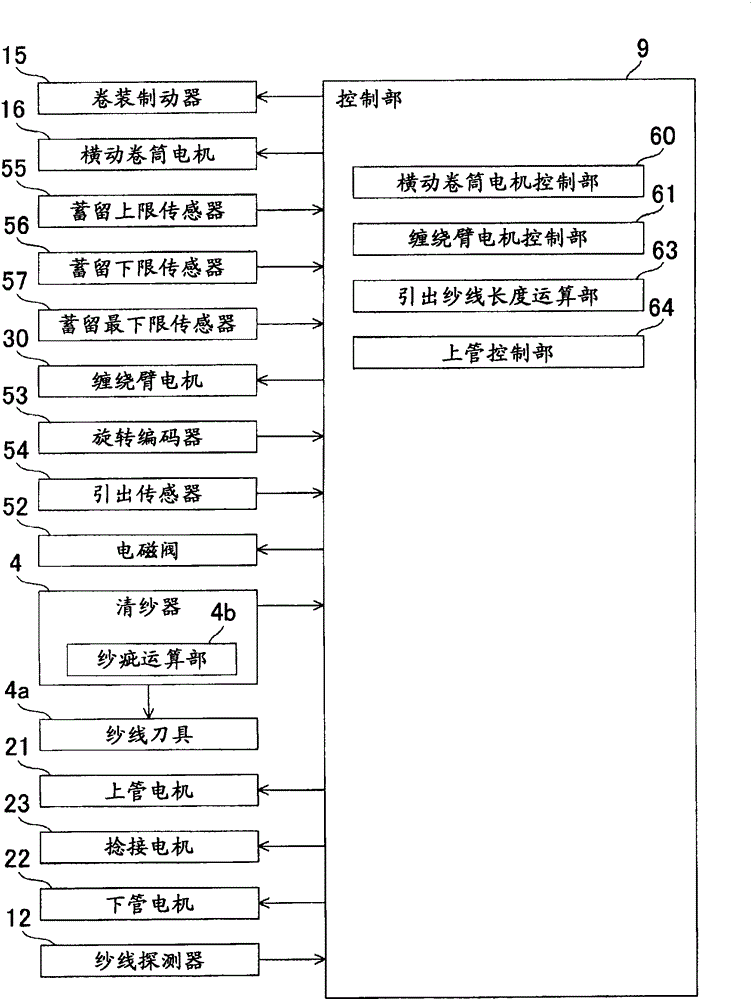

Disclosed is a yarn winder capable of continuing winding yarn during knotting of the yarn. Specifically disclosed is a yarn winder which comprises a yarn supplying unit (3) that unwinds yarn (Y) from a yarn supplying bobbin (B); a yarn winding unit (5) that winds the yarn (Y) as a package (P); an accumulator (7) that is disposed between the yarn supplying unit (3) and the yarn winding unit (5) and that accumulates the yarn (Y); and a yarn end drawing mechanism (W) that draws an end of the accumulated yarn (Y) to the yarn supplying unit (3) when the yarn supplying bobbin (B) is changed, when the yarn is cut, or when the yarn runs out.

Owner:MURATA MASCH LTD

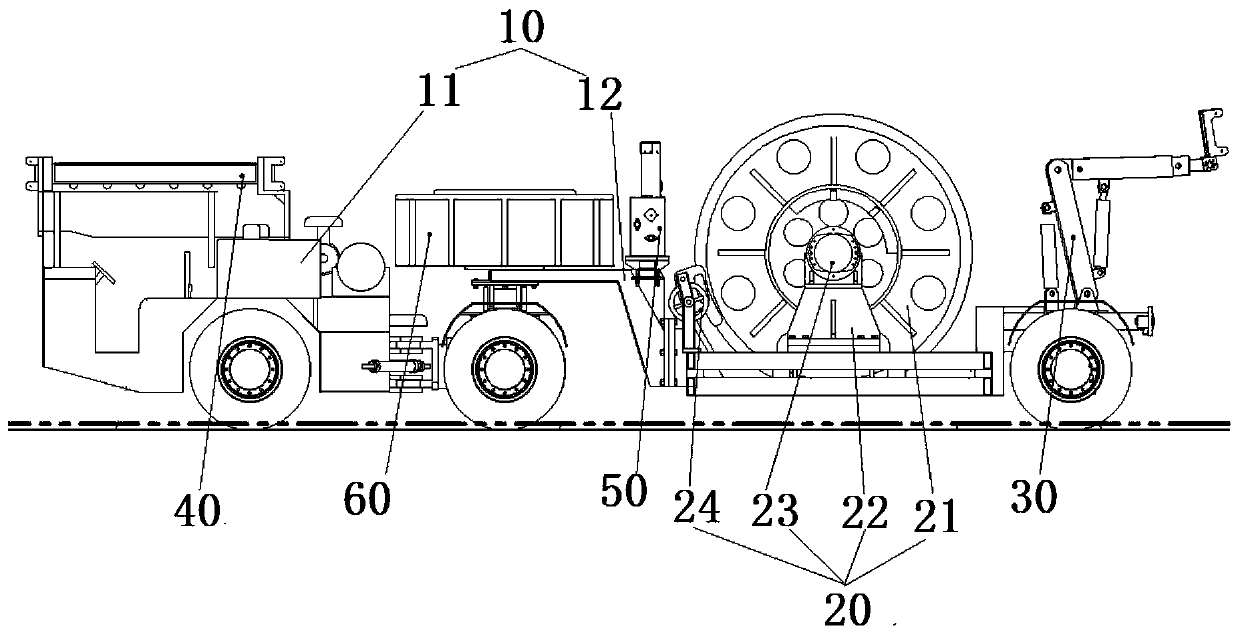

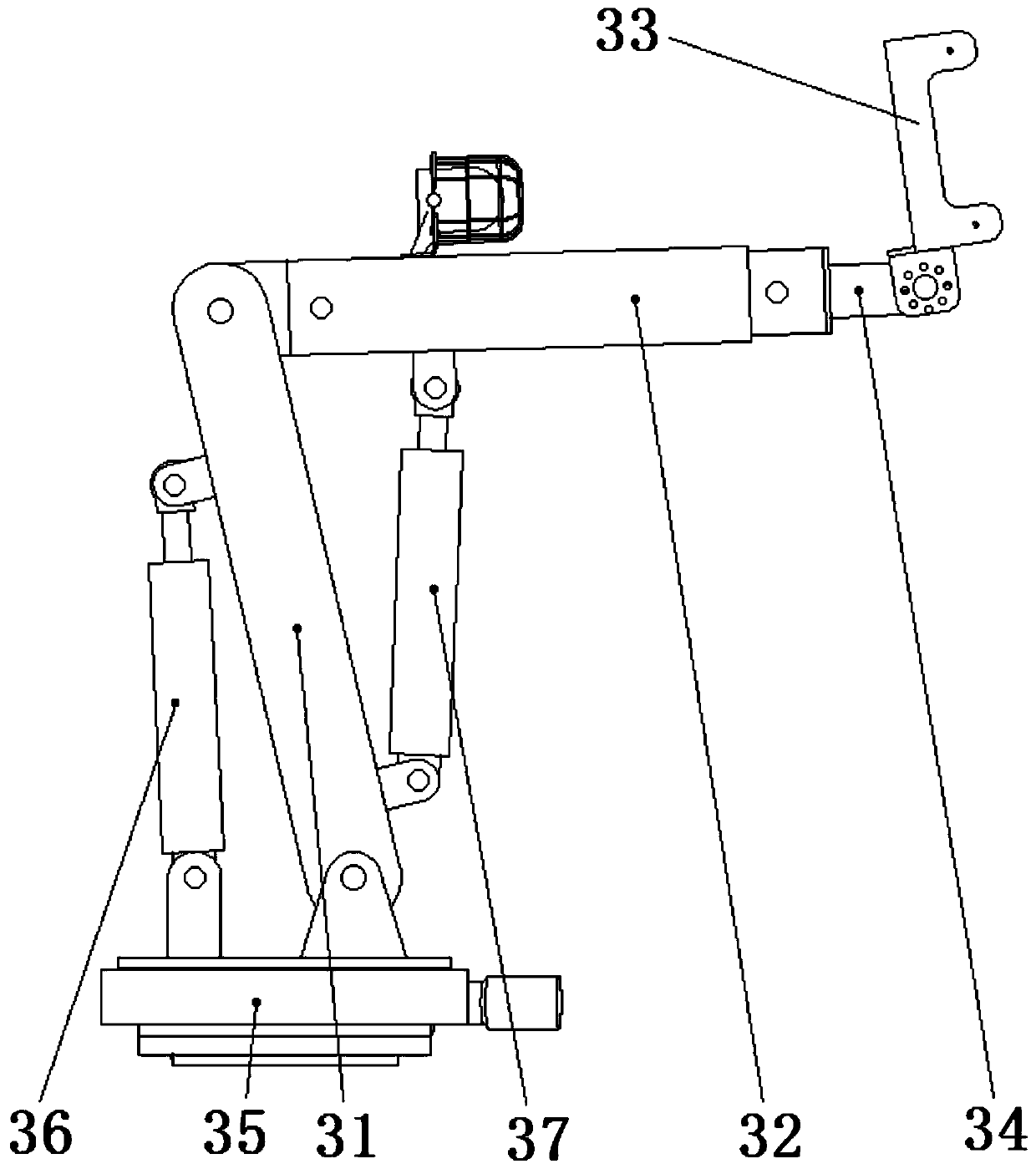

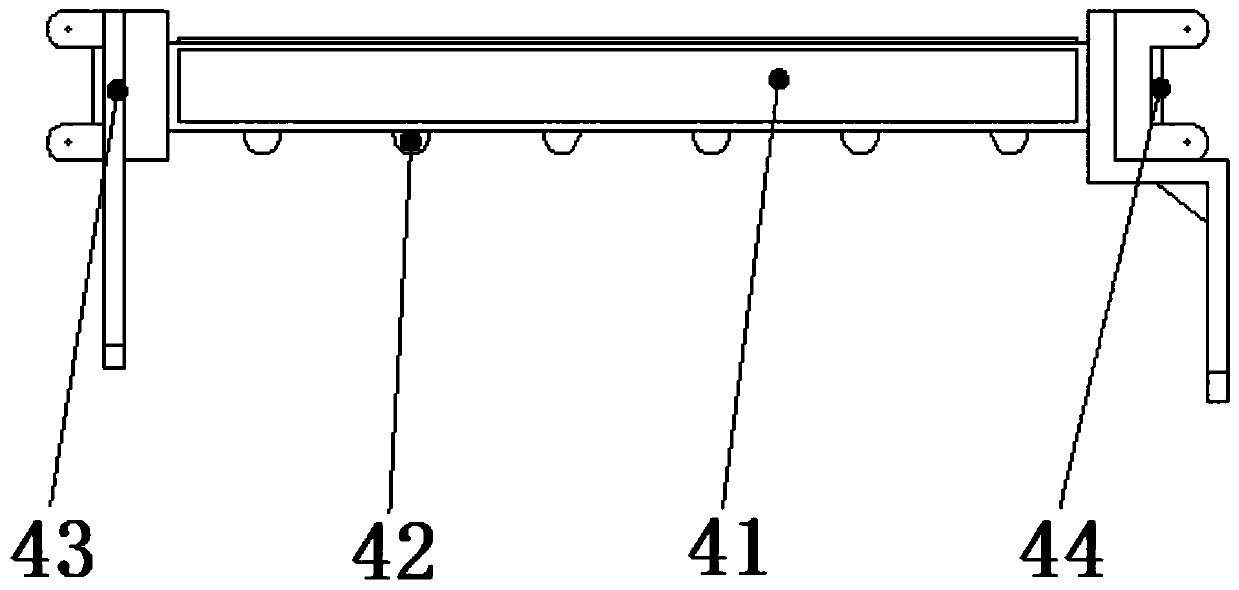

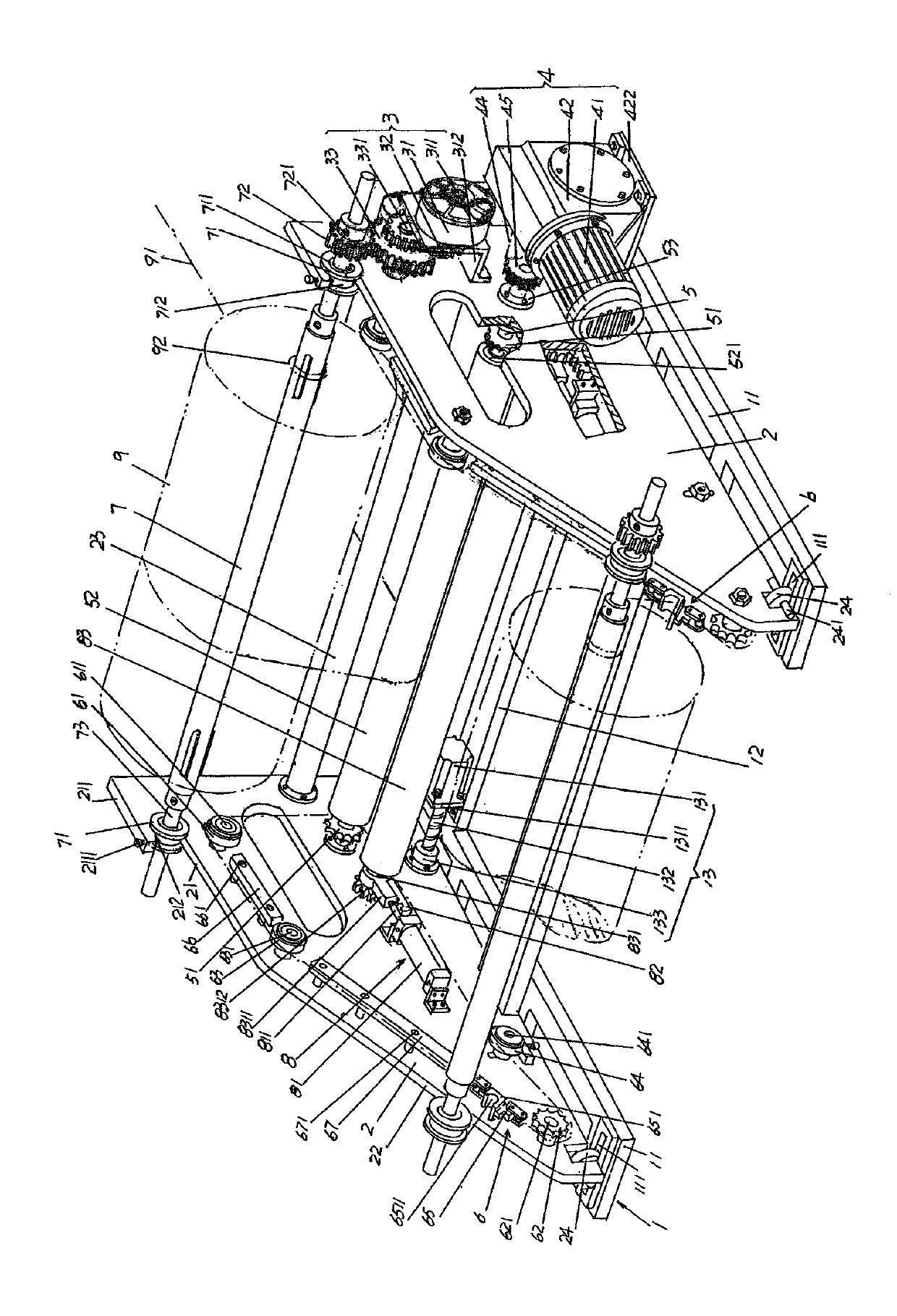

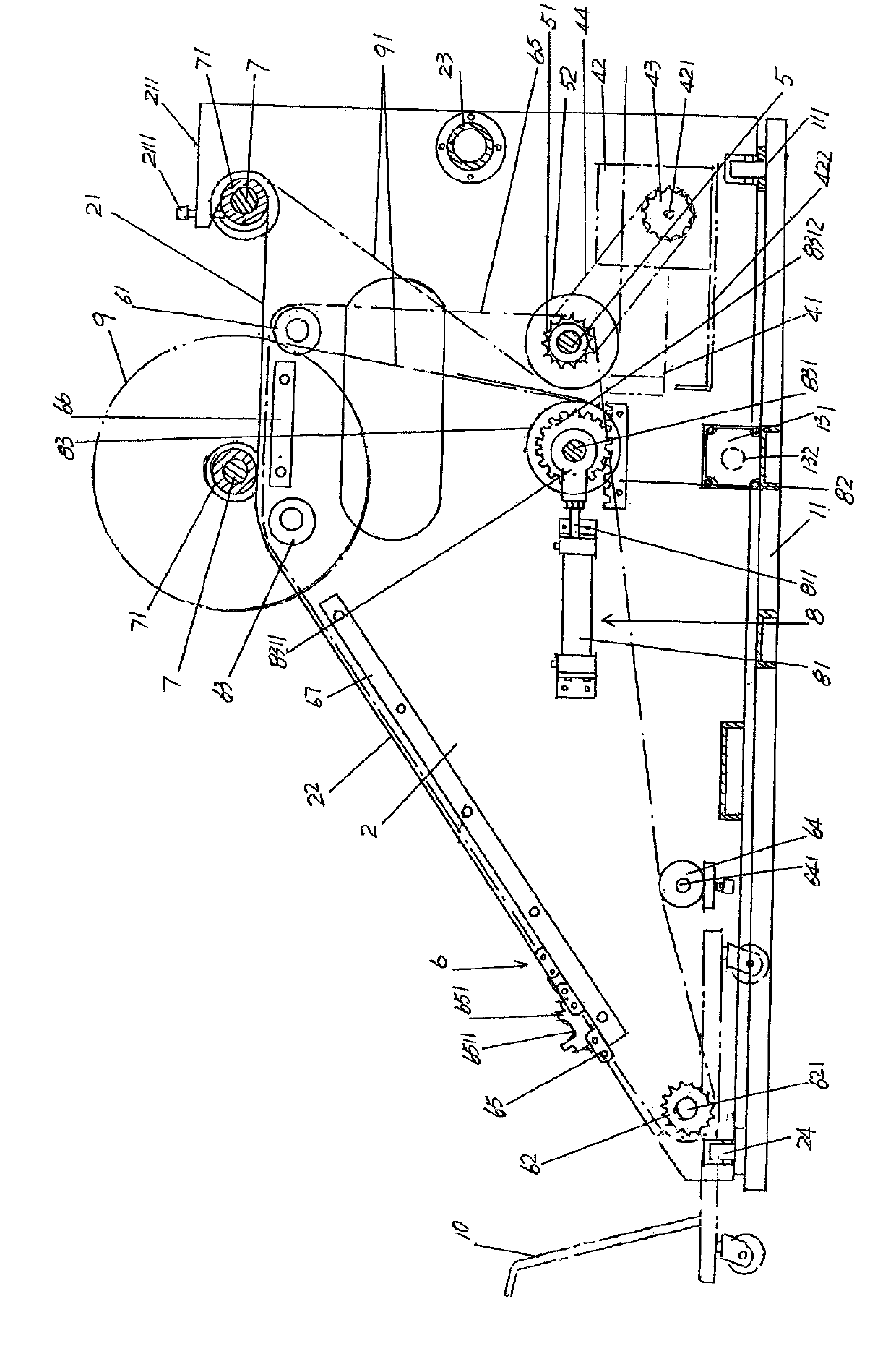

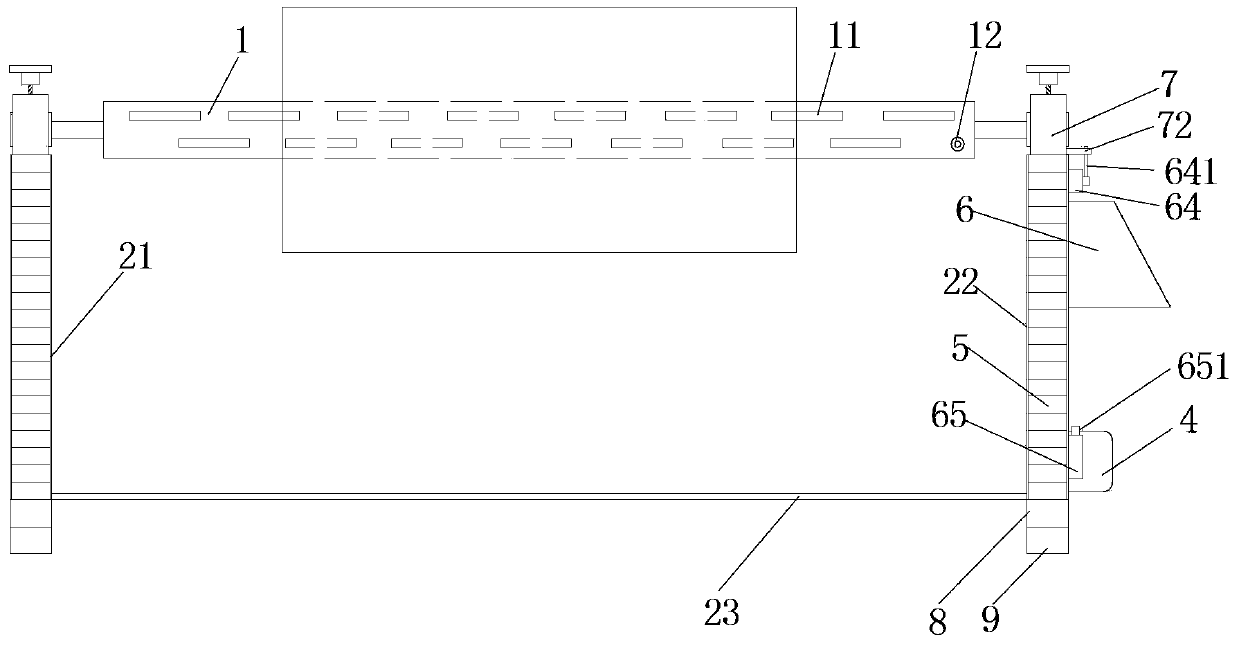

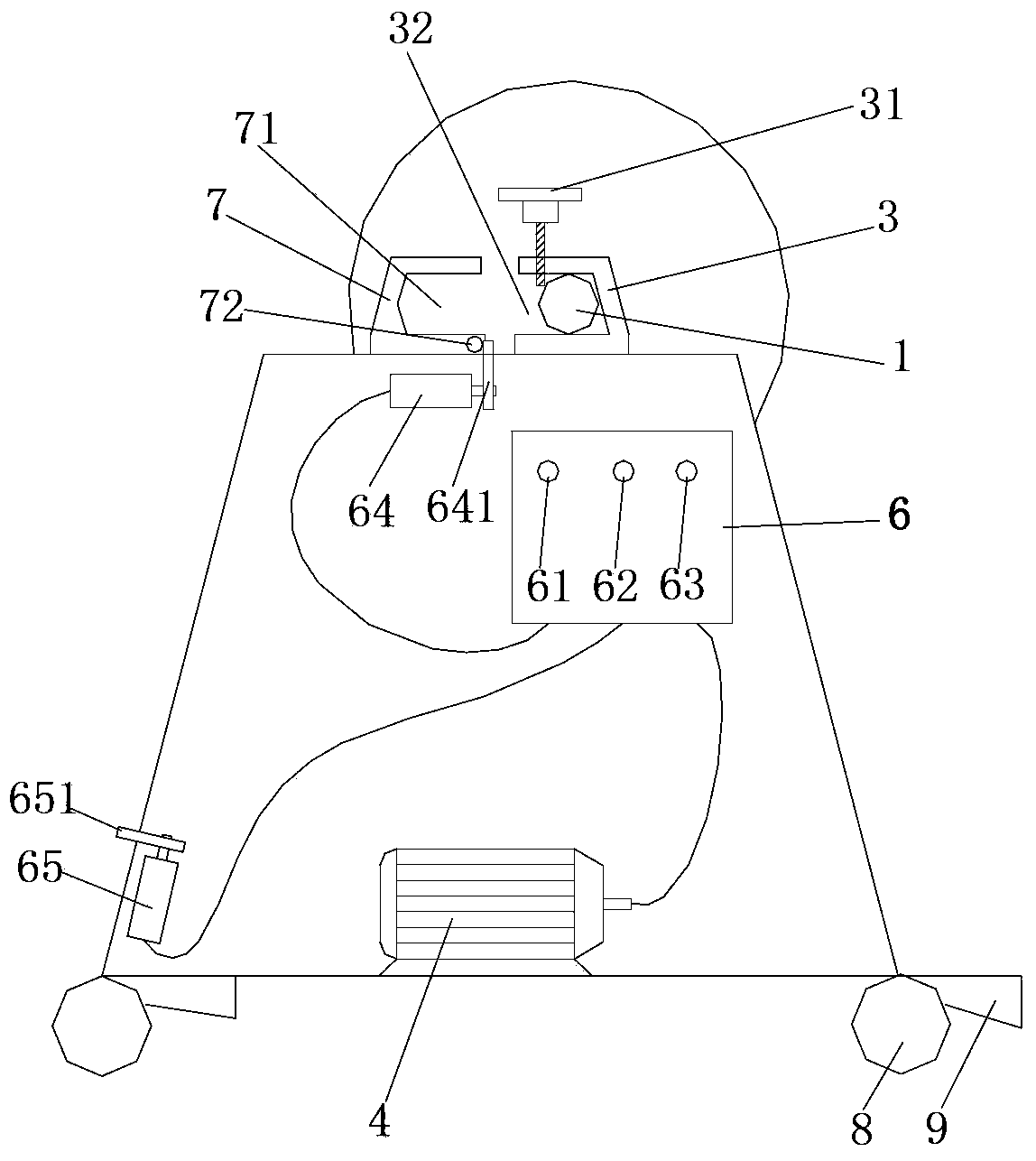

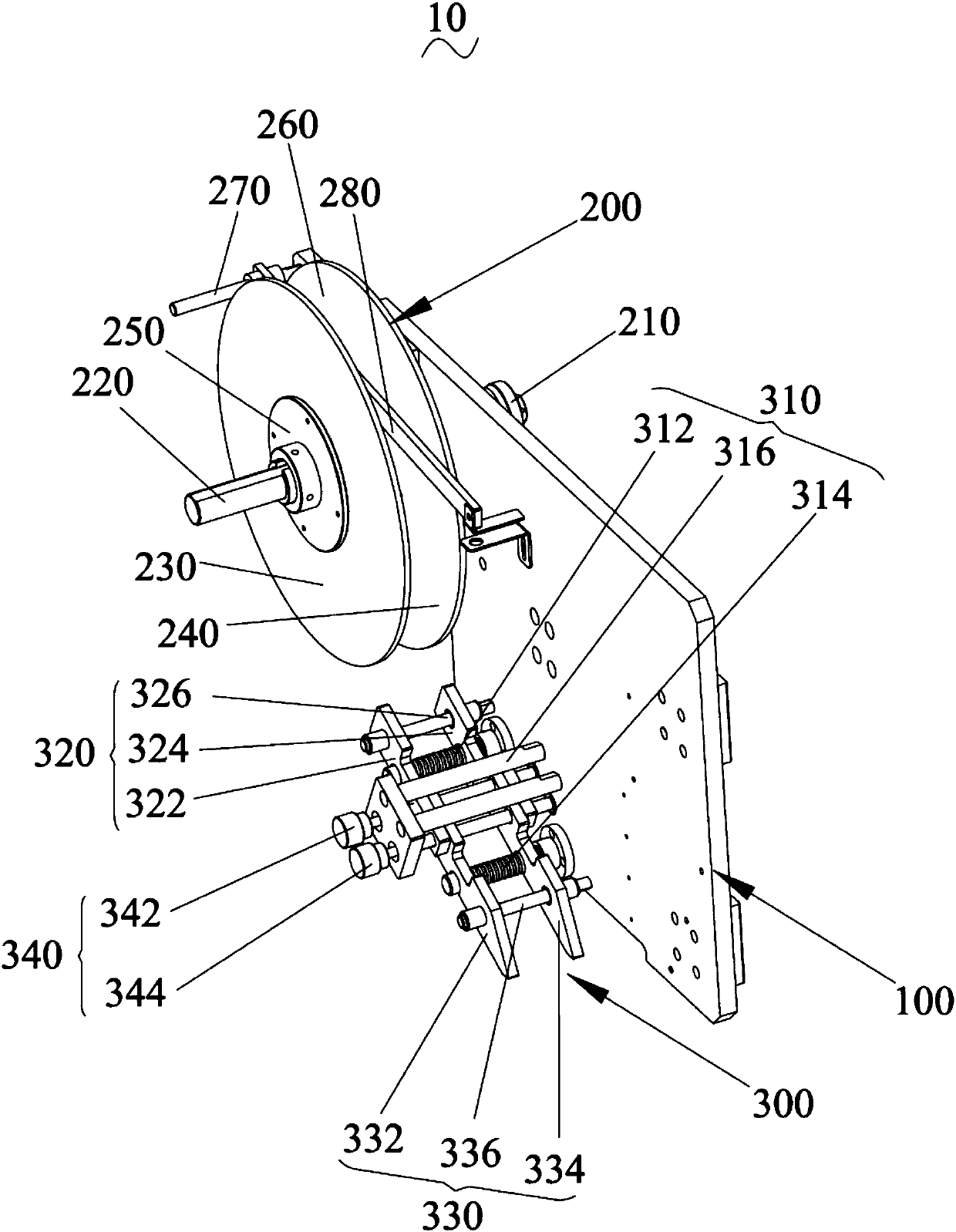

Cable winding and unwinding vehicle

PendingCN109911718AGuaranteed cleanlinessImprove unwinding efficiencyCleaning using toolsManipulatorElectrical and Electronics engineering

Owner:LANG FANG JING LONG GRAND IND MACHINERY CO LTD

Film reel unrolling machine

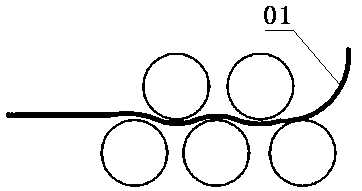

The invention discloses a film reel unrolling machine, and belongs to the field of special equipment used in film adhesive tape production. The film reel unrolling machine comprises a machine base, a pair of wall boards, a carrier roller driving mechanism, a carrier roller lifting power mechanism, a traction transmission shaft, carrier roller traction mechanisms and a carrier roller. The film reel unrolling machine is characterized in that the film reel unrolling machine further comprises a quick reel replacing mechanism, the quick reel replacing mechanism comprises unrolling acting cylinders, racks and an unrolling compression roller, wherein the opposite sides of the pair of wall boards are respectively provided with one unrolling acting cylinder and one rack, the unrolling acting cylinders correspond to each other in position and the racks also correspond to each other in position. The unrolling compression roller corresponds to the front side, in the length direction of a cleaning roller, of the cleaning roller, the two ends of an unrolling compression roller shaft are respectively provided with a compression roller shaft base and a compression roller shaft gear, the compression roller shaft bases are connected with the tail ends of unrolling acting cylinder columns and the compression shaft gears are meshed with the racks. Due to the fact that the quick reel replacing mechanism is added, when a reel needs to be replaced, the quick reel replacing mechanism enables adhesive tape bonded to the starting end of a next film reel to be connected with the tail end of a prior film reel end to end between the unrolling compression roller and the cleaning roller and the unrolling efficiency can be improved without machine halts.

Owner:SUZHOU BAIQI ELECTRONICS MATERIAL

Silicon paper unreeling frame utilizing limit switches

ActiveCN103420190AImprove unwinding efficiencyIncrease productivityArticle deliveryWebs handlingSiliconLimit switch

The invention discloses a silicon paper unreeling frame utilizing limit switches. The silicon paper unreeling frame comprises a reeling roller, a first supporting frame, a second supporting frame and a motor, wherein the first supporting frame is connected with the second supporting frame through a connection rod, a fixing device is arranged above the first supporting frame which is sleeved with a conveying chain, a fixing device is arranged above the second supporting frame which is sleeved with a conveying chain, a lifting control part, the first limiting switch, the second limiting switch and the motor are arranged on one side of the second supporting frame, the lifting control part is connected with the first limiting switch, the second limiting switch and the motor through conductive wires, each conveying chain is provided with a lifting device, a second groove is formed in the middle of each lifting device which is provided with a transverse rod, the reeling roller is of a hollow structure, a plurality of movable blocks are embedded in the reeling roller, and an air inlet hole is formed in one end of the reeling roller. The silicon paper unreeling frame can prevent the phenomenon that reeled silicon paper and the unreeling roller slip, save labor, and protect the lifting devices.

Owner:CIXI QIXINGQIAO ADHESIVE

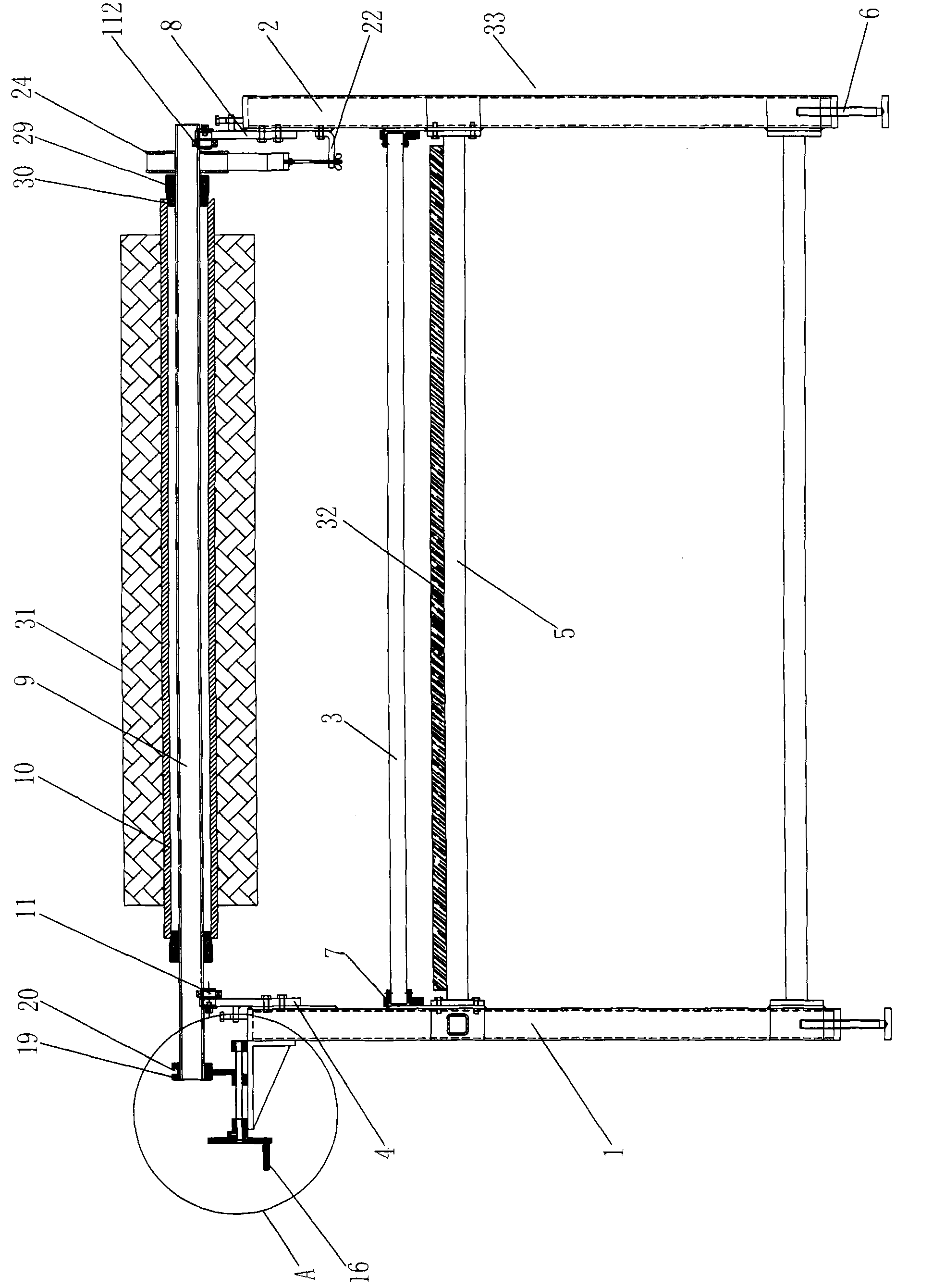

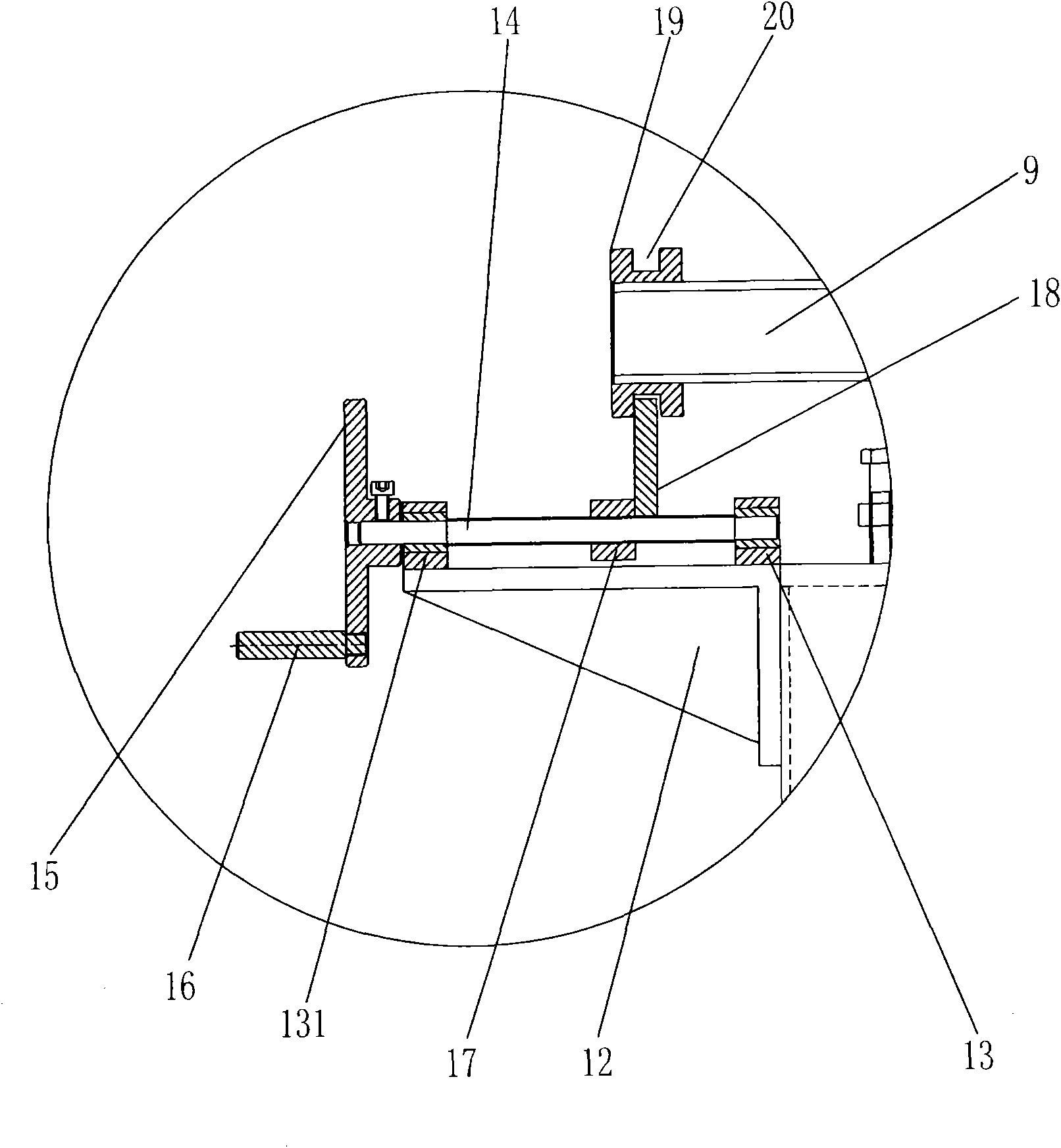

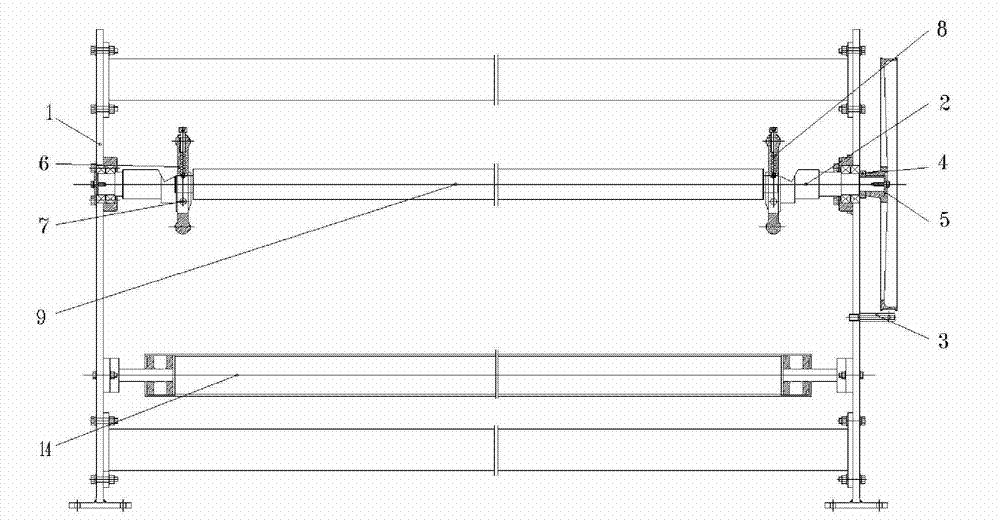

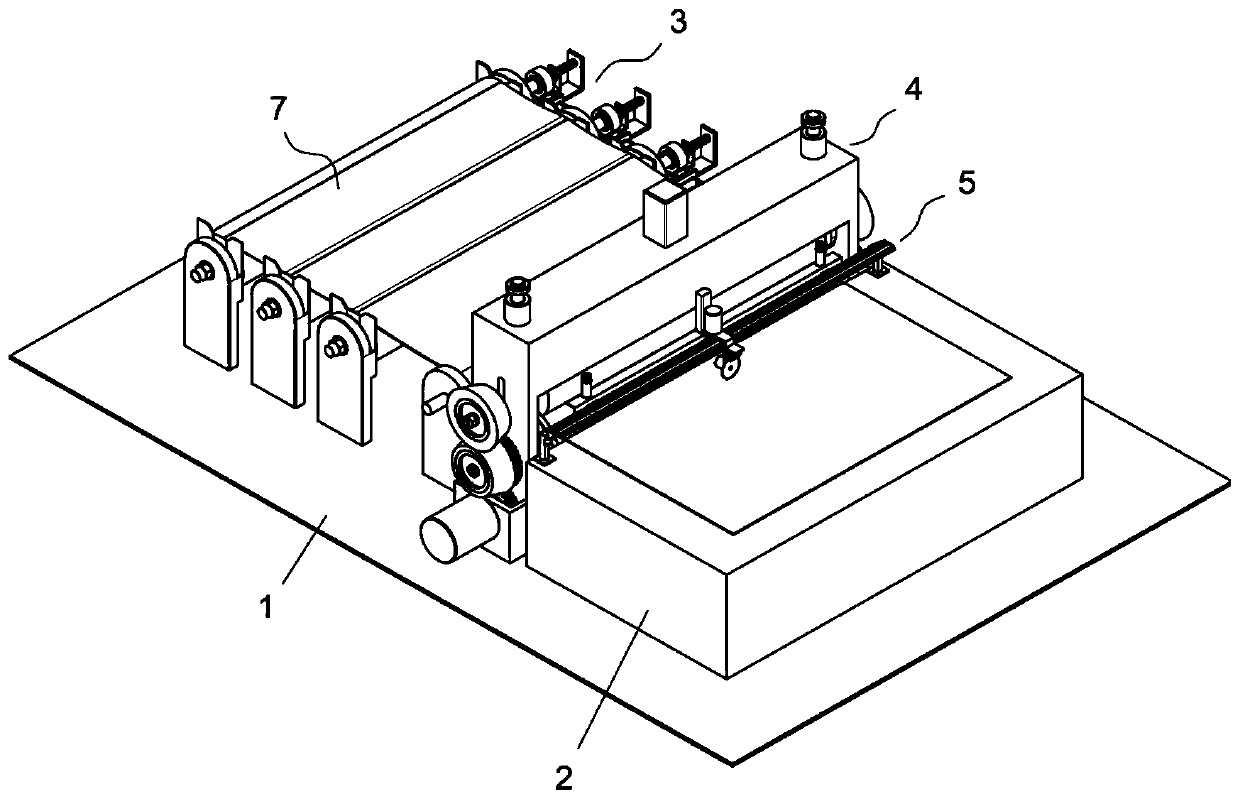

Multiaxial material returning device for cutting reinforced fabric

ActiveCN101967750AAchieve the purpose of correctionGuaranteed cutting qualitySevering textilesWebs handlingEngineeringMechanical engineering

The invention discloses a multiaxial material returning device for cutting a reinforced fabric. The device comprises a material returning mechanism which comprises a bracket, wherein a guide axle is arranged on the bracket; a left upper end and a right upper end of the bracket are provided with a support seat respectively; a support axle is arranged between the two support seats; the two support seat are symmetrically provided with support devices; each support device comprises two pairs of support bearings which are arranged on the two support seats respectively; two ends of the support axle are arranged on the two pairs of support bearings respectively; an edge correction device on the left side of the bracket comprises an edge correction support which is fixedly arranged on the left side of the bracket; two fixing blocks and a screw arranged on the two fixing blocks are fixedly arranged on the edge correction support; the screw between the two fixing blocks is provided with a positioning component; and the support axle is provided with a positioning ring matched with the positioning component. Through the multiaxial material returning device for cutting the reinforced fabric, the fabric on a fabric distribution roller can be unwound to an accurate position and the cutting quality is guaranteed; moreover, the unwinding efficiency of the fabric distribution roller can be improved by adjusting the unwinding speed of the fabric distribution roller, therefore the cutting efficiency can be improved.

Owner:CHANGZHOU HONGFA ZONGHENG ADVANCED MATERIAL TECH

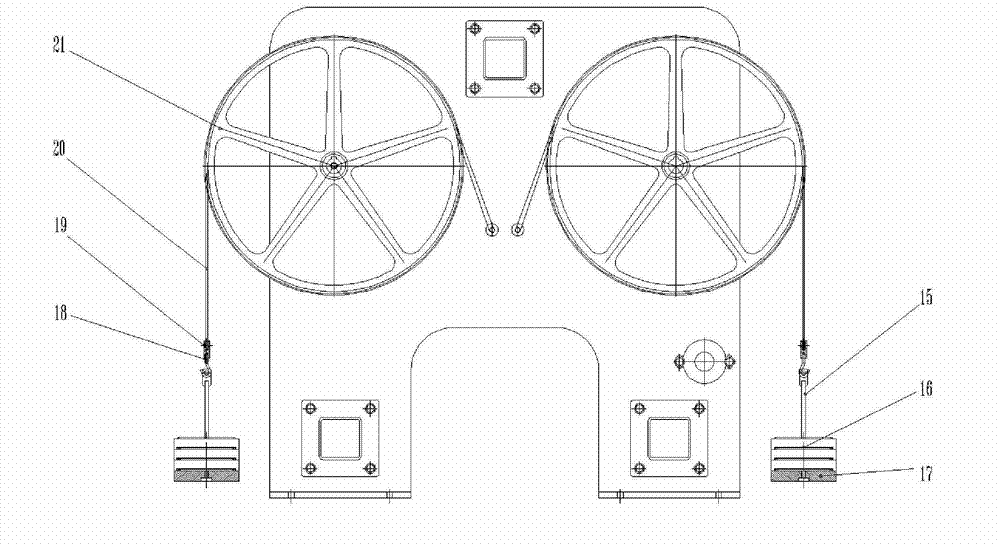

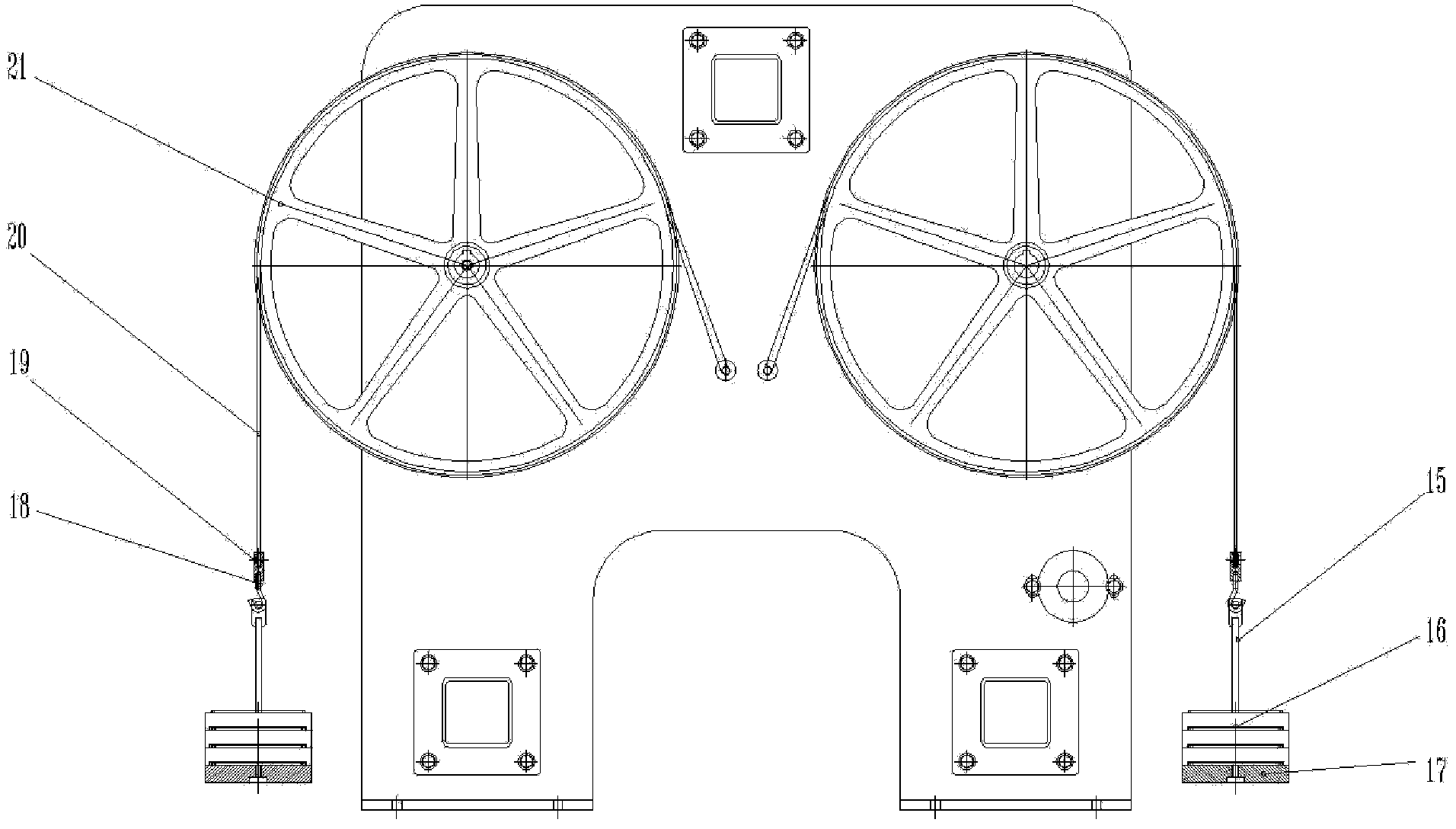

Nonwoven fabric felt unrolling frame

The invention provides a nonwoven fabric felt unrolling frame which can keep constant tensioning force with a nonwoven fabric knitting unit during unrolling of nonwoven fabrics. The nonwoven fabric felt unrolling frame comprises two wall plates of the felt unrolling frame, and a tensioning rod, a felt guide roller and two pneumatic tensioning shaft are connected between the two wall plates. A main shaft head is arranged at one end of the pneumatic tensioning shaft while an auxiliary shaft head is arranged at the other end of the pneumatic tensioning shaft, and a safety flange is mounted on the inner side of each of the main shaft head and the auxiliary shaft head and on the pneumatic tensioning shaft. Bearing blocks are mounted on the inner wall of the two wall plates of the felt unrolling frame corresponding to the left end and the right end of the pneumatic tensioning shaft, the main and auxiliary shaft heads of the pneumatic tensioning shaft are mounted in bearings of the bearing blocks, a fixed plate is mounted outside the auxiliary shaft head, and the main shaft head penetrates through the bearing blocks to extend outside the wall plates. A retaining belt pulley spacer ring is sleeved on a portion, close to the end, of the main shaft head. A brake wheel is mounted at the end of the main shaft head through bolts, and a supporting column horizontally extends outwards on the wall plate at the mounting end of the brake wheel and is positioned below the brake wheel. A brake belt is sleeved on the brake wheel, a connecting plate is fixed to the end of the brake belt, a hook is fixed to the bottom end of the connecting plate through a hook screw, a hanging plate is hung at the bottom of the hook, and a counter weight is placed on the hanging plate.

Owner:CHANGZHOU DIBA TEXTILE MACHINERY

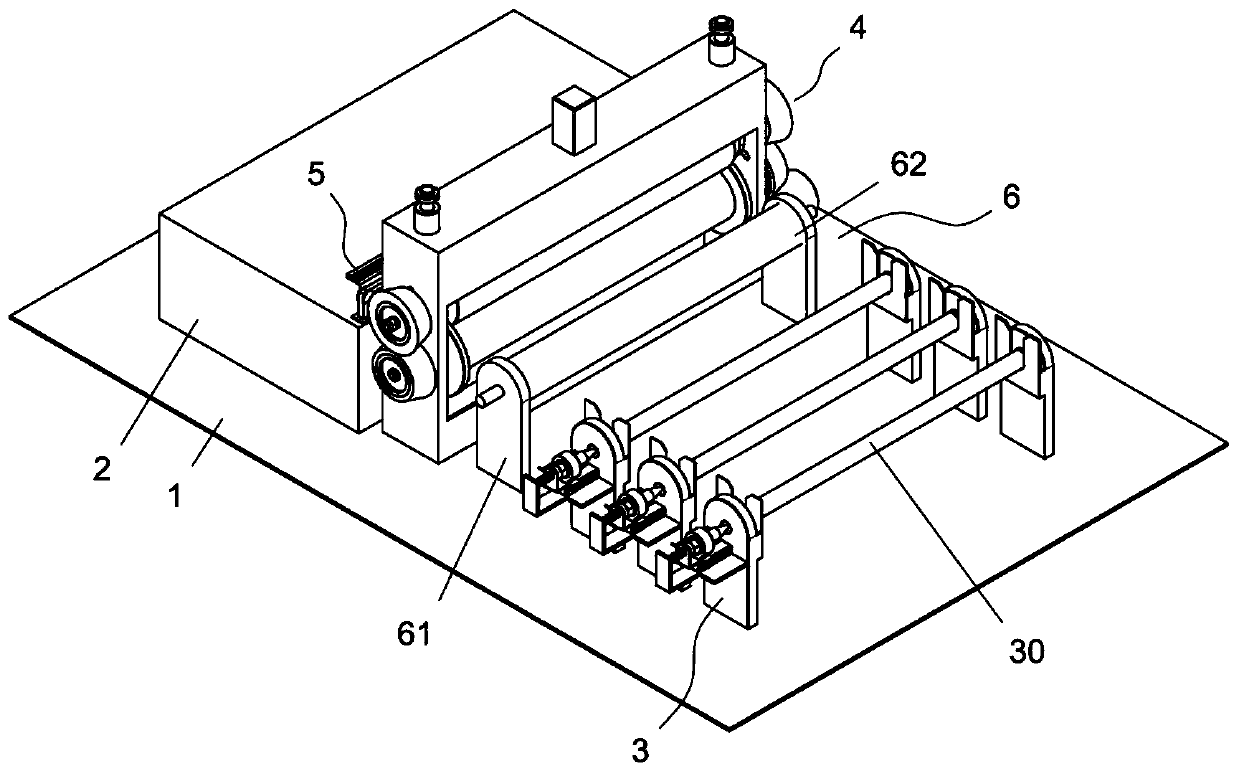

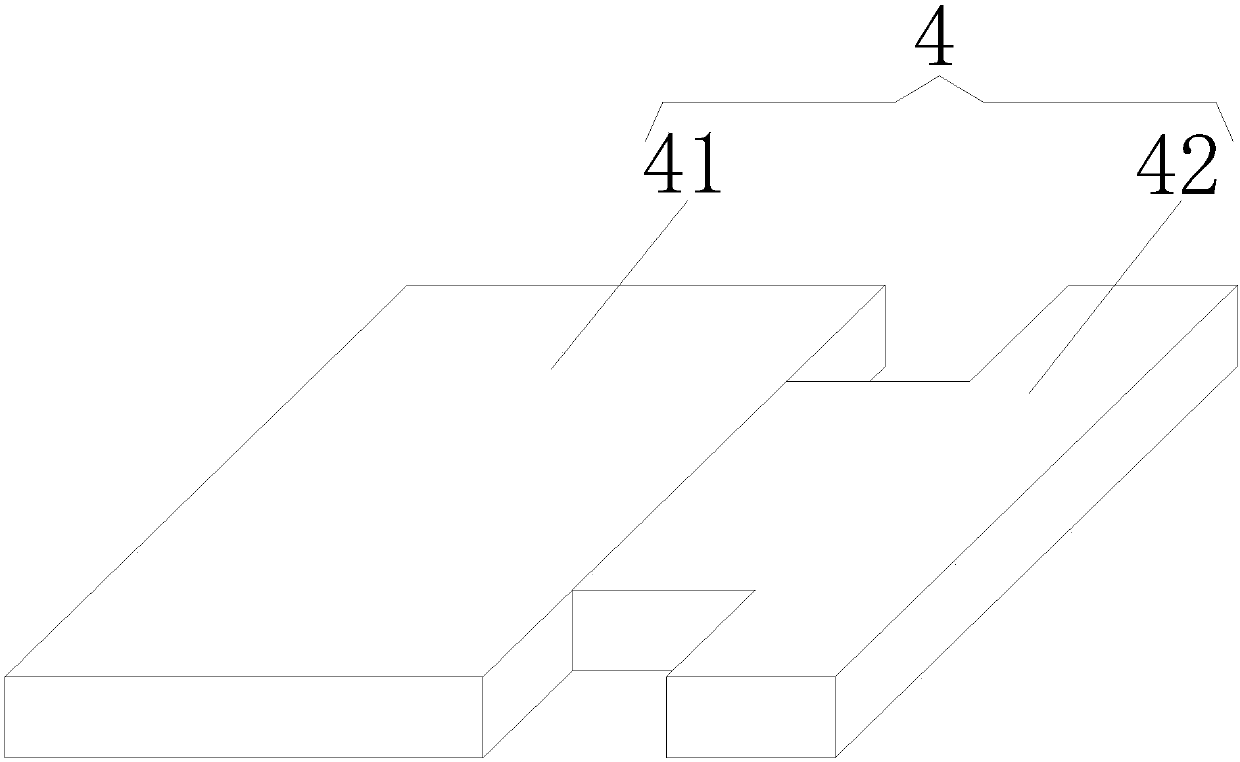

An unwinding device for a modified asphalt production line

InactiveCN104891228AEasy to assemble and disassembleIncrease flexibilityWebs handlingProduction lineEngineering

The invention belongs to the technical field of manufacture and specifically provides an unwinding device for a modified asphalt production line. The technical problem of unreasonable design in the prior art is solved. The unwinding device for a modified asphalt production line comprises a frame. Two unwinding swing arms corresponding to each other are arranged on the frame. One ends, corresponding to each other, of the two unwinding swing arms are articulated to the frame and the other corresponding ends of the two unwinding swing arms are suspended. A plurality of unwinding shafts spaced from each other are arranged between the two unwinding swing arms. The unwinding shafts and a rotating driving mechanism driving the unwinding shafts to rotate are connected and the unwinding shafts rotate asynchronously. The unwinding swing arms are connected with a lifting driving mechanism driving the unwinding swing arms to swing along an arc in the vertical direction. The unwinding device can increase unwinding efficiency and prolong the replacing period.

Owner:徐媛

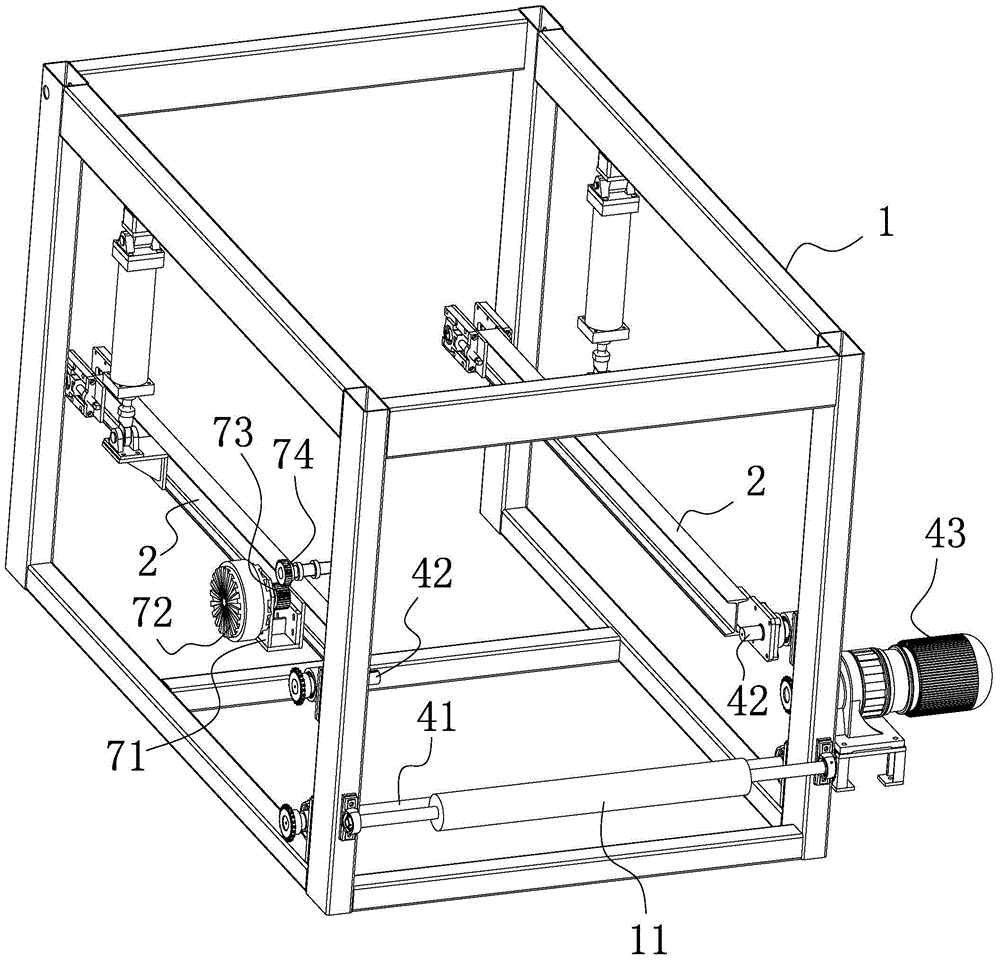

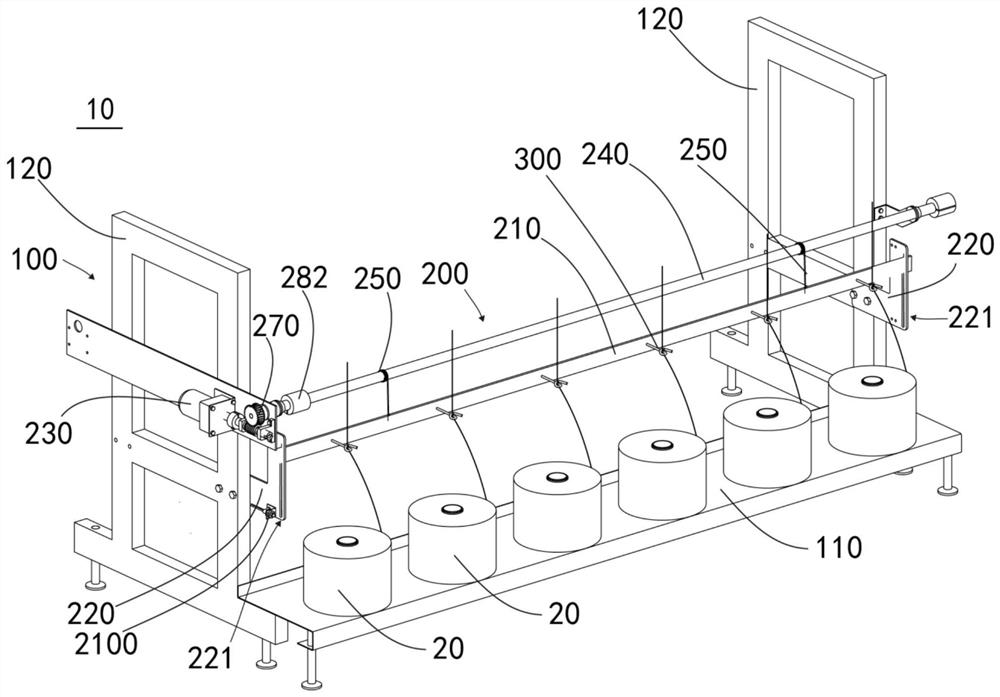

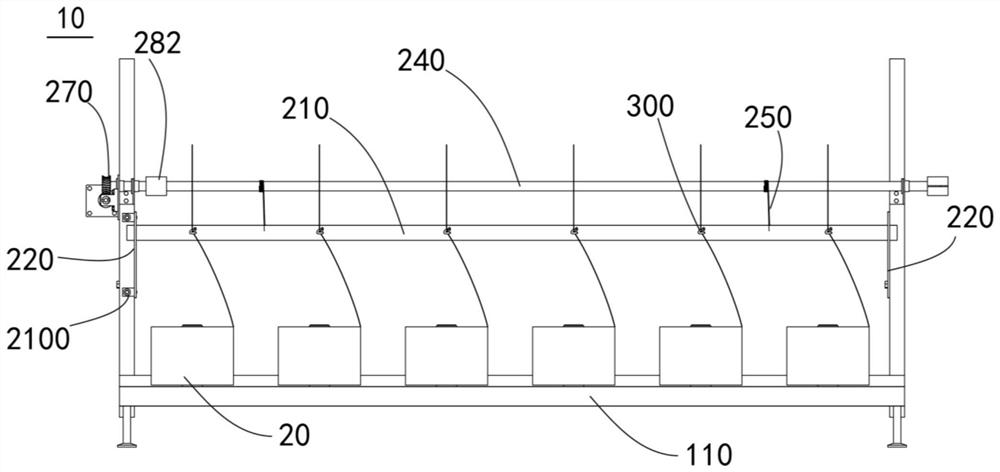

Batch uncoiling device of coiled cloth

The invention discloses a batch uncoiling device of a coiled cloth. The batch uncoiling device of the coiled cloth includes a cloth coiling supporting rack unit, a rolling conveying unit, and a coiling cloth placement platform, wherein a fixing seat of the cloth coiling supporting rack unit is is placed on the operation bottom surface, the cloth coiling supporting rack unit, the rolling conveyingunit and the coiling cloth placement platform are arranged in sequence from front to back, and a level detecting unit is fixedly installed on the coiling cloth placement platform. The batch uncoilingdevice of the coiled cloth is simple in structure and high in practicability, cloth coils can be batch uncoiled and conveyed, and uncoiling information can be collected by a CCD camera in real time sothat the multiple sets of cloths can be smoothly pressed and arranged by the device; and according to the batch uncoiling device of the coiled cloth, a large number of human resources are saved, theuncoiling efficiency is high, and the uncoiling cloth can be batch conveyed to a next station for operation.

Owner:苏州默声熙达设备科技有限公司

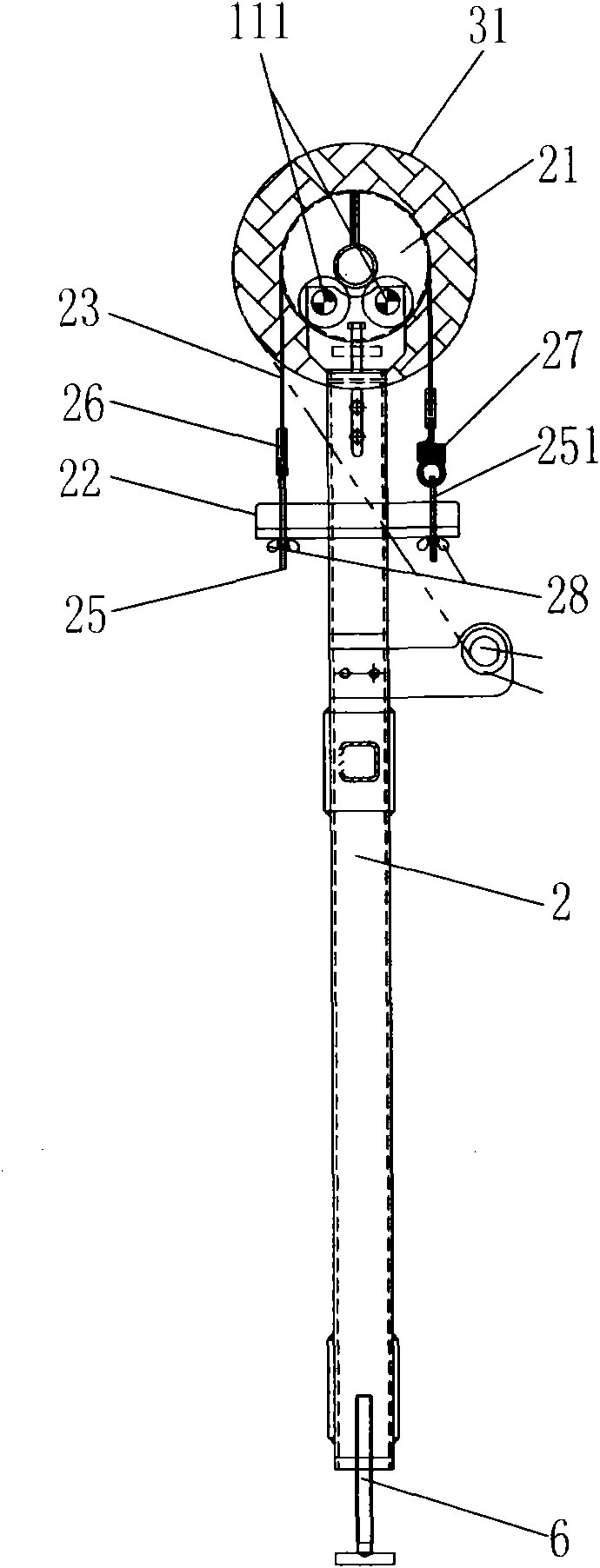

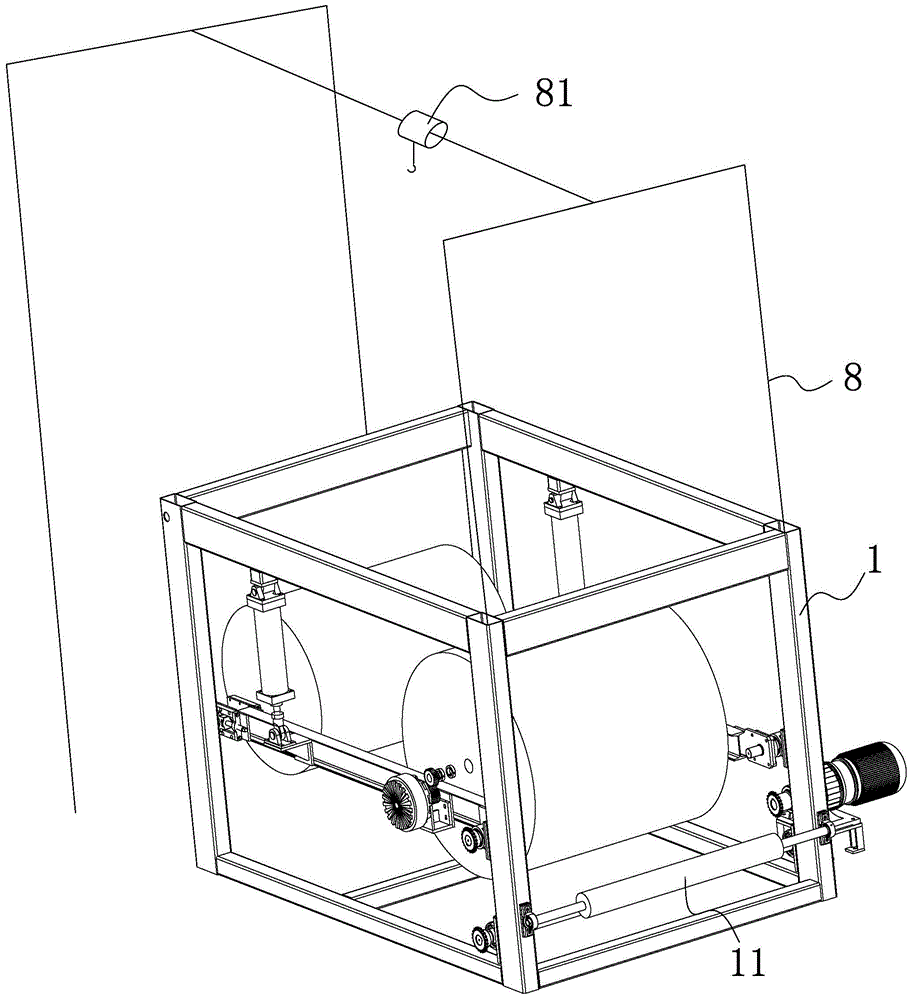

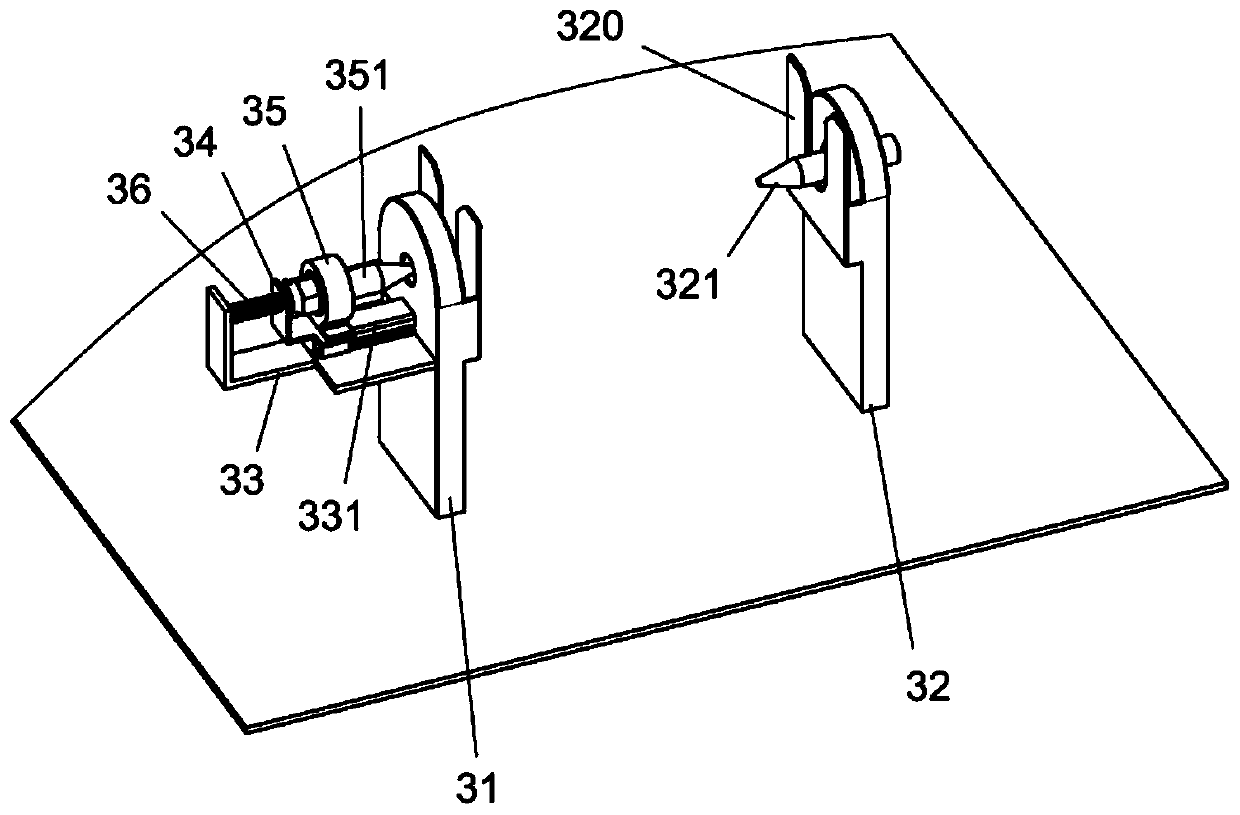

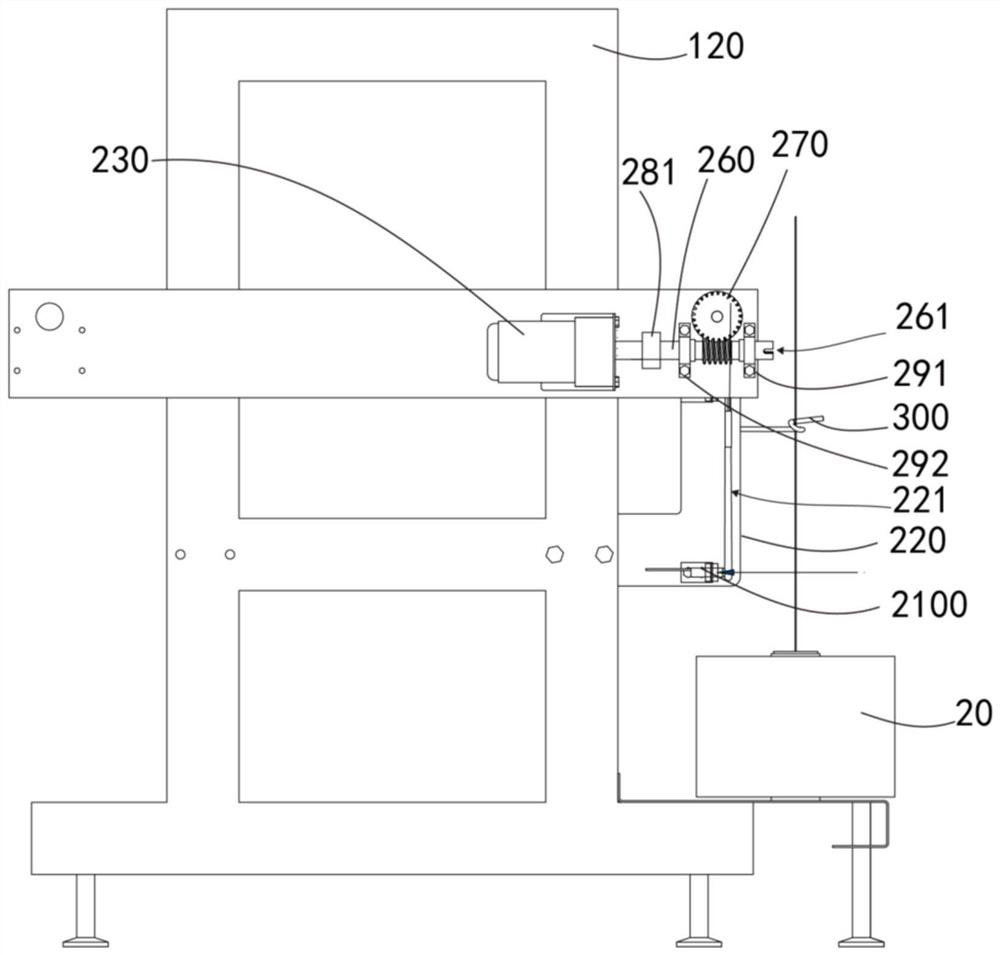

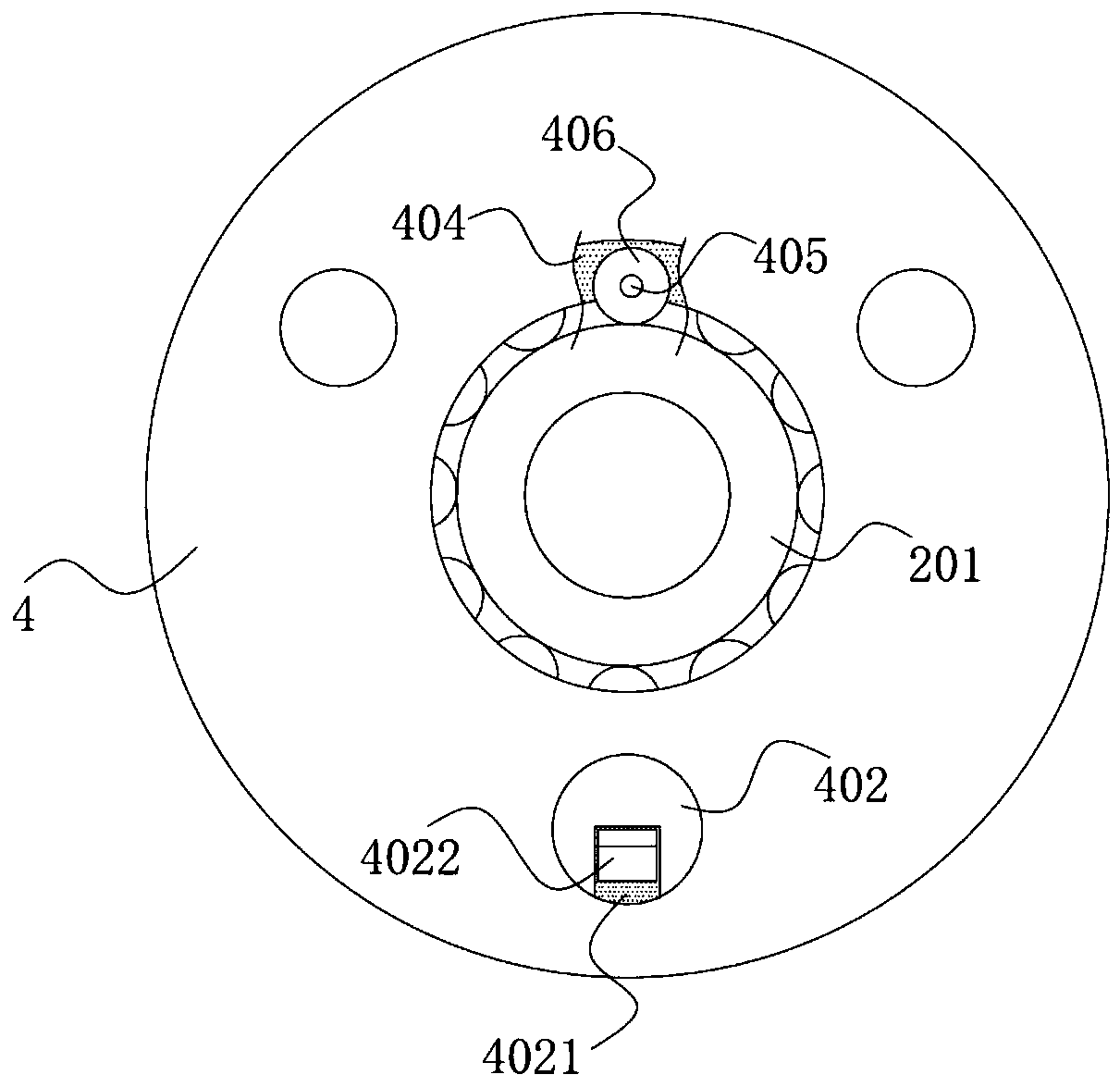

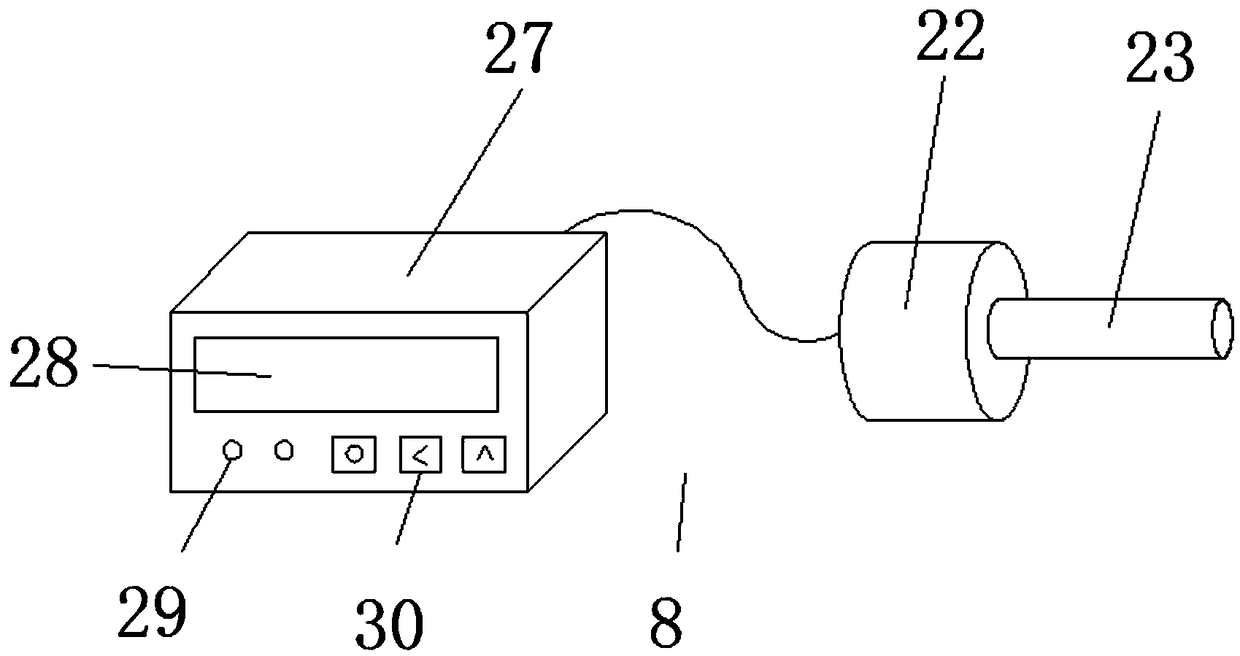

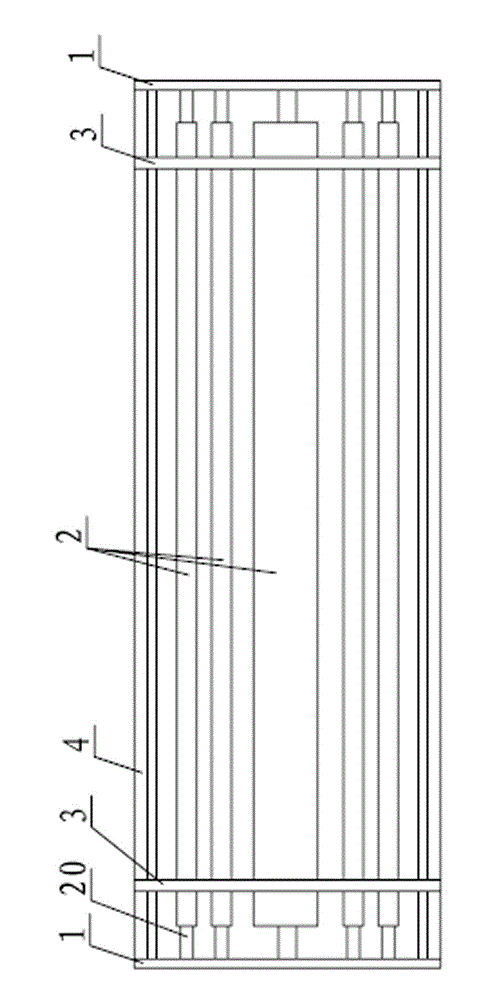

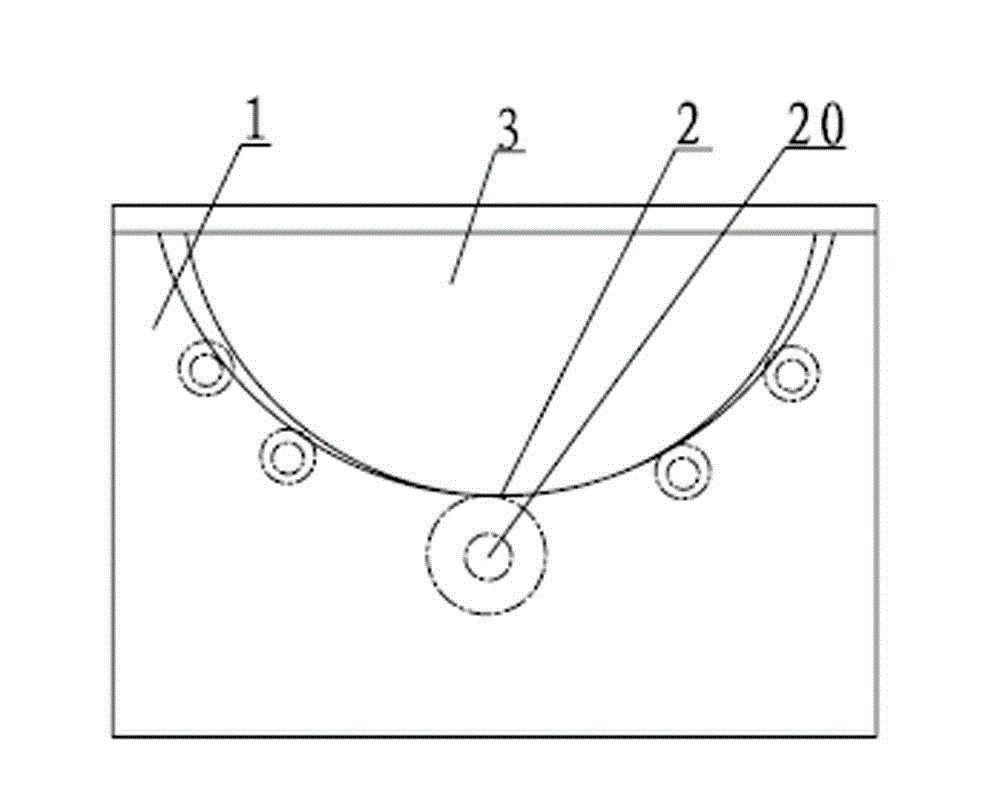

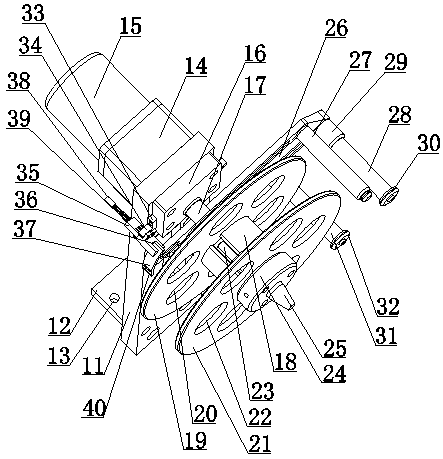

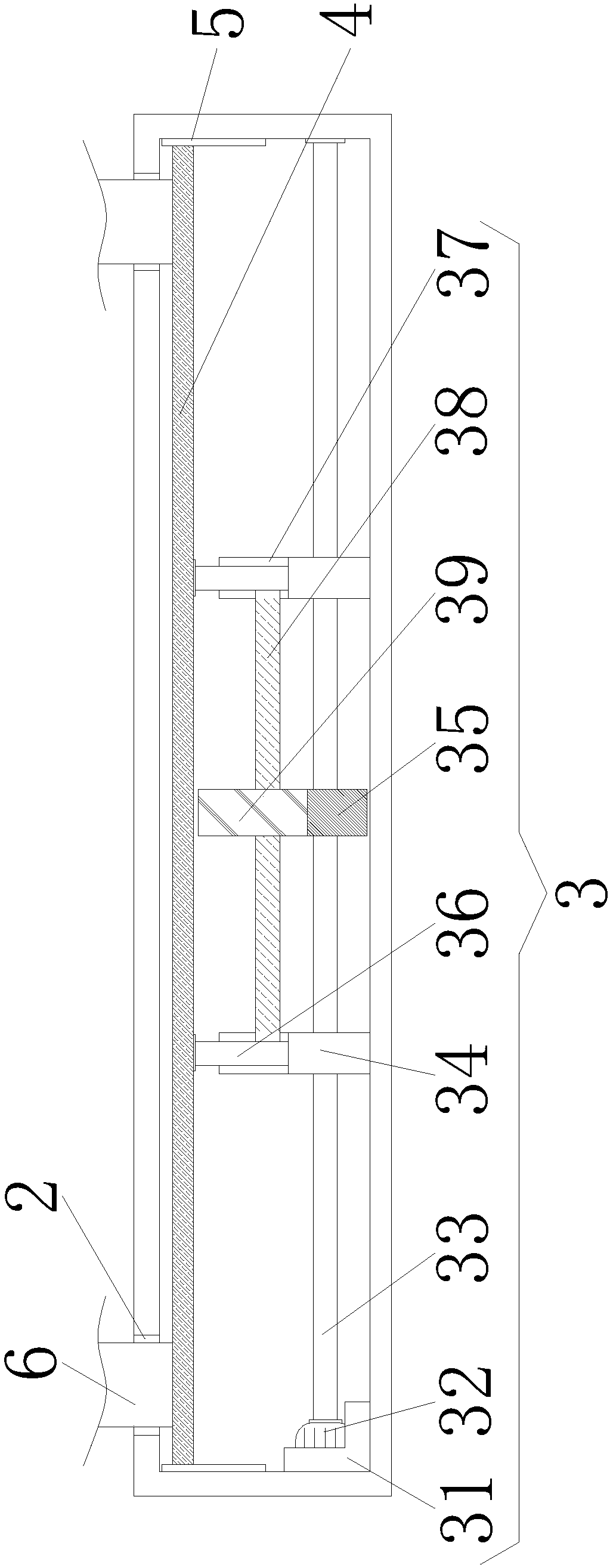

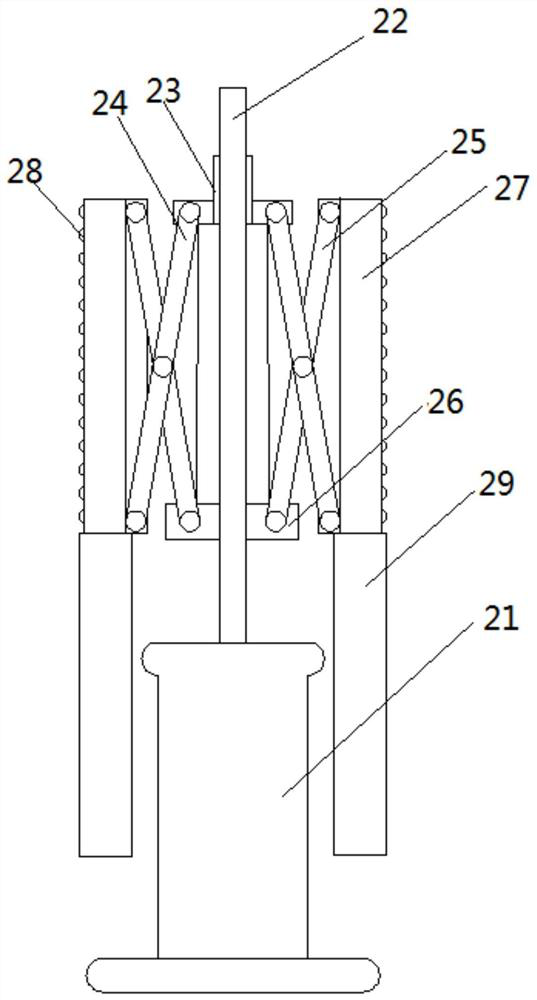

Bobbin yarn unwinding air ring control device and bobbin yarn unwinding equipment

The invention discloses a bobbin yarn unwinding air ring control device and bobbin yarn unwinding equipment. The bobbin yarn unwinding air ring control device comprises a rack, a height adjusting mechanism and an unwinding device, the rack is provided with a placing station for placement of bobbin yarn, the height adjusting mechanism comprises an adjusting plate, a limiting plate and a height adjusting driving part, the limiting plate is arranged on the rack and provided with a limiting channel extending in the vertical direction, the adjusting plate is partially arranged in the limiting channel, and the height adjusting driving part is connected to the adjusting plate and used for driving the adjusting plate to move. The bobbin yarn unwinding equipment comprises a winding device and the bobbin yarn unwinding air ring control device. The bobbin yarn unwinding air ring control device can stabilize a yarn unwinding air ring, the air ring unwinding effect is good, tension on the bobbin yarn is not prone to sudden change in the unwinding process, the phenomena of yarn breakage, damage and hairiness increase are avoided, the product quality is improved, and the unwinding efficiency is improved.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

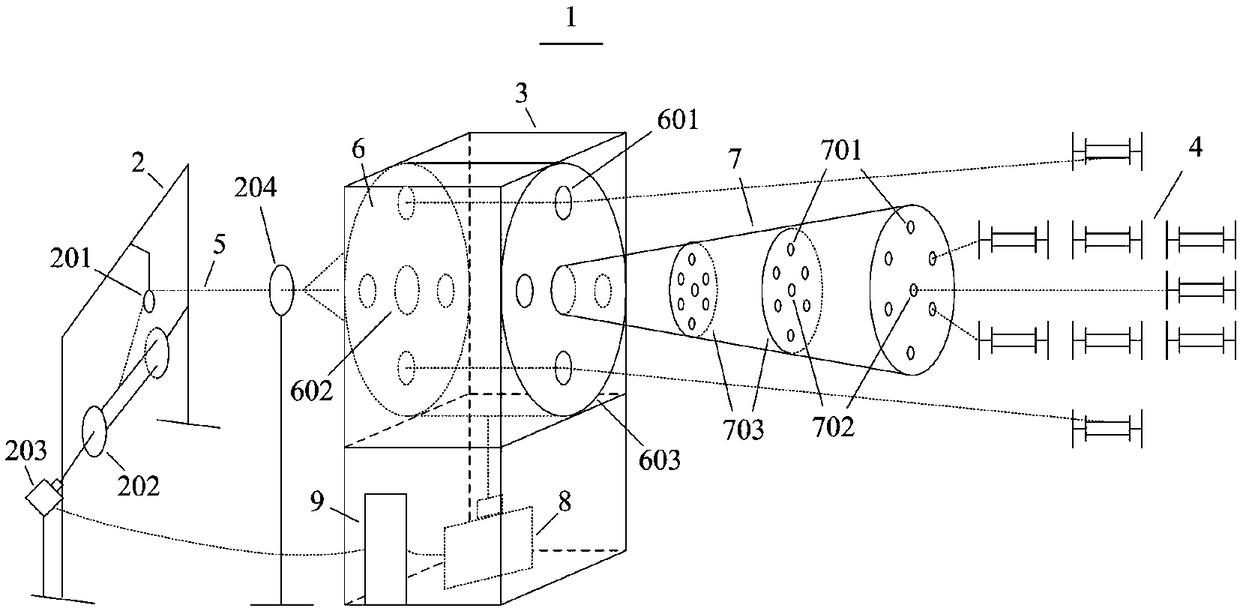

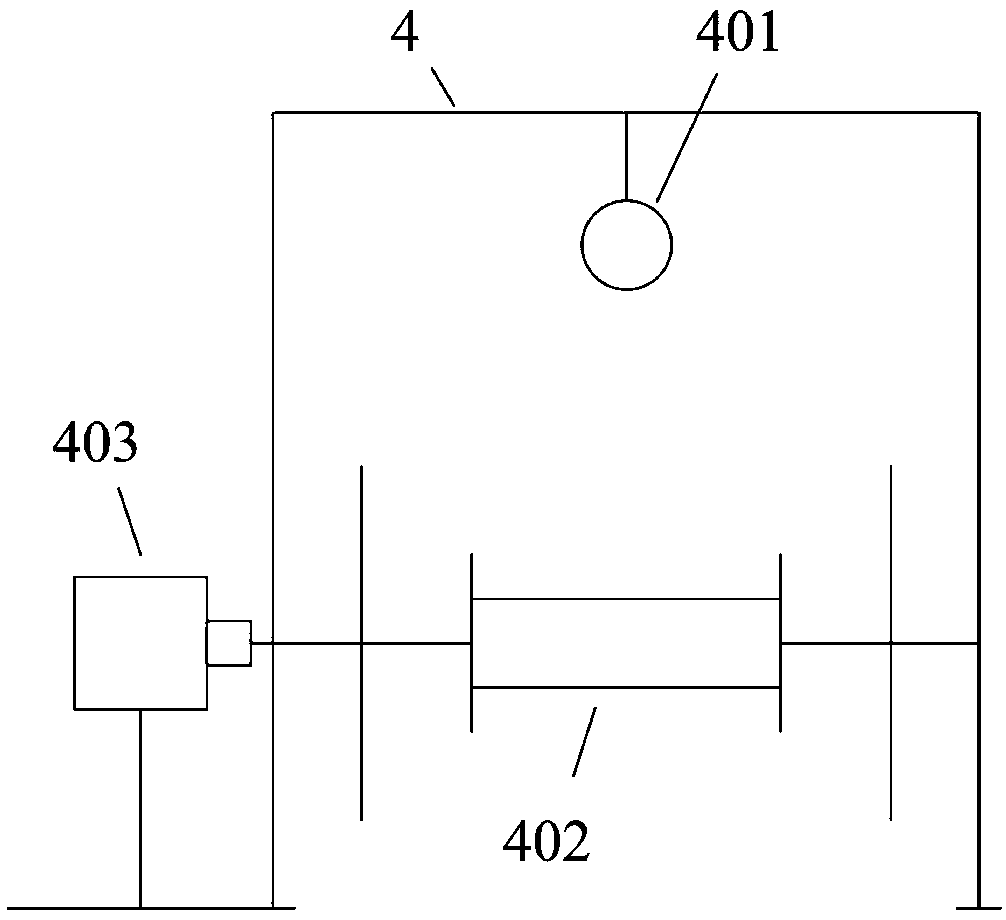

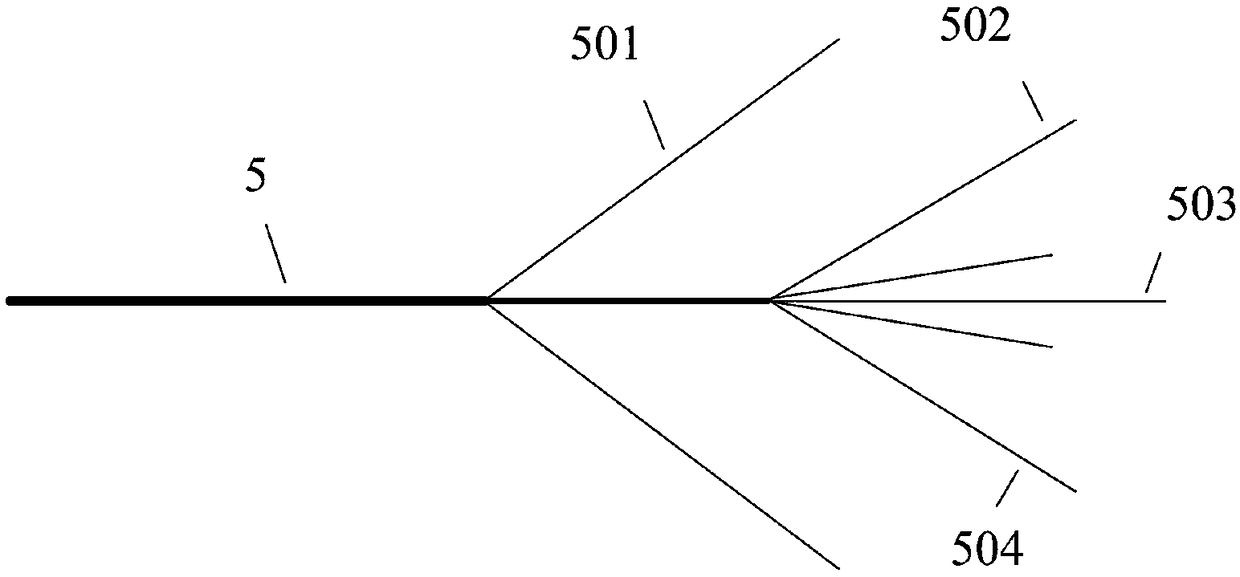

Optical cable retreating machine and realizing method thereof

InactiveCN108732704ARealize the intelligent unwinding functionEasy to operateFibre mechanical structuresYarnElectric machinery

The invention discloses an optical cable retreating machine and a realizing method thereof. The optical cable retreating machine comprises an optical cable retreating device body. The optical cable retreating device is provided with a pay-off frame, a stranding-off frame, a cable receiving frame and an optical fiber finished cable. The middle position of the pay-off frame is provided with a pay-off disc. The upper part of the stranding-off frame is provided with a stranding-off disc, and the lower part is provided with a stranding-off motor and a controller. The middle position of the cable receiving frame is provided with a cable receiving disc. One end of the cable receiving disc is connected with a cable receiving motor. The cable receiving motor is electrically connected with the controller. The controller is electrically connected with a touch screen and a starting / stopping switch. The body structure of the optical fiber finished cable comprises yarns, an optical fiber bundle pipe, a reinforcing member and a filling rope. The optical cable retreating machine and the realizing method realize high stability and high reliability in actual use and realize an intelligent cable retreating function of the optical fiber finished cable. Furthermore the optical cable retreating machine and the realizing method thereof have advantages of convenient operation, time-saving and labor-saving function, high safety and high reliability. No bundle pipe bending is caused in the cable retreating process, and cable retreating efficiency is improved. The optical cable retreating machine andthe realizing method thereof are suitable for popularization.

Owner:ANHUI UNIV OF SCI & TECH

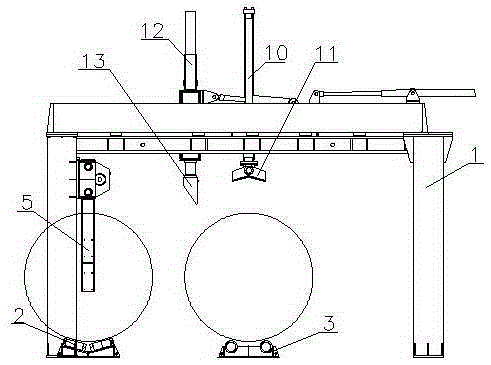

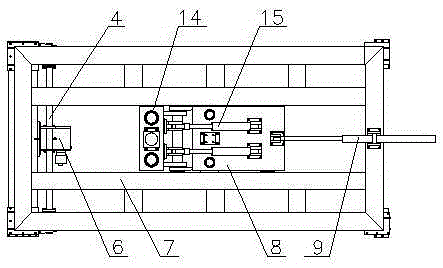

Efficient coiled plate leading device

InactiveCN106734357AReduce labor intensityWon't turnMetal-working feeding devicesPositioning devicesEngineeringUltimate tensile strength

The invention relates to an efficient coiled plate leading device. The efficient coiled plate leading device comprises a portal frame. A centering device is arranged at the left end of the portal frame. A material platform for containing a steel plate coil is arranged below the centering device. A coil pressing device is arranged in the middle of the portal frame. A shovel head device is arranged on the left side of the coil pressing device. A material storage platform is arranged under the coil pressing device. According to the efficient coiled plate leading device, the structure is simple; operation is convenient; the labor intensity of workers is relieved in the uncoiling process; the uncoiling efficiency is high; and the working efficiency is improved.

Owner:JIANGSU YAWEI MACHINE TOOL

Cloth unwinding device

ActiveCN110294345AEnsure consistencyAvoid skewArticle deliveryWebs handlingElectric machineryEngineering

The invention discloses a cloth unwinding device comprising a base. One end of the top of the base is fixedly connected with a fixing seat through a bolt, the fixing seat and the base are both fixedlyconnected with supporting seats, a conveying guide roller is connected between the supporting seats of the base through a bearing, an unwinding roller is connected between the supporting seats of thefixing seat through a bearing, one end of the unwinding roller is fixedly connected with a motor, and the output end of a telescopic cylinder is fixedly connected with a cutting tool. The device effectively ensures the limiting and adjusting consistency in the cloth transmission process, improves the unwinding efficiency, avoids the cloth skew phenomenon, greatly improves the limiting effect on cloth in the transmission process, is accurate in positioning, convenient to adjust, simple in operation and flexible in operation and ensures the work efficiency and quality; and when it is necessaryto cut off the unwinding cloth, the telescopic cylinder is started to drive the cutting tool to move downwards to cut off the cloth placed on a cutting groove, and the cloth unwinding device is convenient to use.

Owner:盐城金云盾网络科技有限公司

Adjustable-angle high-efficiency steel strip unreeling machine

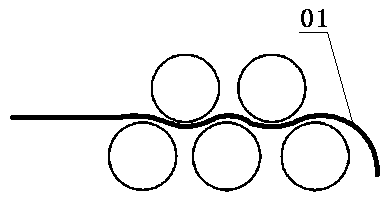

ActiveCN106276343ASelf-adjusting unwinding angleImprove unwinding efficiencyWebs handlingEngineering

The invention discloses an adjustable-angle high-efficiency steel strip unreeling machine which comprises a base. A through hole is formed in the top of the base, an adjusting device is fixedly mounted at the bottom of an inner cavity of the base, clamping devices positioned on two sides of the inner cavity of the base are fixedly mounted above the adjusting device, side faces of the two clamping devices are slidably connected through a sliding device, the bottom of the sliding device is fixedly connected with the top of the adjusting device, one side of the sliding device far away from the adjusting device is fixedly connected with a through hole and extends to a lifting column outside the base, and one end of the lifting column far away from the sliding device is fixedly connected with a fixing table. By the aid of the adjusting device, the sliding device and the lifting column, an uplifting column can push the lifting column to synchronously rise and fall through a push plate in rising and falling movement, and unreeling angles can be automatically adjusted when the fixing table connected with the lifting column stably rises and falls.

Owner:安庆市宏信金属制品有限公司

Rubber pipe conveying and unwinding machine

PendingCN108792771AImprove unwinding efficiencyPractical to useFilament handlingAgricultural engineeringPulley

The invention discloses a rubber pipe conveying and unwinding machine. The rubber pipe conveying and unwinding machine comprises a machine base, a second supporting frame and a winding wheel; a firstsupporting frame is installed on the left side of the top of the machine base; a first rotary shaft is installed at the upper end of the inner side of the first supporting frame; a pulley is installedon the outer side of the first rotary shaft; a second supporting frame is installed on the right side of the first supporting frame; a cylinder is installed in the middle of the top of the second supporting frame; the bottom of the cylinder is connected with a cutting rod through the second supporting frame; a cutter is connected to the bottom of the cutting rod; and the second supporting frame is located on the top of the machine base. By means of the pulley on the first supporting frame and a pipe groove in the winding wheel, four rubber pipes can be unwound on the machine at a time, and the rubber pipe unwinding efficiency is greatly improved; by arranging the cylinder and the cutter on the second supporting frame, the rubber pipes can be cut off when the winding wheel is full but theleft portions of the rubber pipes are still very long, the manual artificial cut-off process is omitted, and the rubber pipe conveying and unwinding machine is relatively practical and suitable for being widely used and popularized.

Owner:NANJING HUI LONG RUBBER PROD CO LTD

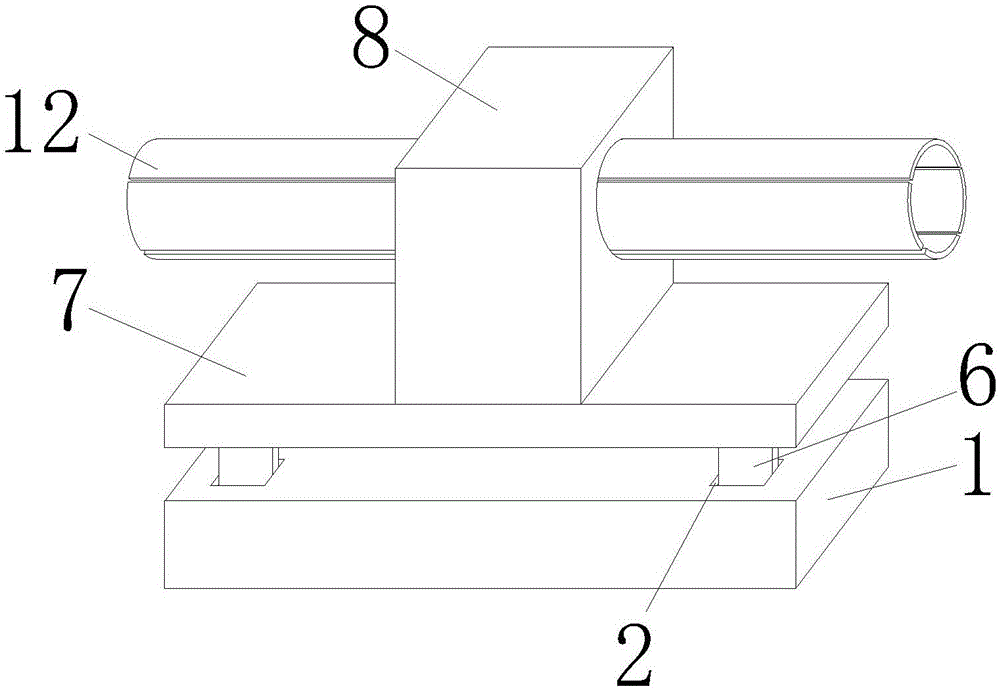

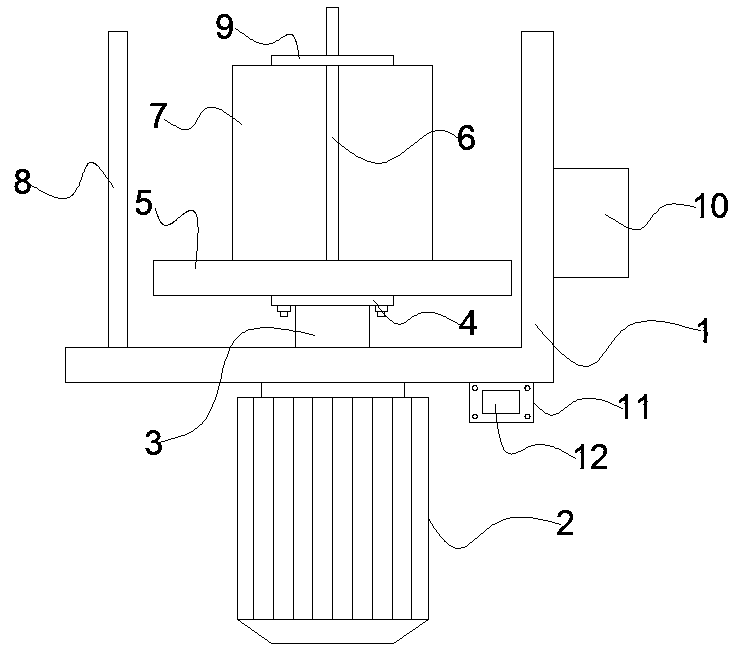

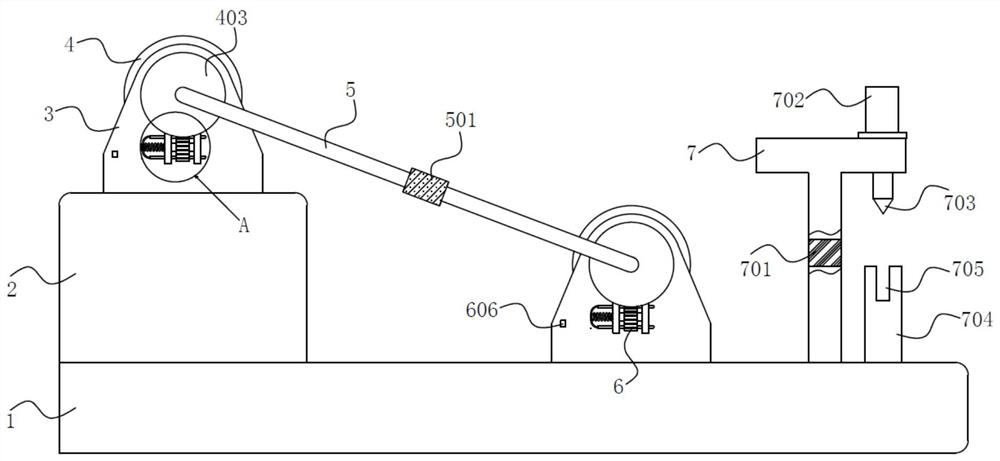

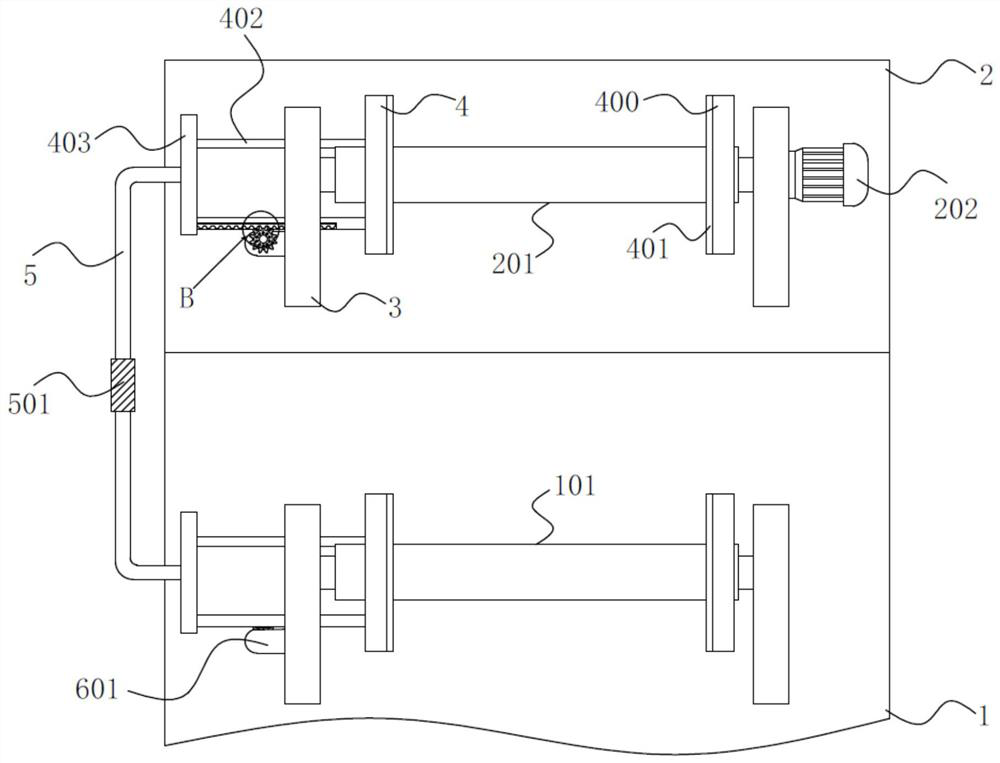

Carbon fiber short shred unwinding device for textile machines

InactiveCN109230872AImprove unwinding efficiencyAccurately measure the lengthFilament handlingRotational axisFiber

The invention discloses a carbon fiber short shred unwinding device for textile machines. The device structurally comprises a base, a side plate, a supporting plate, a rotation motor, a rotation cylinder, a motor adjuster, a traction device and a high-precision length counter. The motor adjuster is arranged at the upper side of the base, the side plate is arranged at the right side of the motor adjuster, and the rotation motor is arranged at the upper end of the left side of the side plate; a rotation shaft is arranged at the right side of the rotation motor, a positioning pin is arranged on the rotation shaft, and the rotation cylinder is arranged at the right side of the positioning pin; baffles are symmetrically arranged at the two sides of the rotation cylinder, the baffle at the leftside abuts against the positioning pin, a fixing sleeve is arranged at the outer side of the baffle at the right side, and a supporting plate is connected to the upper end of the side plate. Accordingto the carbon fiber short shred unwinding device for the textile machines, the two ends of a carbon fiber short shred roll obtained after winding are conveniently limited and controlled, the length of unwinding input of a carbon fiber short shred can be precisely measured, the input amount is accurately controlled, the efficiency of unwinding the carbon fiber short shred roll is higher, and starting and shutdown of the rotation motor can be automatically controlled.

Owner:FOSHAN SANCHUANG KNITTING CO LTD

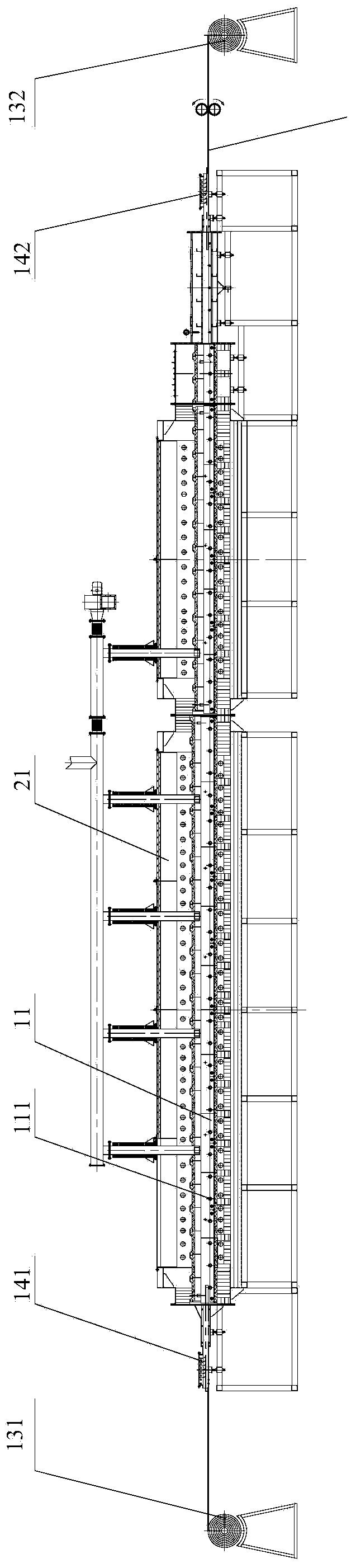

Continuous carbonization equipment and material conveying device

InactiveCN103743232AImprove unwinding efficiencyImprove efficiencyFurnace typesFiberStructural reliability

The invention discloses a material conveying device which comprises a horizontal conveying rail. A plurality of corundum support tubes are arranged on the conveying rail along the horizontal direction, an extension direction of an axis of each corundum support tube is perpendicular to a conveying direction of the conveying rail, the corundum support tubes are sequentially uniformly distributed along the conveying direction of the conveying rail, and carbon fiber pre-oxidation felt matched with the corundum support tubes is arranged above the conveying rail. In the working process, the corundum support tubes cannot react with a surrounding carbon atmosphere, the material conveying device is high in structural strength, whole service life of the material conveying device can be remarkably prolonged, structural reliability of the material conveying device can be remarkably improved, and overall working efficiency of continuous carbonization equipment is improved correspondingly. The invention further discloses the continuous carbonization equipment applying the material conveying device.

Owner:ADVANCED FOR MATERIALS & EQUIP

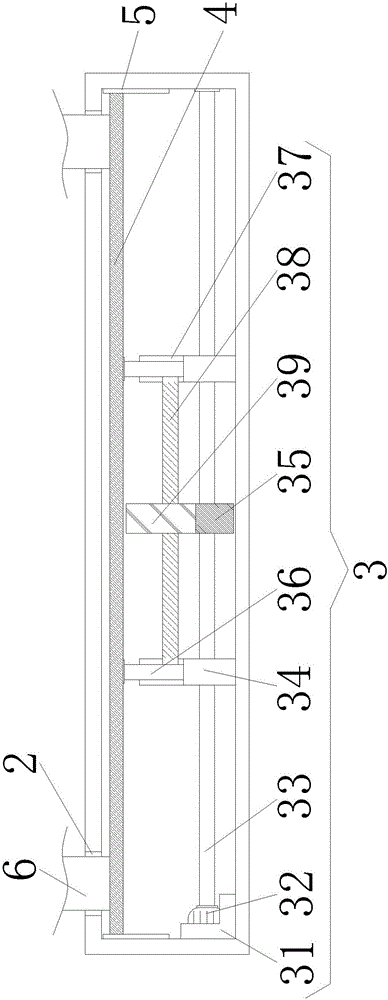

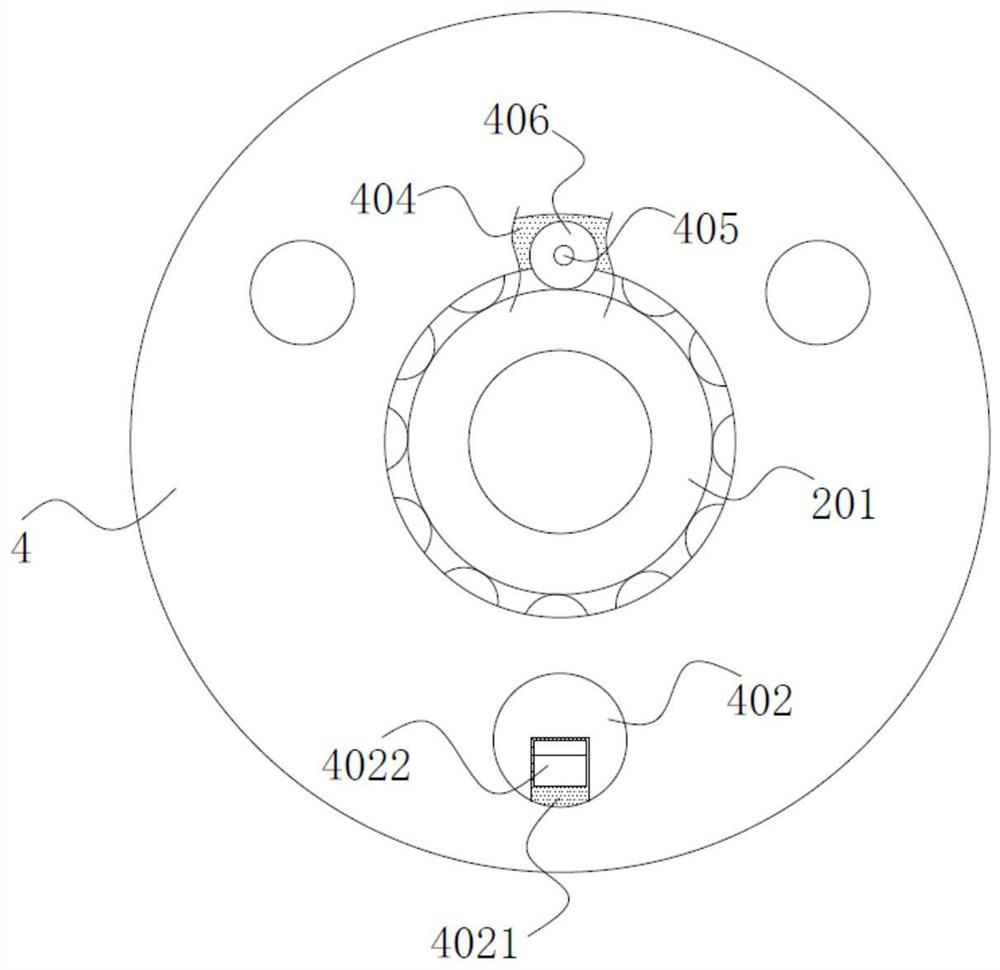

Efficient uncoiling tool of steel coil

InactiveCN108946243APrecise positioningImprove unwinding efficiencyWebs handlingElectric machineryDrive motor

The invention discloses an efficient uncoiling tool of a steel coil. The efficient uncoiling tool of the steel coil is characterized in that a driving motor is arranged on the bottom surface of an L-shaped supporting frame, the output shaft end of the driving motor is fixedly connected with a rotating shaft, a flange connecting disc is arranged at the top end of the rotating shaft, moreover, the shaft outer diameter of the rotating shaft is in tight fit connection with the inner diameter ring of the flange connecting disc, the flange connecting disc is fixedly connected with a rotating disc through bolts, a positioning screw rod is perpendicularly and fixedly connected to the middle position of the rotating disc, a mounting plate is fixedly arranged on the bottom surface of the L-shaped supporting frame, a frequency converter is fixedly arranged on the mounting plate, and the frequency converter is electrically connected with the driving motor. By the adoption of the technical scheme,the efficient uncoiling tool is simple in structure, and the steel coil can be positioned on the rotating disc firmly; and the frequency converter is used for conducting frequency converting control over the driving motor to drive the steel coil to rotate, the uncoiling speed of the steel coil is controllable, the uncoiling efficiency of the steel coil is high, and time and labor are saved.

Owner:张多艳

Unwinding cloth hopper

InactiveCN102795496AReduce frictionImprove unwinding efficiencyWebs handlingStructural engineeringMechanical engineering

Owner:SUZHOU LONGYING WEAVING DYEING DYEING

Winder with spring-fixed creel spindles

ActiveCN103088480AReduce tensionAvoid damageContinuous wound-up machinesOpen-end spinning machinesYarnElectric machinery

The invention relates to a denim yarn winder, in particular to a winder with spring-fixed creel spindles. The winder with spring-fixed creel spindles comprises a servo motor, a creel, and rotor spinning creel spindles on the creel. The creel is provided with at least three beams. Spools synchronously controlled by the servo motor are disposed at the tops of the rotor spinning creel spindles. A spring is disposed at the bottom of each rotor spinning creel spindle and is connected to the corresponding beam of the creel. The denim yarn spools are synchronized by the servo motor, winder tension is lowered, and damage of the denim yarn spools is decreased. By the use of the rotor spinning creel spindles, spool tension is decreased, package is increased, efficiency of unwinding yarns is increased, end breakage rate is decreased and weaving efficiency is improved.

Owner:JIANGSU ZHENGHENG DYEING FINISHING

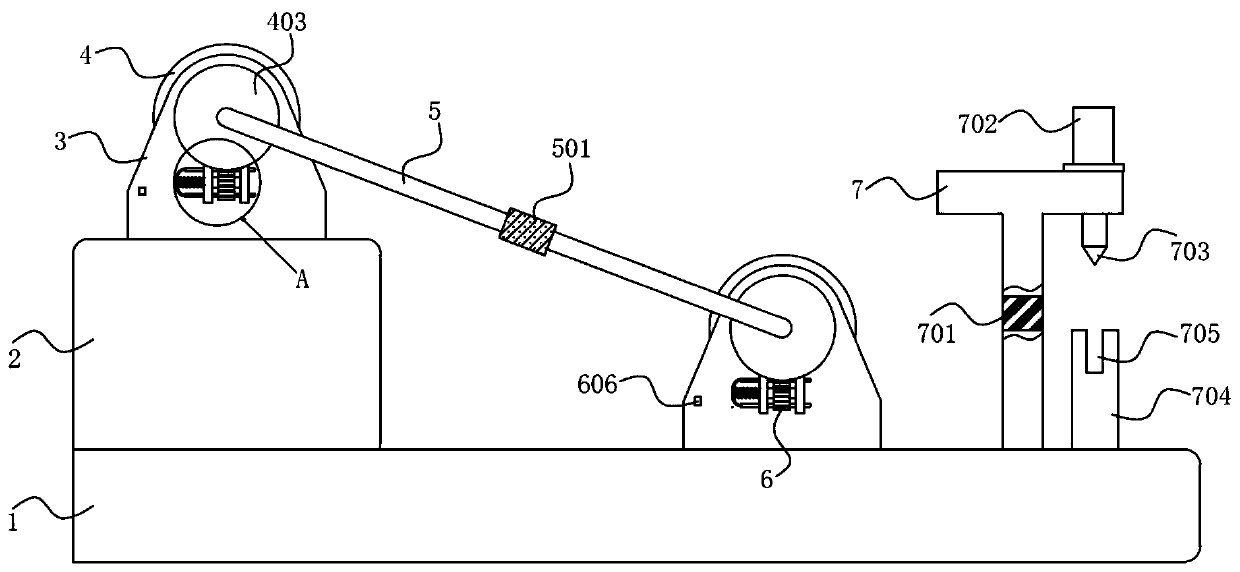

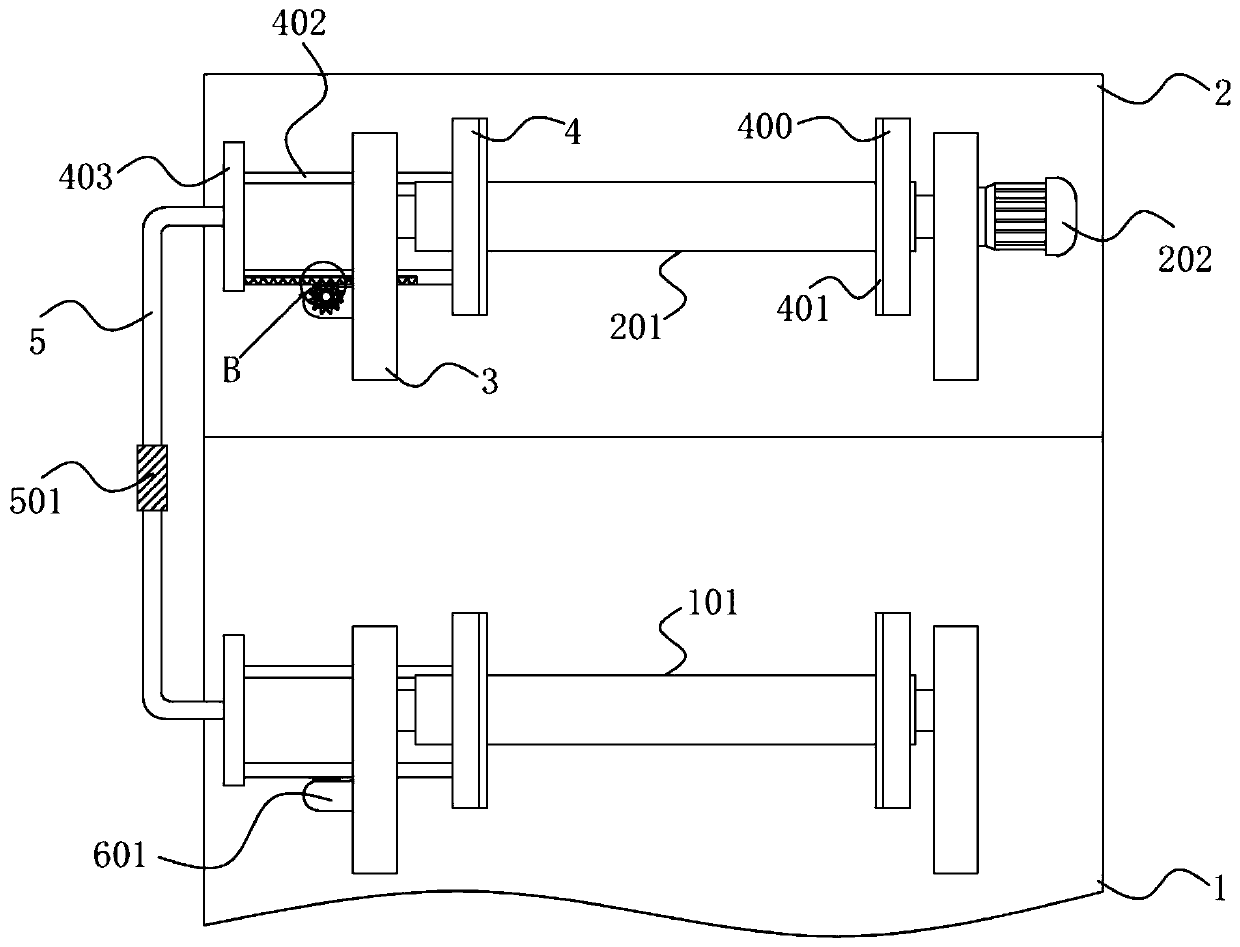

Carbon-fiber chopped yarn unreeling device for textile manufacturing machine

InactiveCN108178014AConvenient limit controlImprove unwinding efficiencyFilament handlingTextile manufacturingFiber

The invention discloses a carbon-fiber chopped yarn unreeling device for a textile manufacturing machine. The carbon-fiber chopped yarn unreeling device comprises a side seat, wherein a bottom plate is arranged at the bottom of the side seat, a fixing box is arranged at the top of the side seat and is mounted on the back of the top of the side seat, a driving motor is arranged at the rear part ofthe fixing box, a driving shaft is arranged at the front part of the driving motor and penetrates through the fixing box and the side seat, a rotary sleeve sleeves the end part of the driving shaft, afirst limiting ring is nested in the inner end of the rotary sleeve, a second limiting ring sleeves the outer end of the rotary sleeve, a side frame is arranged on the front face of the side seat, atraction shaft is arranged at the upper side of the front part of the side frame, and a first traction roller is arranged at the lower side of the front part of the side frame. According to the carbon-fiber chopped yarn unreeling device for the textile manufacturing machine, the two ends of the rotary sleeve can be subjected to limiting control conveniently, so that the two ends of a reeled carbon-fiber chopped yarn reel can be subjected to limiting control conveniently; carbon-fiber chopped yarns can be subjected to unreeling traction control, so that the unreeling efficiency of the carbon-fiber chopped yarns can be higher.

Owner:SUZHOU HONGYE LAMP EQUIP CO LTD

Cloth unwinding device

ActiveCN110294345BEnsure consistencyAvoid skewArticle deliveryWebs handlingElectric machineryStructural engineering

The invention discloses a cloth unwinding device comprising a base. One end of the top of the base is fixedly connected with a fixing seat through a bolt, the fixing seat and the base are both fixedlyconnected with supporting seats, a conveying guide roller is connected between the supporting seats of the base through a bearing, an unwinding roller is connected between the supporting seats of thefixing seat through a bearing, one end of the unwinding roller is fixedly connected with a motor, and the output end of a telescopic cylinder is fixedly connected with a cutting tool. The device effectively ensures the limiting and adjusting consistency in the cloth transmission process, improves the unwinding efficiency, avoids the cloth skew phenomenon, greatly improves the limiting effect on cloth in the transmission process, is accurate in positioning, convenient to adjust, simple in operation and flexible in operation and ensures the work efficiency and quality; and when it is necessaryto cut off the unwinding cloth, the telescopic cylinder is started to drive the cutting tool to move downwards to cut off the cloth placed on a cutting groove, and the cloth unwinding device is convenient to use.

Owner:盐城金云盾网络科技有限公司

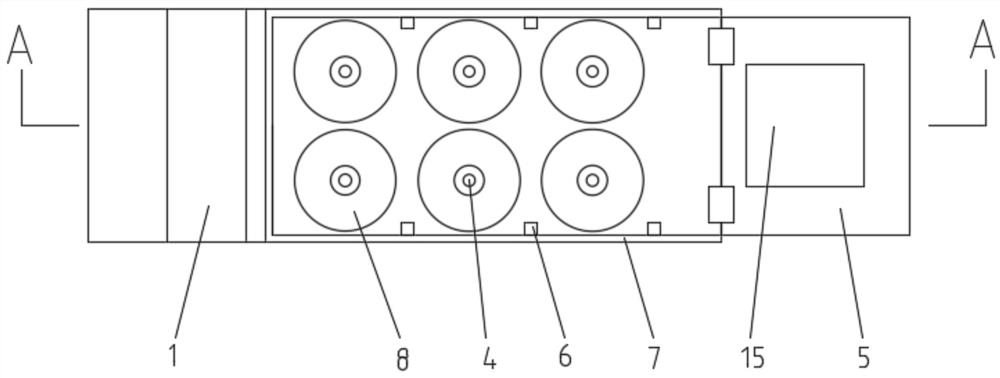

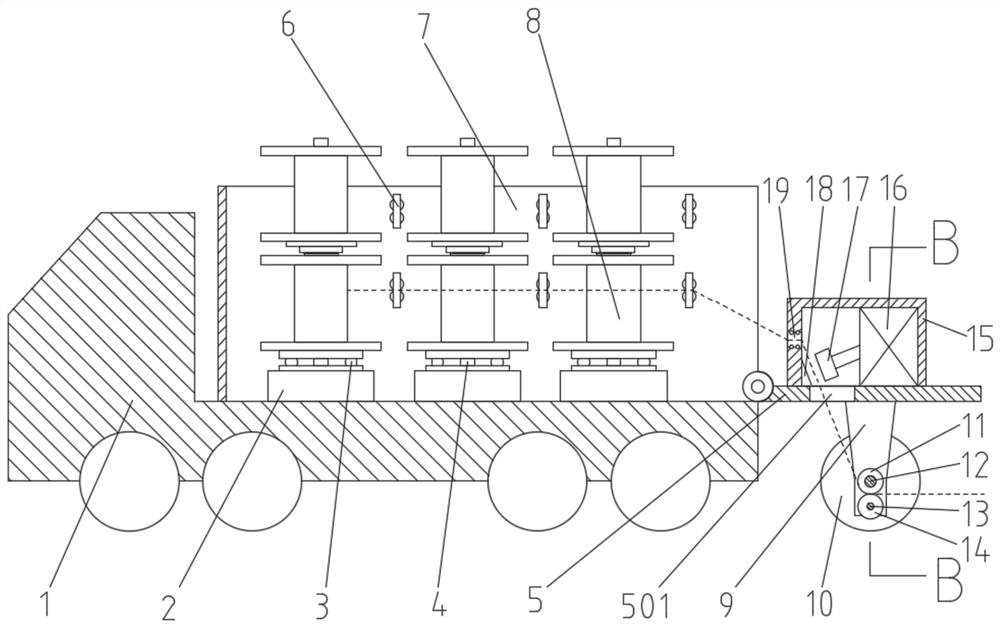

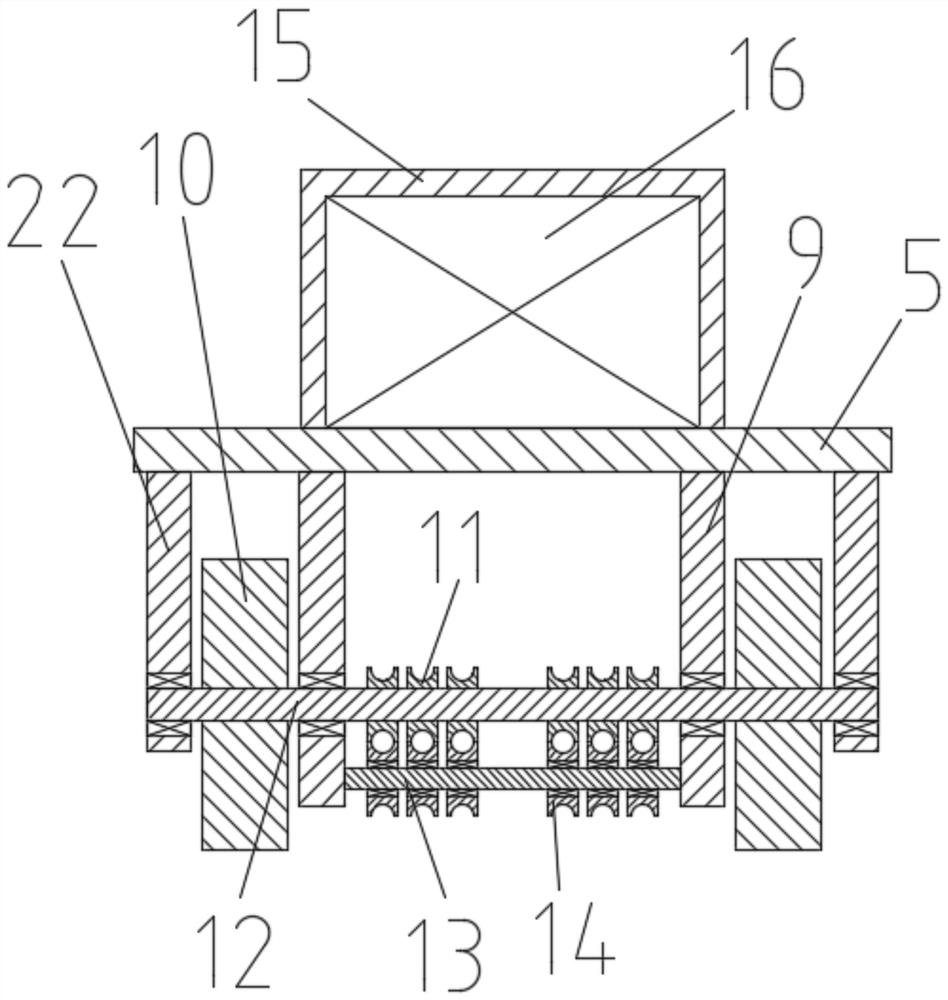

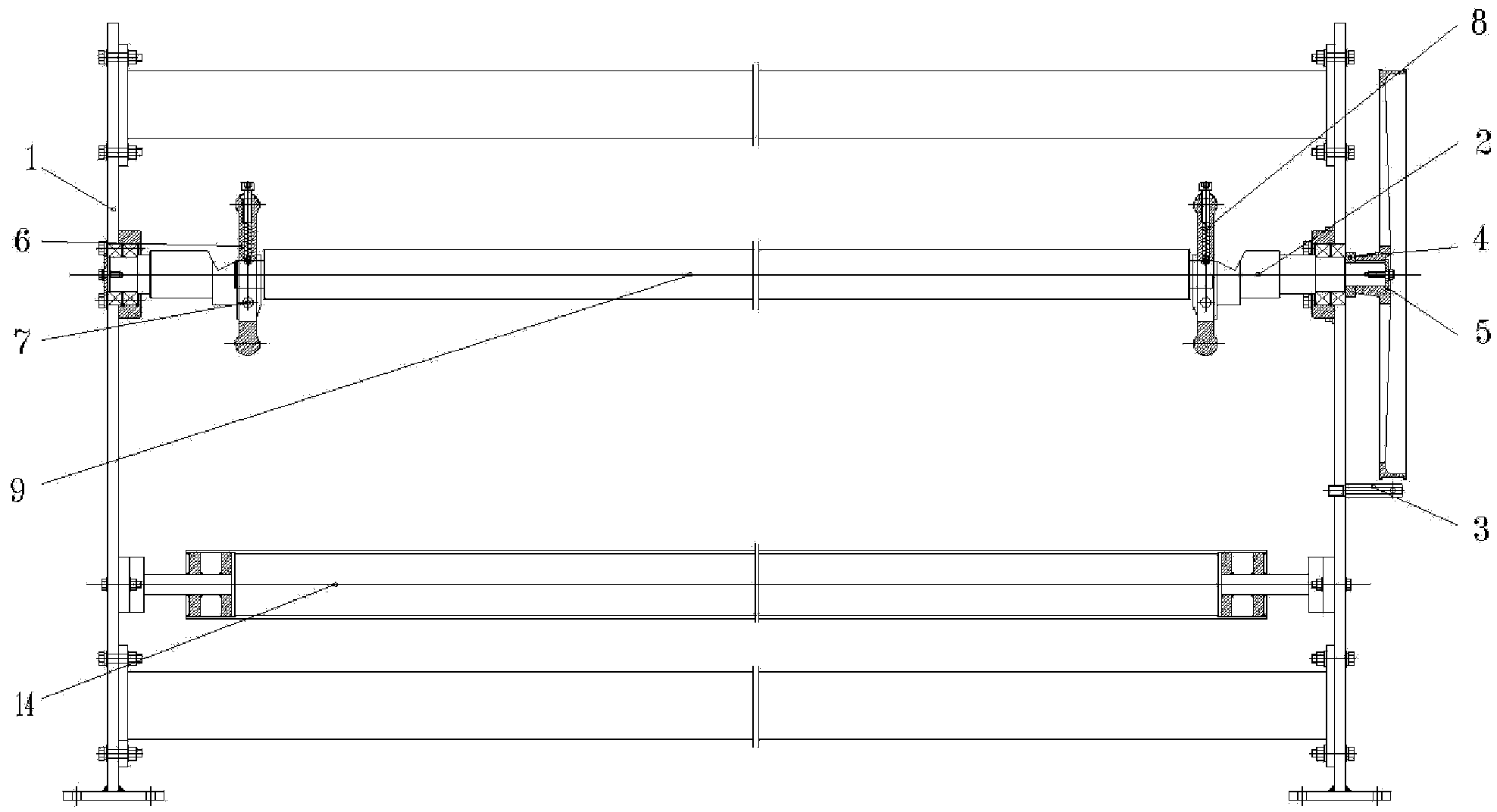

A large diameter cable unwinding car

ActiveCN112938614BExquisite designImprove securityFilament handlingReel unit transportationStructural engineeringElectric cables

A large-diameter cable unwinding vehicle related to the technical field of cable laying construction includes a vehicle body and a vehicle box, the vehicle box includes a bottom box plate, two side box plates and a box door plate; A column is fixed, an unwinding drum is installed on the outer shell of the column, and a plane bearing is arranged between the unwinding drum and the turntable; a plurality of guide wheel assemblies are installed on the inner surface of the side box panel; two sides of the outer panel surface of the box door are fixed on both sides. The inner wheel frame plate, the two inner wheel frame plates are respectively provided with shaft holes, the rotating shaft is fixed with a plurality of transmission wheels and two transmission wheels, the outer ends of the two inner wheel frame plates are connected by a fixed shaft, and the fixed shaft rotating sleeve has many a pressing wheel; a detection box cover is fixed in the center of the box door panel, a plurality of distribution holes are arranged on the panel surface of the detection box cover, a cable detection device for detecting cable damage is arranged in the detection box cover, and a connection detection box is arranged on the panel surface of the box door panel Through holes in the inner cavity of the cover; the large-diameter cable unwinding car can greatly improve the unwinding efficiency and reduce the construction cost.

Owner:STATE GRID CORP OF CHINA +1

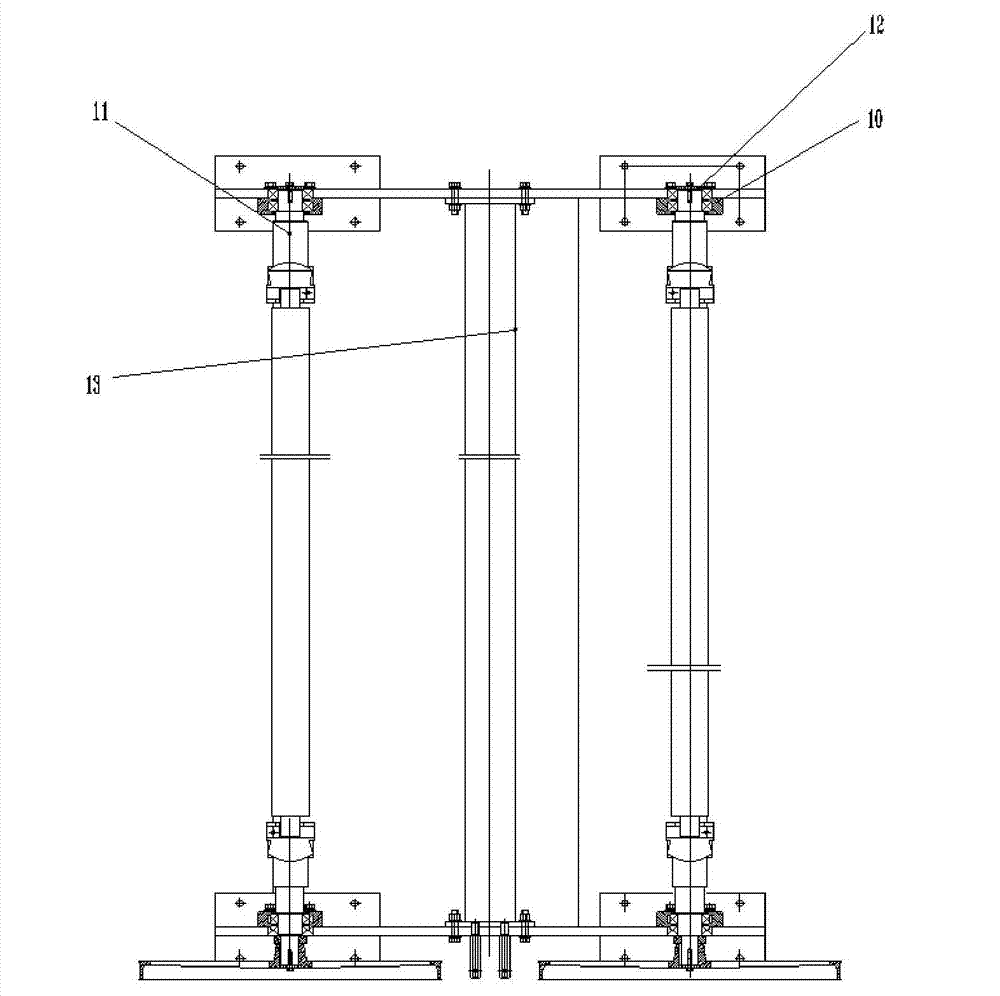

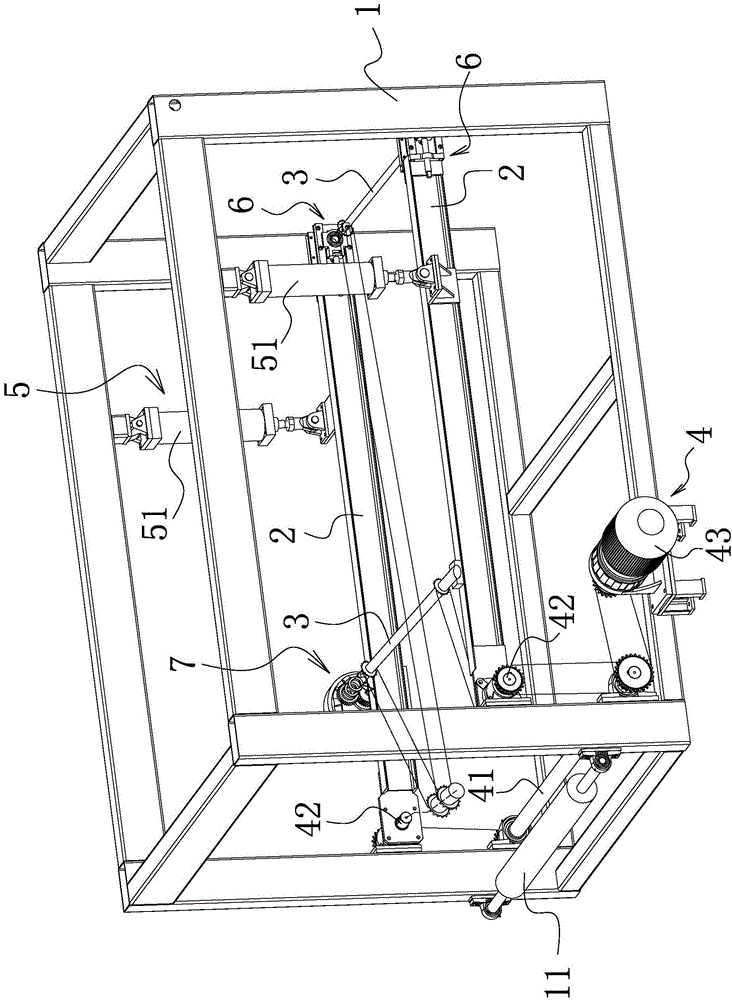

Novel high-efficiency reel uncoiling machine and uncoiling method thereof

PendingCN110422660AReduce the unqualified rate of standingLow costArticle unpackingWebs handlingLoss rateEngineering

The invention provides a novel high-efficiency reel uncoiling machine and an uncoiling method thereof, and relates to the technical field of reel uncoiling. According to the novel high-efficiency reeluncoiling machine and the uncoiling method thereof, first bases are arranged, the number of the first bases is two, first mounting columns are arranged on the upper surfaces of the two first bases, amounting plate is fixedly connected to the positions, close to the top ends, of the outer side walls of the two first mounting columns, a fixing block is fixedly arranged on the back surface of the left side of the mounting plate, an adjusting mechanism is arranged on the position, close to the fixing block, of the back surface of the mounting plate, and a first rotating shaft is connected into the fixing block in a rotating mode. The novel high-efficiency reel uncoiling machine and the uncoiling method thereof have the advantages that reels are reasonably uncoiled, so that the loss rate of products is greatly decreased, and therefore the reject ratio of the standing degree of pins caused by uncoiling is decreased, in addition, the uncoiling efficiency is greatly improved, the cost of processing materials is lowered, meanwhile, the attrition rate of whole equipment is extremely low, and the service life is long.

Owner:NANTONG HUADA MICROELECTRONICS GROUP

A high-efficiency steel strip unwinder with self-adjustable angle

ActiveCN106276343BSelf-adjusting unwinding angleImprove unwinding efficiencyWebs handlingEngineeringSelf adjusting

The invention discloses an adjustable-angle high-efficiency steel strip unreeling machine which comprises a base. A through hole is formed in the top of the base, an adjusting device is fixedly mounted at the bottom of an inner cavity of the base, clamping devices positioned on two sides of the inner cavity of the base are fixedly mounted above the adjusting device, side faces of the two clamping devices are slidably connected through a sliding device, the bottom of the sliding device is fixedly connected with the top of the adjusting device, one side of the sliding device far away from the adjusting device is fixedly connected with a through hole and extends to a lifting column outside the base, and one end of the lifting column far away from the sliding device is fixedly connected with a fixing table. By the aid of the adjusting device, the sliding device and the lifting column, an uplifting column can push the lifting column to synchronously rise and fall through a push plate in rising and falling movement, and unreeling angles can be automatically adjusted when the fixing table connected with the lifting column stably rises and falls.

Owner:安庆市宏信金属制品有限公司

Nonwoven fabric felt unrolling frame

The invention provides a nonwoven fabric felt unrolling frame which can keep constant tensioning force with a nonwoven fabric knitting unit during unrolling of nonwoven fabrics. The nonwoven fabric felt unrolling frame comprises two wall plates of the felt unrolling frame, and a tensioning rod, a felt guide roller and two pneumatic tensioning shaft are connected between the two wall plates. A main shaft head is arranged at one end of the pneumatic tensioning shaft while an auxiliary shaft head is arranged at the other end of the pneumatic tensioning shaft, and a safety flange is mounted on the inner side of each of the main shaft head and the auxiliary shaft head and on the pneumatic tensioning shaft. Bearing blocks are mounted on the inner wall of the two wall plates of the felt unrolling frame corresponding to the left end and the right end of the pneumatic tensioning shaft, the main and auxiliary shaft heads of the pneumatic tensioning shaft are mounted in bearings of the bearing blocks, a fixed plate is mounted outside the auxiliary shaft head, and the main shaft head penetrates through the bearing blocks to extend outside the wall plates. A retaining belt pulley spacer ring is sleeved on a portion, close to the end, of the main shaft head. A brake wheel is mounted at the end of the main shaft head through bolts, and a supporting column horizontally extends outwards on the wall plate at the mounting end of the brake wheel and is positioned below the brake wheel. A brake belt is sleeved on the brake wheel, a connecting plate is fixed to the end of the brake belt, a hook is fixed to the bottom end of the connecting plate through a hook screw, a hanging plate is hung at the bottom of the hook, and a counter weight is placed on the hanging plate.

Owner:CHANGZHOU DIBA TEXTILE MACHINERY

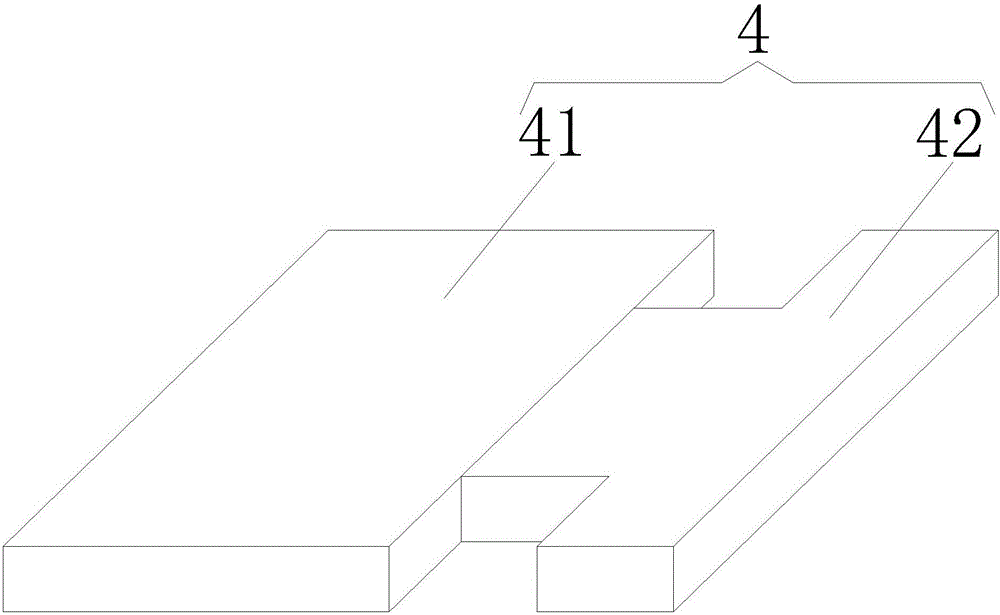

Uncoiler uncoiling operation method

ActiveCN110142311BImprove unwinding efficiencyImprove effective operation rateStructural engineeringConveyor belt

The invention discloses an uncoiler uncoiling operation method. The method comprises the following steps of A, starting a lifting power cylinder when a previous coil of steel coil strip tail is advanced to a sliding sleeve plate, enabling a fixed sleeve plate stopping after rotating a first quadrant oblique angle, and starting a telescopic power cylinder to enable the sliding sleeve plate to extend out of the fixed sleeve plate; B, enabling a conveyor belt to stop advancing so as to enable the steel coil strip tail can stay on the fixed sleeve plate when the previous coil of steel coil strip tail are all fed into the fixed sleeve plate; C, overlapping a next coil of steel coil strip head to the previous coil of steel coil strip tail, starting the conveying belt to enable the next coil of steel coil to enter the conveying belt under traction of the previous coil of steel coil; and D, starting the lifting power cylinder when the next coil of steel coil strip tail enters the conveying belt, enabling the fixed sleeve plate stopping after rotating a fourth quadrant oblique angle clockwise, and meanwhile, starting the telescopic power cylinder to enable the sliding sleeve plate to retract into the fixed sleeve plate. Compared with the prior art, the method can be used for solving the problem that a strip head of an existing steel coil cannot smoothly enter a steel plate conveying channel of an uncoiler to be overlapped with a strip tail of a steel coil of a previous coil.

Owner:LIUZHOU IRON & STEEL

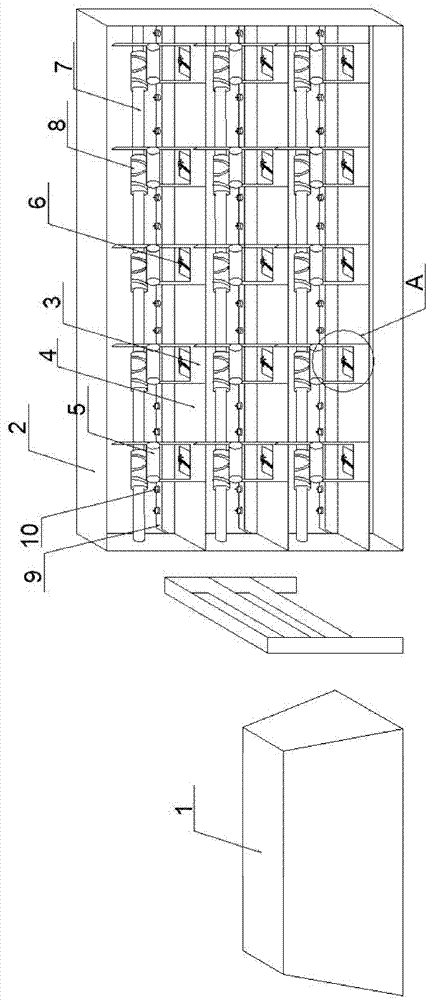

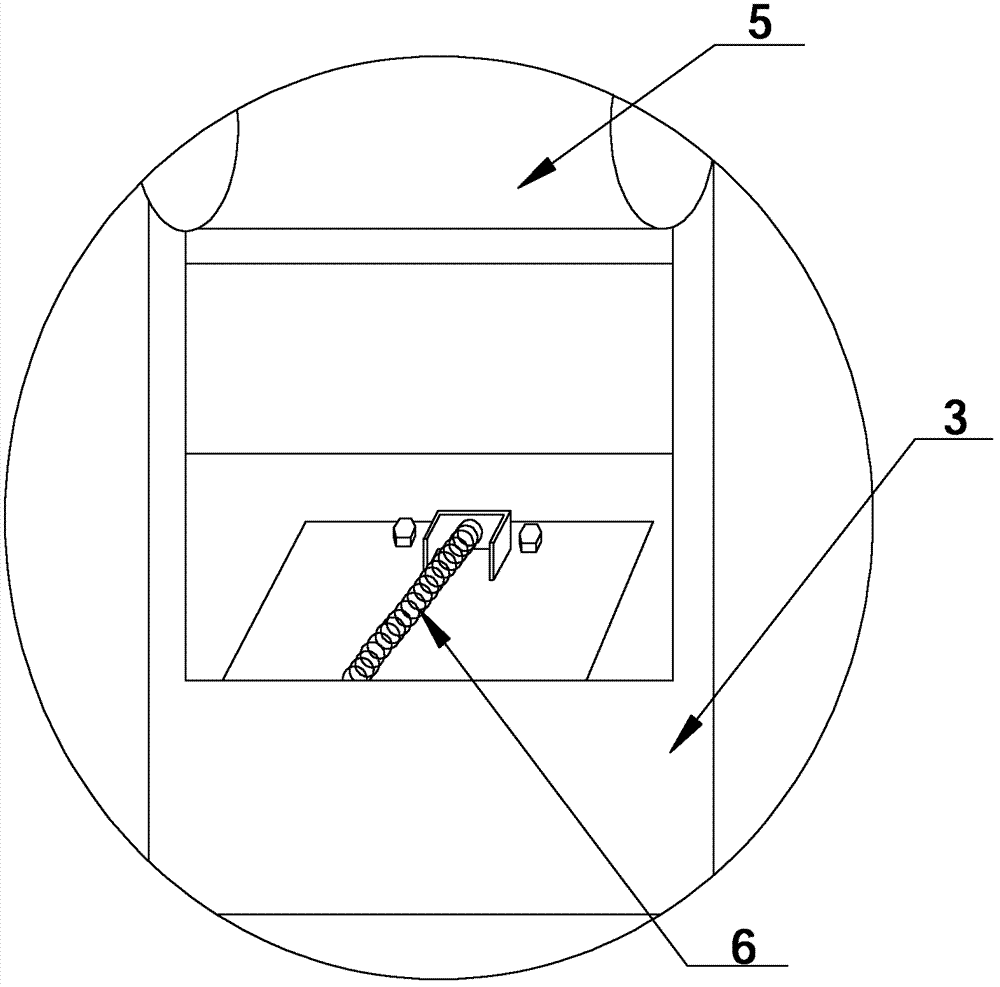

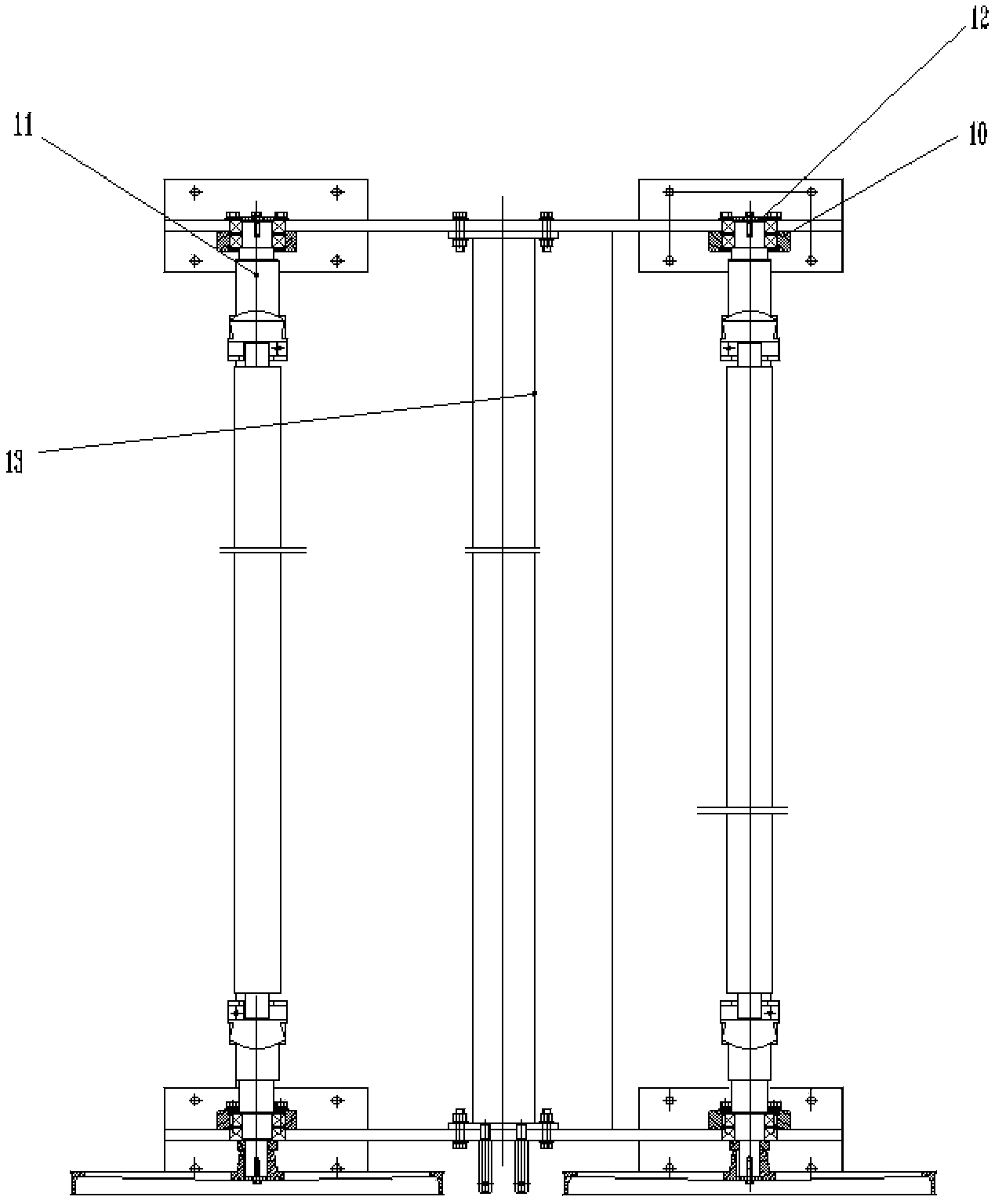

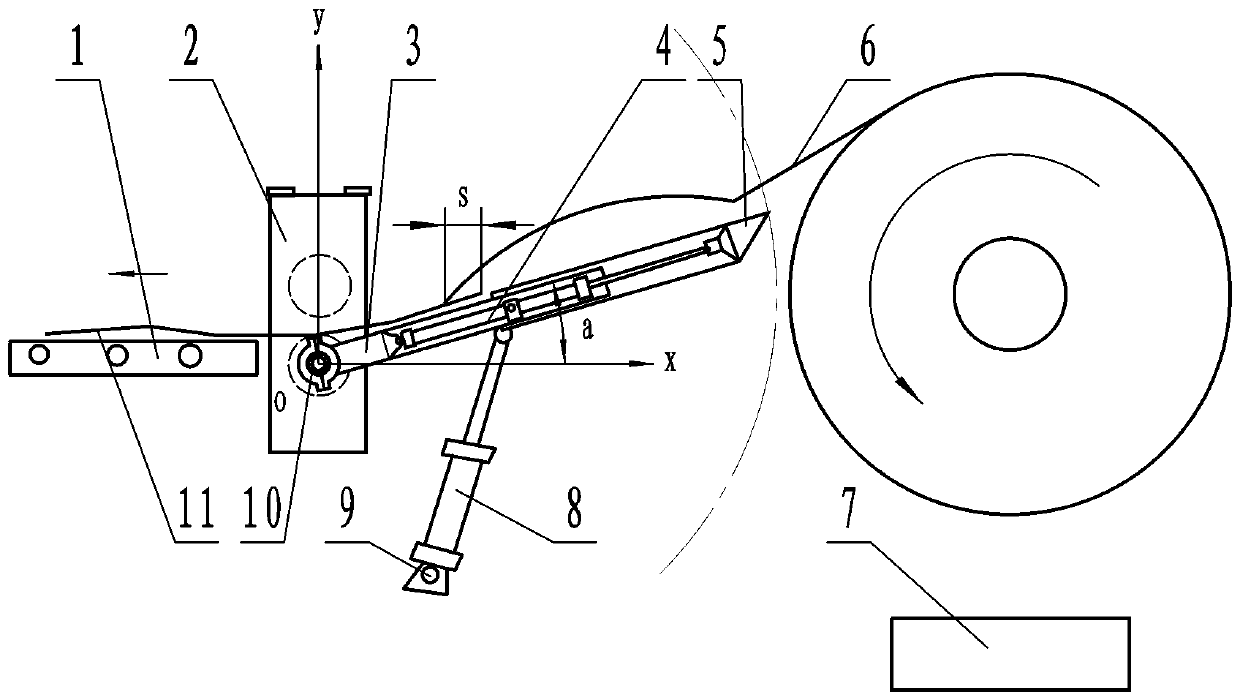

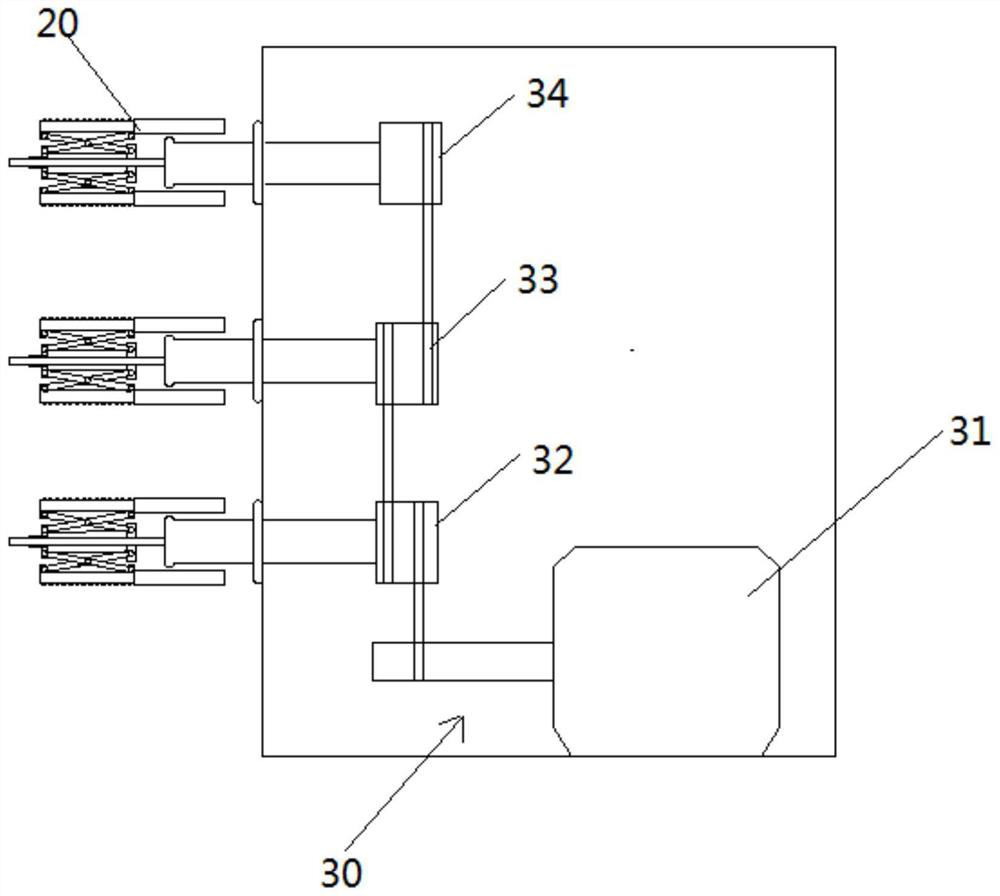

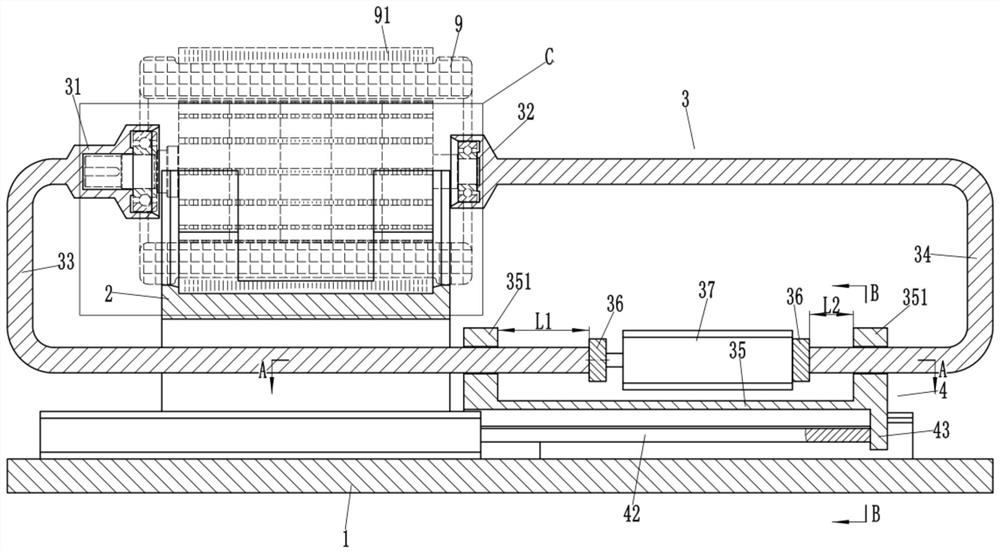

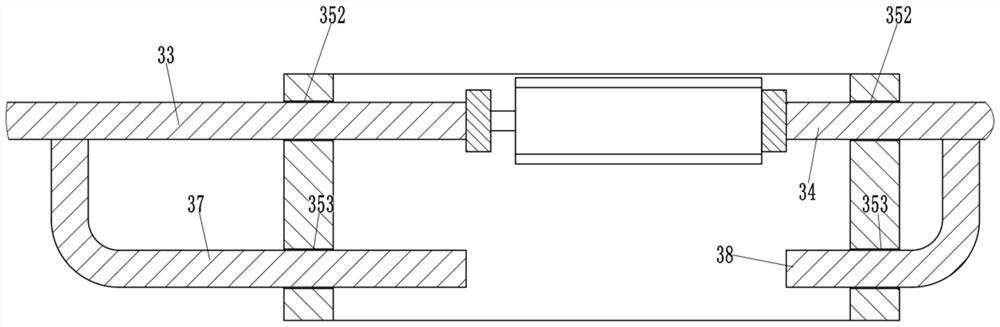

Multi-layer uncoiler

The invention relates to the field of uncoiler equipment, in particular to a multi-layer uncoiler, which comprises a shell, a plurality of shaft heads arranged on the side surface of the shell side by side from top to bottom, a power mechanism arranged in the shell and used for driving the shaft heads to rotate, and a conveying portal frame used for conveying an external steel coil to the shaft head and hanging the external steel coil on the shaft head. A plurality of steel coil structures can be supported at the same time, the uncoiling efficiency is effectively improved, and meanwhile steel coils can be rapidly conveyed to the designated position through the conveying portal frame; a novel design structure is adopted, sliding of a uncoiling plate in a steel pipe is achieved through the idler wheels, the inner surface of a steel coil can make uniform contact with the uncoiling plate, and creases are avoided.

Owner:常州铸越机械有限公司

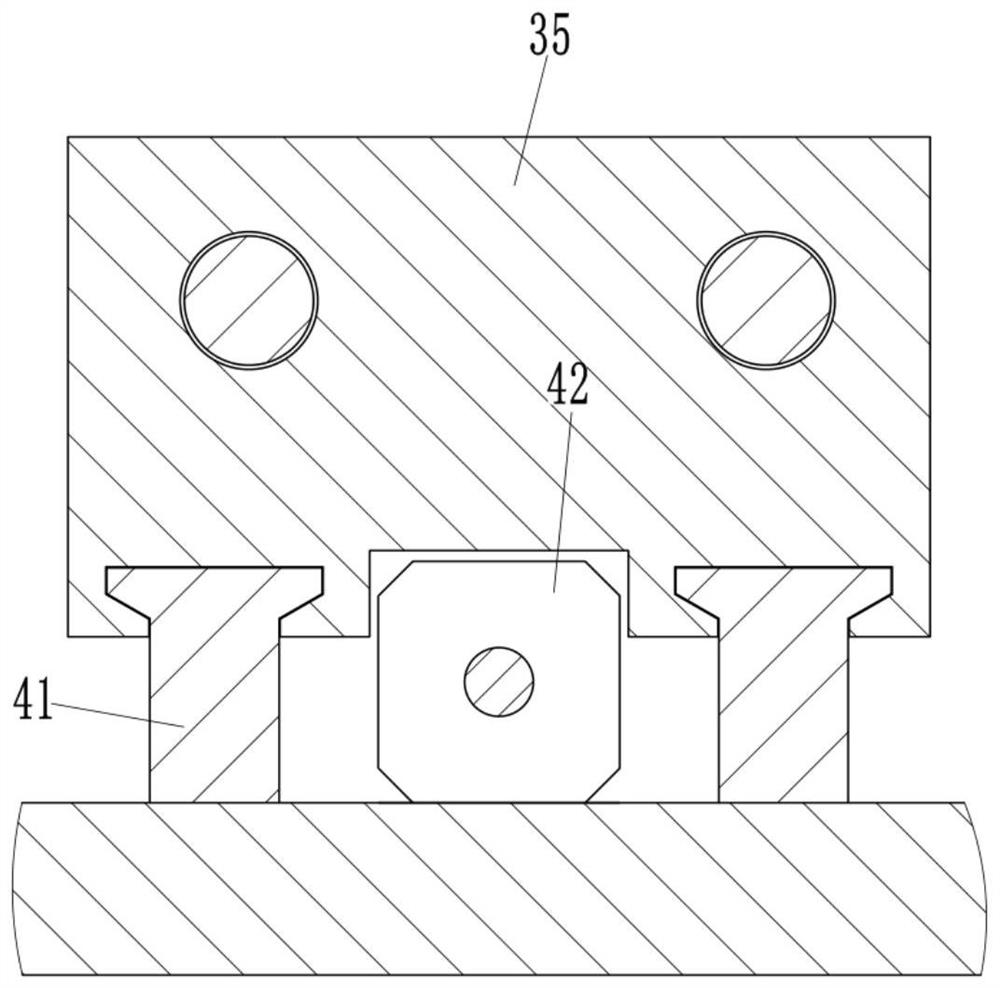

Rotor and stator unsheathing device

InactiveCN111799959AEasy to separateImprove unwinding efficiencyManufacturing dynamo-electric machinesMetal working apparatusClassical mechanicsCylinder block

The invention discloses a rotor and stator unsheathing device, which comprises a bottom plate. A stator positioning seat is fixed on the bottom plate; the left end and the right end of the stator positioning seat are respectively provided with a rotor clamping mechanism. The rotor clamping mechanism comprises a left pressing head and a right pressing head which are coaxially arranged; the left pressing head is fixed to one end of the first U-shaped rod, the right pressing head is fixed to one end of the second U-shaped rod, the extending ends of the other end of the first U-shaped rod and theother end of the second U-shaped rod penetrating through the corresponding guide holes in the two side plates of the U-shaped guide base are fixedly provided with check blocks, and the two check blocks are fixed to a piston rod and a cylinder body of the first oil cylinder. The guide seat is provided with a translation mechanism for driving the guide seat to move left and right. The rotor is fixedthrough the rotor clamping mechanism, the rotor is separated from the stator by horizontally moving the rotor clamping mechanism, workers can be assisted in easily separating the rotor from the stator, and the unsheathing efficiency is greatly improved.

Owner:苏州勋空自动化设备有限公司

Unwinding adjusting device in unwinding mechanism

InactiveCN107758385ABest unwinding positionImprove unwinding efficiencyWebs handlingFeed driveEngineering

The invention discloses an unwinding adjustment device used in an unwinding mechanism, comprising: an unwinding adjustment bracket, an unwinding part and an unwinding adjustment part arranged on the unwinding adjustment bracket; material driver, unwinding drive rod, first unwinding plate, second unwinding plate and unwinding fixing plate; the unwinding adjusting part includes an adjusting bracket fixed on the unwinding adjusting bracket and an adjusting bracket arranged on the adjusting bracket The first positioning assembly, the second positioning assembly and the unwinding regulator; the present invention is a kind of unwinding adjustment device used in the unwinding mechanism. Adjust the position of the entire first positioning assembly and the second positioning assembly to achieve the best unwinding position of the unwinding mechanism, so as to improve the efficiency of unwinding, save time and cost, and improve the accuracy of unwinding. Improve product yield.

Owner:钟立朋

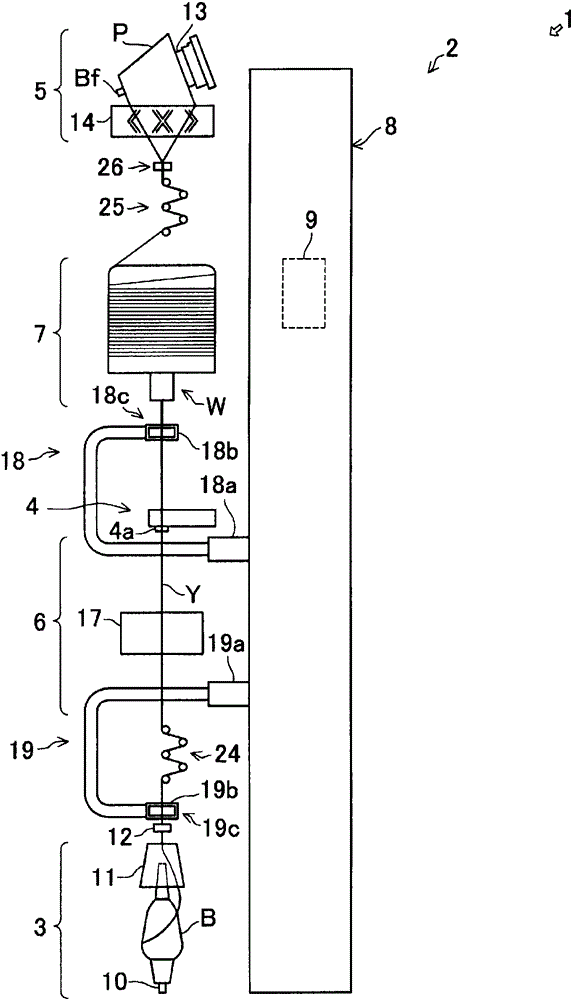

Yarn winding device

A technology for making it possible to continue winding while yarn jointing is carried out is provided. A yarn supplying portion 3 for unwinding a spun yarn Y from a yarn supplying bobbin B, a winding section 5 for winding the spun yarn Y to form a package P, an accumulator 7 provided between the yarn supplying portion 3 and the winding section 5 to store the spun yarn Y, and a yarn end drawing mechanism W for drawing out the yarn end of the stored spun yarn Y to the yarn supplying portion 3 side at the time of bobbin change of the yarn supplying bobbin B, yarn cutting, or yarn breakage are provided.

Owner:MURATA MASCH LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com